Patents

Literature

203 results about "Longitudinal deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

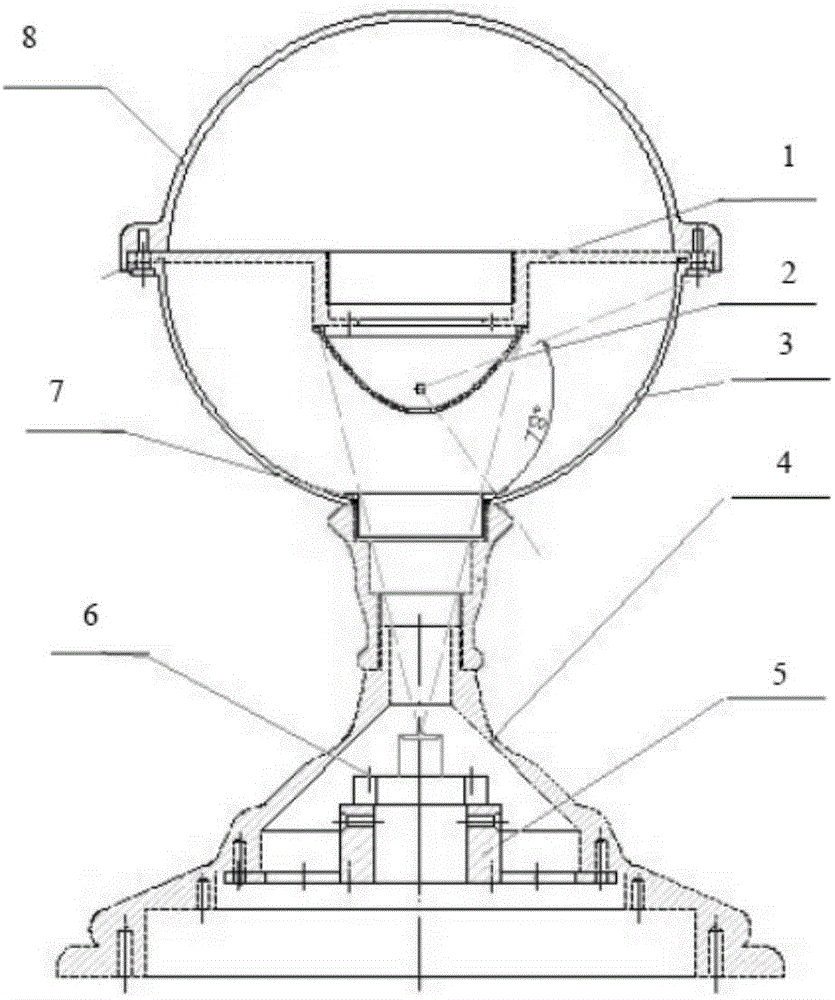

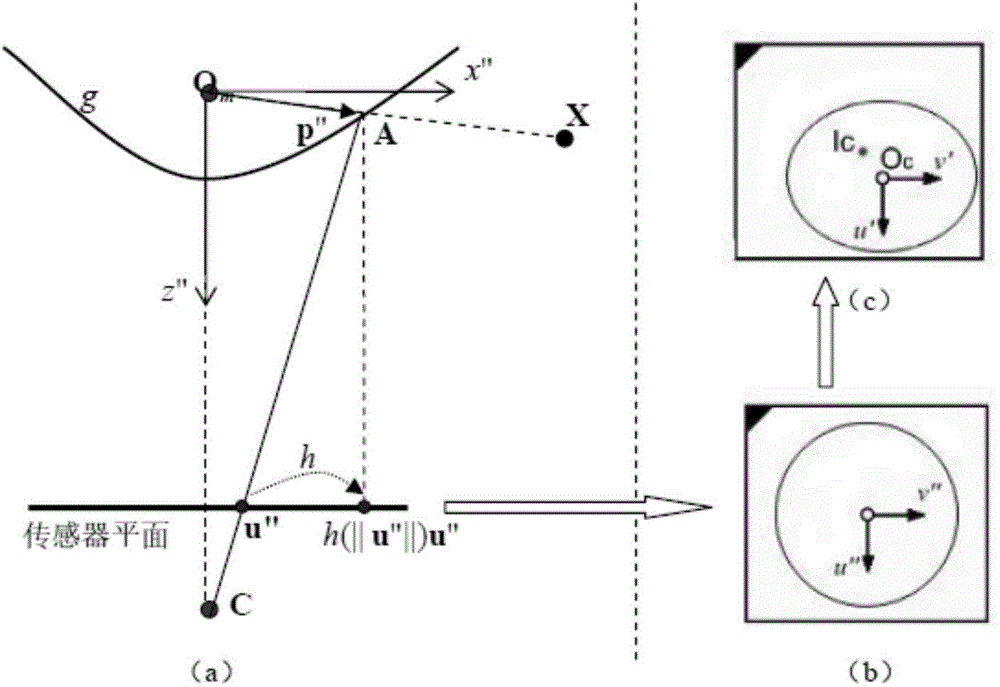

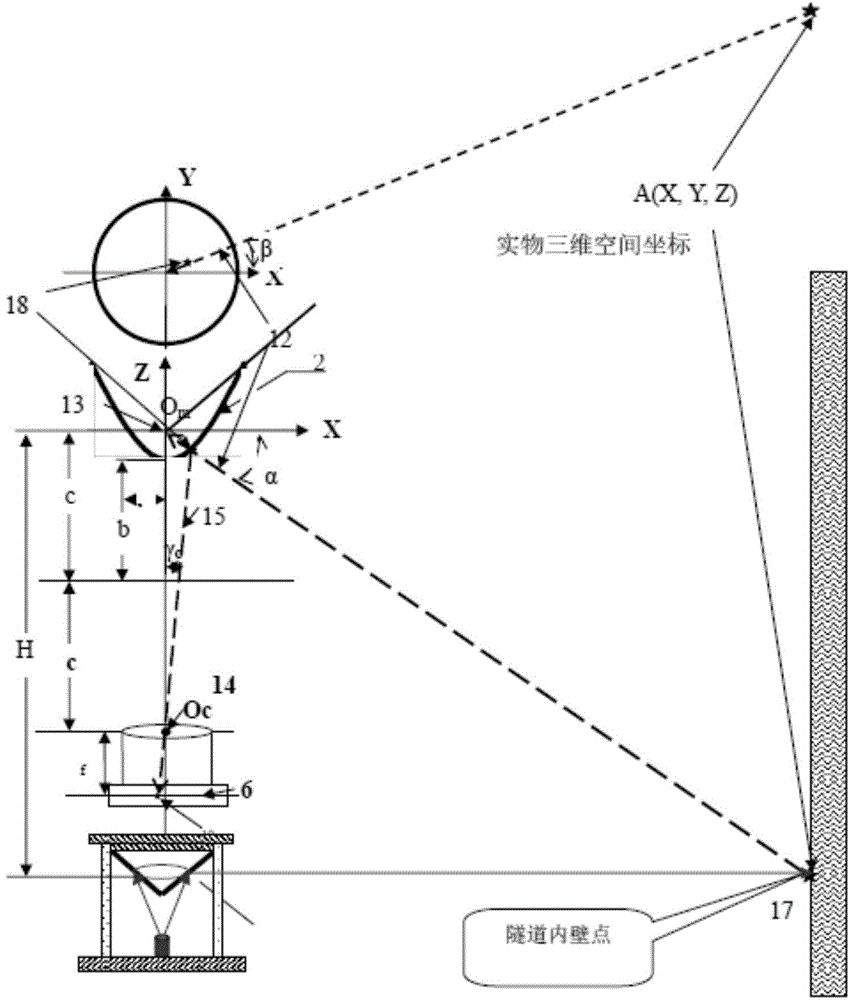

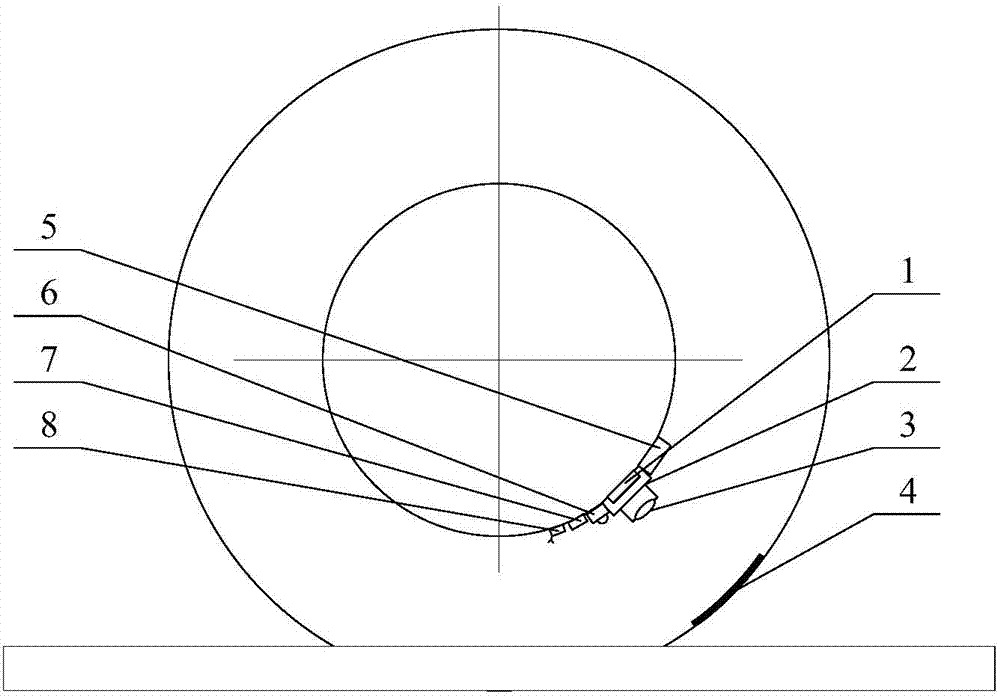

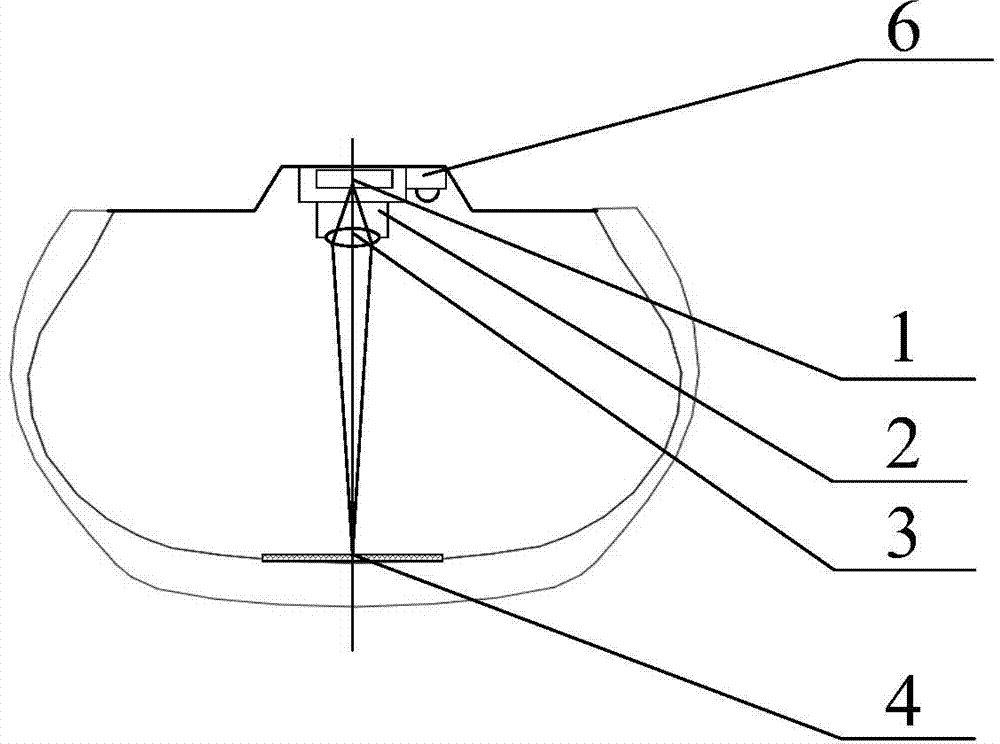

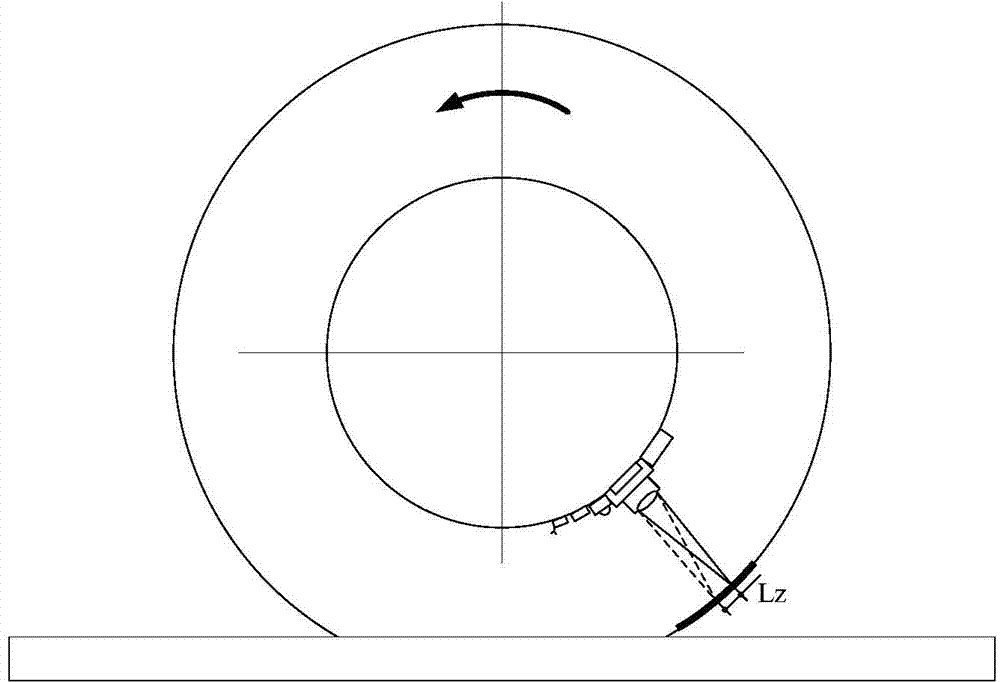

Tunnel full-section high-speed dynamic health detection device and method based on active panoramic vision

The invention discloses a tunnel full-section high-speed dynamic health detection device based on an active panoramic vision. Hardware of the device comprises a tunnel detection trolley, an active panoramic vision sensor, an RFID reader and a processor. System software comprises an omnibearing face laser information analysis and point cloud data obtaining unit, a tunnel center axis extracting unit, a noise reducing and adjustment processing unit, a three-dimensional modeling and deformation analyzing unit, a full tunnel all-section cross section benchmark database, a full tunnel longitudinal section splicing unit, a displacement monitoring and sedimentation monitoring unit, a full tunnel health examination result database and a tunnel longitudinal section variable shift amount three-dimensional visualization unit. Transverse and longitudinal deformation of a tunnel are analyzed and recognized by carrying out machine vision processing on laser scanning fracture surface slice images of the inner wall of the tunnel. The invention further provides a tunnel full-section high-speed dynamic health detection method based on the active panoramic vision, and effective technology support is provided for daily maintenance of tunnels of metros and high-speed rails.

Owner:ZHEJIANG UNIV OF TECH

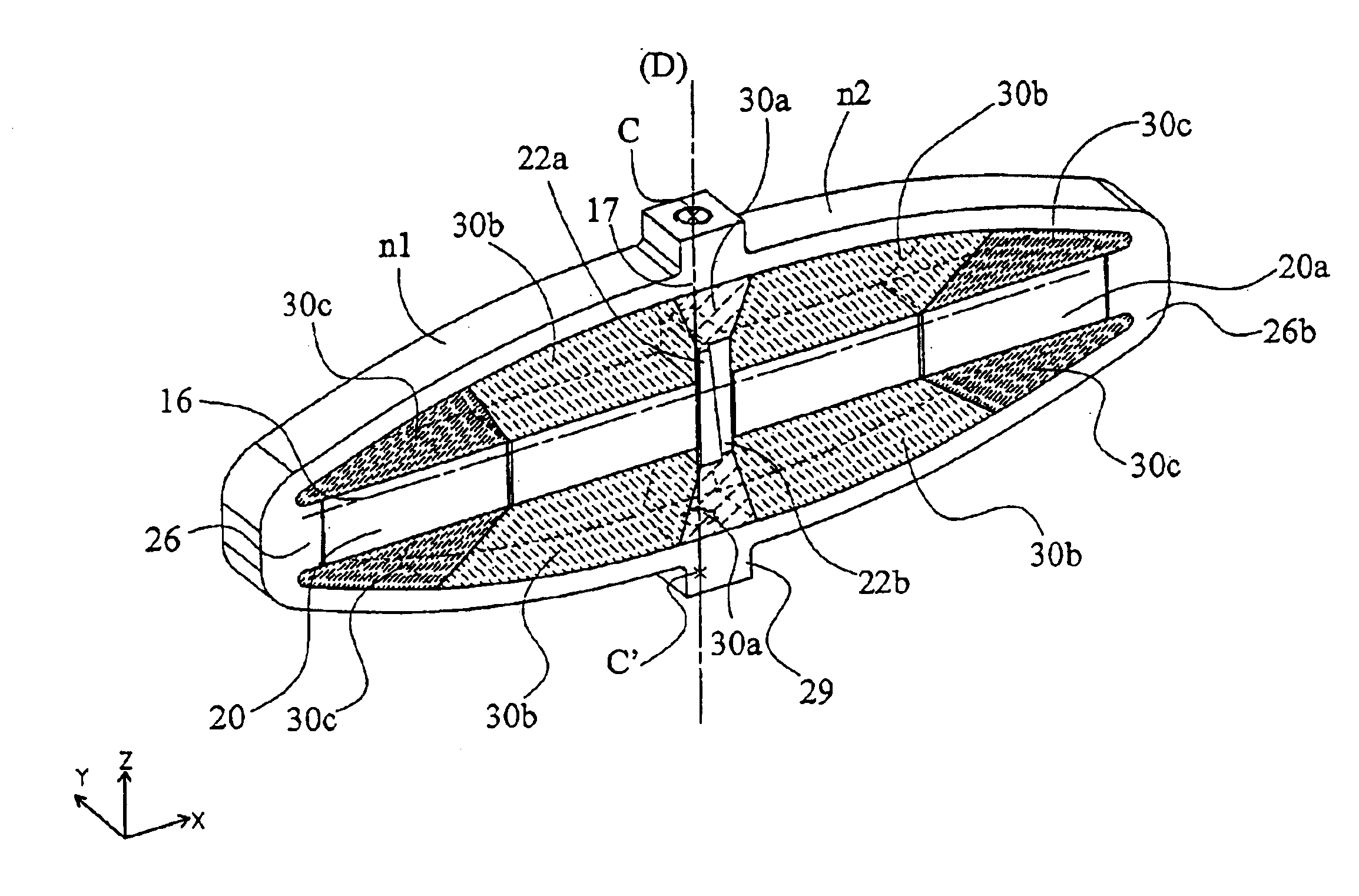

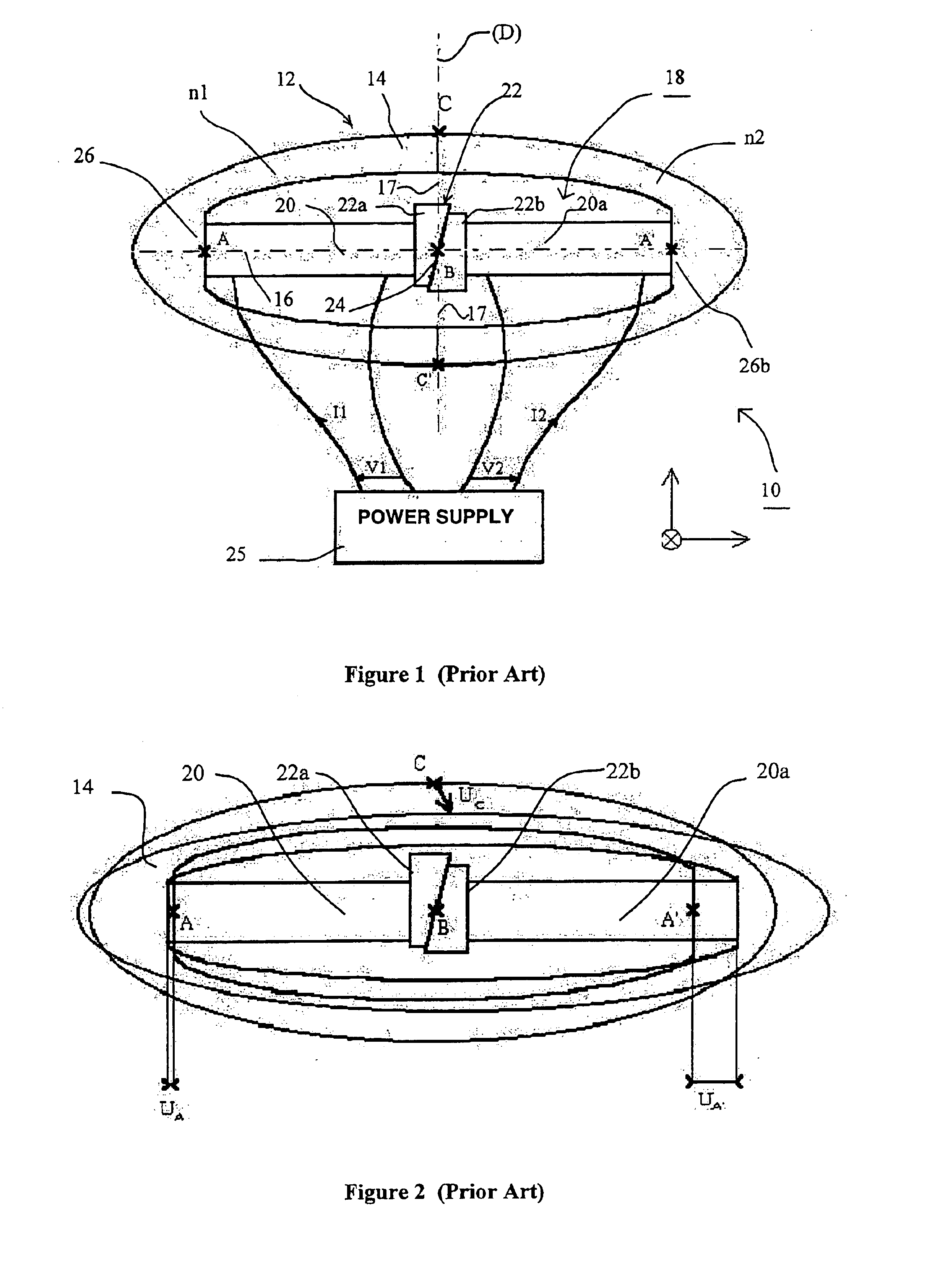

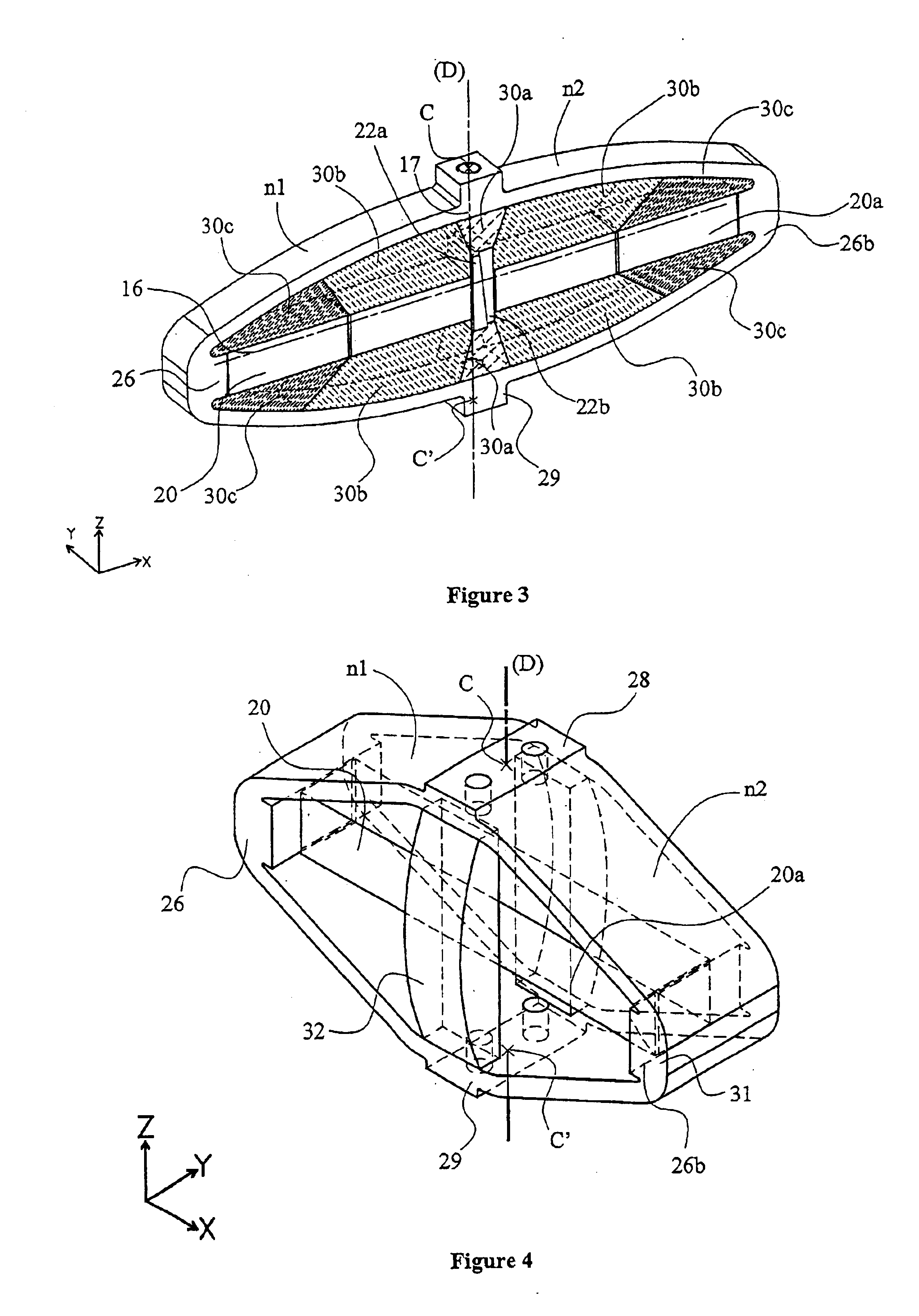

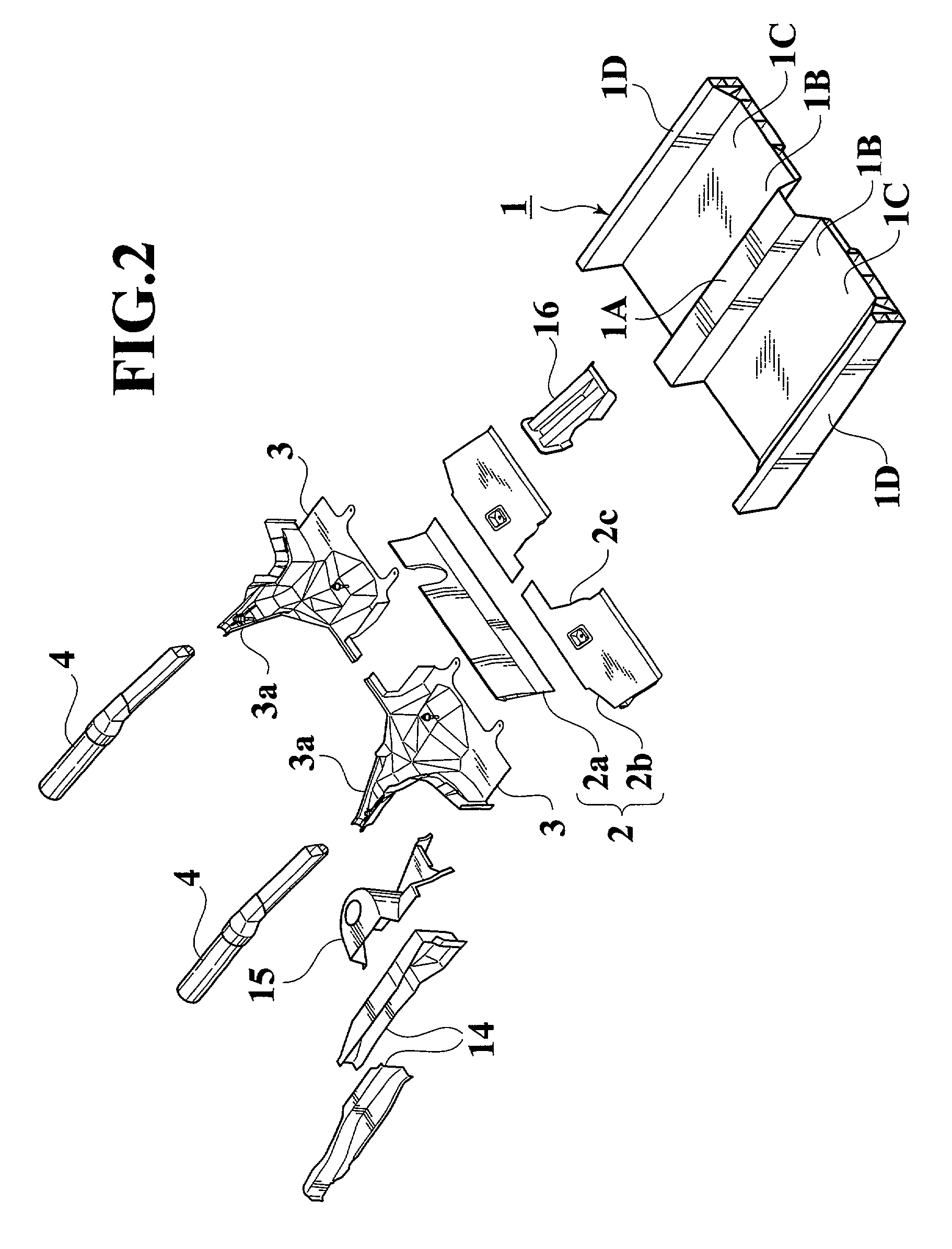

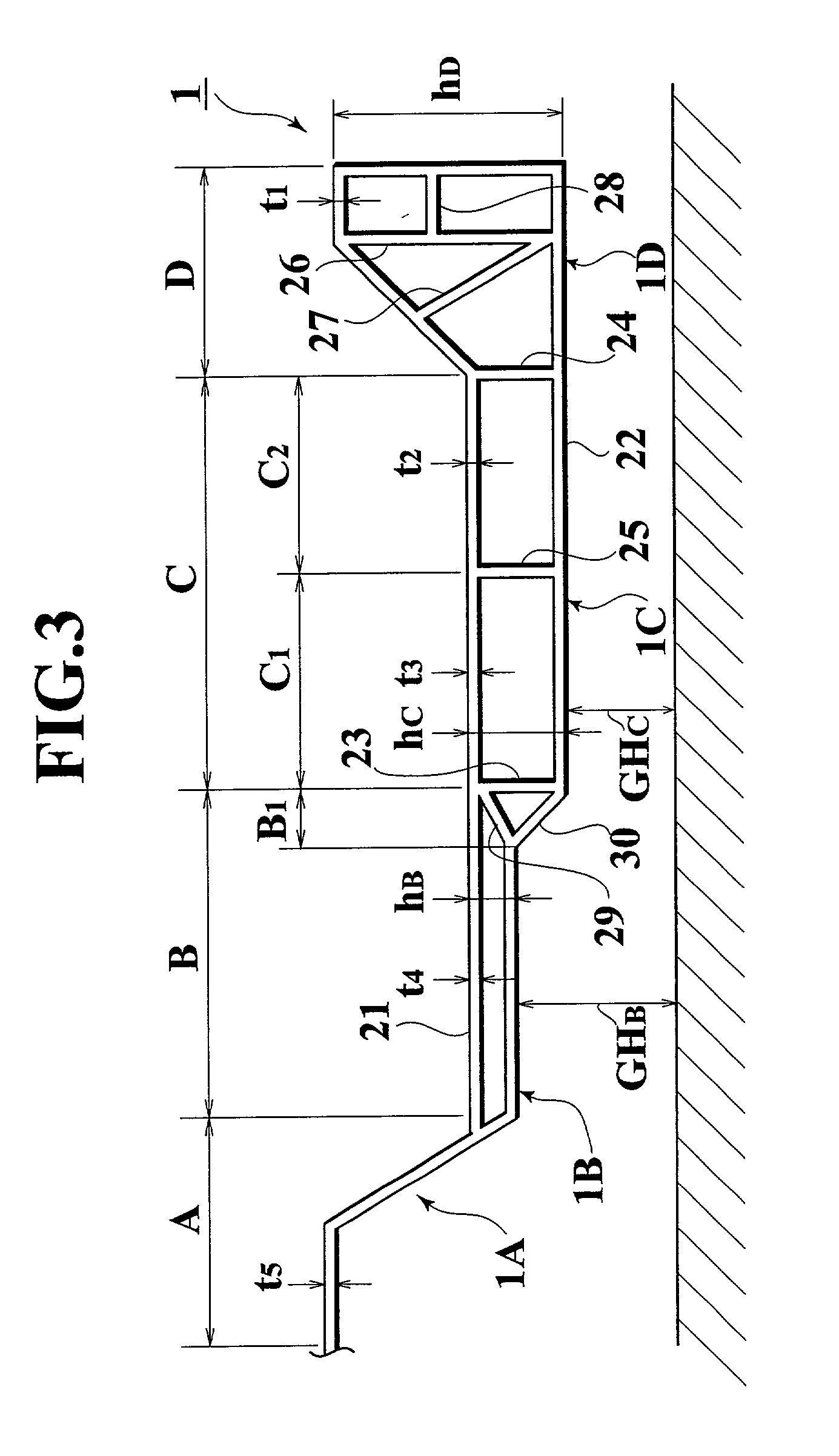

Piezoactive actuator with dampened amplified movement

ActiveUS6927528B2Reduce vibrationIncrease capacityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesElastomerAudio power amplifier

The piezoactive actuator with amplified movement comprises a first sub-assembly formed by a mechanical movement amplifier and a second sub-assembly equipped with piezoactive elements. An interface with a load and an interface with a base, respectively placed at the peaks of a small axis of the shell and designed for actuating the load with respect to the base, define an actuating axis. A longitudinal deformation of the large axis enables a deformation of the small axis to be induced, designed to generate a movement at the interface with the load, the component of which movement along the small axis is amplified. At least one zone made of elastomer material is arranged at least substantially along the actuating axis to dampen deformations and increase the capacity of the actuator to resist external stresses. The actuator comprises at least one free space adjacent to the elastomer material zones in a direction orthogonal to the actuating axis.

Owner:CEDRAT TECH

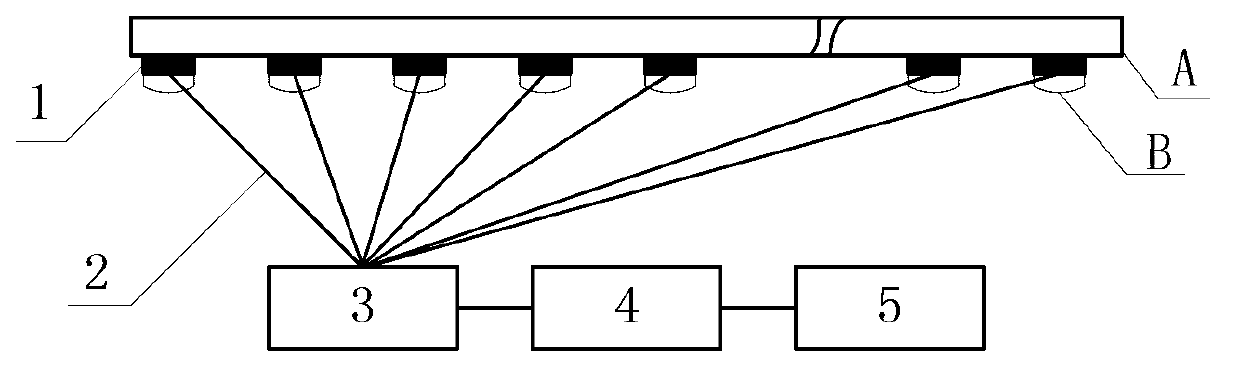

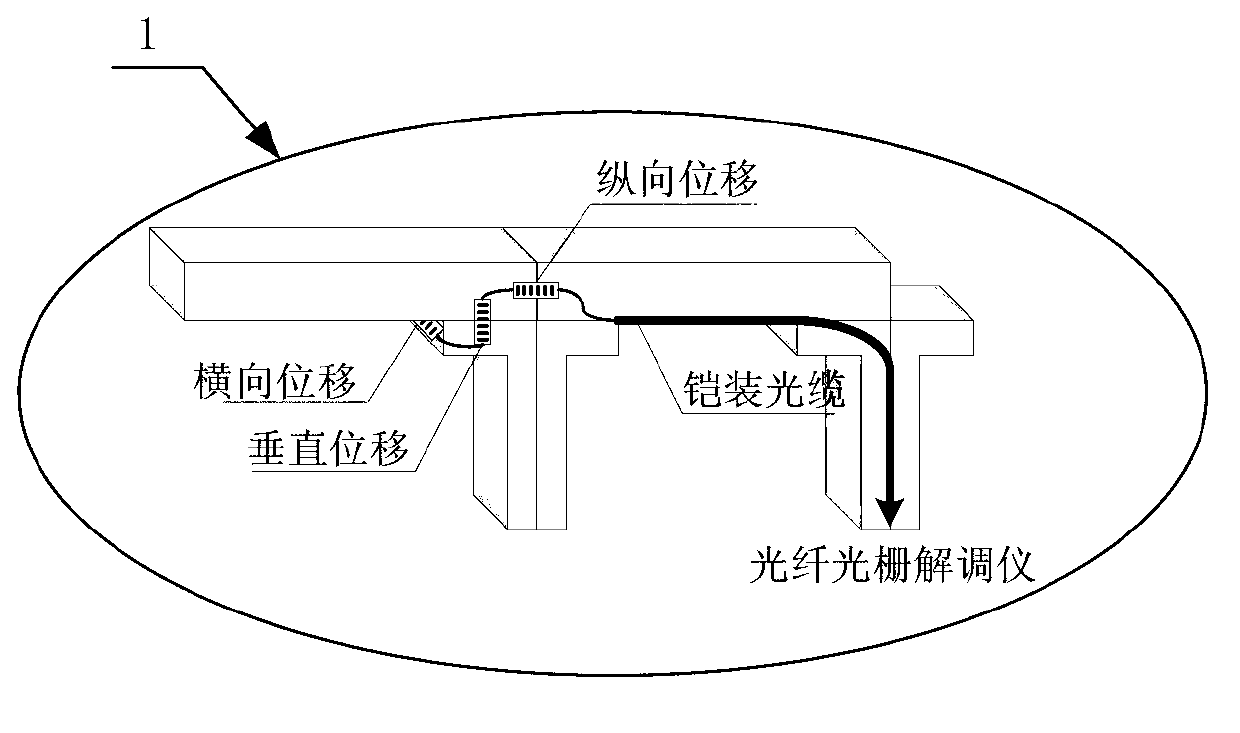

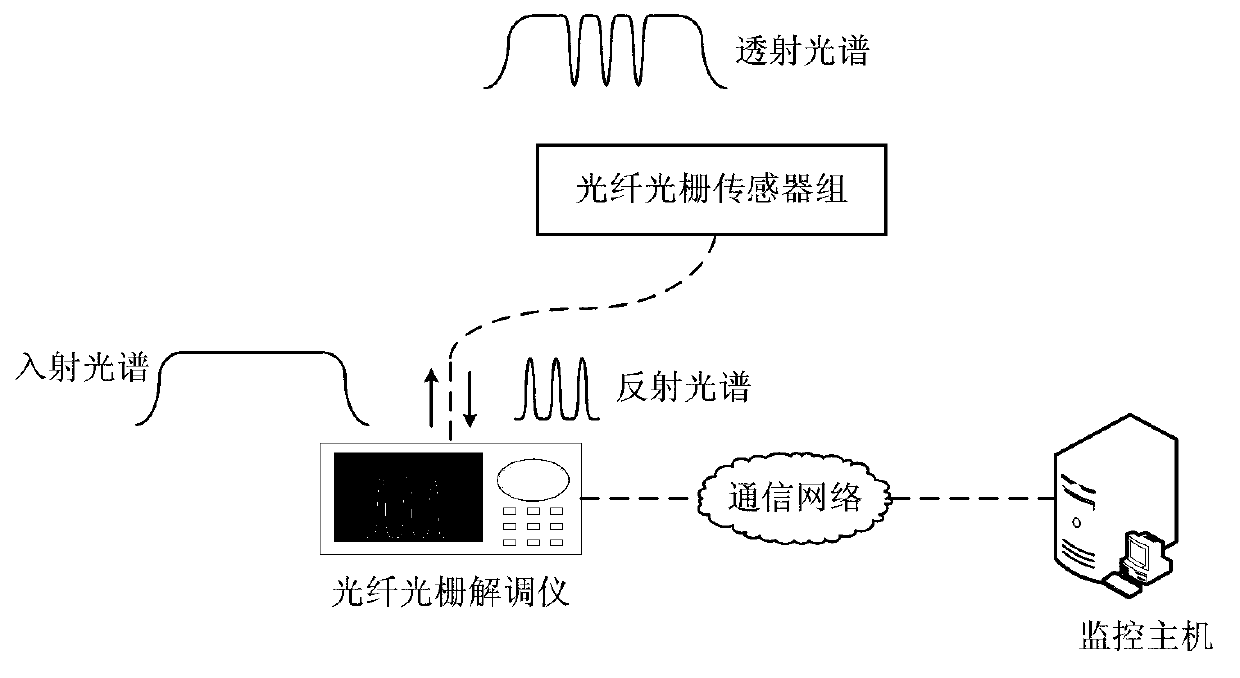

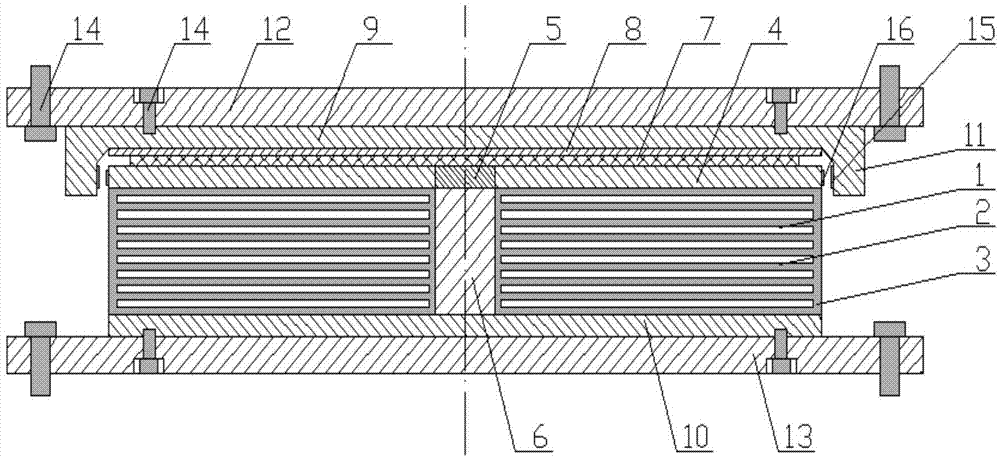

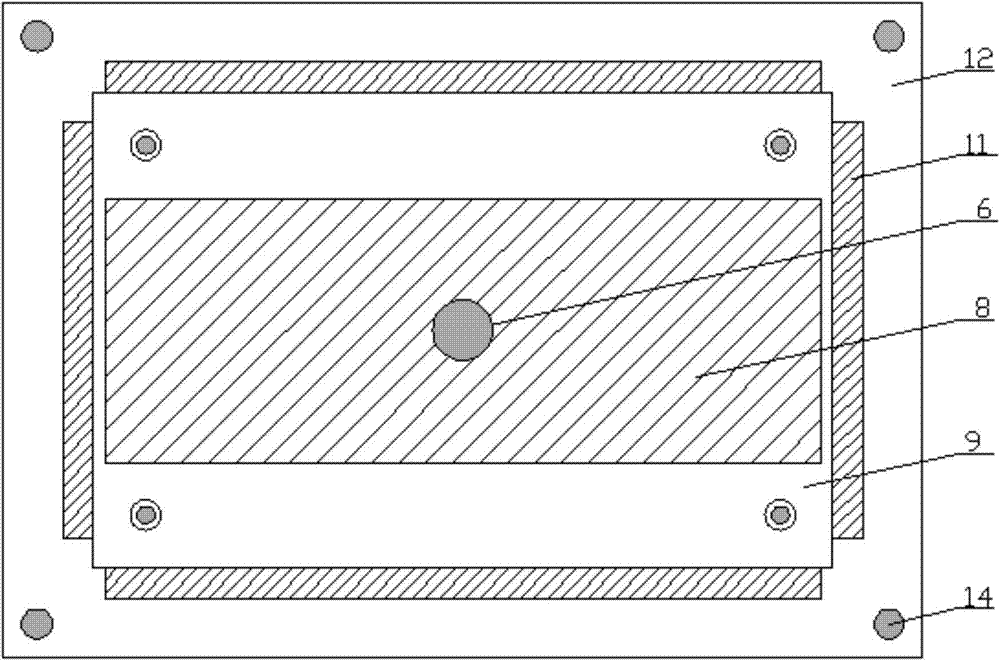

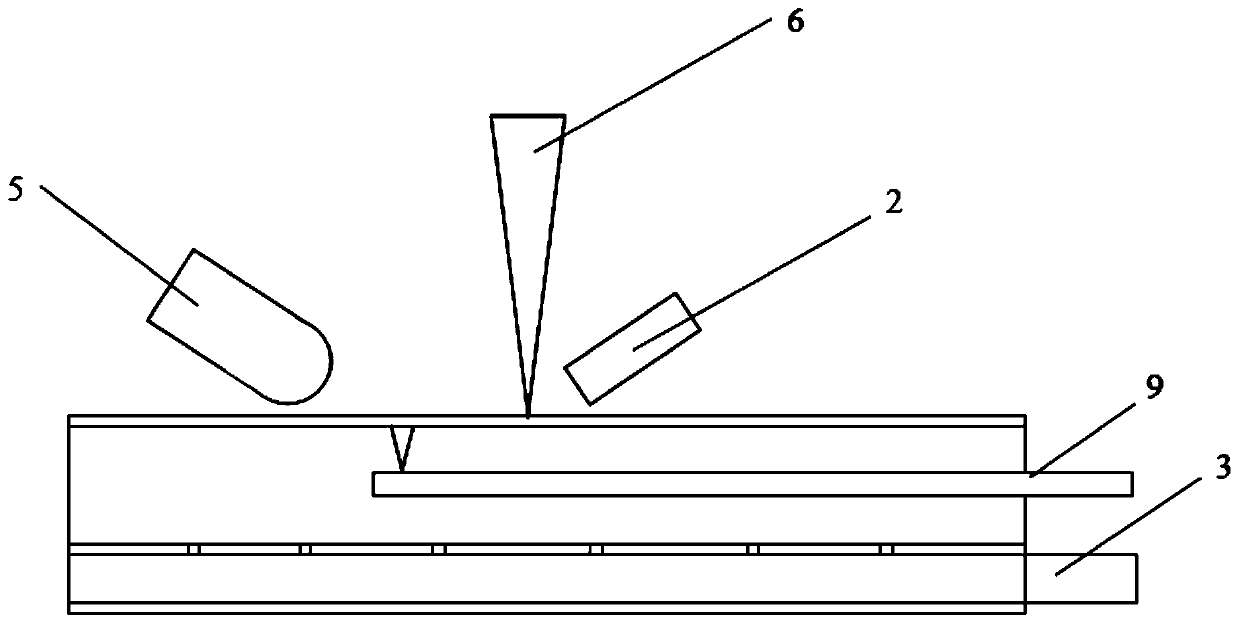

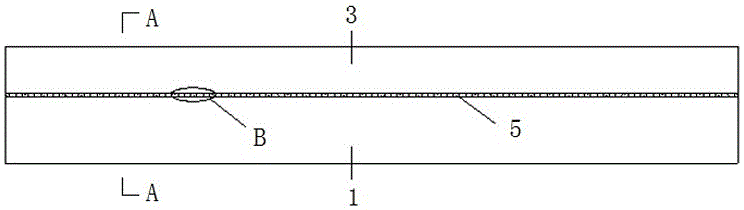

Bridge displacement monitoring system based on optical fiber sensors

InactiveCN103134432ARealize structural safety and health monitoringImprove anti-interference abilityUsing optical meansLongitudinal deformationThrough transmission

The invention provides a bridge displacement monitoring system based on optical fiber sensors. The bridge displacement monitoring system comprises at least one fiber grating strain sensor group, a fiber grating demodulating instrument and a monitoring host. The fiber grating strain sensor group is fixed on monitoring points of a bridge and used for monitoring transverse deformation, longitudinal deformation and vertical deformation of the bridge. The fiber grating demodulating instrument is connected with the fiber grating strain sensor group through transmission optical fibers. Detecting light emitted from a light source inside the fiber grating demodulating instrument shoots into all fiber grating displacement sensors in a monitoring area. The fiber grating demodulating instrument is used for demodulating wavelength sensing signals generated by the fiber grating strain sensor group. The monitoring host is used for receiving demodulation data of the fiber grating demodulating instrument through a communication network and analyzing the displacement state and the health status of the bridge based on the demodulation data. Through adoption of the fiber grating sensing technology and utilization of communication optical fibers and cables to transmit the sensing signals, the bridge displacement monitoring system based on the optical fiber sensors has the advantages of being strong in anti-interference capacity, high in sensitivity, good in stability, free from power supply in a monitoring field, and capable of achieving displacement state monitoring of the long-distance bridge, and the like.

Owner:NANJING UNIV

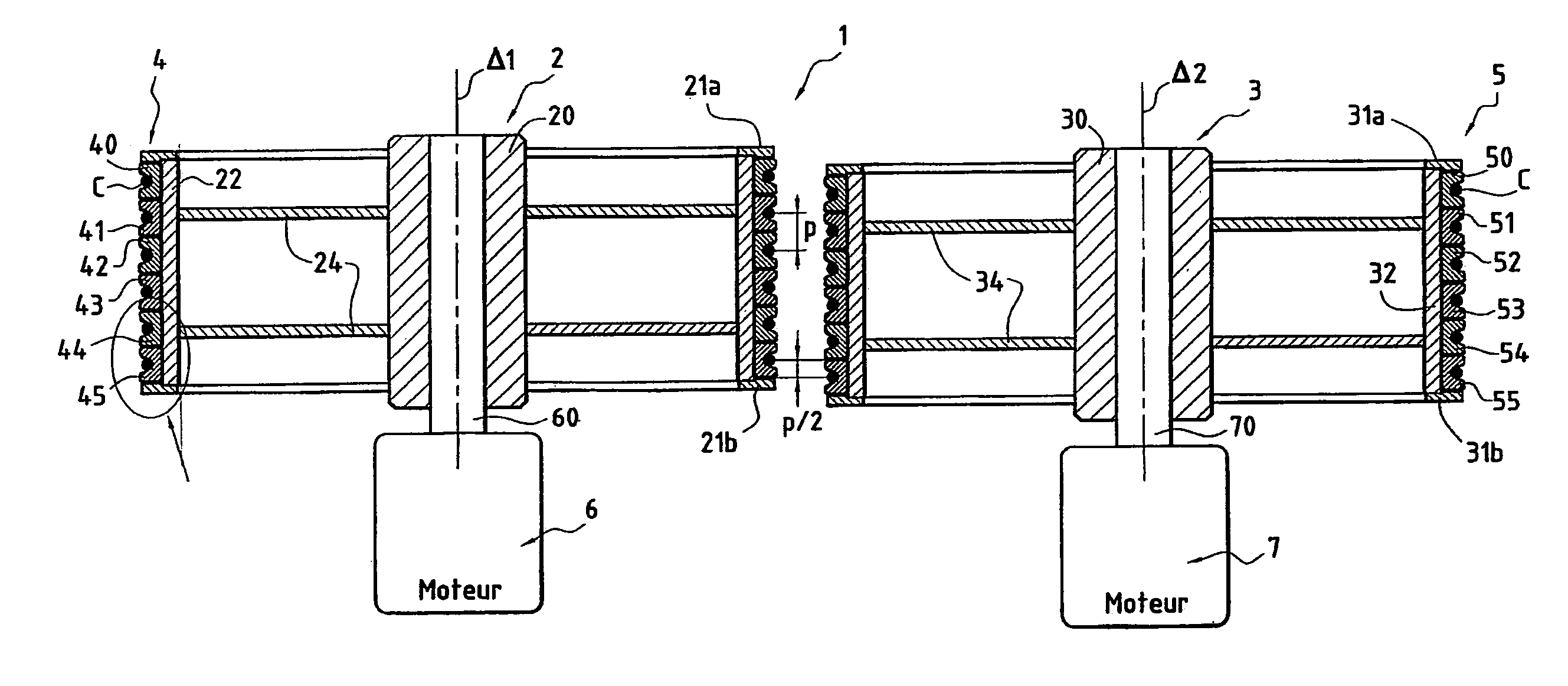

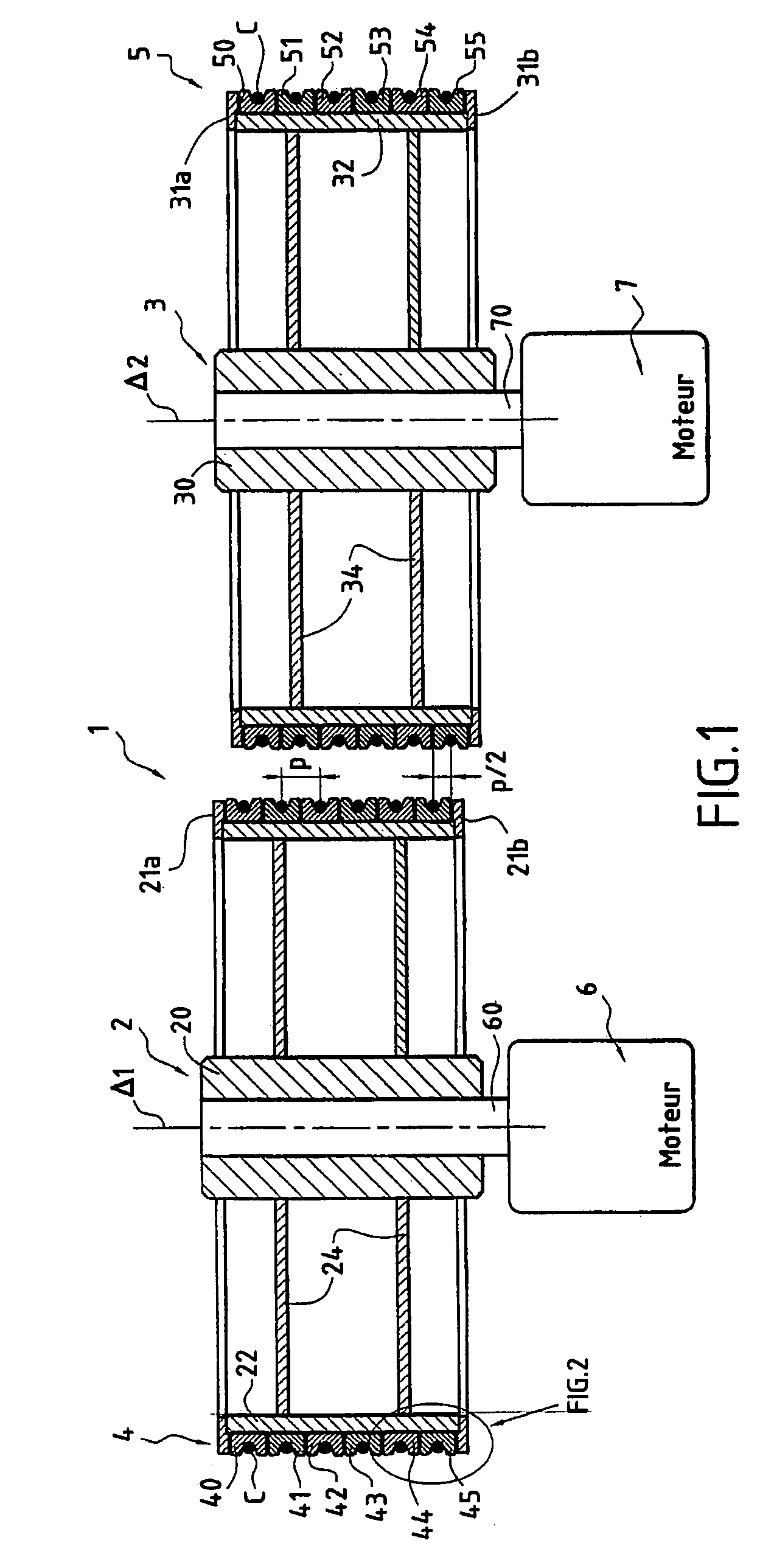

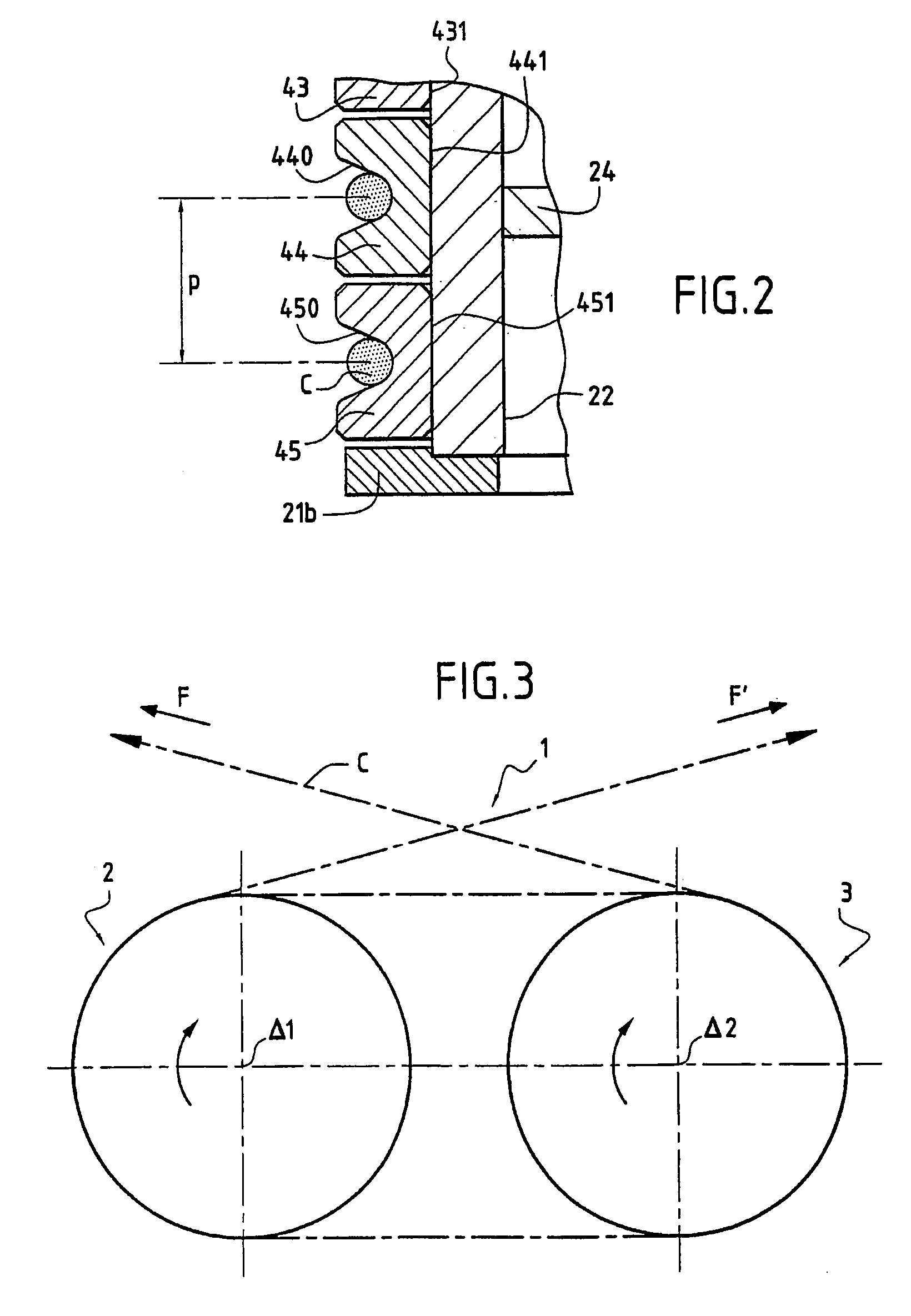

Capstan winch

The invention concerns a so-called capstan winch (1) comprising drums (2, 3) driving a cable (C) and provided with a peripheral wall (22, 32) around which are strung independent peripheral rings (40–45, 50–55). Said rings are provided with a peripheral groove designed to receive the cable (C) and are made of an elastic material so as to allow both the cable (C) to be driven and a relative sliding movement between the peripheral rings (40–45, 50–55) and the peripheral wall (22, 32), the relative sliding movement being of amplitude substantially equal to longitudinal deformation of the cable (C), when it is subjected to tension stresses. The two drums (2, 3) can be axially offset relative to each other (p / 2) and their axes of rotation (Δ1, Δ2), may form a non-null angle of inclination. The invention is particular applicable to deep sea oil exploration.

Owner:KLEY FRANCE

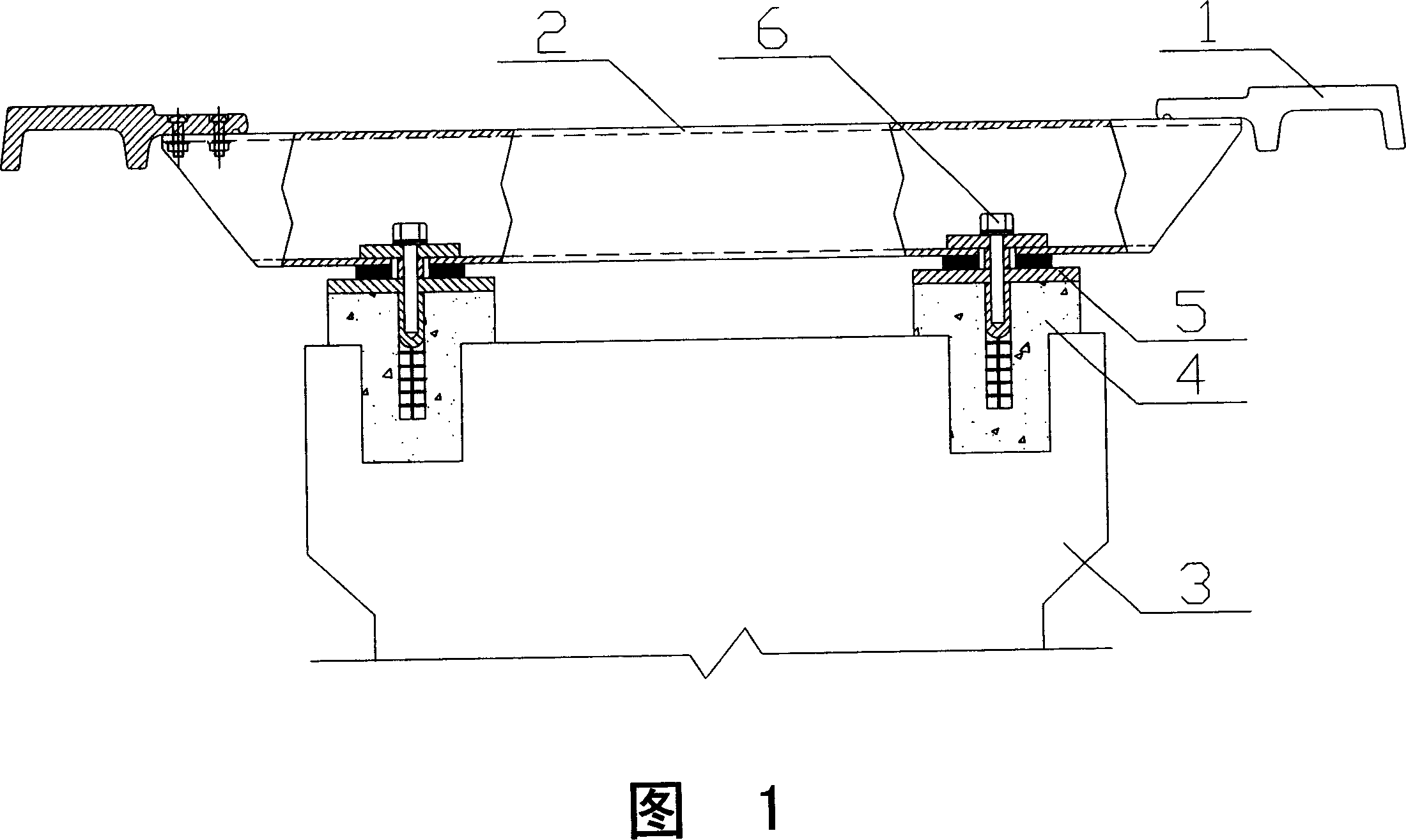

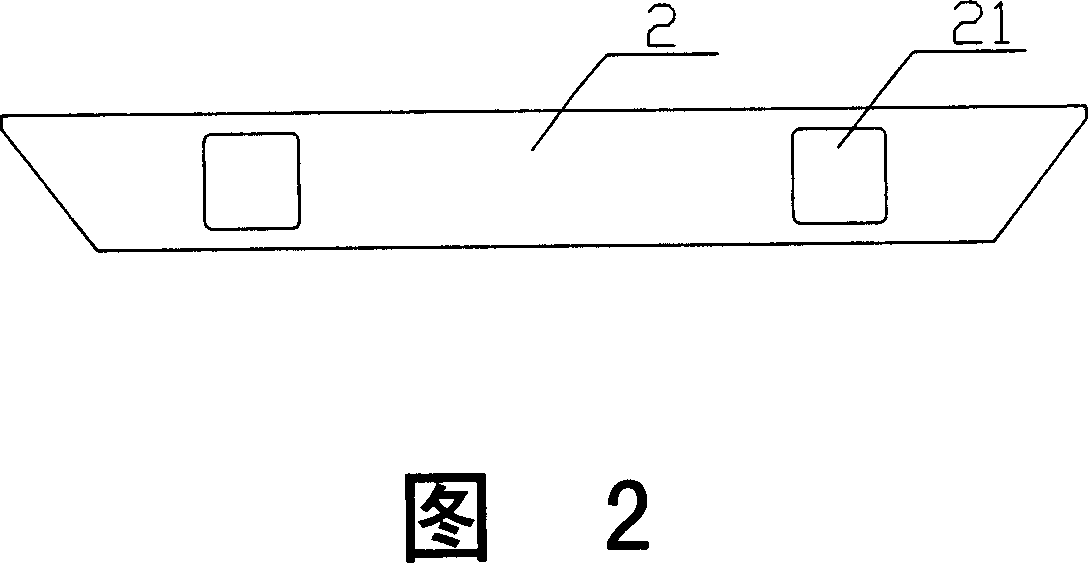

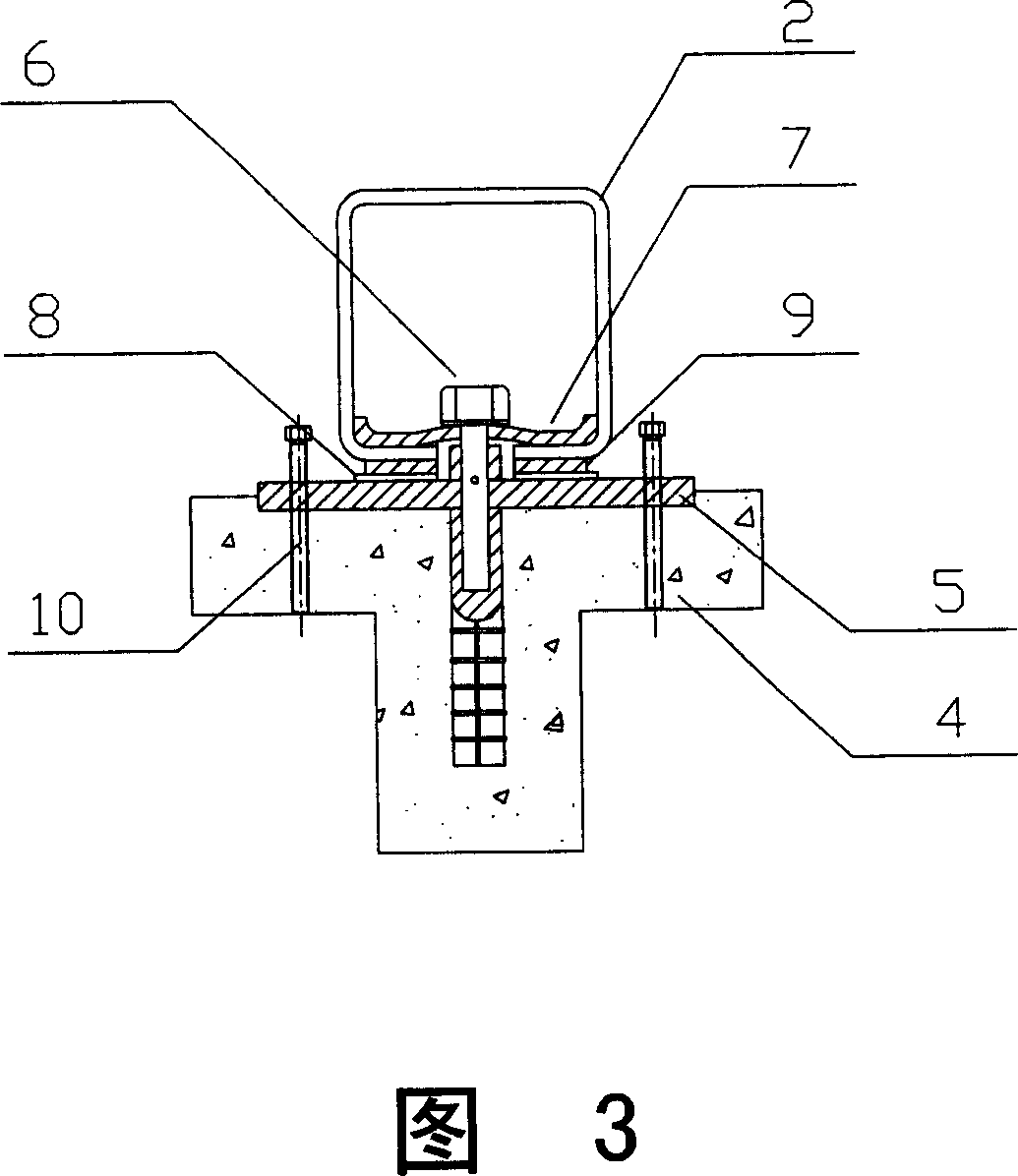

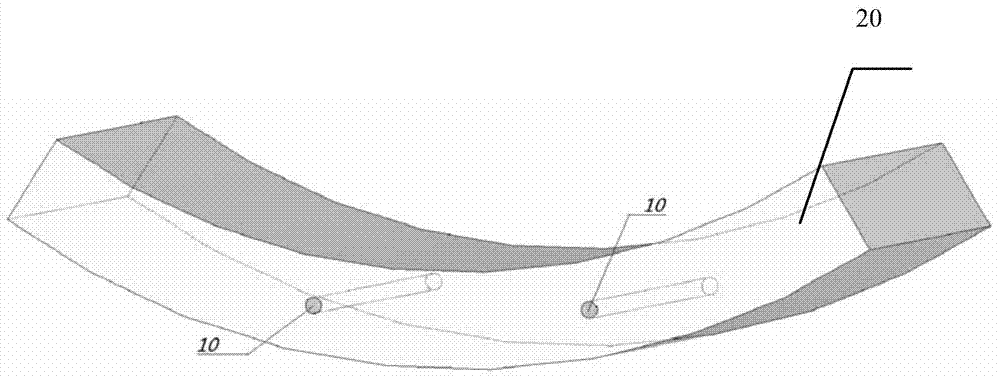

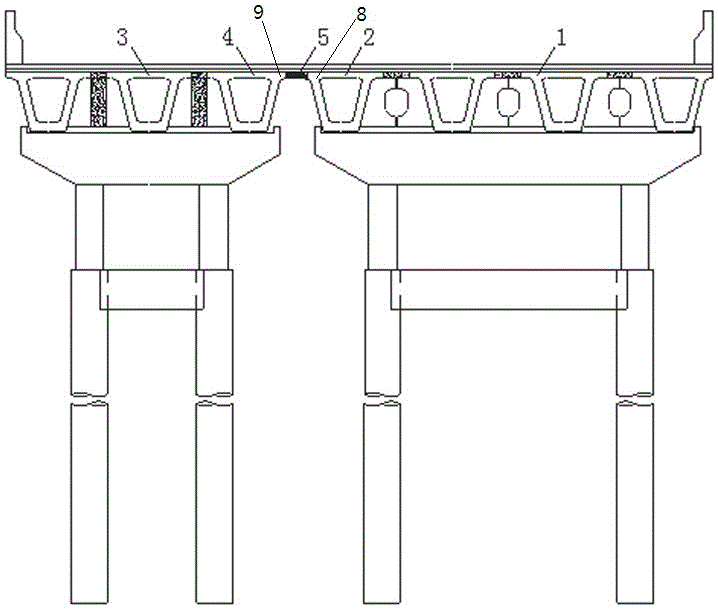

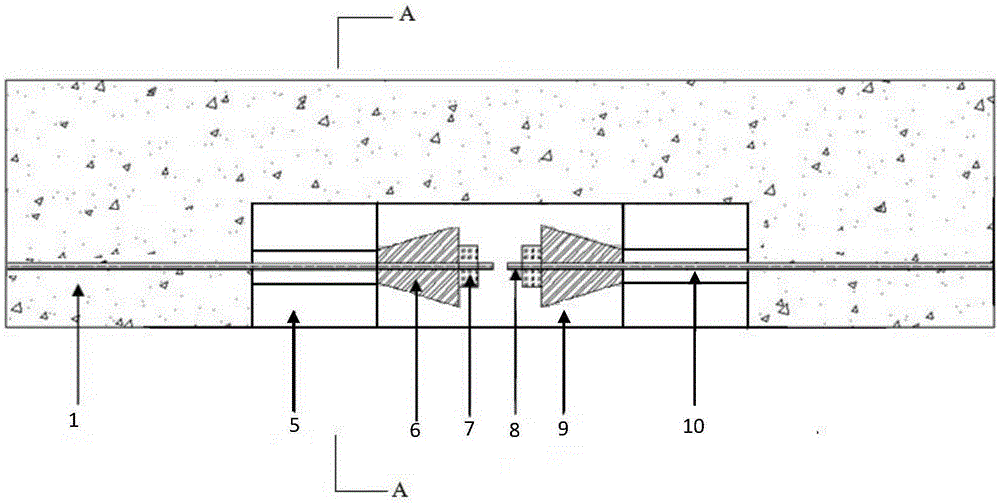

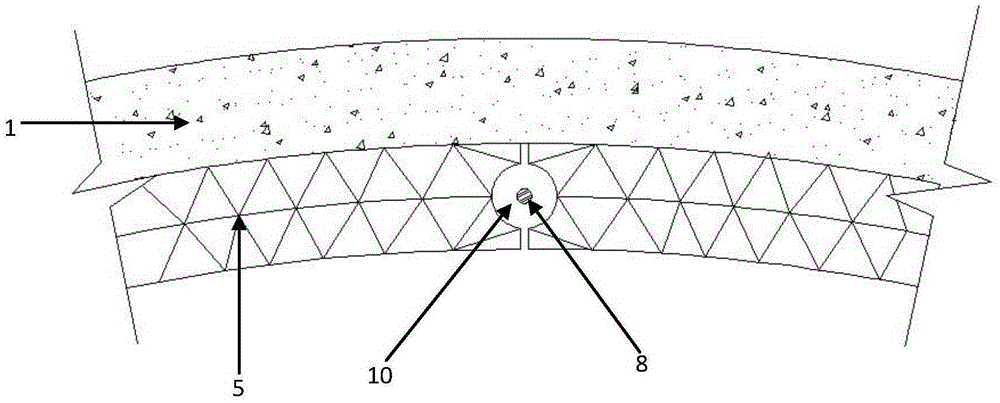

Track structure of magnetic floating traffic and manufacturing method therefor

InactiveCN101063286AImprove safety and reliabilityImprove rigidityRailway tracksDistortionSteel tube

The invention provides a track structure of magnetic floating traffic, comprising a track beam, railroad ties supported and fixed on the track beam via a connecting structure and a track supported and fixed at two sides of the upper surface of the railroad ties, wherein the connecting structure comprises a fixer and a concrete block, the railroad tie is made from hollow square steel tube. The invention also provides a relative production, comprising that preparing the track beam with preformed holes, preparing a track arranger formed by a track and railroad ties, while the railroad tie is made from hollow square steel tube, connecting and fixing the arranger on the track beam via the connecting structure, while the connecting structure comprises a fixer and a concrete block. The invention uses square tubular steel railroad ties to improve the rigidity, distortion resistance, and longitudinal deformation resistance, to improve the safety and reliability of the track, and uses a novel flexible buckle plate to make installment easy and improve vibration proof ability.

Owner:SHANGHAI MAGNETIC SUSPENSION COMM ENG TECH RES CENTE

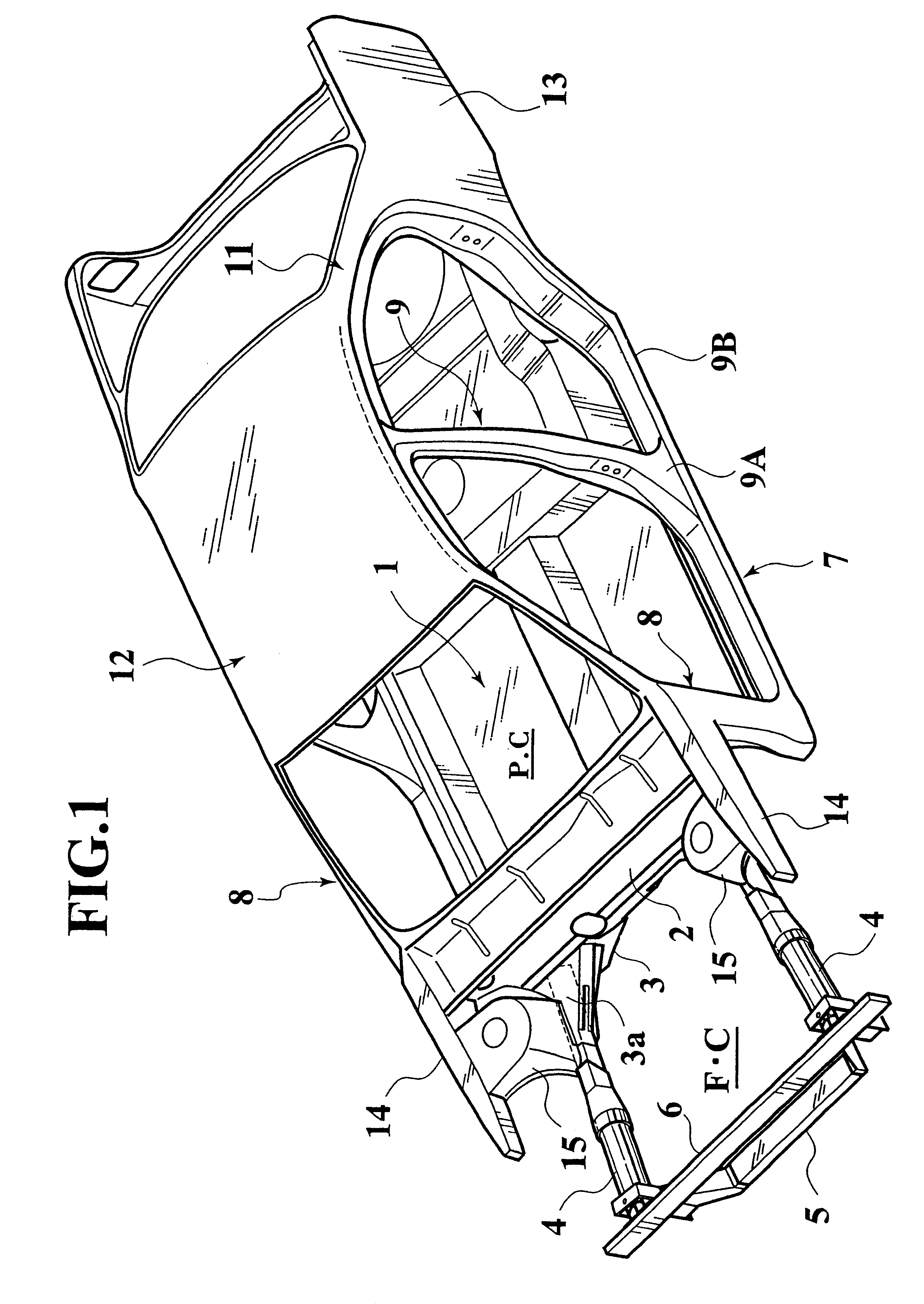

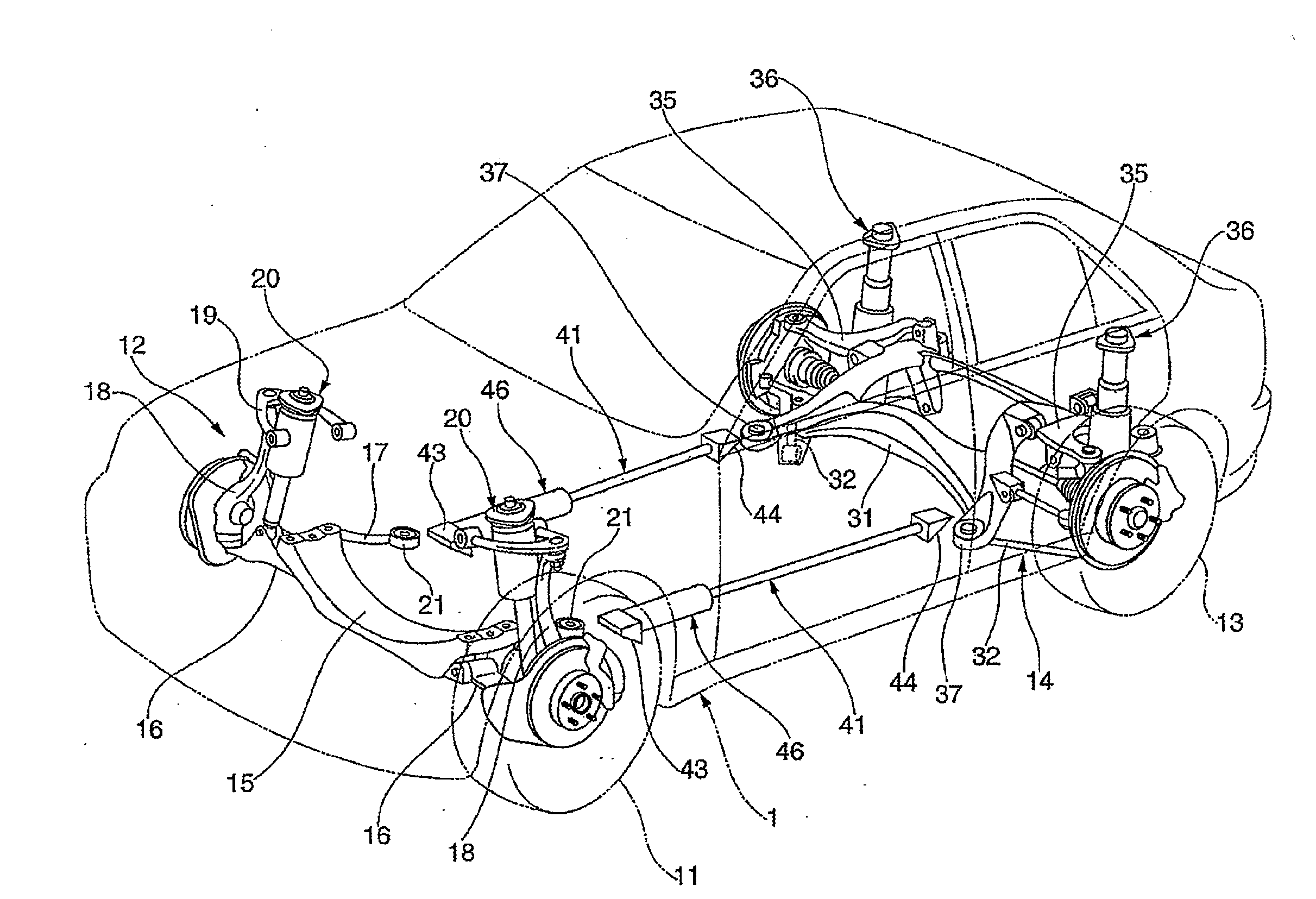

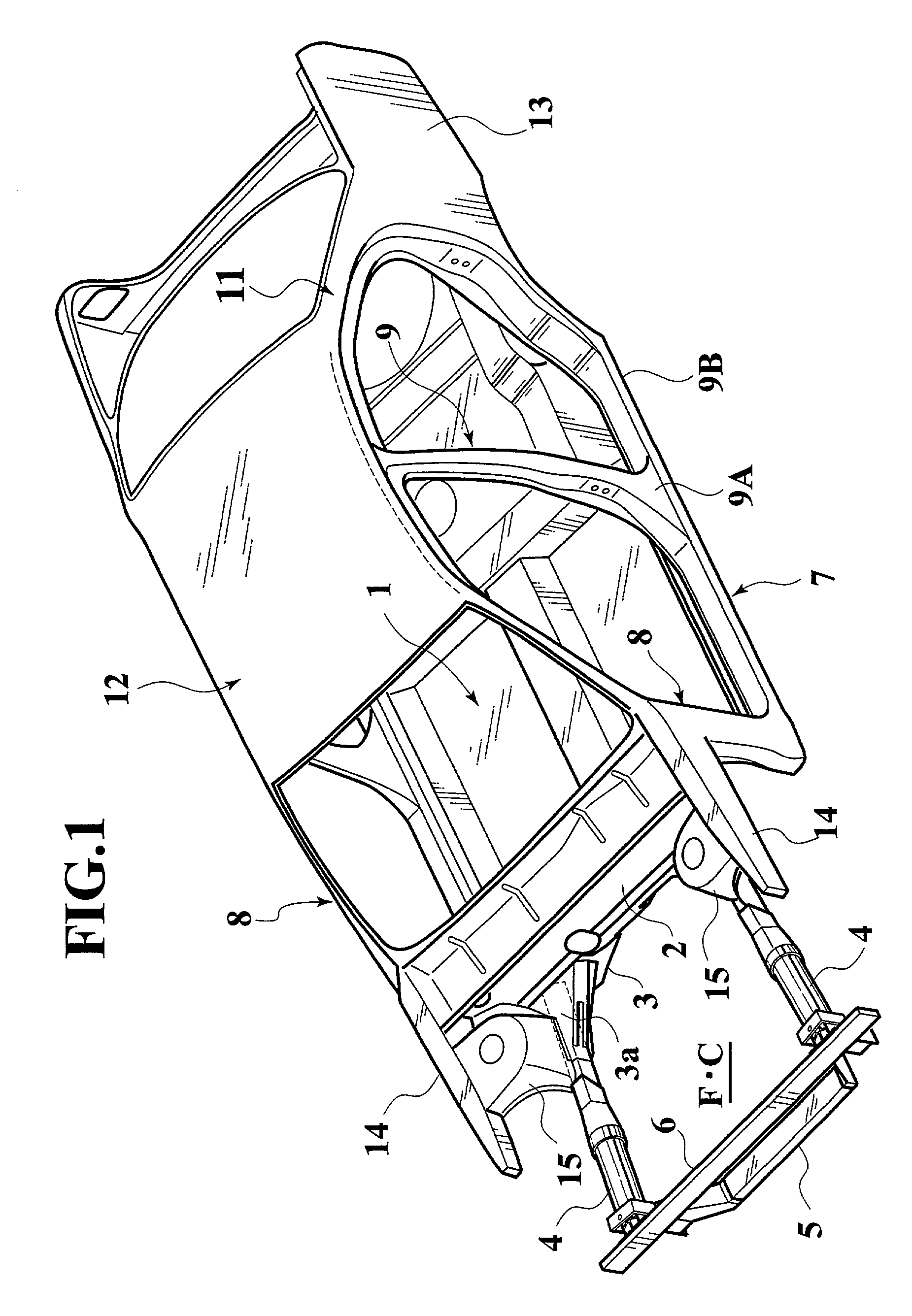

Frame structure for vehicle

A frame structure capable of increasing collision energy absorption includes a floor member or structure. The floor member has extruded side sill members which are adapted to undergo lateral buckling in response to side collisions while resisting axial or longitudinal deformation due to end-on collisions. Extruded impact dispersing deformable sections with a smaller rigidity than the associated side sills are provided on the inboard sides of the sills and arranged to smooth buckling and disperse collision energy. At least one extruded, flat, passenger occupancy floor section, which is located inboard of the impact dispersing deformable sections, is provided to prevent buckling deformation and maintain the cabin space.

Owner:NISSAN MOTOR CO LTD

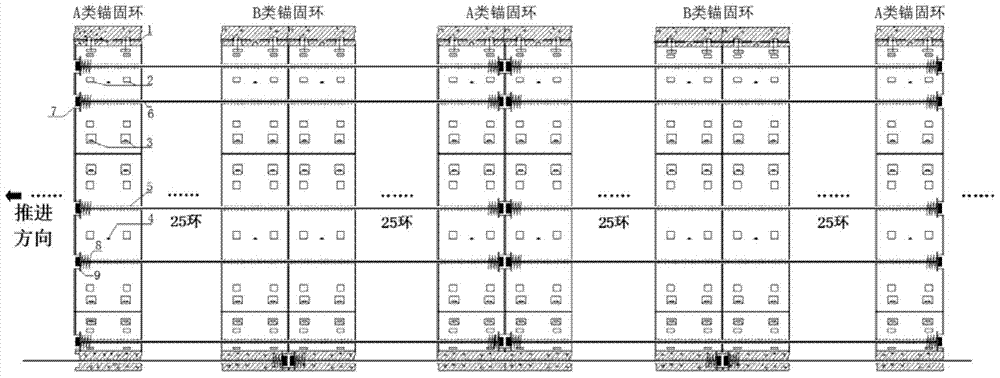

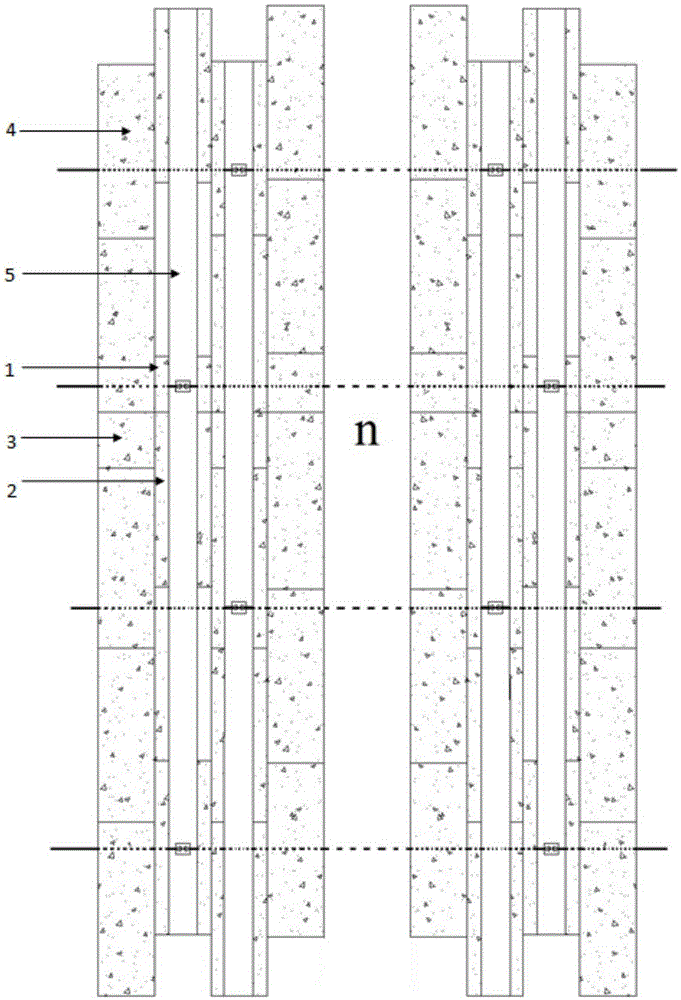

Method for manufacturing shield tunnel longitudinal prestressing concrete lining segment

ActiveCN103790598AIncrease stiffnessGuaranteed stressUnderground chambersTunnel liningWater leakagePre stress

A method for manufacturing a shield tunnel longitudinal prestressing concrete lining segment comprises the steps of (1) respectively and permanently embedding hole making devices at the preset positions of a connecting block, a standard block and an arch base block of each set of circulating district lining ring to make a hole way, and hole ways on adjacent pipe pieces are correspondingly and longitudinally communicated to form a plurality of preset channels which longitudinally penetrate through the circulating districts; (2) respectively penetrating prestressing steel strands into the preset channels, and when one circulating district is spliced, conducting tension and anchorage to form the whole structure. The method is combined with longitudinal high-strength steel strands, the tunnel overall rigidity is improved, longitudinal deformation is reduced, and longitudinal uneven sedimentation is especially reduced. Precompression is exerted on the concrete lining segment in the longitudinal direction, the stress between lining rings is kept well, stretching and error lifting of the joint between the lining rings are avoided, and water leakage is prevented and controlled.

Owner:TONGJI UNIV

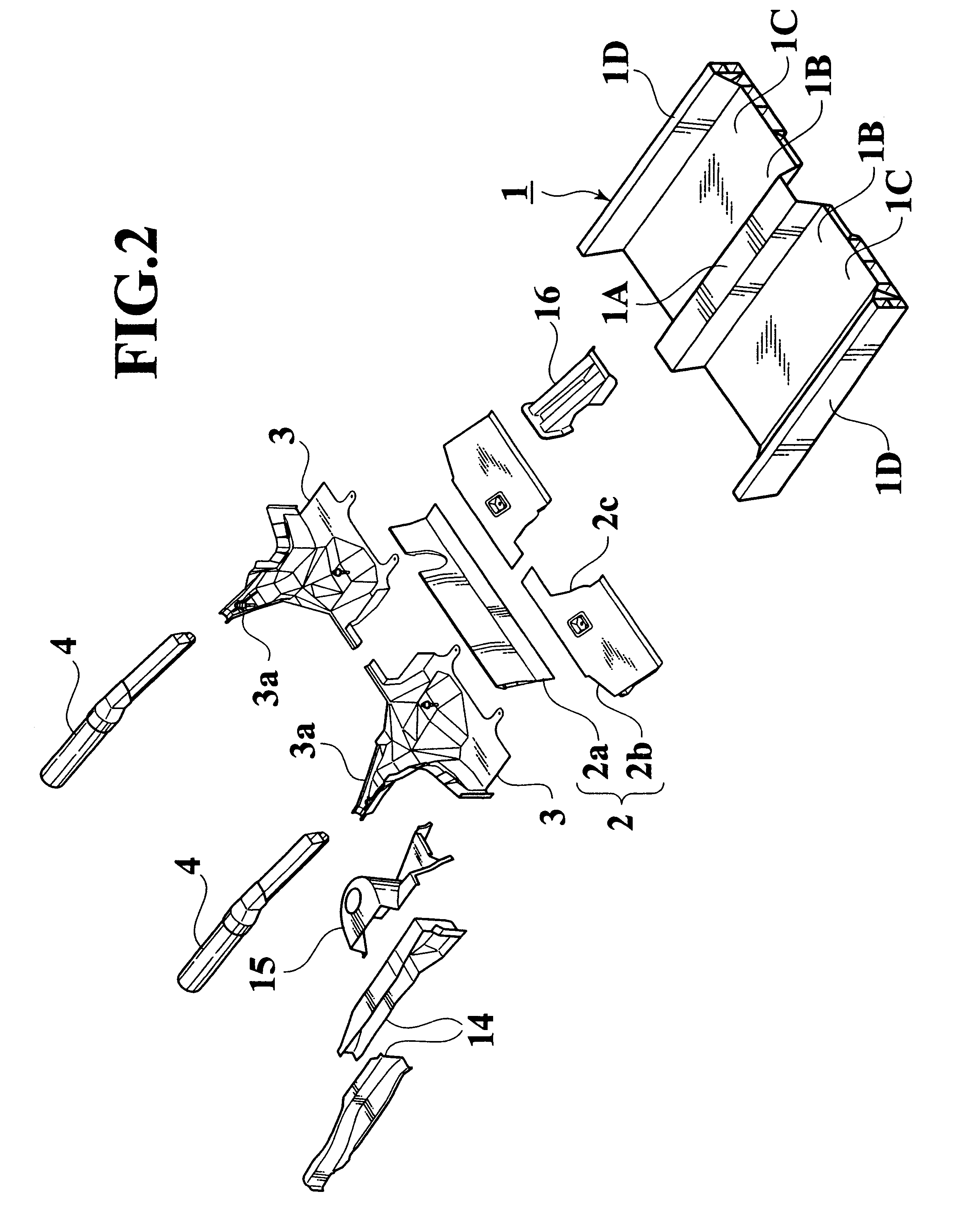

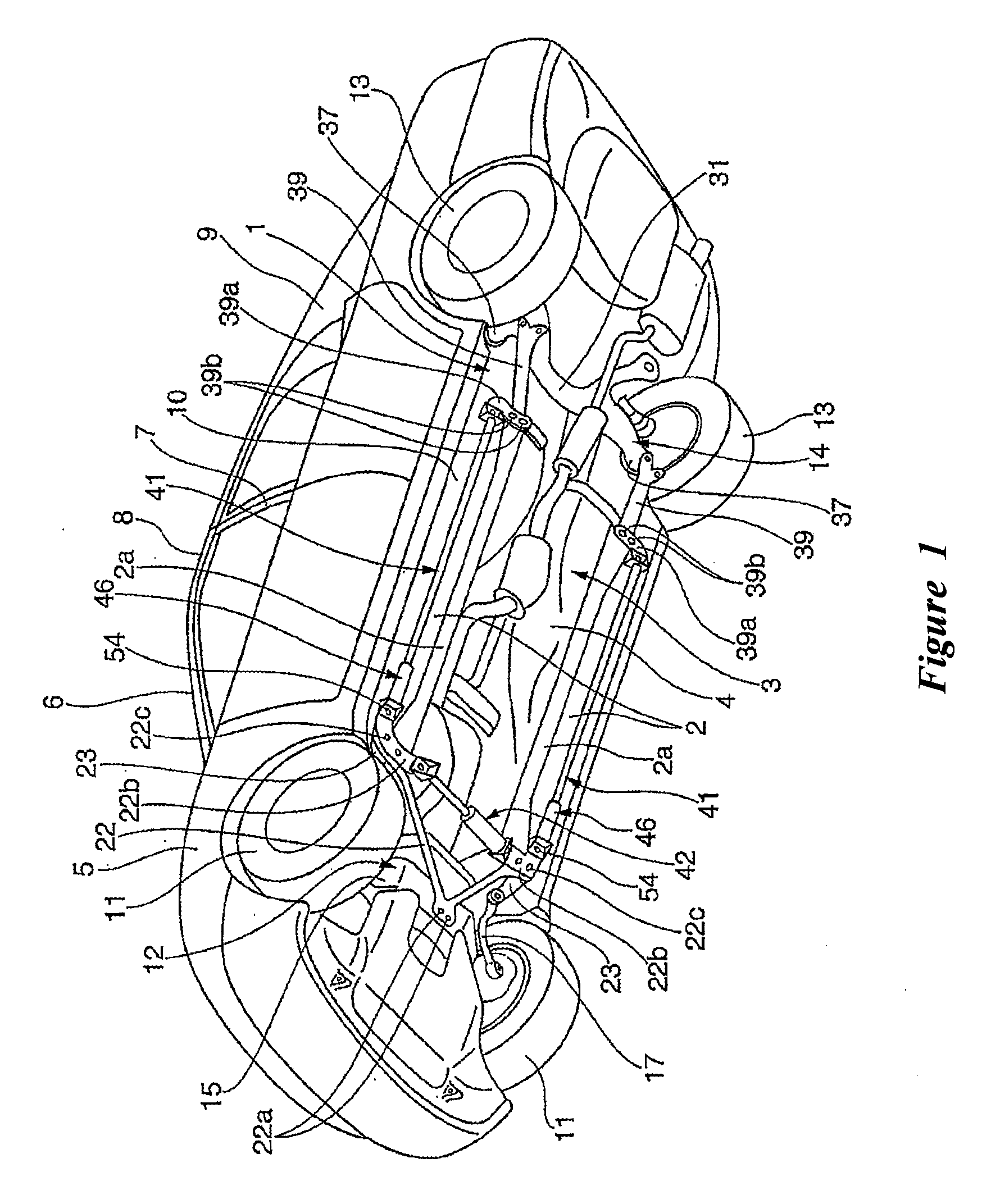

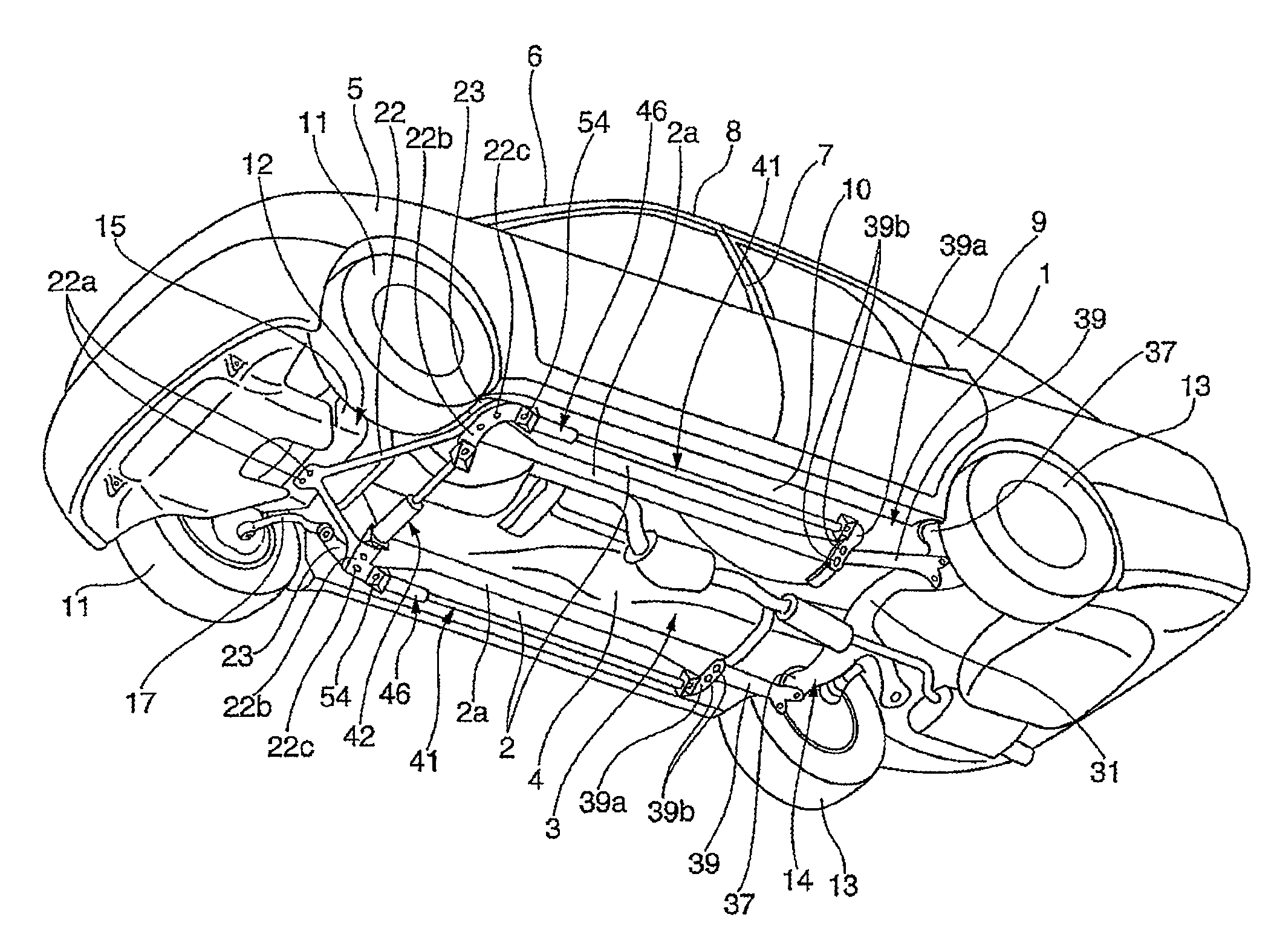

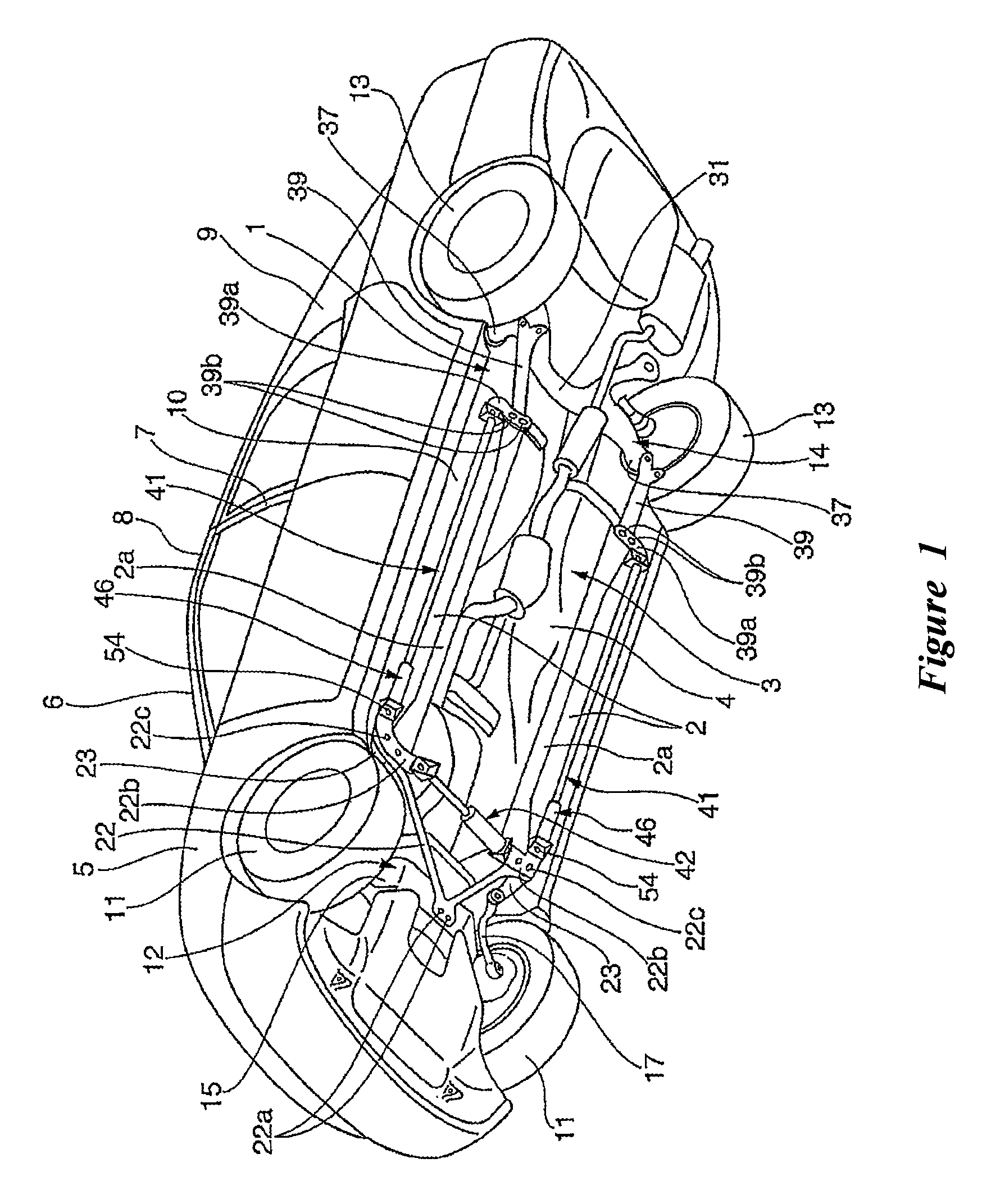

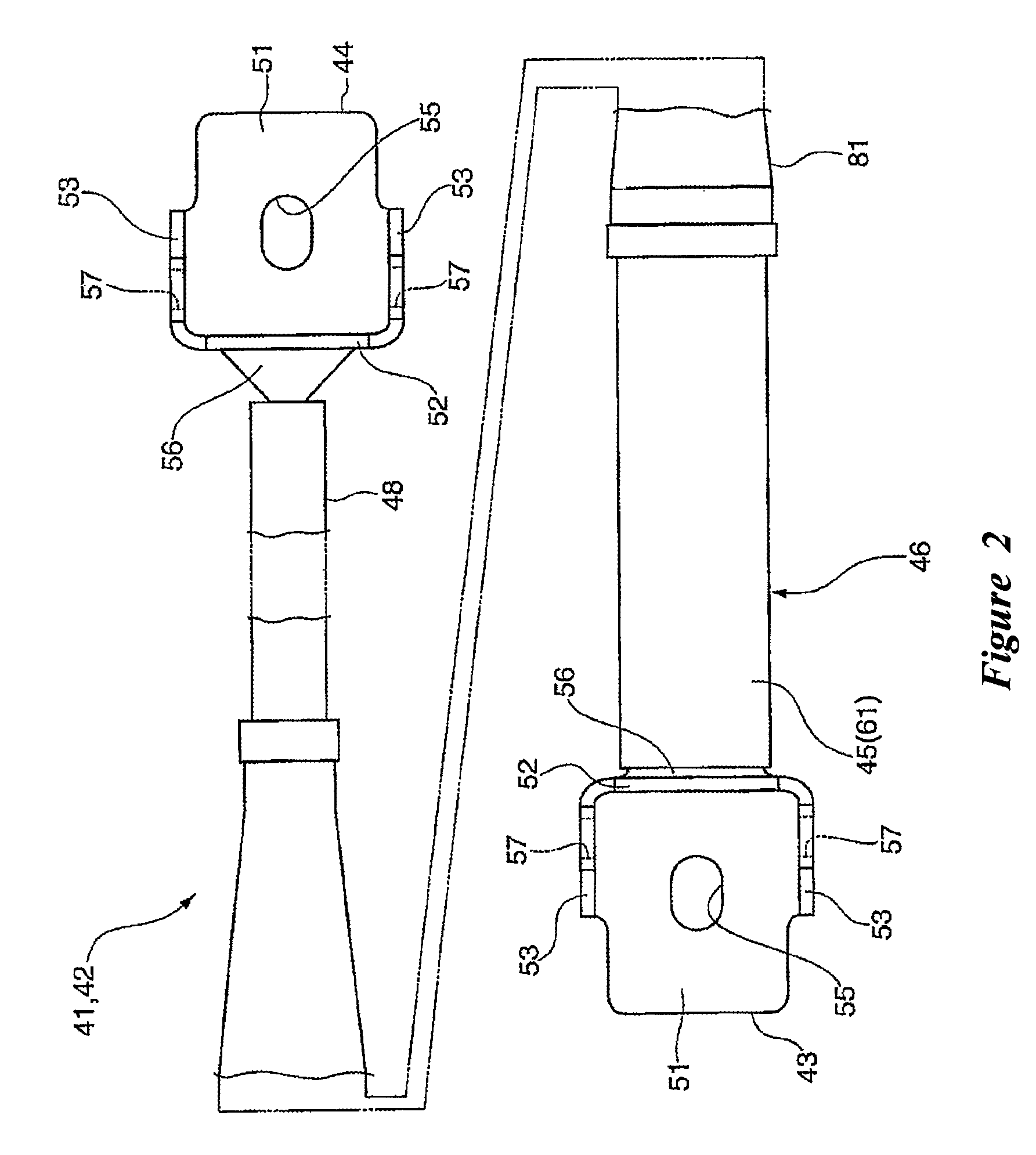

Device for reinforcing vehicle body of vehicle

ActiveUS20090079232A1Reduce spacingReduces serviceabilitySuspensionsVehicle seatsLongitudinal deformationBody frame

A vehicle body reinforcement device comprises an elongated shape with its middle portion comprising a hydraulic damper that produces a damping force against longitudinal deformation. Two vehicle body reinforcement devices may be mounted in a longitudinal manner to a vehicle body frame with a lateral space being defined between the two devices. Both ends of each of the vehicle body reinforcement devices can be removably attached from outside of the vehicle to positions that are exposed outside of the passenger compartment and below the vehicle body.

Owner:YAMAHA MOTOR CO LTD

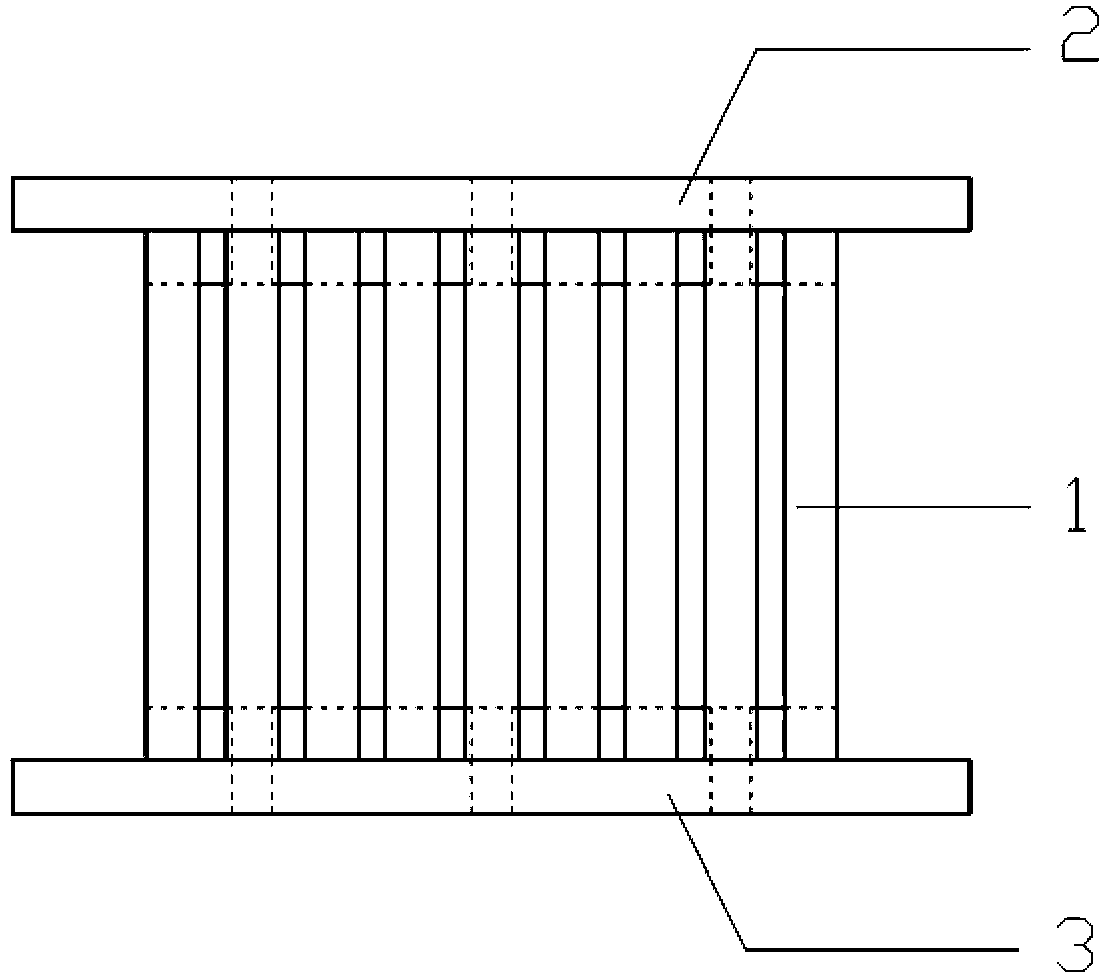

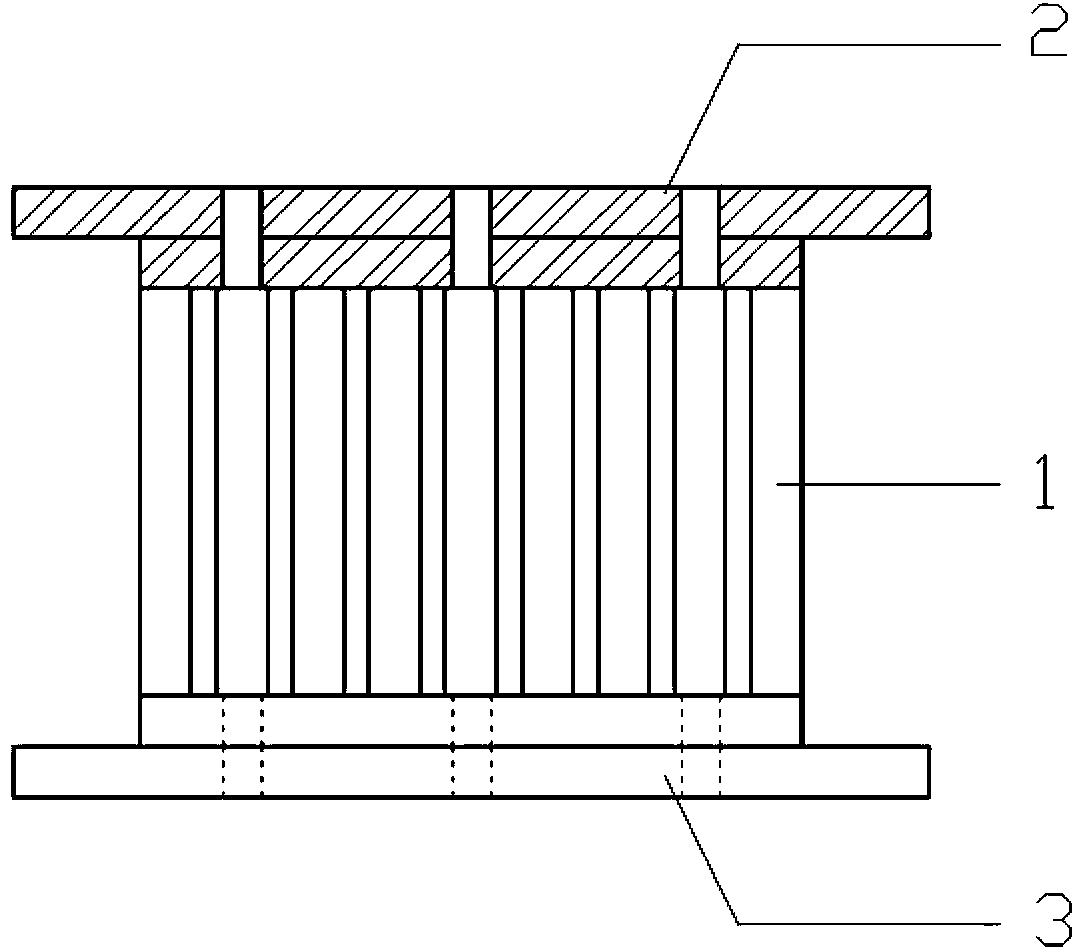

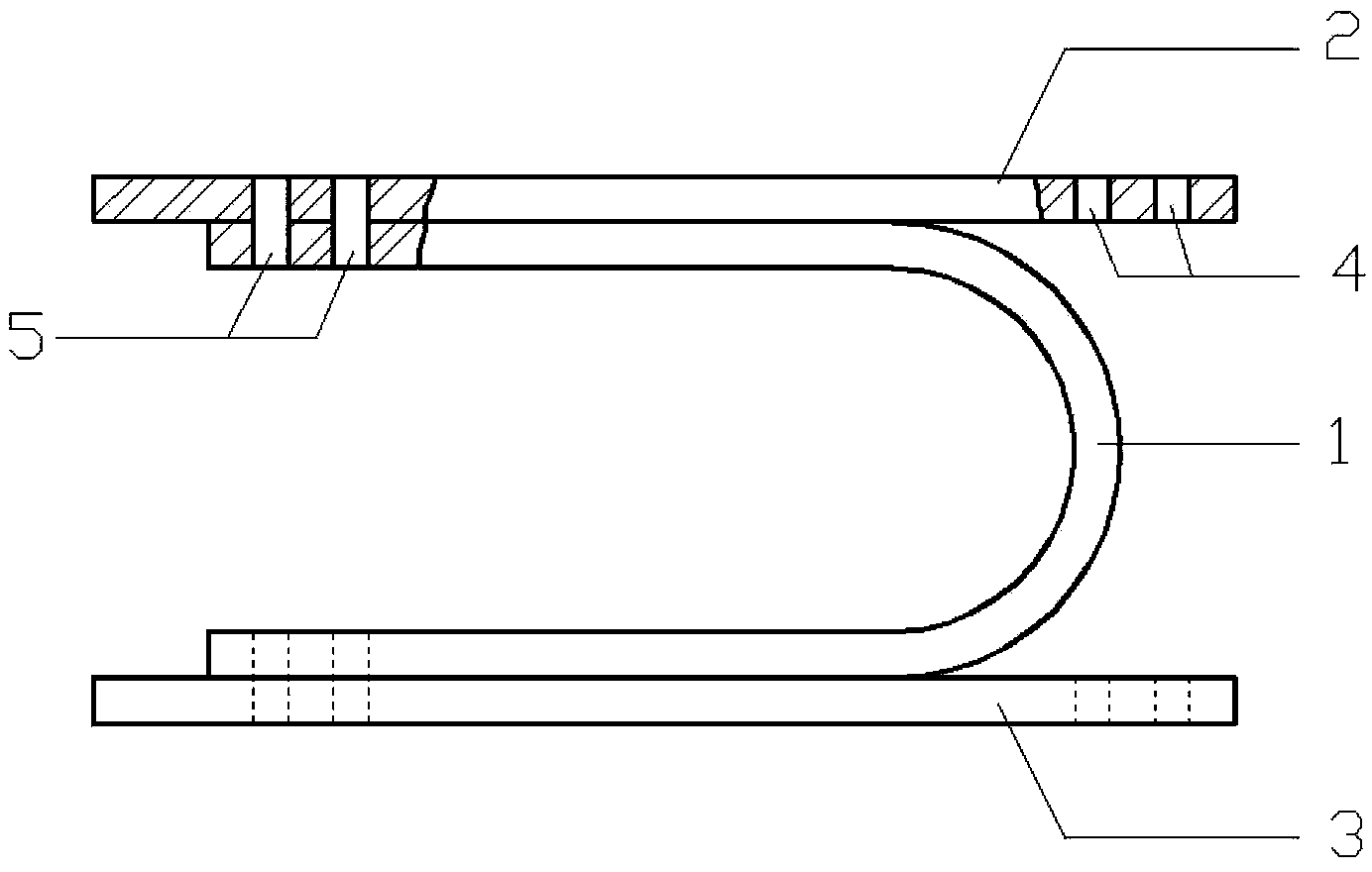

Metal damper and design method thereof

ActiveCN103397595ASolve the disadvantages of poor lateral stability and weak anti-fatigue abilityStrong designabilityBridge structural detailsShock proofingIn planeMetallic materials

The invention provides a metal damper and a design method thereof, and belongs to the technical field of civil engineering structural shock absorption. The damper comprises an upper cover plate, a lower cover plate and a core energy-consuming metal element. The core energy-consuming metal element is a continuous U-shaped slotted metal plate and comprises a circular arc section and two straight sections. A plurality of continuous grooves are formed in the circular arc section and partial straight sections of the slotted metal plate in the width direction at intervals. In design, firstly, the height of the damper is determined according to a building; secondly, the numerical relationship of the thickness of a steel plate, the length of the straight sections and the width of the damper is obtained according to an in-plane resilience formula and an out-plane resilience formula; specific numerical values of the three parameters are adjusted according to an optimizing formula, so that a failure mode, out of expectation, of the damper does not occur; and ultimately, the number of the dampers and the size of a bolt are determined. According to the metal damper and the design method of the metal damper, energy consumption is achieved through metal materials with strong plastic deformation capacity, large longitudinal deformation is achieved through bending deformation, and large sideward deformability and anti-fatigue performance are achieved.

Owner:TSINGHUA UNIV

Device for reinforcing vehicle body of vehicle

ActiveUS7673904B2Reduce spacingReduces serviceabilitySuspensionsSpringsLongitudinal deformationBody frame

A vehicle body reinforcement device comprises an elongated shape with its middle portion comprising a hydraulic damper that produces a damping force against longitudinal deformation. Two vehicle body reinforcement devices may be mounted in a longitudinal manner to a vehicle body frame with a lateral space being defined between the two devices. Both ends of each of the vehicle body reinforcement devices can be removably attached from outside of the vehicle to positions that are exposed outside of the passenger compartment and below the vehicle body.

Owner:YAMAHA MOTOR CO LTD

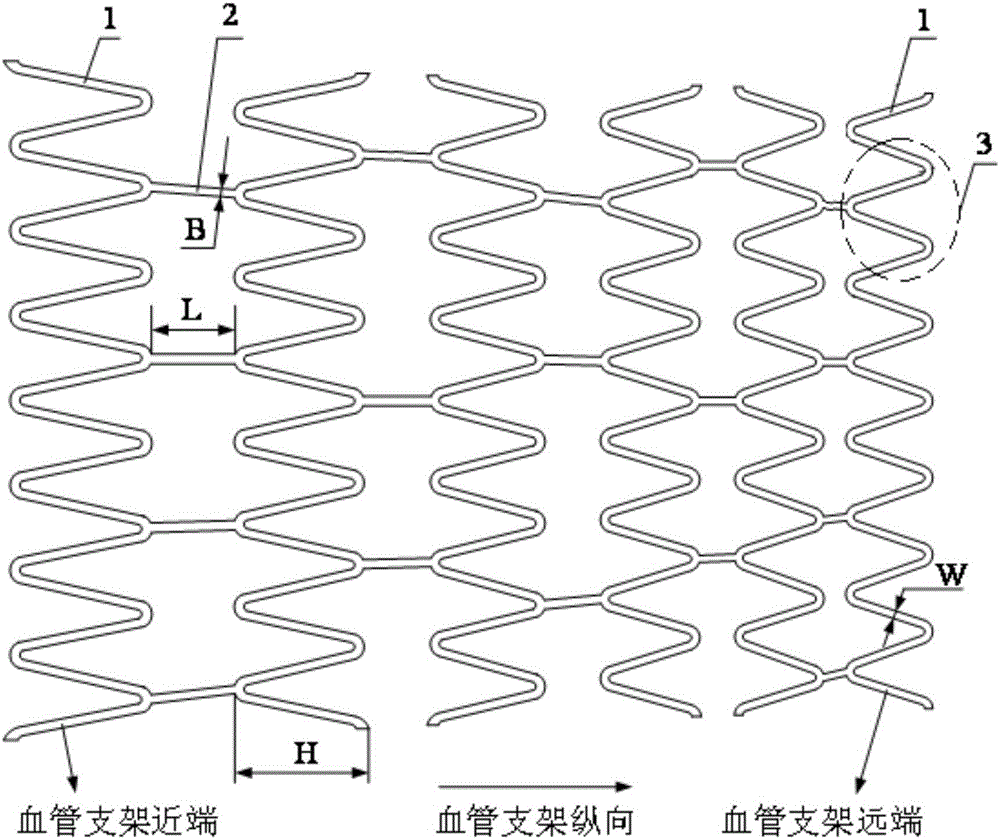

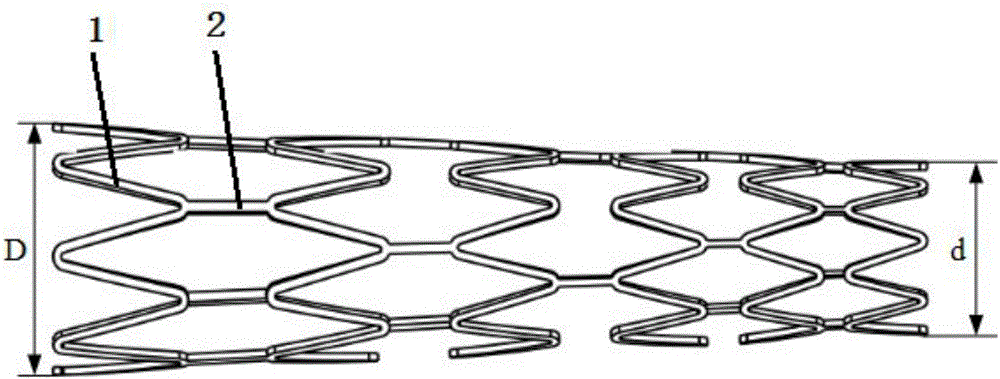

Auto-expansion type tapered intravascular stent

The invention provides an auto-expansion type tapered intravascular stent. The intravascular stent comprises multiple groups of annular supports arranged in the longitudinal direction of the intravascular stent sequentially and connectors connected between every two adjacent groups of annular supports; the annular supports and the connectors are made of shape memory materials through laser engraving, each annular support has multiple sinusoidal-wave-shaped bends in the longitudinal direction of the intravascular stent, every two adjacent groups of annular supports are distributed in a mirror symmetry manner, and the inner diameter of a ring formed by the multiple groups of annular supports is reduced from the near end to the far end of the intravascular stent sequentially; the connectors are linear. A tapered cylindrical structure of the stent can effectively improve the wall attaching performance of the stent and is more capable of reducing longitudinal deformation of the stent, restenosis and other complications.

Owner:JIANGSU UNIV

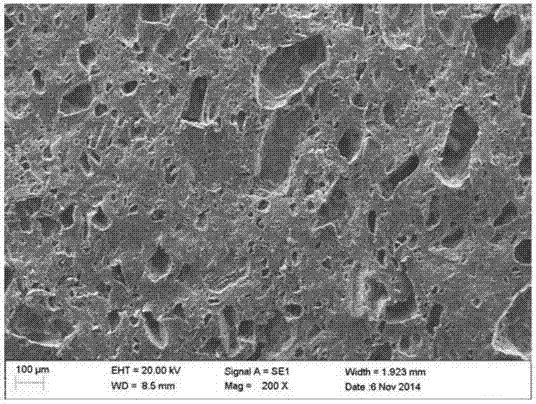

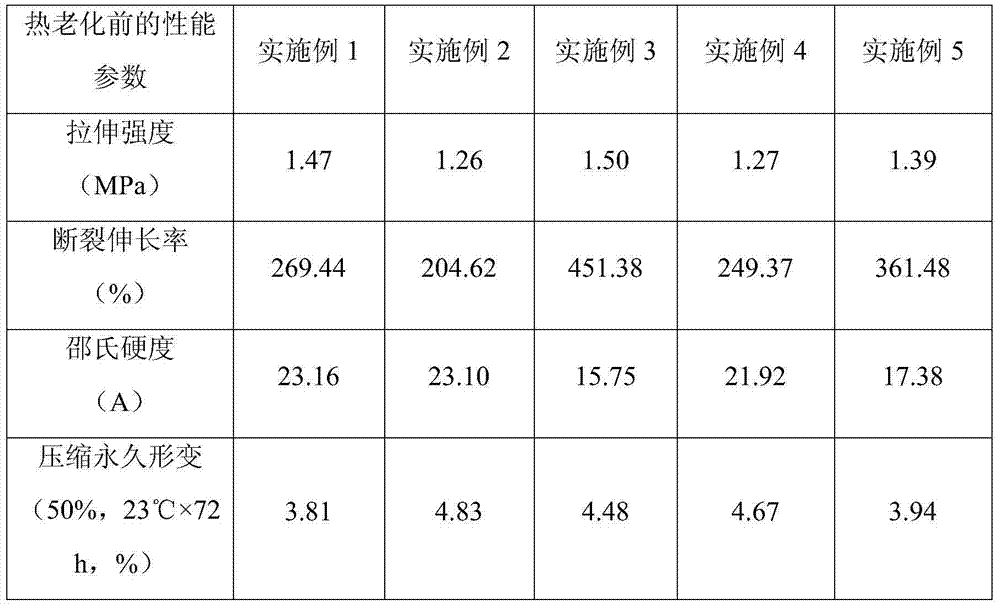

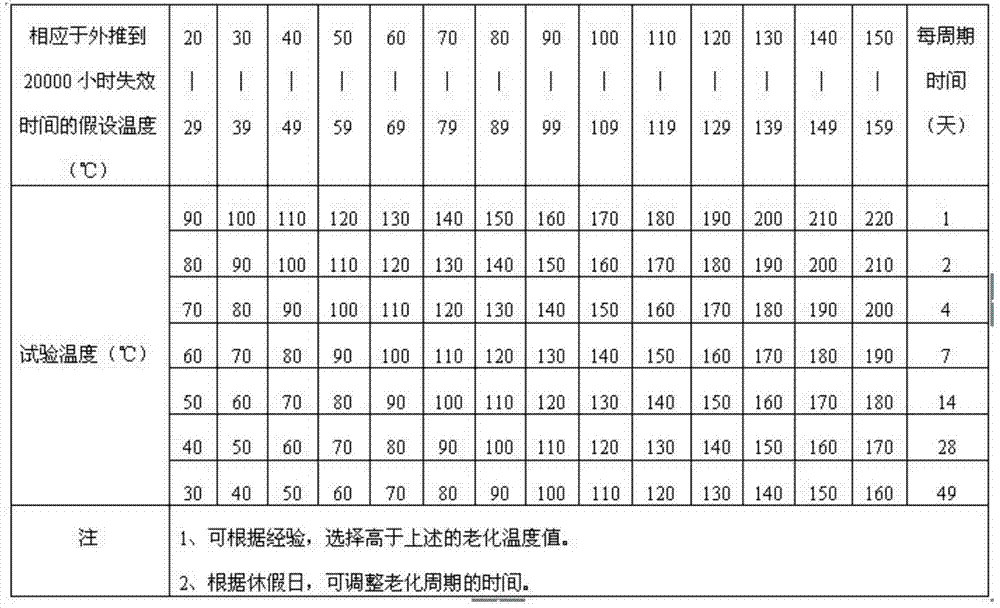

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Frame structure for vehicle

A frame structure capable of increasing collision energy absorption includes a floor member. The floor member has extruded side sill members which are adapted to undergo lateral buckling response to side collisions while resisting axial or longitudinal deformation due to end-on collisions. Extruded impact dispersing deformable sections with a smaller rigidity than the associated side sills are provided on the inboard sides of the sills and arranged to smooth buckling and disperse collision energy. At least one extruded, flat, passenger occupancy floor section, which is located inboard of the impact dispersing deformable sections, is provided to prevent buckling deformation and assure cabin space.

Owner:NISSAN MOTOR CO LTD

Unidirectional lead core rubber vibration insulation support

The invention discloses a unidirectional lead core rubber vibration insulation support which comprises an interlayer steel plate, interlayer rubber, outer wrapping rubber, upper seal plate, a cover plate, a lead core, a Teflon sliding plate, a stainless steel plate, an upper support plate, a lower support plate, limiting plates, an upper connecting plate, a lower connecting plate, an anchor bolt, a lateral stainless steel bar and a guide sliding strip. The led core is tightly pressed into a support reserved hole, and the cover plate is arranged on the lead core. The Teflon sliding plate and the stainless steel plate form a support sliding face, and lubrication between the stainless steel plate and the Teflon sliding plate is conducted through silicone grease. The upper seal plate is bonded with the Teflon sliding plate which is provided with the surface coated with epoxy resin and is subjected to surface activation treatment. The limiting plates are arranged on all the side edges of the upper support plate and allow longitudinal sliding but limit transverse moving. By means of the unidirectional lead core rubber vibration insulation support, the problem that a total link bridge length is large or large longitudinal deformation generated under the conventional load action may be restrained when the vibration insulation support is adopted for a large stride bridge is solved, the application range of the vibration insulation support is broadened, and vibration resistance of the overall bridge is improved.

Owner:NANJING UNIV OF TECH

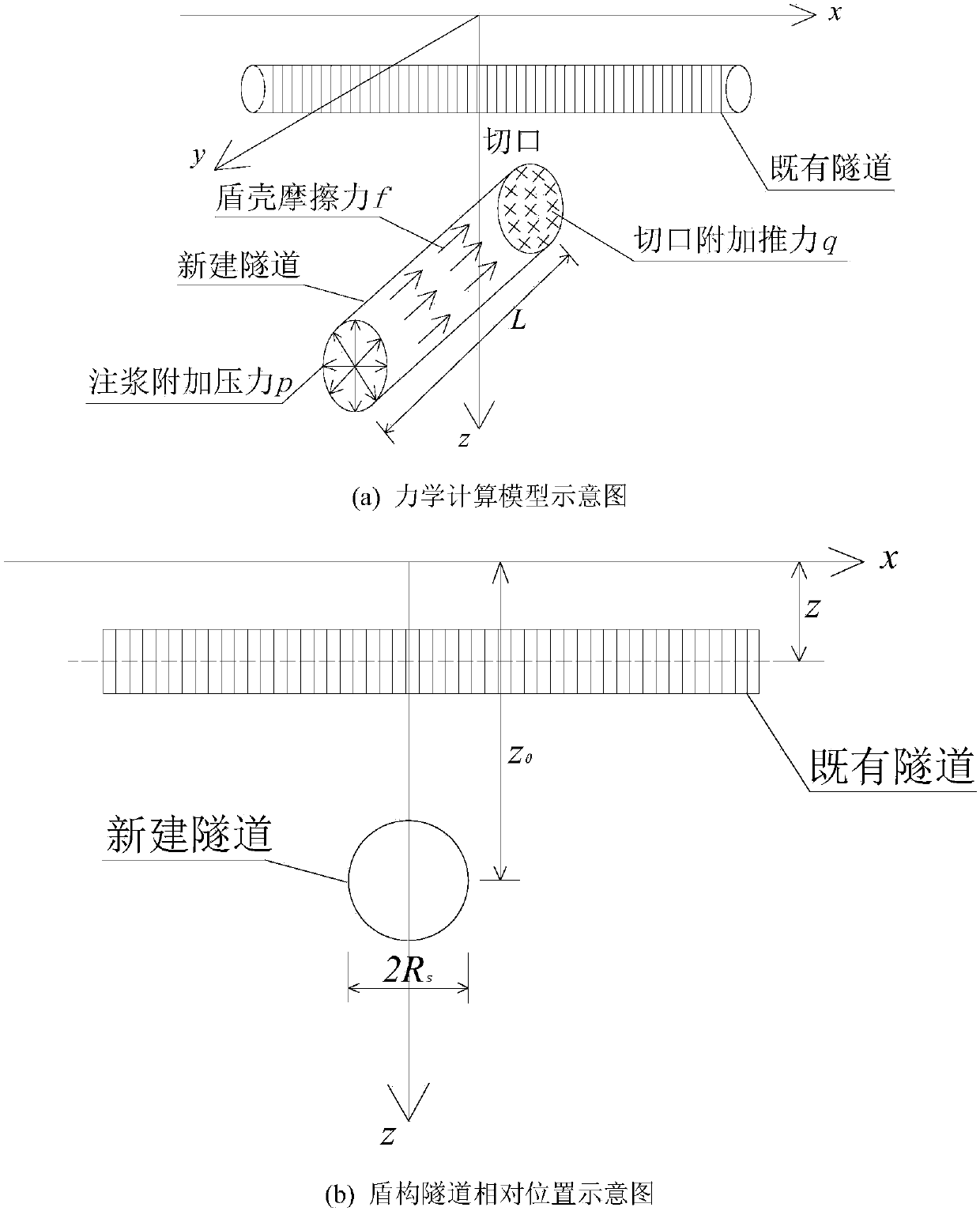

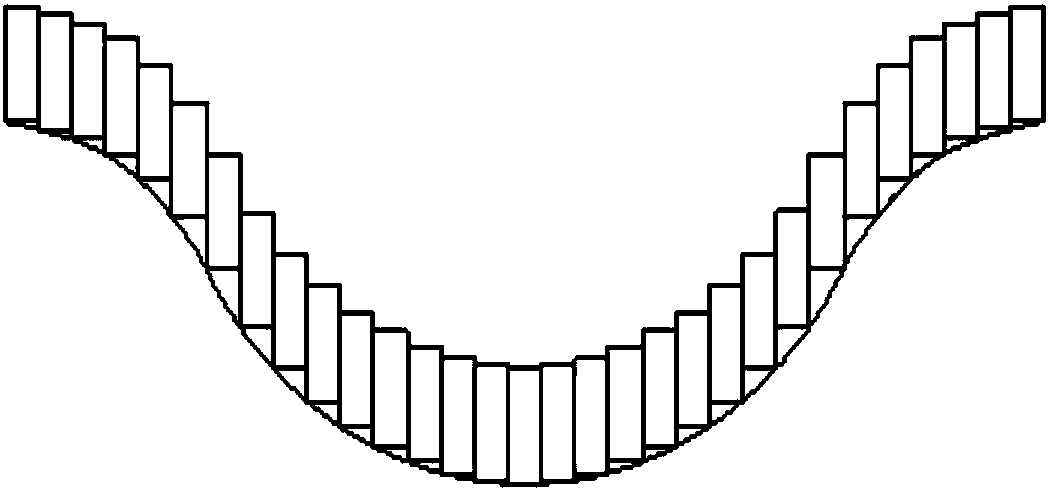

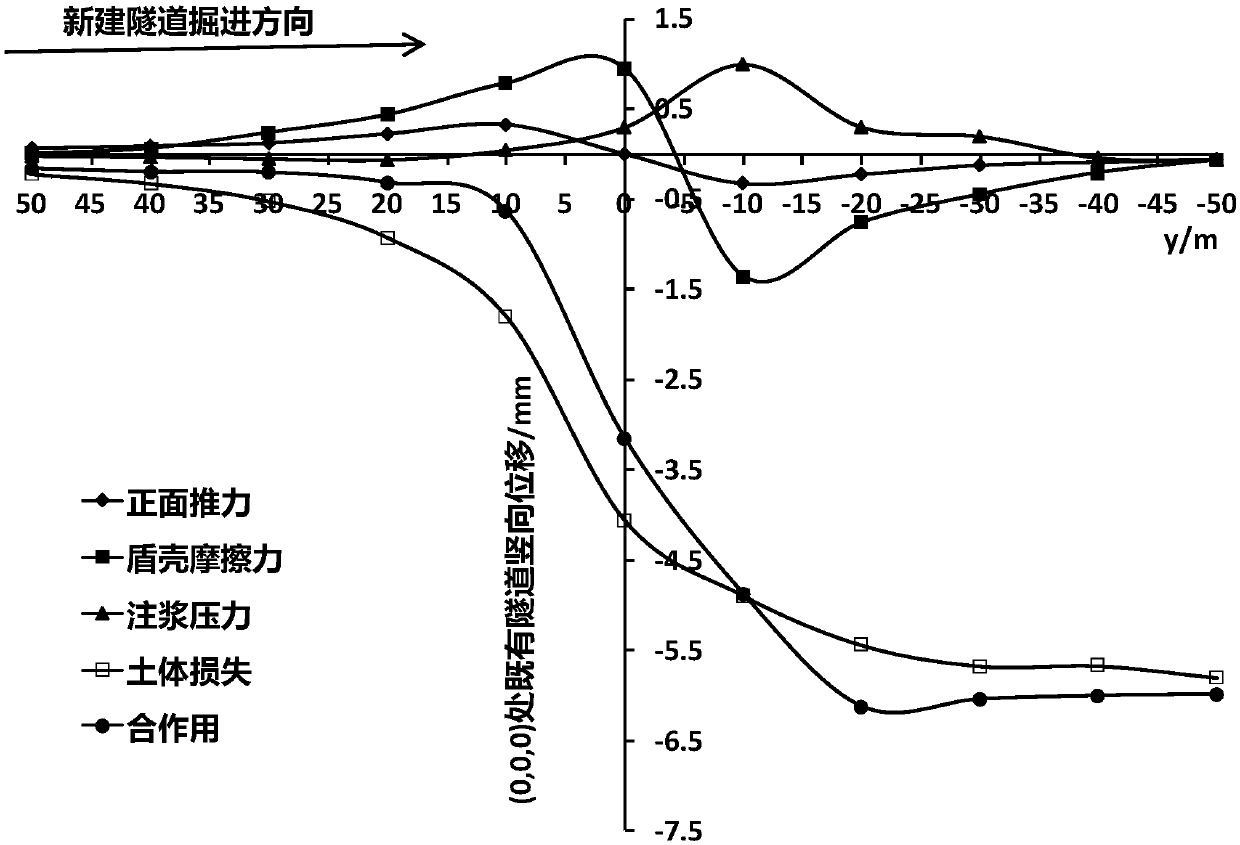

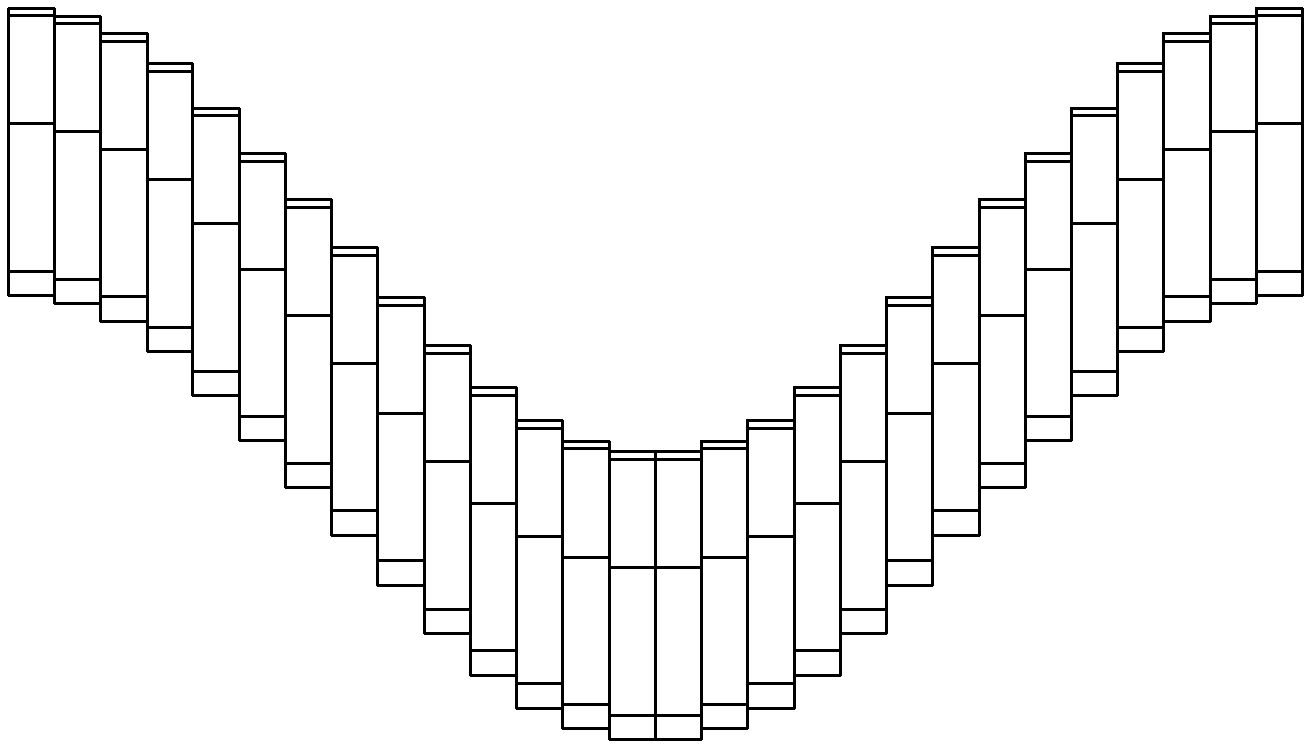

Method for calculating existing shield tunnel displacements caused by new under-crossing tunnels

The invention relates to a method for calculating existing shield tunnel displacements caused by new under-crossing tunnels. The method comprises the following steps of: 1, calculating existing tunneladditional stresses caused by a new under-crossing tunnel: a vertical additional stress <sigma>z-q generated by cutter head additional thrust q, a vertical additional stress <sigma>z-f generated by shield shell friction force f, vertical additional stresses <sigma>z-p1 and <sigma>z-p2 generated by slip casting additional pressure p and an additional stress generated by soil mass loss; and 2, calculating longitudinal deformation of the tunnel on the basis of a principle of minimum potential energy: total potential energy of a shield tunnel, a displacement function of an assumed tunnel lining ring and a variation control equation. The method has the beneficial effects that joint effect among tunnel rings is considered, structural characteristics and physical characteristics of tunnels are sufficiently considered, and longitudinal displacements, caused by new under-crossing tunnels, of existing shield tunnels can be rapidly calculated by utilizing Matlab, so that safety of existing tunnel structures under the action of the new under-crossing tunnels can be judged and relatively accord with practical stress and deformation of the shield tunnels.

Owner:ZHEJIANG UNIV CITY COLLEGE

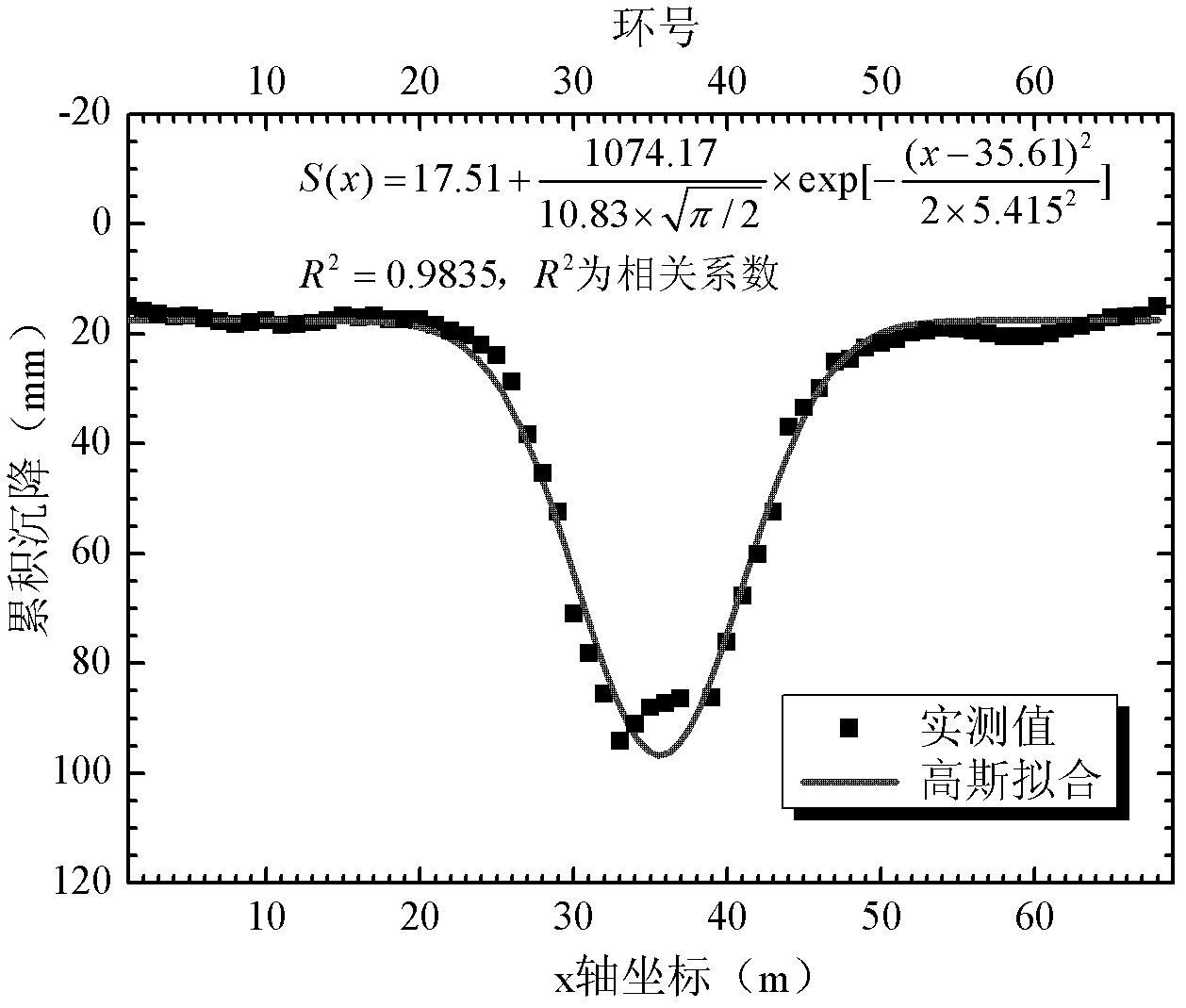

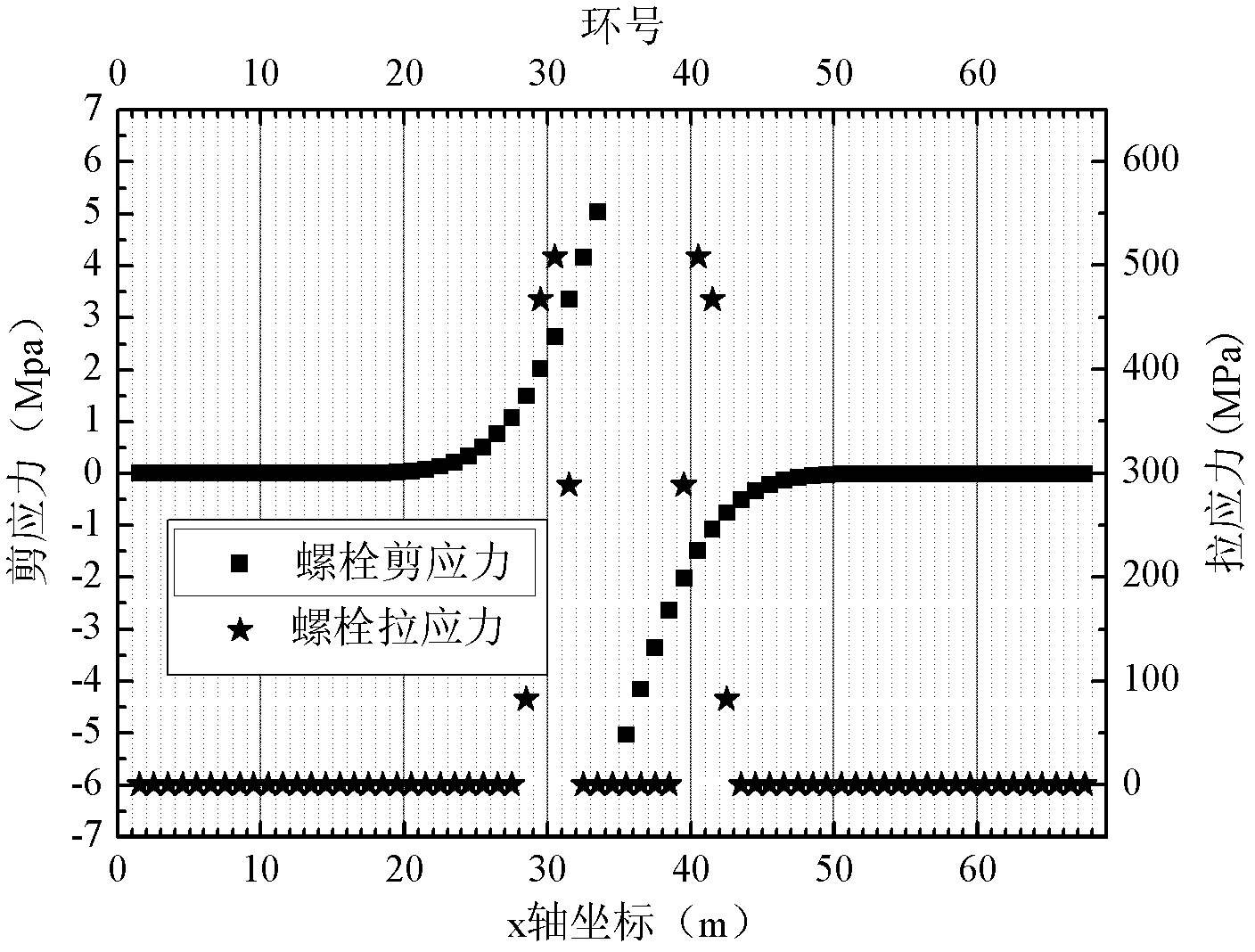

Protection control method for resisting longitudinal deformation through shield tunnel structure in soft soil stratum

The invention discloses a protection control method for resisting the longitudinal deformation through a shield tunnel structure in a soft soil stratum, which comprises the following steps: getting division information of soil layers of shallow soil containing a tunnel, and then extracting soil samples of the soil layer in which the tunnel is located for performing an indoor conventional geotechnical test; utilizing a water level gauge to measure the bulk settling of the tunnel structure, taking the longitudinal direction of the tunnel as a horizontal axis, and taking the accumulated settlingvalues of the tunnel as a longitudinal axis for marking up the accumulated settling values of all rings of the tunnel; performing sectional fitting on an accumulated settling curve of the tunnel and determining a Gaussian fitting equation of the accumulated settling curve; determining the shear force of the tunnel; and determining the shearing stress and the pulling stress of each bolt and controlling the longitudinal deformation of the tunnel according to the obtained shearing stress and the pulling stress of the bolts between the rings of the tunnel. The protection control method adopts a Cosserat non-equilibrium mechanical theoretical system to quantitatively determine the stress of the bolts between the lining rings of the tunnel, and the method is simple, convenient to popularize andsuitable for the control problem of the longitudinal deformation of the shield tunnel.

Owner:SHANGHAI JIAO TONG UNIV

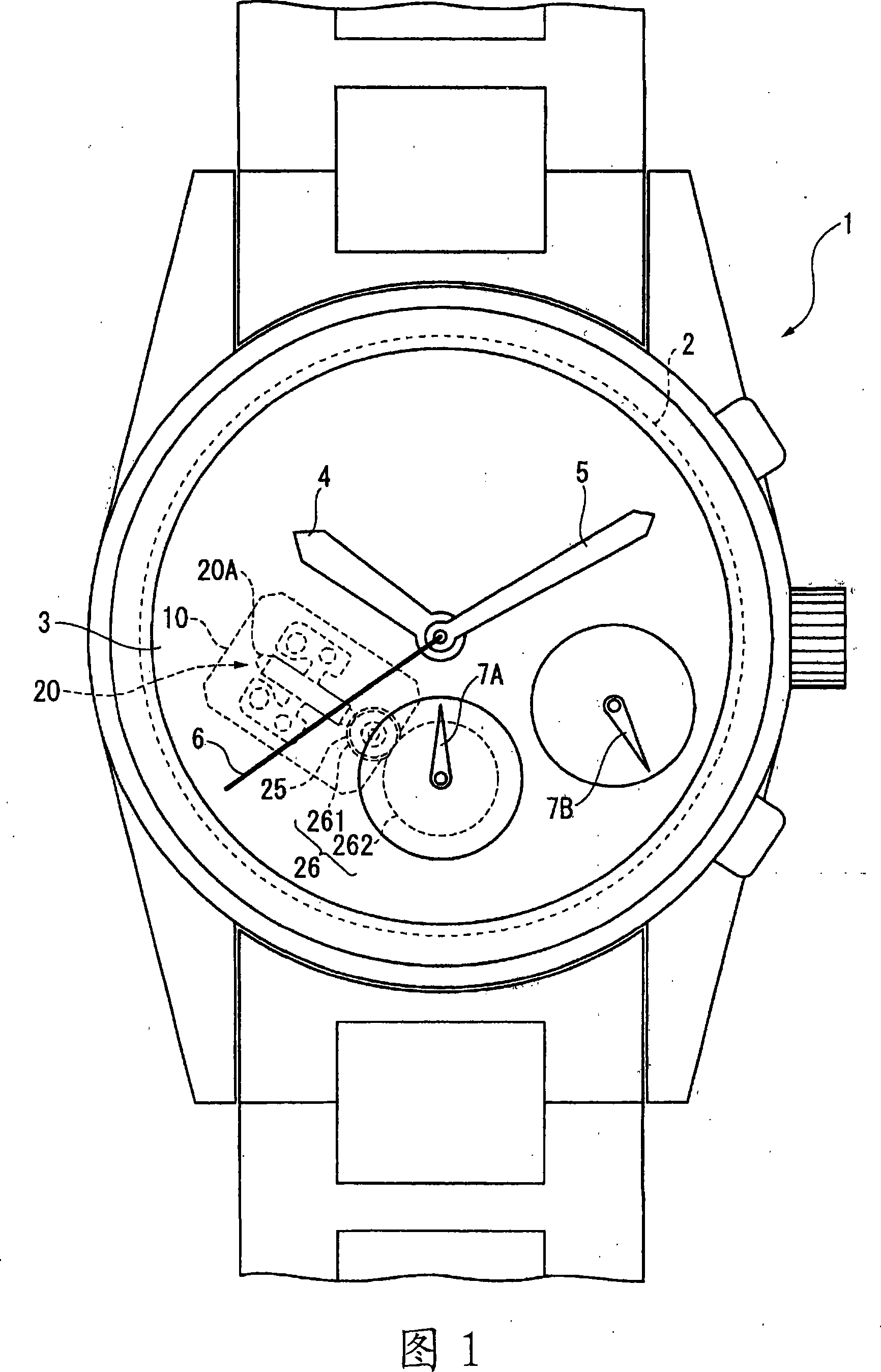

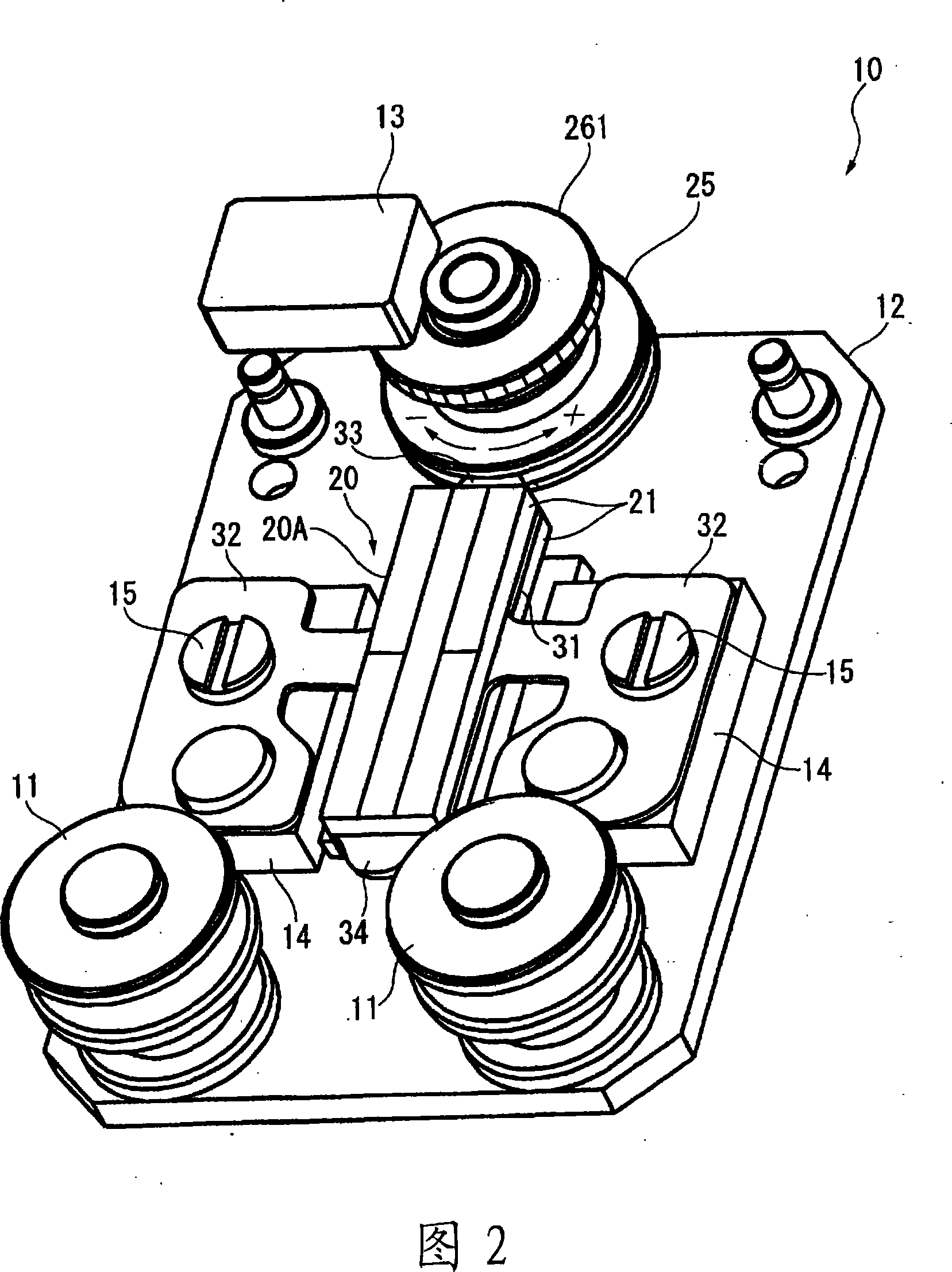

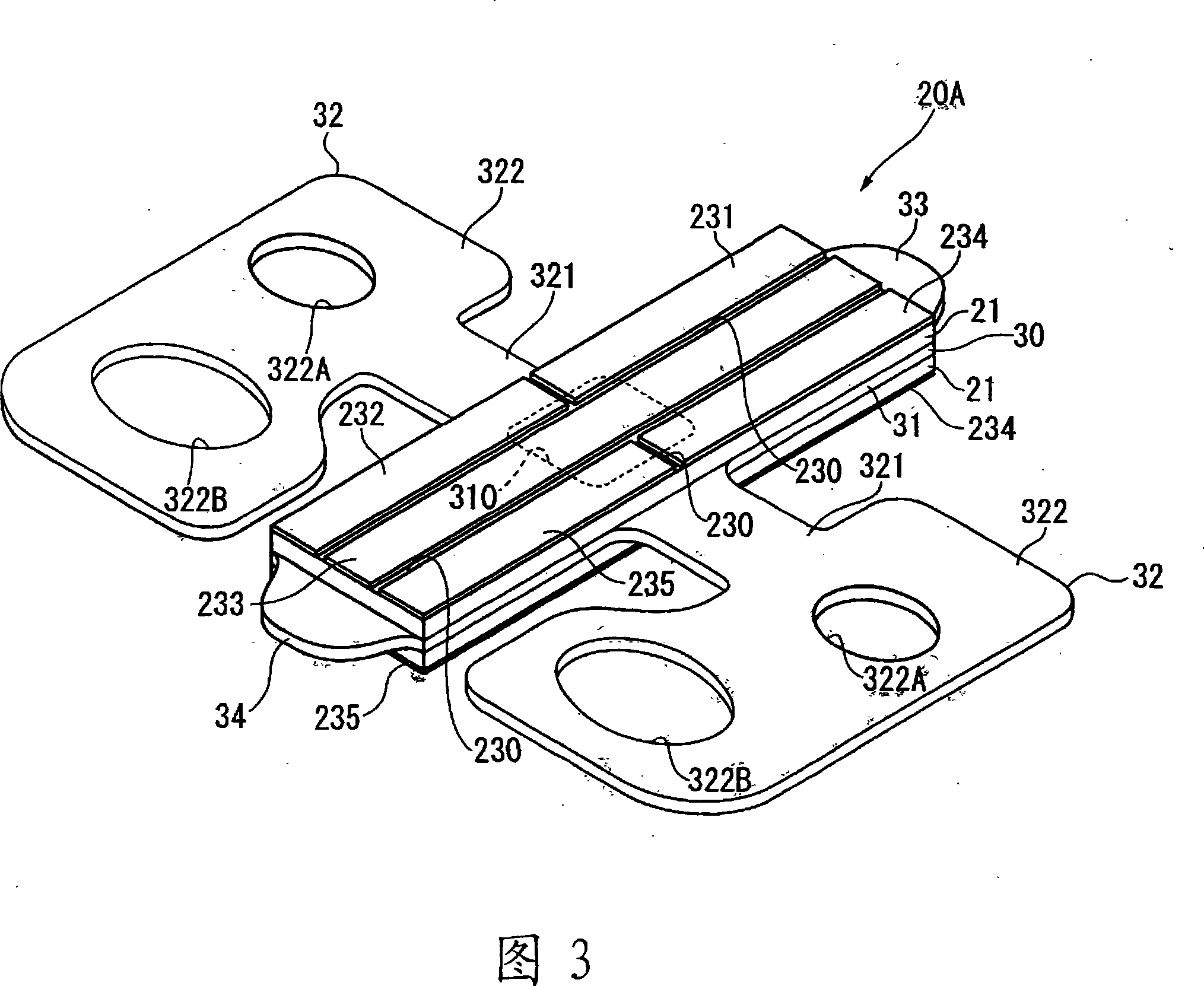

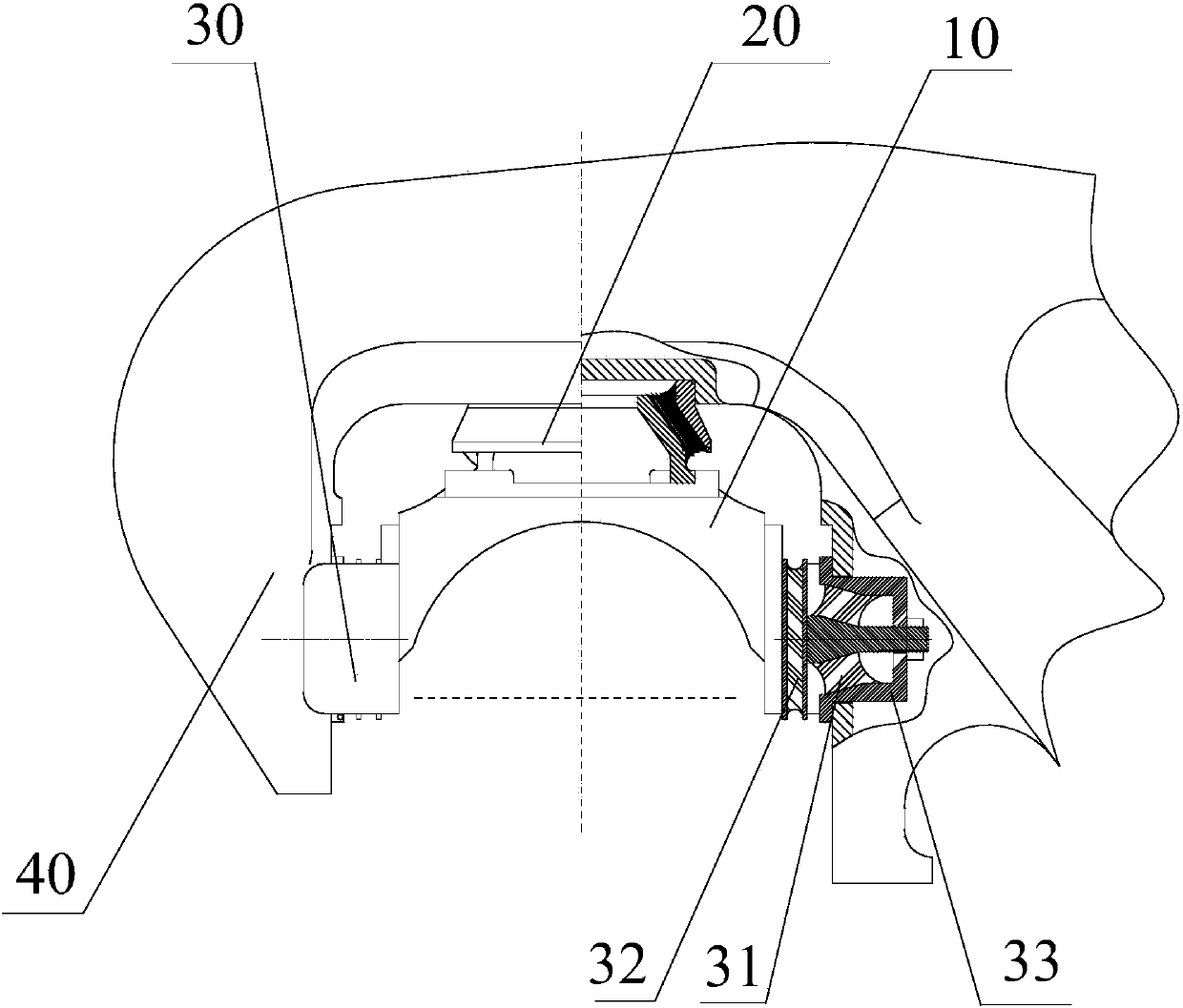

Piezoelectric transducer, piezoelectric actuator, and portable device

InactiveCN101247094AImprove driving efficiencyPiezoelectric/electrostriction/magnetostriction machinesElectric windingPiezoelectric actuatorsTransducer

The present invention provides a piezoelectric vibrating body, a piezoelectric driver, and a portable device. The piezoelectric vibrating body can greatly expand the amplitude, thereby greatly improving the driving efficiency. According to the investigation of the vibration energy density in the piezoelectric vibrating body (40A), through-holes (310) and hollow holes (411-414) are formed in the reinforcement plate main body (41). The part with the greatest deformation caused by longitudinal vibration or bending vibration. In this way, at the through hole and hollow hole formed at the position containing the largest deformation due to longitudinal vibration or bending vibration, the maximum vibration energy in the piezoelectric element (21) is exerted to realize the expansion of the amplitude, and at the same time, by strengthening The displacement of the piezoelectric element (21) toward the out-of-plane direction is restricted by the parts other than the through hole (310) and hollow holes (411-414) in the plate main body (41), so the amplitude of longitudinal vibration and bending vibration is reliable. to expand.

Owner:SEIKO EPSON CORP

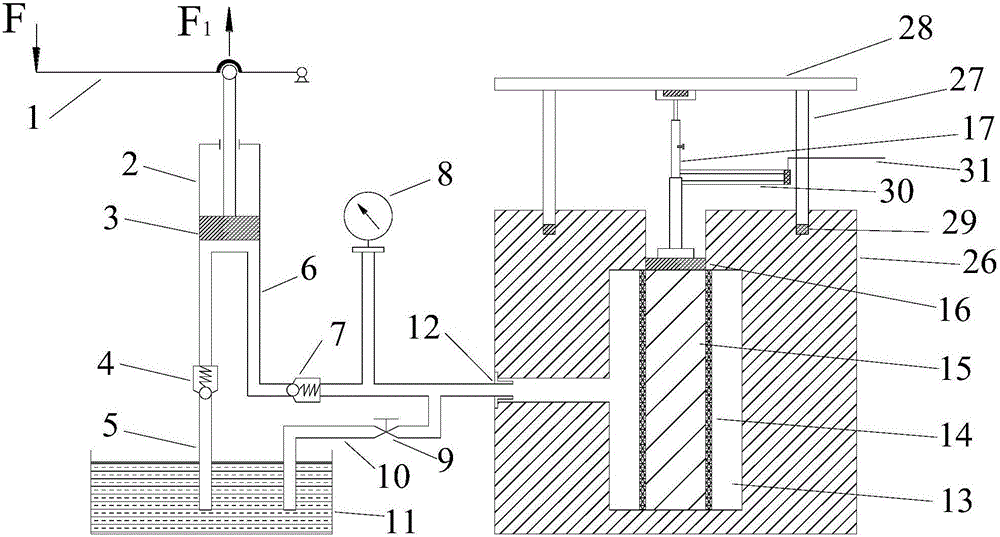

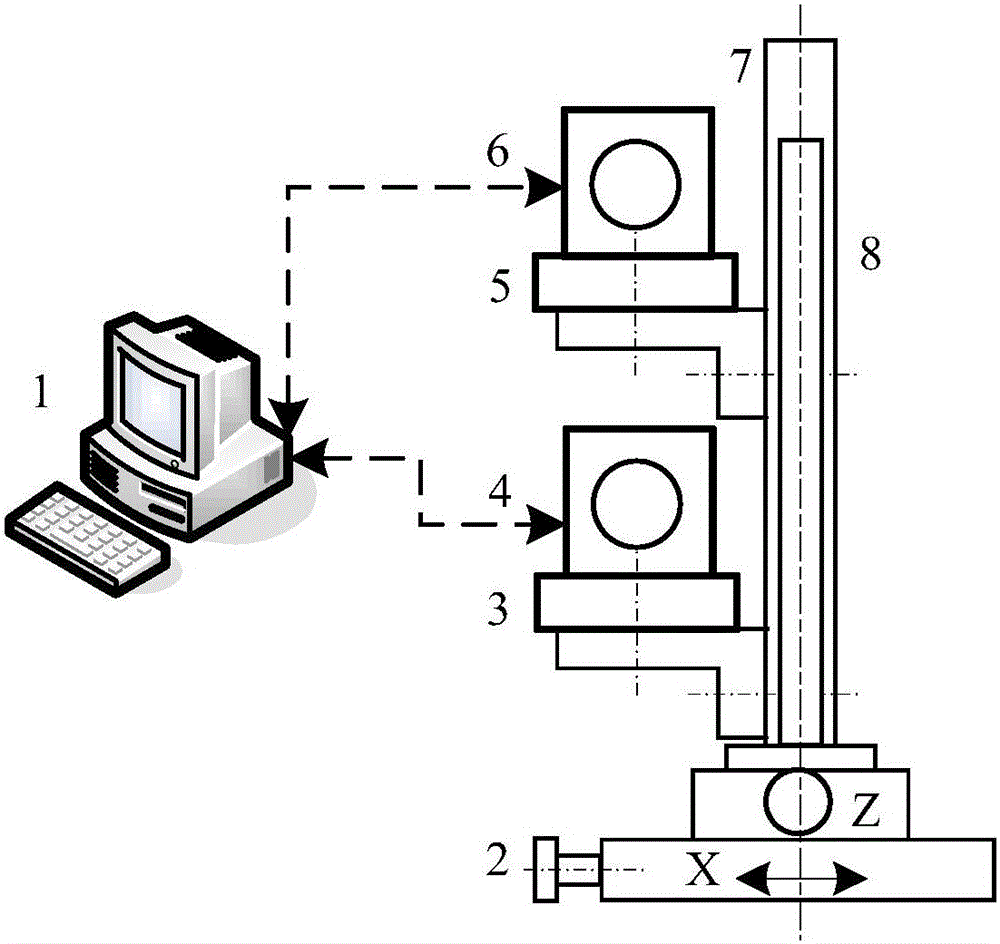

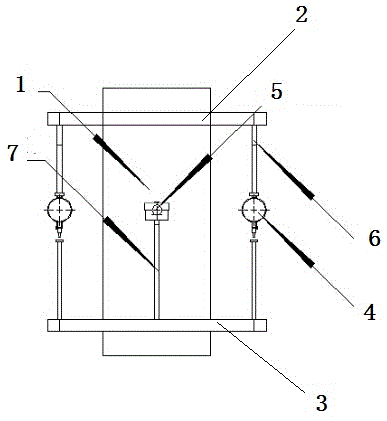

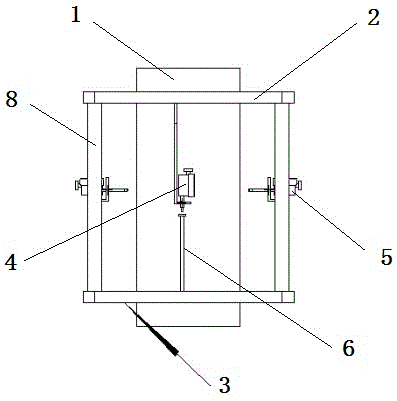

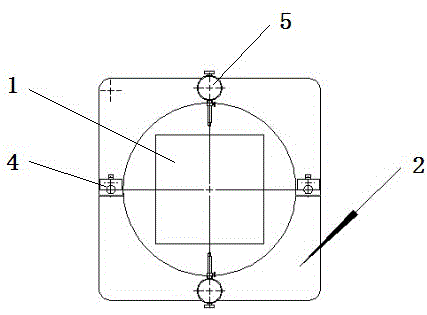

Lateral confining pressure adjustable rock lateral restraint expansion rate determination device

InactiveCN106018111AAdjustable lateral pressureHigh measurement accuracy of expansion deformationMaterial strength using tensile/compressive forcesData acquisitionEngineering

Provided is a lateral confining pressure adjustable rock lateral restraint expansion rate determination device. The device comprises a hydraulic cylinder, a piston is arranged in the hydraulic cylinder, and the hydraulic cylinder is connected with an oil tank, a pressure gauge and a lateral restraint pressure instrument through an oil inlet pipe and an oil outlet pipe respectively; up-and-down movement of the piston is controlled through a lever, oil in the oil tank is delivered into a closed chamber through a pipeline, contraction deformation of a rubber ring in the closed chamber is controlled, and lateral confining pressure is adjusted through a throttle valve; the lateral restraint pressure instrument is connected with a top plate through a supporting column, a telescopic rod is fixed on the top plate, a longitudinal displacement extensometer is arranged on the telescopic rod, access of a computer comprising a data collection system is achieved through a data line, longitudinal deformation of rock sample water swelling is collected in real time, and the rock expansion rate is obtained. According to the lateral confining pressure adjustable rock lateral restraint expansion rate determination device, the defects that for a traditional rock expansion rate experiment device, the lateral confining pressure cannot be controlled accurately, the deformation measurement precision is poor, and deformation and accurate reading are not synchronized are overcome.

Owner:ANHUI UNIV OF SCI & TECH

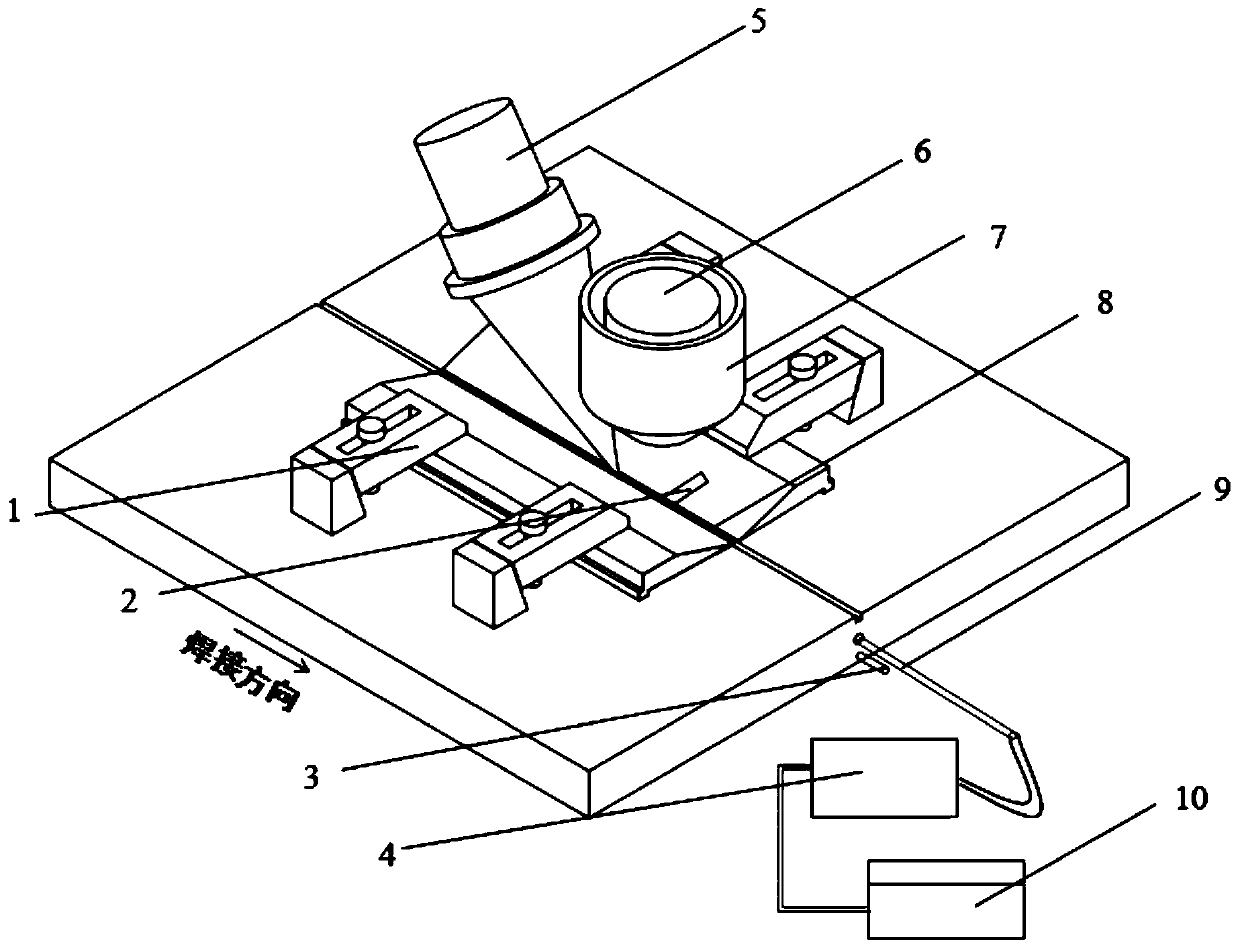

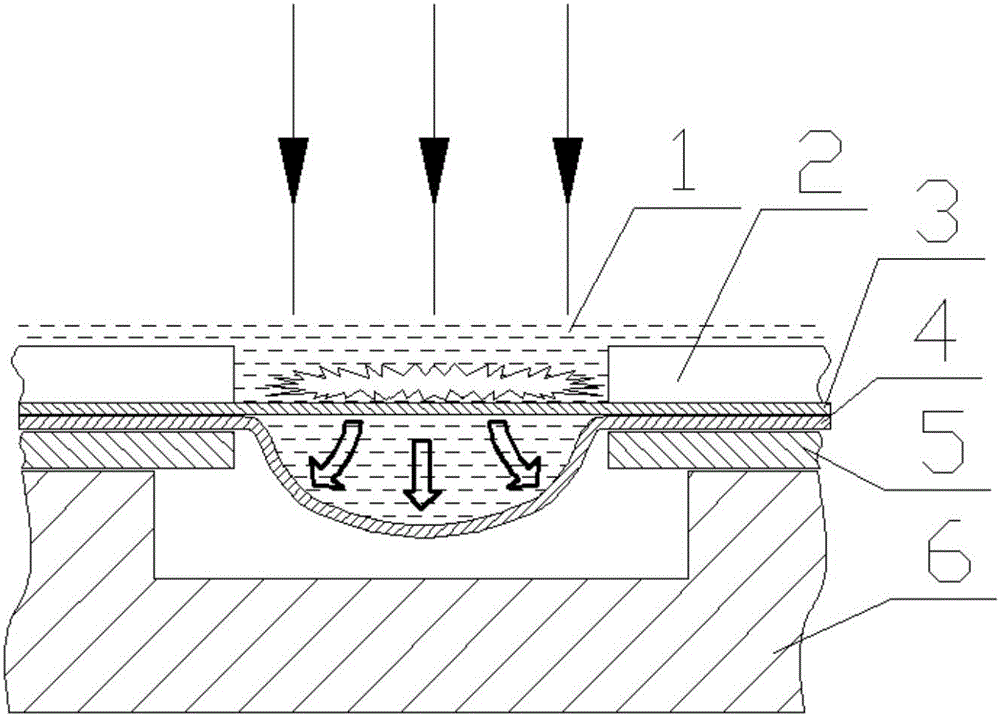

Laser welding method combining ultrasonic welding with chilling

ActiveCN110860795AReduce longitudinal residual stressReduce residual tensile stressLaser beam welding apparatusWelding residual stressUltrasonic welding

The invention belongs to the field of welding, and relates to a laser welding method combining ultrasonic welding with chilling. According to the method, cooling water is applied to the back surface of a welding seam with a certain distance behind a molten pool in the welding process, and ultrasonic vibration is applied to the front surface; the temperature and the flow of the cooling water are determined according to the welding mode used; and the ultrasonic application position, power and force are adjusted according to the mechanical properties of sample materials. According to the method,the welding residual stress can be effectively reduced, and air holes and cracks are reduced, so that the fatigue performance of the welding seam is improved, and meanwhile, transverse and longitudinal deformation of welding is reduced. Longitudinal residual stress and deformation can be effectively reduced through chilling and welding. The ultrasonic impact can counteract the transverse stress caused by chilling and welding, and further inhibit longitudinal stress, so that deformation is effectively reduced; and the acoustic streaming effect and cavitation effect of the ultrasonic can refinecrystal grains and reduce the air holes and cracks, so that the fatigue performance of the welding seam is improved.

Owner:DALIAN UNIV OF TECH

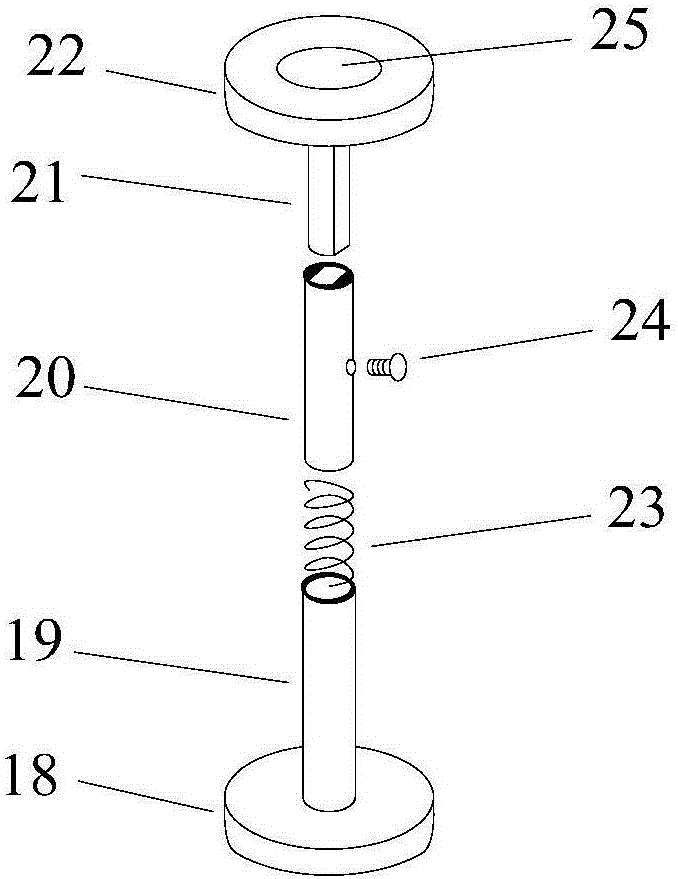

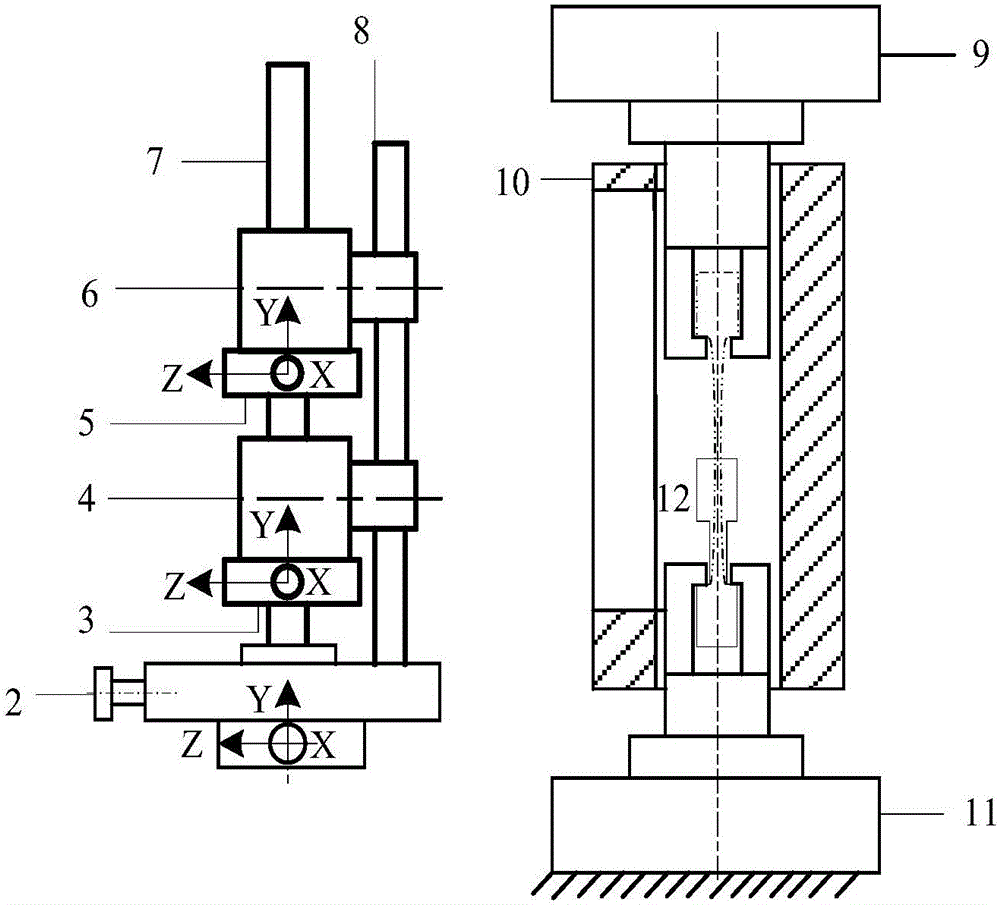

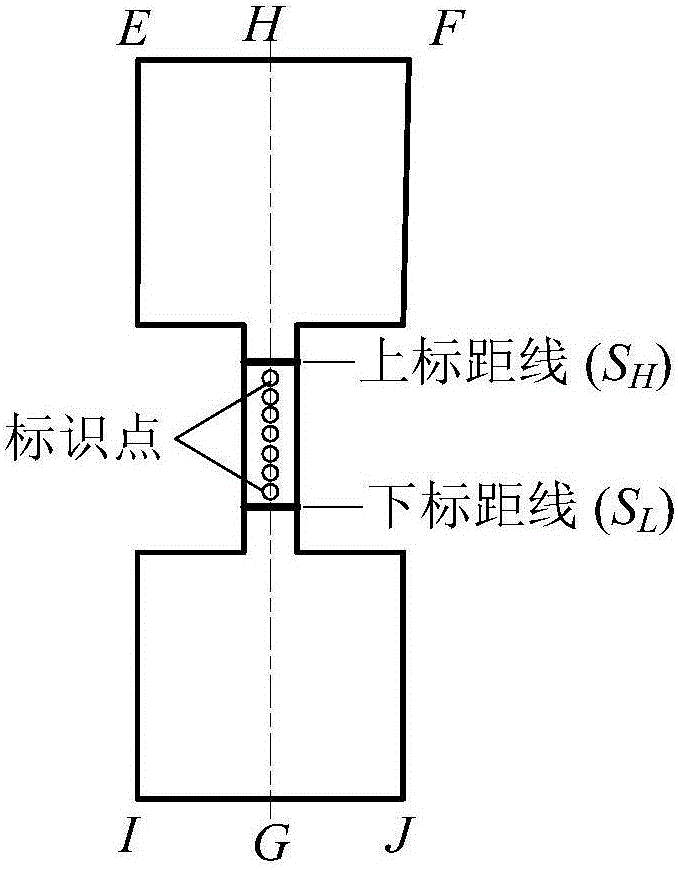

High-temperature superplastic tension large deformation measurement device and method

InactiveCN106124336AEasy CalibrationEasy to measureMaterial strength using tensile/compressive forcesMeasurement deviceTest sample

The invention provides a high-temperature superplastic tension large deformation measurement device and method and belongs to the technical field of instruments. Aiming at the problems in the prior art that errors of measuring deformation amount of superplastic tension test samples under a high-temperature condition are relatively large, the generation and development of necking cannot be judged and recorded and the like; the device comprises a high-temperature furnace tension mechanism and a deformation amount measurement mechanism; in a measurement process, a tension deformation process is recorded by two sets of cameras fixed on an adjustable tripod head; after calibration through steps including standard test sample calibration and the like, the sizes of transverse and longitudinal deformation of the tension test sample can be obtained through measuring the changes of image length and the errors can also be corrected to obtain a result which is closest to a real condition; the problems of the generation and development of necking and the like can be recorded through the device.

Owner:JILIN UNIV

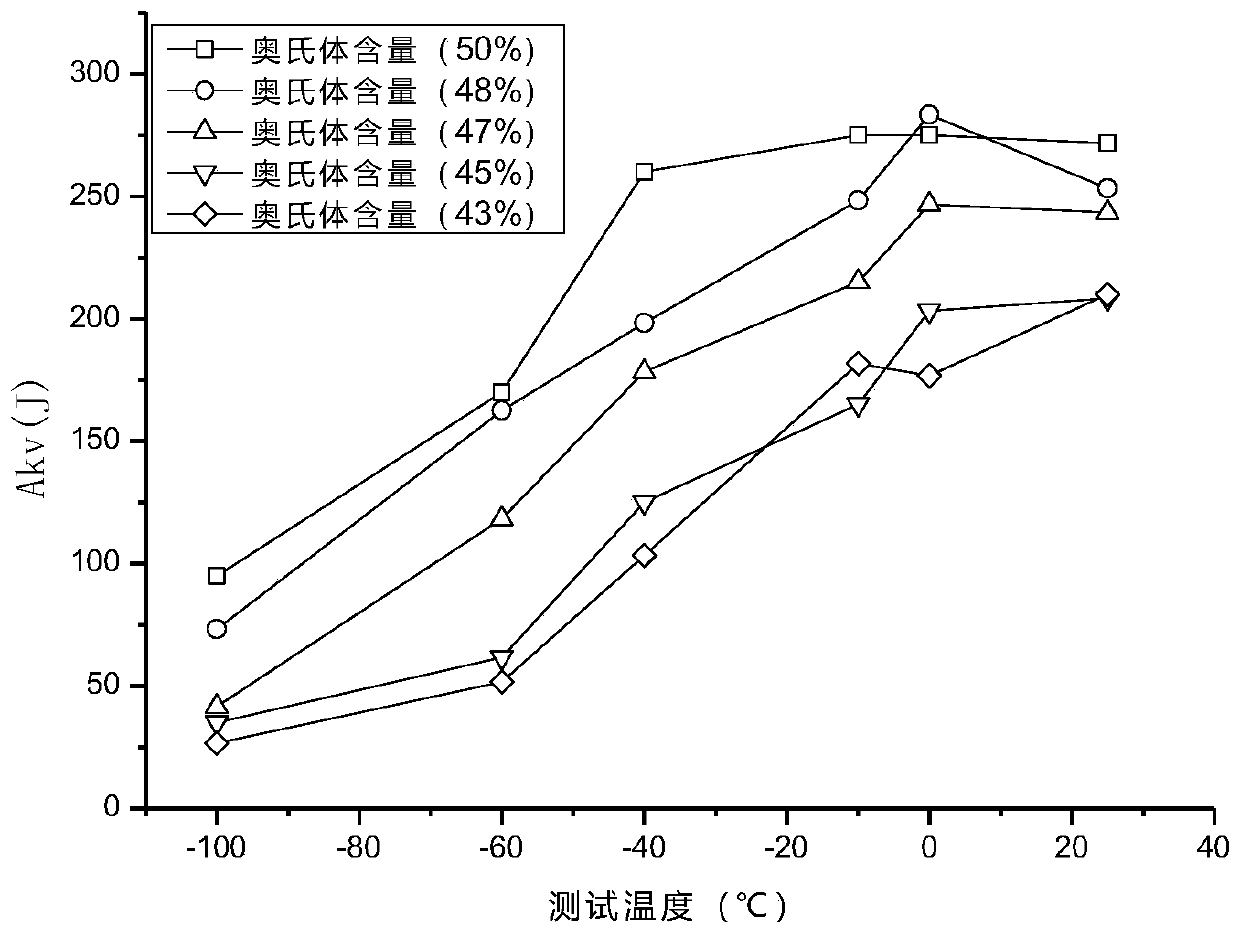

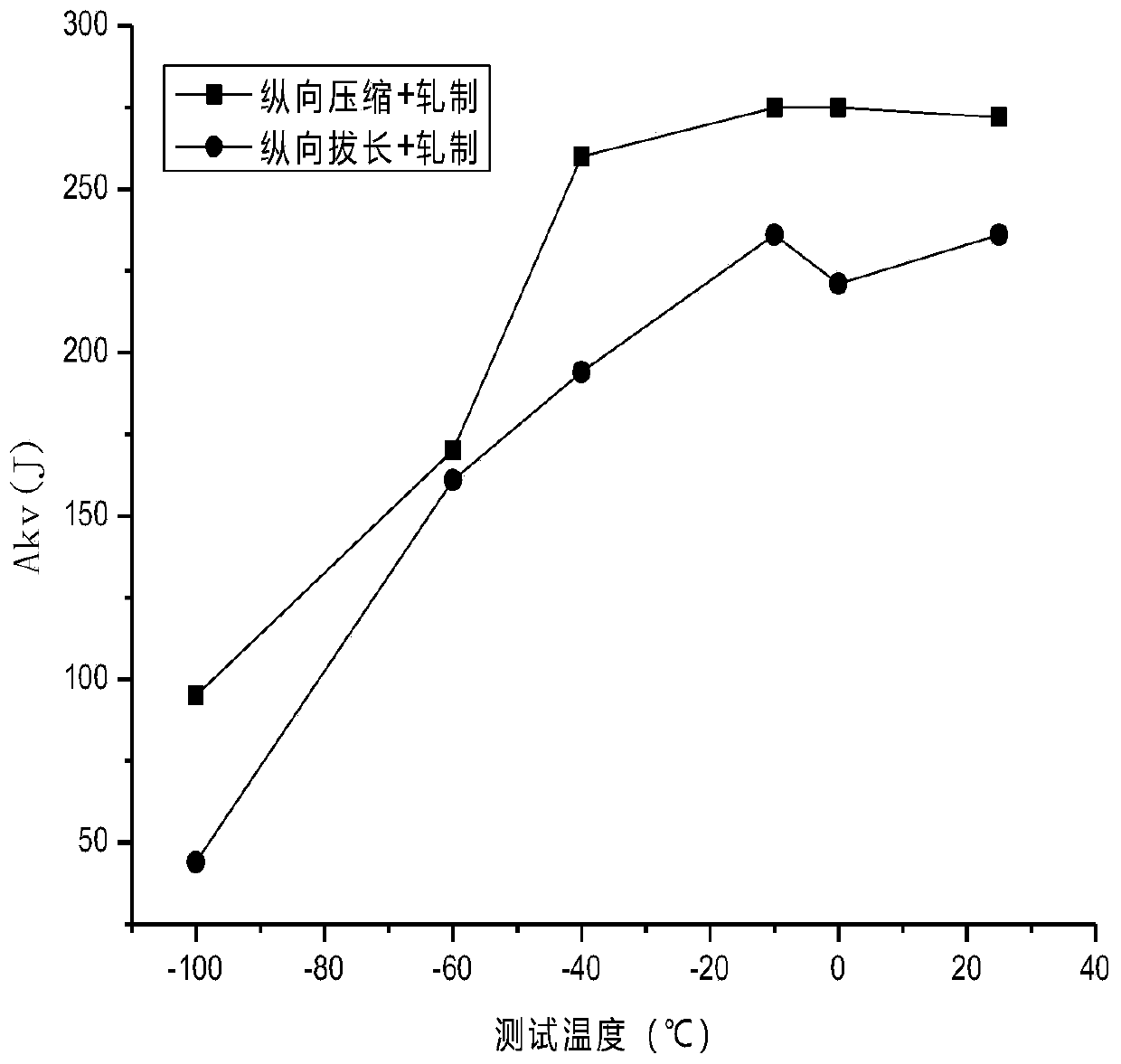

Process method for improving impact toughness of double-phase stainless steel

The invention relates to a process method for improving the impact toughness of double-phase stainless steel, and belongs to the technical field of stainless steel machining. The technical problems that double-phase stainless steel in the prior art is poor in toughness during low temperature, and the critical temperature at which the toughness of the double-phase stainless steel is remarkably reduced is high are solved. The method includes the following process steps that S1, metal raw materials are smelted into molten steel; S2, the molten steel is smelted into a continuous casting billet ora steel ingot with a continuous casting or die casting method; S3, the continuous casting billet or the steel ingot is heated at the temperature of 1,150-1,250 DEG C, hammer cogging is carried out, and a forging-state billet is manufactured; S4, the forging billet is heated at the temperature of 1,050-1,250 DEG C, the total deformation ratio of a finished product is larger than or equal to 5.0, the transverse deformation ratio / the longitudinal deformation ratio is larger than or equal to 0.30, and the length-width ratio of austenite is controlled to be 1.0-4.0; and S5, the product is subjectedto solution treatment, and the content of the austenite is controlled to be 46-55%. The process method is used for improving the low-temperature toughness of the double-phase stainless steel and reducing the critical temperature at which the toughness of the double-phase stainless steel is remarkably reduced.

Owner:CENT IRON & STEEL RES INST +1

Method of testing Poisson's ratio of concrete

ActiveCN104931352AEasy and fast testingAvoiding the pitfalls of lossy strain gaugesMaterial strength using tensile/compressive forcesConversion coefficientsStructural engineering

The invention relates to a method of testing Poisson's ratio of concrete. The method includes: performing testing by pressurizing in static elastic modulus test, selecting a concrete specimen of specified size, selecting a specified test area on the concrete specimen and a test scheme, placing transverse strain gauges at the centers of two opposing sides of the concrete specimen, placing longitudinal strain gauges at positions, determined distances away from the upper and lower end faces, on two longitudinal sides of the concrete specimen, precisely measuring and recording transverse deformation and longitudinal deformation, and calculating the Poisson's ratio of the concrete through the transverse deformation, the longitudinal transformation and a conversion coefficient. The method has the advantages that measuring is precise and fast, testing cost is lowered and repeatability is good.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

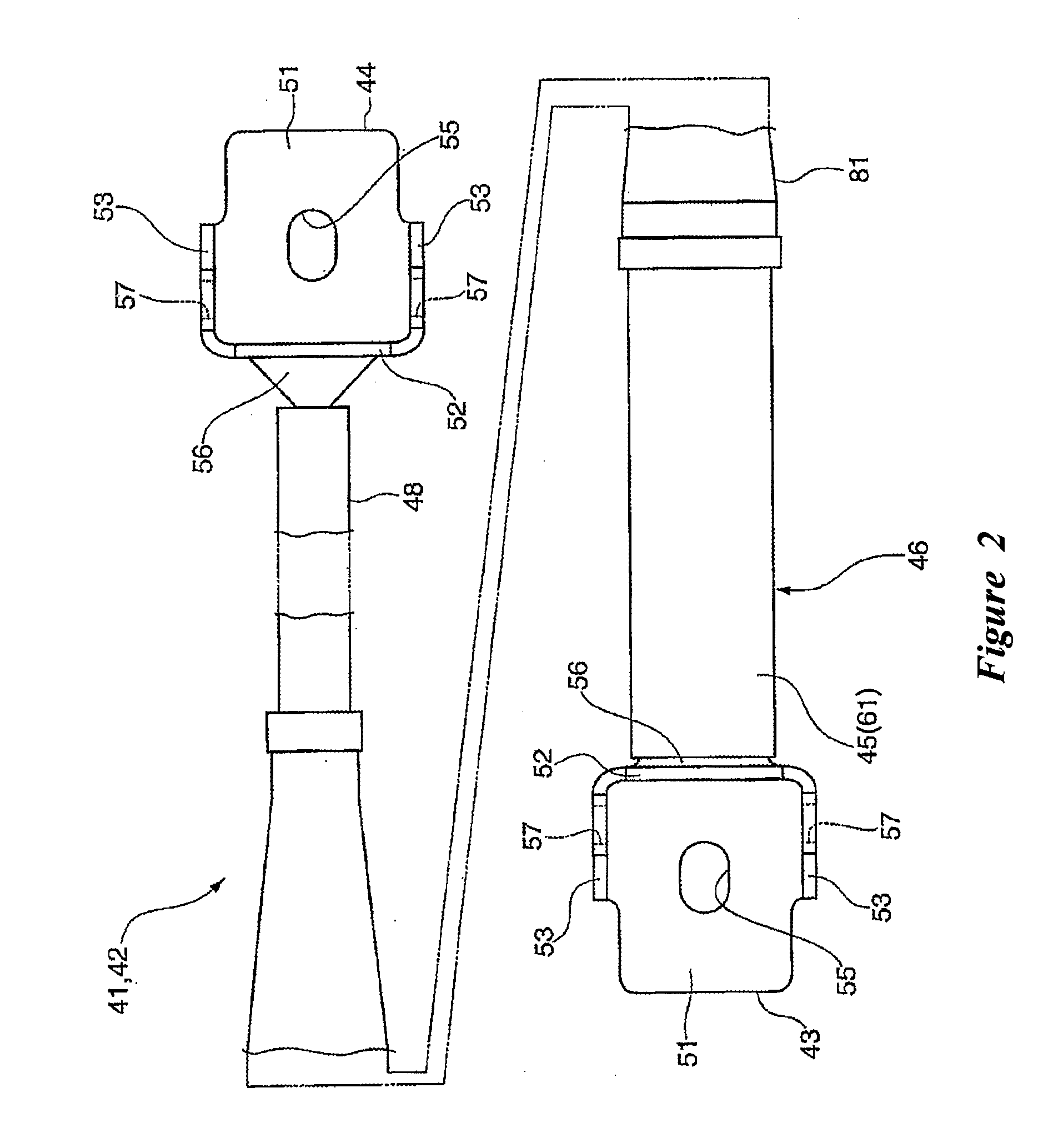

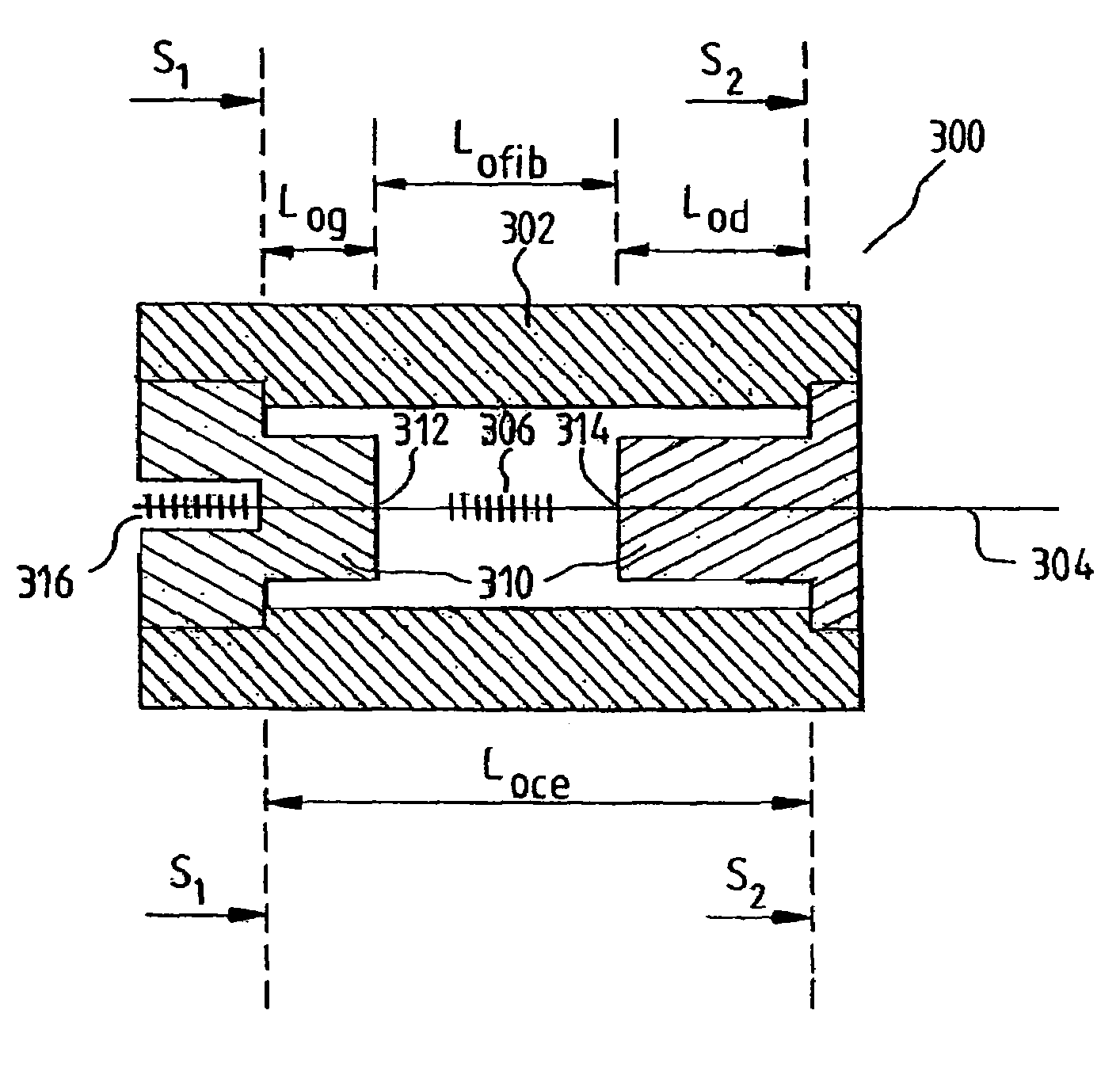

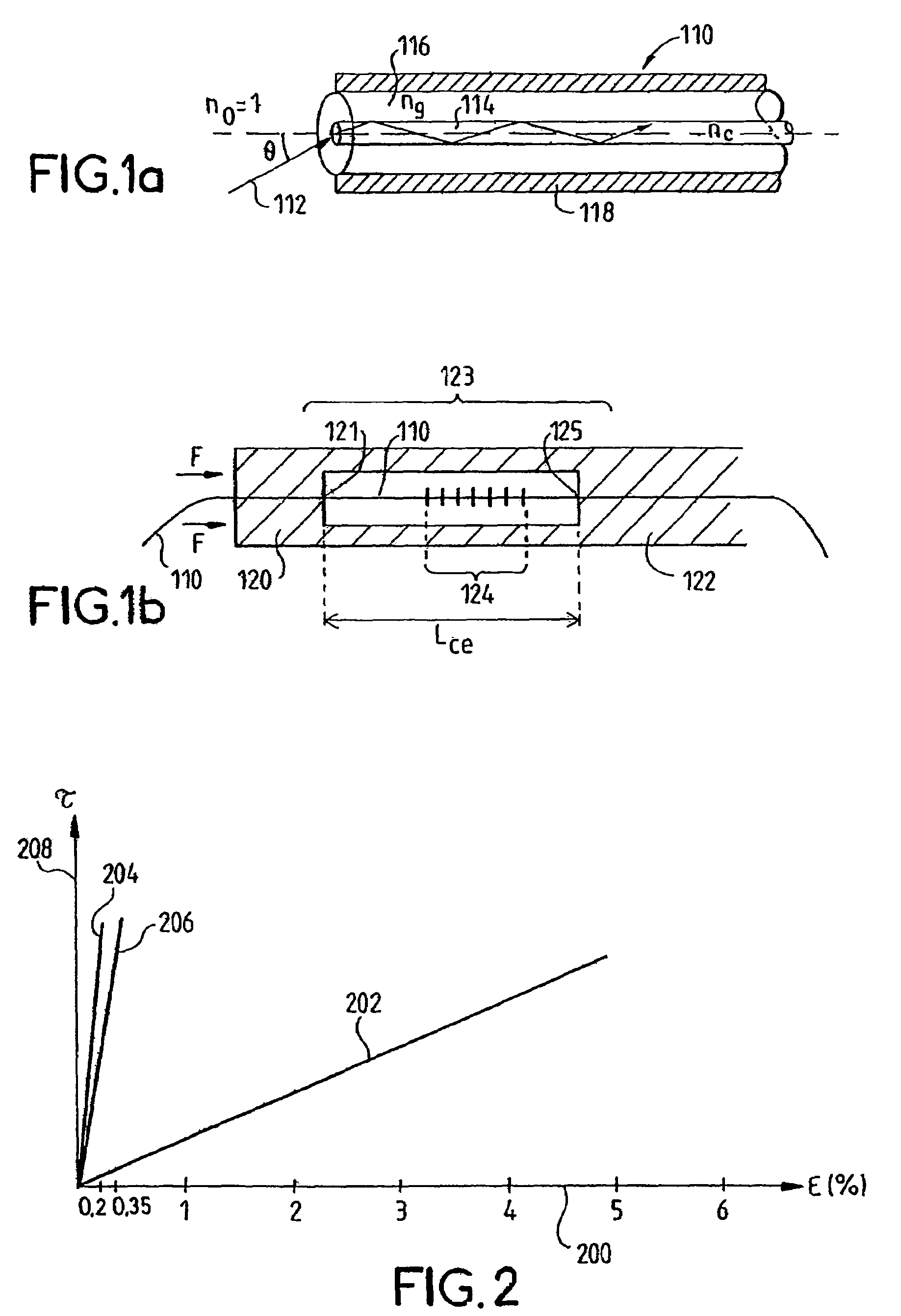

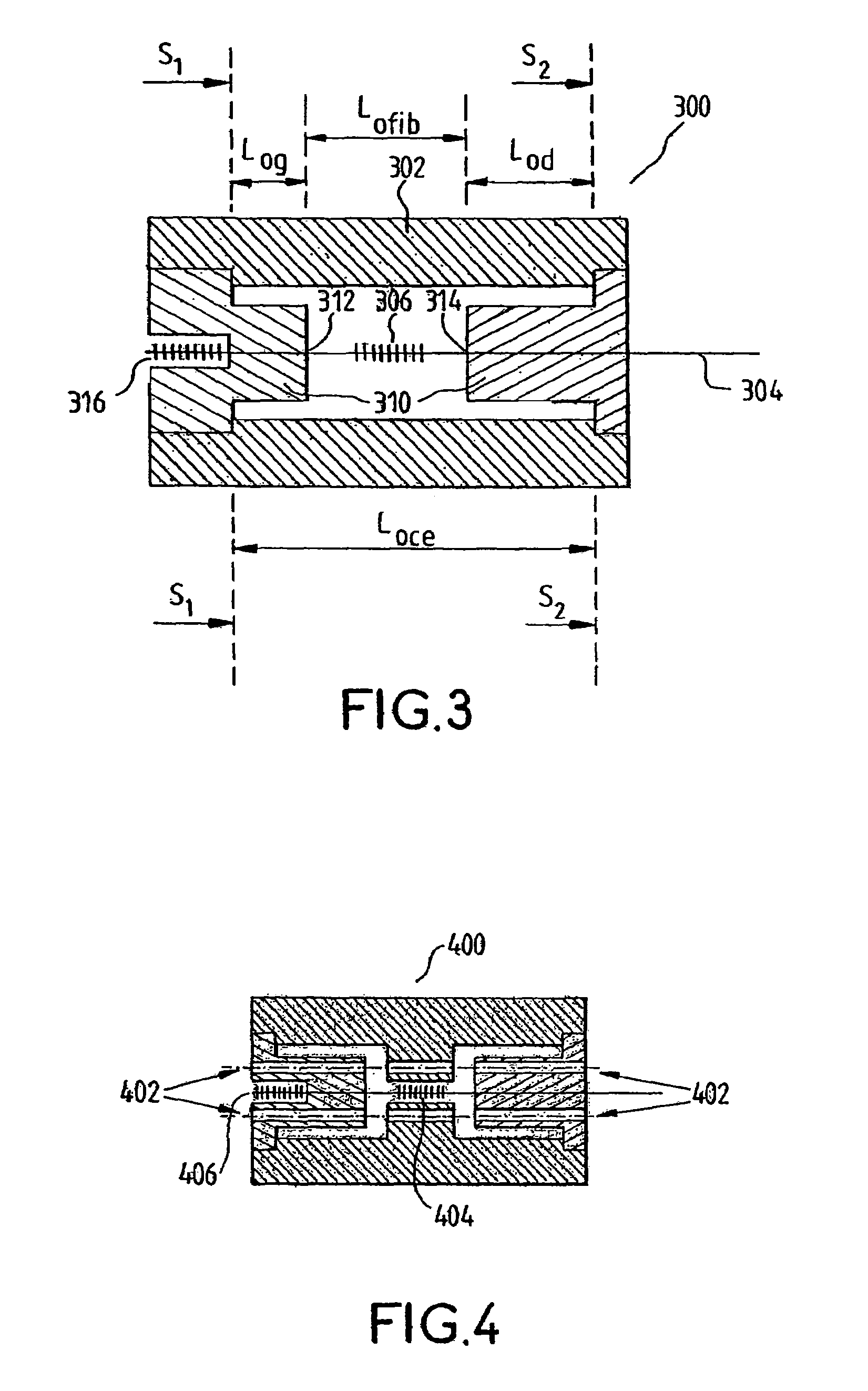

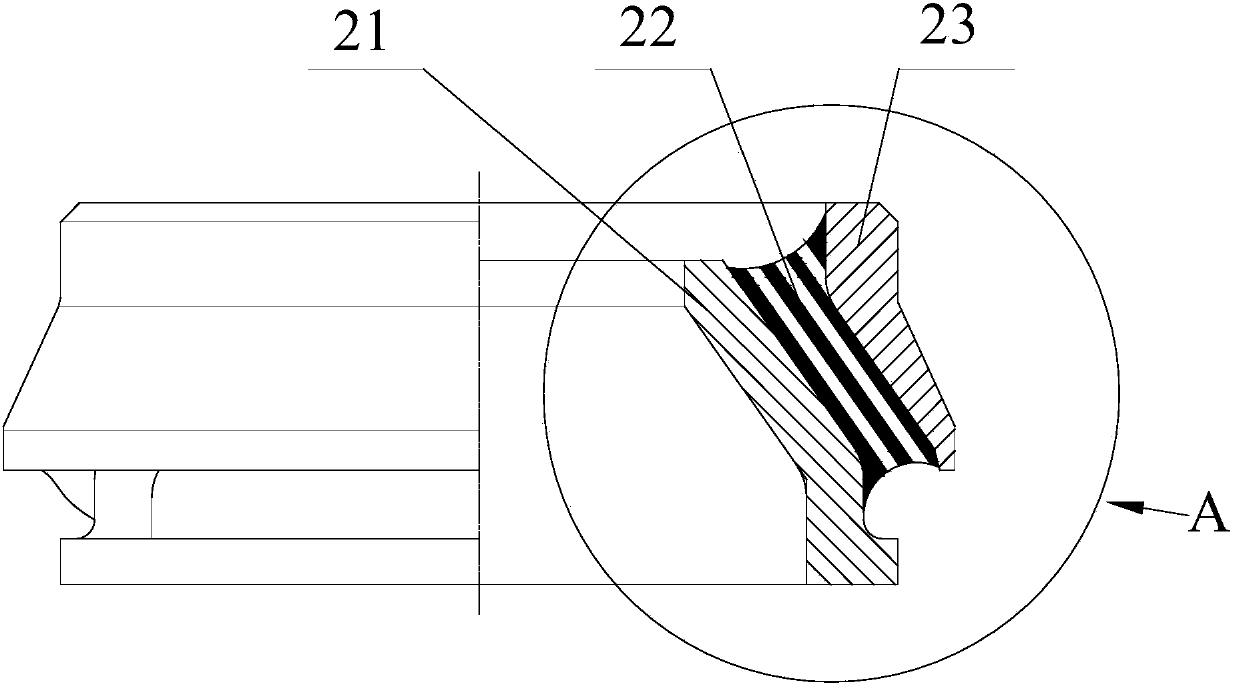

Uniaxial thermal and/or mechanical deformation-measuring device system and method employing a Bragg grating optical fibre

InactiveUS7406877B2Easy to measureIncrease in effective indexThermometers using material expansion/contactionForce measurement by measuring optical property variationFiberGrating

Uniaxial deformation-measuring device includes a section of optical fiber equipped with a Bragg grating aligned with the measurement axis, and a test body subjected to the deformations to be measured., this device includes the fixing points for attaching the fiber to the test body. The fixing points are separated by a distance (Lfib) having a variation (ΔLfib). When the test body is stressed by the deformation, the effective length (Lce) of the test body has an elongation (ΔLce). The length (Lfib) of the section of optical fiber and the effective length (Lce) of the measurement body are such that the longitudinal deformation (ΔLfib / Lfib) of the section of optical fiber is strictly greater than the originating deformation (ΔLce / Lce) of the test body, thus defining an amplification factor K which is strictly greater than 1 and which is equal to the quotient (ΔLfib / Lfib) / (ΔLce / Lce) in the first order.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

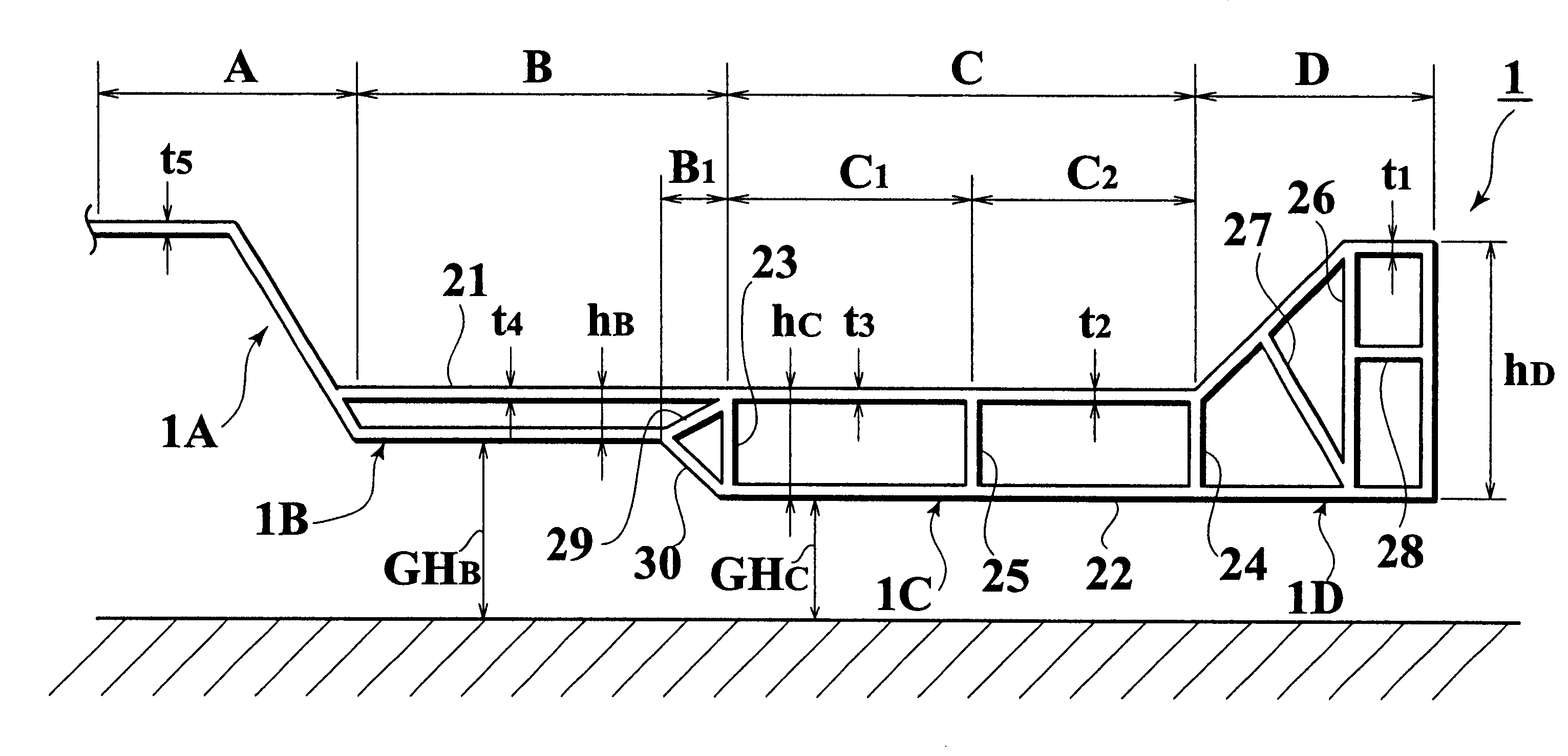

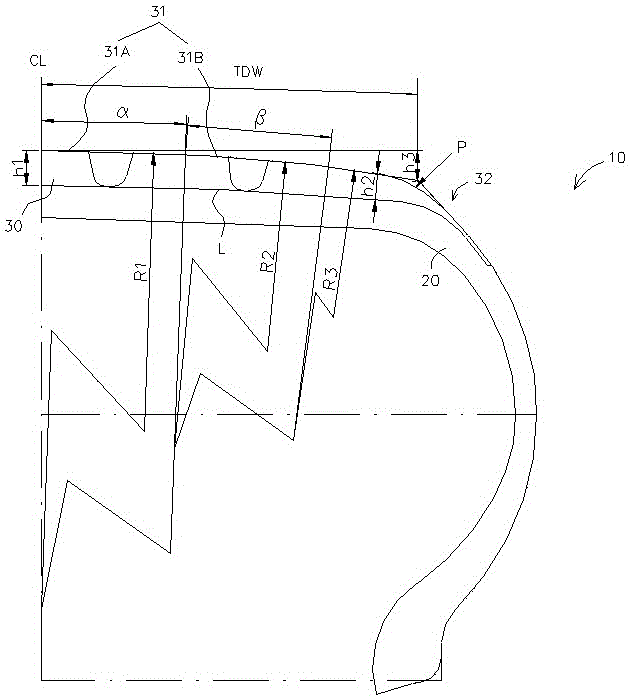

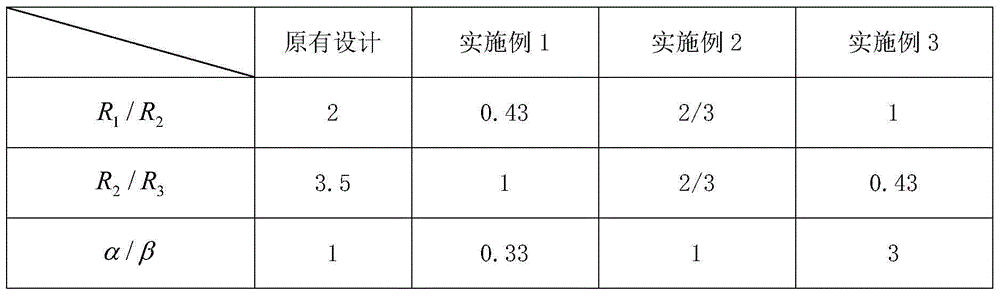

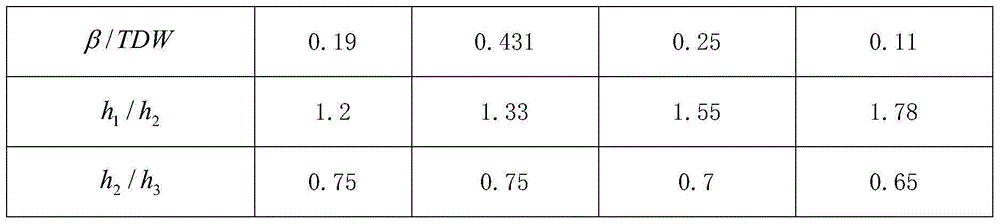

Inflatable car radial tire with low-rolling resistance tread contour

ActiveCN105059058ALower horizontalReduce longitudinal deformationSpecial tyresTyre tread bands/patternsRolling resistanceArc length

The invention provides an inflatable car radial tire with a low-rolling resistance tread contour. Under the condition that other properties of the tire are not reduced, the purposes of improving the grounding condition, improving the deformation when the tire is in contact with the ground as well as reducing the tire rolling resistance are achieved by improving and controlling the tire tread contour shape. The tire comprises a tread, and the contour of the tread is sequentially divided into a first-section crown arc and a second-section crown arc on a tire radial section from the intersection of a tire equatorial plane and a tire tread contour to a tire crown at the starting part of a tire shoulder; the outer diameter R1 of the first-section crown arc, the outer diameter R2 of the second-section crown arc and the outer diameter R3 of the tire tread contour at the tire shoulder have the following relationship: 0.43<=R1 / R2<=1 and 0.43<=R2 / R3<=1; and the arc length alpha of the first-section crown arc, the arc length beta of the second-section crown arc and the tread width TDW have the following relationship: 0.33<=alpha / beta<=3 and 0.11<=beta / TDW<=0.431. According to the invention, by controlling smooth transition from the tire crown to the tire shoulder, the uniform distribution of stress in the tire grounding process is ensured, the horizontal and longitudinal deformation of the tire in a running process is reduced, and the tire rolling resistance is reduced.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

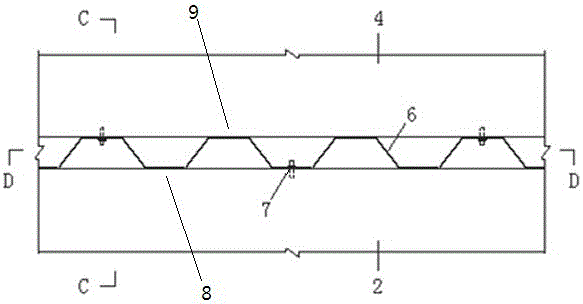

Bridge widening structure adopting corrugated steel sheet connecting parts and construction method thereof

ActiveCN106351132AAvoid shear damageEasy to useBridge erection/assemblyBridge strengtheningSheet steelHigh intensity

The invention relates to a bridge widening structure adopting corrugated steel sheet connecting parts and a construction method thereof. The bridge widening structure comprises a new bridge, an old bridge and a joint crack. The old bridge and the new bridge are transversely connected through the joint crack. The corrugated steel sheet connecting parts for connecting an edge beam flange plate of the old bridge and an edge beam flange plate of the new bridge are arranged in the joint crack. The corrugated steel sheet connecting parts comprise vertically-arranged corrugated steel sheets and bolts. The corrugated steel sheets are arranged between the edge beam flange plate of the old bridge and the edge beam flange plate of the new bridge and connected with the edge beam flange plate of the old bridge and the edge beam flange plate of the new bridge respectively through the bolts. Long-strip-shaped holes allowing the bolts to penetrate are formed in the straight sheet sections on the two sides of the corrugated steel sheets, and the bolts are friction type high strength bolts. According to the bridge widening structure, it can be guaranteed that longitudinal deformation of a main beam of the new bridge is not restrained by a main beam of the old bridge, transverse bridge direction bending deformation generated by the new bridge and the old bridge obtained after widening is reduced, shear failure of an old bridge support is avoided, and the use performance of the widened bridges is guaranteed; the construction period is shortened, and good economic benefits are achieved.

Owner:FUZHOU UNIV

Rigidity-variable positioning device for bogie axle box of railway vehicle

ActiveCN103693063ASimple structureImprove general performanceAxle-boxes mountingHorizontal forceElastomer

A rigidity-variable positioning device for a bogie axle box of a railway vehicle comprises a vertical elastomer and longitudinal elastomers. The vertical elastomer is arranged between the top face of an axle box bearing saddle and the bottom face of a side-rack guide frame. The longitudinal elastomers are arranged between the axle box bearing saddle and the front lateral side as well as the back lateral side of the side-rack guide frame respectively. Each longitudinal elastomer at least comprises a low-rigidity elastic element and a high-rigidity elastic element. The low-rigidity elastic elements are arranged in elastomer pre-compressing devices and are connected with the large-rigidity elastic elements in series under the action of pre-compressing loads F1. The longitudinal elastomers have large longitudinal compression rigidity on the condition of small longitudinal deformation and displacement quantity, and can ensure the railway vehicle to have a high snakelike critical speed during linear running to meet the need of accelerated running of the vehicle; the longitudinal rigidity of the longitudinal elastomers starts to decrease on the condition that the longitudinal deformation and displacement quantity reaches a preset level, so that proper horizontal force between wheel tracks when the railway vehicle runs on curved tracks can be guaranteed, and further, safety in curve running of the vehicle is guaranteed.

Owner:CRRC YANGTZE CO LTD

Preparation method of TC4 wide and thick plate with excellent comprehensive performance

The invention relates to a preparation method of a TC4 wide and thick plate with excellent comprehensive performance, and belongs to the technical field of hot working forming of titanium alloy. The technical problem to be solved is that the lateral and longitudinal deformation amount is large in the rolling process, and the product performance anisotropy is prominent. The preparation method of the TC4 wide and thick plate includes heating a TC4 blank by using a walking beam furnace; adopting the mode of lateral rolling combined with longitudinal rolling for first rolling to obtain an intermediate blank; middle shearing the intermediate blank, heating and warming the blank and then conducting second rolling in the mode of the lateral rolling combined with the longitudinal rolling; finallyconducting annealing straightening heat treatment to obtain a TC4 wide and thick plate product. According to the preparation method, the total lateral and longitudinal deformation of the blank can beclose to minimize the performance anisotropy to the greatest extent and obtain a wide TC4 plate product with uniform equi-axial structure cross-section and the comprehensive performance.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

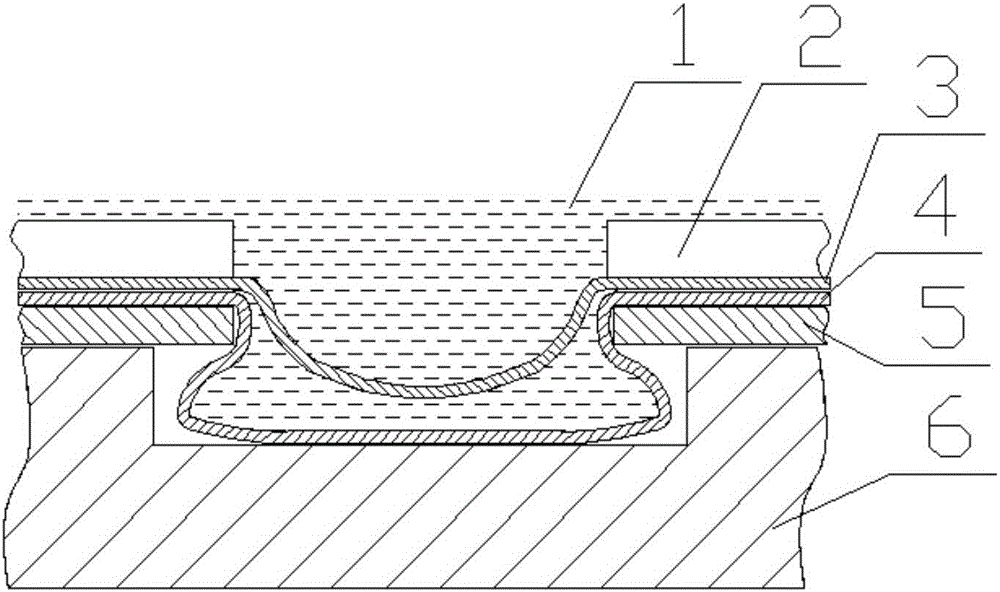

Laser-driven hydro-bugling board riveting method and structure

ActiveCN106392320AAchieve rivetingLarge amount of interlock embeddedWelding/soldering/cutting articlesMetal working apparatusEngineeringLaser light

The invention relates to a laser-driven hydro-bugling board riveting method and structure, and belongs to the field of advanced laser manufacturing. The laser-driven hydro-bugling board riveting method mainly comprises the steps that A, a lower board is placed on a forming mold provided with a groove, and the lower board is provided with a through hole; B, an intermediate board is placed on the lower board, and the intermediate board is provided with a bump located in the through hole; C, liquid is injected into the bump, and an upper board is placed on the intermediate board; D, the upper board is pressed by means of a pressing device; and E, the upper board is impacted through laser light, so that the upper board deforms downwards, impact force is transmitted to the bump through the liquid in the bump, the bump is made to generate transverse and longitudinal deformation towards the space below the through hole, and thus the intermediate board and the lower board are riveted. According to the laser-driven hydro-bugling board riveting method and structure, unidirectional impact force is changed into multidirectional force through the liquid, high-strength riveting of different boards is achieved by means of simple equipment, and the cost is extremely low.

Owner:SHANDONG UNIV

Tire deformation online testing device and testing method based on light streams

InactiveCN103884293ASimple structureEasy to integrateUsing optical meansTyre measurementsMicrocontrollerVehicle dynamics

The invention provides a tire deformation online testing device and a testing method based on light streams. Instantaneous measurement of a deformed tire body during running can be achieved, and slip angles, slip rate and other motion information and tire lateral force, aligning toque, longitudinal force and other force information of tires can be obtained through data processing and model calculation. The testing device consists of a light stream sensor, a lens bracket, a lens, a light reflecting surface, a single chip microcomputer, a light source, a wireless transmission module and a battery. By adopting the testing device, in-tire longitudinal deformation measurement and in-tire lateral deformation measurement can be performed based on the light stream sensor. The testing device and the testing method can provide real-time tire body deformation information in all directions for chassis electric control systems of passenger vehicles and commercial vehicles, corresponding tire force and tire-road-surface adhesion information can be obtained by further combining the tires and whole vehicle dynamics, and accordingly the chassis electric control performance and whole vehicle safety are improved. The tire deformation online testing device is simple in structure, easy to integrate, low in cost, suitable for mass production and high in efficiency.

Owner:JILIN UNIV

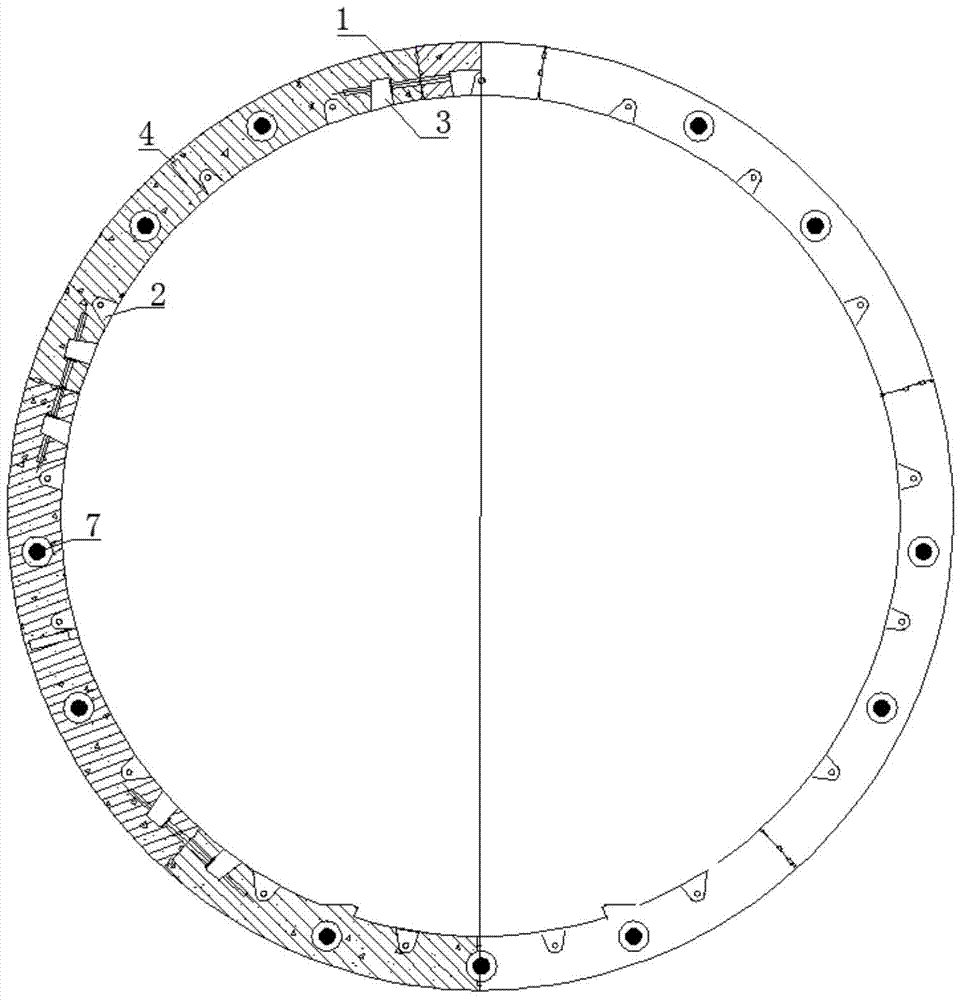

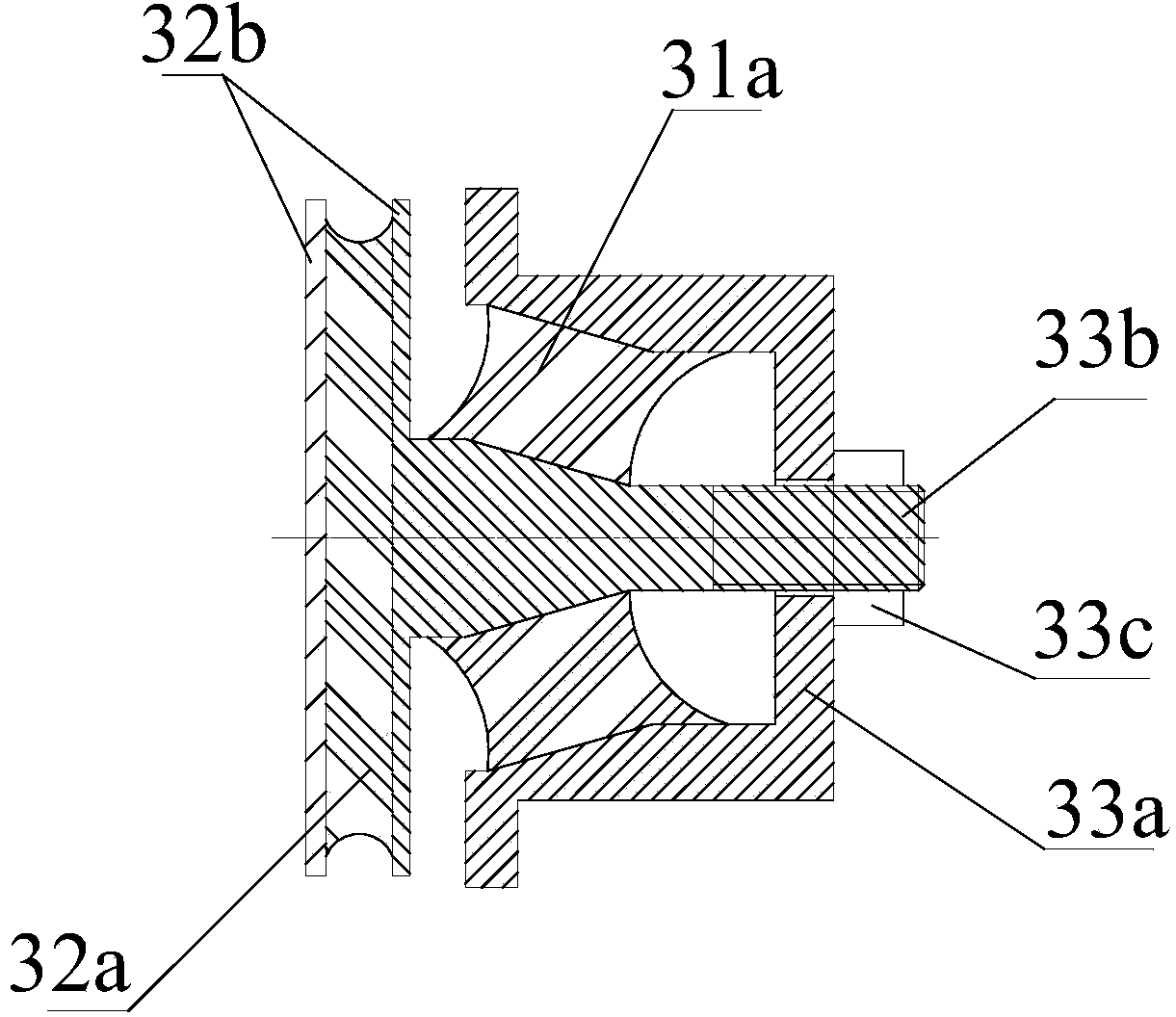

Shield tunnel duct piece both-way prestress strengthening device and construction method

ActiveCN105401957AAvoid DrawbacksTo achieve reinforcementUnderground chambersTunnel liningPre stressUltimate tensile strength

The invention discloses a shield tunnel duct piece both-way prestress strengthening device and a construction method. The device comprises a plurality of sets of combined duct pieces arranged in the circular direction, and at least one ring of special duct piece is arranged in the middle of each combined duct piece. A plurality of sets of ordinary duct pieces coaxial with the combined duct pieces are arranged between the adjacent combined duct pieces. A stress ring is embedded in each ring of special duct piece. Each stress ring comprises at least two sections of half stress rings. The two stress rings, the same in position, on every two adjacent combined duct pieces are connected through a fastening structure. The shield tunnel duct piece both-way prestress strengthening device has the beneficial effects that the stress rings are arranged in the circular direction of the duct pieces, the duct pieces are supported through the stress rings in the circular direction, and the strengthening of the duct pieces in the circular direction is achieved; in the longitudinal direction of the duct pieces, the duct pieces are tightly extruded through steel strands, and uneven longitudinal deformation of the tunnel duct pieces is limited; longitudinal and circular-direction strengthening is carried out on the duct pieces at the same time, a simply supported beam effect is formed through the duct pieces within a certain length range, the uneven settlement or uneven load resisting capability of the duct pieces is improved, and the strength of the shield tunnel duct pieces is improved.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com