Multifunctional and intelligent monitoring anchor rod device

An intelligent monitoring and multi-function technology, applied in mining equipment, installation of bolts, instruments, etc., can solve the problems of easy damage, failure, and poor bolt effect of the bolt's stress point, so as to increase the life and wide adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

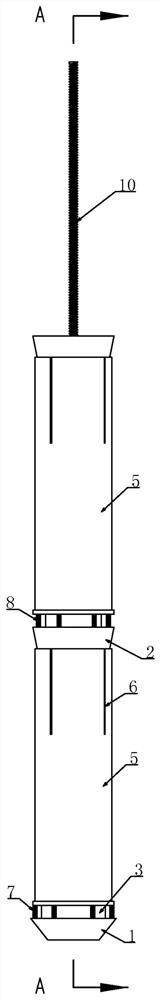

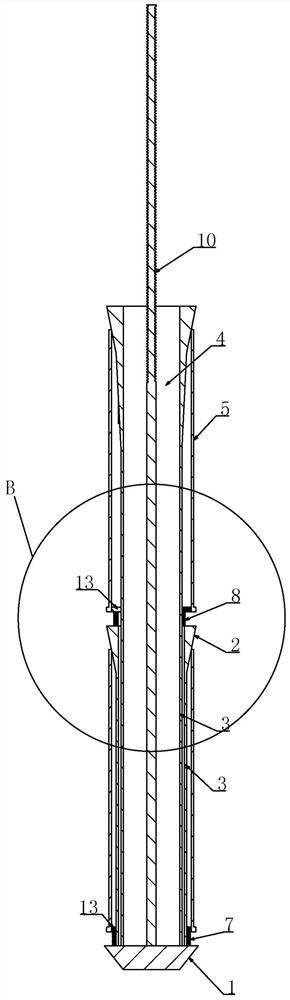

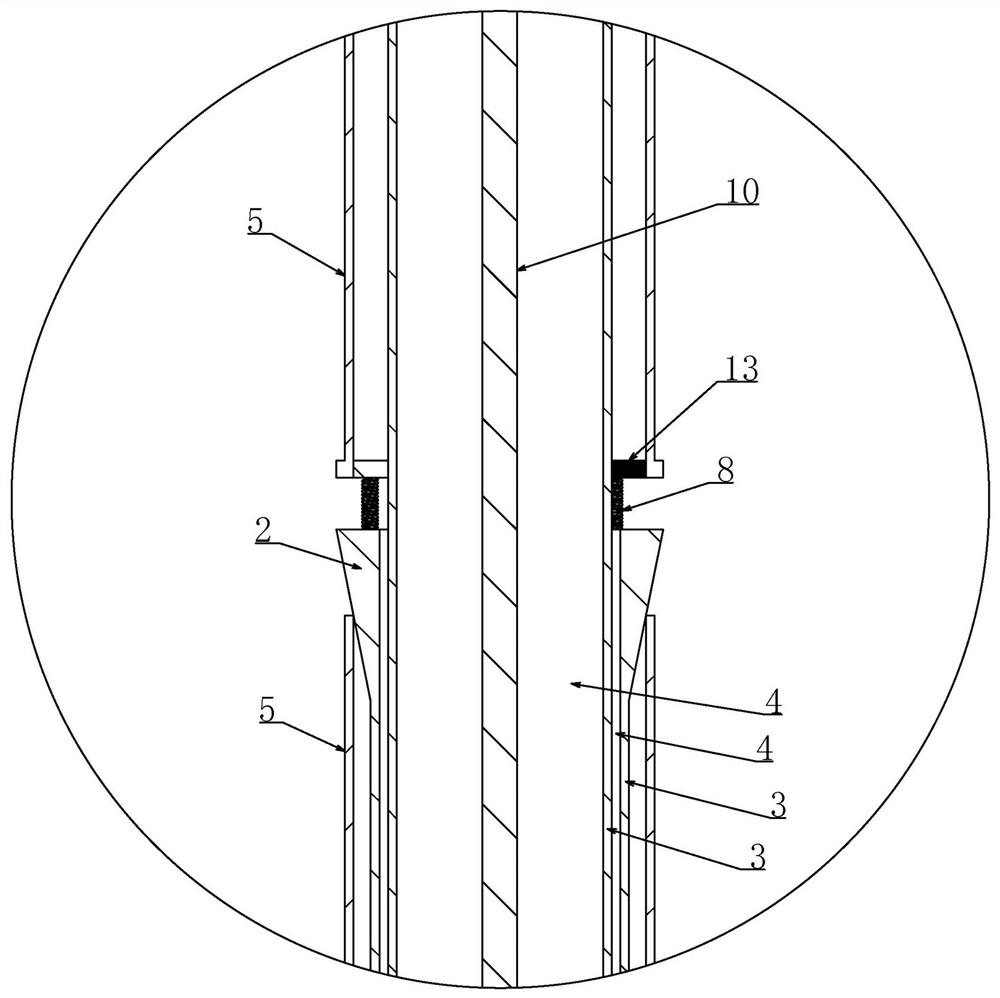

[0043] Embodiment 1, the technical solution is a multifunctional and intelligent monitoring bolt device, which includes an anchoring end 1 placed at the bottom of the anchor hole 9, and is characterized in that the anchoring end 1 is arranged axially and outwardly at intervals of several A circular frustum body 2 with an axially outwardly large and internally small, the axially inner end of the circular frustum body 2 is coaxially connected with a tension body 3, and the axially outer end of the circular frustum body 2 is provided with an axially inwardly penetrating tension body 3 through the hole 4, the tension body 3 at the innermost end in the axial direction is fixed on the anchoring end 1, and the tension body 3 at the axial outer side passes through the conical frustum body 2 and the tension body 3 adjacent to the axial inner side It passes through the hole 4 and is fixed on the anchoring end 1. The axial inner part of the circular frustum body 2 is covered with a sleeve...

Embodiment 2

[0060] Embodiment 2, on the basis of Embodiment 1, a screw 10 is fixed at the center of the anchoring end 1, and the screw 10 passes through the through hole 4 in the axially outermost conical body 2 toward the axially outward, and the A tray 11 is sheathed on the portion of the screw 10 passing through the outermost conical body 2 in the axial direction, and a nut 12 is screwed on the screw 10 on the axial outer side of the tray 11 .

[0061] A fourth through hole 28 can be opened on the tray 11 in this embodiment, and the lead wire of the displacement sensor is drawn out from the fourth through hole 28, thereby being installed on the electric control box 19 outside the anchor hole 9.

[0062] In this embodiment, a screw rod 10 is added, which is a conventional anchoring method, and one more level of protection can be set according to the situation. The screw rod 10 is fixed at the center of the anchor end 1, and then the axial outer end of the screw rod 10 extends out to the ...

Embodiment 3

[0063] Embodiment 3, on the basis of Embodiment 1, the anchoring end 1 is anchored at the axial inner end of the anchor hole 9, and the side wall of the sleeve 5 on the axial inner side of the slot 6 is anchored in the anchor hole 9, so The inner wall of the anchor hole 9 at the groove 6 is attached to the sleeve pipe 5 .

[0064] It is arranged in this way that when the side wall of the anchor hole 9 moves, the sleeve pipe 5 has a tendency to move axially outward, and the sleeve pipe 5 cooperates with the frustum 2 so that the sleeve pipe 5 has a tendency to open axially to the outside. Clinging to the side wall of the anchor hole 9, the increased expansion force prevents the side wall of the anchor hole 9 from moving outward in the axial direction. The fixation between the pipe 5 and the anchor hole 9 breaks during the movement of the rock mass, resulting in failure of the entire anchorage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com