Patents

Literature

33results about How to "Deformation Monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

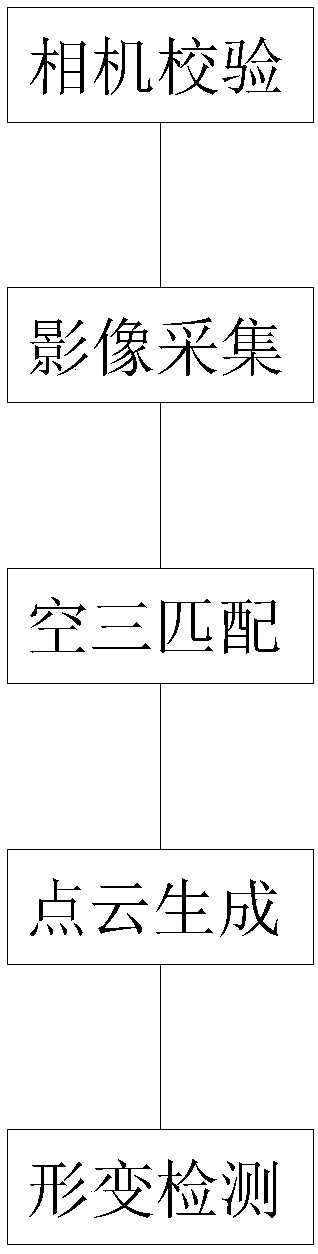

Method for carrying out tunnel rapid deformation measurement by close-range photography

PendingCN108458665ARealize 3D modelingDeformation monitoringUsing optical meansMulti cameraPoint cloud

The invention discloses a method for carrying out tunnel rapid deformation measurement by close-range photography. The method includes camera calibration for calculating the internal orientation element of an imaging system; image acquisition for placing a stereoscopic photography system in the tunnel to acquire the images of the measurement area; three-dimensional matching for giving the rough offset amount between the two images of the matched image pair; point cloud generation for generating the three-dimensional point cloud of the internal structure of the tunnel to construct a three-dimensional model; deformation detection for acquiring the three-dimensional point cloud generated at different time phase in the same region and fitting the generated three-dimensional point cloud by means of kriging interpolation to obtain a fitted curved surface, making the difference of the fitted curved surface at different time phases to obtain a point cloud interpolation graph, so that the deformation monitoring of the tunnel is realized. According to the method for carrying out the tunnel rapid deformation measurement by close-range photography, the photographing measurement is assisted bya multi-camera stereoscopic photography system to obtain the inner orientation element and the distortion parameter of the camera, so that the three-dimensional modeling of the surface of the tunnel is realized, and the deformation of the tunnel in the construction period is monitored.

Owner:中铁八局集团第二工程有限公司

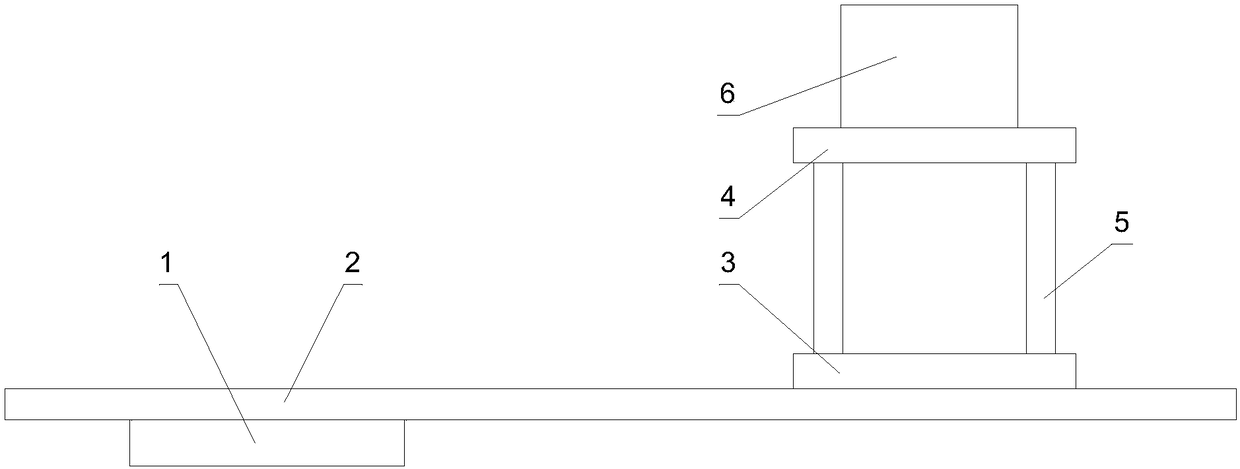

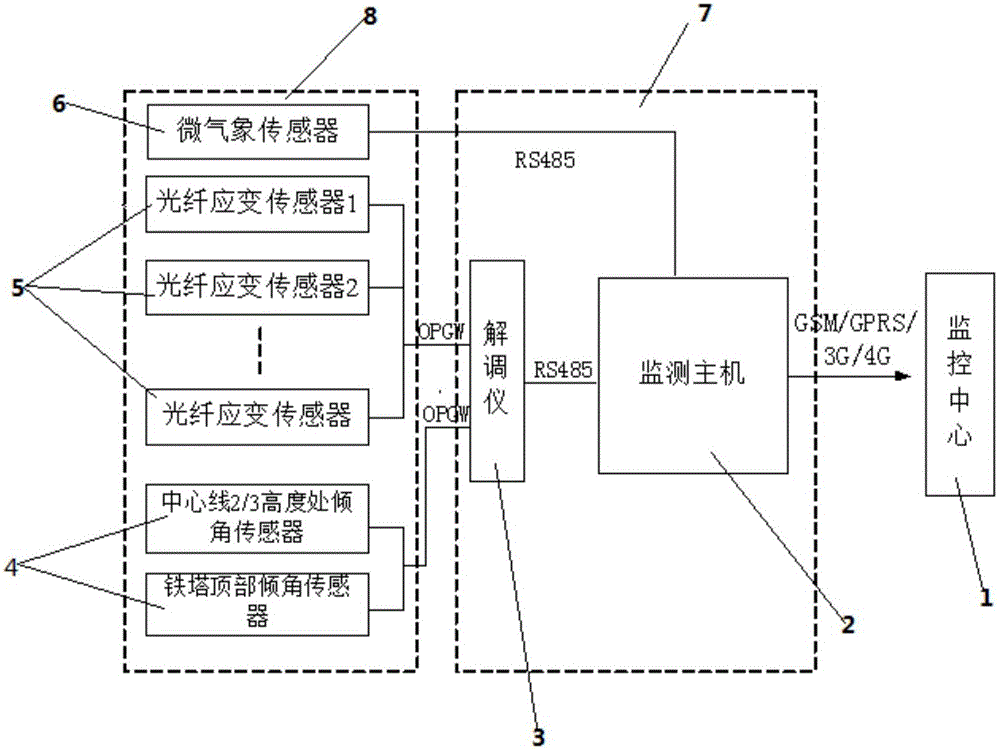

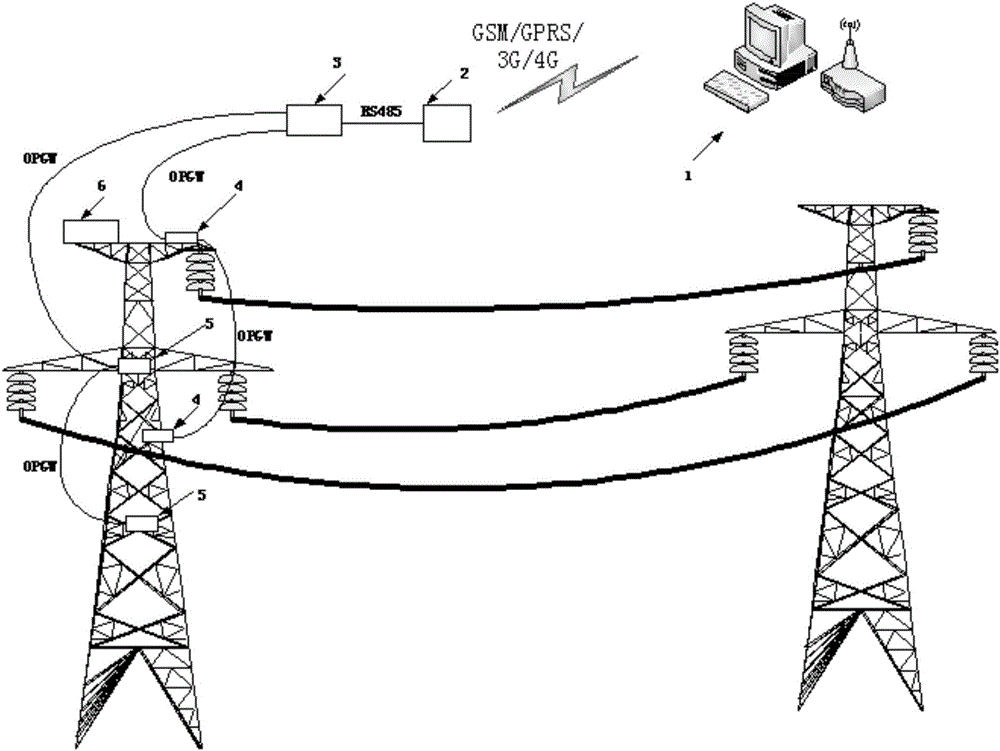

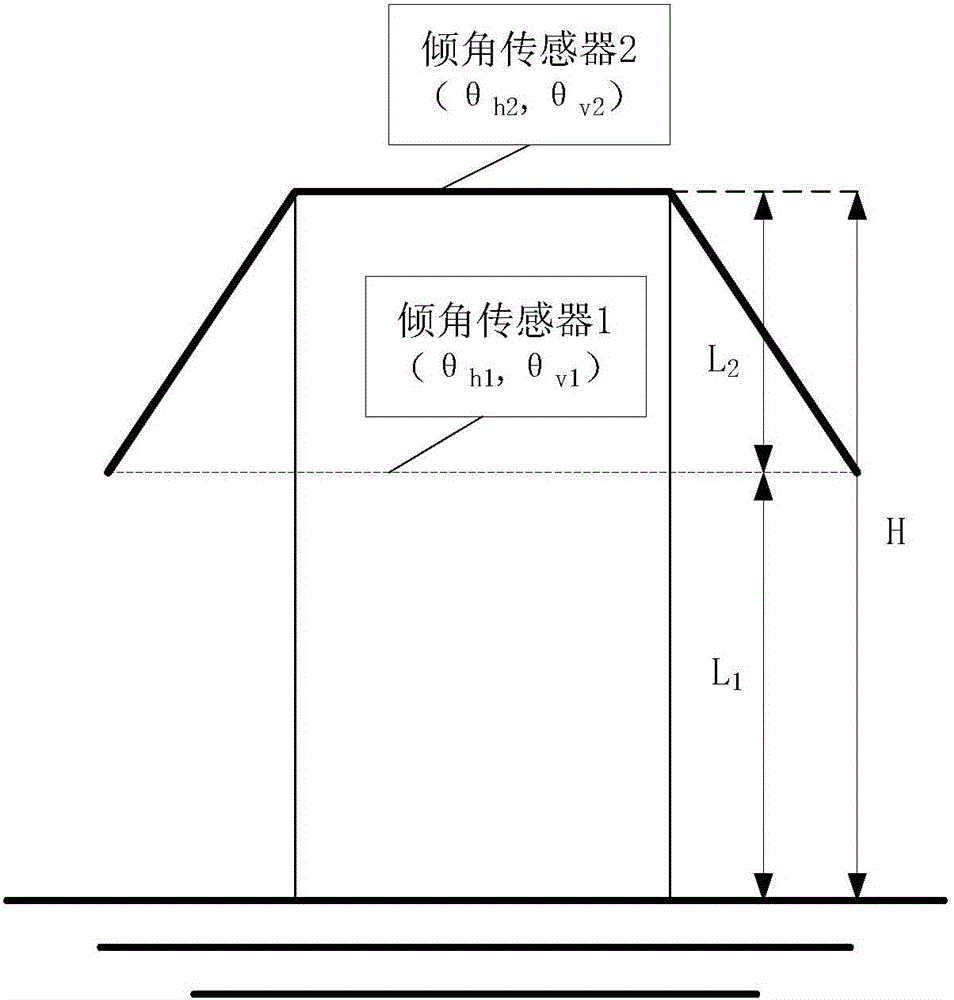

Fiber-grating-based power transmission line iron tower deformation on-line monitoring device and method

InactiveCN105783756ADeformation monitoringReal-time monitoring of deformationUsing optical meansIncline measurementFiberGrating

The invention discloses a fiber-grating-based power transmission line iron tower deformation on-line monitoring device. The fiber-grating-based power transmission line iron tower deformation on-line monitoring device comprises a monitoring center, a substation and a monitoring terminal, wherein the substation and the monitoring terminal are connected with the monitoring center in sequence. The monitoring terminal comprises a plurality of fiber grating strain sensors. The fiber grating strain sensors are connected with a fiber grating demodulator in the substation through an OPGW. A fiber grating inclination sensor group is also connected with the fiber grating demodulator. The fiber grating inclination sensor group is connected with the fiber grating demodulator in the substation through an OPGW. The fiber grating demodulator is connected with a detection host. The detection host is also connected with a microclimate sensor. The problem that tiny deformation of an iron tower cannot be accurately monitored through an existing detection method is solved. The invention also discloses a monitoring method of the fiber-grating-based power transmission line iron tower deformation on-line monitoring device.

Owner:XI'AN POLYTECHNIC UNIVERSITY

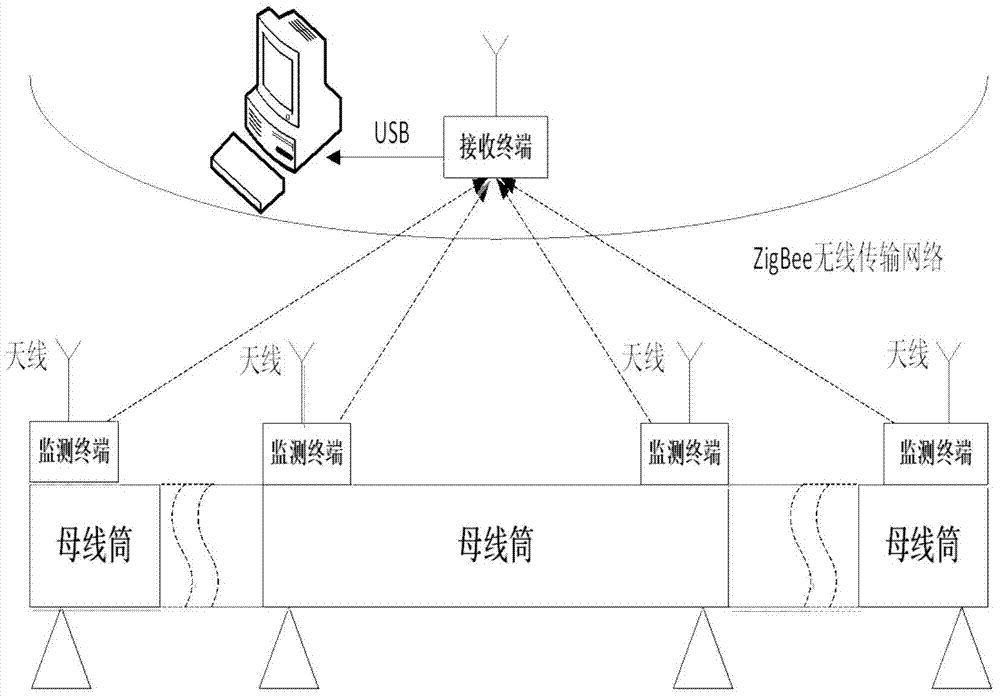

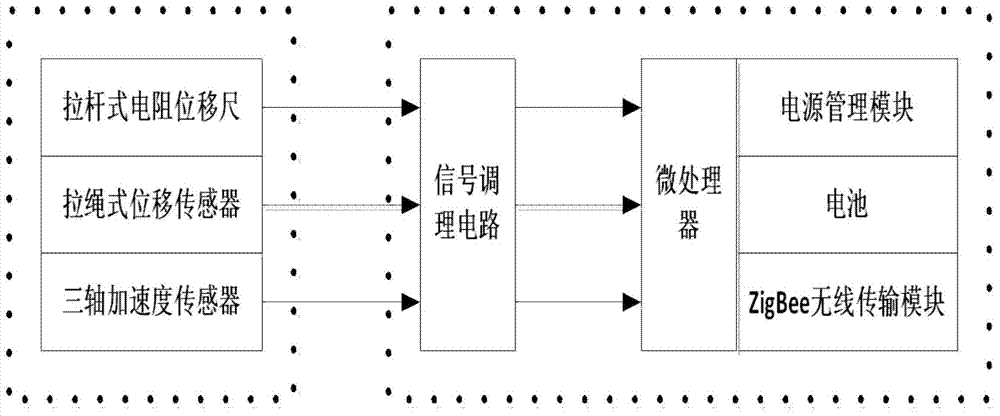

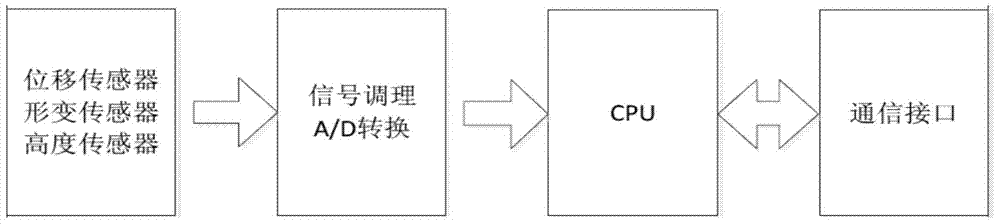

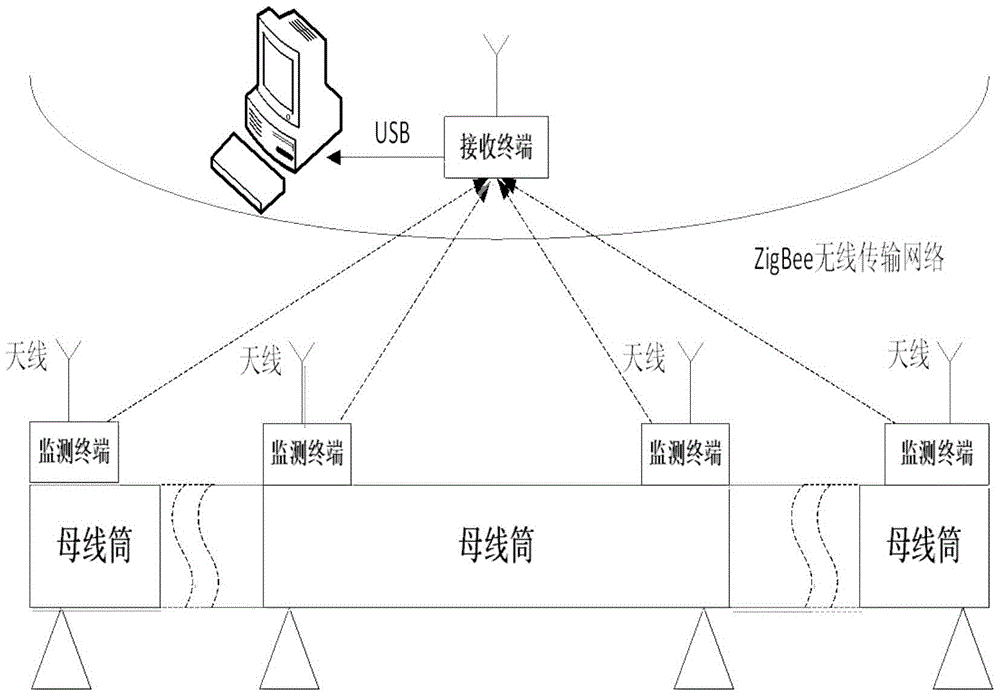

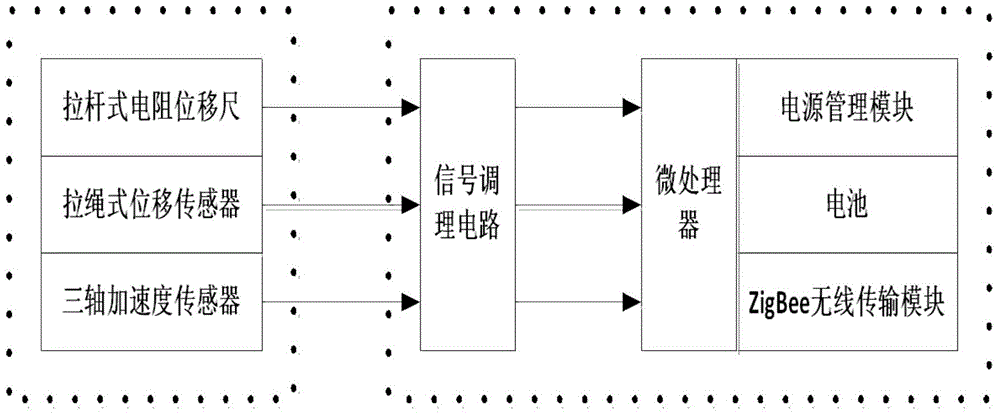

Online monitoring system for GIS busbar barrel

InactiveCN104779568ADeformation monitoringAccurate monitoringCircuit arrangementsBus-bar installationAxial displacementBusbar

The invention relates to an online monitoring system for a GIS busbar barrel. The online monitoring system comprises a monitoring terminal arranged on the barrel and a data processing unit connected with the monitoring terminal, wherein the monitoring terminal comprises a pull rod resistance displacement rule used for detecting the axial displacement of a barrel wall relative to a support, a stay cord displacement sensor used for detecting the displacement of the barrel relative to the ground, and a three-axis acceleration sensor used for detecting the axial and radial warping degrees of the barrel relative to a horizontal plane. By adopting the monitoring system, real-time monitoring can be realized, routing inspection work of workers is reduced, and the labor cost is reduced. Meanwhile, the operation safety of a busbar is improved, accidents, such as cracking of a busbar support, can be effectively prevented, and safety hazards and economic loss caused by bad breakdown repair can be avoided. The system is particularly applied to northwestern districts with a high diurnal temperature difference, high altitude regions, tundra regions and southern geological sedimentation districts.

Owner:PINGGAO GRP +3

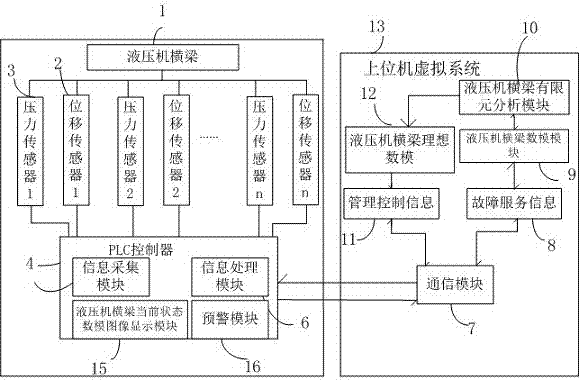

Large hydraulic press crossbeam parallel control system

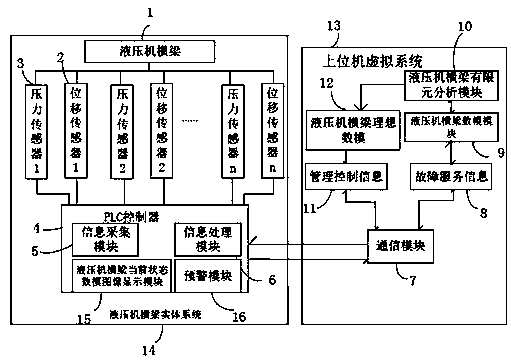

ActiveCN107042653AImprove fault monitoring rateReduce failurePressesService informationElement analysis

The invention discloses a large hydraulic press crossbeam parallel control system. The large hydraulic press crossbeam parallel control system comprises a hydraulic press crossbeam physical system and an upper computer virtual system which are connected through communication modules. The hydraulic press crossbeam physical system comprises a hydraulic press crossbeam, a plurality of displacement sensors and a plurality of pressure sensors which are arranged at stress concentration positions of the hydraulic press crossbeam, and a PLC; both the displacement sensors and the pressure sensors are connected with the PLC; the upper computer virtual system comprises failure service information and management control information which are directly in communication with and in handshake with the PLC, hydraulic press crossbeam finite element analysis modules are transmitted to hydraulic press crossbeam ideal digital analogy, then the management control information is obtained through a contrastive analysis, and the management control information is in handshake with the PLC through the communication modules. According to the large hydraulic press crossbeam parallel control system, fault emergency monitoring efficiency is improved, and useful empirical data for optimization design of the large hydraulic press in later period, compensation of deflection deformation and the like are provided.

Owner:南通华德锻压机床有限公司

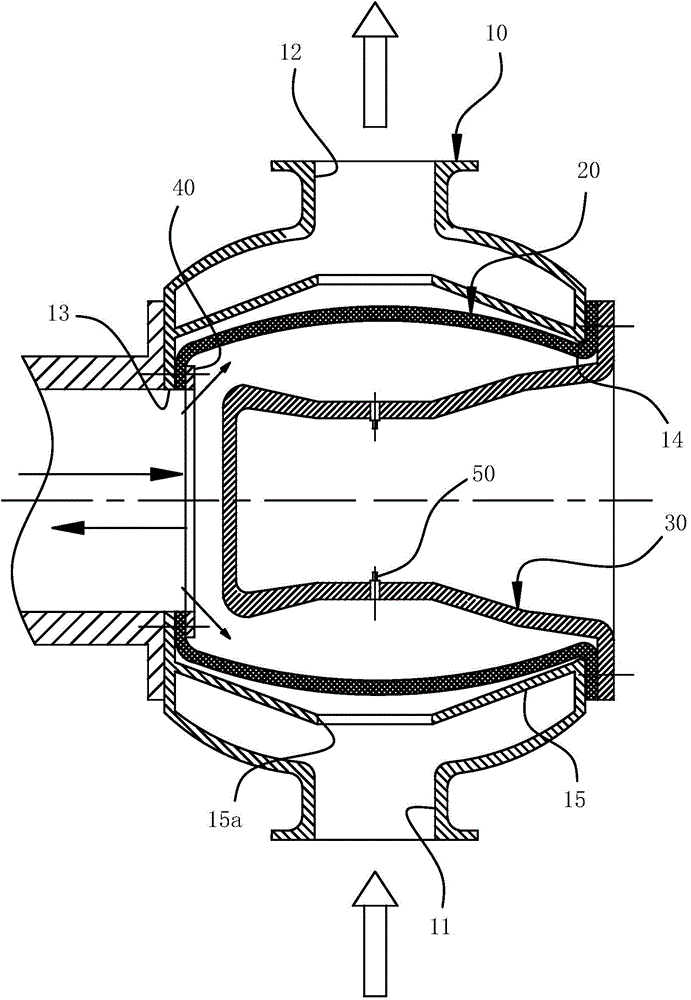

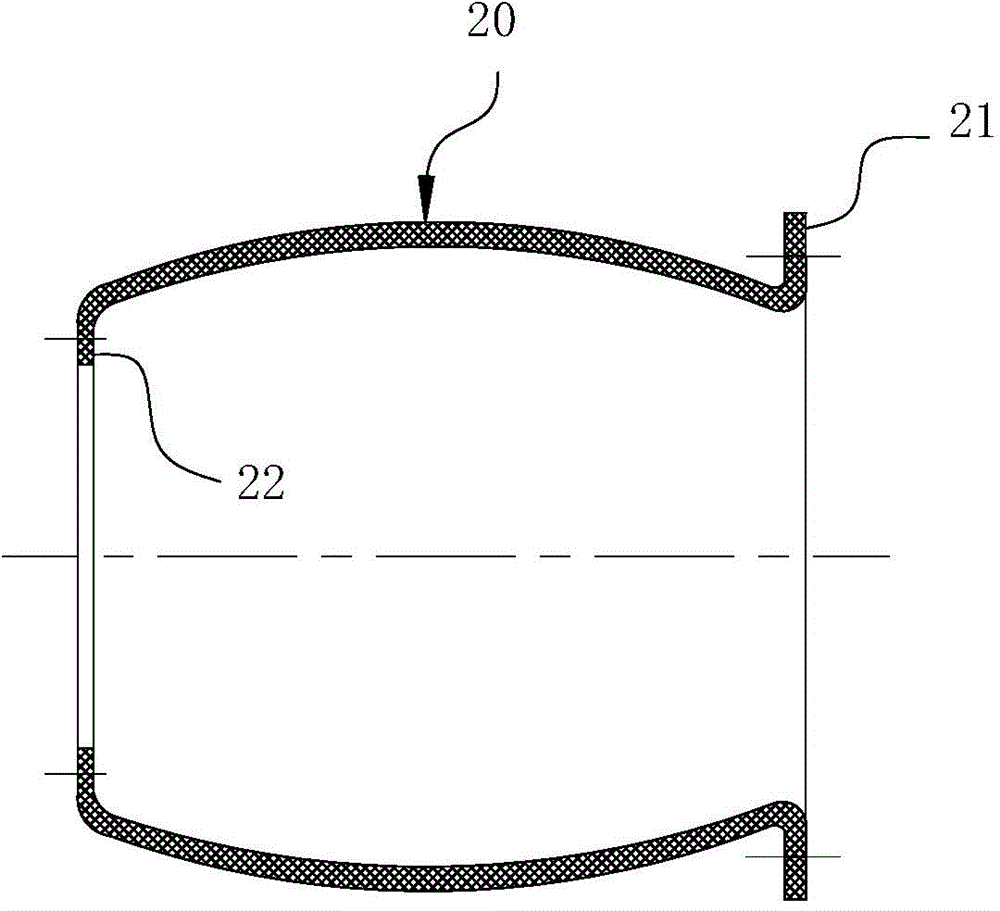

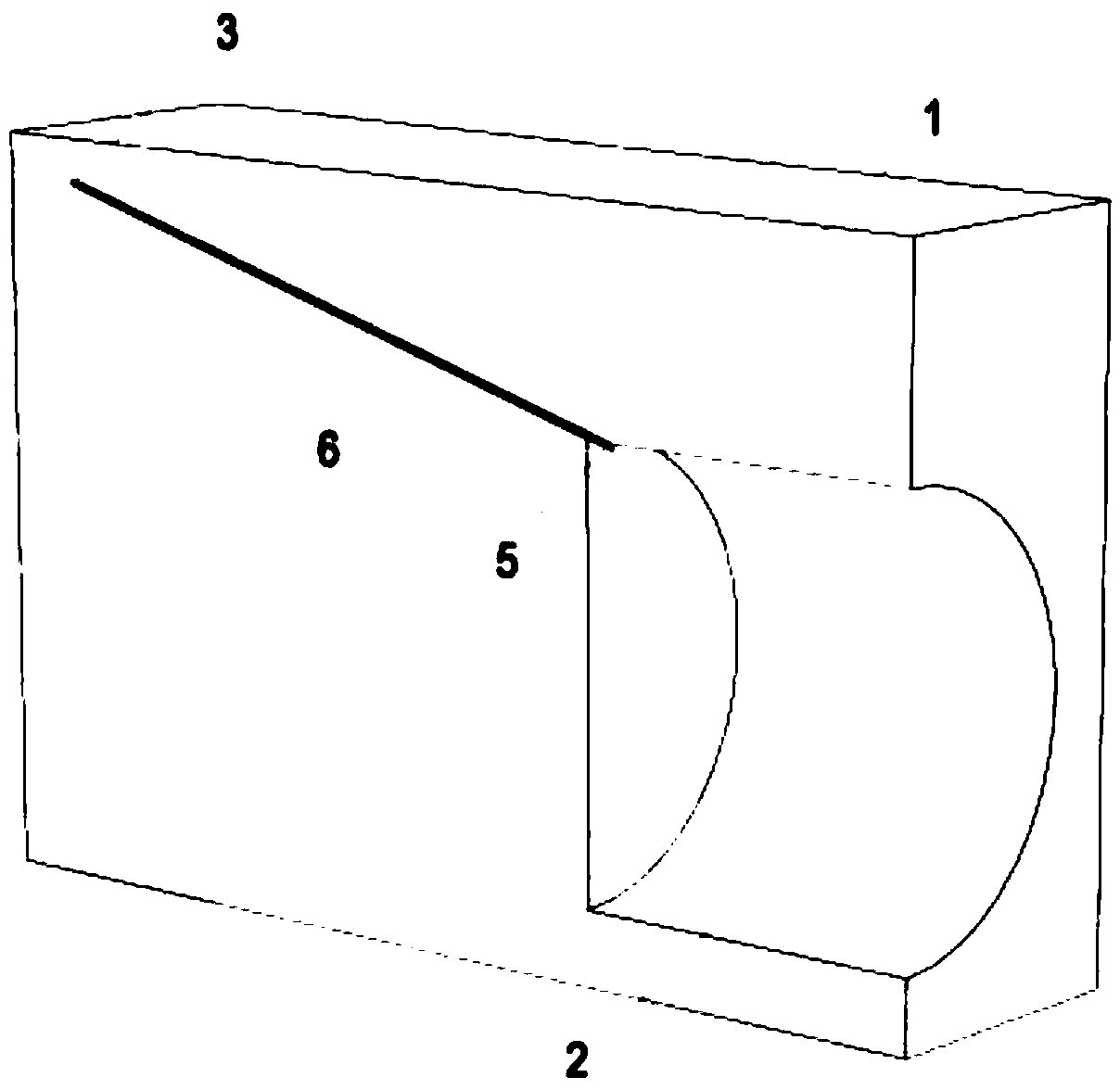

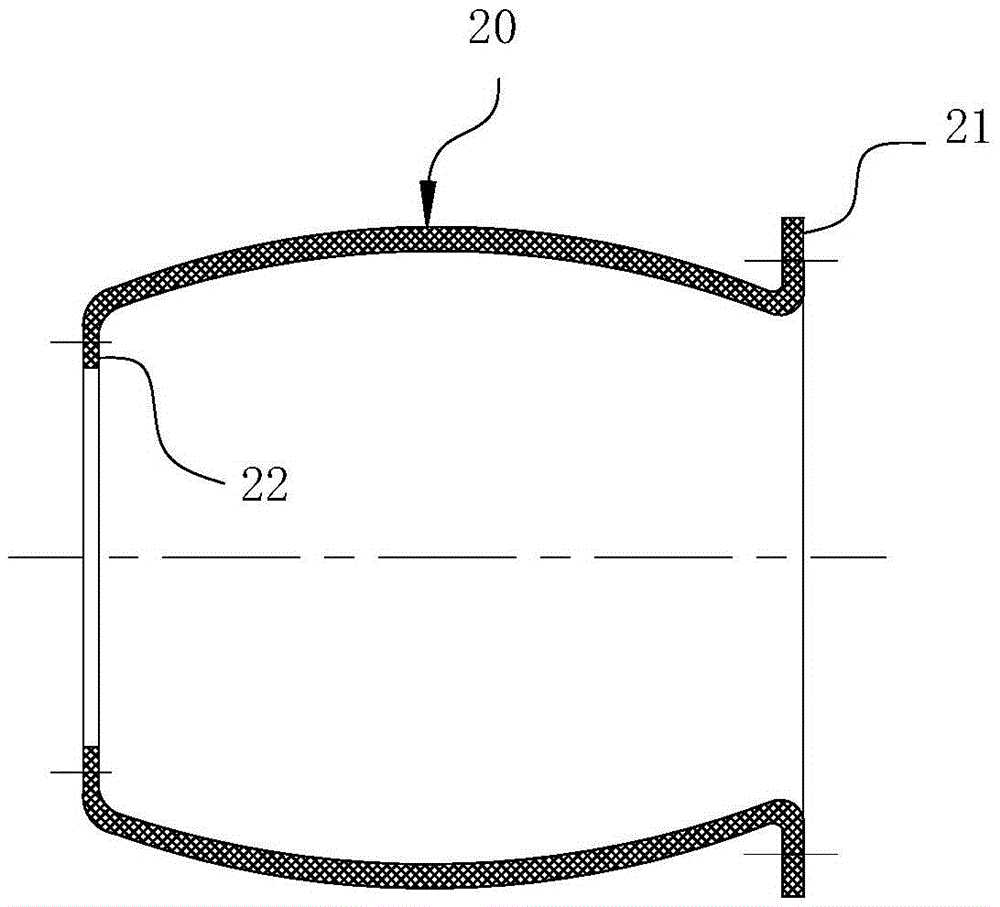

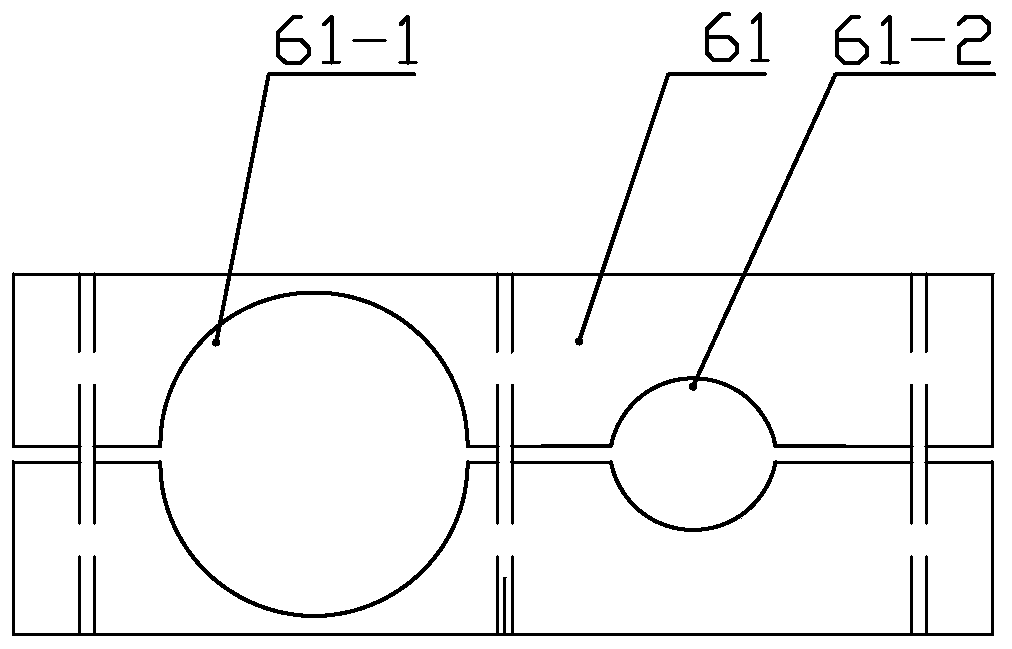

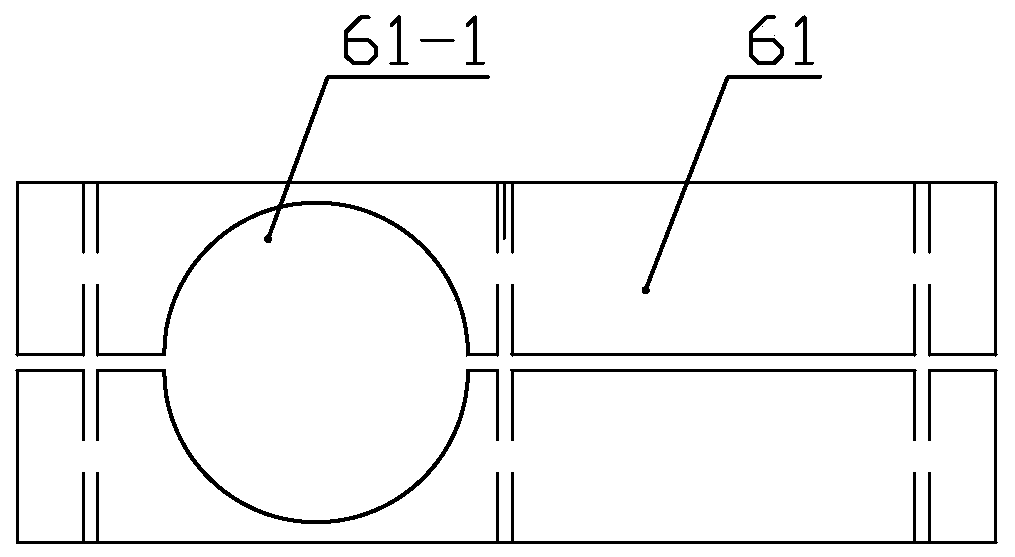

Convenient-to-dismount diaphragm pump

ActiveCN104358675AStrong resistance to tensile fatigueReduce labor intensityPositive displacement pump componentsFlexible member pumpsDiaphragm pumpEngineering

The invention belongs to the field of a volume pump, and particularly relates to a convenient-to-dismount diaphragm pump with the advantages that the monitoring can be realized in proper time, and a diaphragm leaf can be fast dismounted and replaced on line. The convenient-to-dismount diaphragm pump comprises a pump body and the diaphragm leaf, wherein liquid inlet and outlet holes and hydraulic holes are respectively formed in the pump wall of the pump body, a located pump cavity of the liquid inlet and outlet holes and a located pump cavity of the hydraulic holes are separated through the diaphragm leaf, the pump body also comprises a repair hole, the repair hole is sealed by an end cover, the appearance of the diaphragm leaf is of a sleeve-shaped structure, a pipe opening formed at one end of the diaphragm leaf is fixedly connected with the hole end surface of the hydraulic holes through screw bolts, a pipe opening formed in the other end of the diaphragm leaf extends towards the repair hole and is provided with an outer flange, the outer flange is arranged in a way of being matched with the surfaces between the hole ends, positioned at the outer wall parts of the the pump body, of the repair hole, and the end cover is pressed on the outer flange and is arranged in a way of being fixedly connected with screw bolts arranged between the pump walls of the pump body. The convenient-to-dismount diaphragm pump has the advantages that the monitoring and dismounting problems of the exiting conventional diaphragm pump can be effectively solved, the dismounting convenience and the maintenance replacement efficiency are high, and the work intensity of maintenance personnel can be greatly reduced.

Owner:HEFEI UNIV OF TECH +1

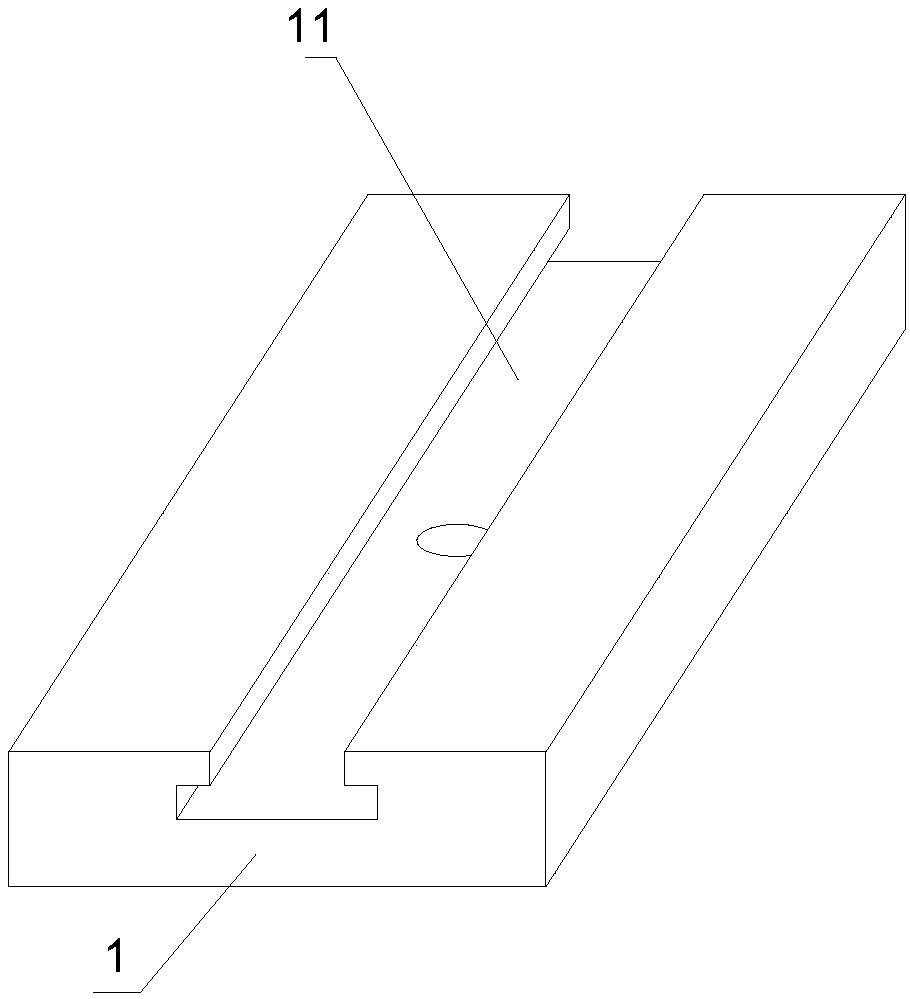

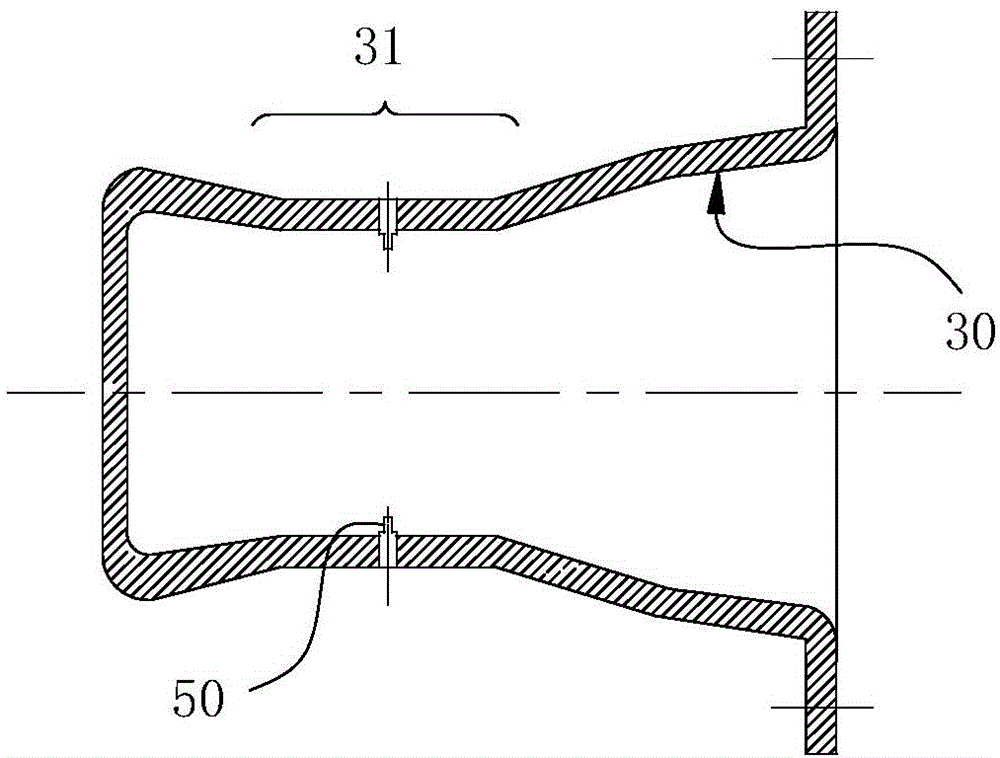

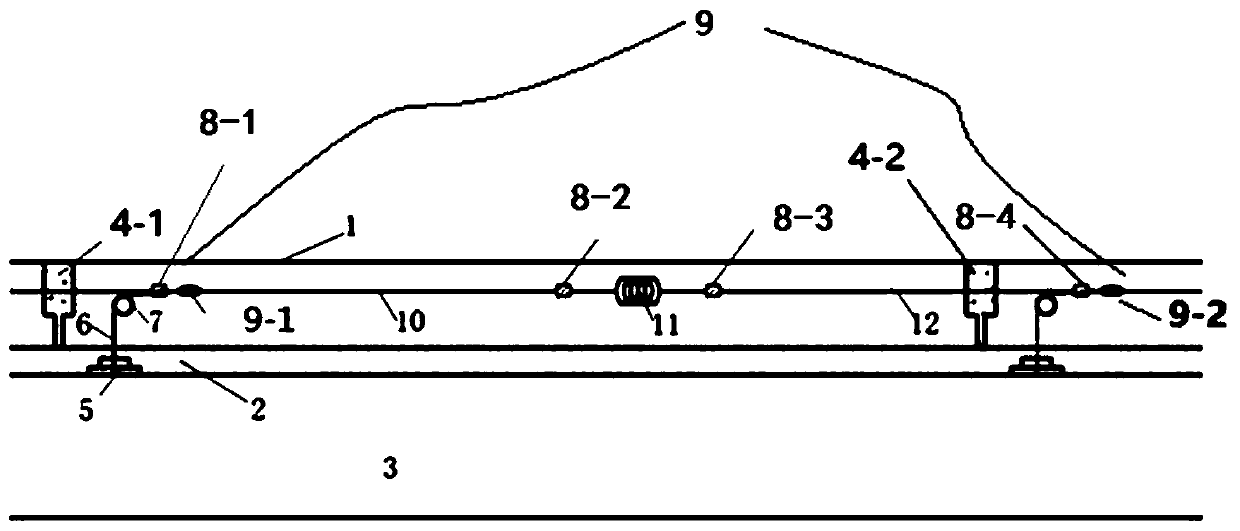

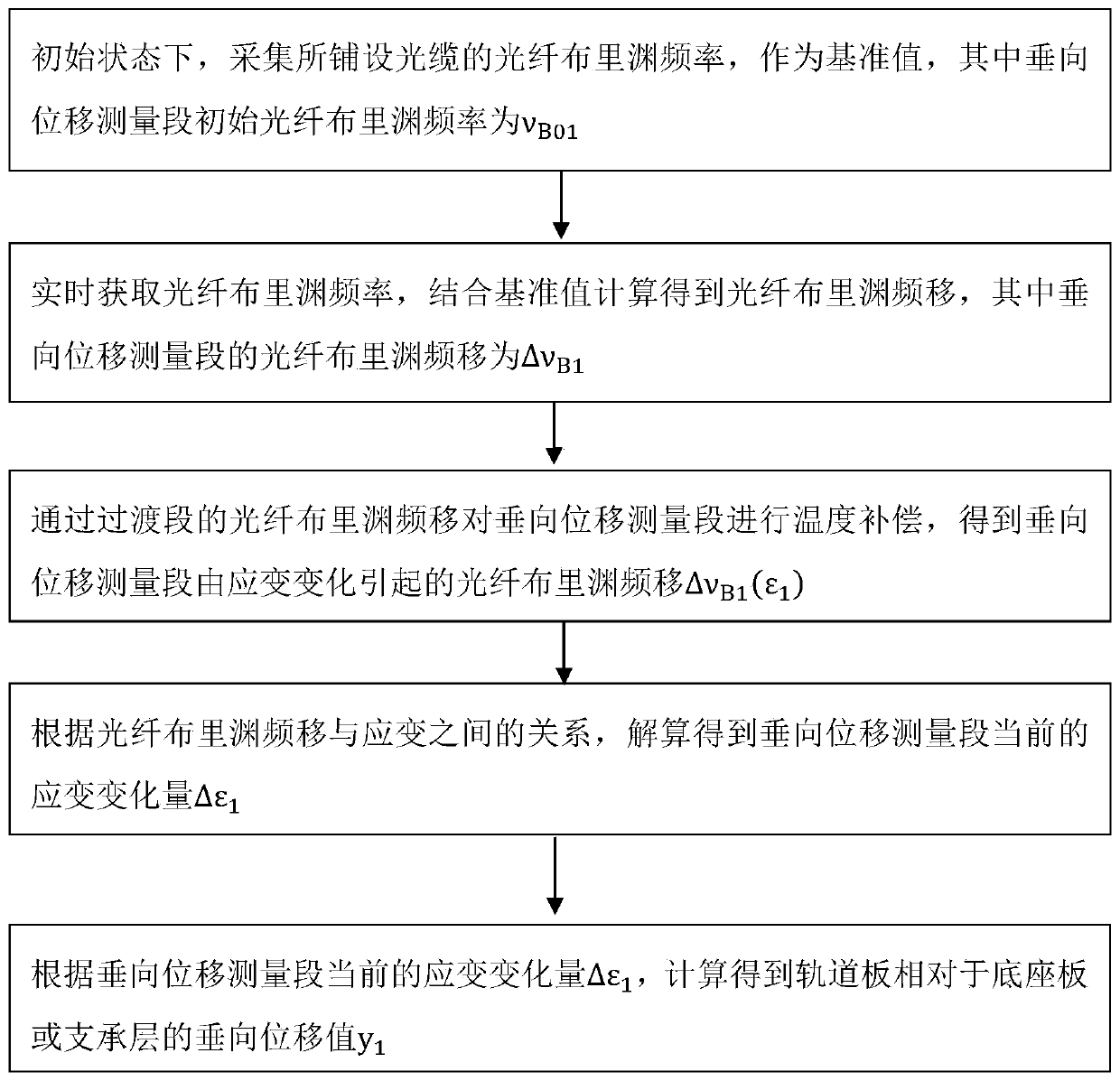

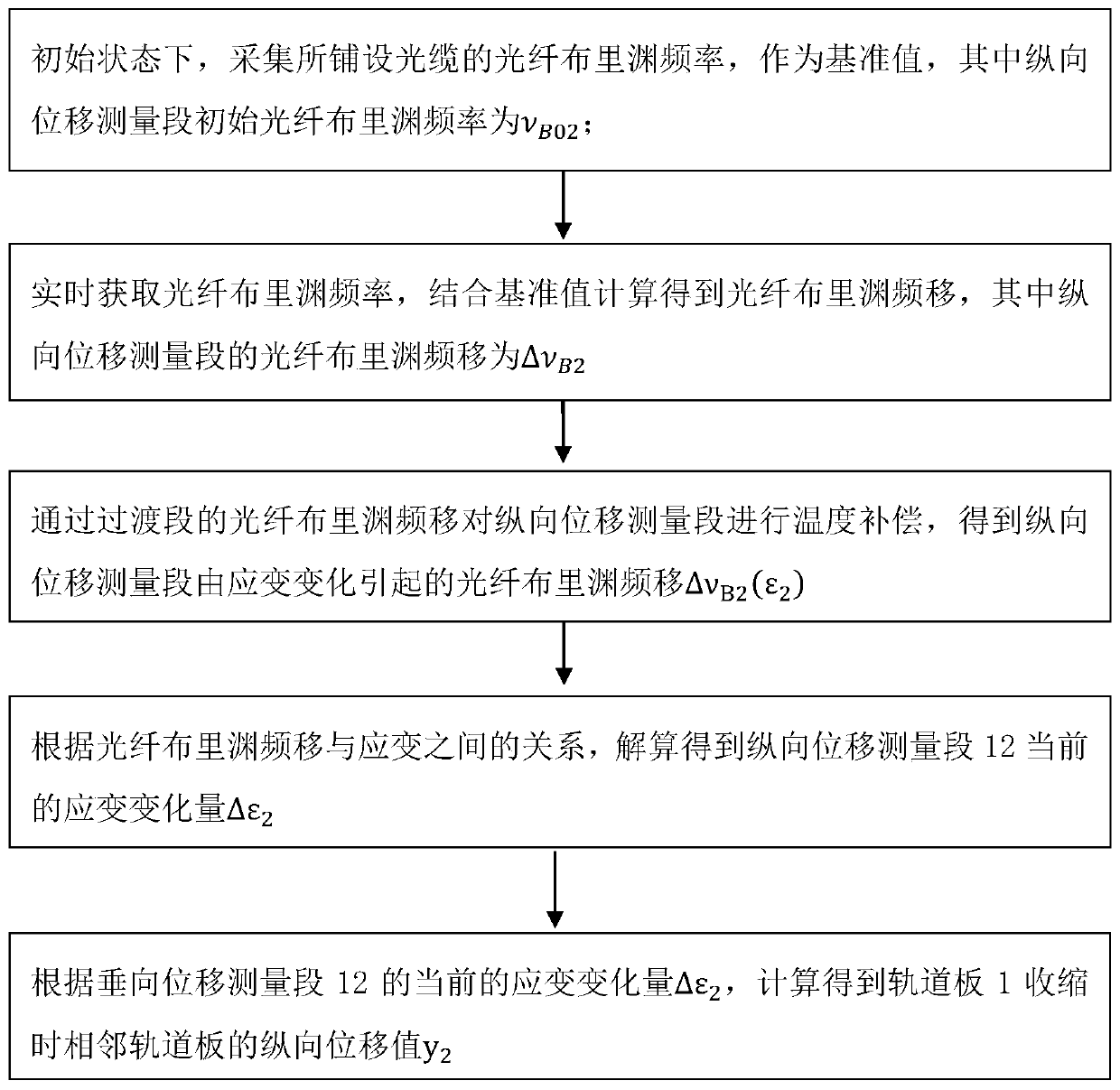

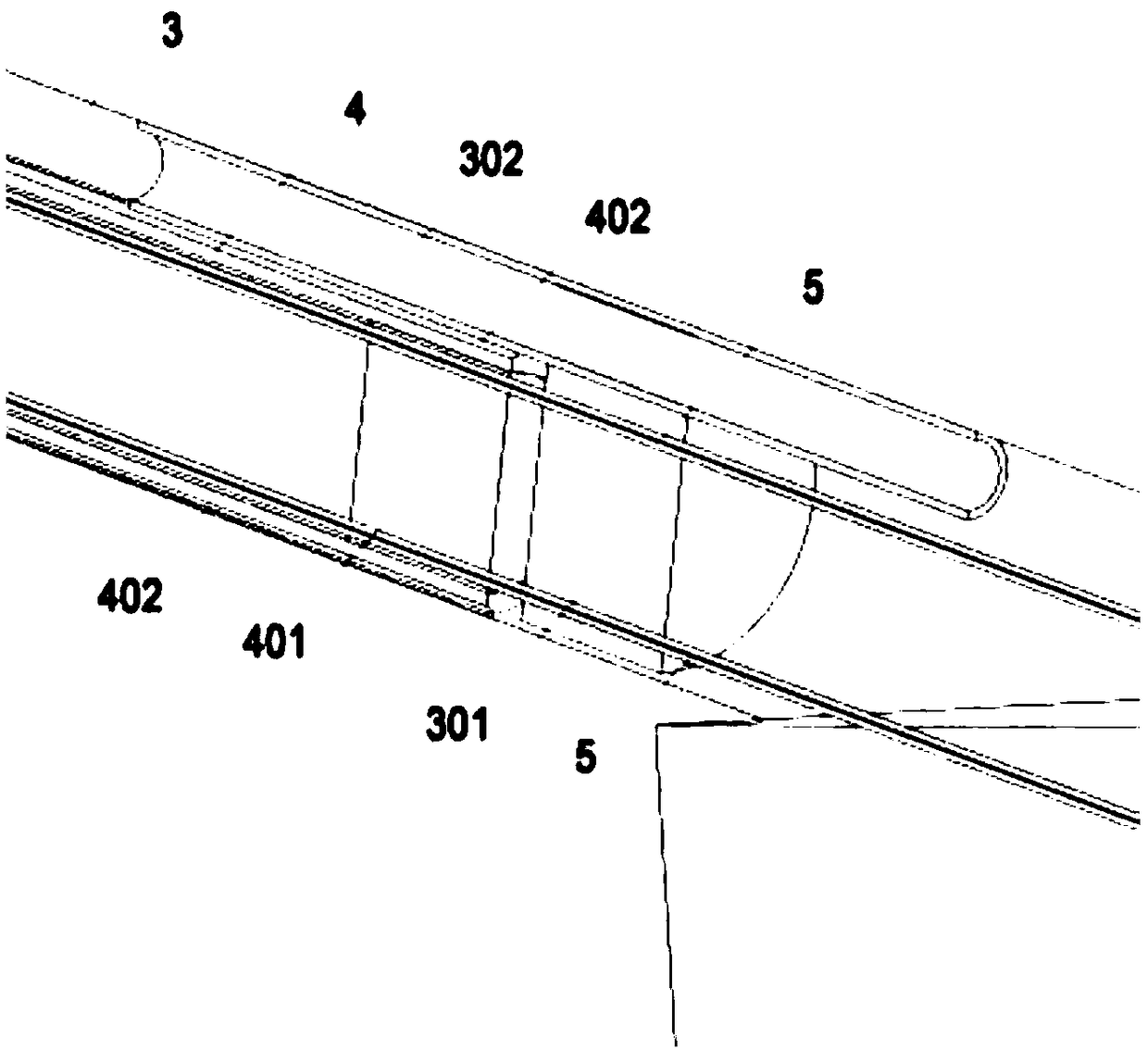

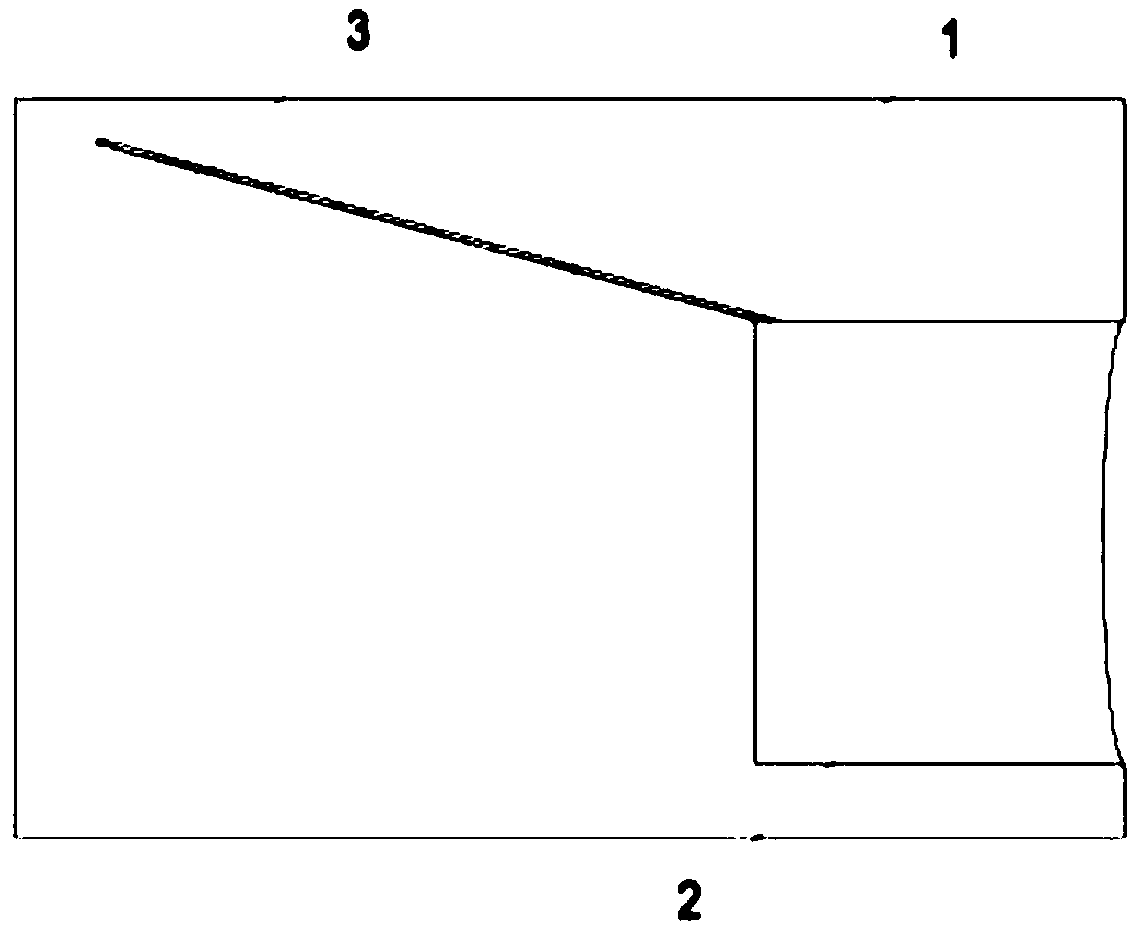

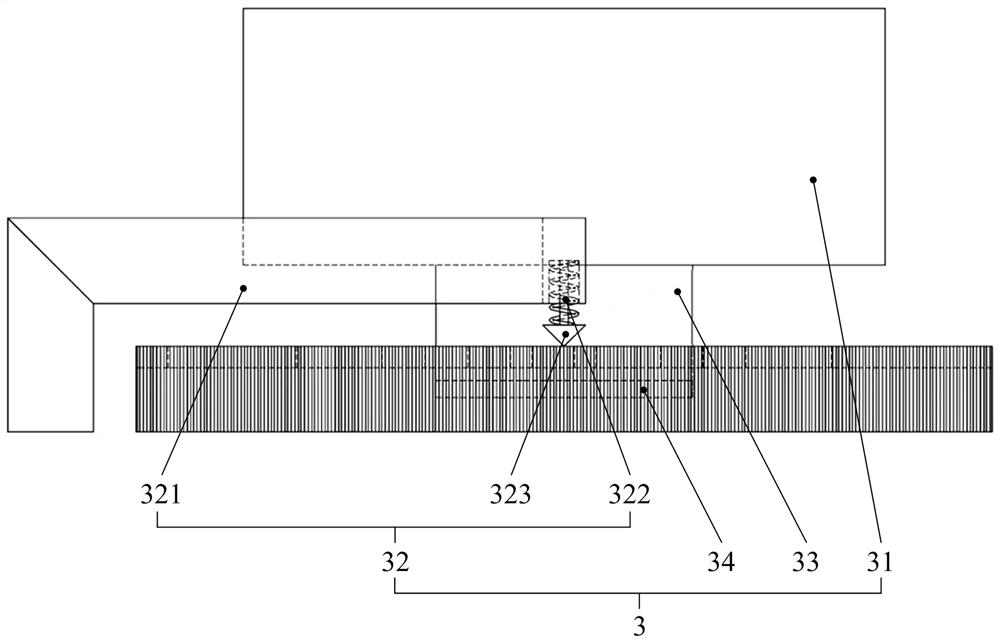

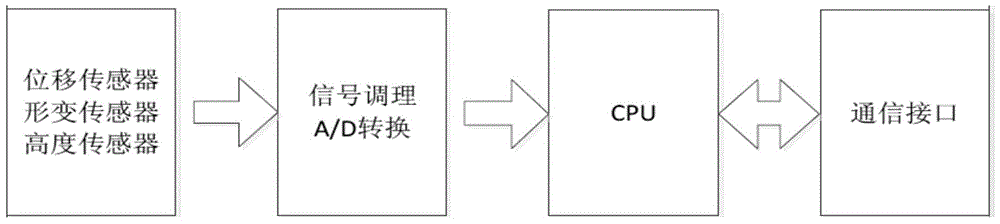

Track board deformation monitoring device and method and online monitoring system

The invention discloses a track board deformation monitoring device. The monitoring device comprises an optical cable, a fastening device and a detection host. The optical cable comprises a vertical displacement measuring section, a transition section and a longitudinal displacement measuring section which correspond to a vertical displacement measuring area, a transition area and a longitudinal displacement measuring area respectively. The vertical displacement measuring section and the longitudinal displacement measuring section are of pre-tensioned state, and the transition section is of afree state. The detection host obtains fiber signals of the vertical displacement measuring section and the longitudinal displacement measuring section, carries out temperature compensation by combining fiber signals of the transition section, and resolves to obtain vertical displacement of a track board relatively to a base plate or a supporting layer and longitudinal displacement between adjacent track boards. The invention also discloses a monitoring method and an online monitoring system, the system monitors state information of the track board in real time, and performs alarm and positioning under the condition that a preset alarm threshold is exceeded.

Owner:CR TECHCAL DEV CORP +3

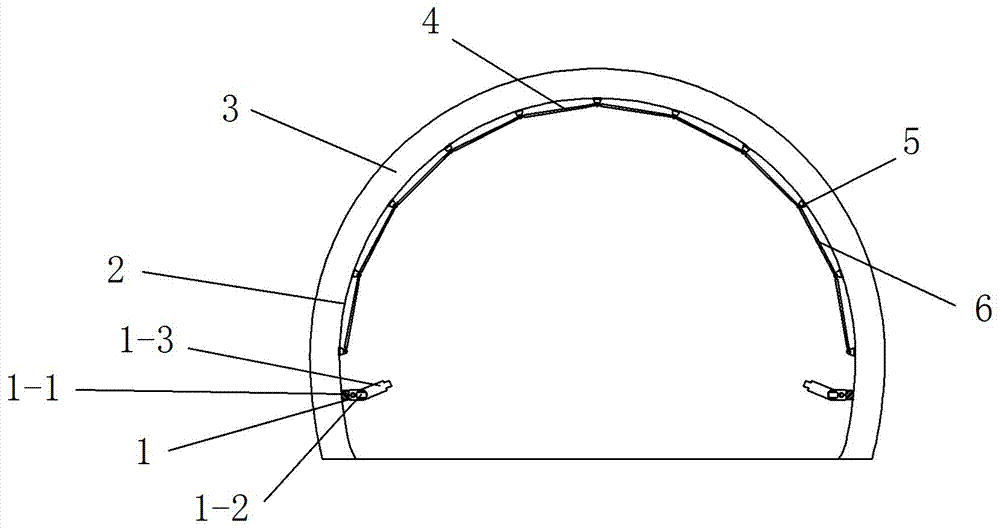

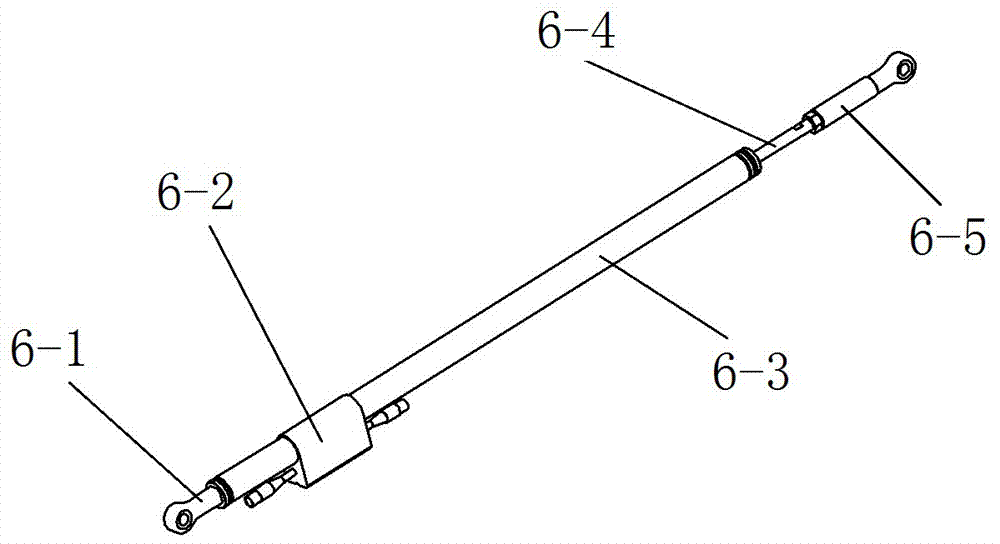

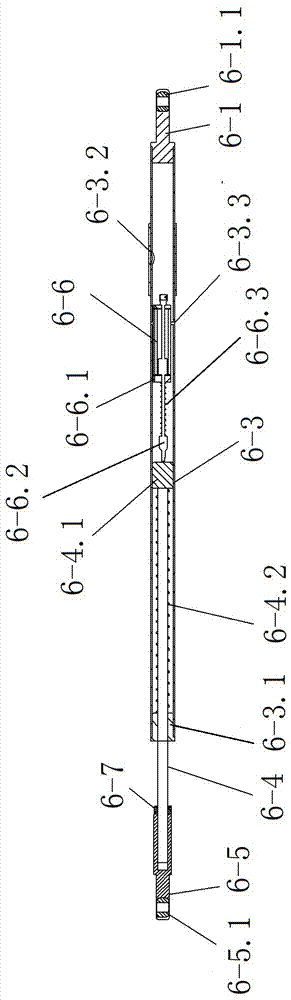

Advanced monitoring device for tunnel excavation surrounding rock whole process deformation curve and implementation method thereof

ActiveCN109141265AAvoid disasterEnsure safetySurveying instrumentsUsing optical meansElastomerEngineering

The invention discloses an advanced monitoring device for a tunnel excavation surrounding rock whole process deformation curve and an implementation method thereof. The device comprises a steel tube elastomer, a height difference meter structure and embedded optical fibers, wherein the height difference meters form an equidistant series structure and are fixed in the steel tube; the embedded optical fibers are packaged in grooves on the surface of the steel tube; the height difference meters, the embedded optical fibers and the steel tube form a deformation coordination structure, and throughcalculating height difference changes and optical fiber deformation conditions, the surrounding rock deformation can be calculated. The implementation method comprises steps of drilling, steel tube mounting, height difference meter assembling, embedded optical fiber packaging and borehole sealing and grouting. The deformation curve of the surrounding rock in front of the tunnel excavation face canbe tested and calculated, which provides support for dynamic design, construction and safety of the project.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

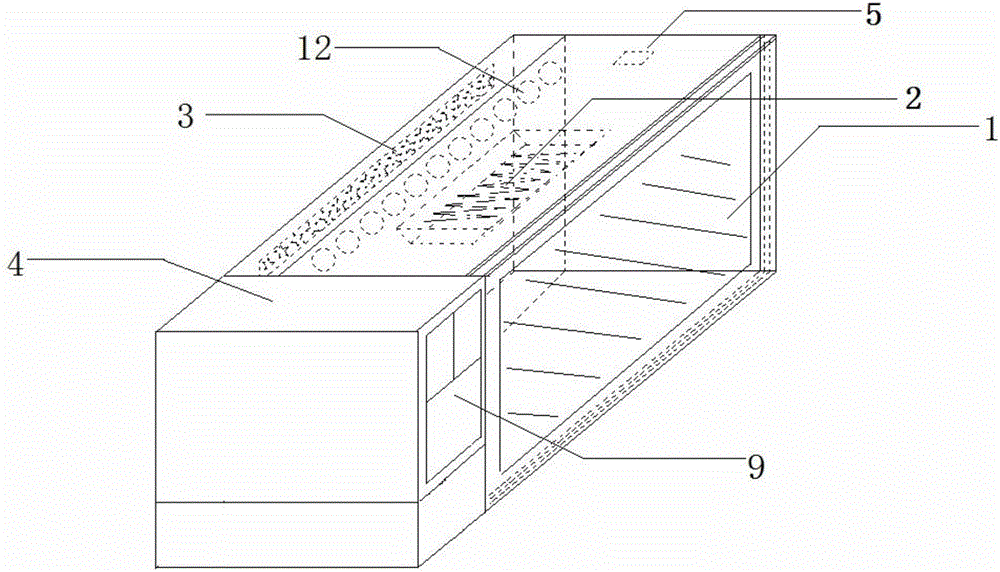

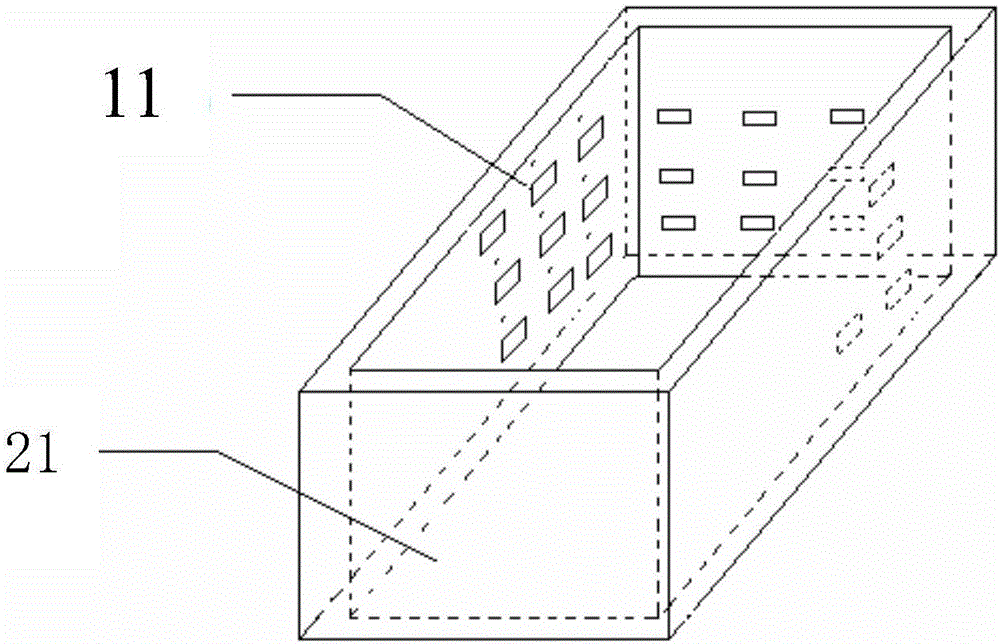

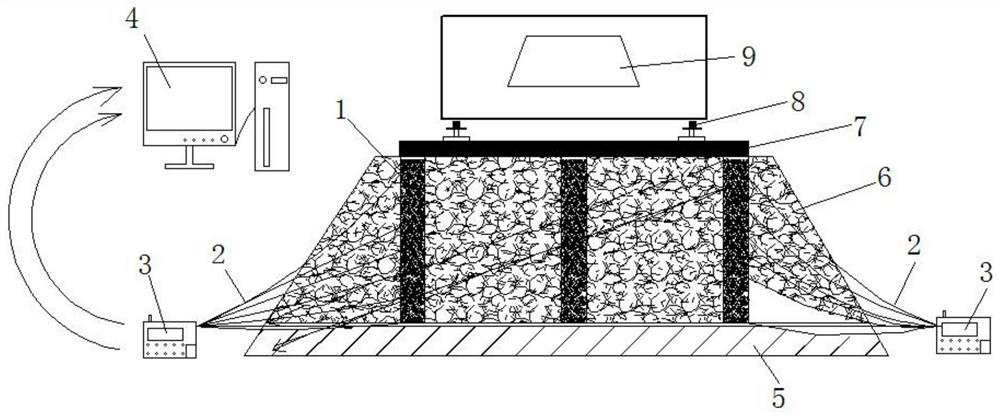

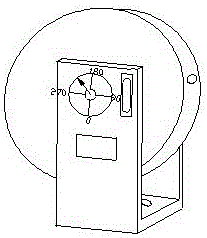

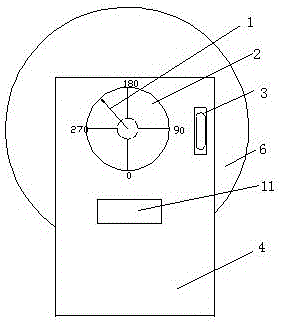

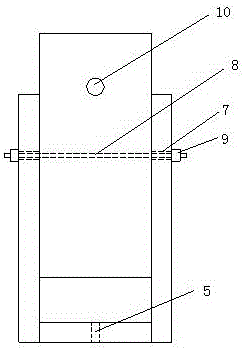

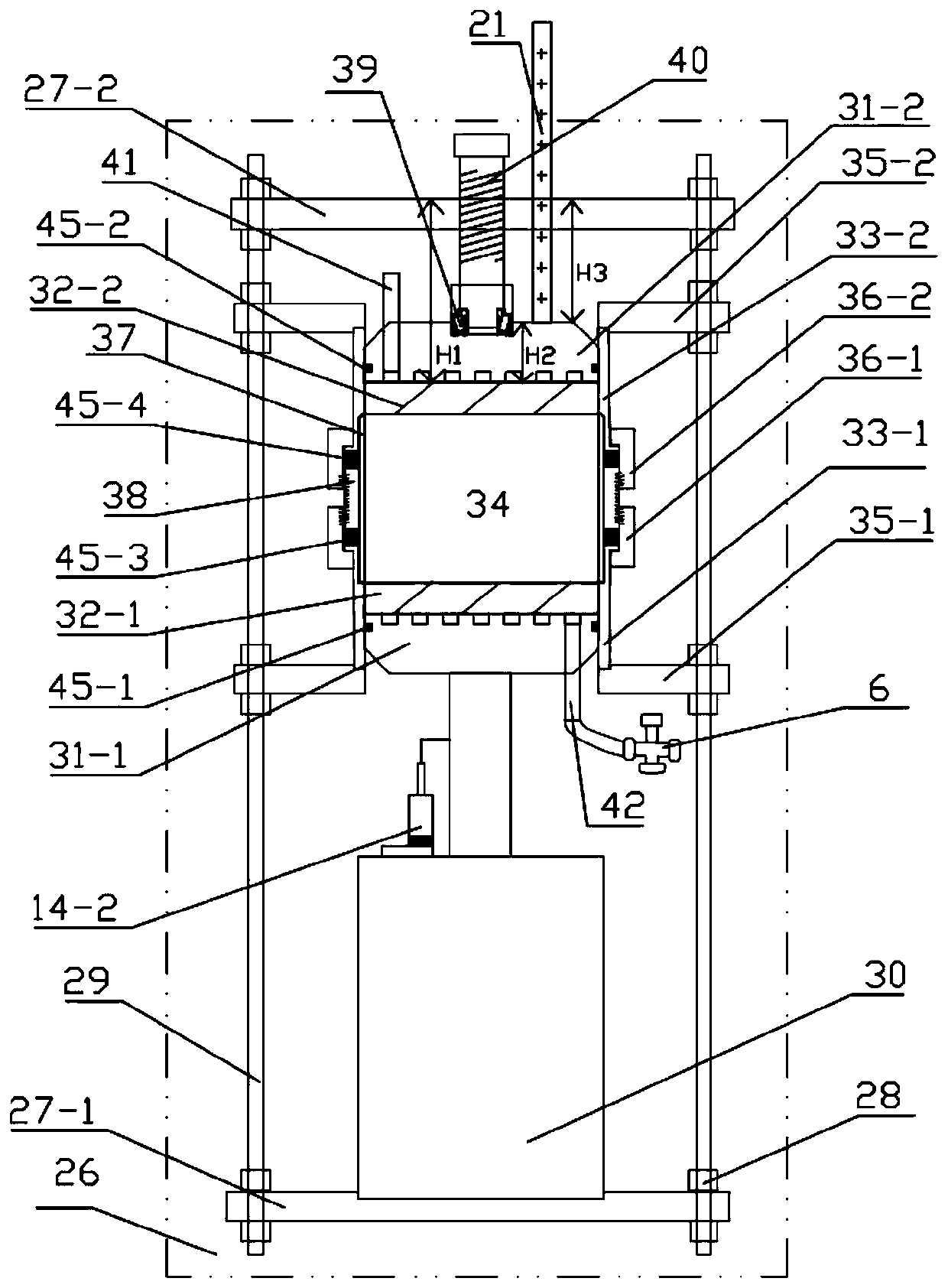

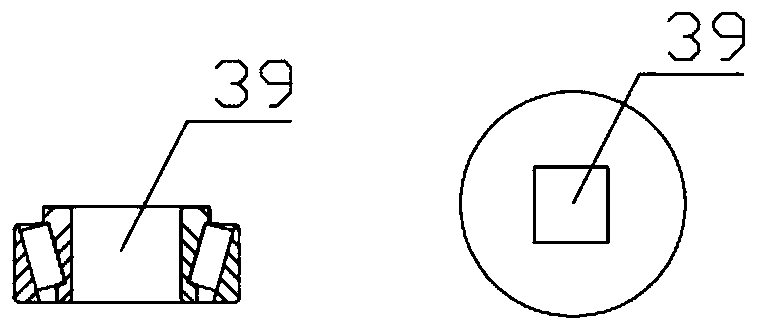

Freezing and thawing cycle action based model test box for tailing dam

PendingCN106442161AImprove sealingIndependentMaterial strength using tensile/compressive forcesTailings damThermal insulation

The invention discloses a freezing and thawing cycle action based model test box for a tailing dam, and belongs to the technical field of model tests for dam bodies. The freezing and thawing cycle action based model test box for the tailing dam comprises a main box body and a model box, wherein the main box body comprises a heat-preservation box body; the front of the heat-preservation box body is provided with a box door; the top of the heat-preservation box body is provided with a heating-up device; the bottom of the heat-preservation box body is provided with a transmission bottom plate; a first temperature sensor is arranged inside the heat-preservation box body; the rear part of the heat-preservation box body is provided with a compartment; an upper part in the compartment is provided with an air blowing device; the heat-preservation box body which is right ahead the air blowing device is provided with an air ventilation hole; a condensing pipe is arranged inside the compartment; the outer side of the heat-preservation box body is provided with an operation and display double-function panel; the model box comprises a thermal-insulation box body; the inner side wall of the thermal-insulation box body is provided with a stress sensor; a second temperature sensor and a pressure sensor are arranged in the thermal-insulation box body; the thermal-insulation box body is provided with a transverse constraining component, a vertical loading device and a displacement and deformation monitoring device.

Owner:LIAONING TECHNICAL UNIVERSITY

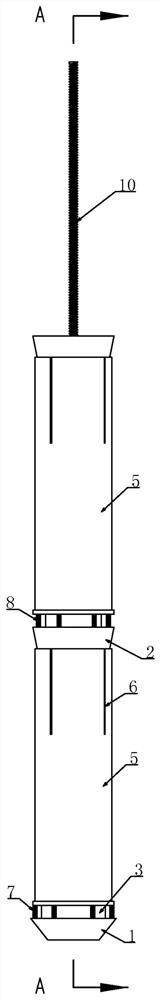

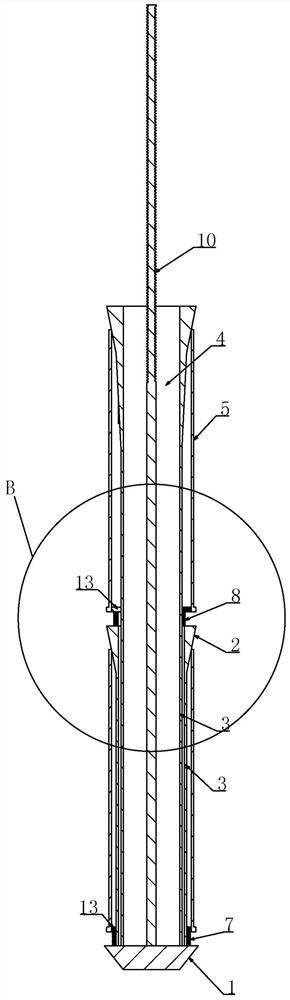

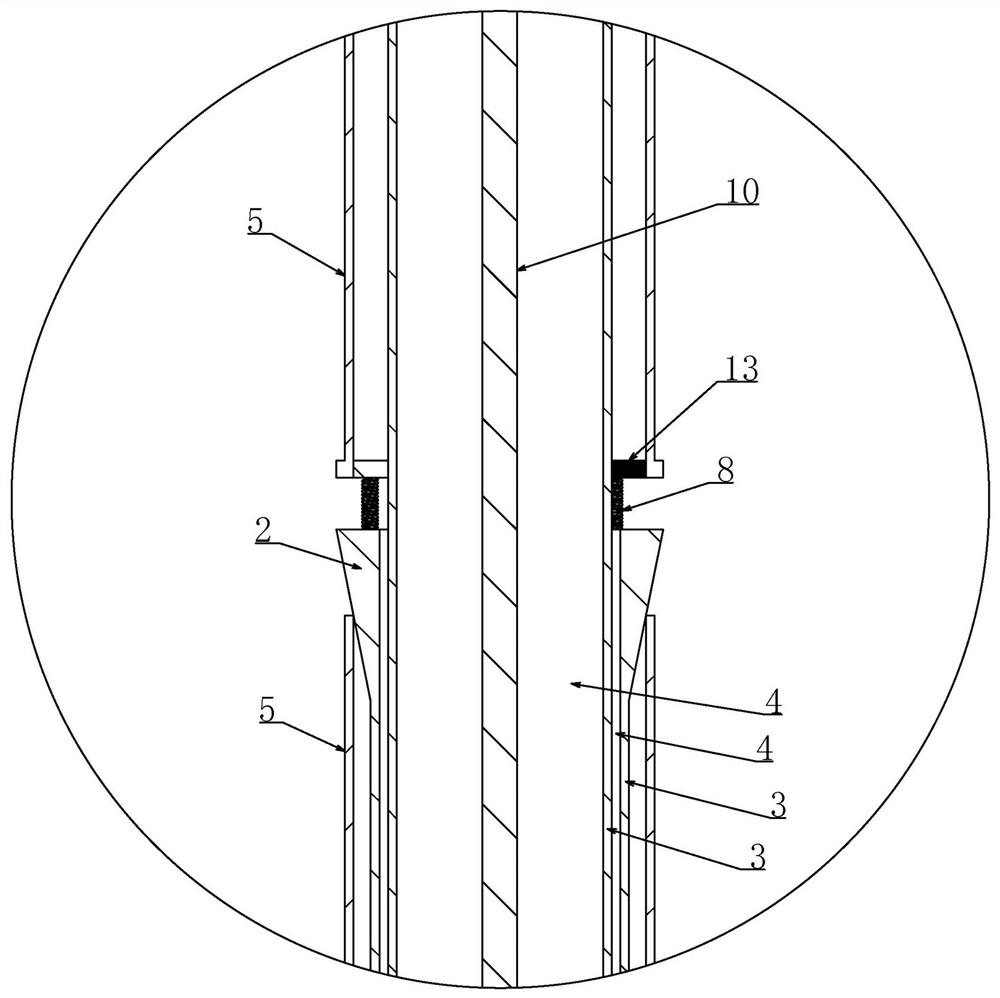

Multifunctional and intelligent monitoring anchor rod device

PendingCN114000899AExtend your lifeWide adaptabilityMining devicesFoundation testingAcoustic emissionRock bolt

The invention provides a multifunctional and intelligent monitoring anchor rod device. The problem that an existing anchor rod cannot monitor rock mass deformation at different levels is solved. According to the invention, an early warning effect on disasters can be achieved through monitoring of acoustic emission. The temperature of a slope and the pressure or humidity of underground water can be monitored. A plurality of circular truncated cone bodies with large outsides and small insides are arranged on the outer side of the anchoring end at intervals in the axial direction, the inner ends of the circular truncated cone bodies are coaxially connected with tension-bearing bodies, penetrating holes penetrating through the tension-bearing bodies inwards in the axial direction are formed in the axial outer ends of the circular truncated cone bodies, the tension-bearing body at the innermost end is fixed to the anchoring end, each outer tension-bearing body penetrates through the penetrating hole in the adjacent circular truncated cone body and the tension-bearing body on the axial inner side of the outer tension-bearing body to be fixed to the anchoring end, the axial inner part of each circular truncated cone body is sleeved with a sleeve with the lower end slidably arranged on the tension-bearing body in a sleeved mode, and the axial outer end of the sleeve is provided with a plurality of open grooves extending towards the axial inner side. The early warning effect on disasters is achieved through monitoring of acoustic emission. The temperature of the slope and the pressure or humidity of underground water are monitored.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

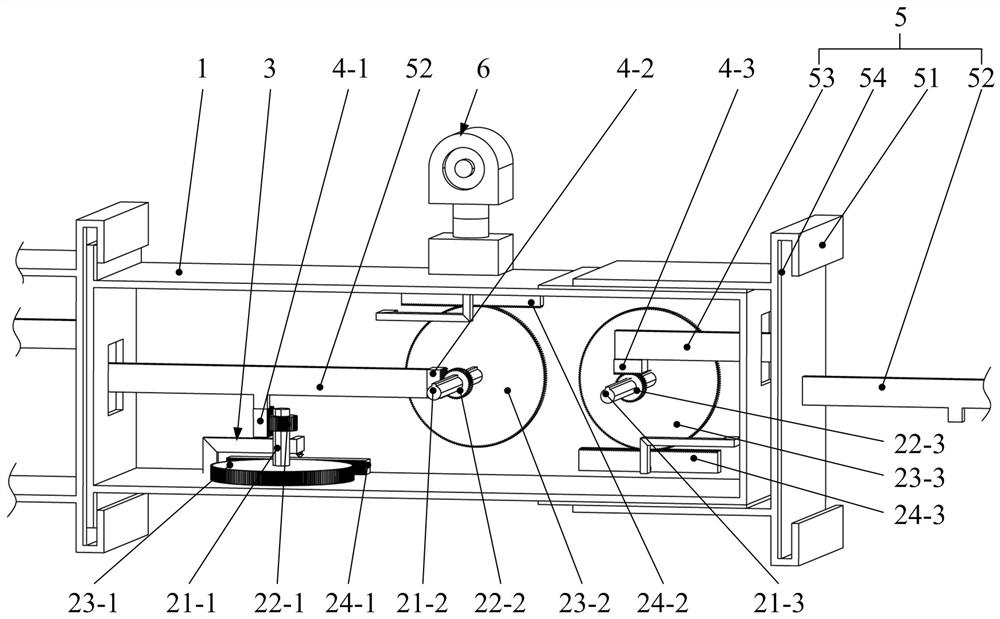

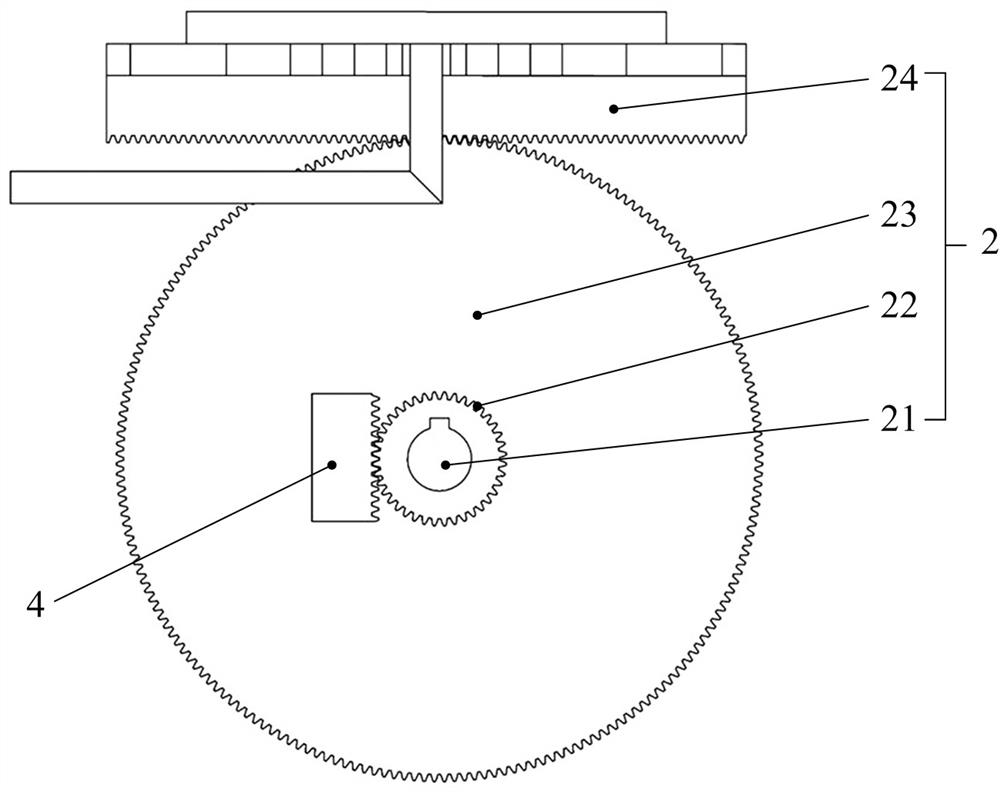

Steel truss girder chord member three-direction deformation monitoring and early warning device and installation method thereof

ActiveCN114777727ADeformation MonitoringDeformation monitoring and early warningMeasurement devicesStands/trestlesTerminal equipmentDeformation monitoring

The invention discloses a steel truss girder chord member three-direction deformation monitoring and early warning device and an installation method thereof. The steel truss girder chord member three-direction deformation monitoring and early warning device comprises a box-shaped shell. A transverse deformation monitoring mechanism, a vertical deformation monitoring mechanism and a longitudinal deformation monitoring mechanism are sequentially arranged in the box-shaped shell from left to right at intervals, each monitoring mechanism comprises a displacement amplifying unit and a signal transmitting unit, and even micro deformation of a steel truss chord member can be monitored through cooperation of the displacement amplifying units and the signal transmitting units. Corresponding deformation data are obtained through terminal equipment, and meanwhile, when the deformation exceeds a set threshold value, early warning is carried out; in addition, the device further comprises a displacement conduction mechanism and a leveling mechanism, and a plurality of devices can be arranged on the steel truss girder chord member to be detected in an end-to-end connection mode, and initial position adjustment is carried out. The deformation monitoring and early warning device is reasonable in structural design, high in monitoring precision, convenient to install and capable of monitoring and early warning the steel truss chord member in real time in an all-around mode, and it is guaranteed that a bridge runs safely all the time.

Owner:CHANGAN UNIV

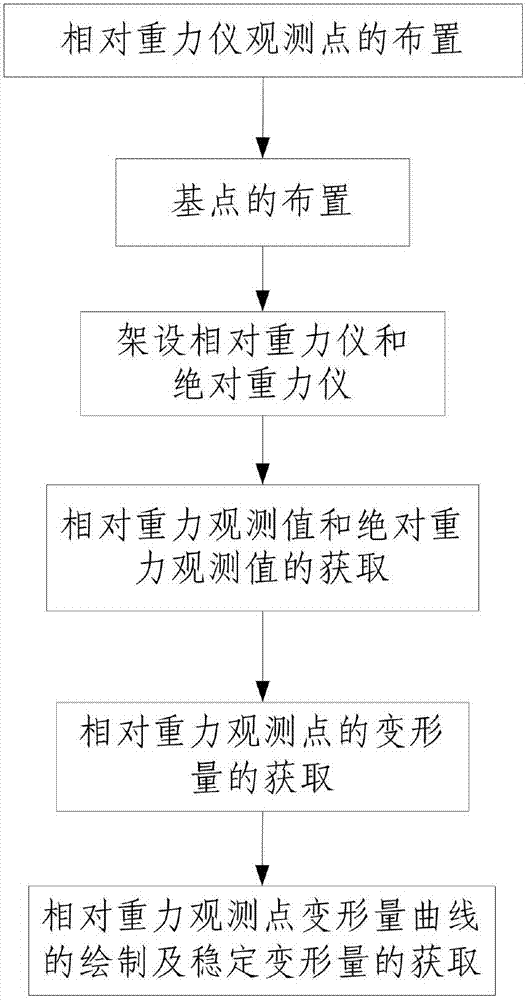

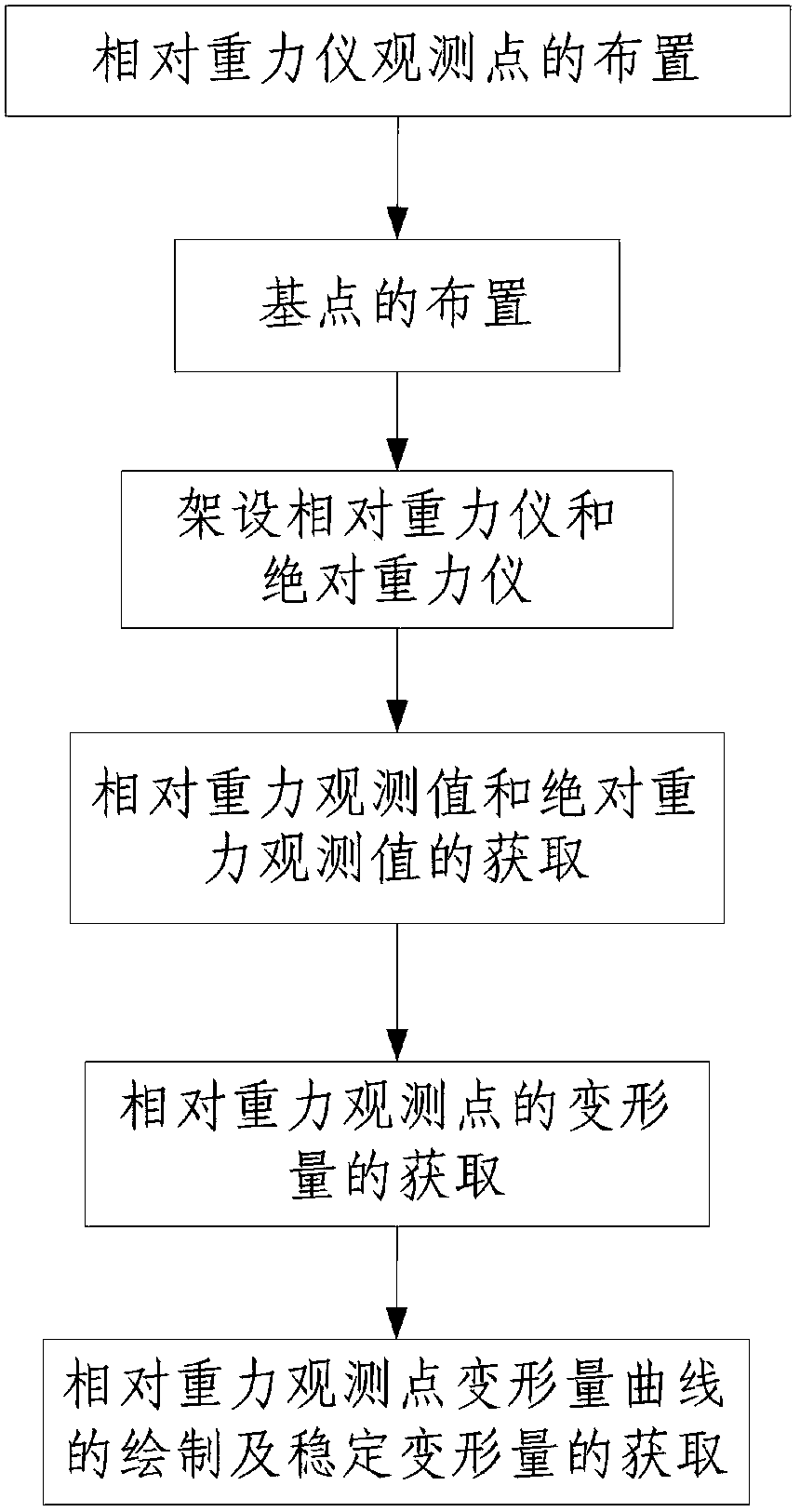

Mine goaf deformation and stability evaluation method based on Bouguer gravity anomaly

InactiveCN107036575AThe method steps are simpleEasy to implementMeasurement devicesAbsolute gravityObservation point

The invention discloses a mine goaf deformation and stability evaluation method based on Bouguer gravity anomaly. The mine goaf deformation and stability evaluation method comprises a step1, arrangement of relative gravimeter observation points; a step2, arrangement of base points; a step3, erecting of gravimeters and absolute gravimeters; a step 4, acquisition of relative gravity observation values and absolute gravity observation values; a step 5, the acquisition of the deformation amounts of the relative gravity observation points; a step 6, drafting of a relative gravity observation point deflection curve and acquisition of stable deformation amounts. The mine goaf deformation and stability evaluation method is advantageous in that the steps are simple, a design is reasonable, costs are low, and use operation is convenient; by adopting the Bouguer gravity anomaly, the deformation amounts of the mine goaf is monitored, and monitoring results are accurate; the stability of the mine goaf is evaluated according to the deformation amounts of the mine goaf, and the stable deformation amounts of the mine goaf are acquired, and practicability is strong.

Owner:XIAN UNIV OF SCI & TECH

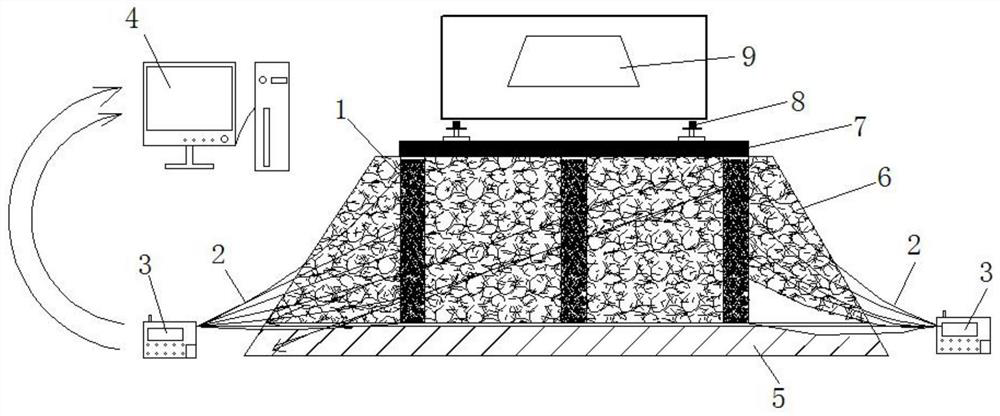

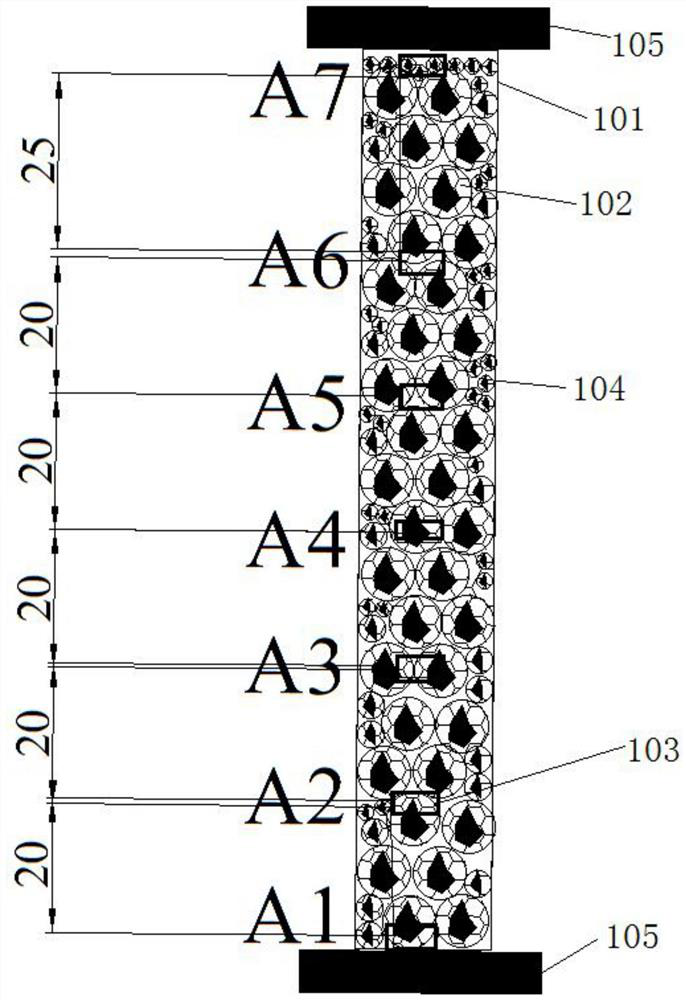

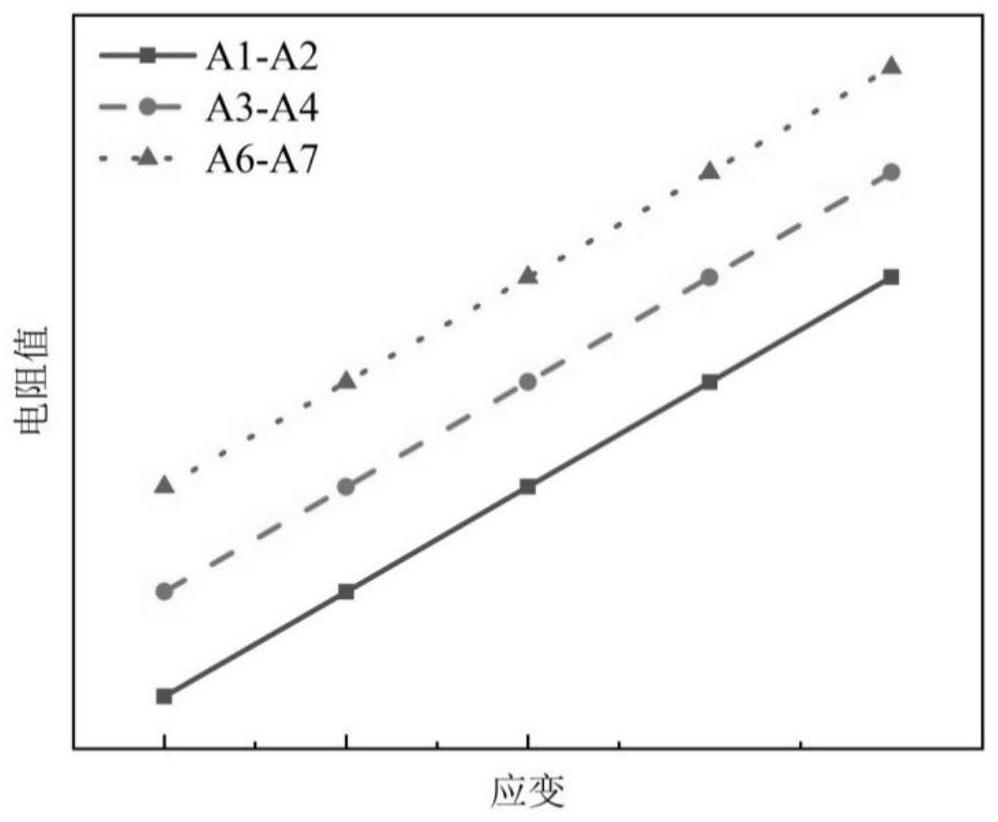

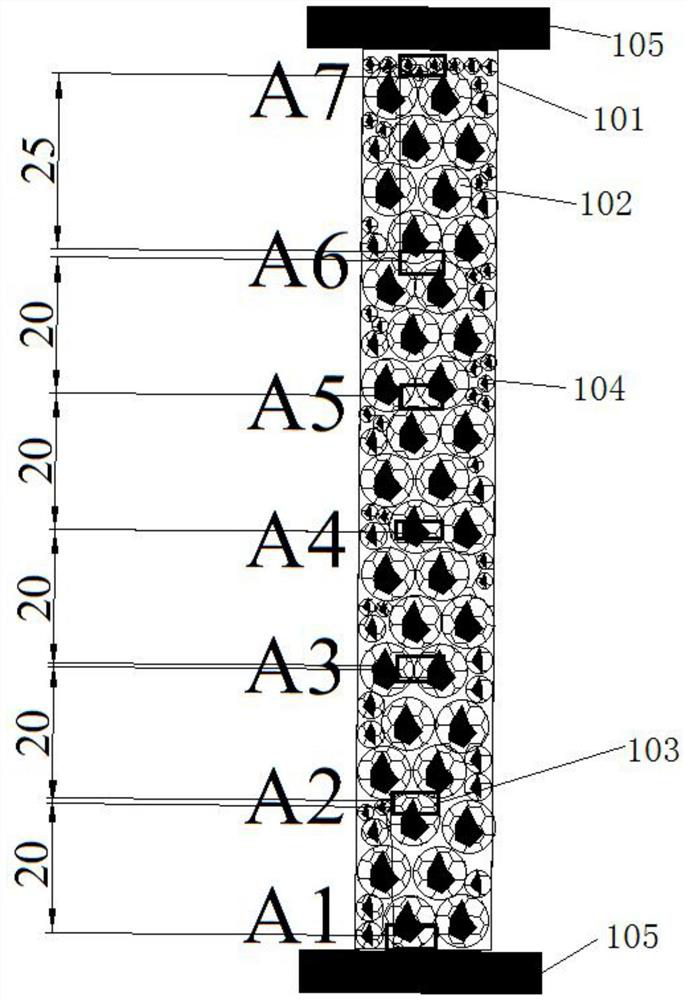

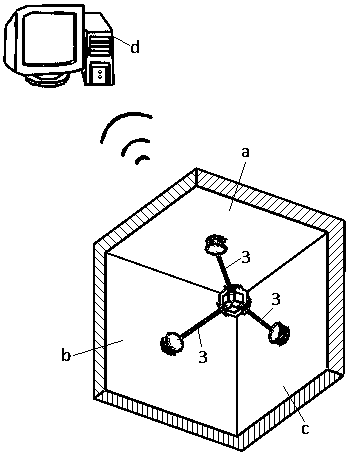

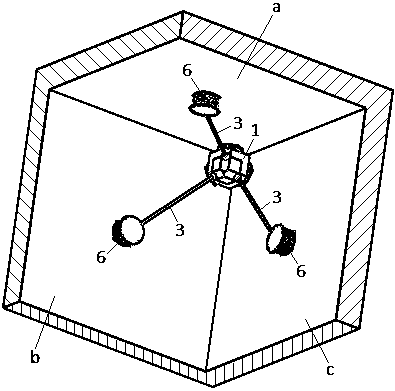

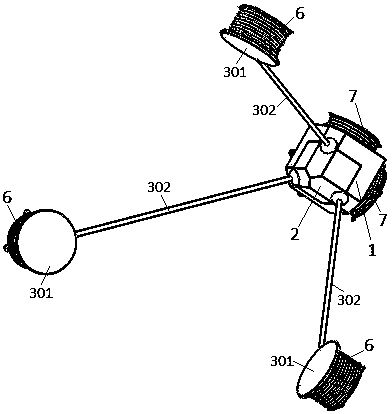

A monitoring device for internal deformation and fine particle loss of track subgrade

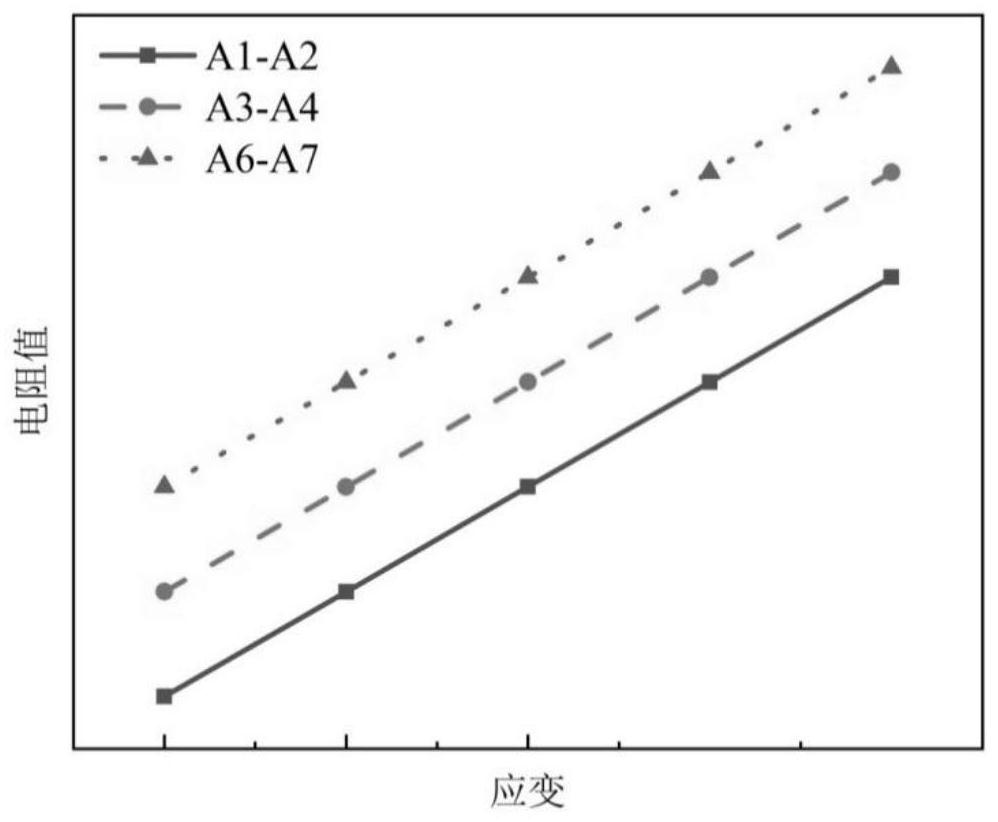

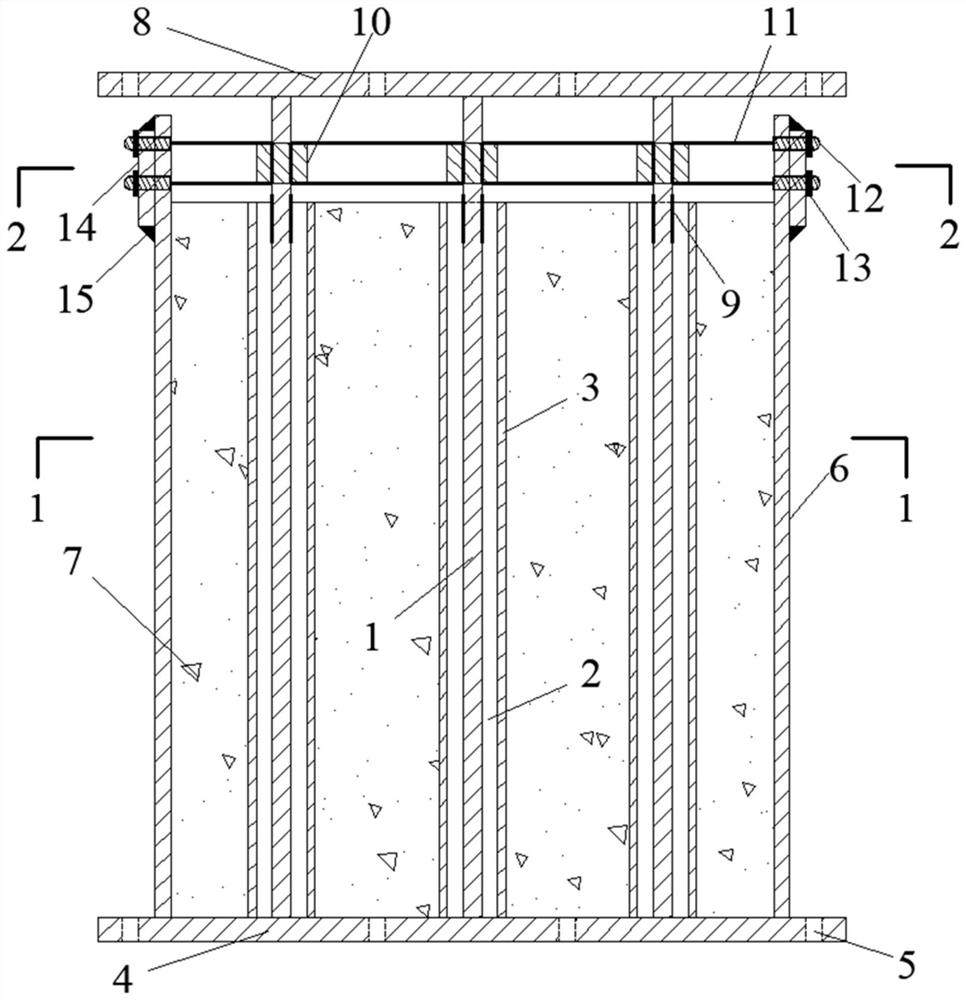

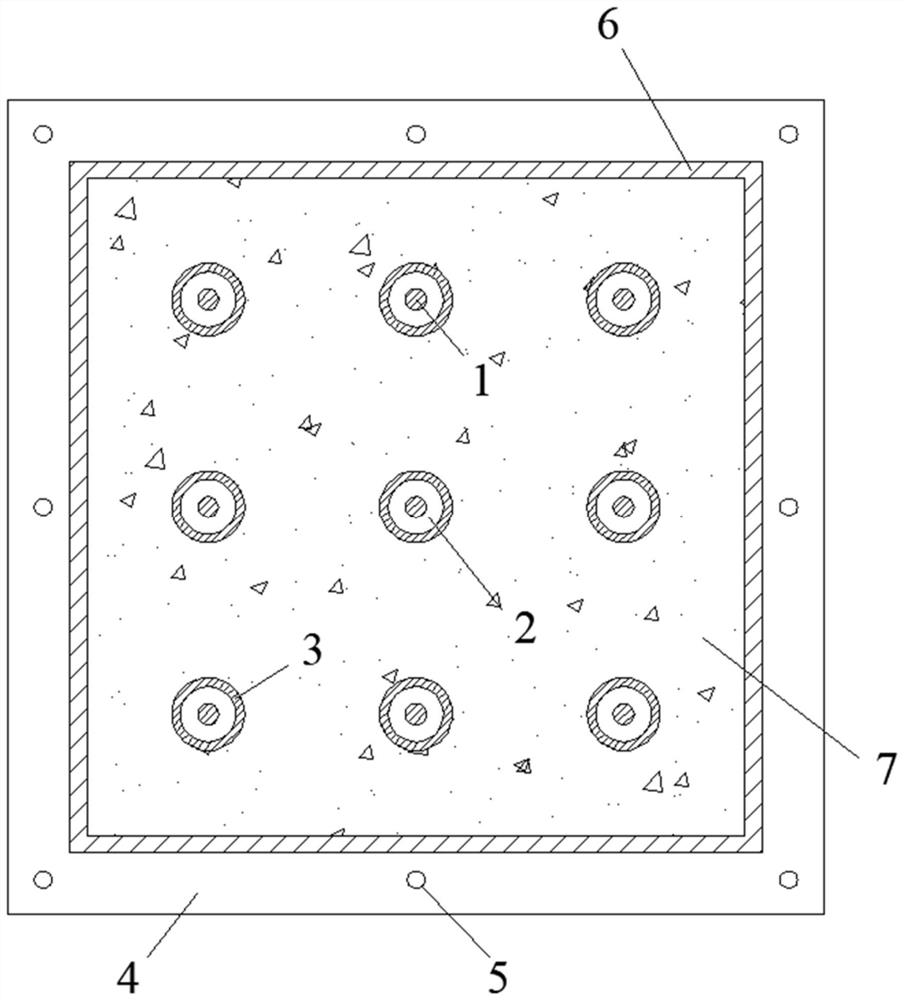

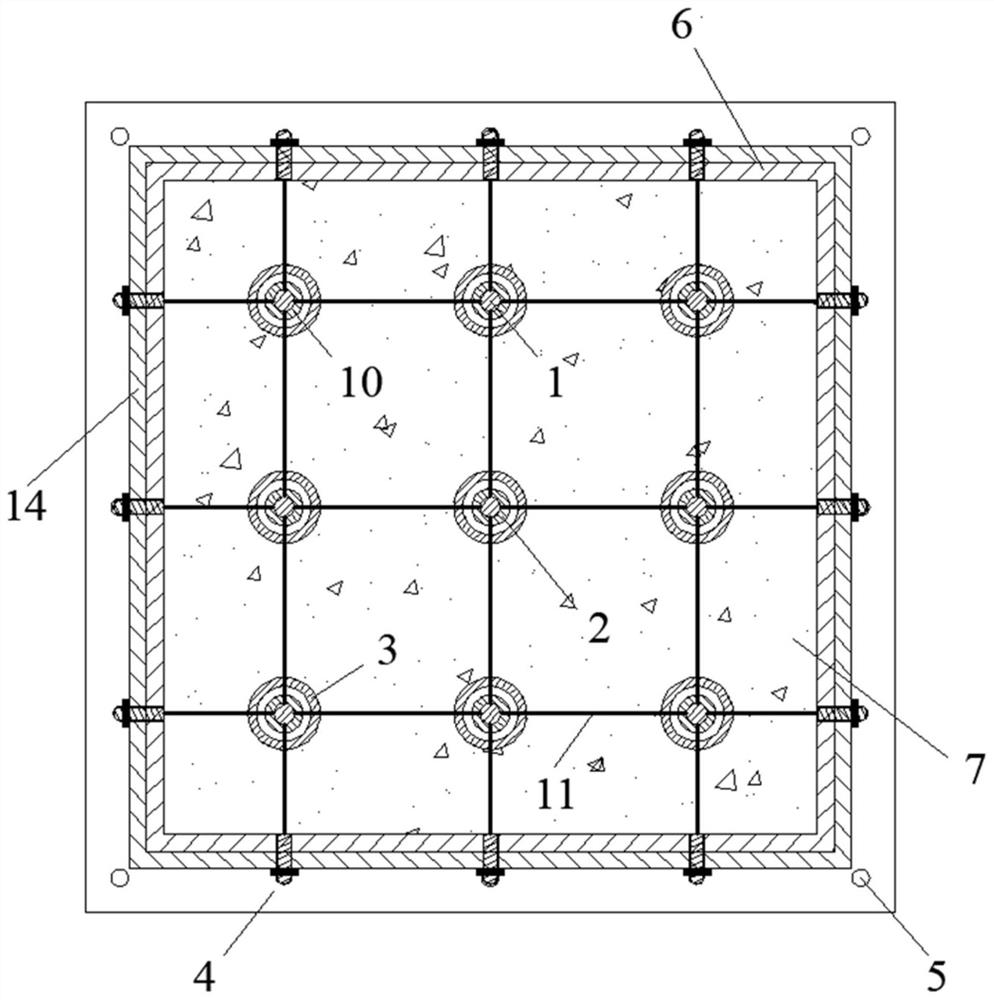

ActiveCN112160305BReduce wearDeformation monitoringResistance/reactance/impedenceElectric/magnetic area measurementsEngineeringMechanical engineering

The invention discloses a monitoring device for internal deformation and fine particle loss of a track subgrade, and relates to the field of monitoring devices; it includes an internal damage monitoring device arranged in the ballast layer of the roadbed, and the internal damage monitoring device is connected with a resistance collector through a wire. The resistance collector is wirelessly connected with a resistance signal receiver. The device for monitoring the internal deformation and loss of fine particles of the rail subgrade provided by the present invention can realize real-time and continuous monitoring of the deformation and loss of fine particles in the railway subgrade under rail traffic load under remote conditions, and is economical and convenient, and has high practical value.

Owner:WENZHOU UNIV

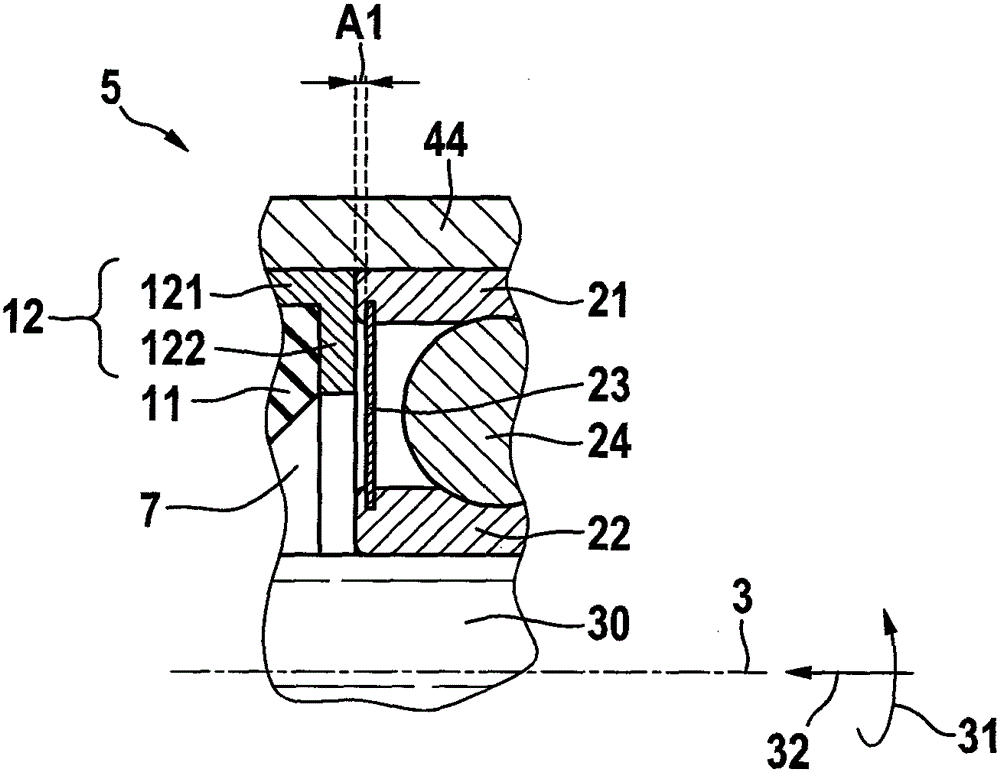

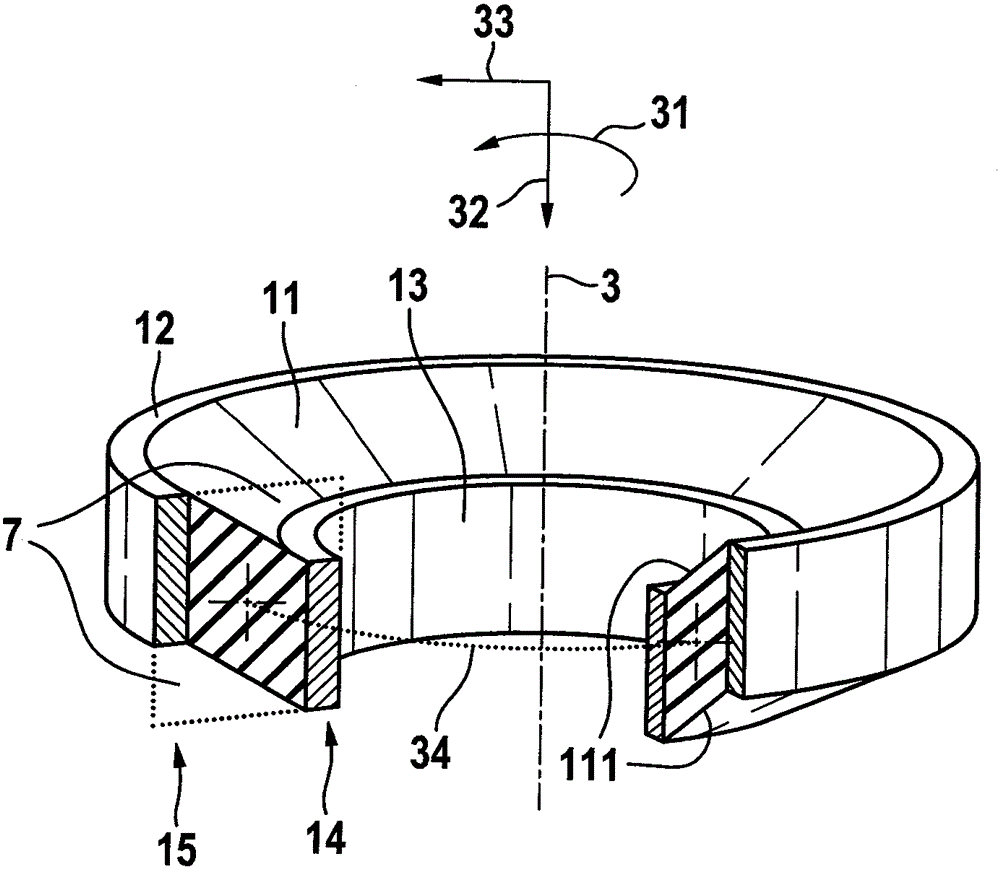

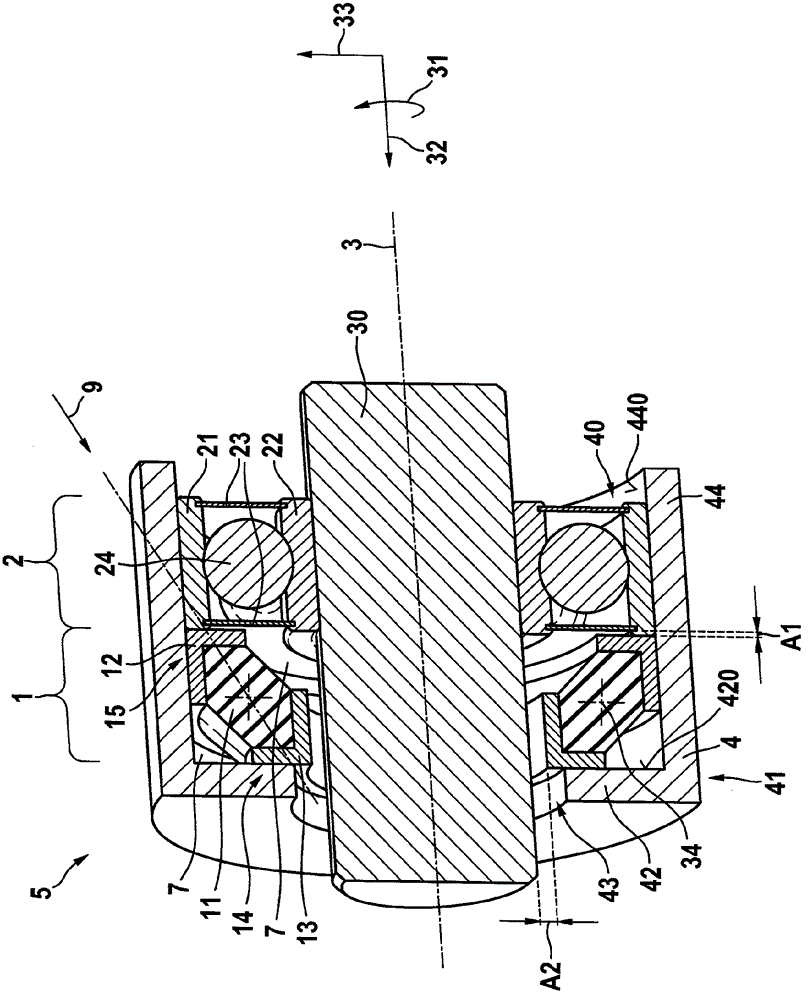

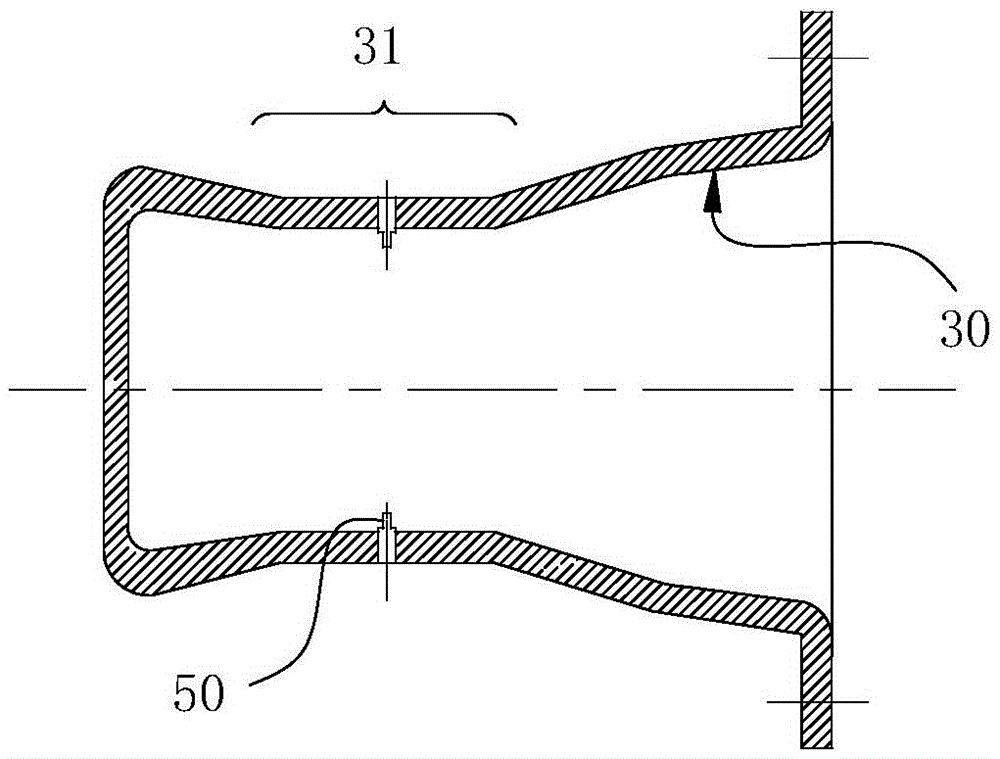

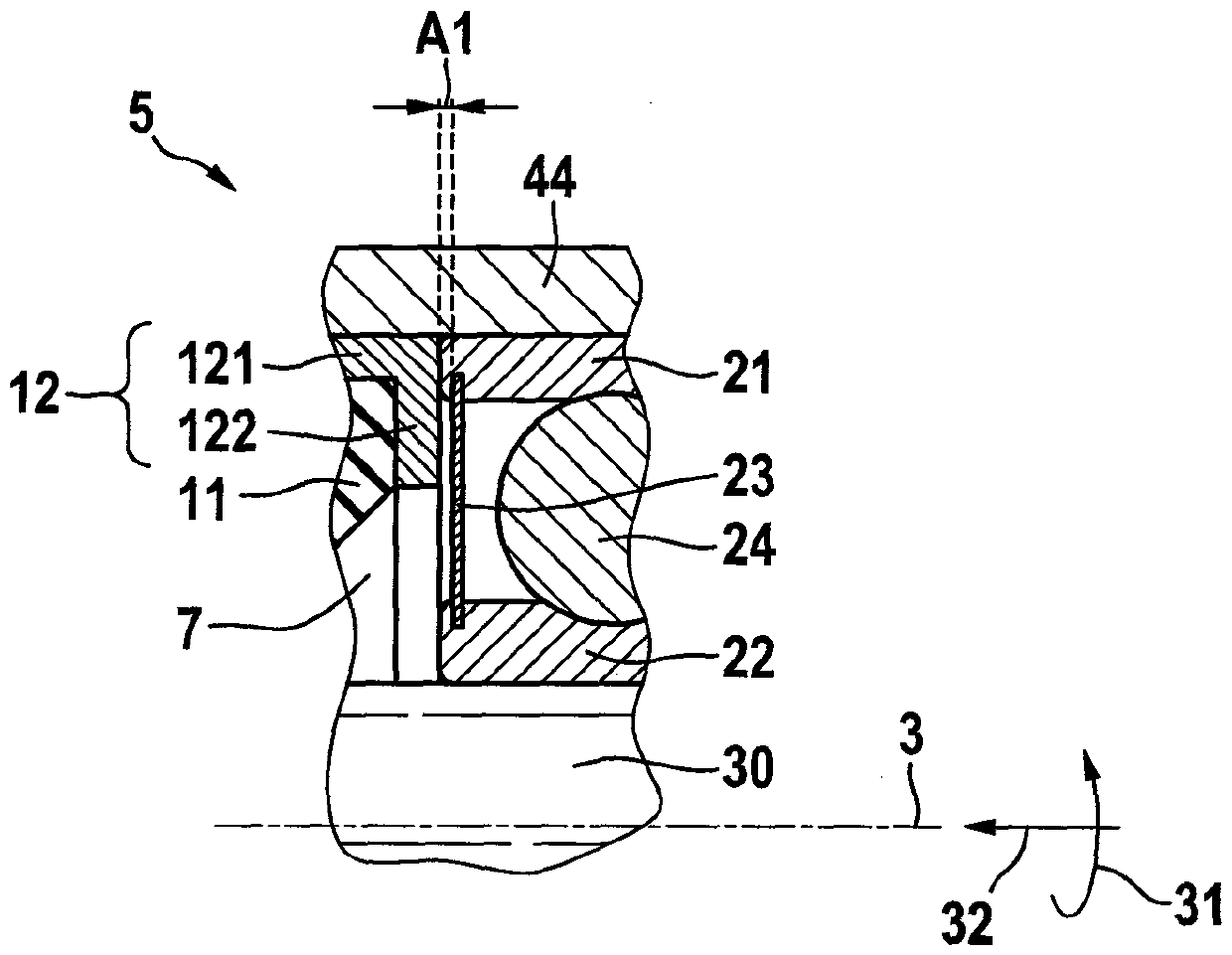

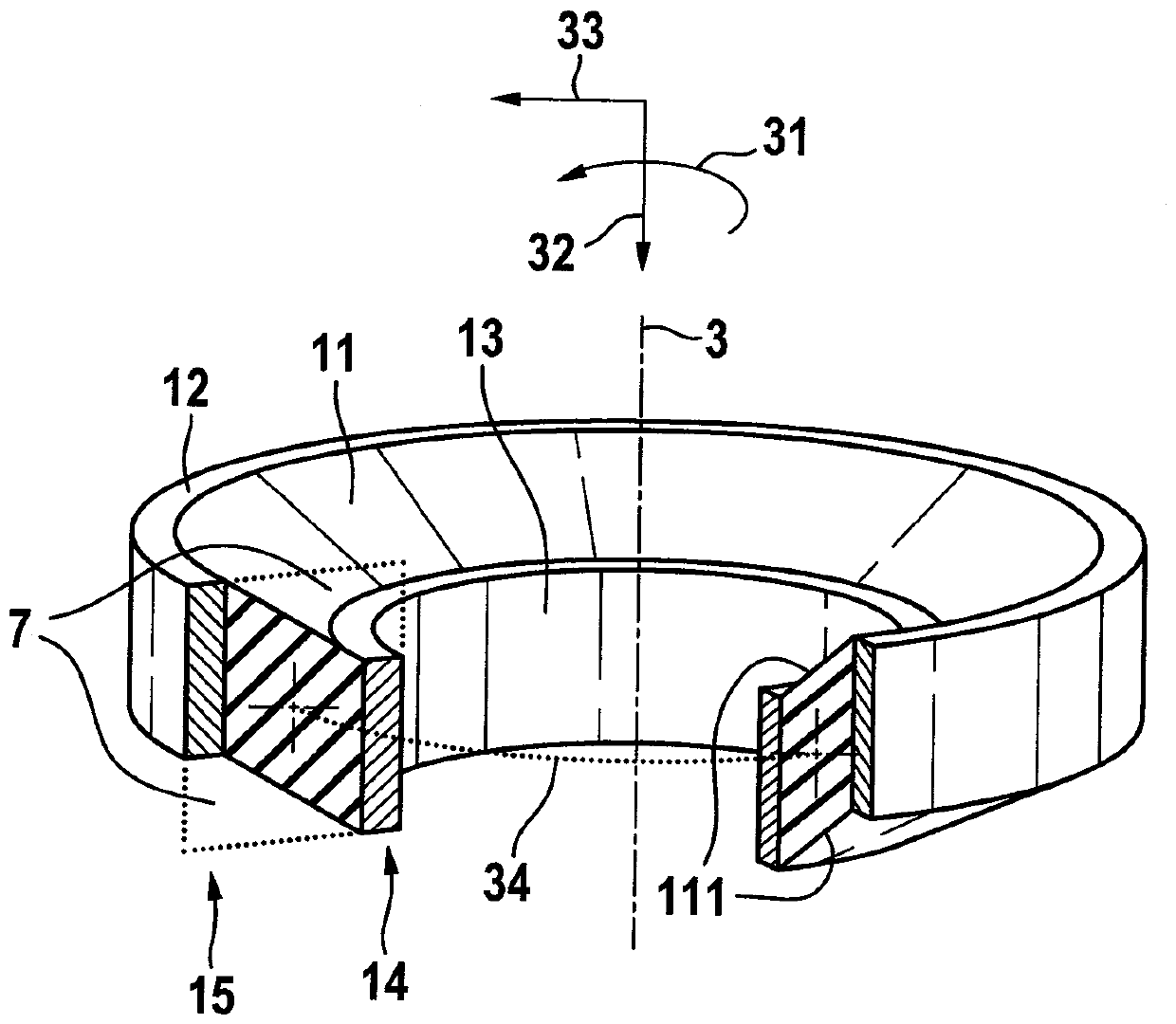

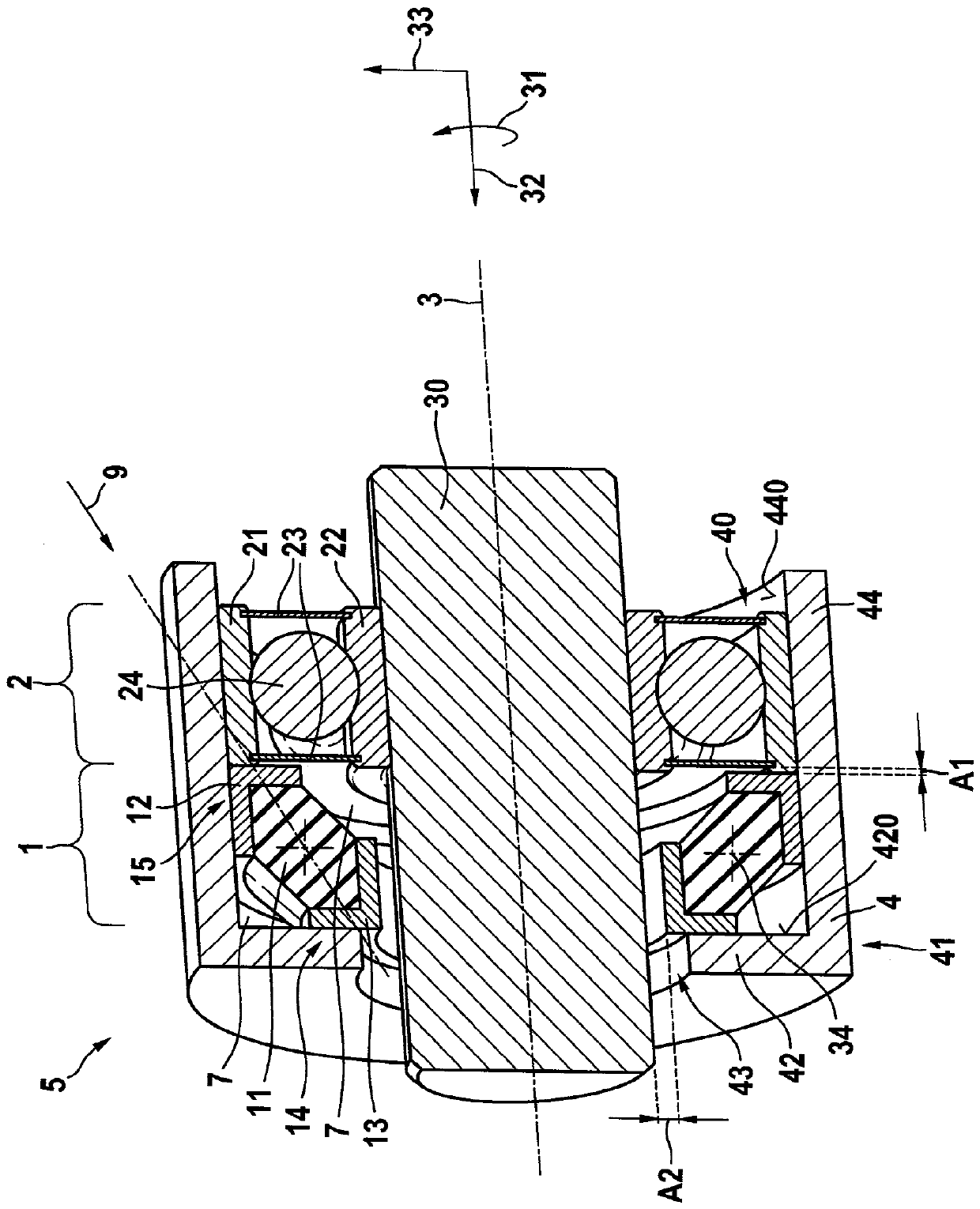

Spring For Preloaded Bearing And Structural Component With Spring And Rolling Bearing

The present invention relates to a spring for a preloaded bearing, in particular a rolling bearing, with an elastomeric core, wherein the elastomer core comprises a support sleeve of a hardenable material is disposed cohesively, and is formed less elastic than the elastomeric core. The present invention also relates to a structural component, which comprises a housing member, a bearing and the spring.

Owner:ROBERT BOSCH GMBH

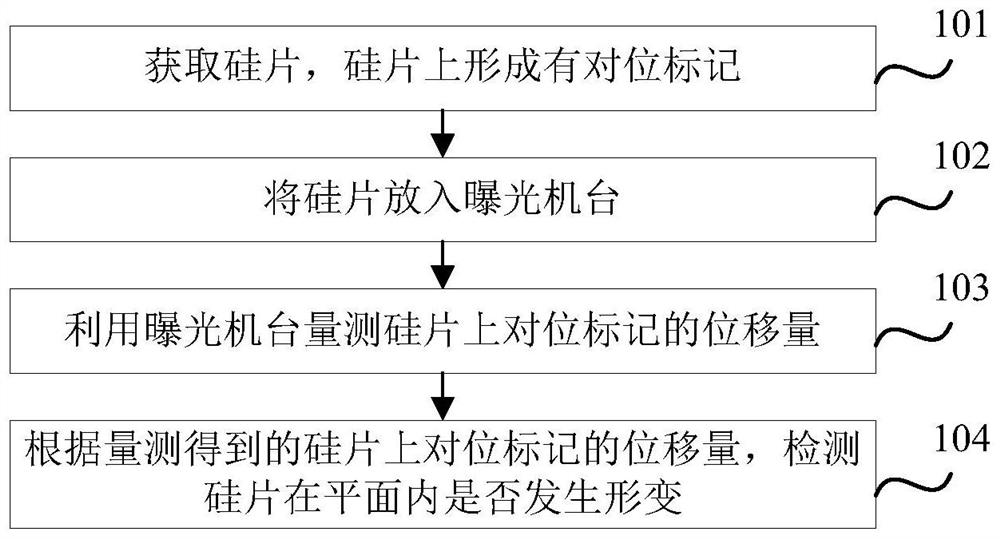

Method for detecting plane deformation of silicon wafer

PendingCN113506753ADeformation monitoringSolve the problem that the in-plane deformation of the silicon wafer cannot be detectedSemiconductor/solid-state device testing/measurementPhotomechanical exposure apparatusEngineering physicsSilicon chip

The invention discloses a method for detecting plane deformation of a silicon wafer, and relates to the field of semiconductor manufacturing. The silicon wafer plane deformation detection method comprises the following steps: obtaining a silicon wafer, wherein an alignment mark is formed on the silicon wafer; putting the silicon wafer into an exposure machine table; measuring the displacement of the alignment mark on the silicon wafer by using the exposure machine; and detecting whether the silicon wafer deforms in a plane or not according to the measured displacement of the alignment mark on the silicon wafer. The problem that the deformation condition of a silicon wafer in a plane cannot be detected at present is solved. The effect of effectively monitoring the deformation condition of the silicon wafer in the plane is achieved.

Owner:HUA HONG SEMICON WUXI LTD

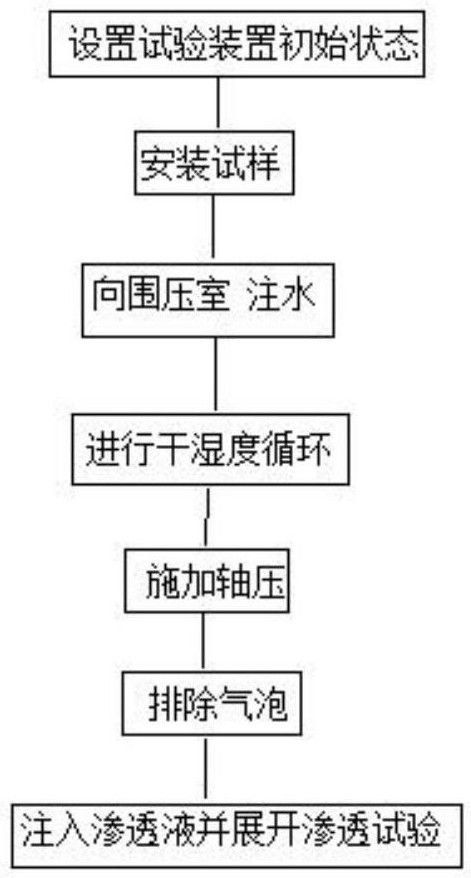

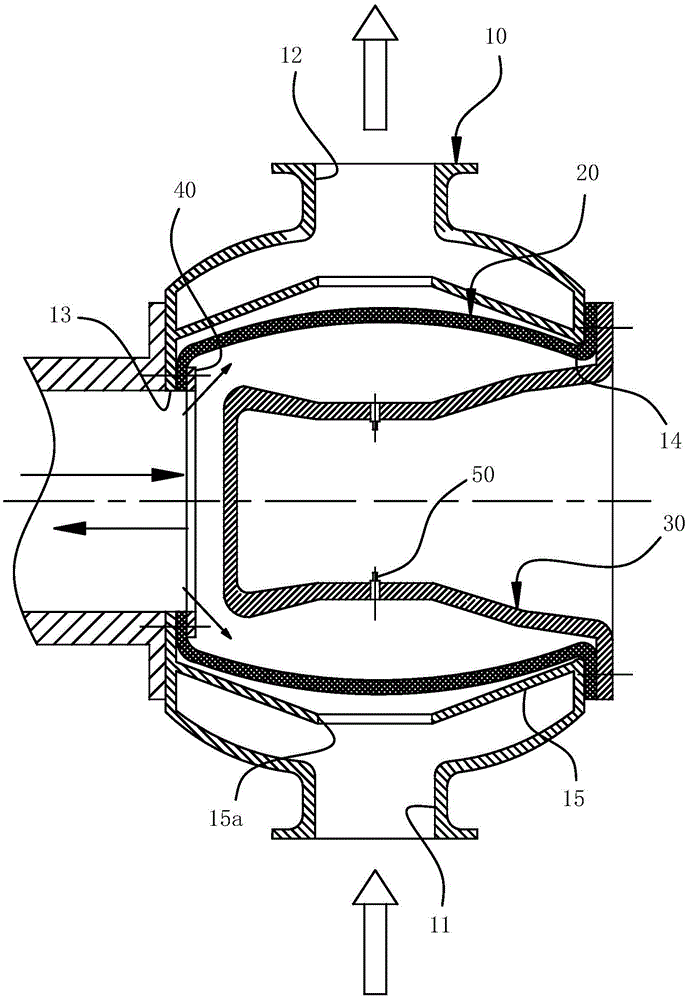

Temperature-stress integrated control flexible wall penetration test method under dry-wet cycle

PendingCN113899671AEasy to implementExtended service lifePermeability/surface area analysisNuclear energy generationSoil scienceConsolidation (soil)

The invention provides a temperature-stress integrated control flexible wall penetration test method under a dry-wet cycle, and relates to the field of geotechnical tests of geotechnical engineering. The test method comprises the steps of dryness and humidity circulation, axial pressure application, bubble removal, penetration test and the like, and a series of penetration tests of different dry and wet circulation times, different test temperatures, different consolidation pressures, different injection air pressures, different injection confining pressures and the like can be carried out on different samples; and a large amount of data about pressure-deformation-permeation of the soil body is obtained, so that the determination of the permeability coefficient under a plurality of influence factors is realized, the defects of the existing flexible wall permeability test are overcome, and more manpower and time are saved.

Owner:HEFEI UNIV OF TECH +2

A detachable diaphragm pump

ActiveCN104358675BStrong resistance to tensile fatigueStrong expansion efficiencyPositive displacement pump componentsFlexible member pumpsDiaphragm pumpEngineering

The invention belongs to the field of a volume pump, and particularly relates to a convenient-to-dismount diaphragm pump with the advantages that the monitoring can be realized in proper time, and a diaphragm leaf can be fast dismounted and replaced on line. The convenient-to-dismount diaphragm pump comprises a pump body and the diaphragm leaf, wherein liquid inlet and outlet holes and hydraulic holes are respectively formed in the pump wall of the pump body, a located pump cavity of the liquid inlet and outlet holes and a located pump cavity of the hydraulic holes are separated through the diaphragm leaf, the pump body also comprises a repair hole, the repair hole is sealed by an end cover, the appearance of the diaphragm leaf is of a sleeve-shaped structure, a pipe opening formed at one end of the diaphragm leaf is fixedly connected with the hole end surface of the hydraulic holes through screw bolts, a pipe opening formed in the other end of the diaphragm leaf extends towards the repair hole and is provided with an outer flange, the outer flange is arranged in a way of being matched with the surfaces between the hole ends, positioned at the outer wall parts of the the pump body, of the repair hole, and the end cover is pressed on the outer flange and is arranged in a way of being fixedly connected with screw bolts arranged between the pump walls of the pump body. The convenient-to-dismount diaphragm pump has the advantages that the monitoring and dismounting problems of the exiting conventional diaphragm pump can be effectively solved, the dismounting convenience and the maintenance replacement efficiency are high, and the work intensity of maintenance personnel can be greatly reduced.

Owner:HEFEI UNIV OF TECH +1

Device for monitoring internal deformation and fine particle loss of track roadbed

ActiveCN112160305AReduce wearDeformation monitoringResistance/reactance/impedenceElectric/magnetic area measurementsTrackwayClassical mechanics

The invention discloses a device for monitoring internal deformation and fine particle loss of a track roadbed, and relates to the field of monitoring devices. The device for monitoring internal deformation and fine particle loss of the track roadbed comprises an internal damage monitoring device arranged in a roadbed railway ballast layer; the internal damage monitoring device is connected with aresistance acquisition instrument through a wire; and the resistance acquisition instrument is wirelessly connected with a resistance signal receiver. According to the device for monitoring the internal deformation and the fine particle loss of the track roadbed, real-time continuous monitoring of the deformation and the fine particle loss in a railway roadbed under a rail traffic load under a remote condition can be realized, the device is economical and convenient, the practical value is higher.

Owner:WENZHOU UNIVERSITY

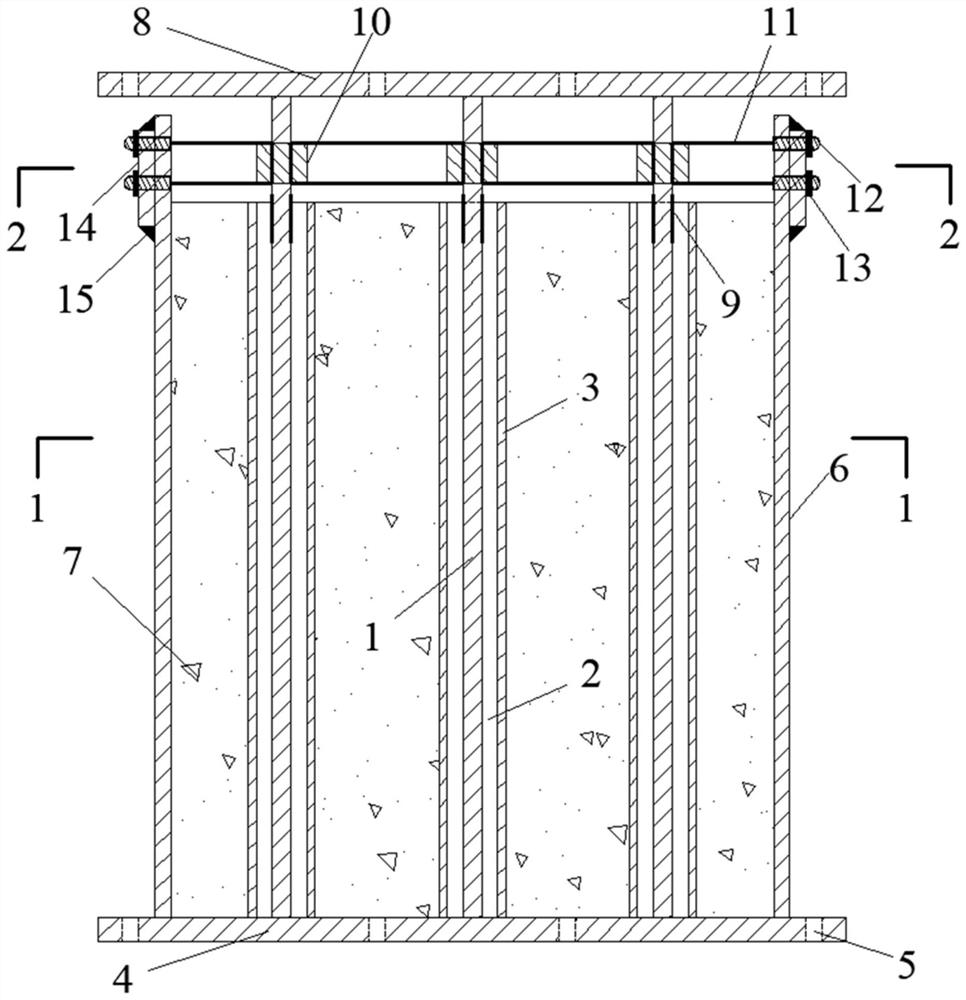

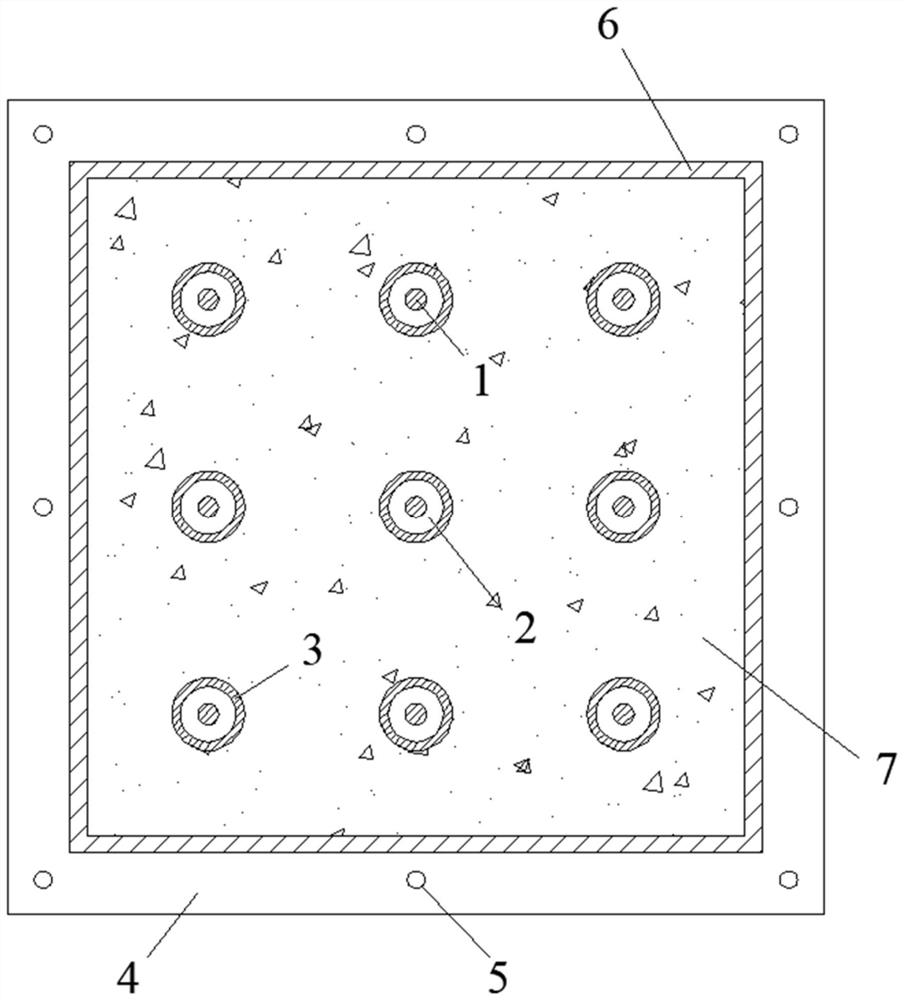

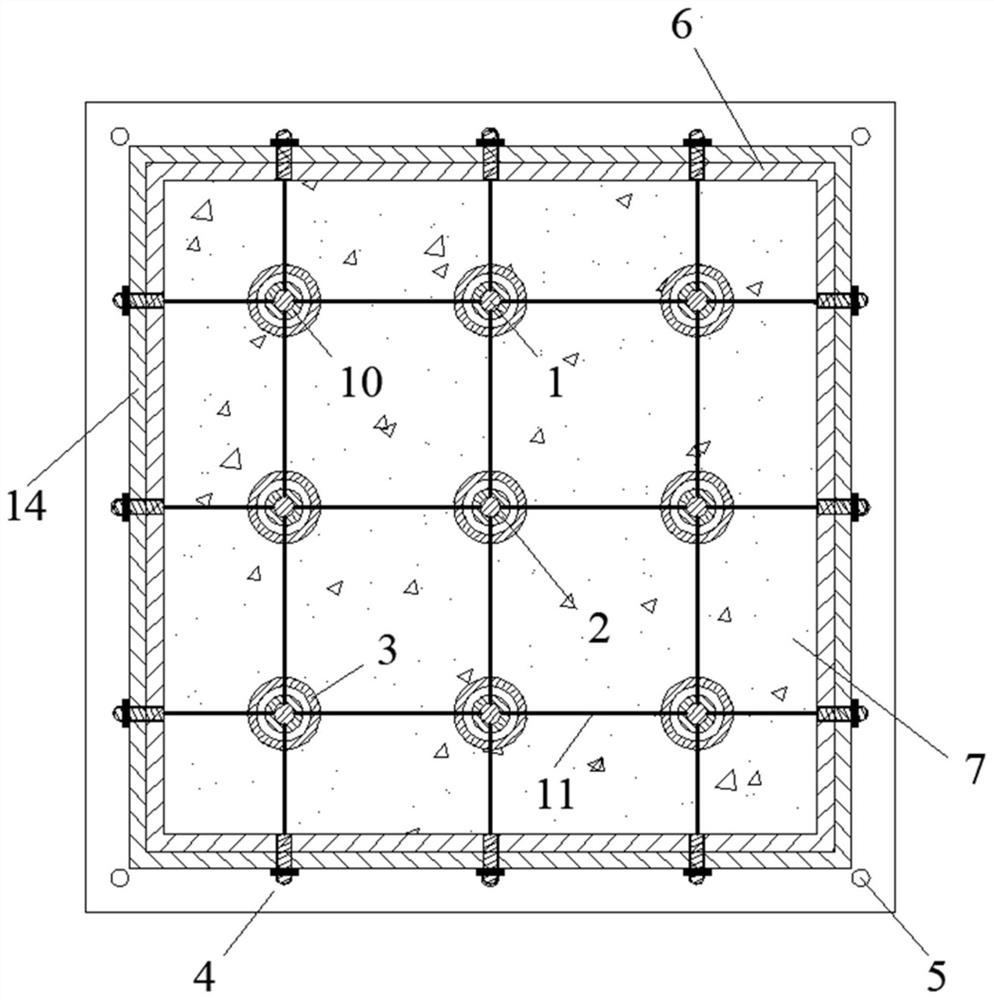

Multi-dimensional seismic isolation support based on vertical variable stiffness and horizontal self-return

ActiveCN111910789ADeformation MonitoringPowerful and uniqueProtective buildings/sheltersShock proofingVertical vibrationStructural engineering

The invention relates to a multi-dimensional seismic isolation support based on vertical variable stiffness and horizontal self-return. The support is mainly composed of a sleeve component, a lower connecting plate, a side coaming, concrete, an upper connecting plate and SMA self-return assemblies; under strong vertical seismic excitation, an inner core is bent, and the vertical rigidity of the support is greatly reduced so as to realize seismic isolation; in the horizontal direction, lantern rings are welded to the upper portion of the inner core, the lantern rings are connected through the SMA self-return assemblies, the lantern rings are connected with the side coaming through the SMA self-return assemblies, a structural seismic isolation layer can laterally move to a certain degree toachieve horizontal seismic isolation, and returning can be achieved through the SMA self-return assemblies after lateral movement; and a sensor can be arranged at the position where the inner core possibly makes contact with an outer pipe so as to monitor the working state of the support. Compared with the prior art, the support realizes multi-dimensional seismic isolation through the rigidity change after a pressing rod is bent and the characteristic of self-return after horizontal lateral movement, is suitable for structural multi-dimensional seismic isolation with a vertical vibration control function, and has the characteristics that the structure is simple, the cost is relatively low, and the reliability is relatively high.

Owner:TONGJI UNIV

Underground pipe gallery deformation monitoring system

ActiveCN107860305AInnovative designAchieve conversionElectrical/magnetic solid deformation measurementHemt circuitsEngineering

The invention provides an underground pipe gallery deformation monitoring system, which comprises a base, a filling block, turning handles, resistors, resistor springs, turning handle springs, base springs and a circuit chip. The base is mounted in the included angle of pipe gallery walls; the filling block is filled in a cut cube block cavity of the base; each resistor installation cavity and a filling block resistor cavity of the base and the filling block form a cylindrical cavity; the inner side of each cylindrical cavity is equipped with one resistor; and the opening of each cylindrical cavity is in a throat shape, and is embedded by a spherical block of the turning handle. When a horizontal wall, a first vertical wall and a second vertical wall are in relative rotation, the walls drive driving slices at the outer ends of the turning handles to move; the inner end of each turning handle rotates, and an eccentric plate at the innermost end of each turning handle presses or releasesa pole plate at the outer side of each resistor, so that the distance between the two pole plates of the resistor changes, length and cross-sectional area of metallic mercury in a soft shell changes,resistance changes, and voltage between the two pole plates of the resistor changes; and by monitoring the change of the voltage value, relative rotated angle of the walls can be calculated.

Owner:XIAMEN KINGTOP INFORMATION TECH

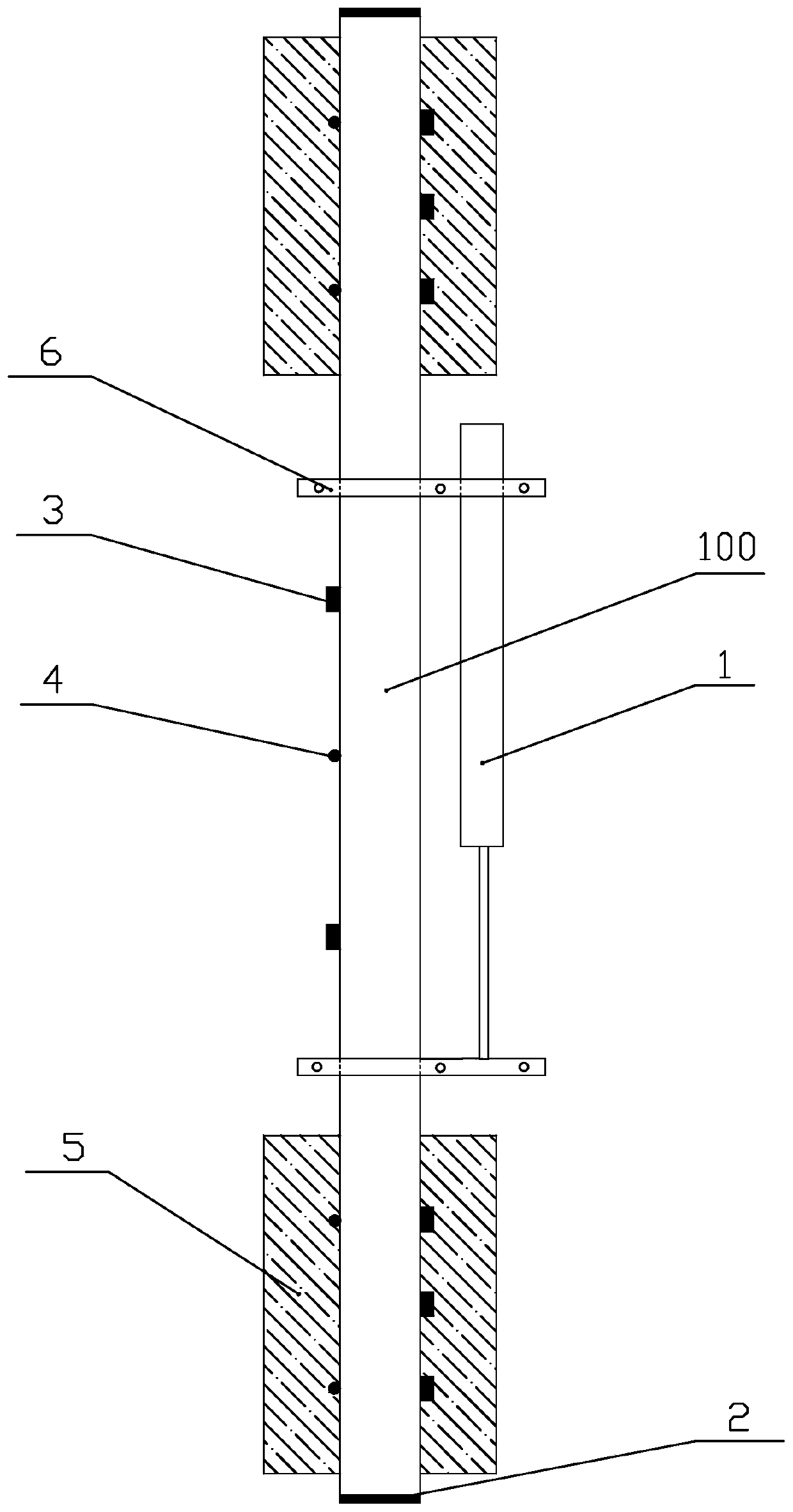

Tension-tension fatigue testing device for fiber rod body and fatigue performance evaluation method

InactiveCN110553937ASimple structureWide range of applicationsMaterial strength using repeated/pulsating forcesFatigue testingStrain sensor

The invention discloses a tension-tension fatigue testing device for a fiber rod body and a fatigue performance evaluation method, and belongs to the technical field of civil engineering. The problemsthat the application of fiber composite material rod bodies in bridge stay cables, ground anchors and the like is greatly limited and the application and development of new materials and new structures in civil engineering are hindered due to lack of research on the tension-tension fatigue test of the fiber reinforced composite material rod bodies in the prior art are solved. The fiber rod body is vertically arranged, and the upper part and the lower part of the fiber rod body are anchored through anchorage devices respectively. A plurality of strain sensors and a plurality of temperature sensors are bonded to the surface of the fiber rod body; piezoelectric sensors are respectively adhered to two ends of the fiber rod body; and a displacement sensor is parallel to the fiber rod body. A fixing device comprises two positioning plates which are arranged in parallel up and down, the two positioning plates are fixedly arranged on the fiber rod body between the two anchorage devices, and the upper part of the displacement sensor is fixedly connected with the fiber rod body through one positioning plate.

Owner:HARBIN INST OF TECH

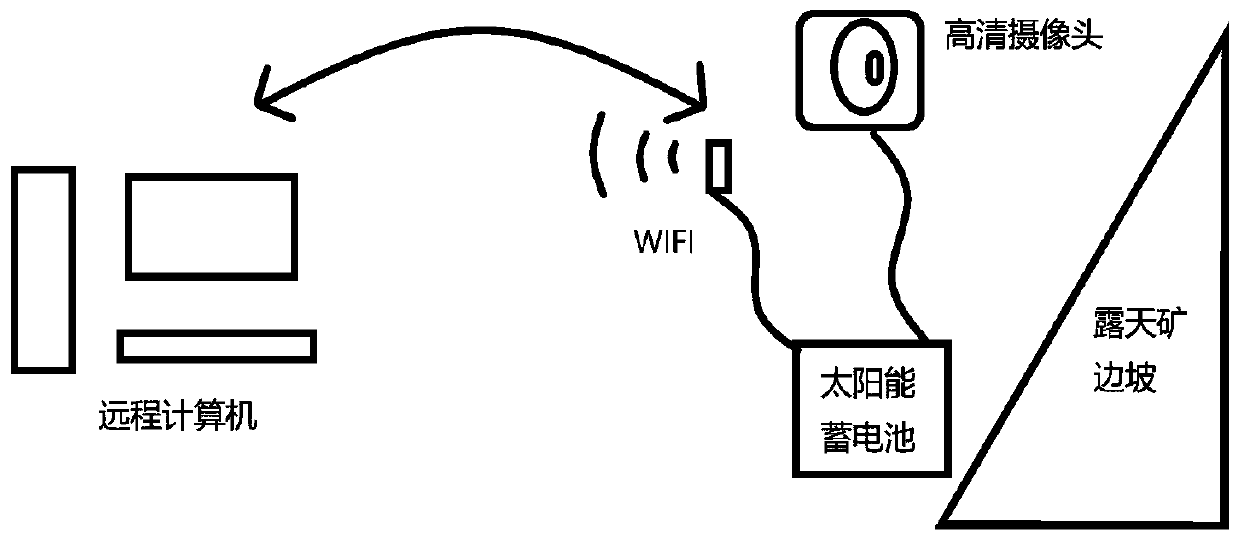

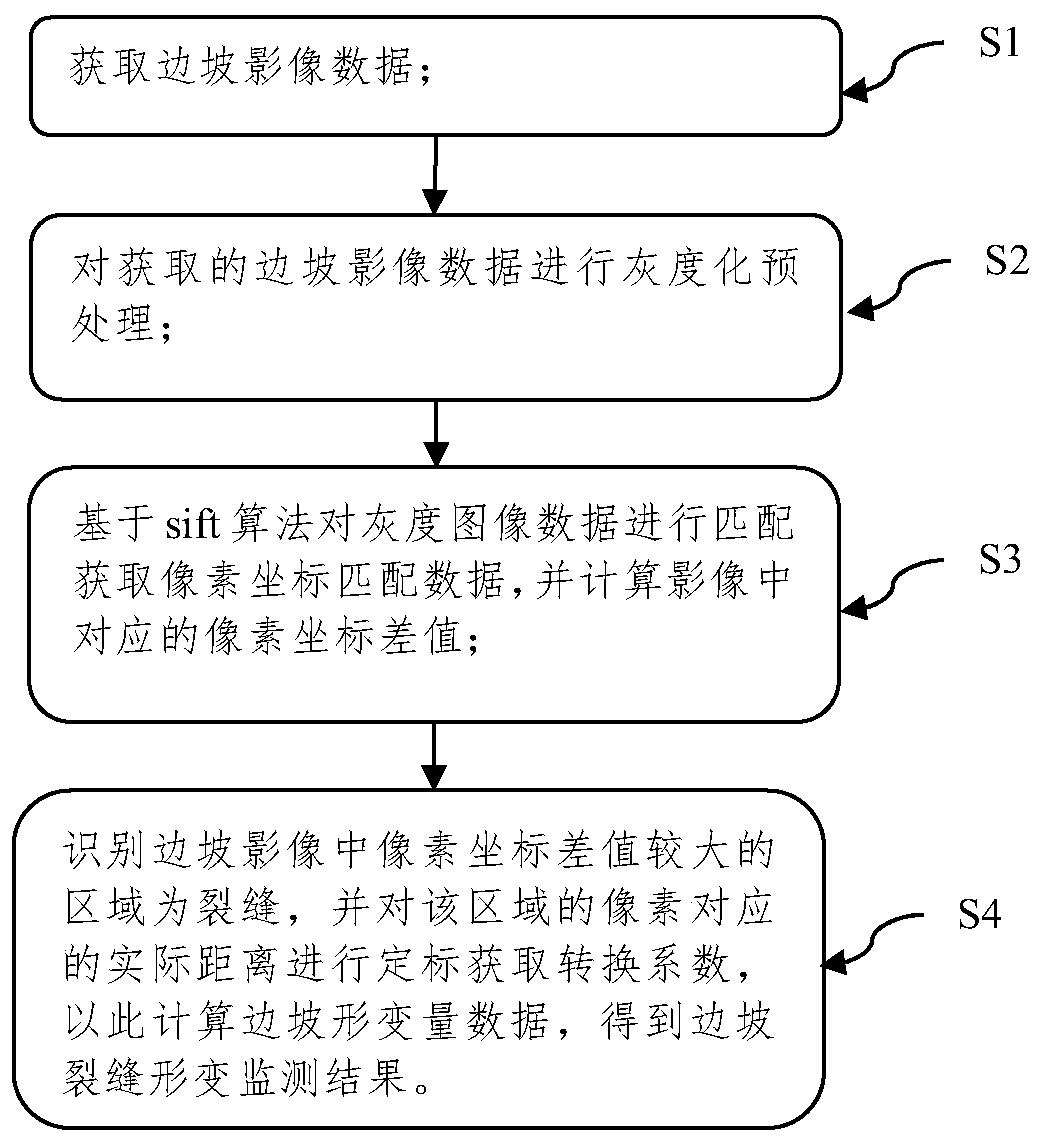

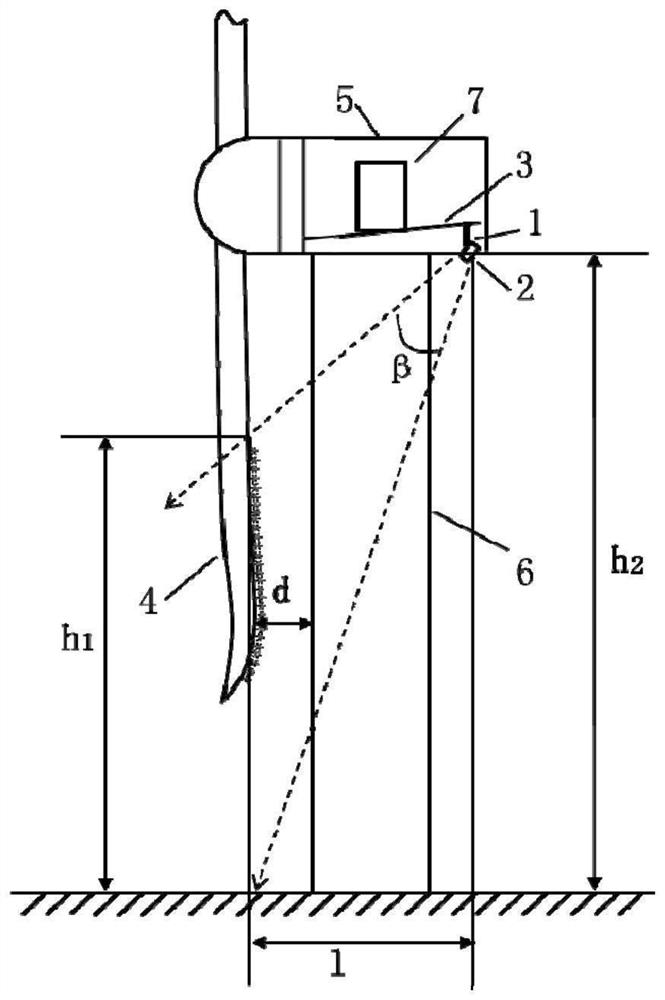

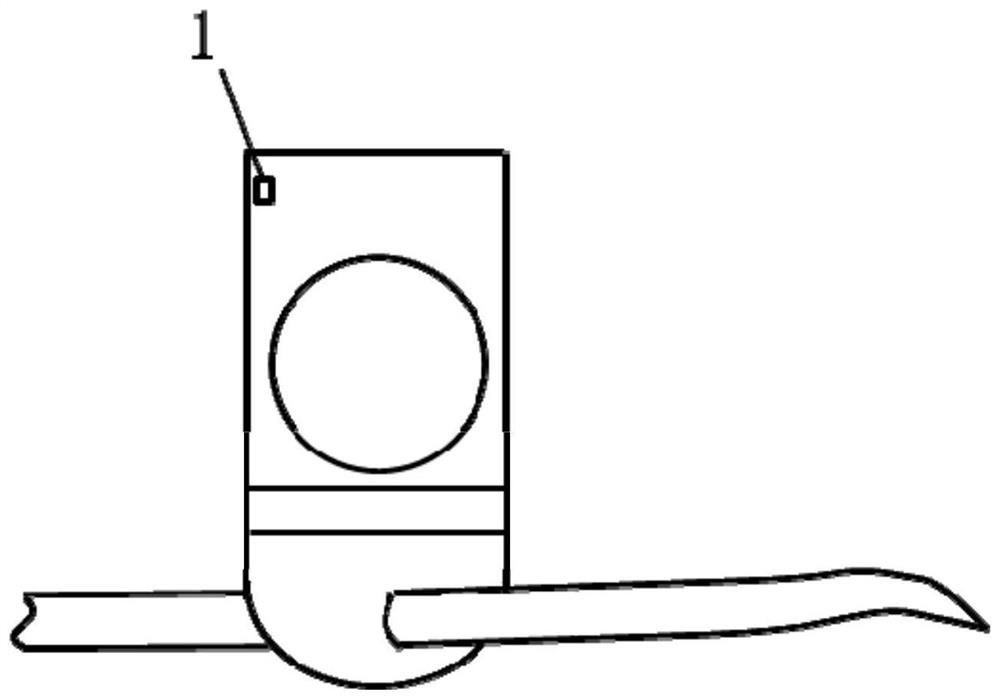

Slope image real-time acquisition device, and slope crack real-time recognition deformation monitoring method

InactiveCN110645900AHigh-precision monitoringReal-time acquisition of high-definition image dataImage enhancementImage analysisComputer visionRemote computer

The invention relates to a slope image real-time acquisition device, and a slope crack real-time recognition deformation monitoring method. The slope image real-time acquisition device comprises a HDcamera for collecting slope HD images, a mobile WIFI for network communication of the camera and a remote computer, a solar storage battery for powering the HD camera and the WIFI, and the remote computer for processing image data in real time. The method and device provided in the invention can recognize slope cracks of an open pit mine accurately in a large range in real time, and can monitor deformation information of slope cracks at high accuracy in real time.

Owner:NORTHEASTERN UNIV

Multi-dimensional seismic isolation bearing based on vertical variable stiffness and horizontal self-resetting

ActiveCN111910789BDeformation MonitoringPowerful and uniqueProtective buildings/sheltersShock proofingVertical vibrationClassical mechanics

The invention relates to a multi-dimensional shock-isolation bearing based on vertically variable stiffness and horizontal self-resetting, mainly composed of a sleeve member, a lower connecting plate, a side panel, concrete, an upper connecting plate, and an SMA self-resetting component. Under strong vertical earthquake excitation, the inner core buckles, and its vertical stiffness will be greatly reduced to achieve seismic isolation; in the horizontal direction, the upper part of the inner core is welded with collars, and the SMA self-resetting components are passed between the collars and the collar and the side wall Connection, the structure isolation layer can have a certain side shift to achieve horizontal vibration isolation, and can be reset through the SMA self-resetting component after the side shift occurs. Sensors can be arranged at positions where the inner core and the outer tube may come into contact to monitor the working state of the support. Compared with the prior art, the present invention utilizes the stiffness change after buckling of the compression bar and the self-resetting characteristics after horizontal lateral displacement to realize multi-dimensional seismic isolation, which is suitable for multi-dimensional seismic isolation of structures in which vertical vibration plays a controlling role, and has a simple structure , low cost and high reliability.

Owner:TONGJI UNIV

Parallel Control System of Large Hydraulic Press Beam

ActiveCN107042653BImprove fault monitoring rateReduce failurePressesStress concentrationElement analysis

The invention discloses a large hydraulic press crossbeam parallel control system. The large hydraulic press crossbeam parallel control system comprises a hydraulic press crossbeam physical system and an upper computer virtual system which are connected through communication modules. The hydraulic press crossbeam physical system comprises a hydraulic press crossbeam, a plurality of displacement sensors and a plurality of pressure sensors which are arranged at stress concentration positions of the hydraulic press crossbeam, and a PLC; both the displacement sensors and the pressure sensors are connected with the PLC; the upper computer virtual system comprises failure service information and management control information which are directly in communication with and in handshake with the PLC, hydraulic press crossbeam finite element analysis modules are transmitted to hydraulic press crossbeam ideal digital analogy, then the management control information is obtained through a contrastive analysis, and the management control information is in handshake with the PLC through the communication modules. According to the large hydraulic press crossbeam parallel control system, fault emergency monitoring efficiency is improved, and useful empirical data for optimization design of the large hydraulic press in later period, compensation of deflection deformation and the like are provided.

Owner:南通华德锻压机床有限公司

A method and device for automatically measuring deformation of tunnel section

ActiveCN105136115BWill not cause traffic difficultiesDeformation monitoringProfile tracingEngineering

Owner:BEIJING ZHONGLI ZHIYAN INTERNET OF THINGS TECH CO LTD

An on-line monitoring system for gis bus bar

InactiveCN104779568BDeformation monitoringAccurate monitoringCircuit arrangementsBus-bar installationAxial displacementBusbar

The invention relates to an online monitoring system for a GIS busbar barrel. The online monitoring system comprises a monitoring terminal arranged on the barrel and a data processing unit connected with the monitoring terminal, wherein the monitoring terminal comprises a pull rod resistance displacement rule used for detecting the axial displacement of a barrel wall relative to a support, a stay cord displacement sensor used for detecting the displacement of the barrel relative to the ground, and a three-axis acceleration sensor used for detecting the axial and radial warping degrees of the barrel relative to a horizontal plane. By adopting the monitoring system, real-time monitoring can be realized, routing inspection work of workers is reduced, and the labor cost is reduced. Meanwhile, the operation safety of a busbar is improved, accidents, such as cracking of a busbar support, can be effectively prevented, and safety hazards and economic loss caused by bad breakdown repair can be avoided. The system is particularly applied to northwestern districts with a high diurnal temperature difference, high altitude regions, tundra regions and southern geological sedimentation districts.

Owner:PINGGAO GRP +3

Deformation and Stability Detection Method of Mine Goaf Based on Bouguer Gravity Anomaly

InactiveCN107036575BThe method steps are simpleEasy to implementMeasurement devicesObservation pointAbsolute gravity

The invention discloses a mine goaf deformation and stability evaluation method based on Bouguer gravity anomaly. The mine goaf deformation and stability evaluation method comprises a step1, arrangement of relative gravimeter observation points; a step2, arrangement of base points; a step3, erecting of gravimeters and absolute gravimeters; a step 4, acquisition of relative gravity observation values and absolute gravity observation values; a step 5, the acquisition of the deformation amounts of the relative gravity observation points; a step 6, drafting of a relative gravity observation point deflection curve and acquisition of stable deformation amounts. The mine goaf deformation and stability evaluation method is advantageous in that the steps are simple, a design is reasonable, costs are low, and use operation is convenient; by adopting the Bouguer gravity anomaly, the deformation amounts of the mine goaf is monitored, and monitoring results are accurate; the stability of the mine goaf is evaluated according to the deformation amounts of the mine goaf, and the stable deformation amounts of the mine goaf are acquired, and practicability is strong.

Owner:XIAN UNIV OF SCI & TECH

An automatic monitoring device for full-section deformation of an underground chamber and a method for applying the device

InactiveCN103954229BFull-Section Deformation MonitoringDeformation MonitoringUsing optical meansProfile tracingFast measurementLaser probe

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

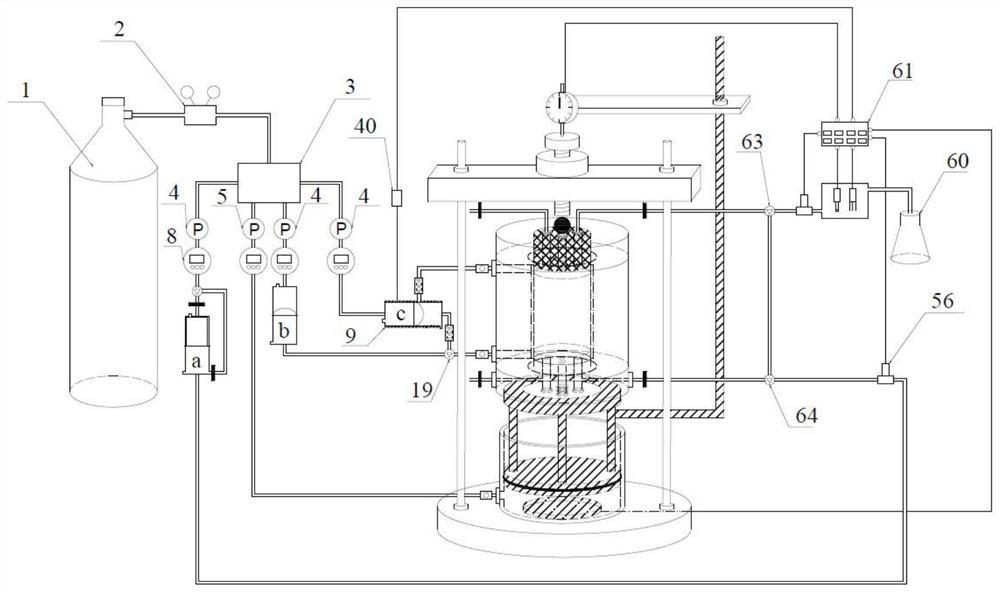

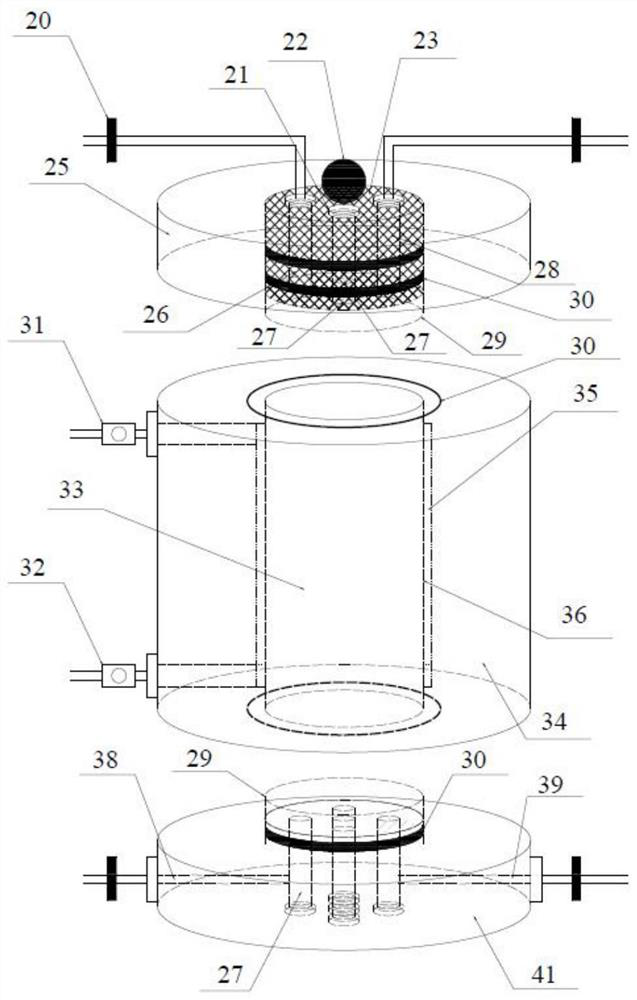

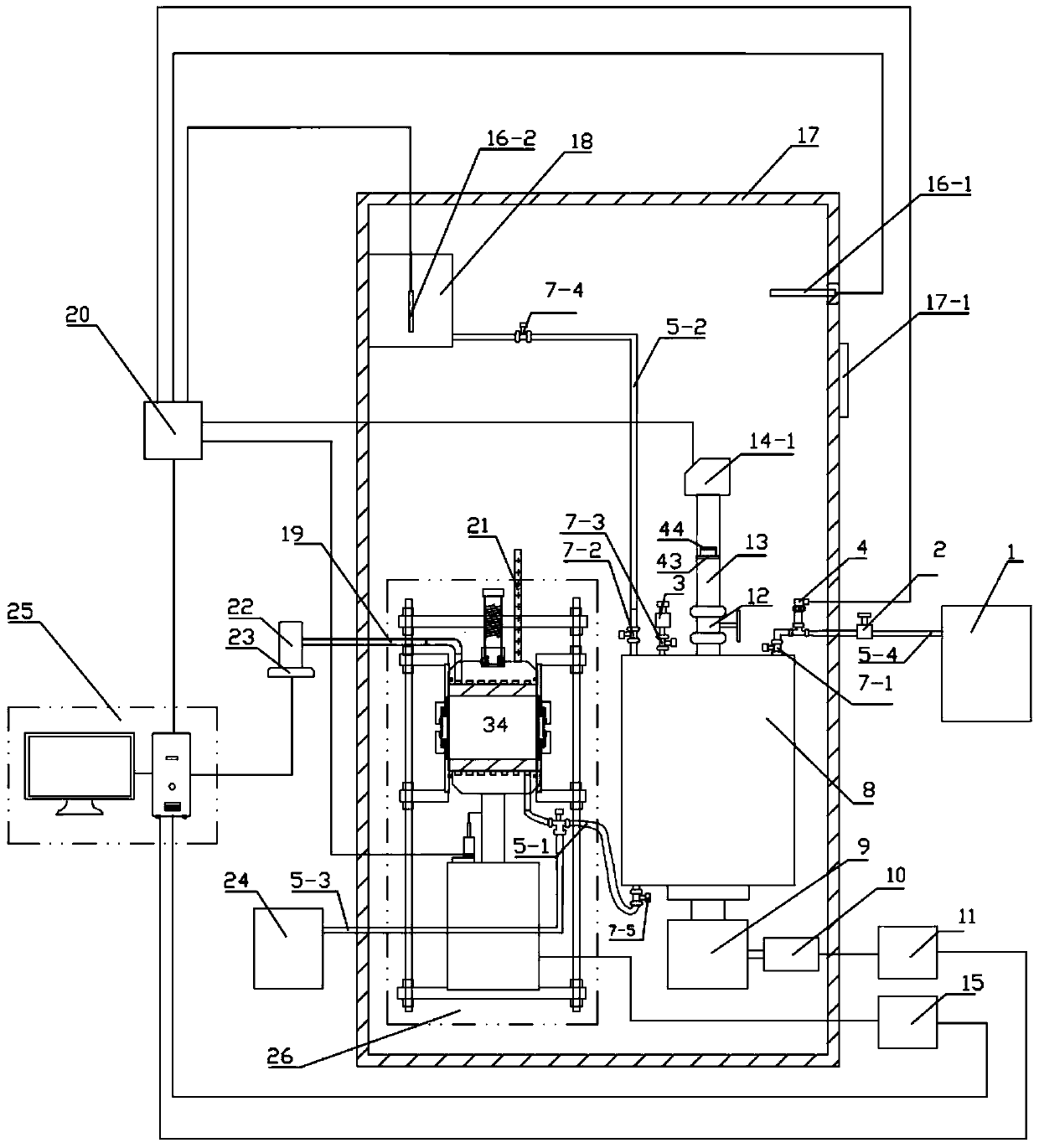

Permeability Testing Experimental System for Low Permeability Clay

ActiveCN108344676BPrecise head difference changeReliable results from the initial hydraulic gradientPermeability/surface area analysisData acquisitionOsmotic coefficient

The invention provides a permeability test experimental system of low-permeability clay, and belongs to the field of geotechnique clay permeability tests. The system comprises a water head supply unitcapable of supplying tiny water heads and high-pressure water heads, a sample treatment unit for clamping and pressurizing samples, a water supply and storage unit for providing percolating fluid andcollecting the fluid, a data acquiring and processing unit for acquiring and processing experimental data, and an incubator for controlling experimental environments. According to the system, the principles of variable water heads and constant water heads of the geotechnique permeability tests are combined, the modern data acquisition technology is introduced, and the test precision is effectively improved. On the aspect of scientific research, a device can provide temperatures, loads and water head differences to be used as variables, when low-permeability clay samples with different water contents are provided, the water contents can serve as variables for permeability research of the samples, and application of conversion between the constant water heads and the variable water heads can be carried out. On the aspect of engineering parameter requirements, the device can adopt the high-pressure variable water heads to test the permeability coefficient of the low-permeability clay, and the experimental time is effectively shortened.

Owner:JILIN UNIV

Springs for preloading rolling bearings and structural components with springs and rolling bearings

The present invention relates to a spring for a preloaded bearing, in particular a rolling bearing, with an elastomeric core, wherein the elastomer core comprises a support sleeve of a hardenable material is disposed cohesively, and is formed less elastic than the elastomeric core. The present invention also relates to a structural component, which comprises a housing member, a bearing and the spring.

Owner:ROBERT BOSCH GMBH

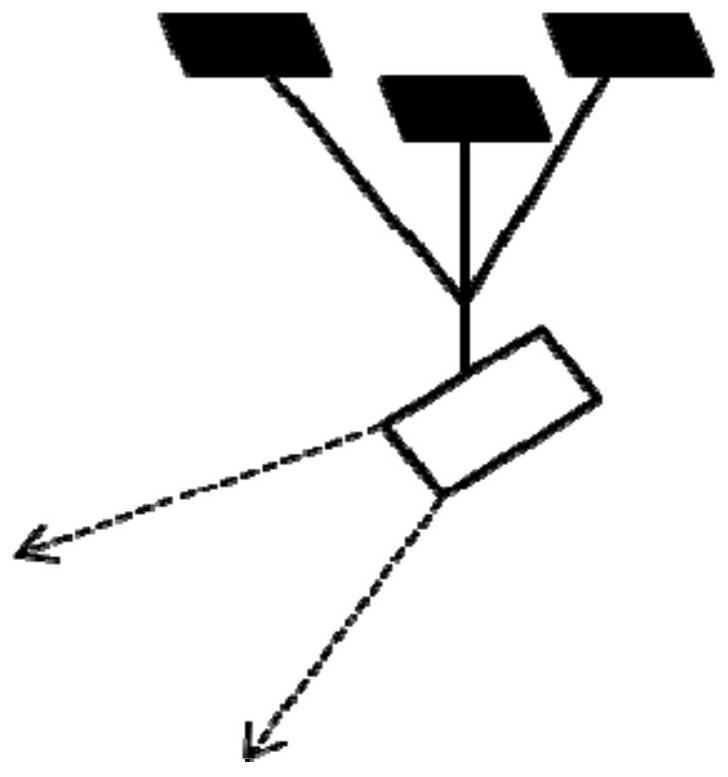

A method for real-time prediction of the risk of tower sweeping when blades pass through the tower

ActiveCN112502911BImprove securityAvoid Tower Sweeping AccidentsWind motor controlWind motor supports/mountsRisk levelMillimetre wave

Owner:东方电气风电股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com