Convenient-to-dismount diaphragm pump

A technology of diaphragm pumps and diaphragms, which is applied in the field of volumetric pumps, can solve problems such as difficulty in improving tensile performance and fatigue resistance, time-consuming and labor-intensive labor intensity, complicated disassembly and assembly of external pipelines, etc., and achieves high maintenance and replacement efficiency and low labor costs. Reduced strength and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

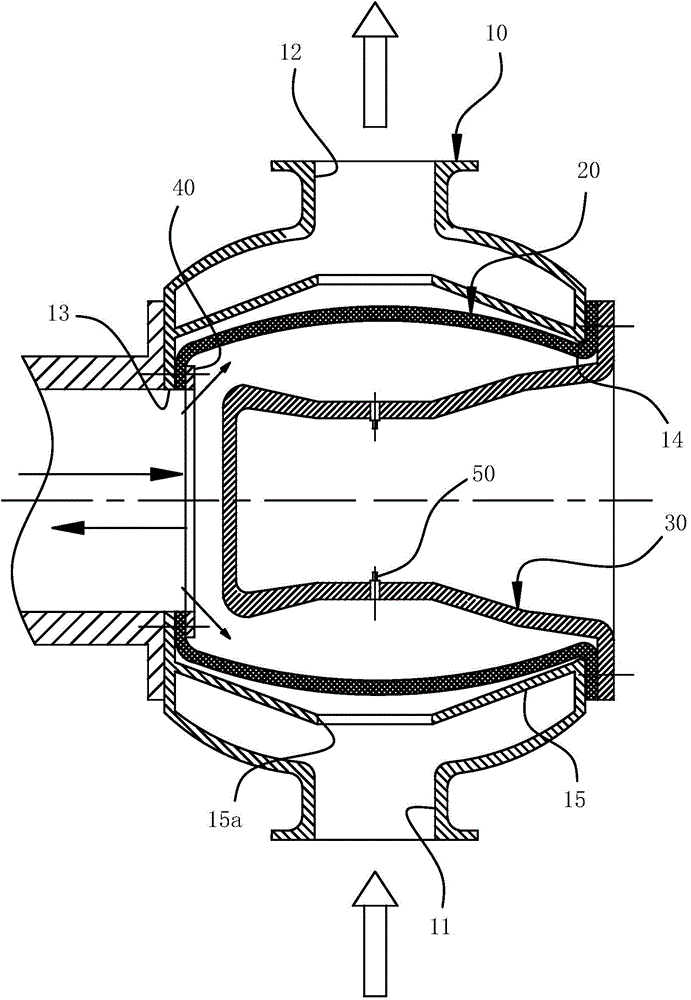

[0028] For ease of understanding, here in conjunction with accompanying drawing, to the concrete implementation structure of the present invention, be further described as follows:

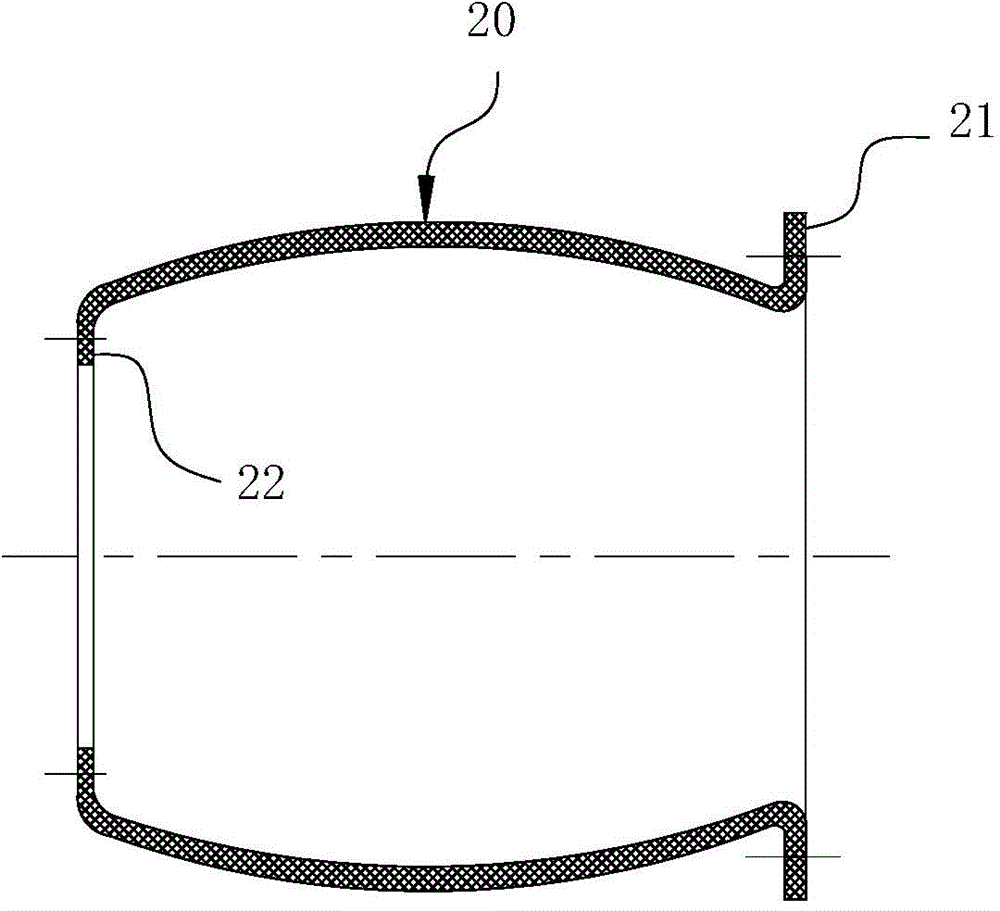

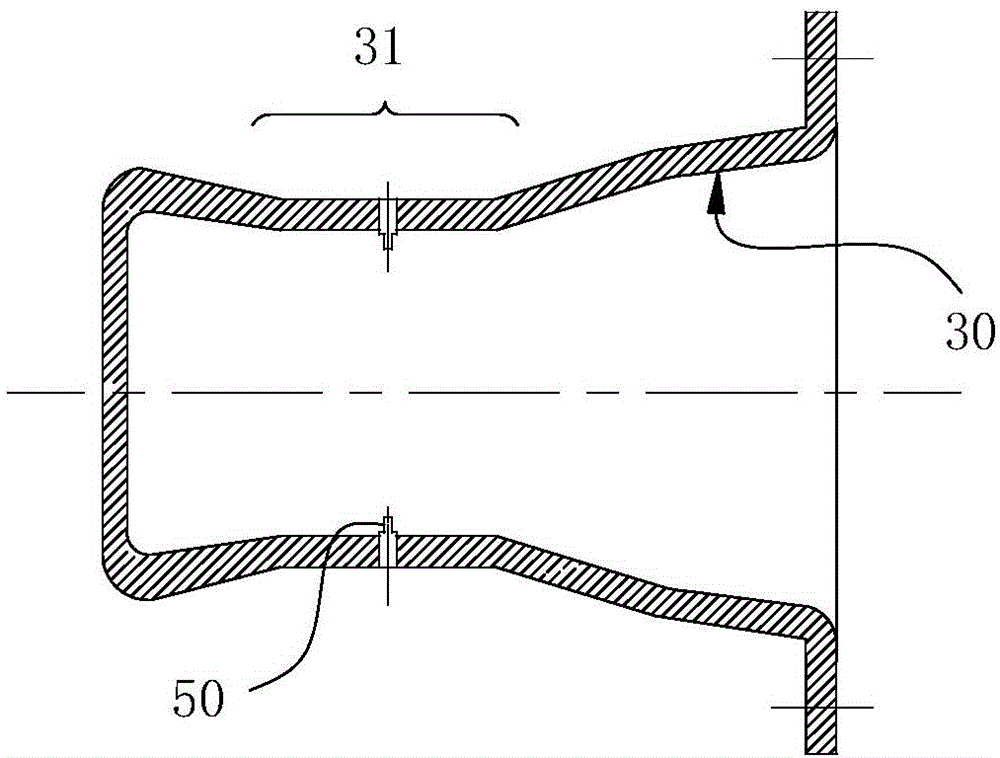

[0029] Concrete structure of the present invention, as Figure 1-3 As shown, it is mainly composed of a drum-shaped pump body 10 with a convex arc-shaped drum body that constitutes a hydraulic cavity and a medium circulation space. A hydraulic hole 13 connecting the external hydraulic station and the hydraulic cavity inside the pump is arranged through the drum surface on one side of the pump body 10 , and a maintenance hole 14 is arranged on the drum surface on the other side. The convex arc-shaped drum body of the pump body 10 is coaxially arranged to communicate with the medium chamber in the pump cavity to pump the medium inlet hole 11 and the liquid outlet hole 12, and the liquid inlet hole 11 and the liquid outlet hole 12 are respectively connected to the external upper discharge device and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com