Method for forming annular end tooth edge line of arc-shaped end tooth vertical mill

A technology of circular arc end teeth and end mills, which is applied in the field of circular arc edge line modeling, and can solve problems such as easy interference and difficulty in ensuring smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

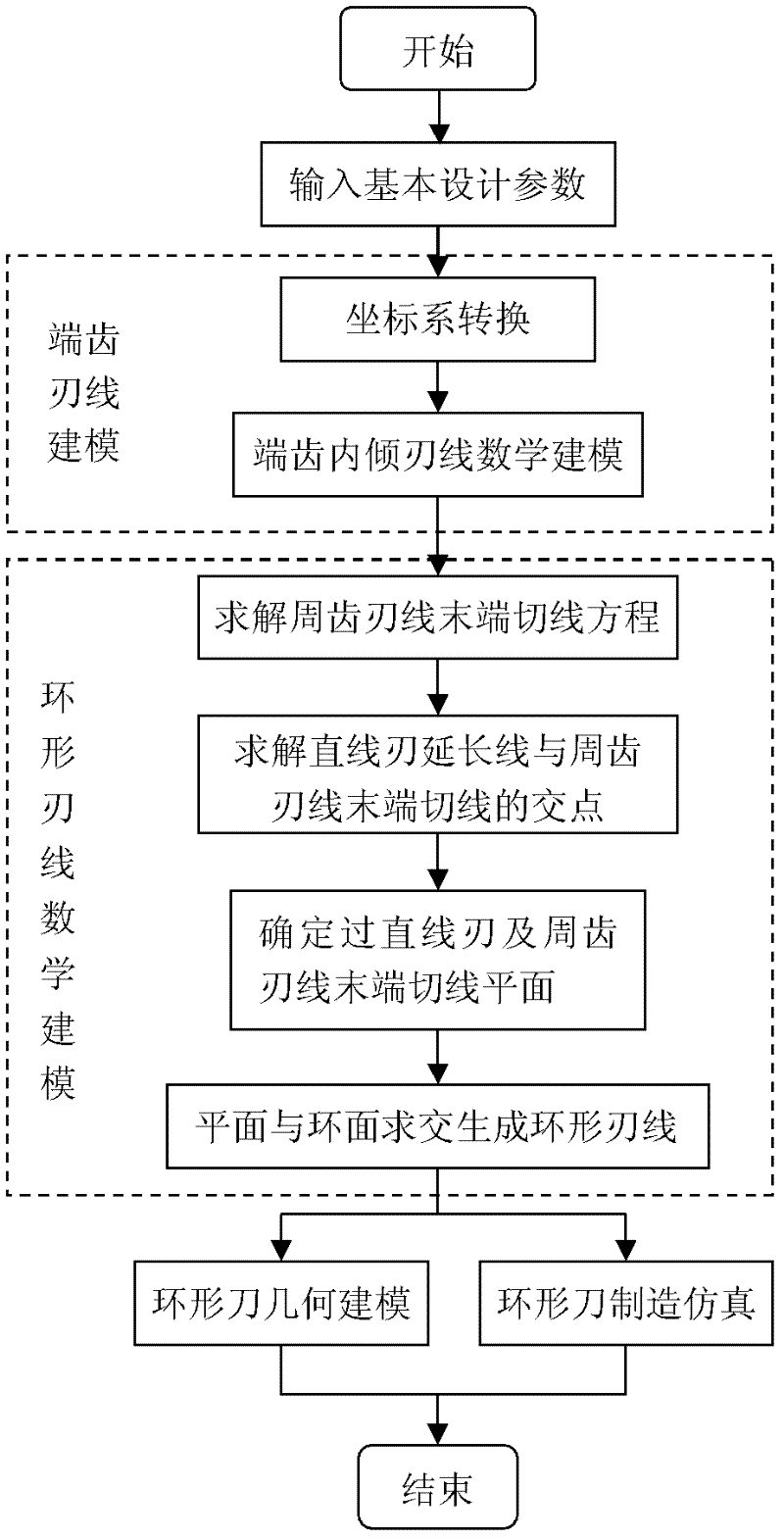

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] An end mill with a ring radius of 3 is selected as a design example. The detailed parameters are as follows:

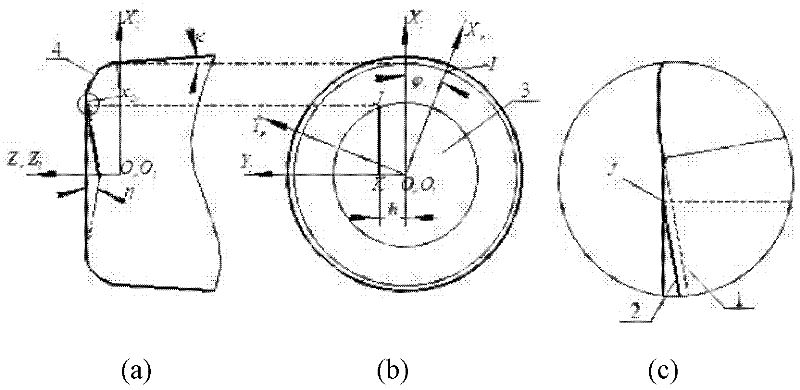

[0093] Peripheral edge is equal helix angle edge line, helix angle β=39°, circumferential tooth taper angle κ=4°; end tooth inclination angle η=3°, tooth eccentricity h=1, tooth over-center amount l=2.

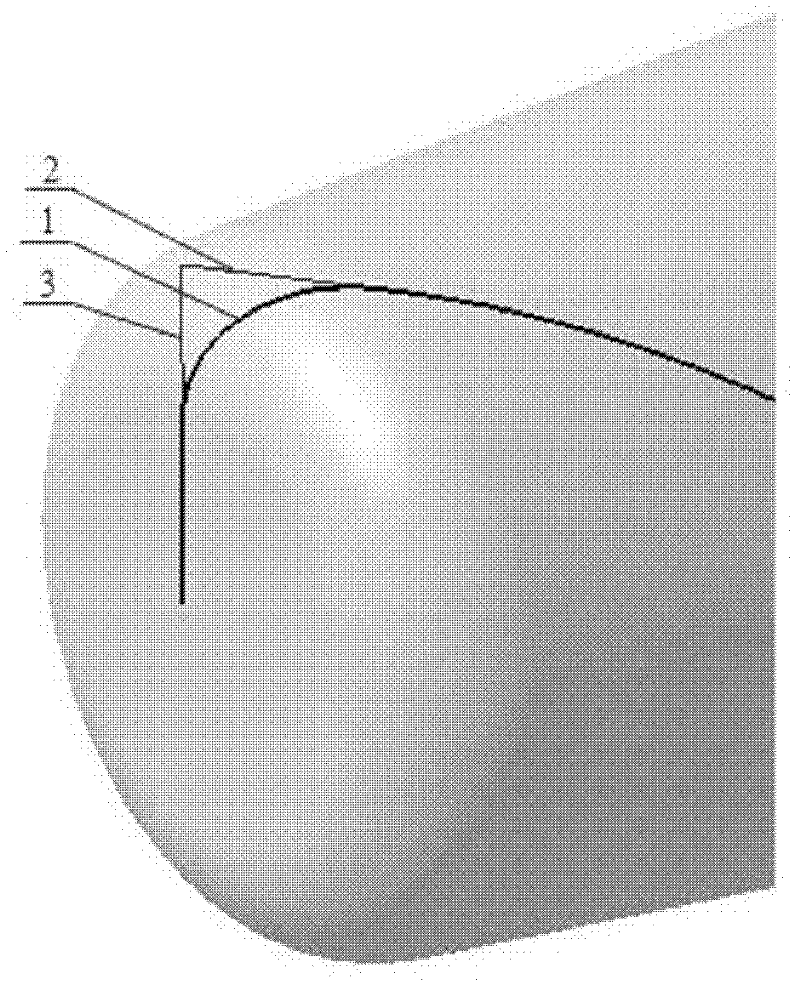

[0094] The formed end tooth straight edge and annular edge are as attached Figure 4 Shown. As attached Figure 4 As shown in a, the straight edge of the end tooth has an inclination angle, Figure 4 b represents the off-center amount and over-center amount of the straight edge, Figure 4 The annular edge of the end tooth shown in c is smoothly connected with the straight edge of the end tooth and the edge line of the peripheral tooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com