An automatic monitoring device for full-section deformation of an underground chamber and a method for applying the device

An automatic monitoring and underground chamber technology, which is applied in cross-section drawing, measuring equipment, surveying and navigation, etc., can solve the problems of short monitoring time, time-consuming monitoring, and low accuracy of monitoring instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

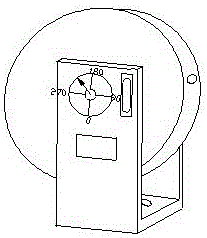

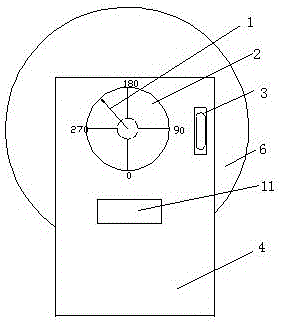

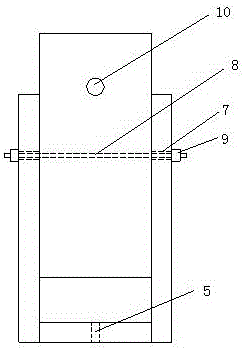

[0025] to combine figure 1 , figure 2 As shown in Fig. 1, an automatic monitoring device for full-section deformation of an underground chamber, including an angle measuring mechanism and a distance measuring mechanism, the angle measuring mechanism is used to measure the angle between the laser probe and the horizontal plane, and the distance measuring mechanism is used to measure the The distance between the walls, the two cooperate with each other to accurately determine the specific coordinates of each point on the chamber wall.

[0026] In the goniometric mechanism, the pointer 1 is fixed on the rotating rod 8 and placed at the center of the dial 2 and rotates together with the rotating rod 8, and the specific rotation of the rotating rod 8 is displayed through the dial 2 Angle, the level 3 is placed on the right side of the dial 2 and fixed on the base 4 together with the pointer 1 and the dial 2, and the base 4 is fixed on the wall of the chamber through the fixing ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com