An on-line monitoring system for gis bus bar

A monitoring system and busbar technology, which are applied in the field of high-voltage electrical appliance manufacturing and high-voltage switchgear, can solve problems such as unfavorable real-time monitoring, poor measurement accuracy, and high labor costs, so as to reduce inspection work, improve safety, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

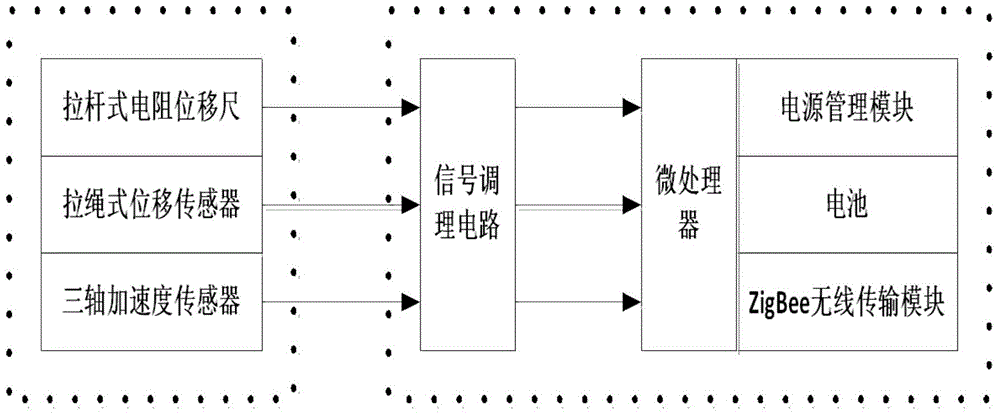

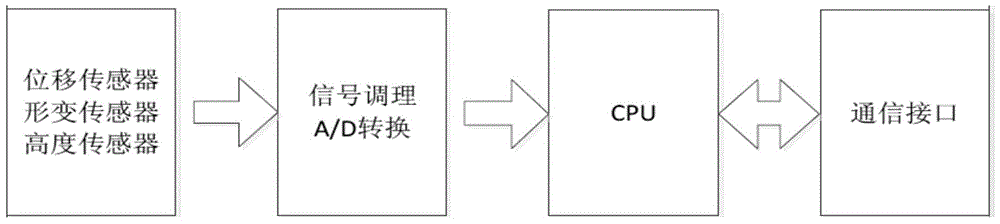

[0020] An online monitoring system for a GIS busbar cylinder, comprising a monitoring terminal arranged on the cylinder and a data processing unit connected to the monitoring terminal; the monitoring terminal includes a pull rod for detecting the axial displacement of the cylinder wall relative to the support type resistance displacement scale, a pull-cord displacement sensor for detecting the displacement of the cylinder relative to the ground, and a three-axis acceleration sensor for detecting the axial and radial warpage of the cylinder relative to the horizontal plane.

[0021] Based on the above technical solutions and in conjunction with the accompanying drawings, the following specific implementation is given.

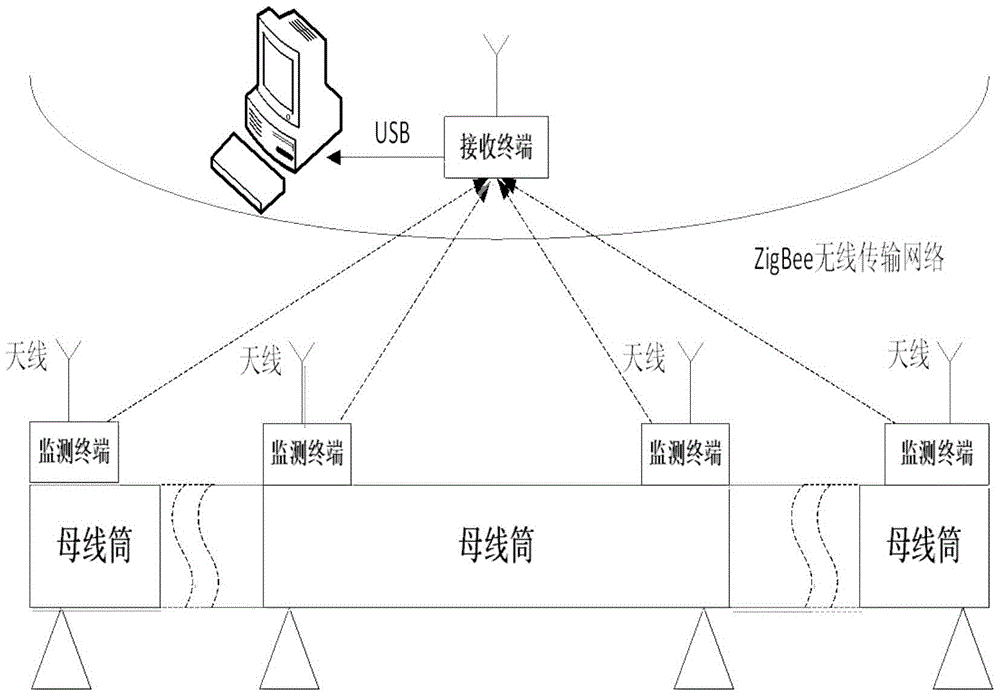

[0022] like figure 1 As shown, the online monitoring system is used for real-time monitoring of the GIS bus barrel, including a monitoring te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com