Unidirectional lead core rubber vibration insulation support

A lead-rubber bearing and rubber technology, which is applied to bridge parts, bridges, buildings, etc., to achieve the effects of reasonable structure, cost saving, and wide range of application objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

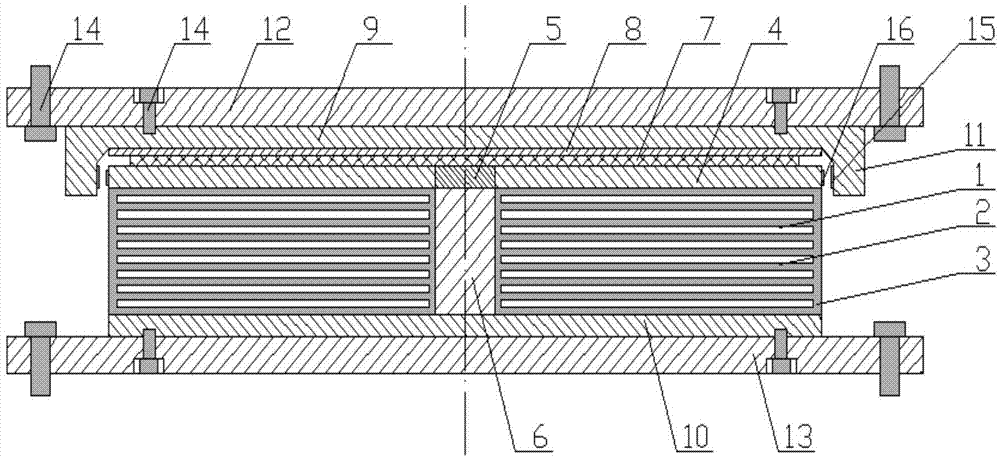

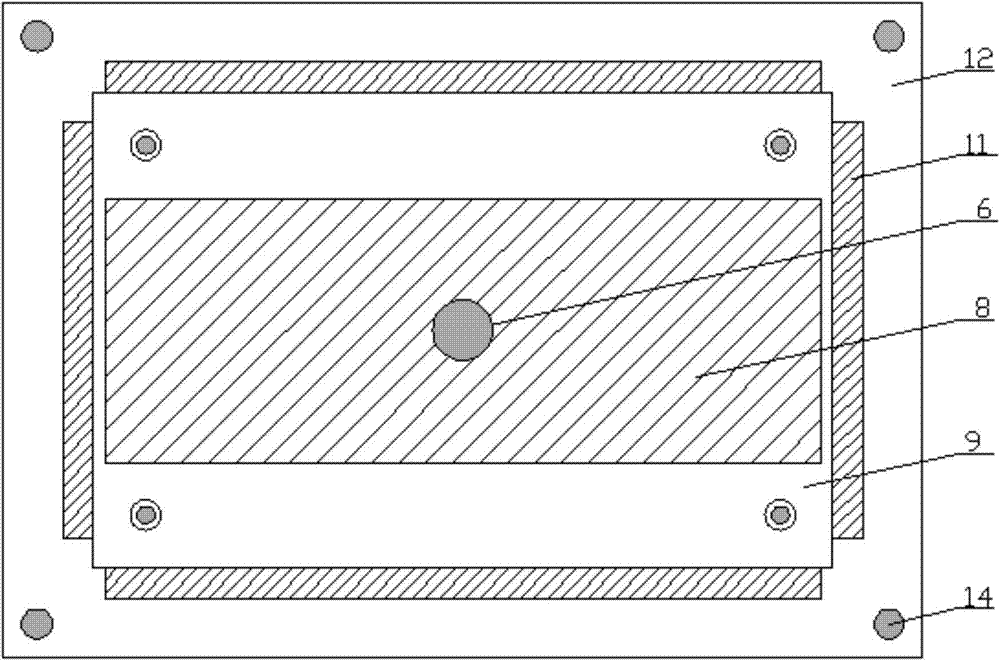

[0024] Such as figure 1 , 2 As shown, a one-way shock-absorbing and isolating lead rubber bearing includes sandwich steel plate 1, sandwich rubber 2, outsourcing rubber 3, upper sealing plate 4, cover plate 5, lead core 6, polytetrafluoroethylene slide plate 7, stainless steel Plate 8, upper support plate 9, lower support plate 10, limit plate 11, upper connecting plate 12, lower connecting plate 13, anchor bolt 14, lateral stainless steel bar 15, guide slide bar 16, the sandwich steel plate 1 Set at intervals with the interlayer rubber 2 to form a laminated structure with reserved holes in the middle, the top and bottom layers of the laminated structure are interlayer rubber 2, the upper sealing plate 4 is arranged on the upper layer of the laminated structure, and the lower support plate is arranged below 10. Outsourcing rubber 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com