Temperature-stress integrated control flexible wall penetration test method under dry-wet cycle

A dry-wet cycle and test method technology, which is applied in the fields of permeability/surface area analysis, suspension and porous material analysis, instruments, etc., can solve the problems of permeability coefficient measurement error, complex realization process, and side leakage without consideration, and achieve extension Long service life, simple implementation method, and reduced injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

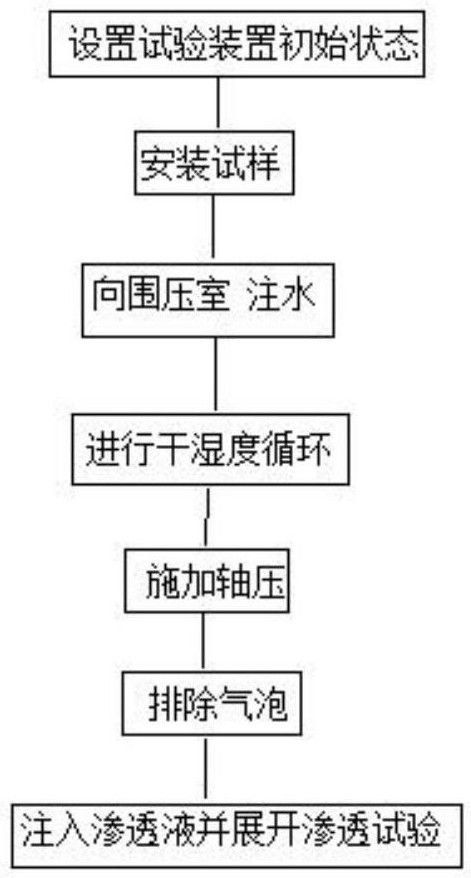

[0095] The flexible wall penetration test method of temperature-stress integrated control under the dry-wet cycle of the present invention comprises the following steps:

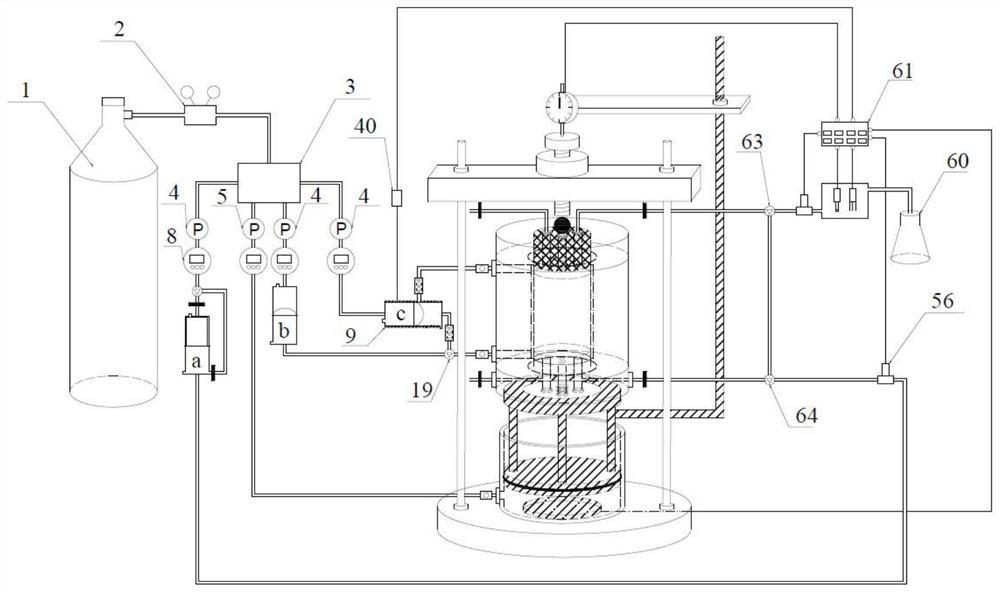

[0096] Step 1, setting up a flexible wall permeameter, which includes a test device, a pressurizing device, a permeation system, and a confining pressure system.

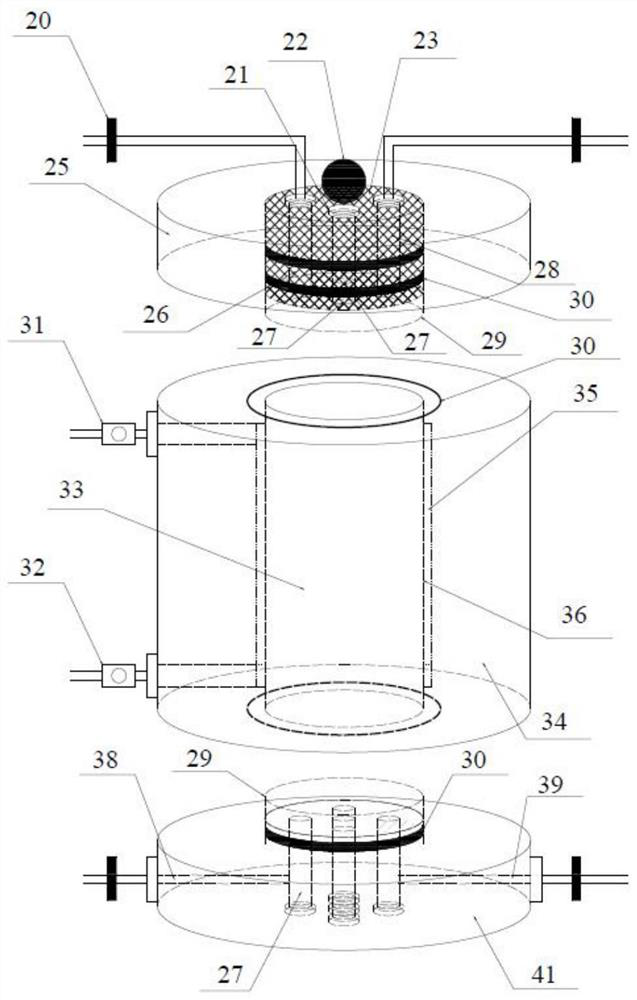

[0097] A pressurizer 3 and an injection chamber a are included in the permeation system, and an injection chamber b and an injection chamber c are included in the confining pressure system; the three injection chambers have the same shape, and are composed of an upper half chamber, a lower half chamber and a flexible chamber. The flexible rubber membrane 15 divides each injection chamber into two spaces closed up and down, and a liquid injection hole 16 is opened on the side wall of the lower half chamber close to the fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com