Process method for improving impact toughness of double-phase stainless steel

A technology of duplex stainless steel and process method, which is applied in the field of stainless steel processing, can solve the problems of duplex stainless steel such as reduced toughness, high critical temperature, and poor toughness, and achieve the effects of improving overall toughness, improving impact toughness, and high impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

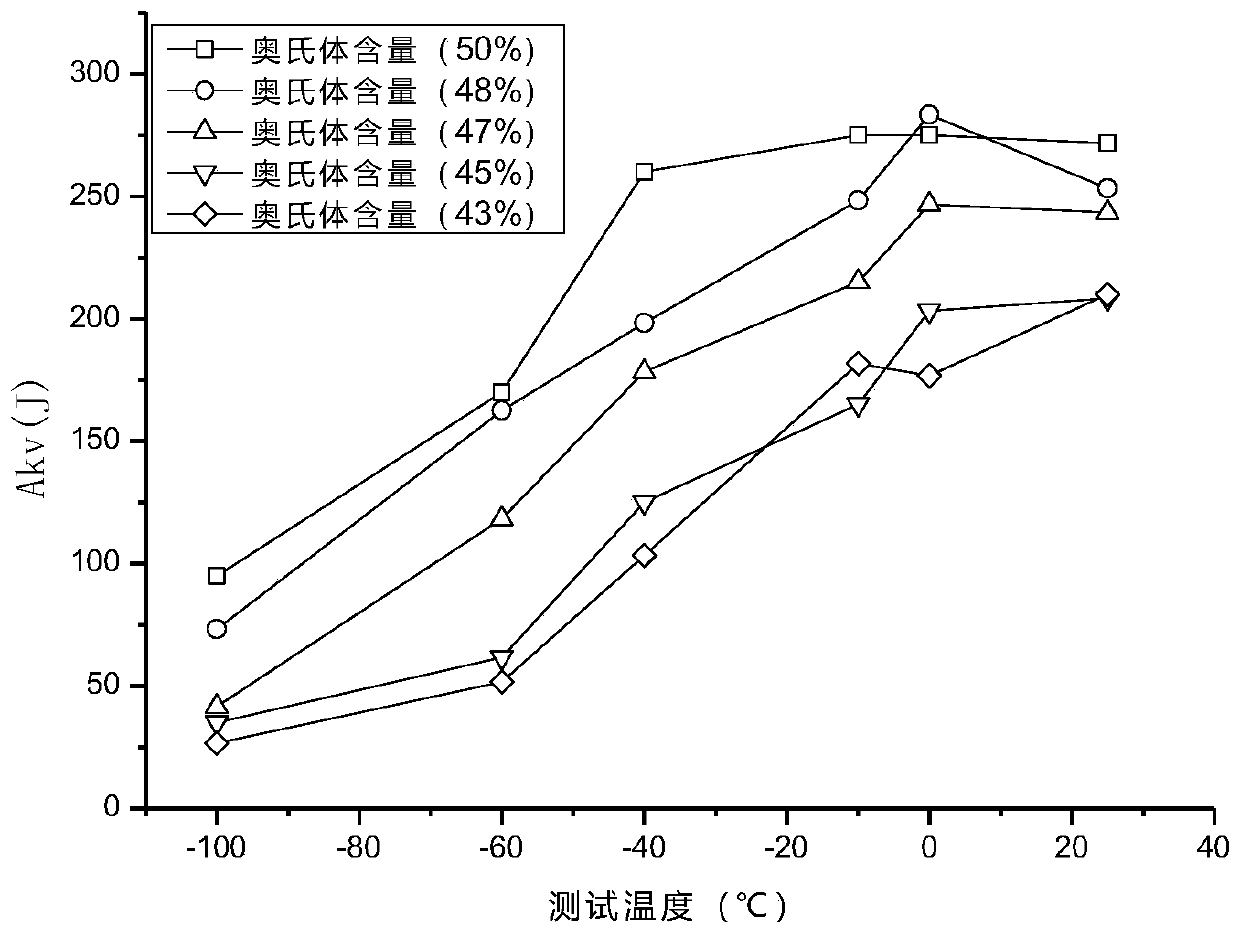

[0053] In this example, solid solution treatment is carried out at 1050-1100°C, and the austenite content is controlled at 45-55% and the N α / N γ ≤0.12.

[0054] S32750 duplex stainless steel molten steel is smelted by EAF+AOD+LF, poured into steel ingots, subjected to compression deformation along the longitudinal direction with a deformation ratio of 1.5, and then subjected to elongation deformation along the longitudinal direction with a deformation ratio of 7.0 to make a forged billet.

[0055] Cut S32750 duplex stainless steel plate-shaped test billet, its chemical composition and content (wt%) are: C: 0.02; Cr: 25.22; Ni: 7.15; Mo: 3.94; N: 0.27; Mn: 0.63; Si: 0.48; Cu: 0.22; the rest is Fe and unavoidable impurities. After solution treatment at different temperatures (1050, 1070, 1100, 1150, 1200°C), duplex stainless steels with different structures are prepared. The transverse V-type impact toughness was measured at room temperature, 0°C, -10°C, -40°C, -60°C, -100°C...

example 2

[0070] In this embodiment, the aspect ratio of the austenite is controlled between 1.0 and 4.0 by controlling rolling deformation.

[0071] S32750 duplex stainless steel molten steel is smelted by EAF+AOD+LF, poured into steel ingots, subjected to compression deformation along the longitudinal direction with a deformation ratio of 1.5, and then subjected to elongation deformation along the longitudinal direction with a deformation ratio of 7.0 to make a forged billet.

[0072] Cut S32750 duplex stainless steel plate blank, its chemical composition and content (wt%) are: C: 0.02; Cr: 25.22; Ni: 7.15; Mo: 3.94; N: 0.27; Mn: 0.63; Si: 0.48; Cu : 0.22; the rest is Fe and unavoidable impurities), and according to Figure 2-1 Transverse or longitudinal rolling as shown, marked as "transverse rolling" and "longitudinal rolling", with a deformation ratio of 1.5, was made into test billets with different austenitic aspect ratios, the ratio of lateral deformation / longitudinal deformatio...

example 3

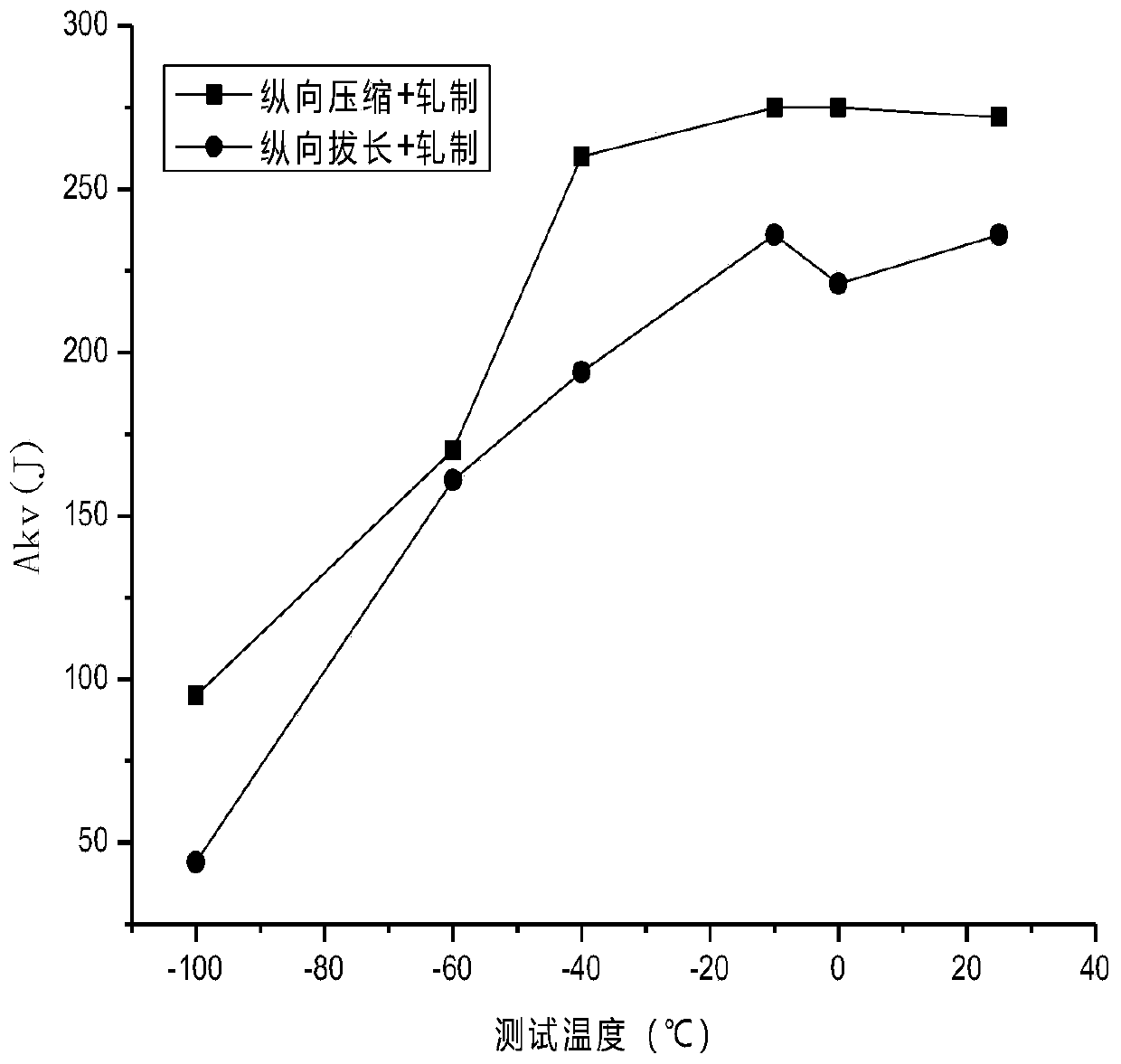

[0084] In this embodiment, the aspect ratio of the austenite is controlled between 1.0 and 4.0 by controlling the deformation ratio of forging+rolling.

[0085] S32750 duplex stainless steel molten steel is smelted by EAF+AOD+LF, poured into steel ingots, subjected to compression deformation along the longitudinal direction with a deformation ratio of 1.5, and then subjected to elongation deformation along the longitudinal direction with a deformation ratio of 7.0 to make a forged billet.

[0086] Cut S32750 duplex stainless steel square, its chemical composition and content (wt%) are: C: 0.02; Cr: 25.22; Ni: 7.15; Mo: 3.94; N: 0.27; Mn: 0.63; Si: 0.48; Cu: 0.22 ; the rest are Fe and unavoidable impurities), according to Figure 3-1 As shown, respectively carry out forging compression (longitudinal compression deformation ratio 3.0) and forging elongation (longitudinal elongation deformation ratio 1.5) along the longitudinal direction to make a slab, and then roll along the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com