Freezing and thawing cycle action based model test box for tailing dam

A model test and freeze-thaw cycle technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of the lack of automatic control of test model dam placement and the inability to meet the gradient temperature control form , increase the number of test personnel and other issues, to achieve the effect of good sealing, high accuracy, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

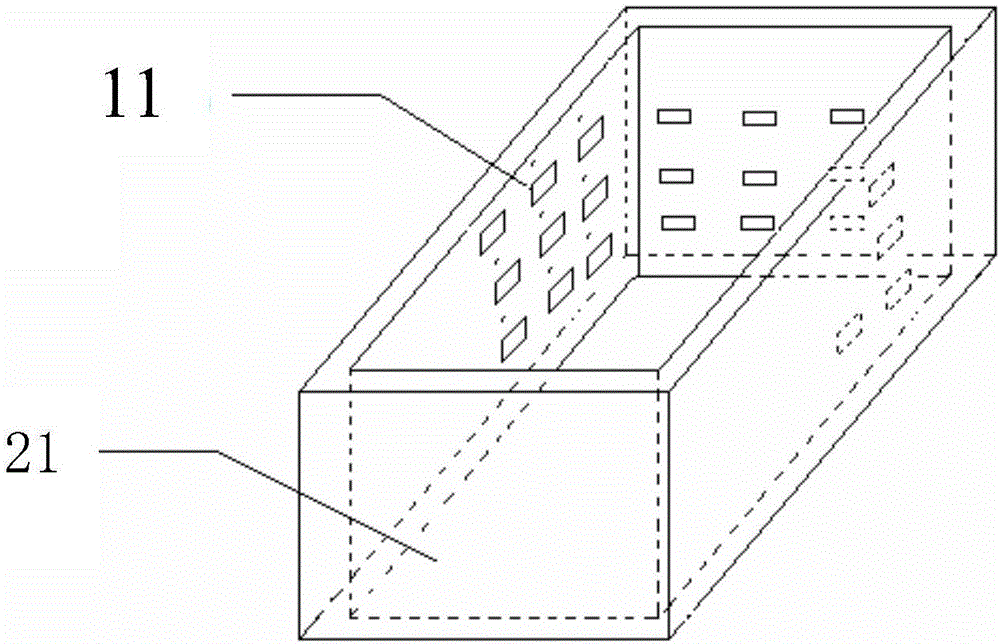

[0032] A tailings dam model test box based on freeze-thaw cycles, including a main box body and a model box 14.

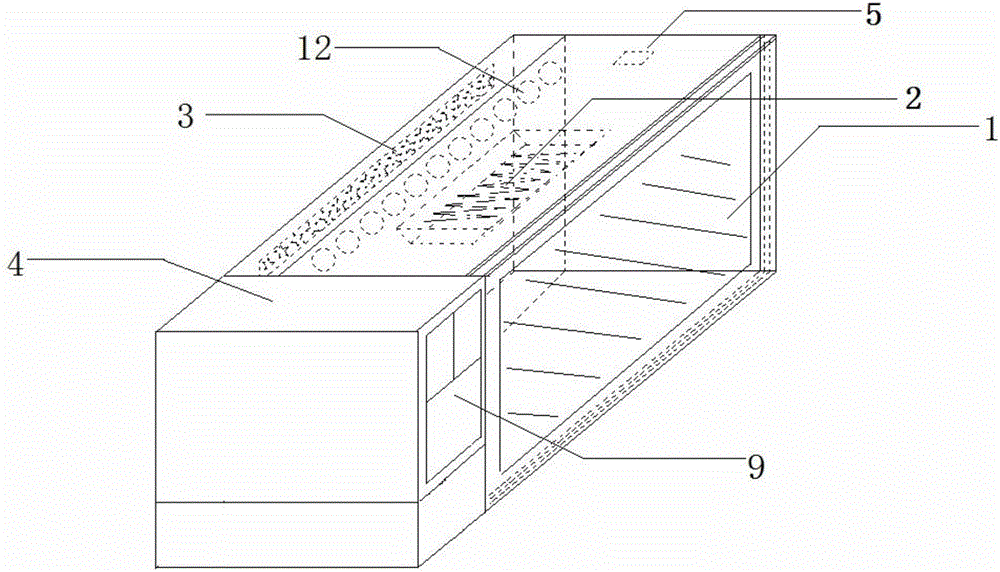

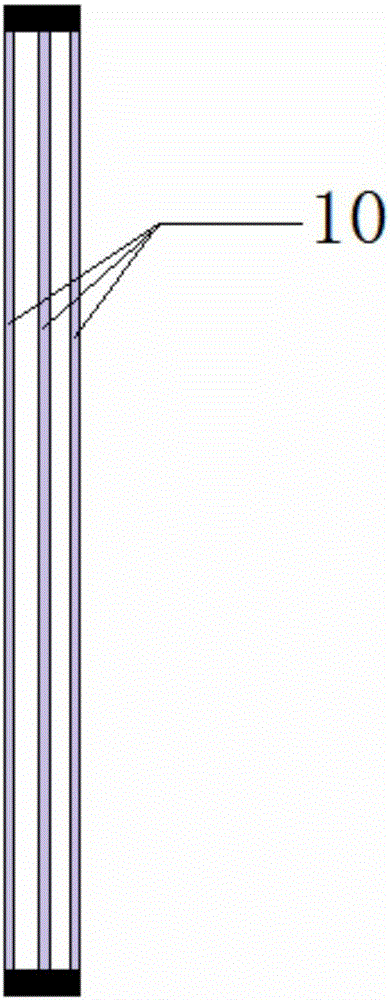

[0033] Such as figure 1 As shown, the main box includes an insulated box 4, a door 1 is arranged at the front of the insulated box 4, and a heating device 2 is arranged on the top of the insulated box 4. In this embodiment, the heating The device 2 adopts an infrared heating device; the bottom of the insulated box 4 is provided with a transmission base plate, the inside of the insulated box 4 is provided with a first temperature sensor 5, and the rear of the insulated box 4 is provided with a compartment. The upper part of the inside is provided with a row of blowing devices 3, and a row of ventilation holes 12 are arranged on the heat preservation box 4 directly in front of the blowing devices 3, and the ventilation hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com