Patents

Literature

34results about How to "Reduce inspection work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

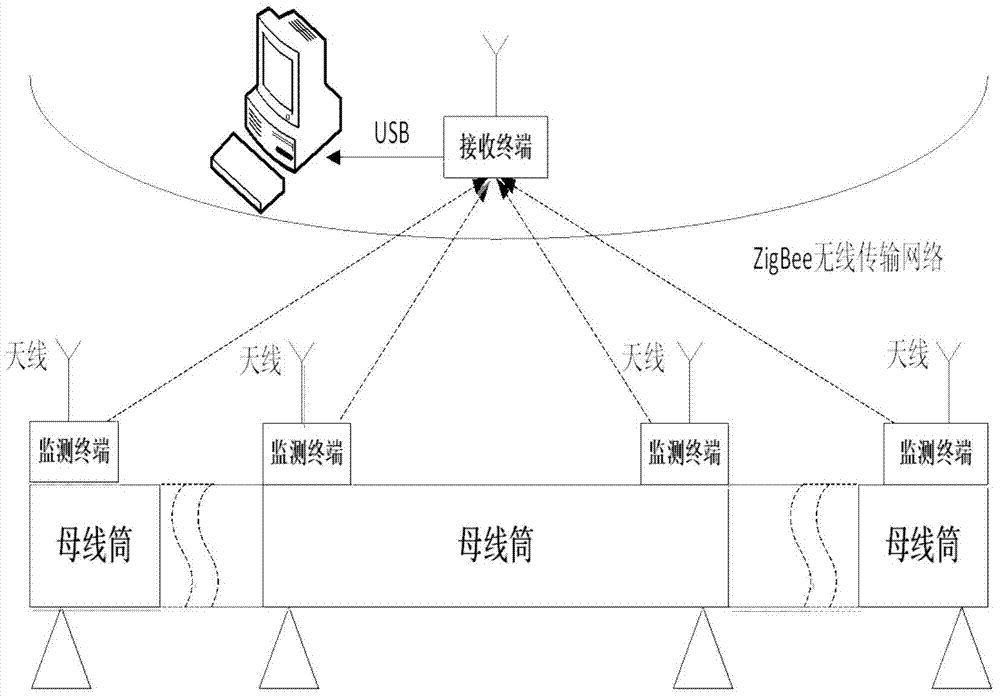

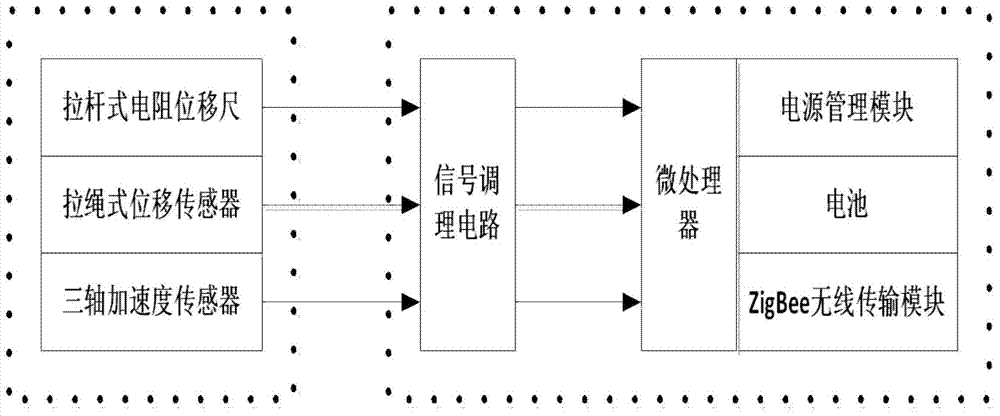

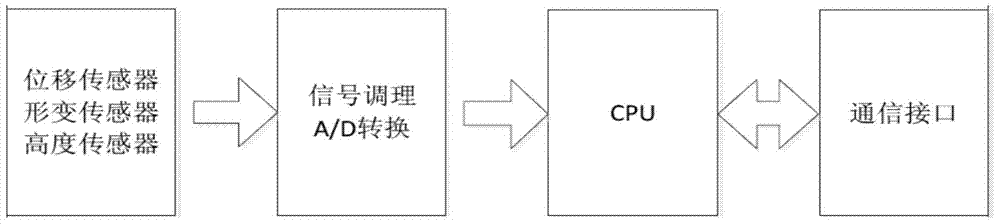

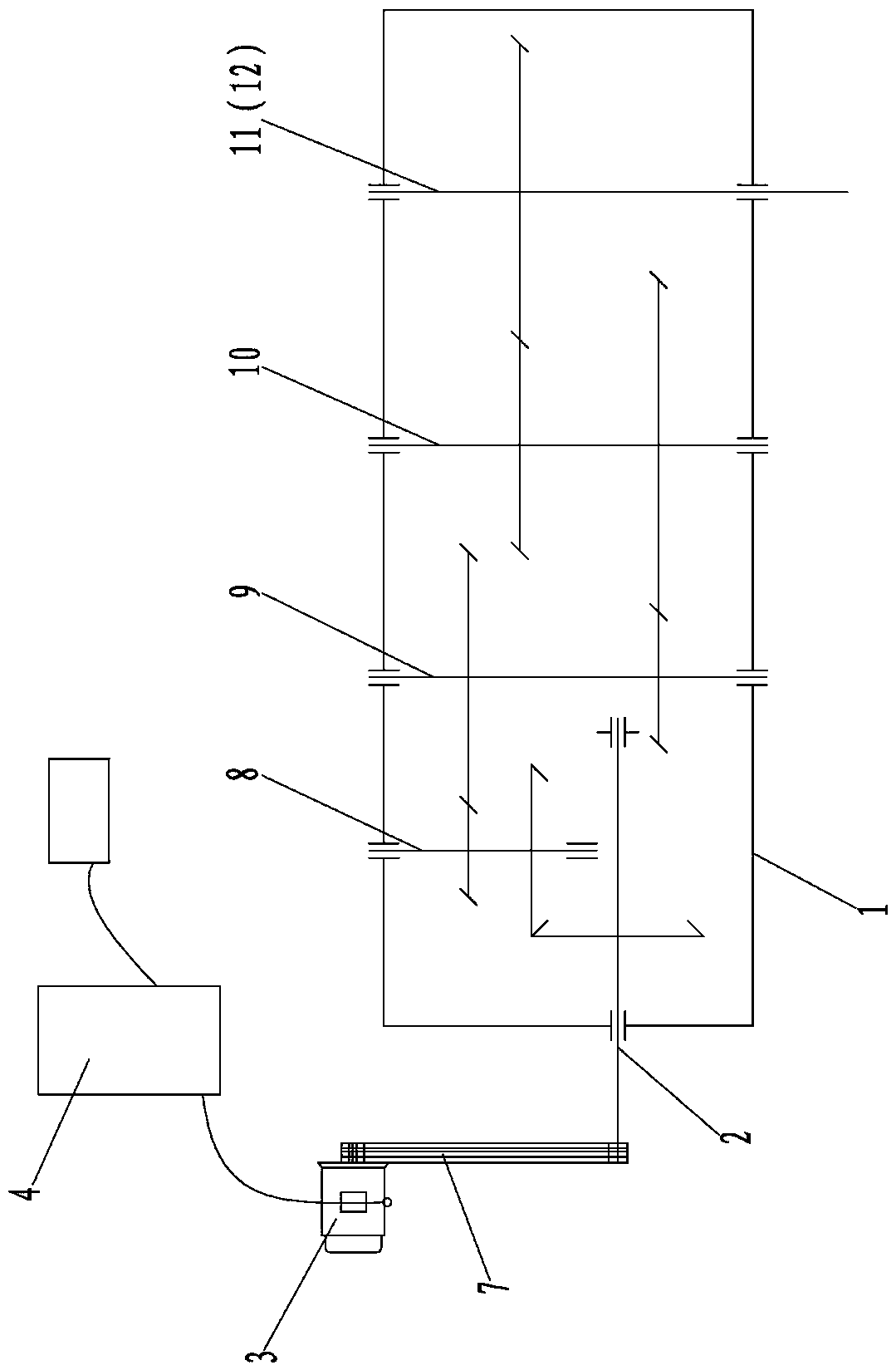

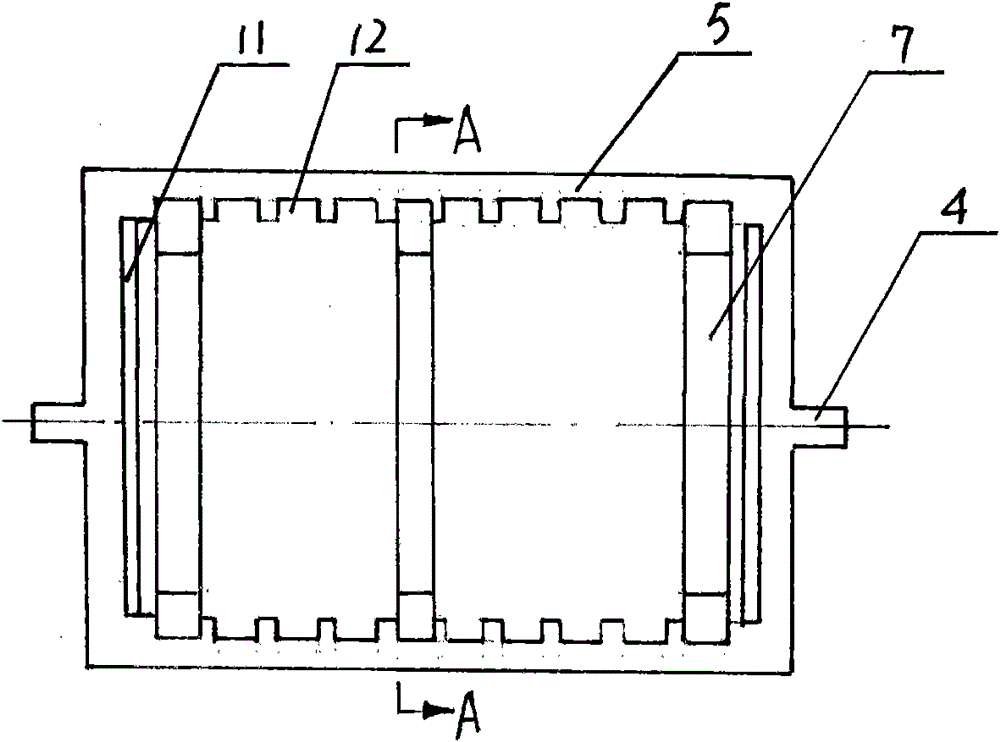

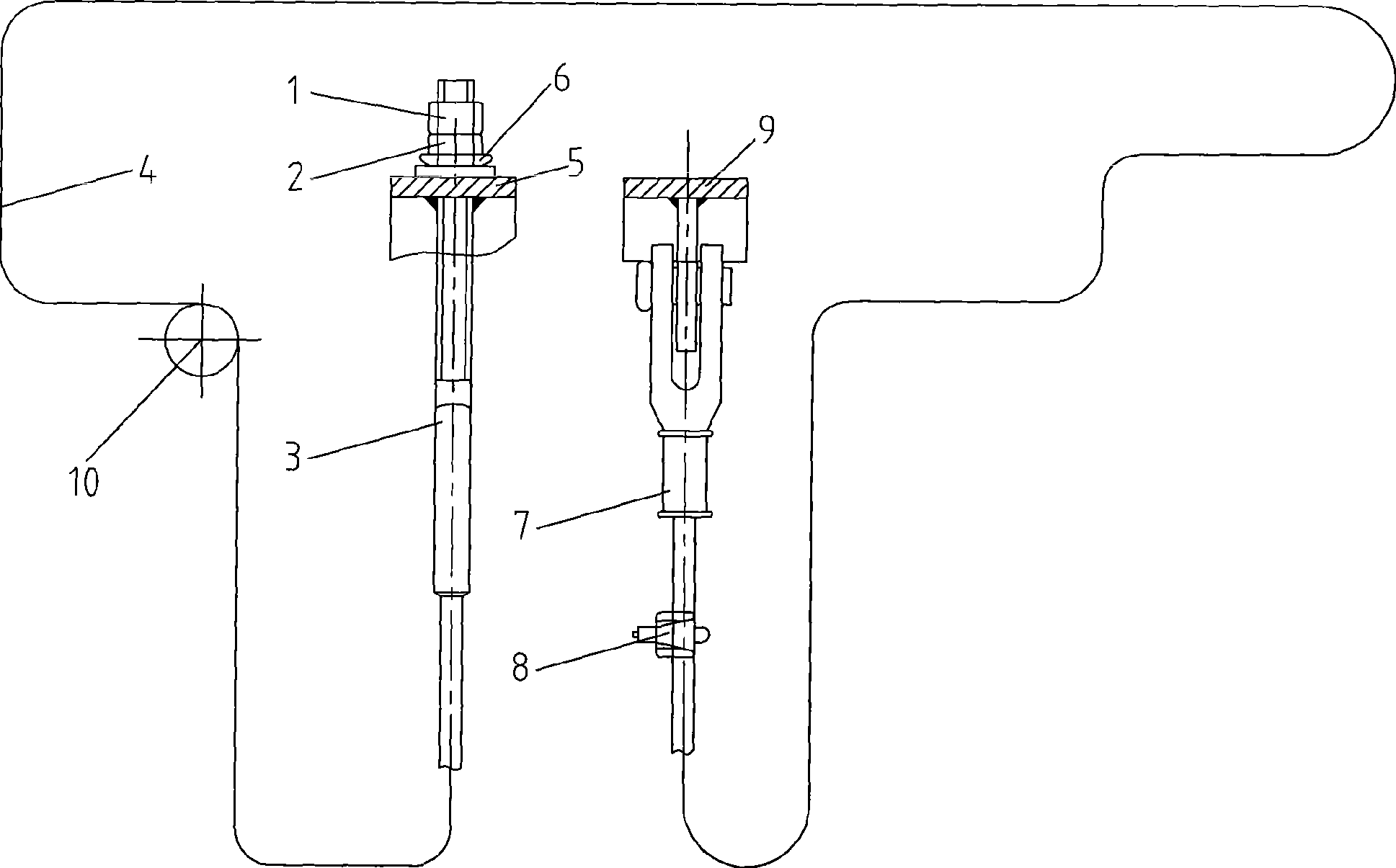

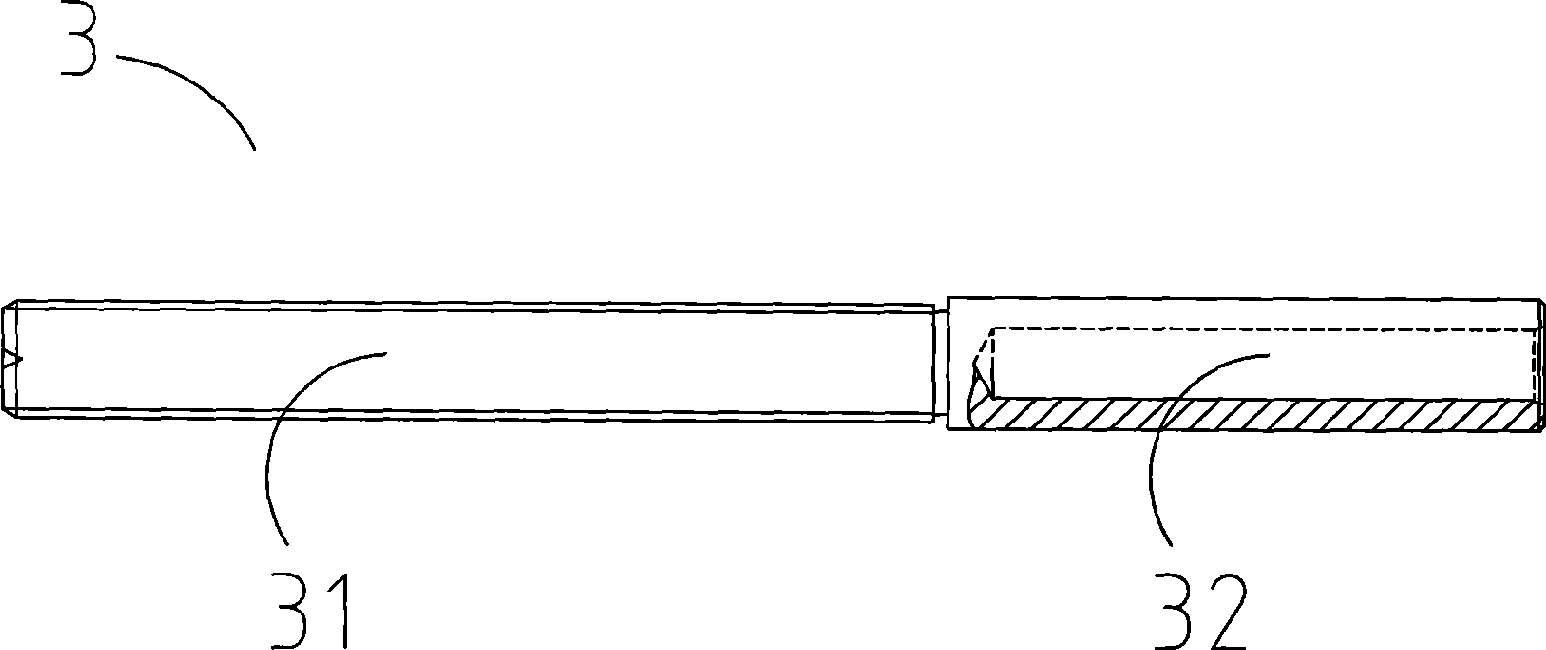

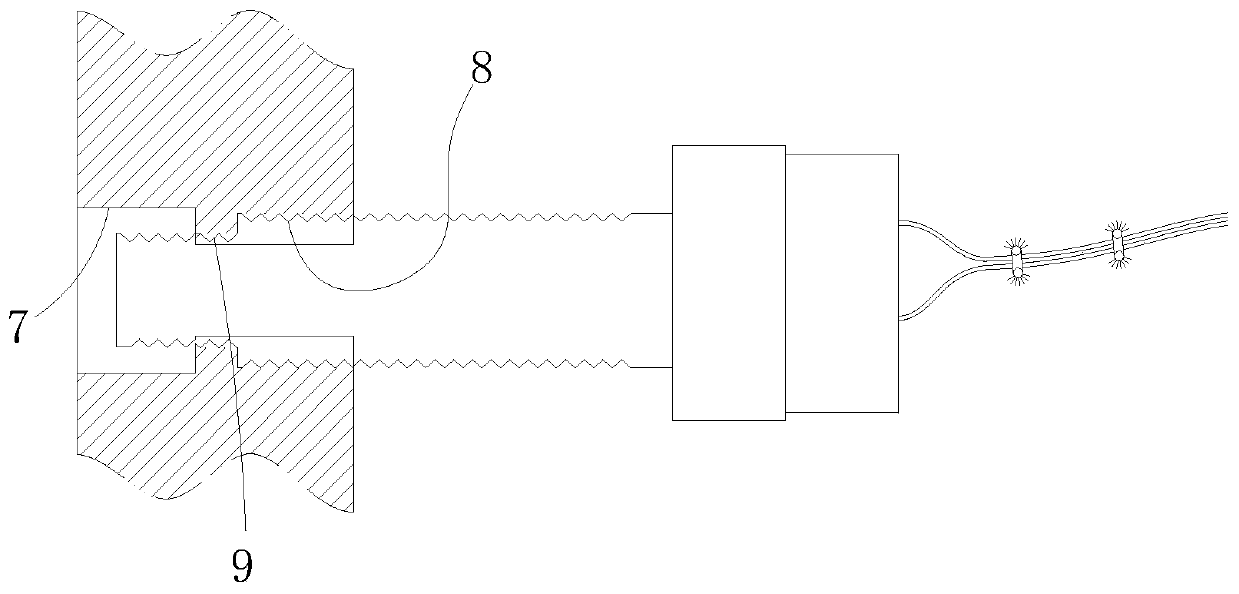

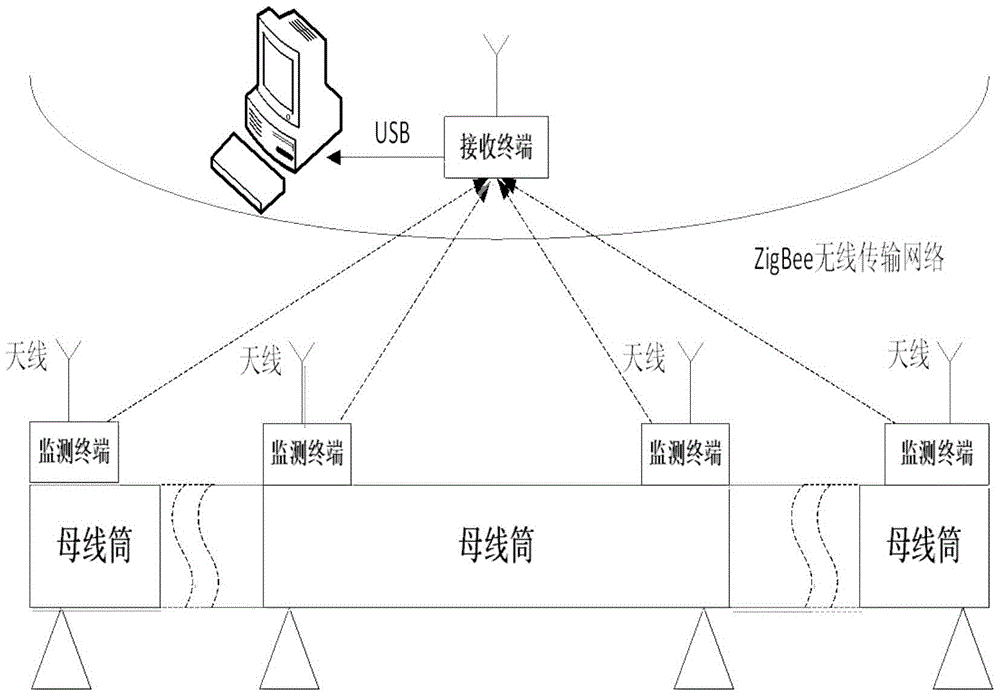

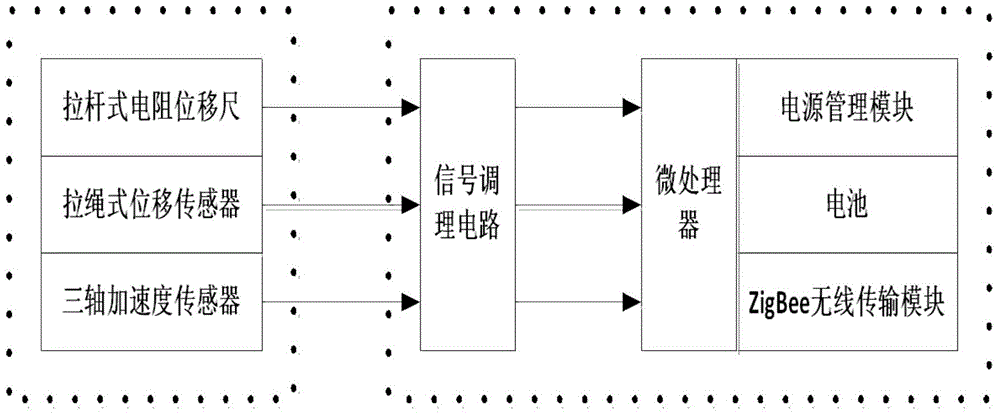

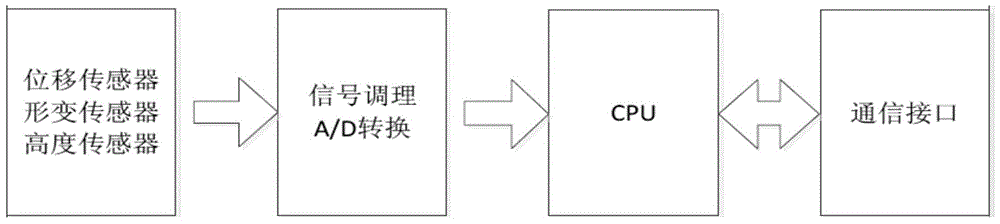

Online monitoring system for GIS busbar barrel

InactiveCN104779568ADeformation monitoringAccurate monitoringCircuit arrangementsBus-bar installationAxial displacementBusbar

The invention relates to an online monitoring system for a GIS busbar barrel. The online monitoring system comprises a monitoring terminal arranged on the barrel and a data processing unit connected with the monitoring terminal, wherein the monitoring terminal comprises a pull rod resistance displacement rule used for detecting the axial displacement of a barrel wall relative to a support, a stay cord displacement sensor used for detecting the displacement of the barrel relative to the ground, and a three-axis acceleration sensor used for detecting the axial and radial warping degrees of the barrel relative to a horizontal plane. By adopting the monitoring system, real-time monitoring can be realized, routing inspection work of workers is reduced, and the labor cost is reduced. Meanwhile, the operation safety of a busbar is improved, accidents, such as cracking of a busbar support, can be effectively prevented, and safety hazards and economic loss caused by bad breakdown repair can be avoided. The system is particularly applied to northwestern districts with a high diurnal temperature difference, high altitude regions, tundra regions and southern geological sedimentation districts.

Owner:PINGGAO GRP +3

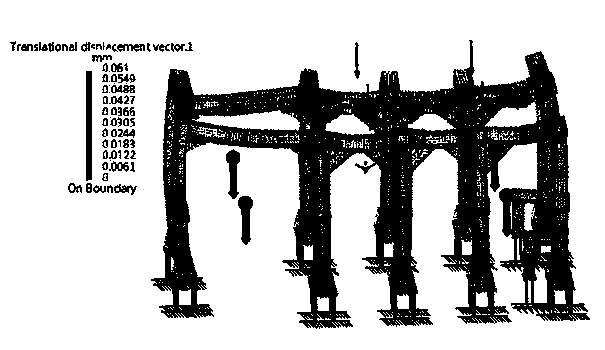

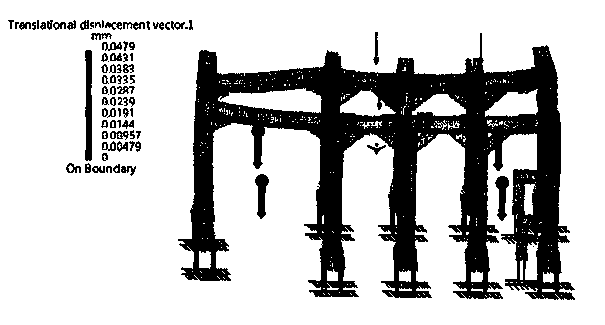

Optimized design method of airplane process equipment

InactiveCN104112029AReasonable preparationOptimal framework design schemeSpecial data processing applicationsProcess equipmentProcess engineering

The invention discloses an optimized design method of airplane process equipment. Under the premise that fixture strength requirements are met, strain analysis is performed on a fixture of the process equipment, structural size is optimized, failing of a positioning function of the process equipment due to the fact that the fixture is insufficient in strength and wasting of a material due to the fact that the fixture is excessive in strength are avoided, weight after weight reducing is reduced by at least one tenth when compared with that of a conventional design method; in a three-dimensional math model, processing areas different in accuracy level are marked by colors, the math model together with a drawing is used during numerical-control processing and three-dimensional coordinate detection, processing accuracy requirements can be determined more visually, processing time can be reduced, and manufacturing and detection cost can be saved.

Owner:SHANGHAI SHANGFEI AIRCRAFT EQUIP MFG

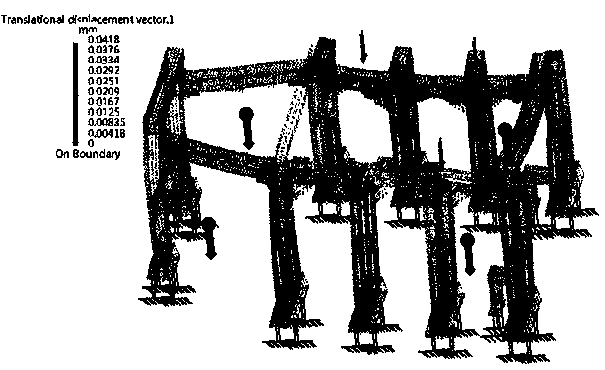

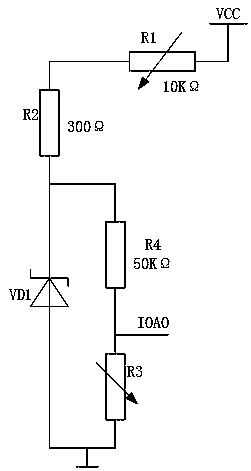

Visual water pressure warning device with indoor fire hydrant

The invention provides a visual water pressure warning device with an indoor fire hydrant. The visual water pressure warning device comprises the fire hydrant located in a fire hydrant box, wherein a firefighting self-rescue reel matched with the fire hydrant is arranged in the fire hydrant box, a three-way joint is mounted at the top of the fire hydrant, one port of the three-way joint is provided with a fire hydrant opening, and another port of the three-way joint is connected with a gate valve; the gate valve is connected with a firefighting hose which is mounted in the fire hydrant box through a hose support, a hydraulic monitoring displayer is arranged on the firefighting hose, a door of the fire hydrant box is provided with a pressure display light, and the pressure display light is connected with the hydraulic monitoring displayer. When hydraulic valve linkage display light strips are jacked up under pressure of firefighting water, the red light strip is showed under the non-water-pressure (normal pressure) condition, the yellow light strip is showed when a set pressure value is higher, and the green light strip is showed when the set pressure value is exceeded.

Owner:喻宙

Oil-water separating sewage drain device for transformer oil reservoir

InactiveCN106422425ASolve the problem of stagnant waterReduce operation and maintenance costsLiquid separationLiquid-crystal displayPower switching

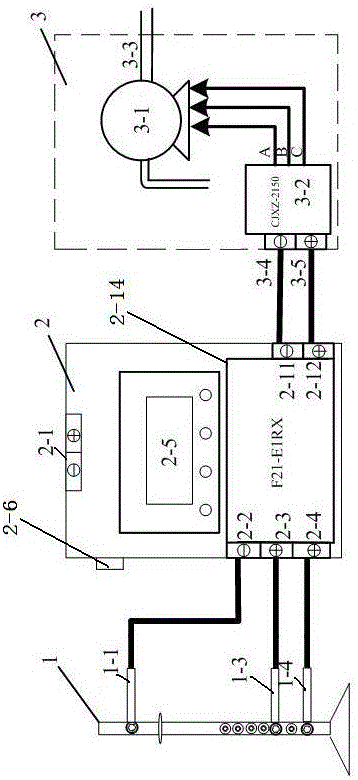

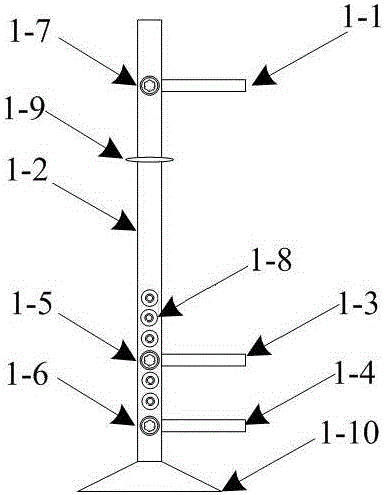

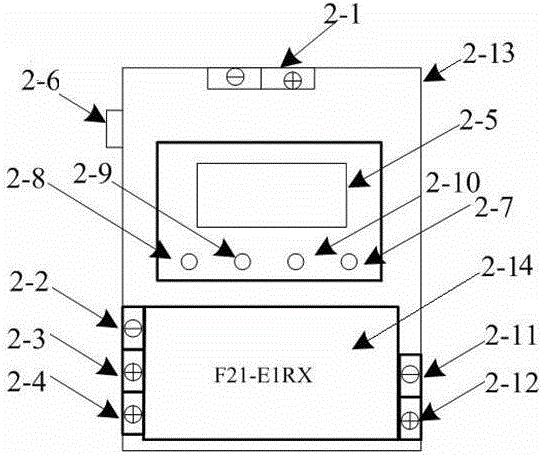

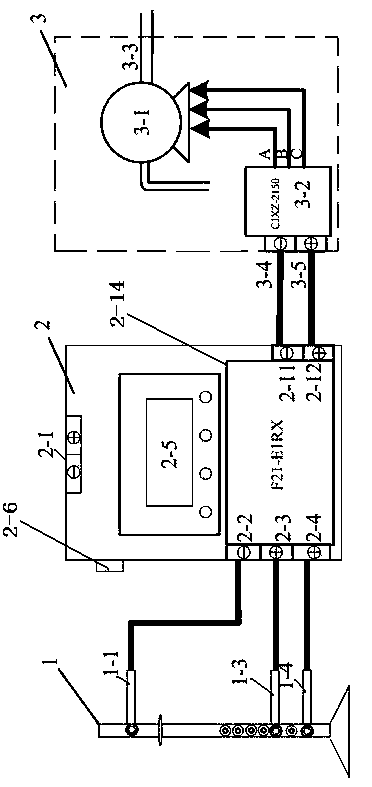

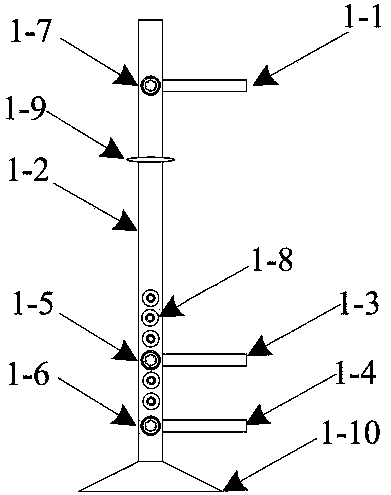

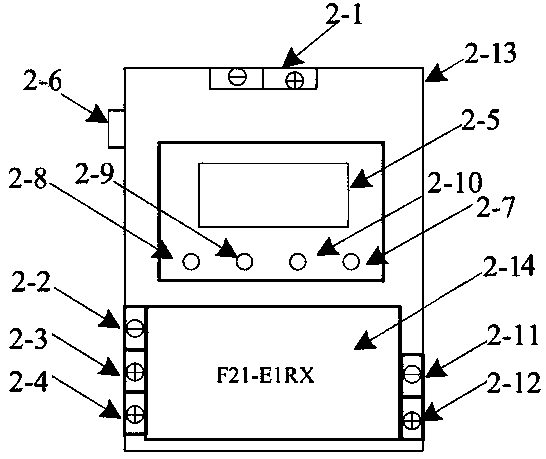

The invention discloses an oil-water separating sewage drain device for a transformer oil reservoir. The device is characterized by being composed of an oil reservoir water level determination device (1), an integrated control device (2) and a sewage drain device (3); the oil reservoir water level determination device (1) comprises a supporting rod substrate (1-10), an adjustable supporting rod (1-2), a zero potential contact chip (1-1), a sewage drain pump start contact chip (1-3), and a sewage drain pump stop contact chip (1-4); the integrated control device (2) comprises a control device body (2-13), a power switch (2-6), a liquid crystal display (2-5), and an F21-E1RX remote control device (2-14); the sewage drain device (3) comprises a sewage drain pump (3-1) and a voltage-sensitive relay CJXZ-2510 (3-2). According to the oil-water separating sewage drain device for the transformer oil reservoir, water in the transformer oil reservoir is monitored in real time and drained in time, therefore, the occurrence of an accident that the surrounding environment is damaged due to occurrence of overflow of transformer oil when the oil reservoir is waterlogged is prevented, and the labor intensity of operation and maintenance staff as well as operation and maintenance cost of the device are reduced.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

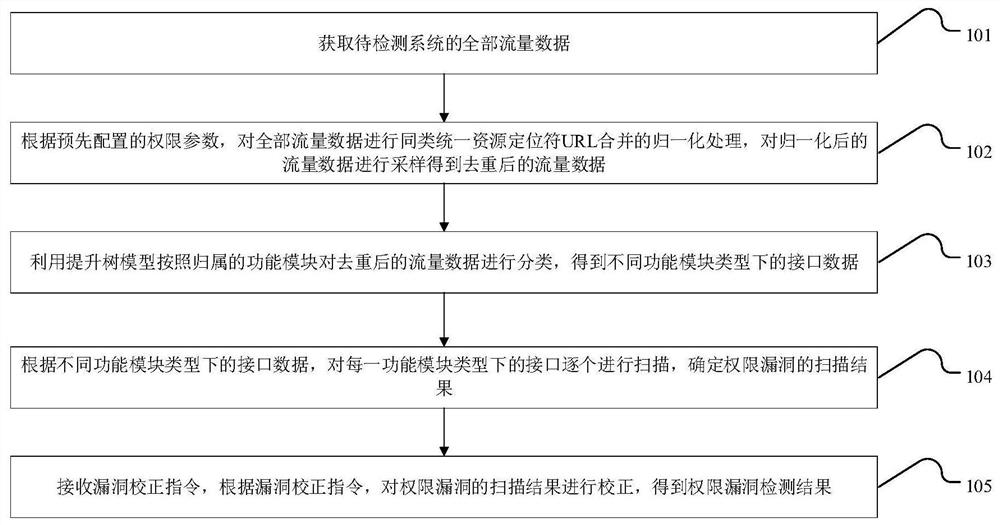

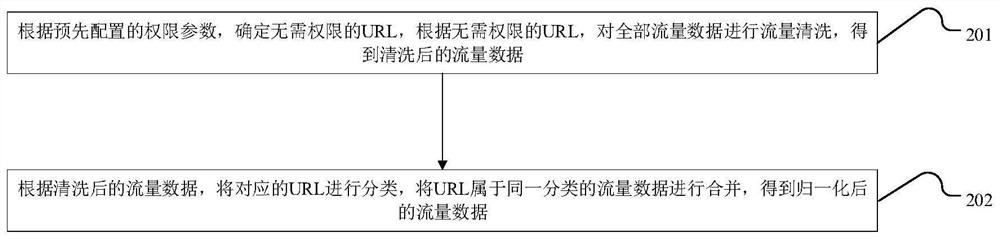

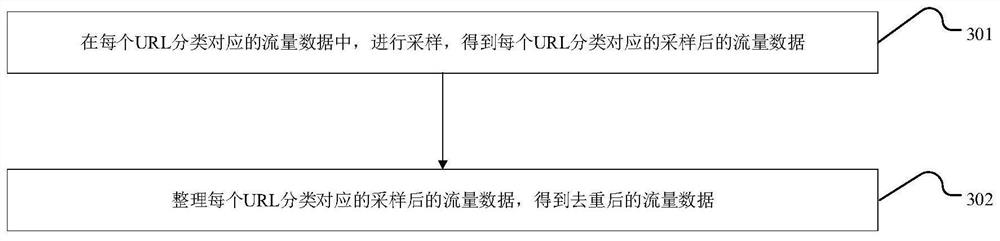

Permission vulnerability detection method and device

PendingCN113127885AReduce duplication of inspection workReduce inspection workOther databases indexingPlatform integrity maintainanceUniform resource locatorData mining

The invention provides a permission vulnerability detection method and device, and the method comprises the steps of carrying out the same type uniform resource positioning conformity normalization processing of all traffic data according to a pre-configured permission parameter, and carrying out the sampling to obtain deduplicated traffic data; classifying the de-duplicated traffic data according to the affiliated function module by utilizing a lifting tree model to obtain interface data under different function module types; according to the interface data under different functional module types, scanning the interfaces under each functional module type one by one, and determining a scanning result of the permission vulnerability; and receiving a vulnerability correction instruction, and correcting the scanning result of the permission vulnerability to obtain a permission vulnerability detection result. The detection efficiency is improved by removing the repeated flow data; and the vulnerability correction instruction is used for further correction, and long-time communication between developers and a security test team is not needed, so that the detection efficiency is improved, and the detection accuracy is improved. The invention is applied to the field of network security.

Owner:BANK OF CHINA

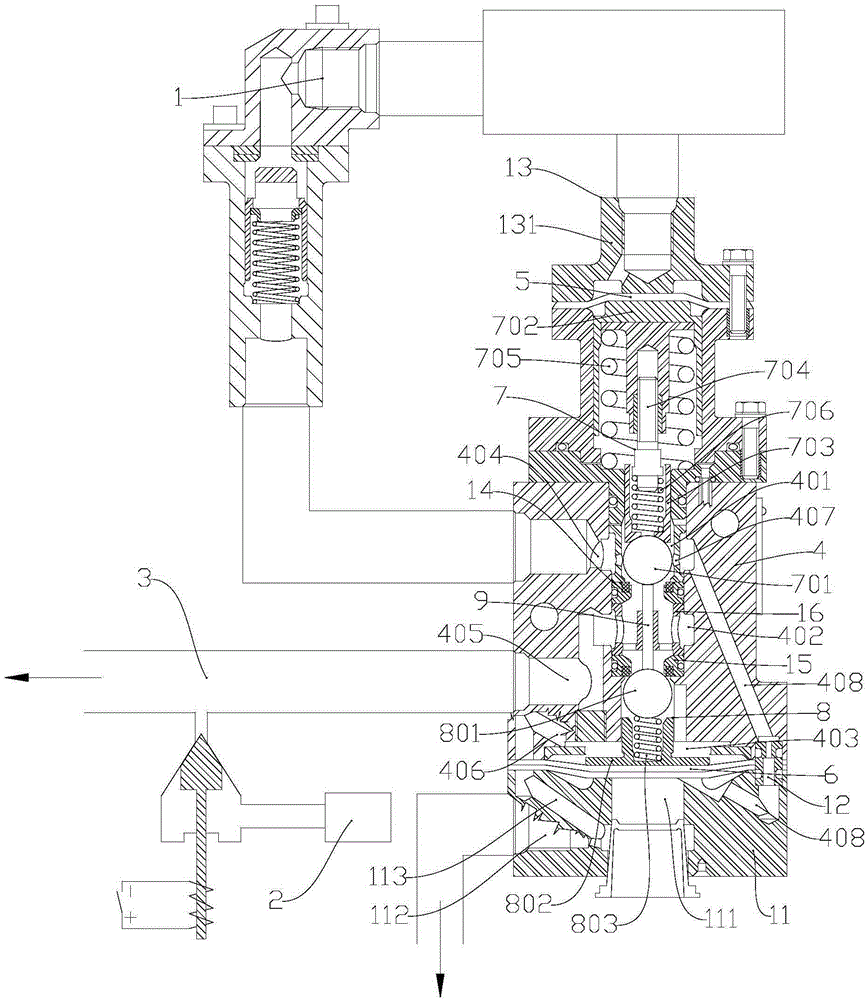

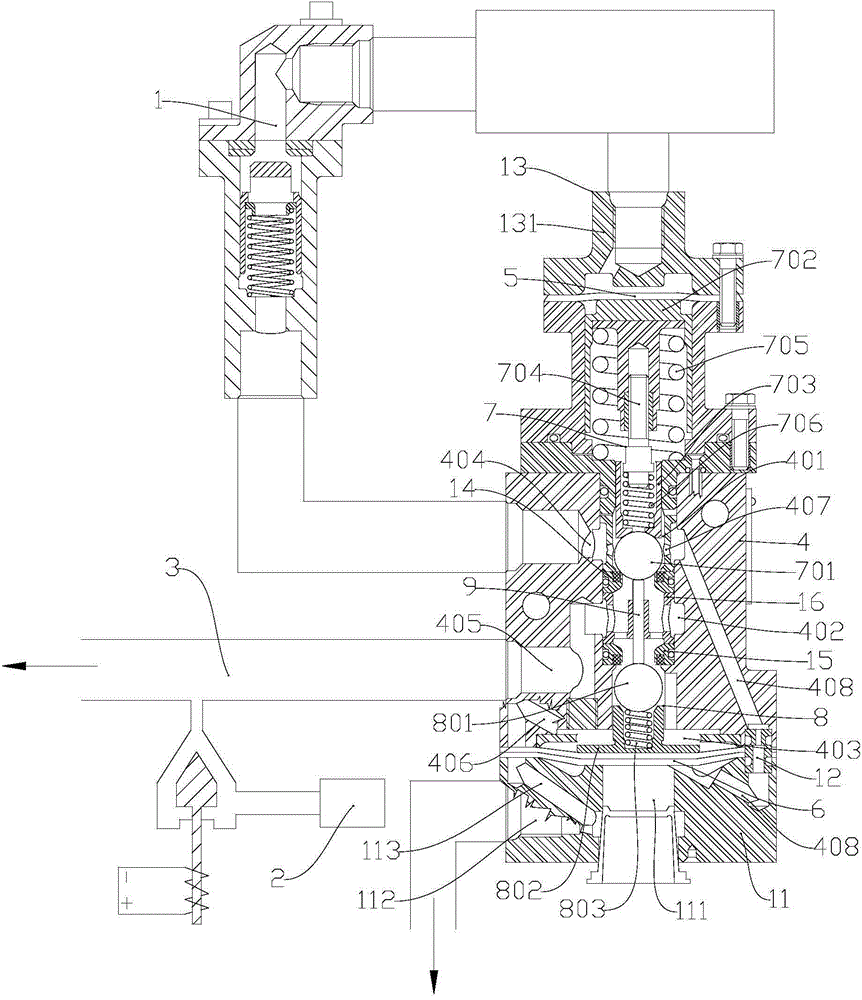

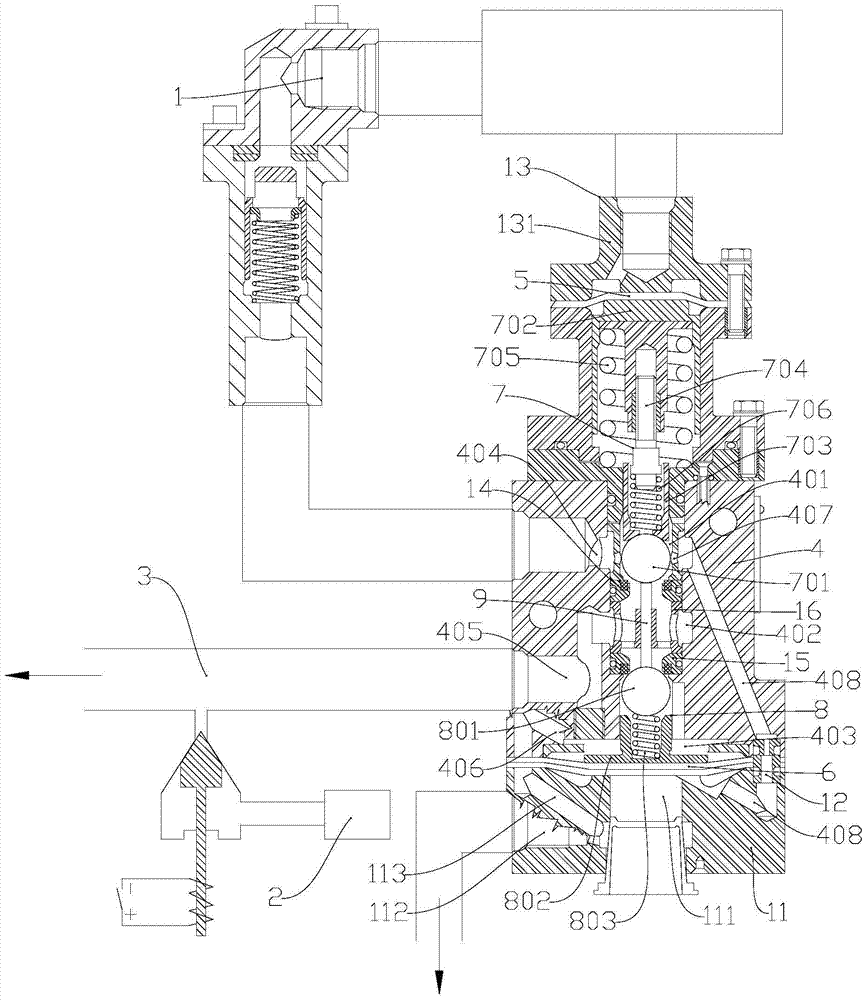

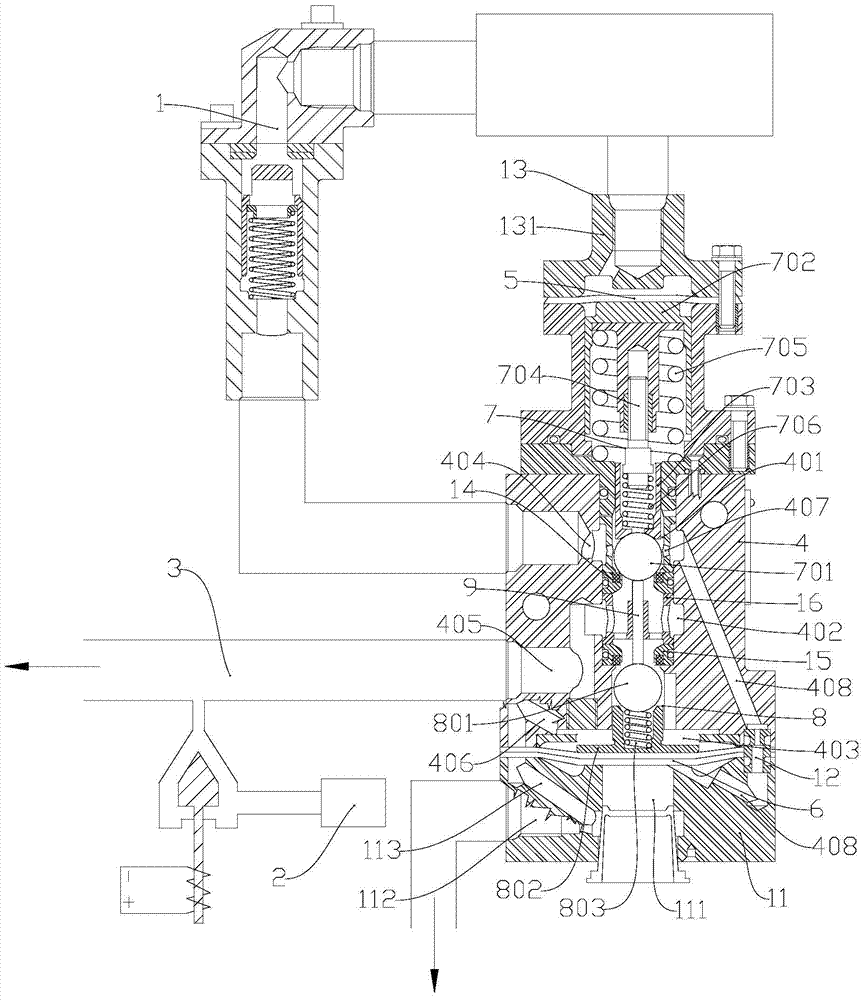

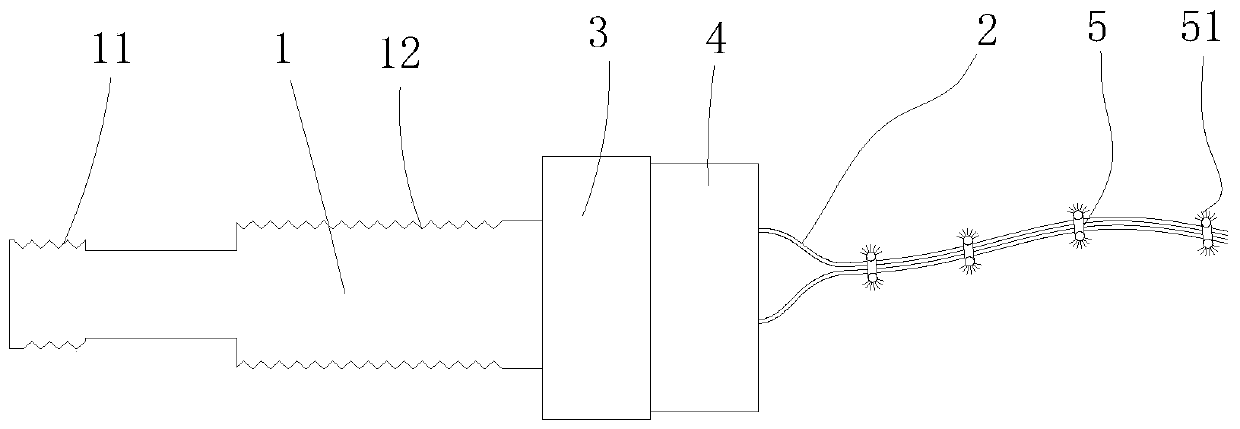

Nozzle oil supply system

ActiveCN104929840AReduce inspection workAvoid failures caused by cloggingHigh pressure gas fuel injectionMachines/enginesEngineeringHigh pressure

The invention discloses a nozzle oil supply system. The nozzle oil supply system comprises a high-pressure fuel supply system for providing high-pressure fuel, a high-pressure gas supply system for providing high-pressure gas, a spraying oil pipe, and a fuel conversion device, wherein the two ends of the spraying oil pipe are respectively connected with a nozzle and the fuel conversion device; the high-pressure fuel supply system is connected with the fuel conversion device, and presses high-pressure fuel, flowing into the fuel conversion device, into the spraying oil pipe under the effect of the fuel conversion device; and the high-pressure gas supply system is communicated with the spraying oil pipe, outwards sprays part fuel in the spraying oil pipe from the nozzle when the high-pressure fuel supply system is closed, and presses the remainder fuel in the spraying oil pipe into the fuel conversion device for outwards flowing. The nozzle oil supply system cannot generate the carbon deposition due to long-time stop of an engine, so that the inspection of the engine before working after the long-time stop is reduced, the fault caused by the blockage of the spraying oil pipe due to the carbon deposition is prevented, and the flight safety is guaranteed.

Owner:CHINA HANGFA SOUTH IND CO LTD

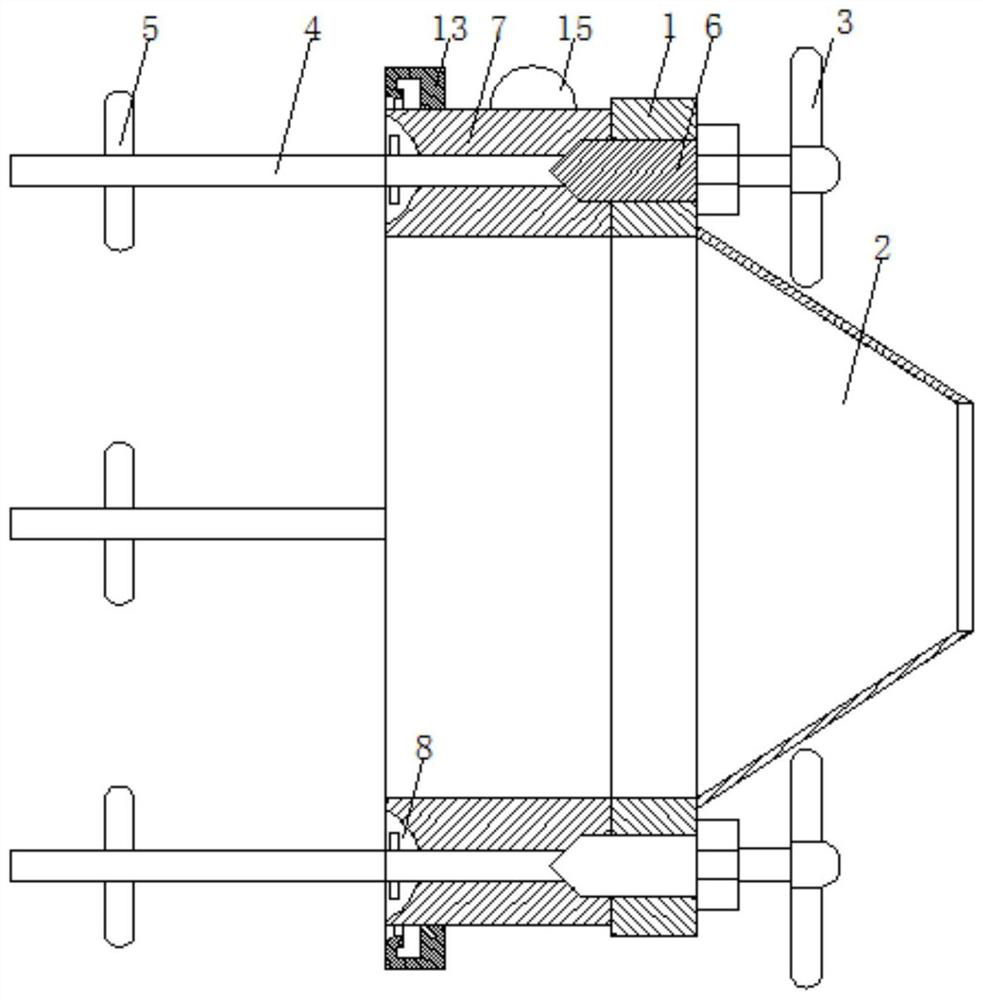

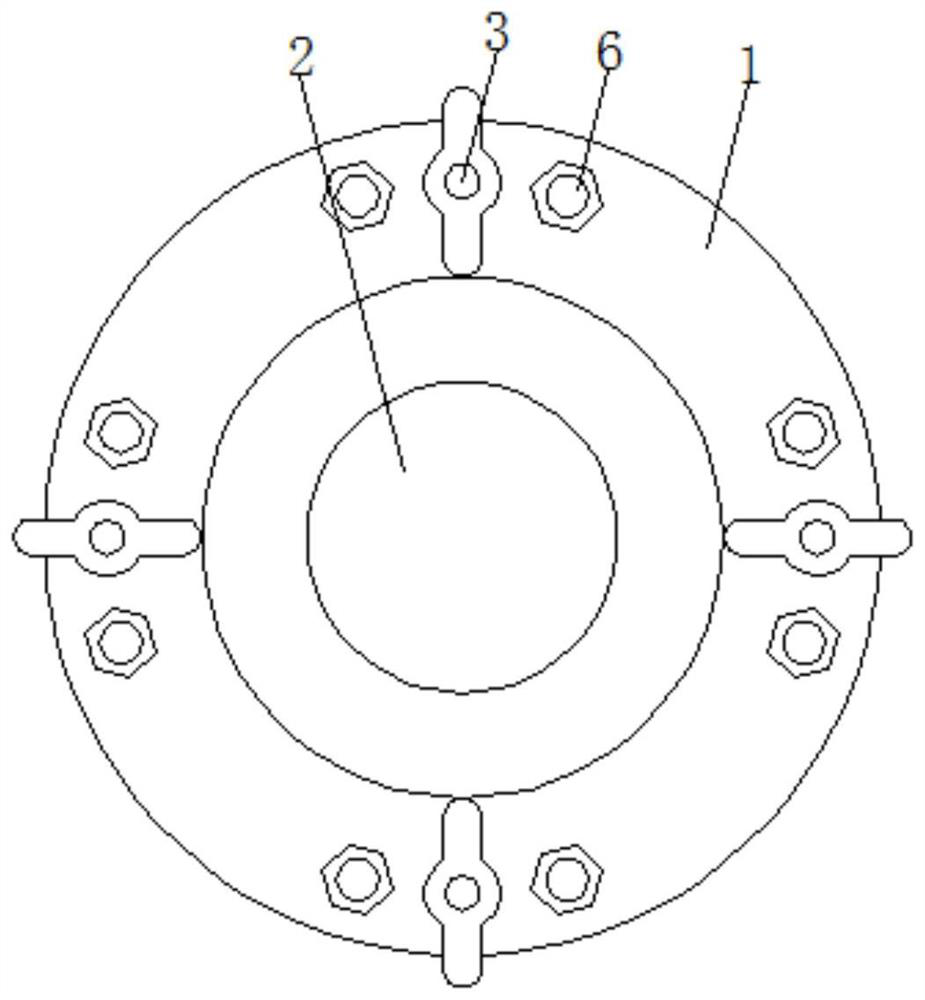

Ring flange convenient to install and capable of preventing excursion

InactiveCN111623046AEasy to installAvoid offsetFlanged jointsPipe elementsStructural engineeringMechanical engineering

The invention relates to the technical field of hardware devices, and discloses a ring flange convenient to install and capable of preventing excursion. The ring flange comprises a first flange; a first connecting port is fixedly connected with the right end of the first flange; a screwing nut is fixedly connected with the surface of the first flange; a fastening bolt is fixedly connected with theleft end of the screwing nut; and a positioning rod is fixedly connected with the surface of the fastening bolt. Through fixed connection between the first flange and a second flange and connection between the second flange and a third flange, the fastening bolt penetrates through a flexible through hole; the third flange is rotated by a certain angle so the positioning rod can be placed in a fixing groove; the screwing nut is fastened at the moment, and the fastening bolt moves inwardly, so the third flange is fixed on the second flange and a sealing ring on the second flange is tightly attached to the third flange; and therefore, the effects that the ring flange is conveniently installed by a worker, installation time is saved, and operation efficiency is greatly improved can be achieved.

Owner:杭州旗芳实业有限公司

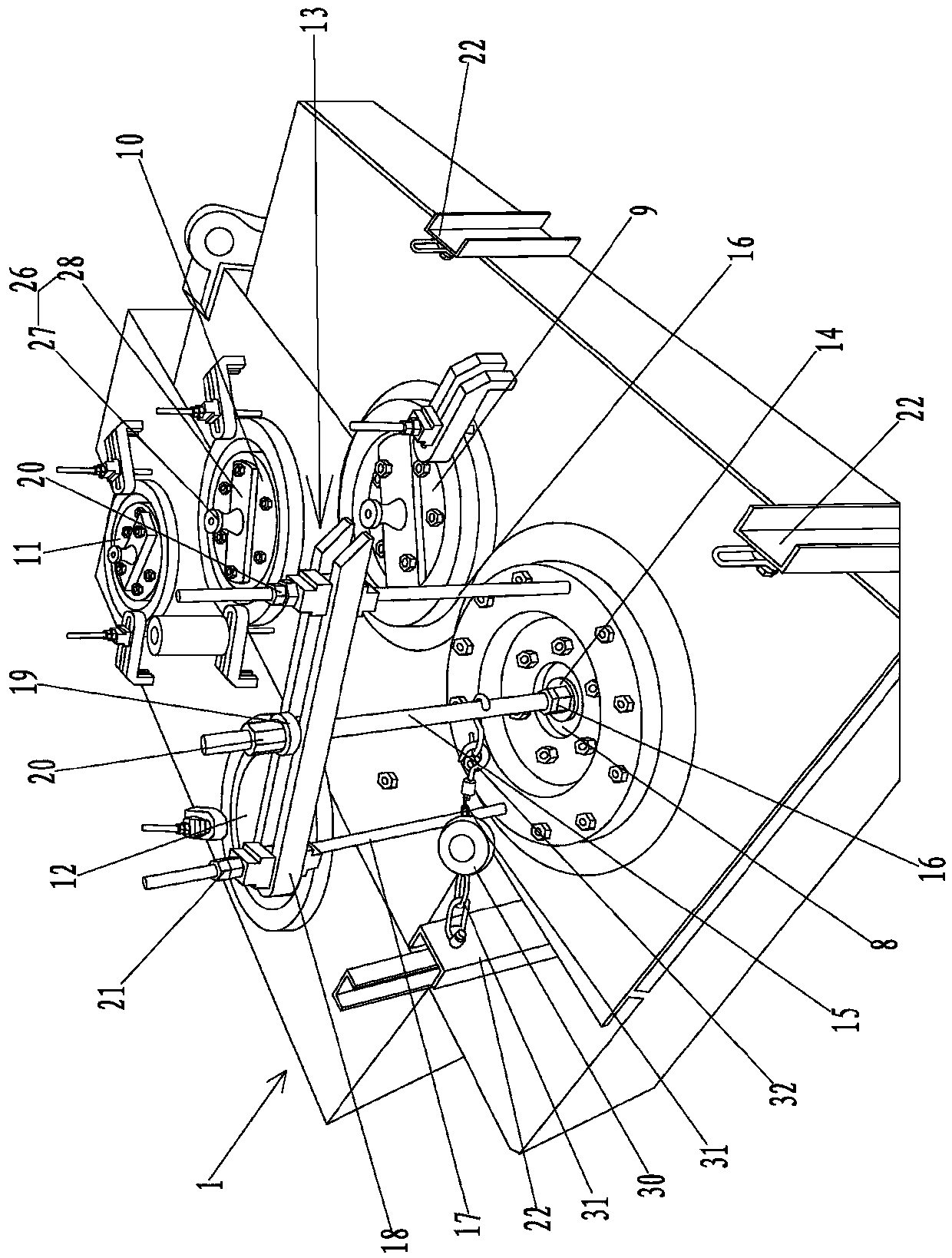

Tooth engagement adjustment method and adjustment system for eccentric bushing type gearbox of heavy multi-stage vertical shaft

PendingCN111059264AIngenious structural designReduce workloadGearing detailsGear wheelControl engineering

The invention relates to a tooth engagement adjustment method and adjustment system for an eccentric bushing type gearbox of a heavy multi-stage vertical shaft. The adjustment method comprises the following steps of adjusting the gearbox to a preset height by a box body positioning assembly; adjusting the axial position of each to-be-adjusted gear to a preset position through each axial positioning device; starting a driving device on an input shaft to apply a radial load force to the to-be-adjusted gear shaft through a load device connected to the to-be-adjusted gear shaft adjacent to the input shaft; stopping the driving device working for a preset time to detect the tooth engaging condition of each to-be-adjusted gear; and when the tooth generation is not qualified, adjusting an eccentric bushing on each to-be-adjusted gear and repeating the previous step; when the tooth engagement is qualified, adjusting the tooth engaging condition of each adjacent to-be-adjusted gear successivelyaccording to the steps, and when the tooth engagement is not qualified, repeating the previous step till adjusting all the to-be-adjusted gears. The method can improve the adjustment accuracy, optimize an operating process and reduce the adjustment workload properly, and the adjustment system is simple and skillful in structural design.

Owner:西马克工程(中国)有限公司

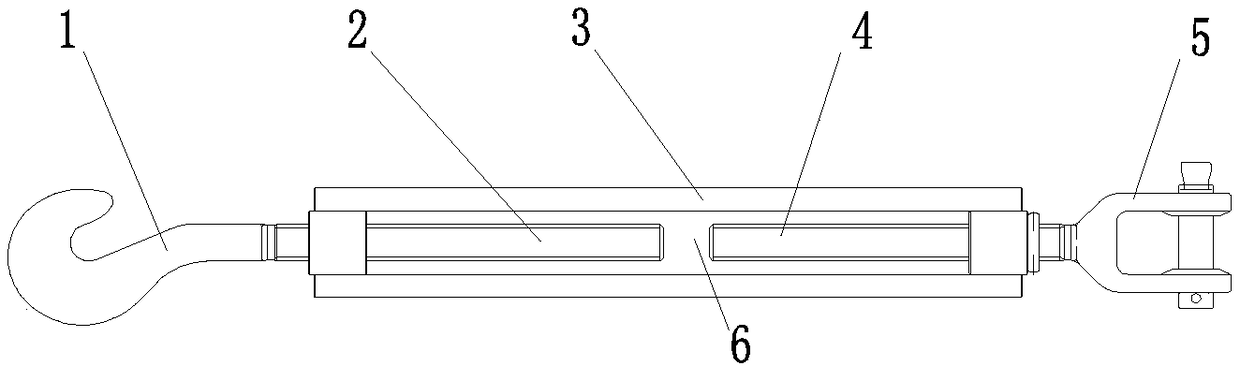

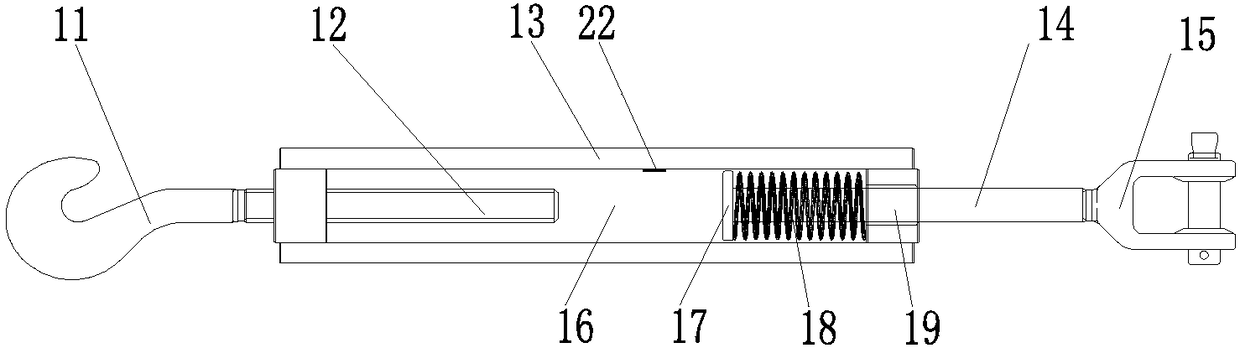

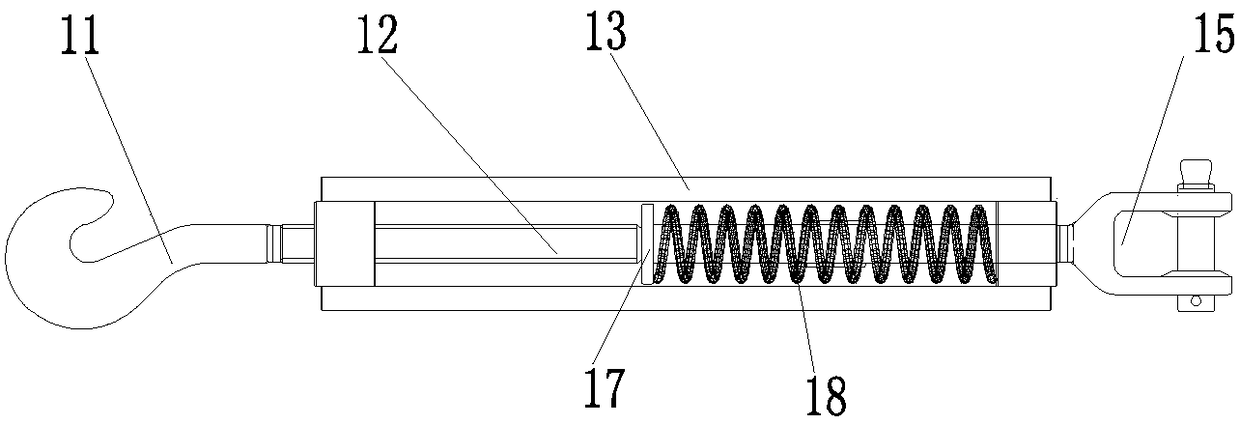

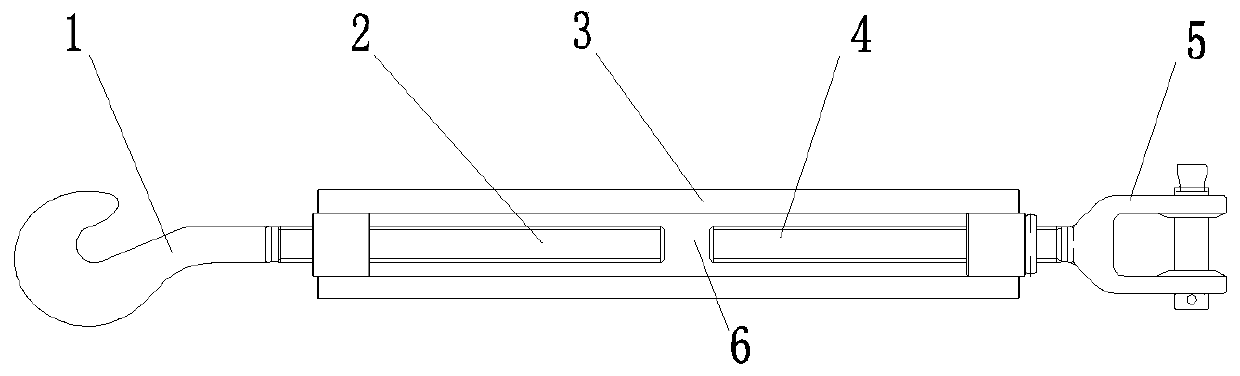

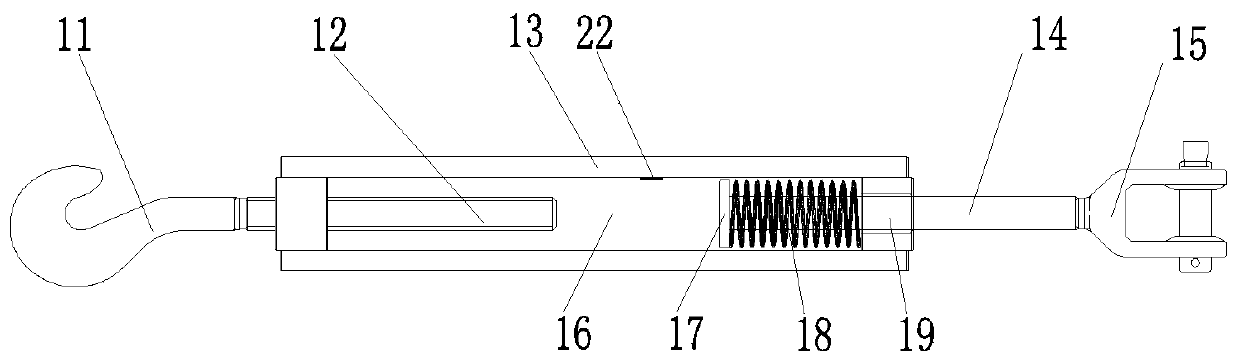

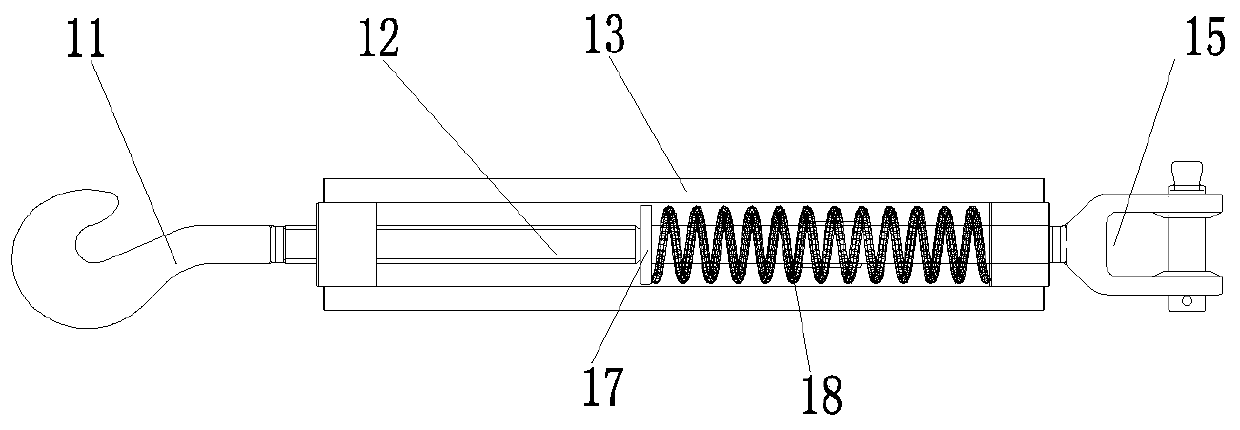

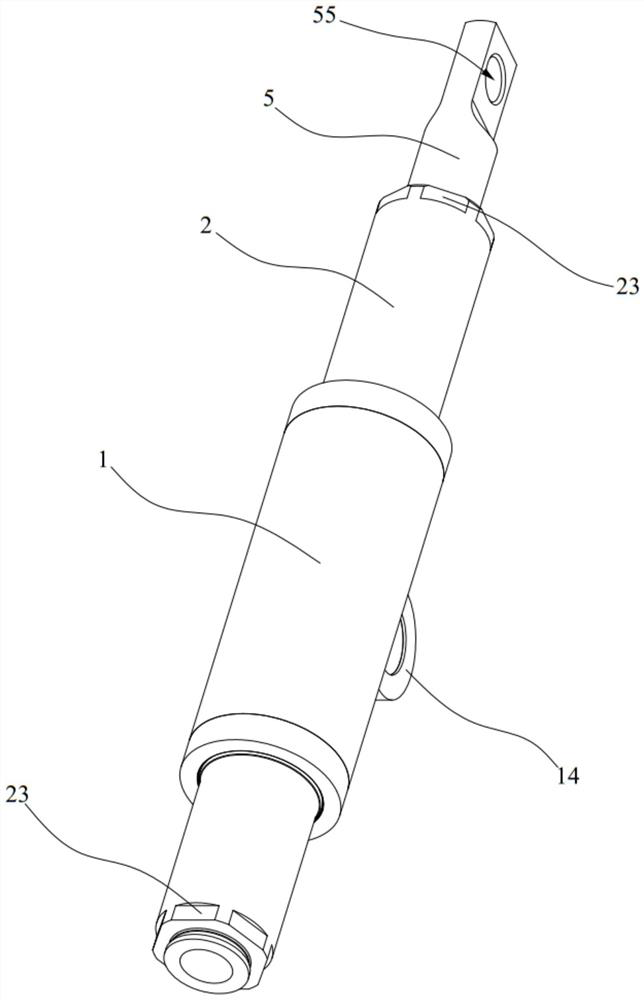

Self-tightening flower basket bolt

The invention provides a self-tightening flower basket bolt. The self-tightening flower basket bolt comprises a bolt body, a first pull rod and a second pull rod, wherein the bolt body is provided with a sleeve, and the first pull rod and the second pull rod are arranged at the two ends of the bolt body. Each pull rod comprises an adjustment rod and a connecting head, wherein each connecting headis located at the front end of the corresponding adjustment rod. The two ends of the bolt body are each provided with a threaded hole. Each adjustment rod penetrates the corresponding threaded hole and extends into the sleeve of the bolt body. The whole adjustment rod of the first pull rod is provided with a thread matched with the corresponding threaded hole. A baffle is arranged at the tail endof the adjustment rod of the second pull rod. An extending-and-contracting component is arranged between the end, close to the inner side of the second pull rod, of the sleeve and the baffle. The middle-rear segment of the adjustment rod of the second pull rod is provided with a locking thread matched with the corresponding threaded hole. The portion, between the locking thread and connecting headof the second pull rod, of the corresponding adjustment rod is a polish rod. When the locking thread is matched with the threaded hole in one end of the bolt body, the extending-and-contracting component is in the compressed state. According to the self-tightening flower basket bolt, the extending-and-contracting component is added on the basis of a common flower basket bolt; the self-tighteningfunction can be achieved; and safety of cargo and transportation tools is guaranteed.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

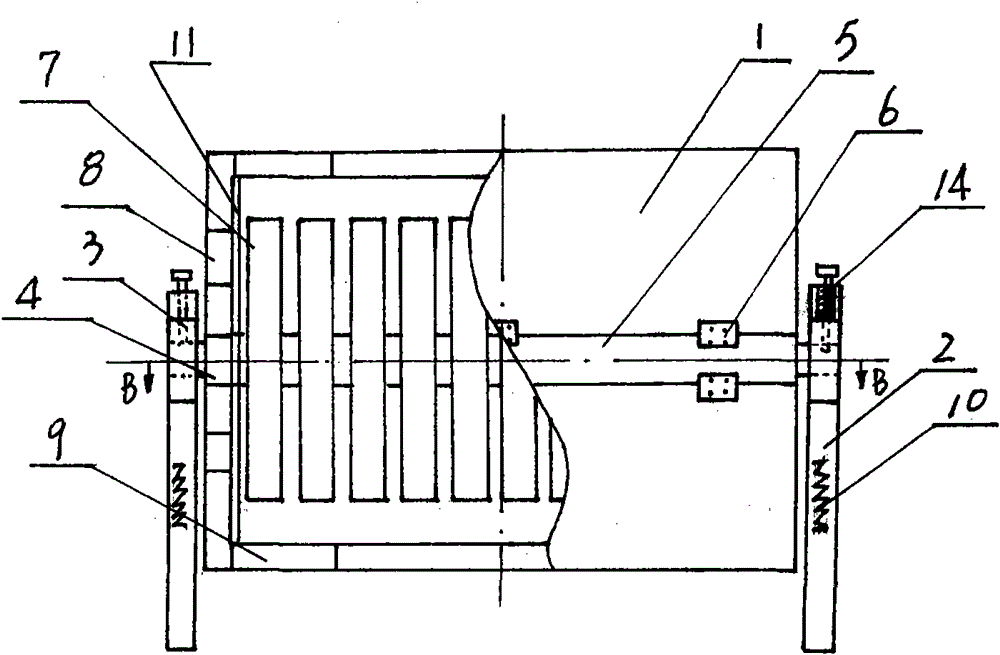

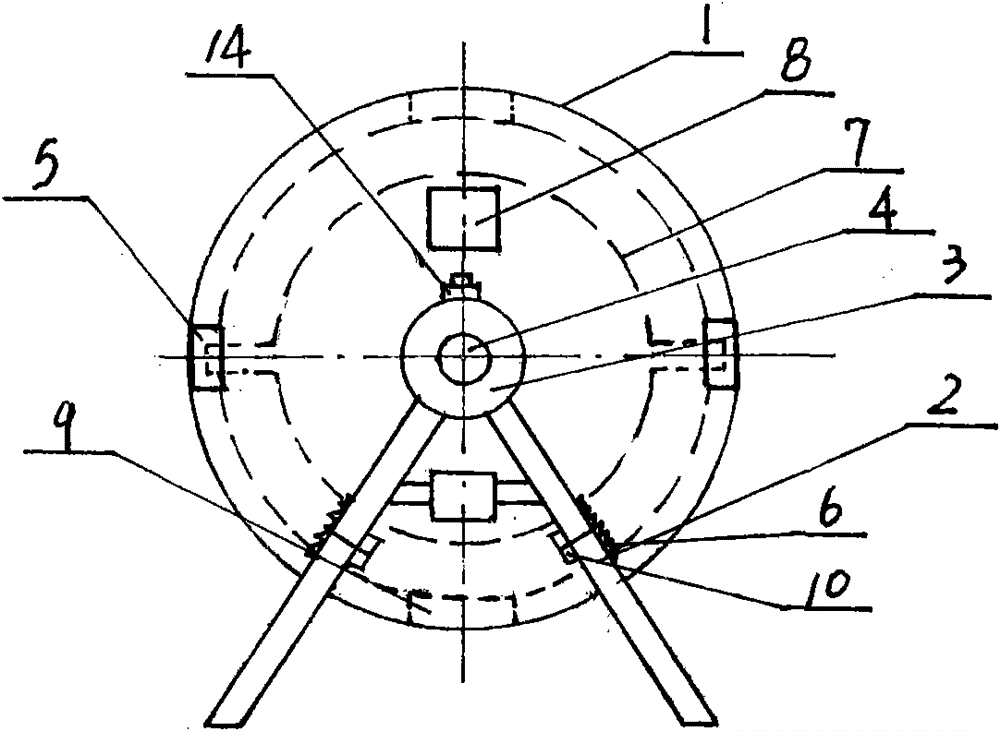

New method for raising bees

The invention discloses a new method for raising bees. The new method utilizes a round rotatable hive, and periodically turns a honeycomb by rotating the hive, so that the head of a queen cell can be upturned after the honeycomb is turned upside down, consequently, the queen cell can be destroyed by worker bees, and thereby the birth of a new queen bee and natural swarming can be controlled. According to the invention, since the round rotatable hive is designed, the birth of a new queen bee and natural swarming can be controlled by periodically turning the honeycomb, and thereby the loss caused by swarming is prevented. Moreover, the honeycomb can be automatically repaired by the bees, consequently, the complex checking work is reduced, the working efficiency is increased, the production cost is reduced, and the income of hivers is increased.

Owner:姜希有

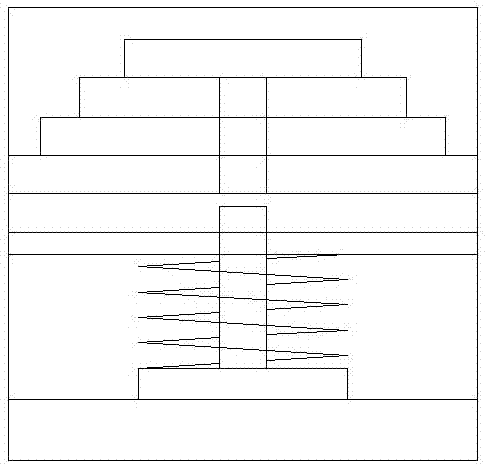

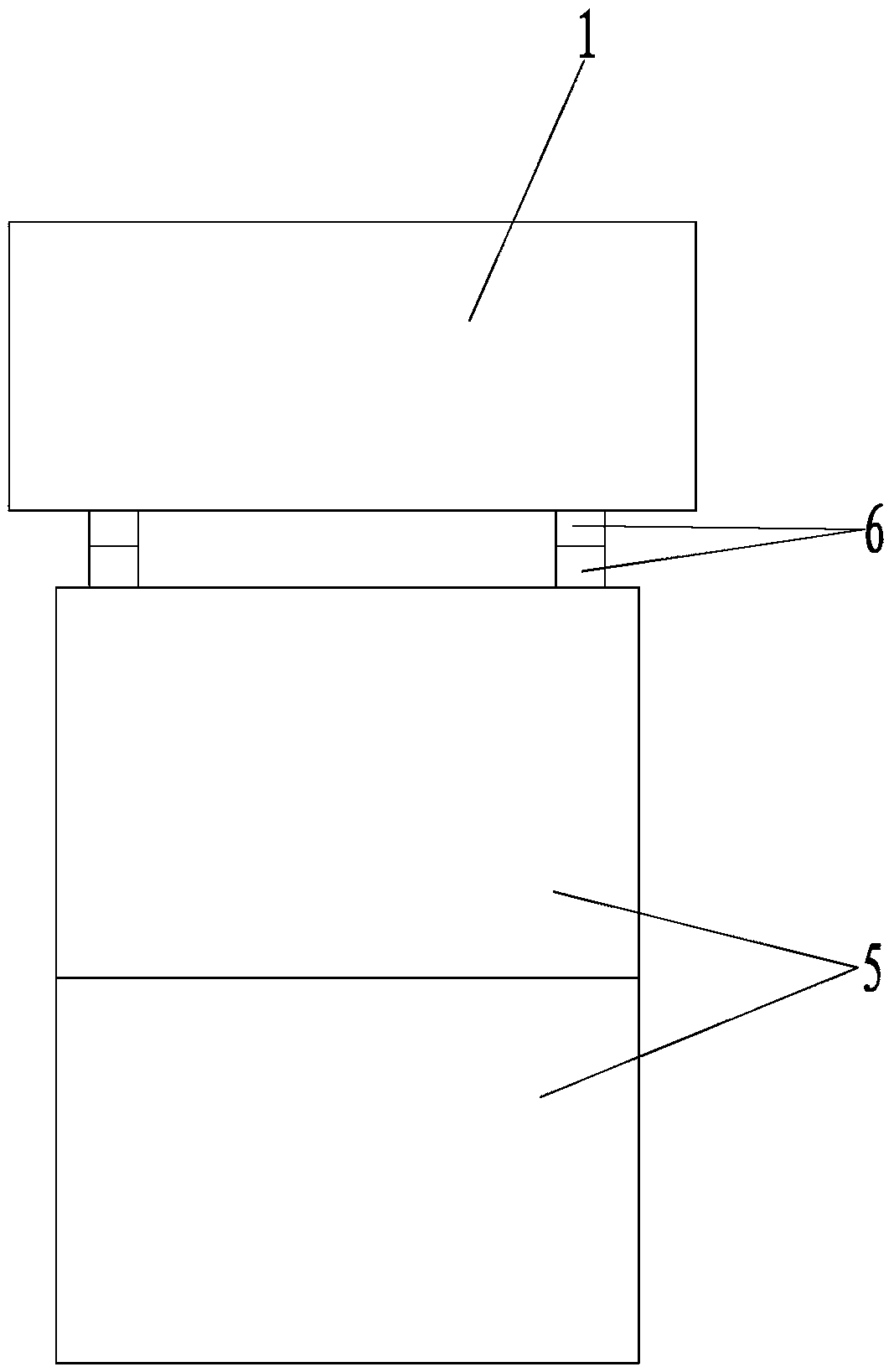

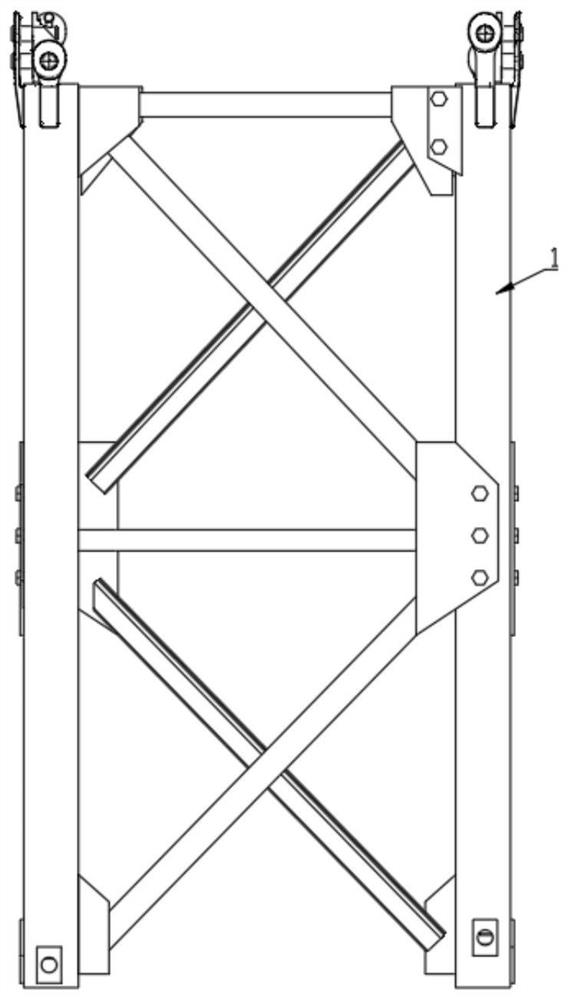

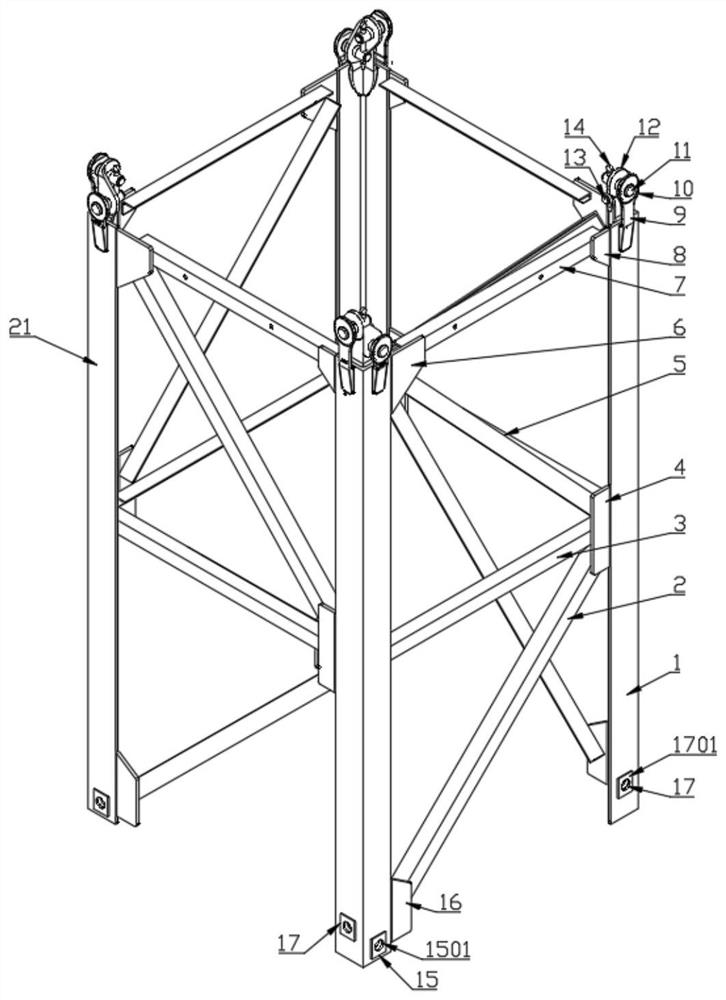

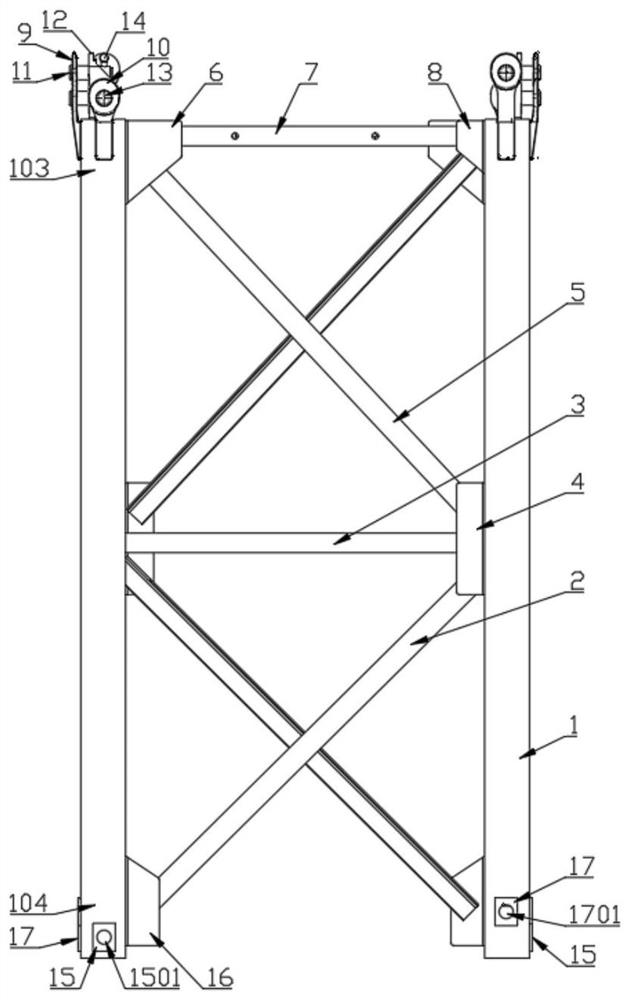

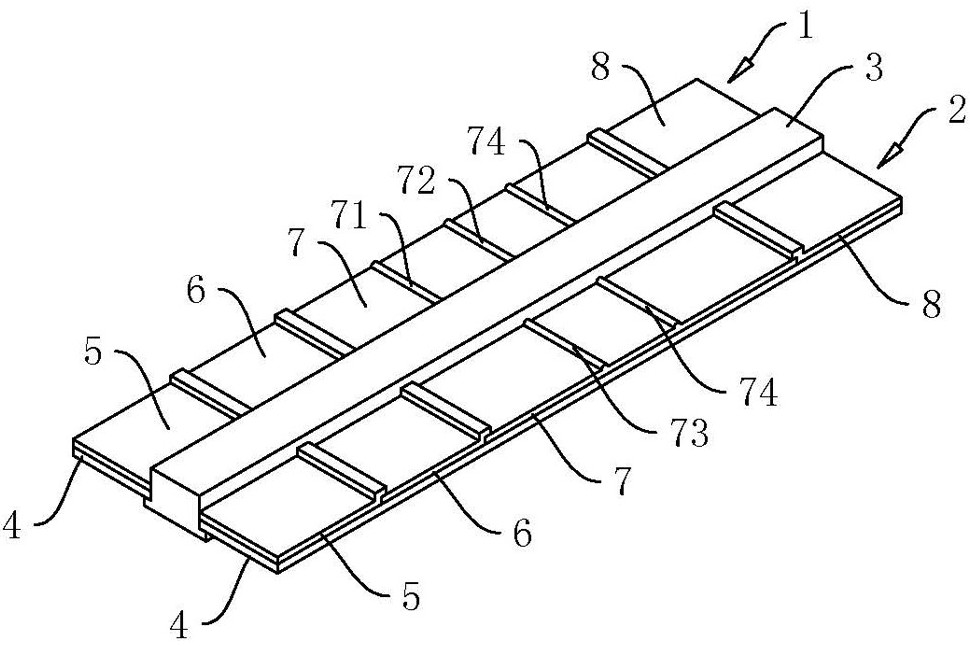

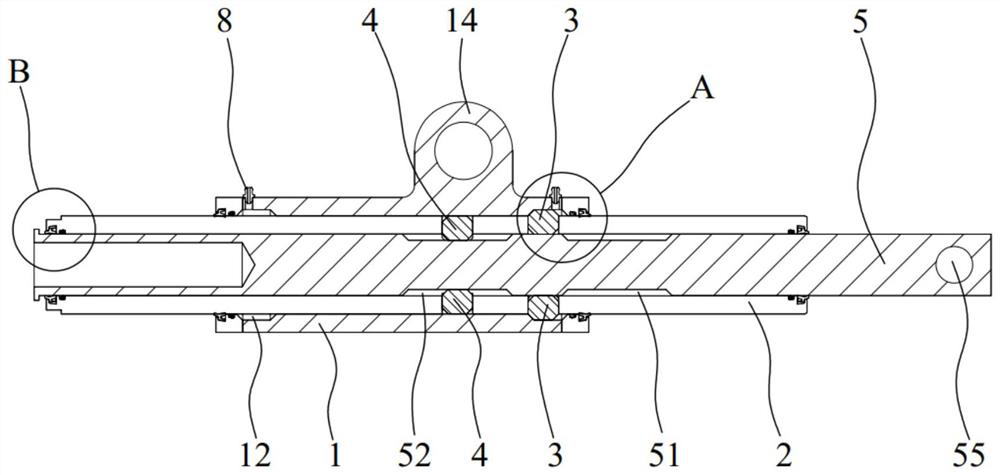

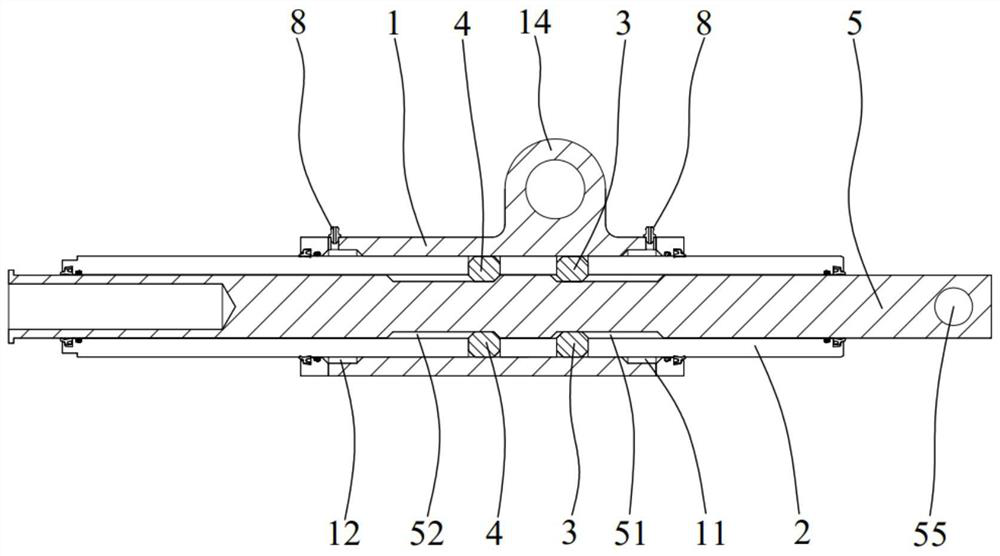

Tower crane standard section and connecting device

InactiveCN112661028ASolve structural safety and high installation costsEliminate potential safety hazardsRod connectionsCranesMechanical engineeringIndustrial engineering

The invention provides a tower crane standard section and connecting device. The device comprises a standard section device and a pin shaft connecting locking device, the standard section device comprises four first main limb columns 1 with angle steel structures, a reinforcing connecting rod, a cross beam rod, an upper connecting plate, a middle connecting plate, a lower connecting plate and the like, the standard section main limb columns adopt the large angle steel structures, the problems of structural safety, high installation cost and the like of a tower crane the standard section can be fundamentally solved, and the potential safety hazard of human factors on standard section connection is eliminated in design. A welding mode is adopted in a whole structure, and the work of field assembly is omitted; sections are connected through the pin shafts, interlocking safety pins are arranged, so that the risk that bolts are loosened due to human errors or improper inspection can be greatly avoided, the potential safety hazard of the standard section connection is thoroughly eliminated, meanwhile, intelligent manufacturing is easy to achieve, and the market competitiveness of products is improved.

Owner:JIANGXI ZHONGTIAN INTELLIGENT EQUIP CO LTD

Super-strength steel tie-back cable at joint for rolling ship elevator and connection structure thereof

InactiveCN101386335AExtended service lifeLifting structure is compactCargo handling apparatusPassenger handling apparatusArchitectural engineeringPulley

The present invention provides a super-strength steel joint inhaul cable used in a roll-on roll-off ship elevator which belongs to the technical field of rope pulling. The steel joint inhaul cable is provided with a structure as follows: one end of a wire rope is connected with a steel pressed joint with a screw; the screw is provided with two nuts used for adjusting the tension of the wire rope; and the other end of the wire rope is connected with a wedge joint. The steel joint inhaul cable is connected with an elevator in a way as follows: one end of the steel pressed joint with the screw which is provided with the nut is fixed on a deck steel clapboard of the elevator, and the wedge joint is fixed on an ear plate of a cabin bottom steel clapboard. The steel joint inhaul cable is fixed, the elevator deck is raised and dropped by the rising and the descending of an oil cylinder, the steel joint inhaul cable is fixed and positioned integrally, and the elevating work is finished by every cable passing nine pulley blocks. The steel joint inhaul cable ensures the elevating structure is more compact, more reasonable and more convenient for changing and the work efficiency is increased.

Owner:广州建峰钢绳索具有限公司

A self -tight flower basket bolt

The invention provides a self-tightening flower basket bolt. The self-tightening flower basket bolt comprises a bolt body, a first pull rod and a second pull rod, wherein the bolt body is provided with a sleeve, and the first pull rod and the second pull rod are arranged at the two ends of the bolt body. Each pull rod comprises an adjustment rod and a connecting head, wherein each connecting headis located at the front end of the corresponding adjustment rod. The two ends of the bolt body are each provided with a threaded hole. Each adjustment rod penetrates the corresponding threaded hole and extends into the sleeve of the bolt body. The whole adjustment rod of the first pull rod is provided with a thread matched with the corresponding threaded hole. A baffle is arranged at the tail endof the adjustment rod of the second pull rod. An extending-and-contracting component is arranged between the end, close to the inner side of the second pull rod, of the sleeve and the baffle. The middle-rear segment of the adjustment rod of the second pull rod is provided with a locking thread matched with the corresponding threaded hole. The portion, between the locking thread and connecting headof the second pull rod, of the corresponding adjustment rod is a polish rod. When the locking thread is matched with the threaded hole in one end of the bolt body, the extending-and-contracting component is in the compressed state. According to the self-tightening flower basket bolt, the extending-and-contracting component is added on the basis of a common flower basket bolt; the self-tighteningfunction can be achieved; and safety of cargo and transportation tools is guaranteed.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

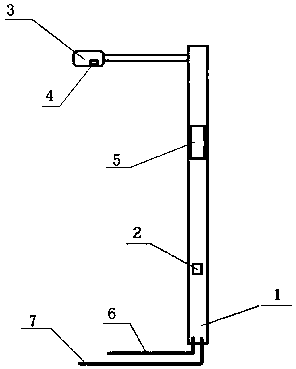

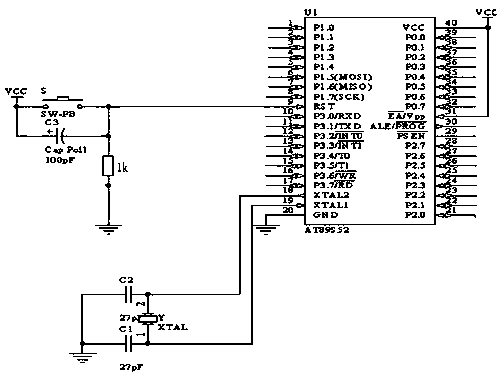

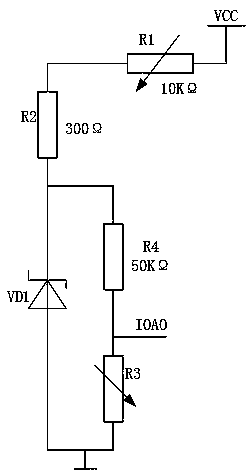

Streetlamp with self-check function

InactiveCN109931548AReduce inspection workFully automatedLighting support devicesElectric circuit arrangementsEngineeringSelf checking

The invention belongs to the technical field of illumination, and particularly relates to a streetlamp with a self-check function. The streetlamp comprises a streetlamp pole and an illumination streetlamp body. The illumination streetlamp body is fixedly arranged at the upper end of the streetlamp pole through a supporting arm. A wireless transmitting module and a power supply centralized controlbox are sequentially arranged in the streetlamp pole from top to bottom. A light detecting module is arranged in the illumination streetlamp body.

Owner:西安发威电子科技有限公司

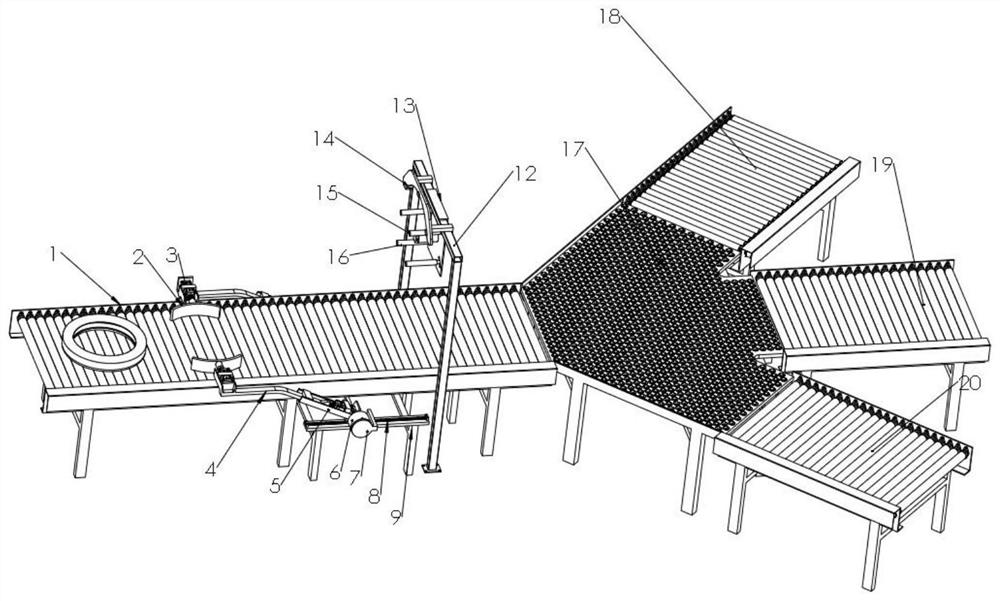

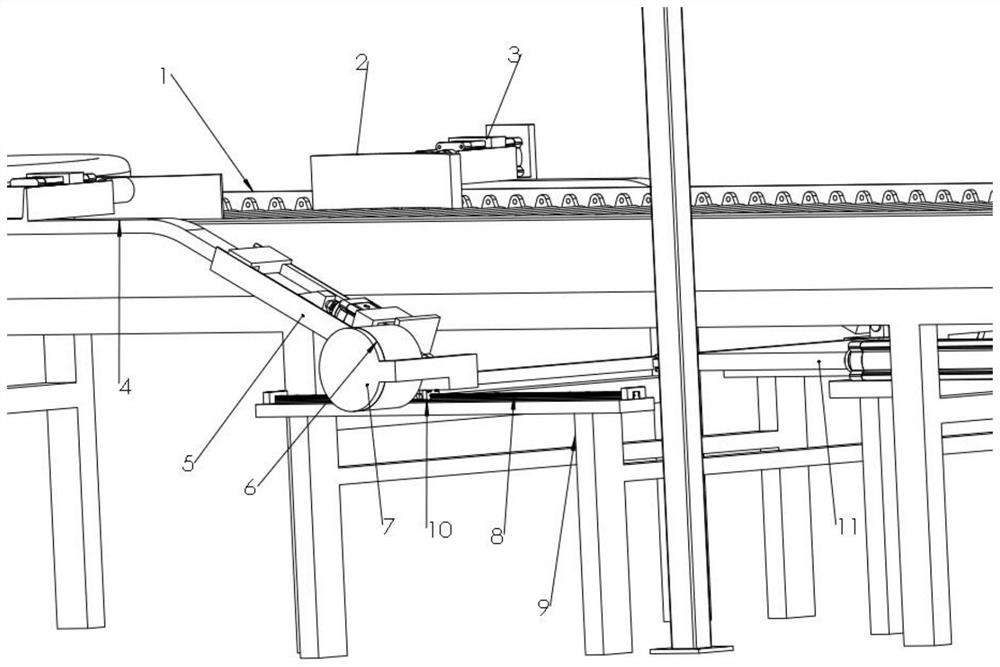

Blank off-line grade judgment device and method

InactiveCN114101098AImprove inspection efficiencyImprove the accuracy of judgmentSortingVulcanizationMechanical engineering

The invention discloses an off-line grade judging device for tire blanks. The off-line grade judging device comprises a main control module, a logistics conveying roller way, a tire blank holding and clamping mechanism, a tire blank supporting and detecting mechanism and a tire blank distributing mechanism. The main control module is connected with and controls other modules; the logistics conveying roller way is connected with the green tire distributing mechanism, the green tire supporting and detecting mechanism is arranged on the front side of the green tire distributing mechanism and used for detecting green tires, and the green tire clamping mechanism is arranged on the front side of the green tire supporting and detecting mechanism and used for grabbing and controlling the green tires to complete detection; and the tire blank shunting mechanism completes tire blank shunting according to a detection result of the tire blank holding and clamping mechanism. According to the invention, the tire blank is detected before being vulcanized, so that the grade of the tire blank is judged in advance, unqualified products are directly returned to be repaired or scrapped, and one-time vulcanization and inspection work is reduced; and qualified products are also graded and marked in advance, so that the efficiency of the inspection process is improved, and the technical blank that only finished tires can be inspected but tire blanks cannot be inspected in advance in the current world tire manufacturing process is solved and filled up.

Owner:ZHEJIANG UNIV +1

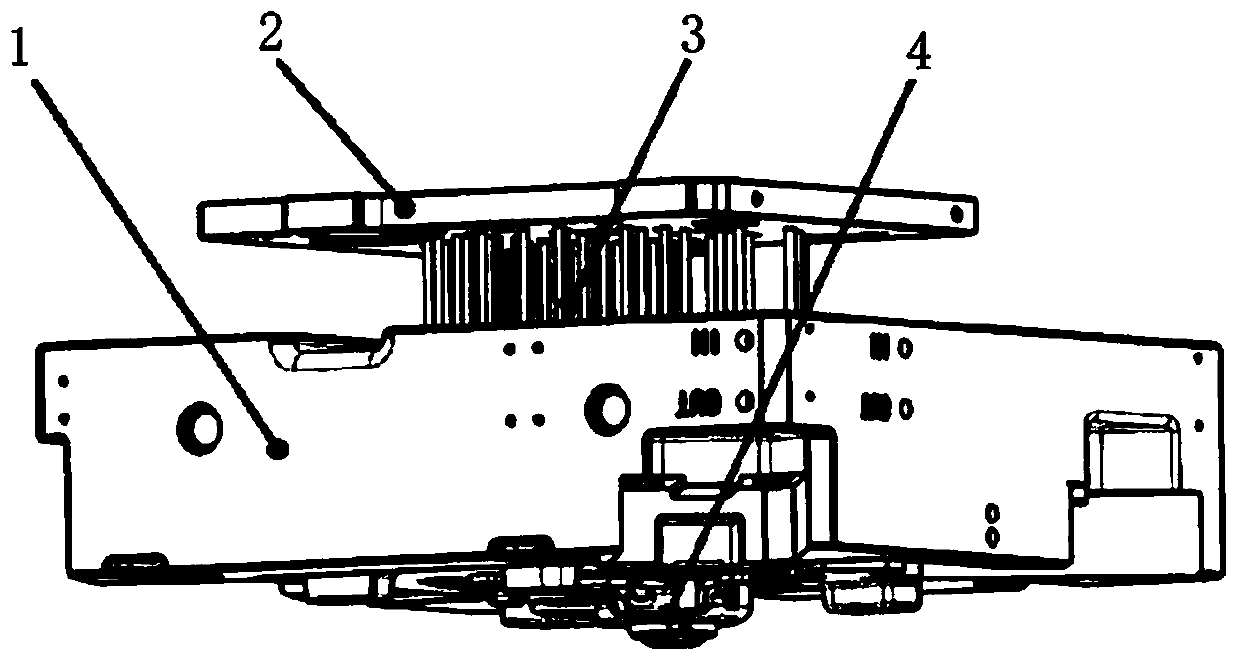

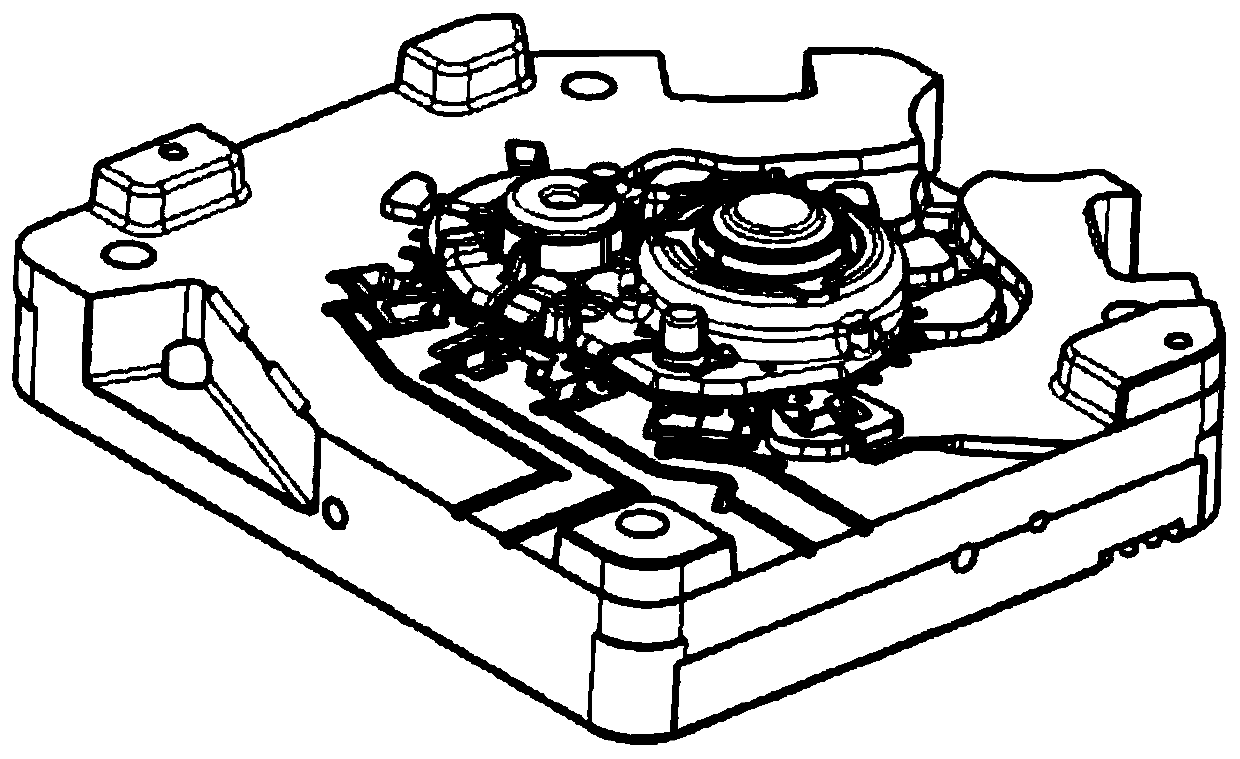

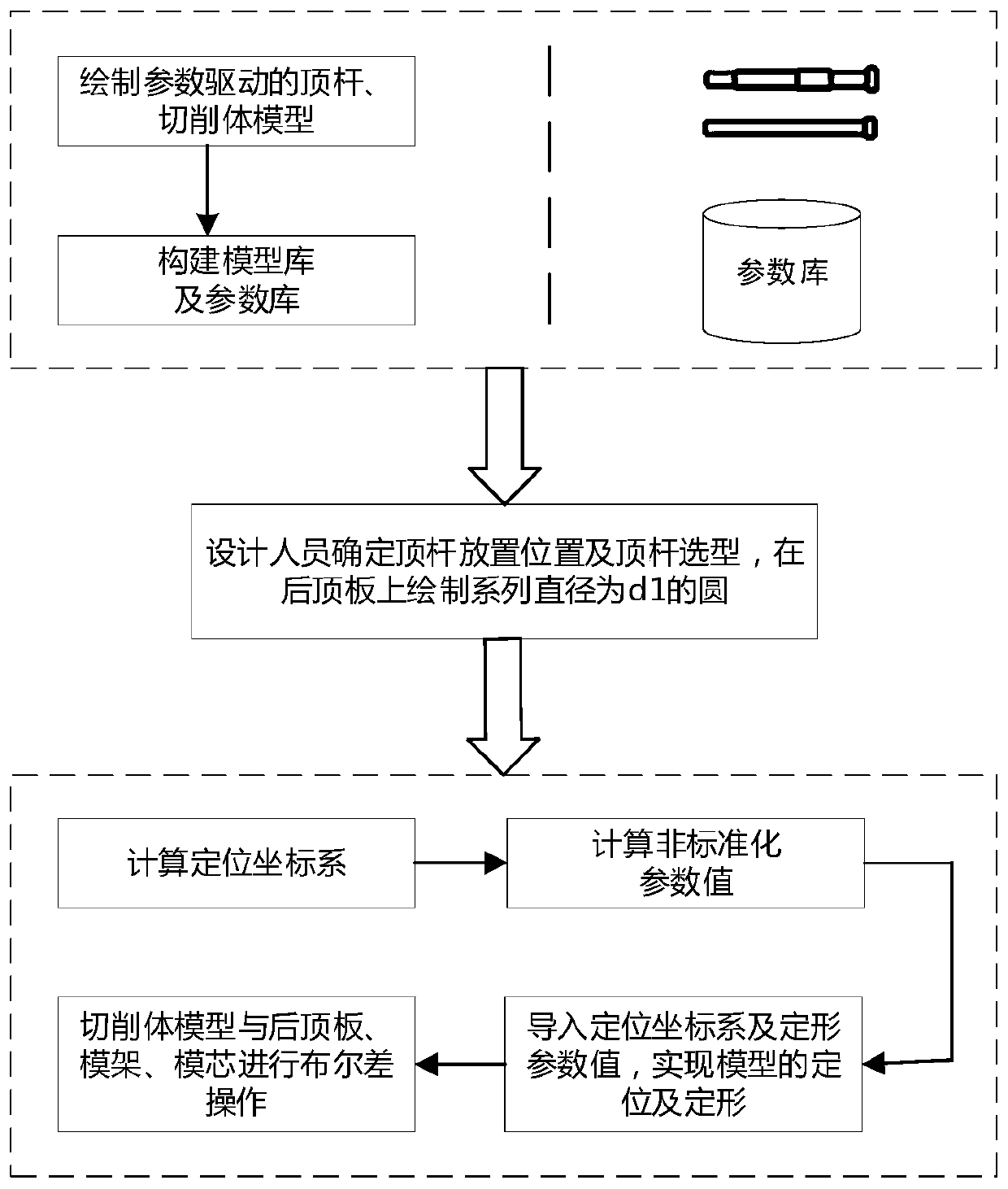

Ejector rod rapid modeling method for die-casting mold

InactiveCN110232209AReduced modeling effortGuaranteed accuracyGeometric CADDesign optimisation/simulationDie castingEngineering

The invention discloses an ejector rod rapid modeling method for a die-casting mold. The ejector rod rapid modeling method comprises the following steps: constructing a parameterized driven ejector rod and cutting body model, and dividing the parameterized driven ejector rod and cutting body model into standard parameters and non-standard parameters by analyzing parameter types, wherein the standardized parameters are assigned by directly reading the parameters in a database, and the non-standardized parameters establish a relationship with a rear top plate, a mold frame and a mold core model,and the non-standardized parameters are deduced reversely by automatically calculating the distances among the rear top plate, the mold frame and the mold core; and calculating a positioning coordinate system of the ejector rod and the cutting body. The ejector rod rapid modeling method has the beneficial effects that when the ejector rod rapid modeling method is adopted, the modeling workload ofmold designers is greatly reduced. By adopting the ejector rod rapid modeling method provided by the invention, the accuracy of the ejector rod and the cutting body model is ensured, and the checkingwork on the model accuracy is directly omitted, and only the placement point of the ejector rod and the type selection are required to be checked accurately, so that the research and development period of the mold is further shortened, and the mold repair cost caused by inaccurate model is reduced.

Owner:ZHEJIANG WANXIANG SYST +1

Streetlamp with self-check alarm function

InactiveCN109931547AReduce detection workImprove work efficiencyElectric circuit arrangementsOutdoor lightingSelf checkingElectrical and Electronics engineering

The invention belongs to the technical field of illumination, and particularly relates to a streetlamp with a self-check alarm function. The streetlamp comprises a streetlamp pole and an illuminationstreetlamp body. The illumination streetlamp body is fixedly arranged at the upper end of the streetlamp pole through a supporting arm. A wireless transmitting module and a power supply centralized control box are sequentially arranged in the streetlamp pole from top to bottom. A light detecting module is arranged in the illumination streetlamp body.

Owner:西安发威电子科技有限公司

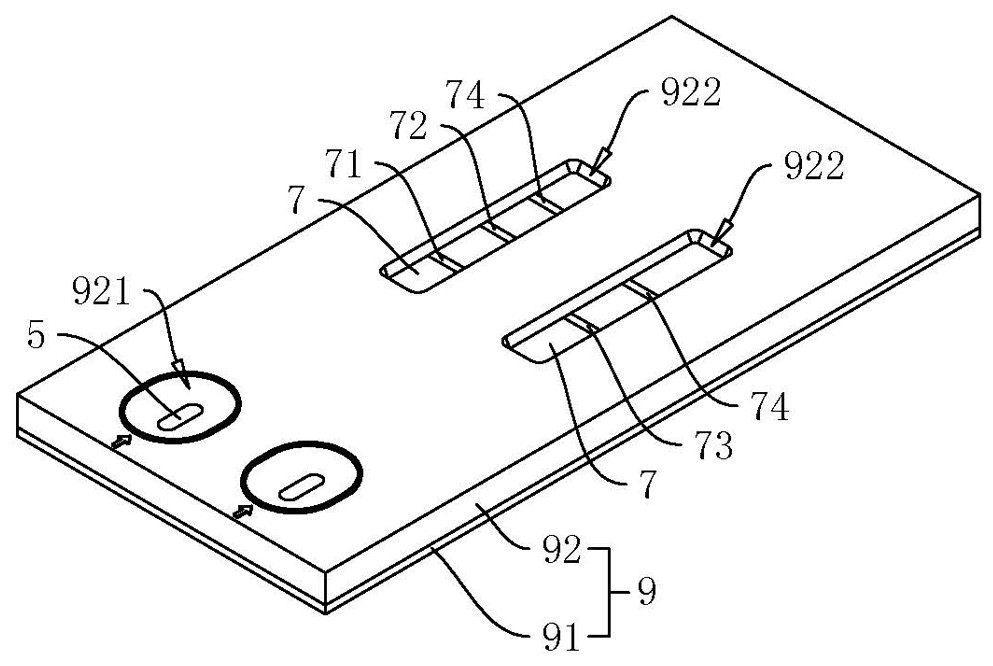

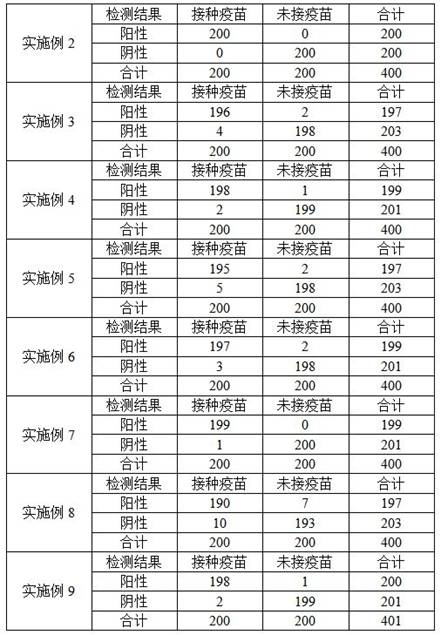

A test strip for joint detection of IgG, IGM and neutralizing antibody, its preparation method and kit

The application relates to the technical field of biomedical detection, in particular to a test strip for joint detection of IgG, IgM and neutralizing antibodies, a preparation method and a kit thereof. The test strip includes a first detection part and a second detection part, both of which include a bottom plate and a sample pad, a binding pad, a detection pad and a water-absorbing pad arranged on the bottom plate and connected in sequence; the binding pad of the first detection part N antigen and S antigen labeled with colloidal gold, the detection pad of the first detection part is provided with a first detection line and a second detection line; the sample pad of the second detection part is coated with ACE2, the Colloidal gold-labeled S-RBD antigen is coated on the binding pad of the second detection part, and a third detection line is arranged on the detection pad of the second detection part. The application can realize on-site high-accuracy rapid detection, and the detection personnel only need to use a test strip to accurately measure IgG, IgM and neutralizing antibodies in the body.

Owner:南京申基医药科技有限公司

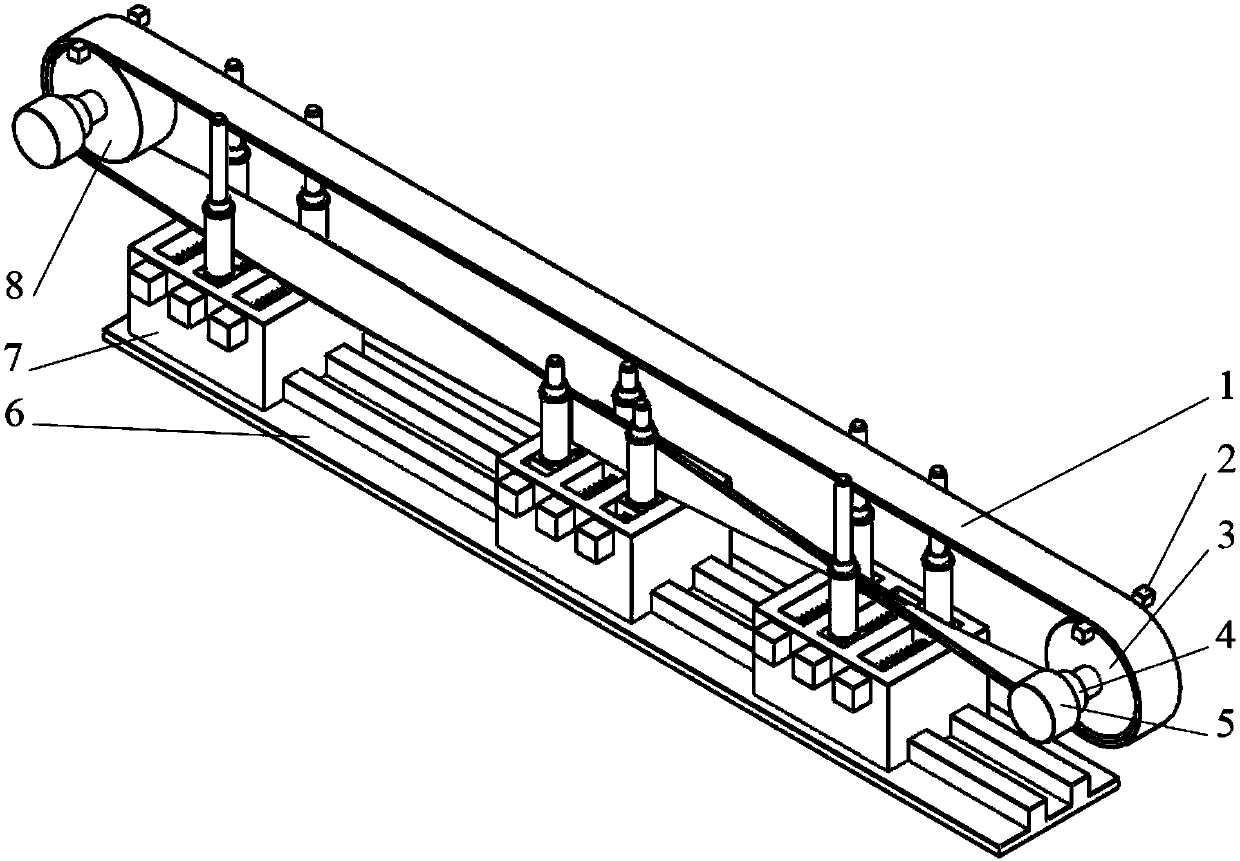

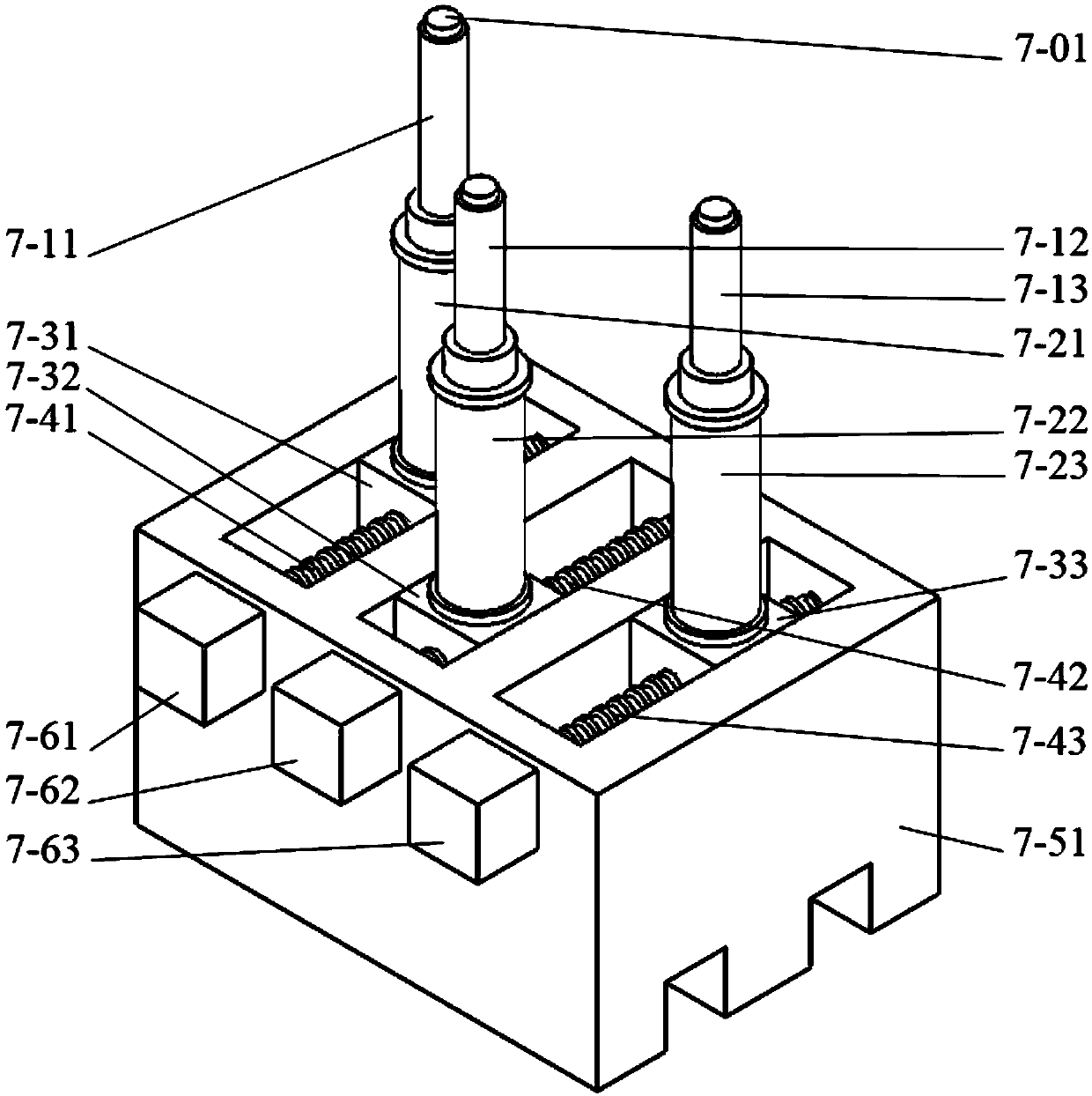

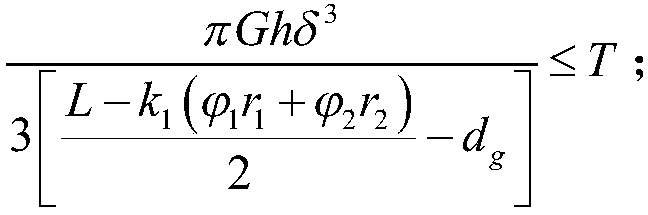

High-precision steel belt transmission and transmission method thereof

ActiveCN108799427AStrong anti-deviation abilitySimple structureGearingTransmission time delayDrive motor

The invention discloses a high-precision steel belt transmission and a transmission method thereof. In the existing steel belt transmission products, steel belt slip, steel belt deflection, transmission time delay and the like of the steel belt transmission system affecting the transmission precision exist all the time. The high-precision steel belt transmission comprises a rack, a driving steel belt wheel, a driven steel belt wheel, a Moebius steel belt, a wheel axle, a drive motor, an off tracking prevention range sensor group, an angular displacement sensor and a tensioning off tracking prevention mechanism. The tensioning off tracking prevention mechanism comprises a guide rail and an auxiliary assembly; and the auxiliary assembly comprises a sliding table,a stepping motor, a lead screw, a sliding block, a tensioning roller, an electric push rod and a tensioning range sensor. Compared with a common steel belt, the Moebius steel belt has higher off tracking prevention capacity. According to the actual load pressure variation, the high-precision steel belt transmission can adjust the tensile force of the steel belt in real time, can prevent slippage and also can control the pressure to the wheel axle within a reasonable range.

Owner:HANGZHOU DIANZI UNIV

Nozzle oil supply system

ActiveCN104929840BReduce inspection workAvoid failures caused by cloggingHigh pressure gas fuel injectionMachines/enginesHigh pressureHigh pressure gas

The invention discloses a nozzle oil supply system. The nozzle oil supply system comprises a high-pressure fuel supply system for providing high-pressure fuel, a high-pressure gas supply system for providing high-pressure gas, a spraying oil pipe, and a fuel conversion device, wherein the two ends of the spraying oil pipe are respectively connected with a nozzle and the fuel conversion device; the high-pressure fuel supply system is connected with the fuel conversion device, and presses high-pressure fuel, flowing into the fuel conversion device, into the spraying oil pipe under the effect of the fuel conversion device; and the high-pressure gas supply system is communicated with the spraying oil pipe, outwards sprays part fuel in the spraying oil pipe from the nozzle when the high-pressure fuel supply system is closed, and presses the remainder fuel in the spraying oil pipe into the fuel conversion device for outwards flowing. The nozzle oil supply system cannot generate the carbon deposition due to long-time stop of an engine, so that the inspection of the engine before working after the long-time stop is reduced, the fault caused by the blockage of the spraying oil pipe due to the carbon deposition is prevented, and the flight safety is guaranteed.

Owner:CHINA HANGFA SOUTH IND CO LTD

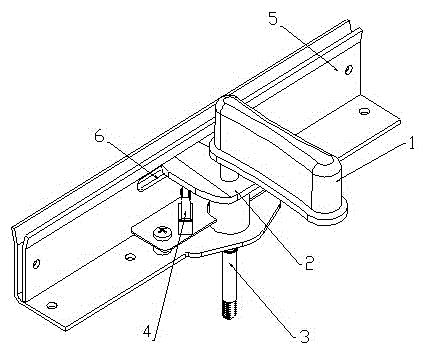

Railway turnout external locking device

PendingCN113562018AAchieve lockingPrevent tamperingLocking mechanisms for pointsStructural engineeringControl theory

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

Oil-water separation and sewage discharge device for transformer oil storage pool

InactiveCN106422425BSolve the problem of stagnant waterReduce operation and maintenance costsLiquid separationLiquid-crystal displayRemote control

The invention discloses an oil-water separating sewage drain device for a transformer oil reservoir. The device is characterized by being composed of an oil reservoir water level determination device (1), an integrated control device (2) and a sewage drain device (3); the oil reservoir water level determination device (1) comprises a supporting rod substrate (1-10), an adjustable supporting rod (1-2), a zero potential contact chip (1-1), a sewage drain pump start contact chip (1-3), and a sewage drain pump stop contact chip (1-4); the integrated control device (2) comprises a control device body (2-13), a power switch (2-6), a liquid crystal display (2-5), and an F21-E1RX remote control device (2-14); the sewage drain device (3) comprises a sewage drain pump (3-1) and a voltage-sensitive relay CJXZ-2510 (3-2). According to the oil-water separating sewage drain device for the transformer oil reservoir, water in the transformer oil reservoir is monitored in real time and drained in time, therefore, the occurrence of an accident that the surrounding environment is damaged due to occurrence of overflow of transformer oil when the oil reservoir is waterlogged is prevented, and the labor intensity of operation and maintenance staff as well as operation and maintenance cost of the device are reduced.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

A temperature-measuring resistor that is not prone to temperature jumps

ActiveCN109141666BEasy to shapePrevent twistingThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceAviation

The invention discloses a temperature measuring resistor with low possibility of temperature value jump. The temperature measuring resistor comprises a temperature measurement probe, the circumferenceof the front end of the temperature measurement probe is provided with forward threads, the circumference of the back end of the temperature measurement probe is provided with counter threads whose diameter is greater than that of the forward threads, an annular groove is arranged between the forward threads and the counter threads, the pitch of the forward threads equals that of the counter threads, the width of the annular groove is greater than the length of the forward threads, the temperature measurement probe is connected with a signal cable via a cable connector, the signal cable is composed of two signal lines, and the cable connector comprises an aviation plug connected with the temperature measurement probe and an aviation socket connected with the signal cable. The temperaturemeasuring resistor has the advantages that the detected temperature value tends not to jump, shutdown due to misoperation of a hydropower station set tends not to occur, a lot of detection and maintenance can be omitted, and the economic benefit of a hydropower station is increased.

Owner:STATE GRID CORP OF CHINA +2

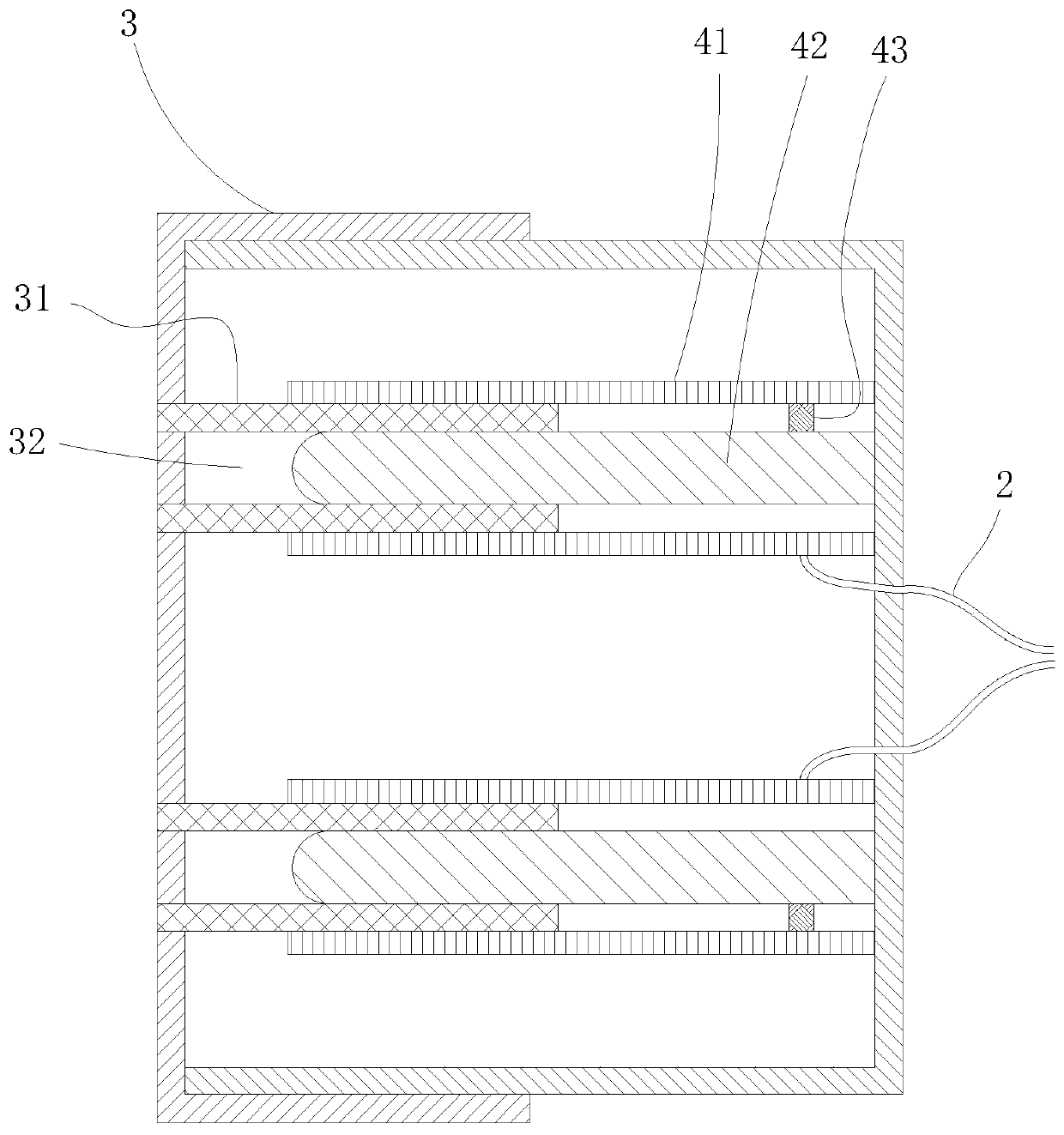

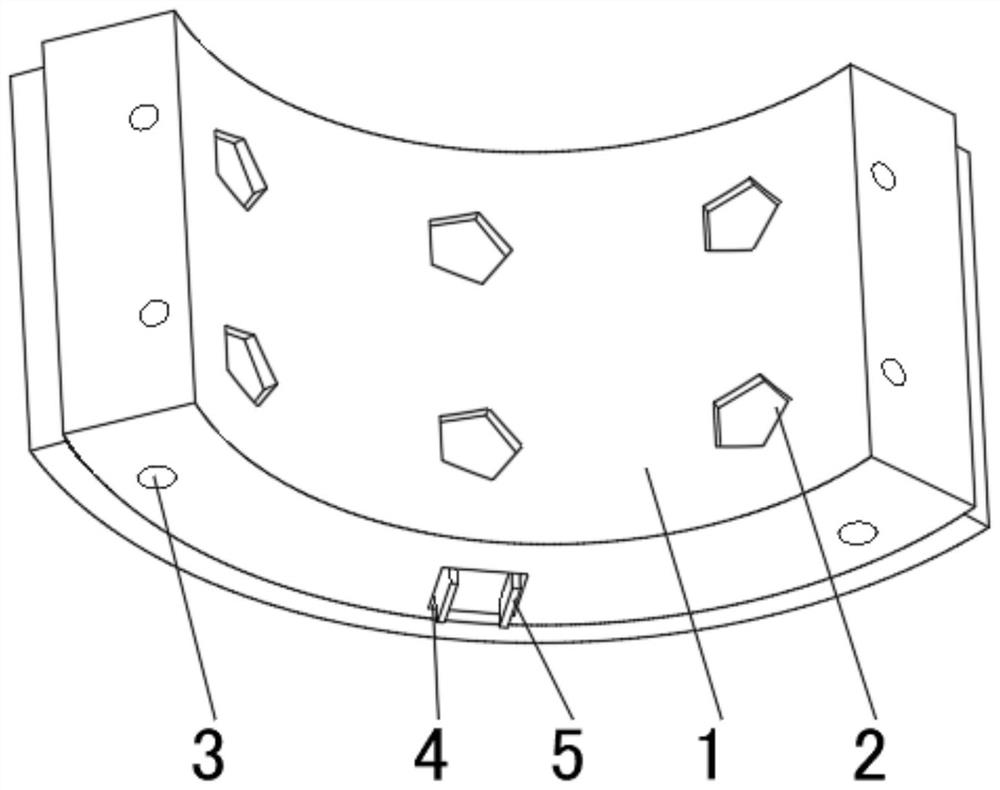

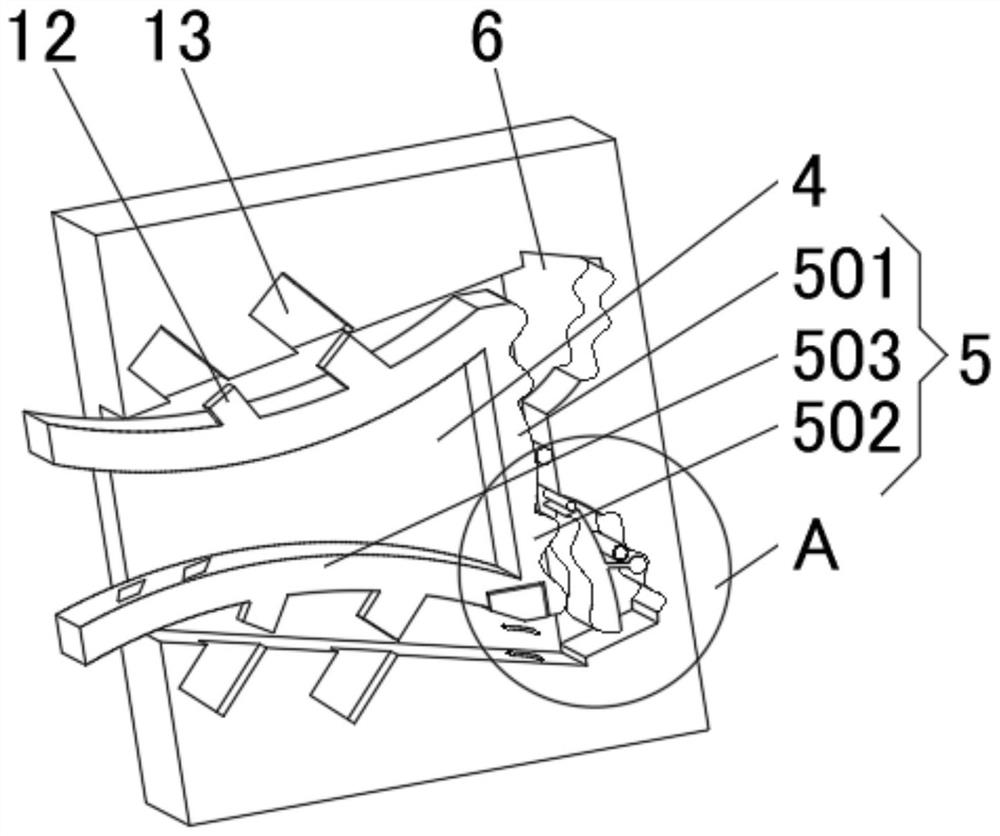

Automatic calibration shield segment

InactiveCN112682068AGuaranteed alignmentEasy alignment and calibrationMining devicesUnderground chambersClassical mechanicsMechanical engineering

The invention discloses an automatic calibration shield segment. The segment comprises an arc-shaped segment body, an annular groove and a longitudinal groove, a calibration groove is formed in one side of the arc-shaped segment body, the calibration groove is a table-shaped groove, a clamping frame is rotatably connected to one side of the inner wall of the calibration groove, and swing grooves are symmetrically formed in one side of the inner wall of the calibration groove. Position correcting devices are installed in the swing grooves, and calibration plates are symmetrically installed on the side, away from the calibration groove, of the arc-shaped segment body. The invention relates to the technical field of tunnel construction. According to the automatic calibration shield segment, the purpose of facilitating calibration between shield segments is achieved, the installation difficulty of the shield segments is reduced, unevenness between the shield segments can be avoided, the butt joint position of the shield segments is automatically calibrated, the inspection work after the shield segments are installed is reduced, the tunnel construction efficiency is improved, damage caused by collision between the shield segments is reduced, the service life of a tunnel is prolonged, and the firmness degree of connection between the shield segments is improved.

Owner:杨亚玲

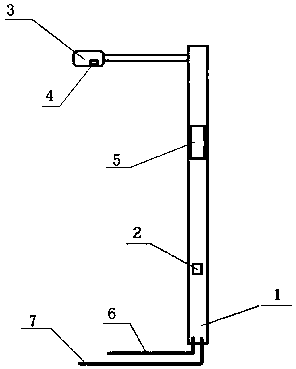

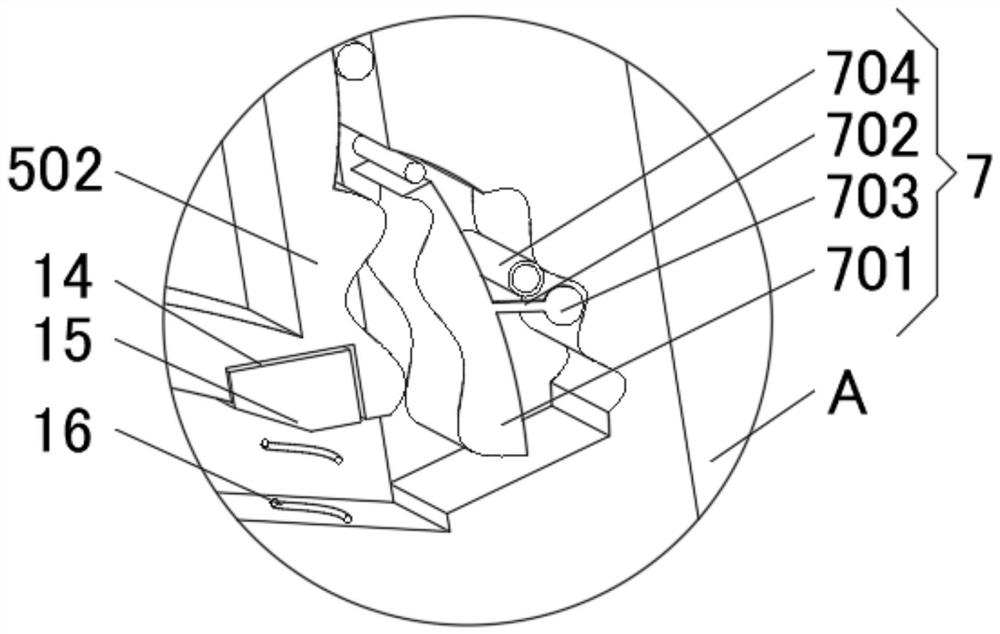

Alarm device for escape hatch

InactiveCN105015416AReduce inspection workSimple structureSignalling/lighting devicesCar drivingEngineering

An alarm device for an escape hatch is composed of an emergency handle (1), a lock shaft (3) and a support assembly (5). A spring bolt (2) is fixedly installed in the middle of the lock shaft (3). The emergency handle (1) is fixedly connected to the top end of the lock shaft (3). The lock shaft (3) is movably connected to the support assembly (5). A lock groove (6) is formed in the support assembly (5). The alarm device is characterized in that a microswitch (4) is fixedly installed on the support assembly (5), installed on one side of the lock shaft (3) and located below the spring bolt (2), and the emergency handle (1) is pulled to drive the lock shaft (3) to rotate so that the spring bolt (2) can enter the lock groove (6) and press down the microswitch (4). The alarm device is simple in structure and convenient and rapid to install, an automobile driver can quite visually recognize whether the escape hatch is opened or closed through a signal lamp, and potential safety hazards during driving are eliminated.

Owner:丹阳市车船装饰件有限公司

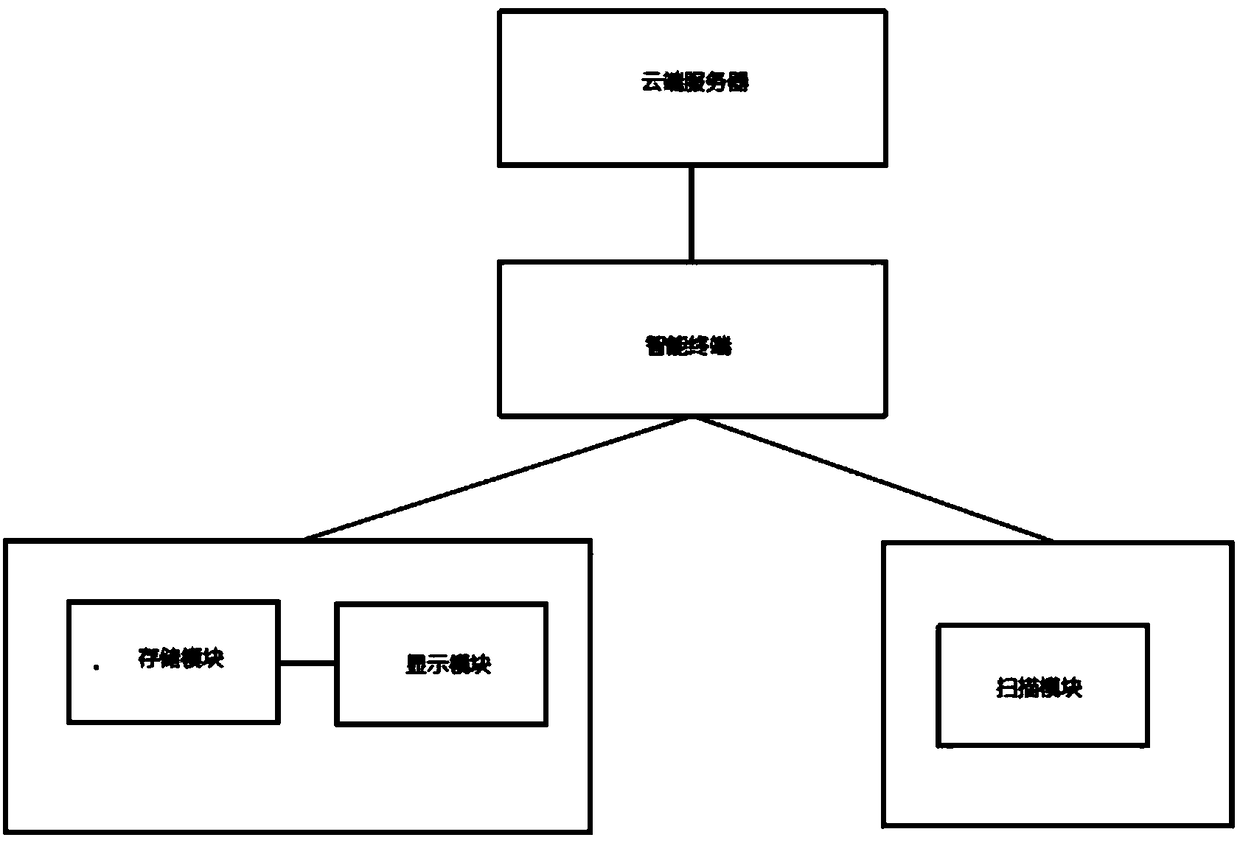

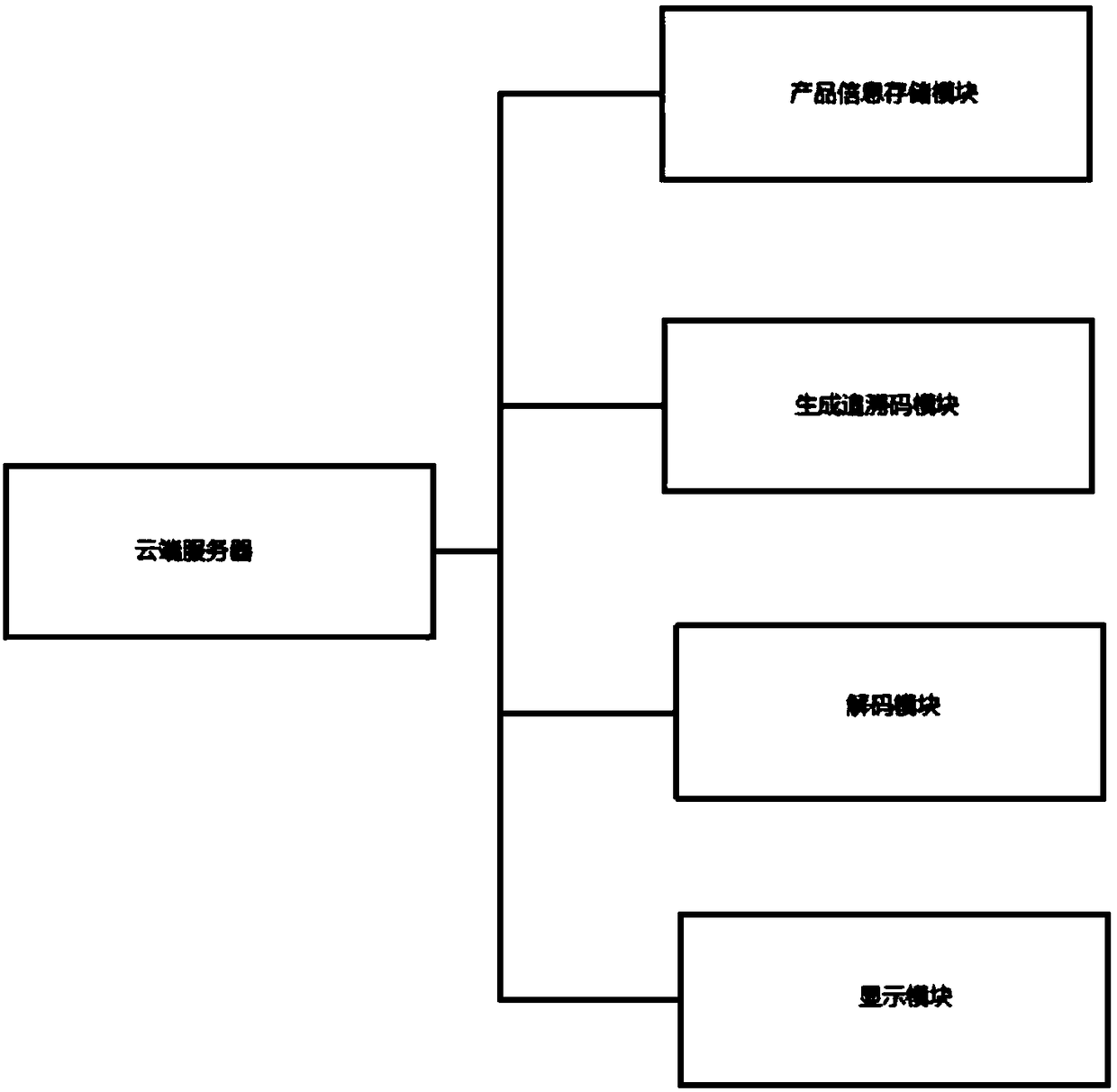

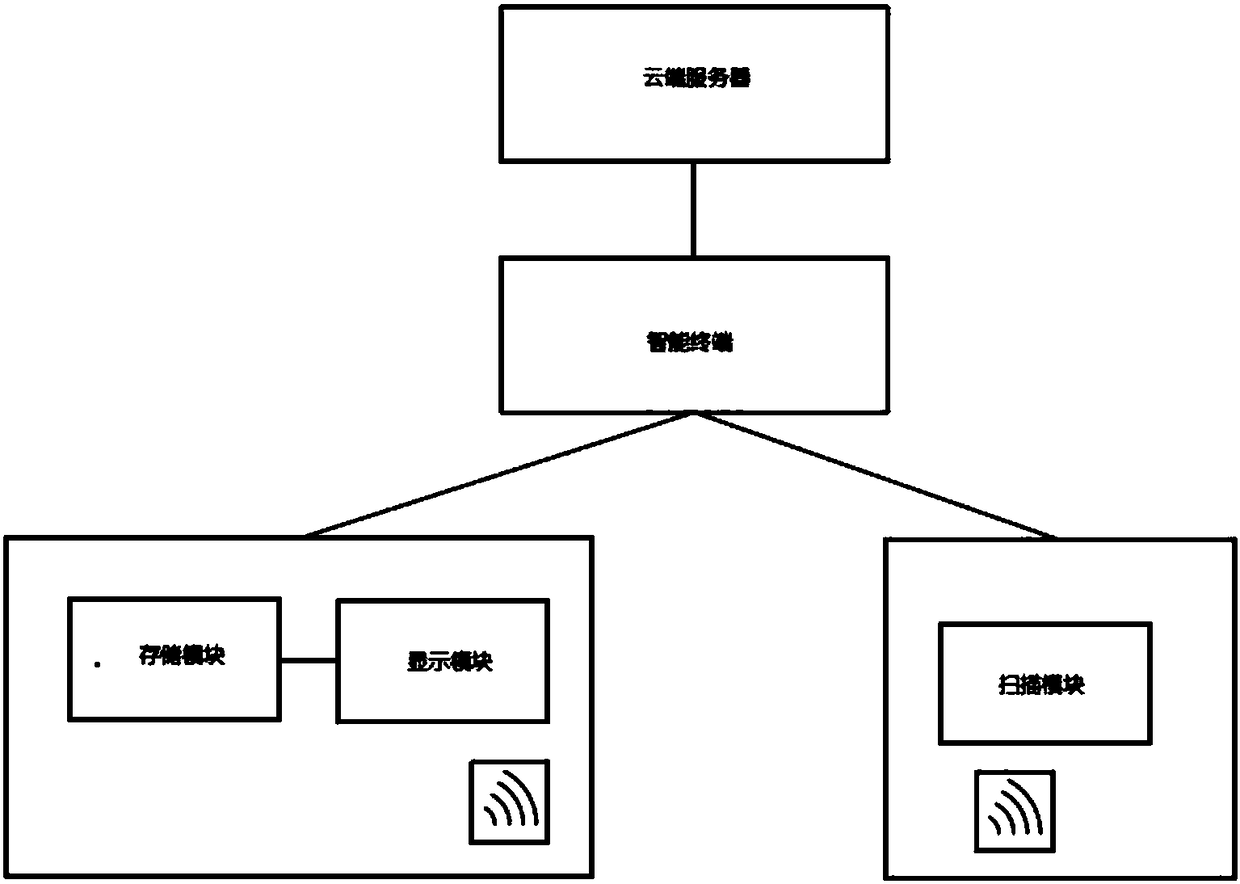

Field management control system and method

InactiveCN108594781AReduce outflowReduce inspection workTotal factory controlProgramme total factory controlData connectionControl system

The invention belongs to the technical field of circular knitting machines and particularly relates to a field management control system and method. The field management control system comprises a cloud server and an intelligent terminal and is characterized in that the cloud server is in data connection with the intelligent terminal, and the intelligent terminal comprises a knitting device and ascanning device. The field management control system has the advantages that the scanning device scans the knitting equipment or products of the knitting device through scanning equipment, managementstaff can fast find out the problems of the knitting equipment or products, the staff can immediately determine the knitting equipment which produces unqualified products when the unqualified productsare detected or the staff can timely discover the problems of the products when the knitting equipment fails, the outflow or inspection of the unqualified products is reduced, ordered production field management is achieved, and production efficiency is increased.

Owner:福建中织源网络科技有限公司

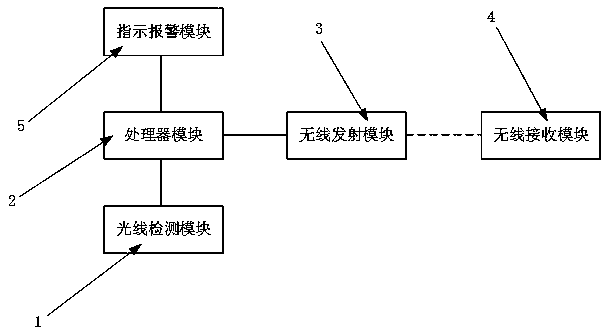

Street lamp self-checking alarm system

The invention belongs to the technical field of lighting, and particularly relates to a street lamp self-checking alarm system which comprises a light detecting module, a processor module, a wirelesstransmitting module, a wireless receiving module and an indicating alarm module. The processor module is electrically connected with the light detecting module, the indicating alarm module and the wireless transmitting module. The wireless transmitting module is wirelessly connected with the wireless receiving module.

Owner:西安发威电子科技有限公司

An on-line monitoring system for gis bus bar

InactiveCN104779568BDeformation monitoringAccurate monitoringCircuit arrangementsBus-bar installationAxial displacementBusbar

The invention relates to an online monitoring system for a GIS busbar barrel. The online monitoring system comprises a monitoring terminal arranged on the barrel and a data processing unit connected with the monitoring terminal, wherein the monitoring terminal comprises a pull rod resistance displacement rule used for detecting the axial displacement of a barrel wall relative to a support, a stay cord displacement sensor used for detecting the displacement of the barrel relative to the ground, and a three-axis acceleration sensor used for detecting the axial and radial warping degrees of the barrel relative to a horizontal plane. By adopting the monitoring system, real-time monitoring can be realized, routing inspection work of workers is reduced, and the labor cost is reduced. Meanwhile, the operation safety of a busbar is improved, accidents, such as cracking of a busbar support, can be effectively prevented, and safety hazards and economic loss caused by bad breakdown repair can be avoided. The system is particularly applied to northwestern districts with a high diurnal temperature difference, high altitude regions, tundra regions and southern geological sedimentation districts.

Owner:PINGGAO GRP +3

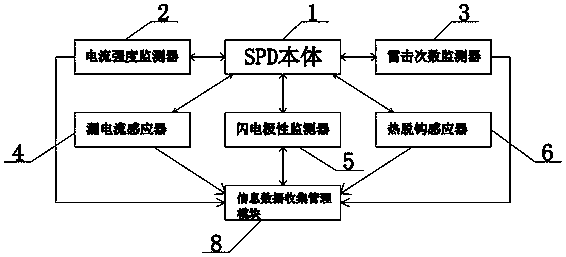

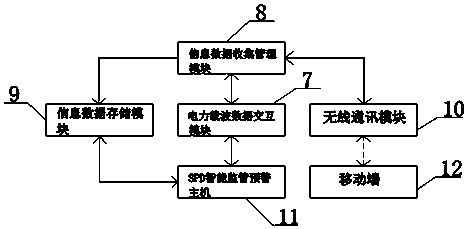

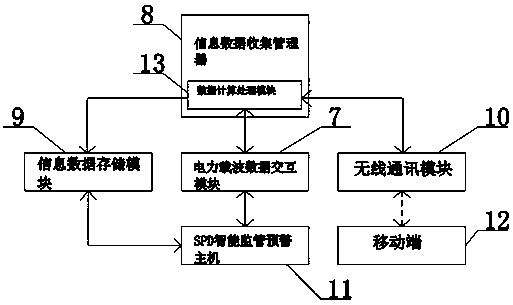

Intelligent SPD system based on power line carrier technology

InactiveCN110278009ATimely maintenanceAvoid lostPower distribution line transmissionAlarmsLightning strokesCollection management

The invention discloses an intelligent SPD system based on a power line carrier technology. The system comprises an intelligent SPD, an SPD information interaction management device and an SPD intelligent supervision early warning host. The information data collection management module is respectively in signal connection with the current intensity monitor, the lightning stroke frequency monitor, the leakage current inductor, the lightning polarity monitor and the thermal unhooking inductor to collect each group of data. The information data collection management module is in signal connection with the information data storage module and is used for storing each group of acquired data into the information data storage module. The information data collection management module is in signal connection with the wireless communication module and is used for transmitting collected data to the Internet of Things, and the information data collection management module is in signal connection with the power line carrier data interaction module and is used for transmitting the collected data to the SPD intelligent supervision early warning host through a power line carrier technology so as to realize remote data monitoring. The intelligent SPD system has the advantages of remotely monitoring the SPD state and reducing the accident rate and the maintenance cost, and is mainly used for SPD intelligent monitoring.

Owner:安徽省建筑设计研究总院股份有限公司

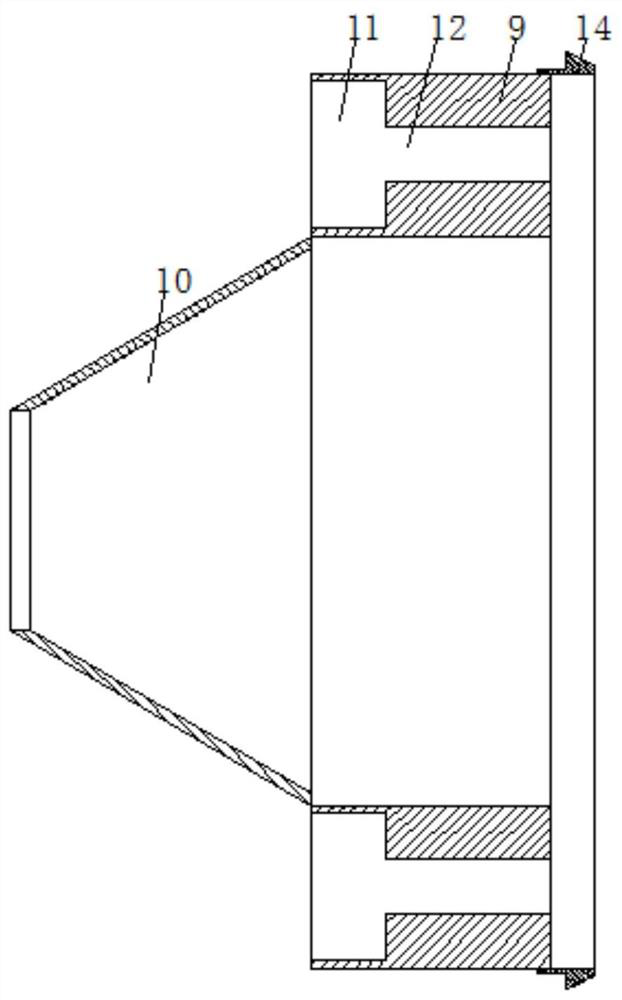

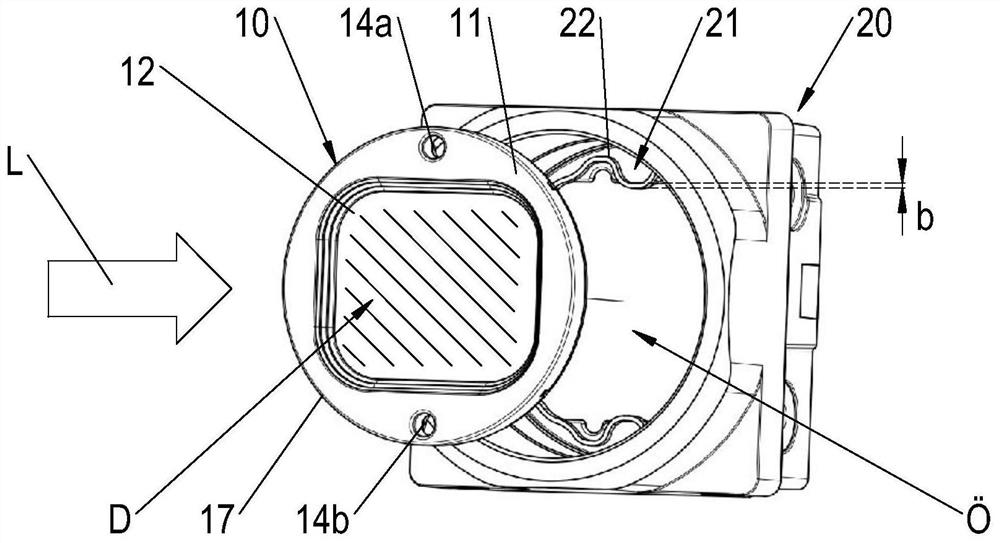

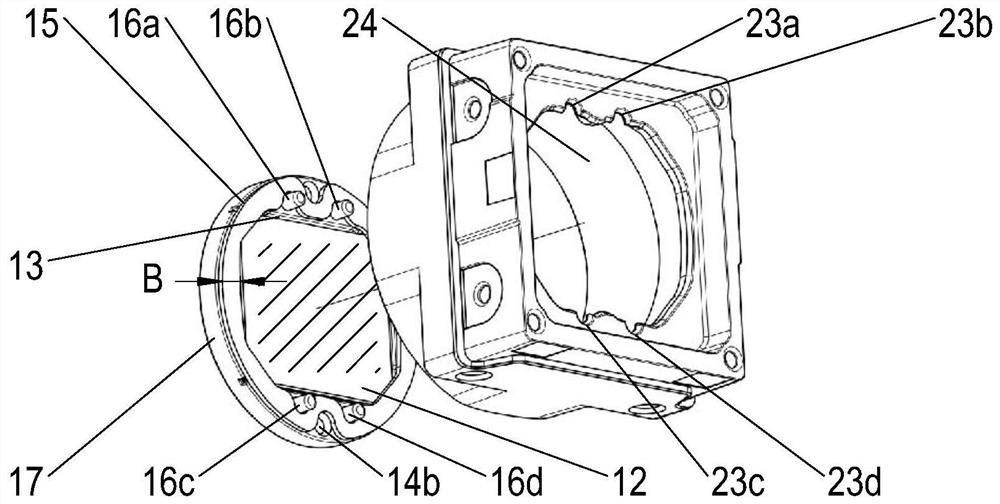

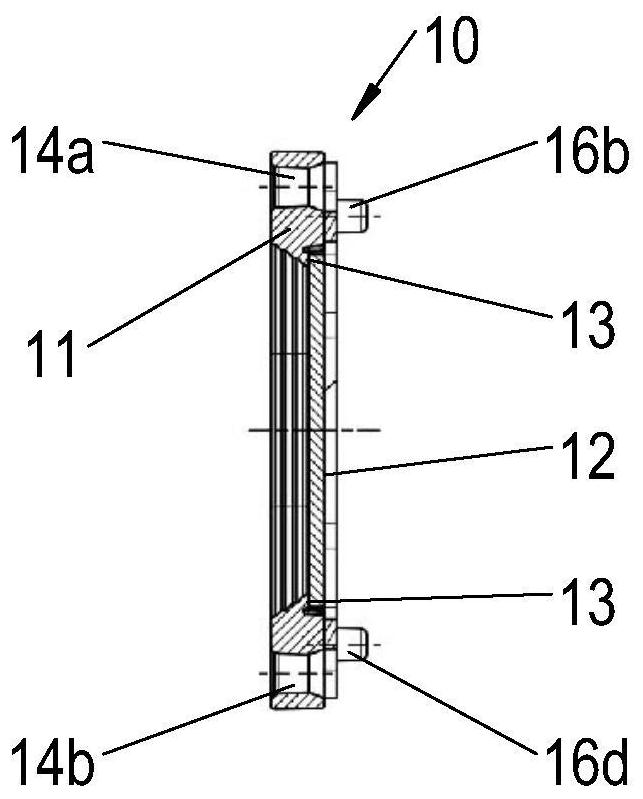

Insertion element with adhesive ring, assembly, lens interface, camera, and manufacturing method

ActiveCN112051698AEasy to fixReduce pollutionMaterial gluingCamera filtersLight beamMechanical engineering

The invention relates to an insertion element (10, 10 ') for detachable insertion into a lens interface (20) of a camera, said insertion element comprising: a frame element (11, 11'), in which a channel (D, D ') for a provided beam path (L) is formed and which has at least two detachment openings (14a, 14b, 14a', 14b '), and an adhesive ring (15, 15 '') secured to the frame element (11, 11 '') foradhering the insertion element in the lens interface, the adhesive ring (15, 15 '') surrounding the channel (D). The invention also relates to an assembly comprising the aforementioned insertion element and comprising a support disc as a removal tool, and to a camera having the aforementioned lens interface (20) and the aforementioned insertion element, and to a method for producing the aforementioned insertion element.

Owner:BASLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com