Underground pipe gallery deformation monitoring system

A monitoring system and integrated pipe gallery technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve problems such as twisting and cracking, and achieve the effect of novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

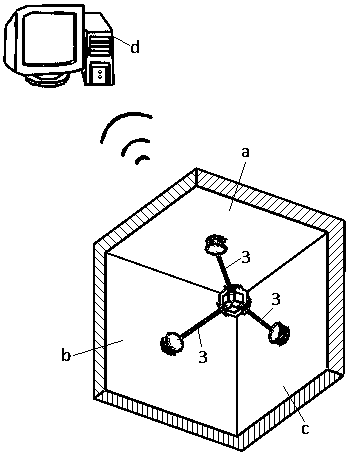

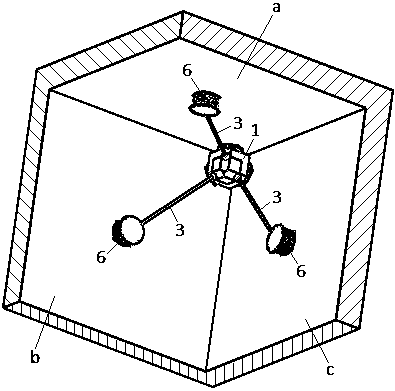

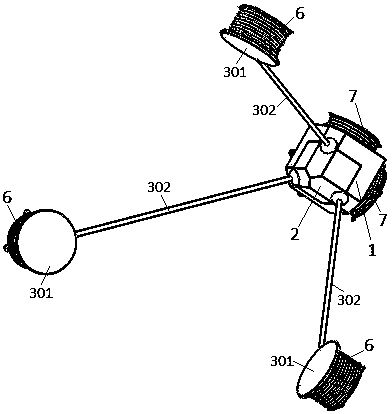

[0050] A deformation monitoring system for an underground comprehensive utility gallery of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0051]It includes a base 1, a filling block 2, a turning handle 3, a resistance 4, a resistance spring 5, a turning handle spring 6, a base spring 7, and a circuit chip 8.

[0052] like Figure 5 , Figure 7 , Figure 16 , Figure 17 , Figure 18 As shown, the base 1 is a regular hexahedron, which is installed at the angle formed by the horizontal wall a, the first vertical wall b, and the second vertical wall c. vertical cavity; the filling block 2 can just fill the cube block cut off by the base 1, and is pasted in the cavity on three sides of the base 1 that are perpendicular to each other; on the contact surfaces of the base 1 and the filling block 2, respectively There are resistor installation cavity 101 and filler block resistor cavity 201, each res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com