Automatic calibration shield segment

A shield segment and automatic calibration technology, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of increasing installation difficulty, inconvenient calibration, and uneven shield segment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

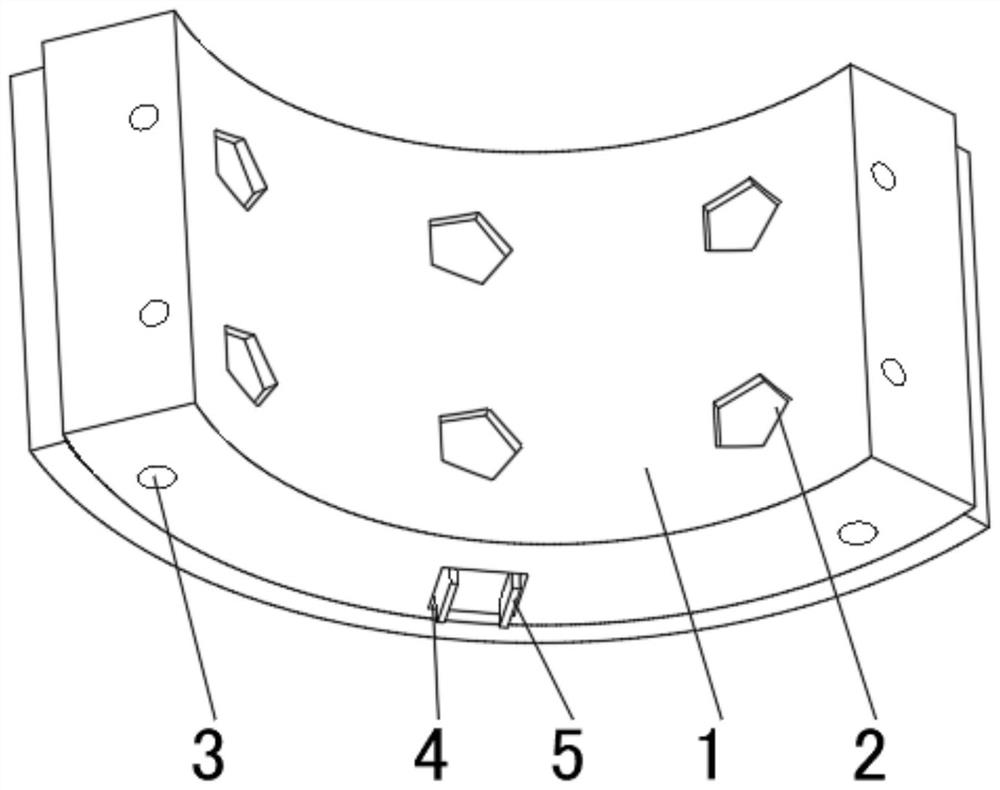

[0030] see Figure 1-4 , the present invention provides a technical solution: an automatic calibration shield segment, including an arc-shaped sheet body 1, an annular groove 2 and a longitudinal groove 3, one side of the arc-shaped sheet body 1 is provided with a calibration groove 4, and the calibration groove 4 It is a table-shaped groove, and one side of the inner wall of the calibration groove 4 is rotatably connected with a positioning frame 5, and the side of the arc-shaped sheet body 1 away from the calibration groove 4 is symmetrically installed with a calibration plate 8, and the calibration plate 8 is an elastic arc-shaped plate.

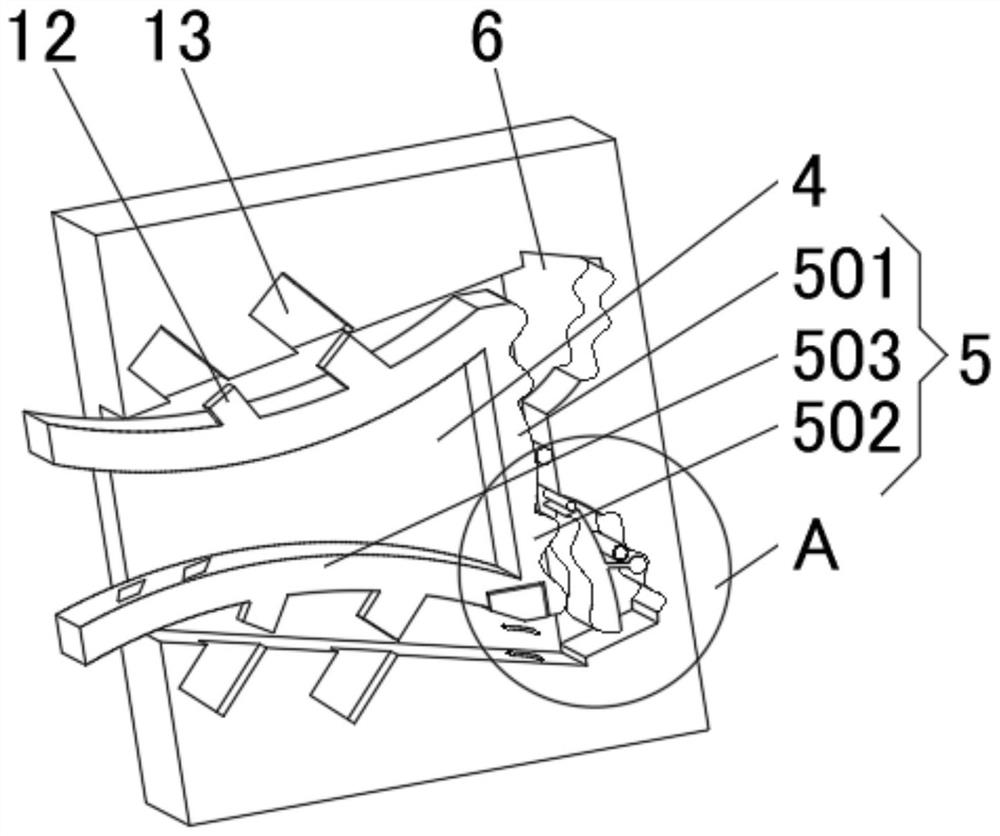

[0031] The positioning frame 5 includes an arc plate 501, which is rotationally connected to one side of the inner wall of the calibration groove 4, and both ends of the arc plate 501 are fixedly connected with a corrugated rod 502, and the corrugated rod 502 is far away from one end of the arc plate 501 An inner concave plate 503 is fixe...

Embodiment 2

[0035] see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, a swing groove 6 is provided symmetrically on one side of the inner wall of the calibration groove 4, and a rectifying device 7 is installed inside the swinging groove 6, and the rectifying device 7 includes extrusion Plate 701, the extruding plate 701 is rotatably connected with the inner wall of the swing groove 6, the radian of the extruding plate 701 is the same as that of the corrugated rod 502, and the side of the extruding plate 701 away from the corrugated rod 502 is fixedly connected with an extruding rod 702. The ball 703 is fixedly connected with a metal pipe 704 on one side of the inner wall of the swing groove 6 .

[0036] When in use, the calibration plate 8 on one side of the newly installed shield segment is aligned into the inside of the clamping frame 5, and when the calibration plate 8 moves to the innermost end of the clamping frame 5, the corrugated ...

Embodiment 3

[0038] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, an anti-skid groove 9 is provided on one side of the calibration plate 8, and an anti-skid device 10 is installed inside the anti-skid groove 9, and the inner wall of the clamping frame 5 is evenly provided with The one-way groove that the anti-slip device 10 is compatible with.

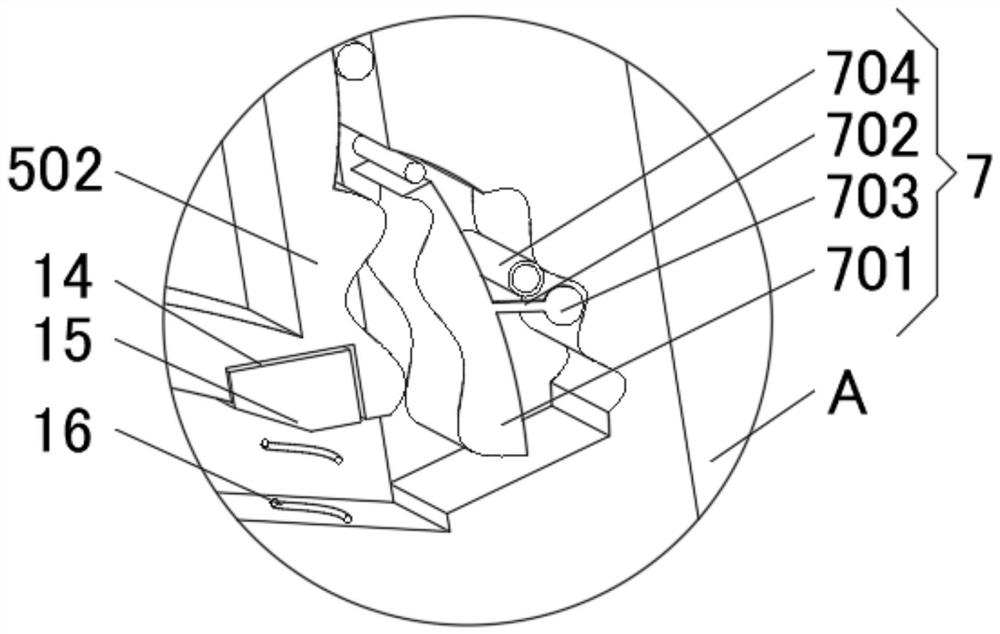

[0039] One side of the inner concave plate 503 is uniformly equipped with inclined blocks 12 , and both sides of the inner wall of the calibration groove 4 are provided with gripping grooves 13 matching with the inclined blocks 12 .

[0040] The anti-skid device 10 includes an anti-skid plate 101, one side of the anti-skid plate 101 is evenly provided with a protective groove 102, both sides of the inner wall of the protective groove 102 are rotatably connected with a laminated plate 103, and the bottom of the laminated plate 103 is fixedly connected with a rubber ball 104.

[0041] One side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com