Patents

Literature

167results about How to "Guaranteed stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

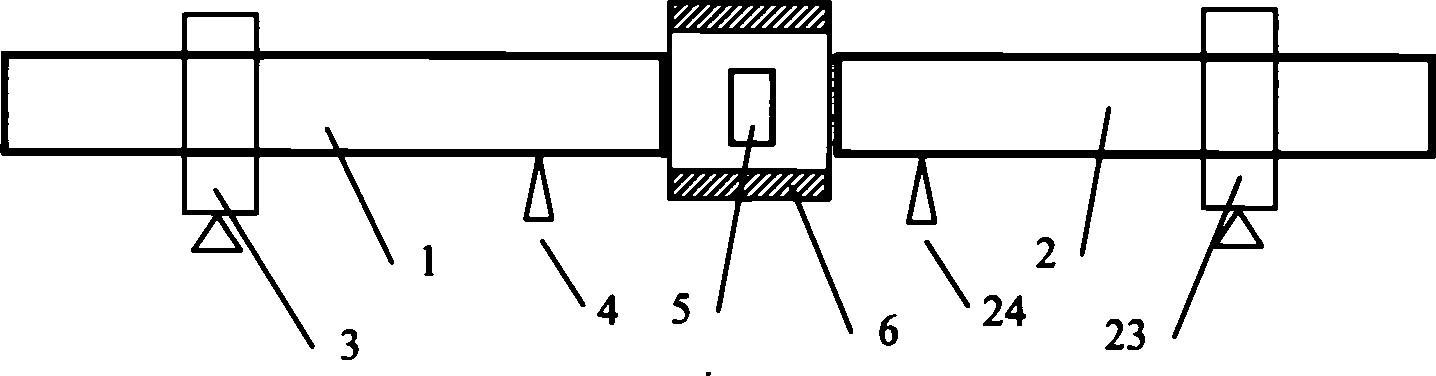

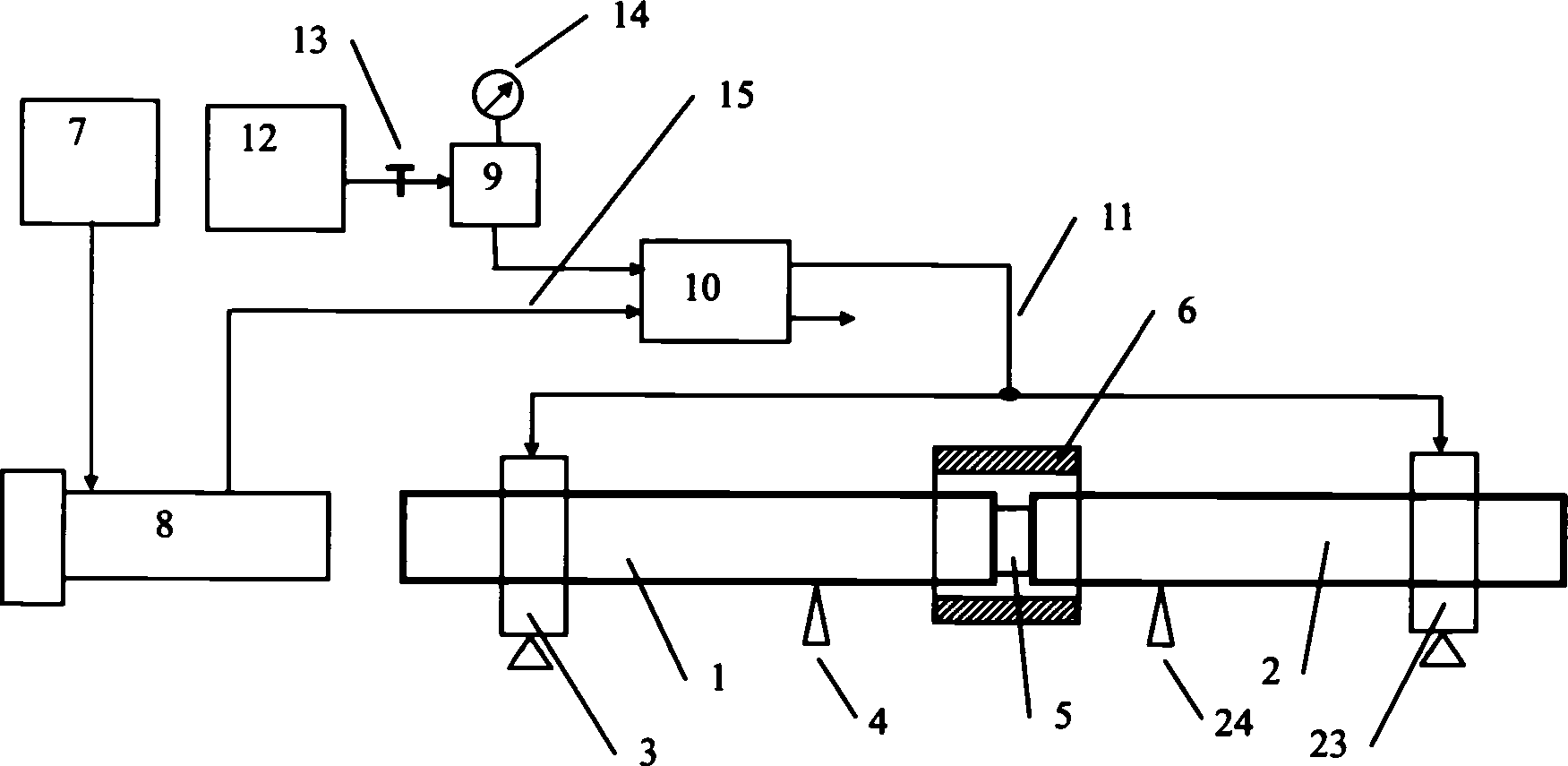

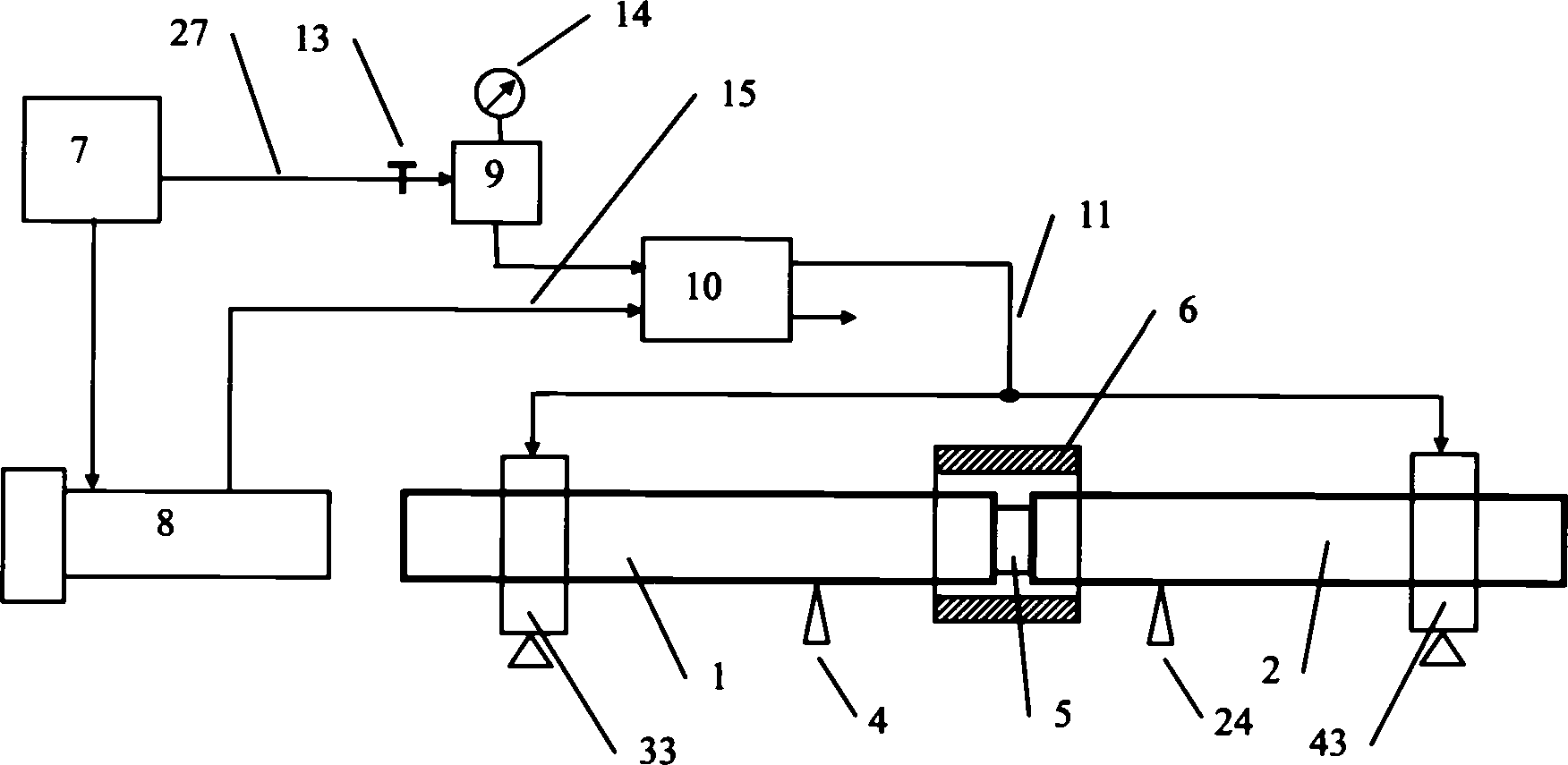

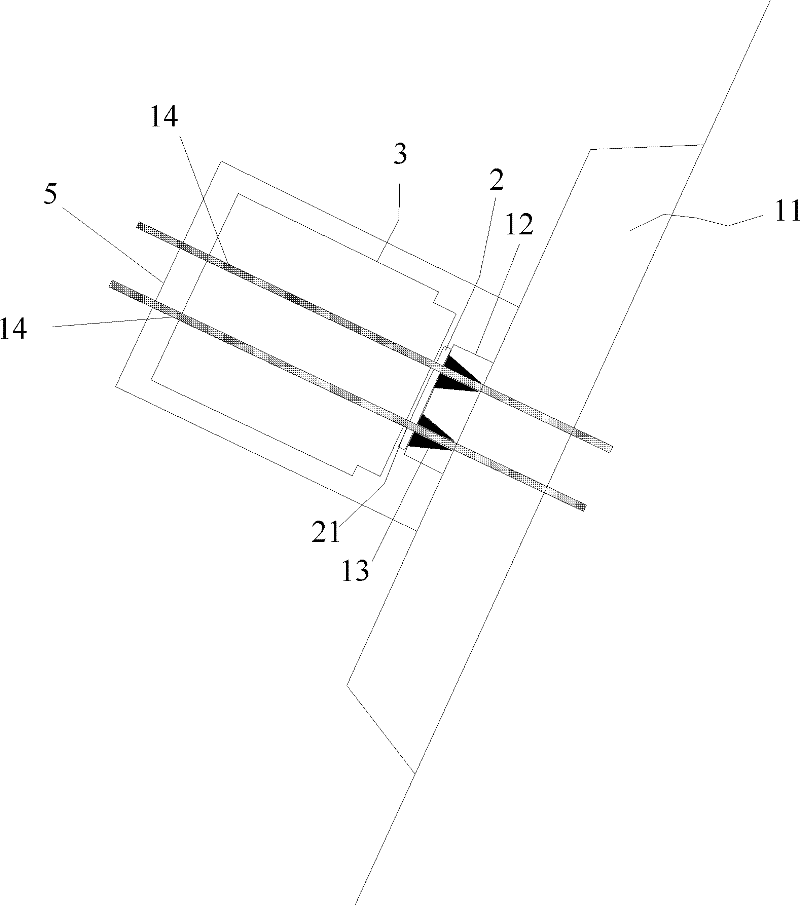

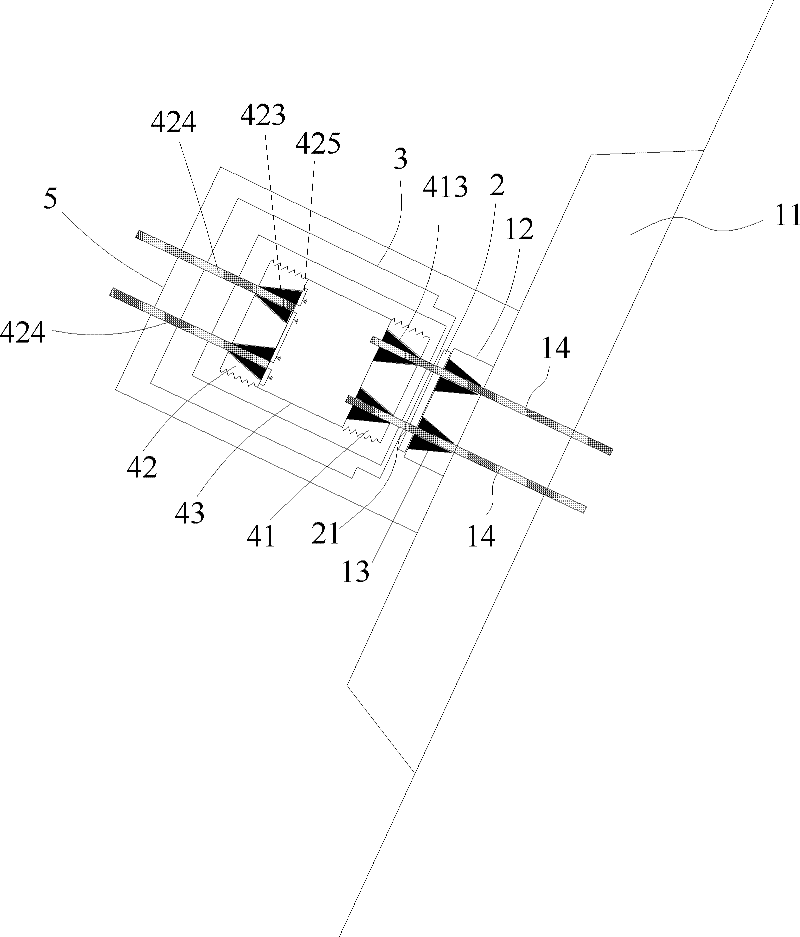

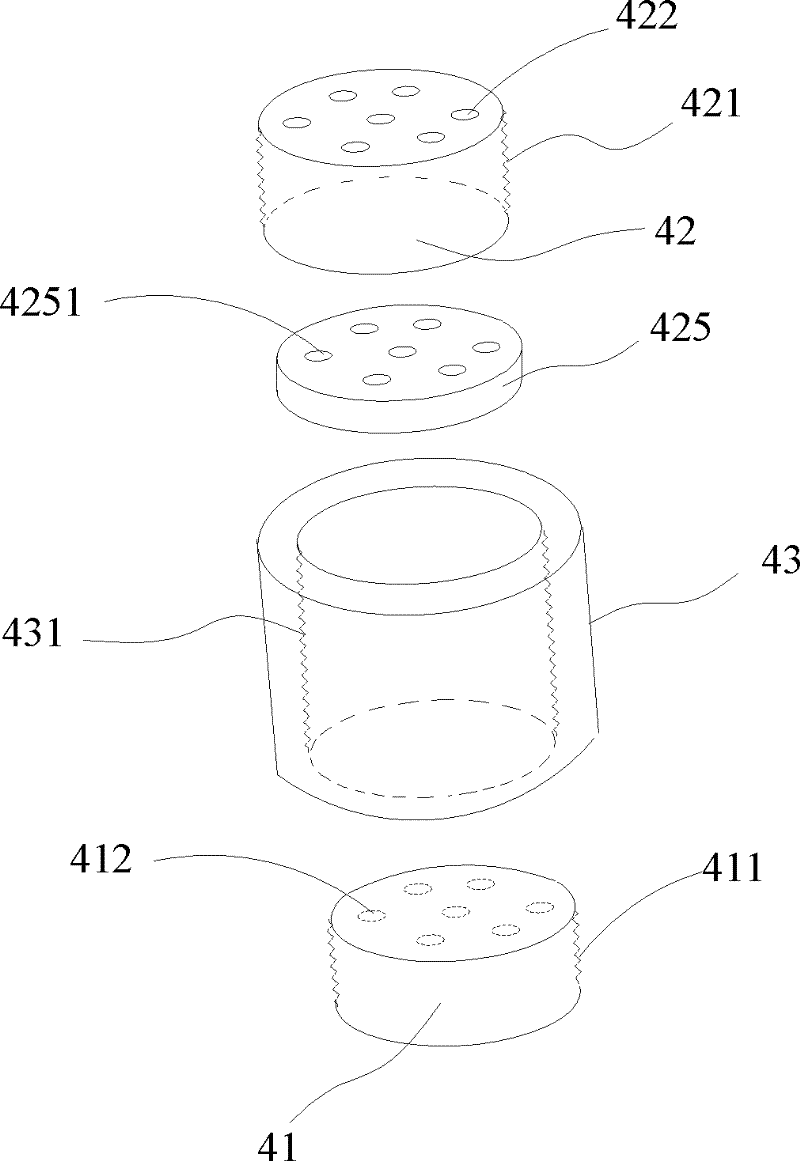

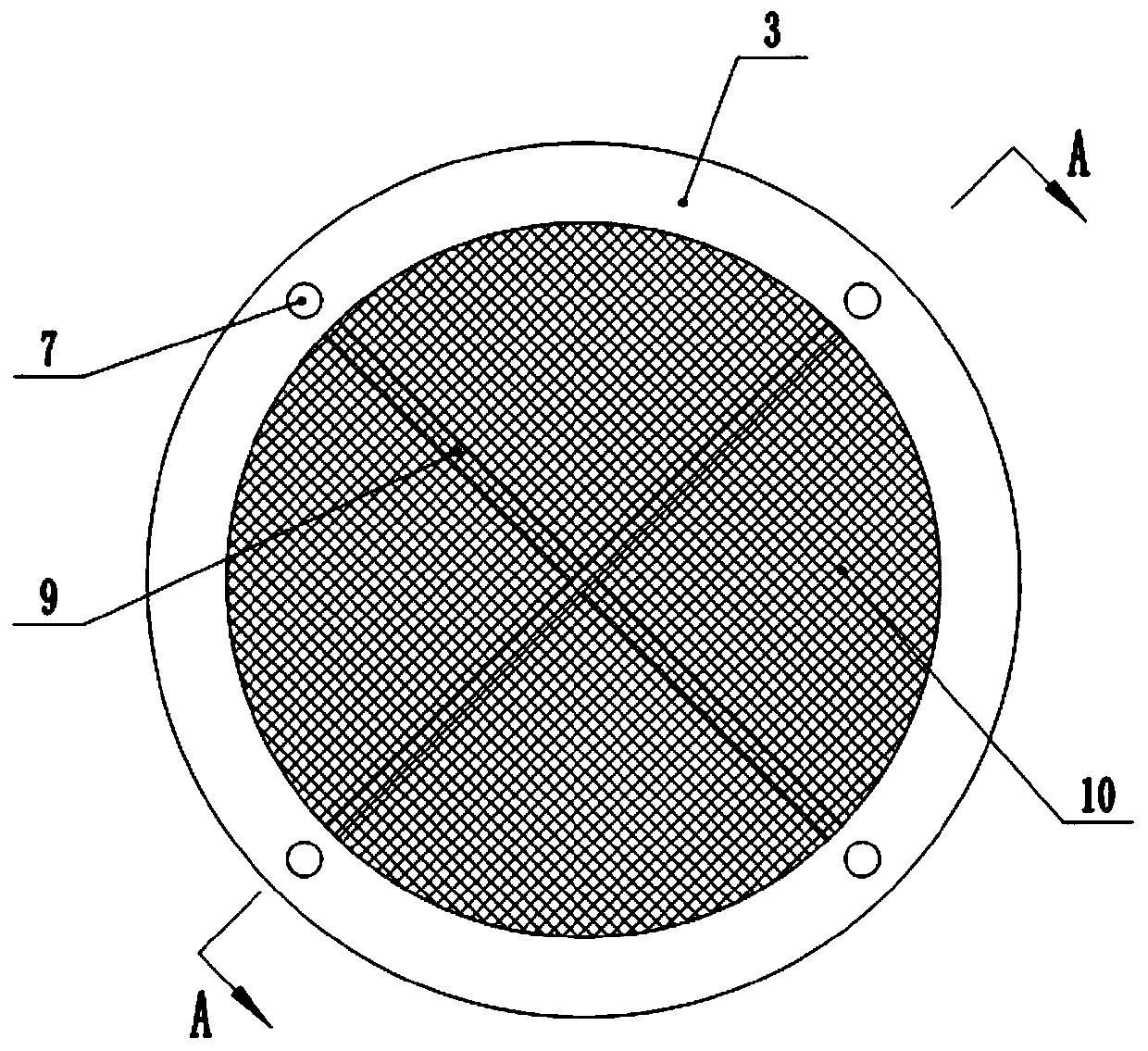

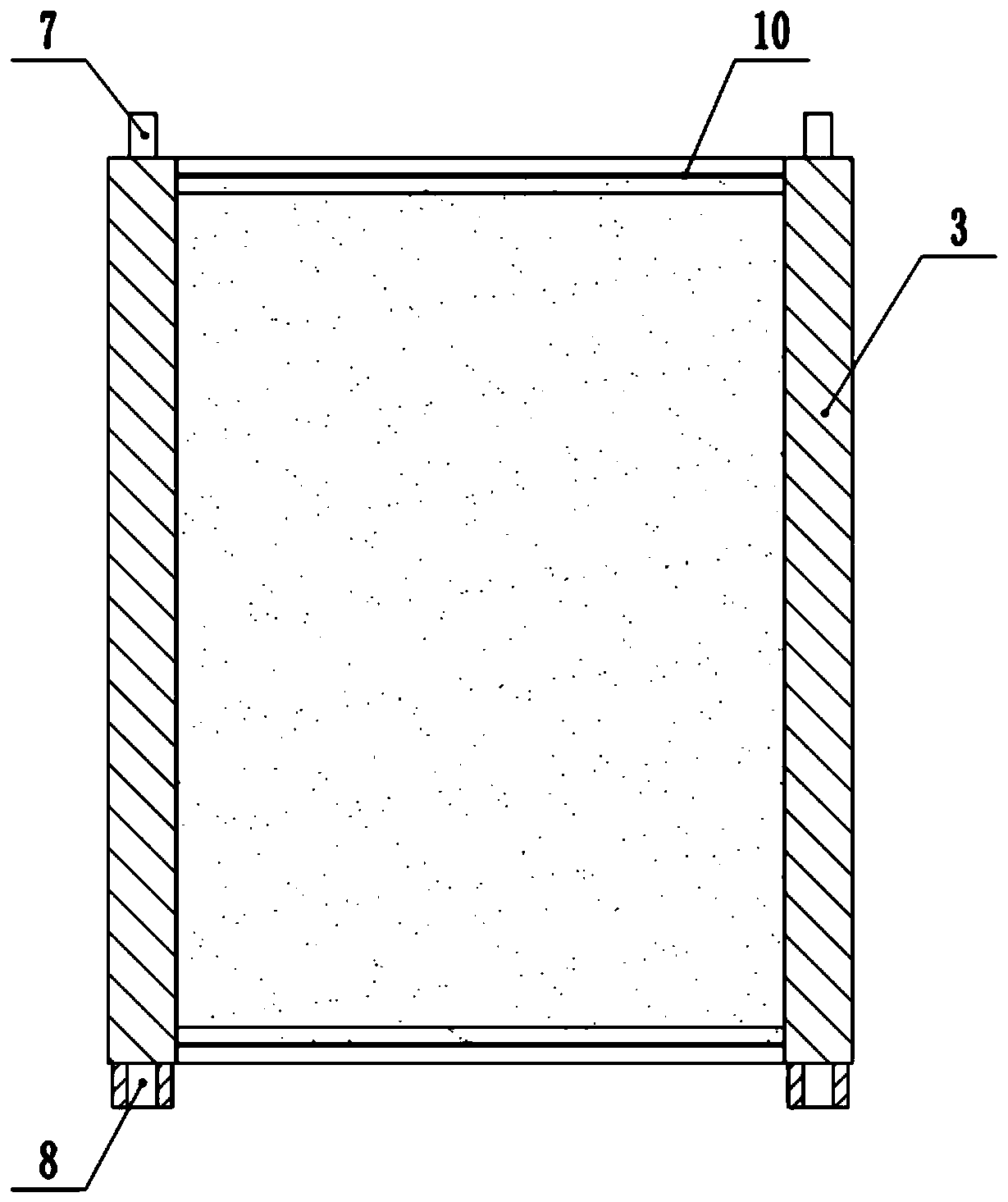

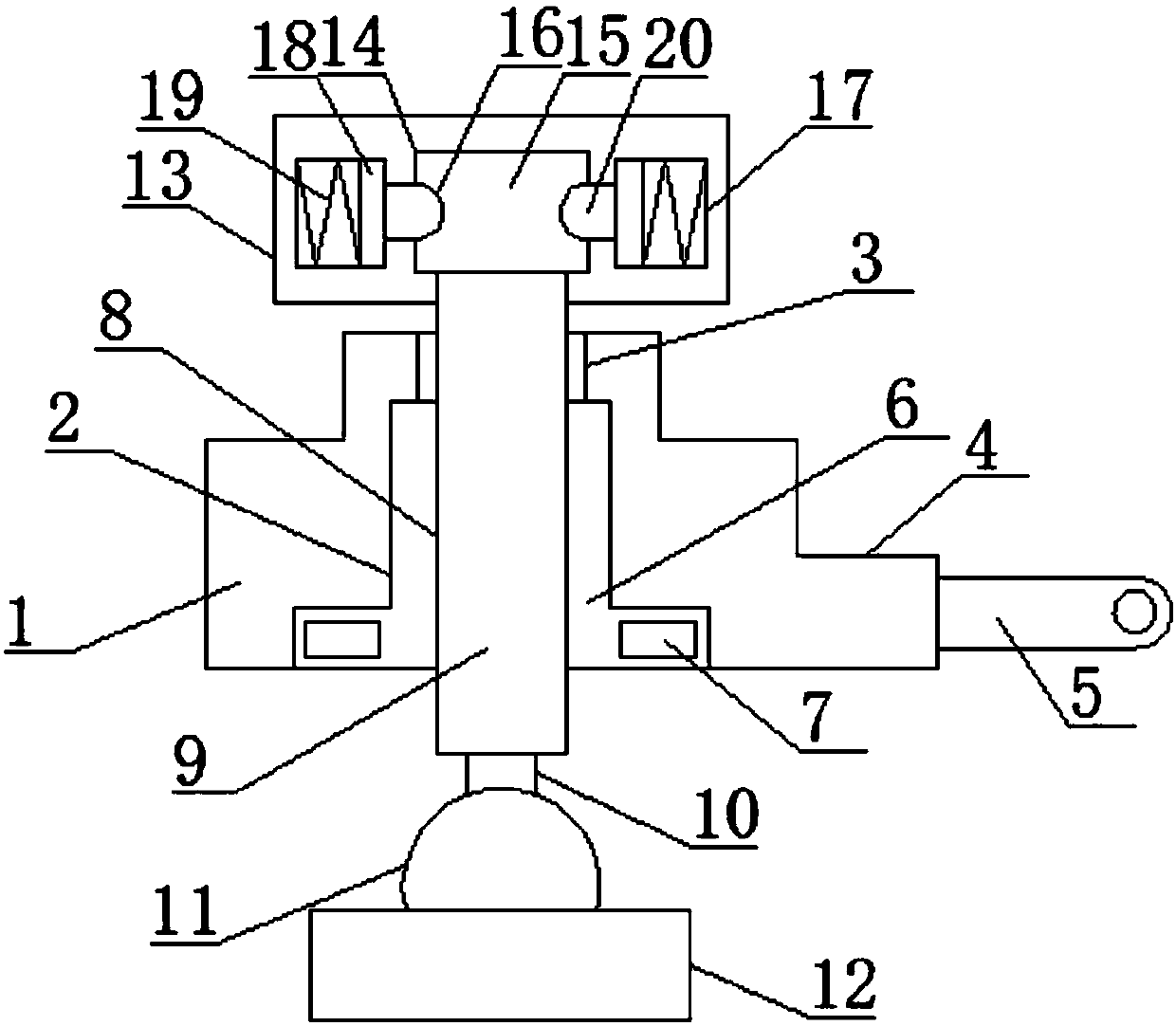

Double-air path bidirectional automatic assembling device for high-temperature Hopkinson pressure bar experiment

InactiveCN1888851AGuaranteed synchronicityReduce temperature unevennessStrength propertiesEngineeringAtmospheric pressure

Two-way double steam paths self-motion assembled equipment for high temperature Hopkinson pressure-bar experiment belongs to material high temperature dynamic mechanics capability research field. Each gas driving rack set on incidence perch and transmission perch and push them towards specimen in assembling to form two-way assemble in order to keep specimen in the availability heating range. Push the driving gas path of rack and separate setting of air cannon startup gas path and set gas chief valve control the switch of driving gas path and air cannon startup gas path. It makes the driving rack and air cannon startup linkage without influence. Set small gas storage tin as driving gas source and control its air pressure to control the driving speed of the driving rack. It can keep the assembled stability of the equipment and enhance assembled success probability. It assures the synchronism of assembled equipment when the stress wave arrives to specimen to avoid the temperature of specimen rapidly drop for leaving heat fountain.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

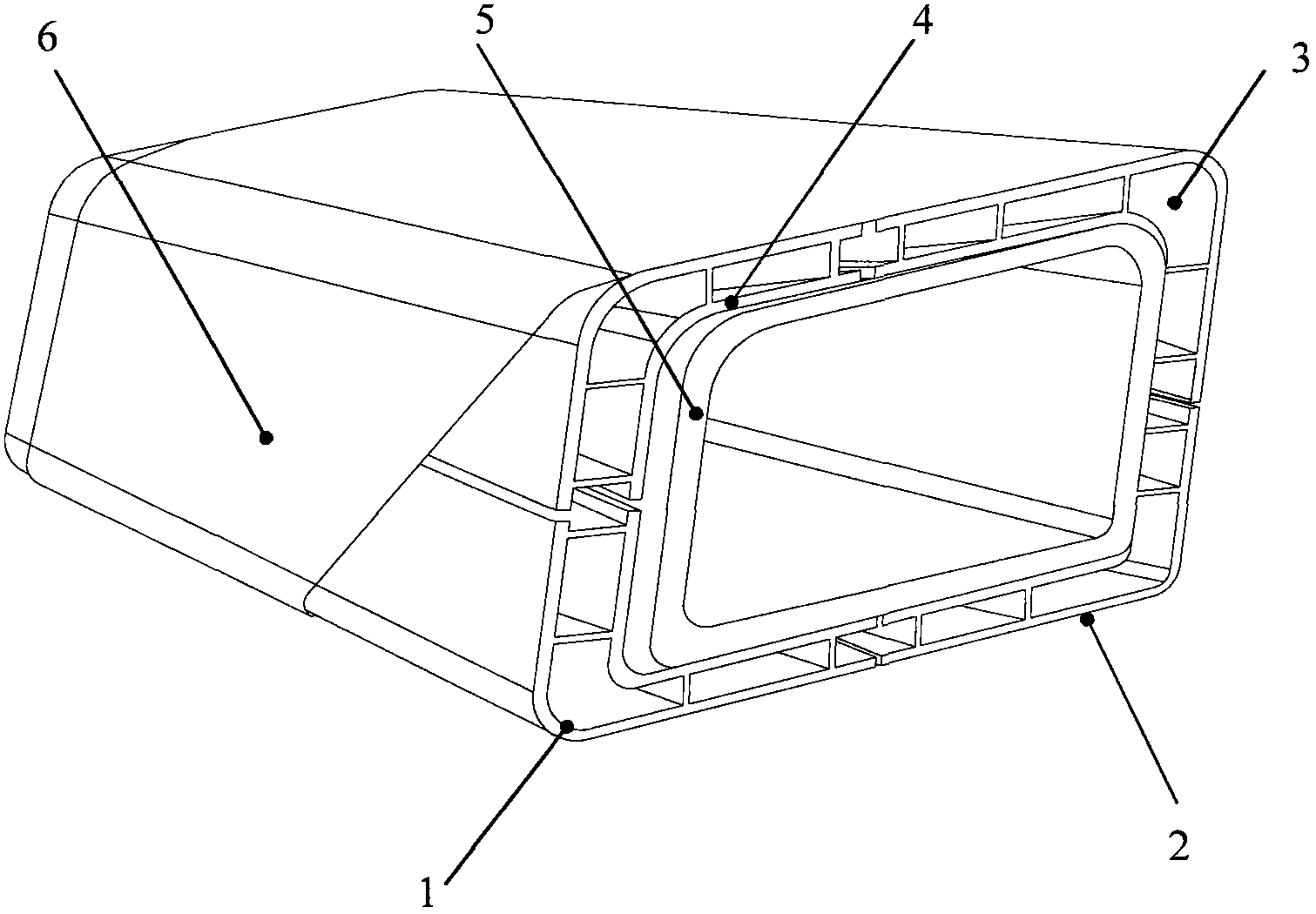

Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

InactiveCN102672435AOvercoming shape constraintsOvercome the processShaping toolsLaser beam welding apparatusTitanium alloyMetal

The invention belongs to the field of sheet metal and welding processing, and relates to an integral forming method for a thin-walled titanium alloy part with an irregularly-shaped curved surface. The integral forming method aims at overcoming the defects that the shape of parts processed through the prior art is limited or the procedure and the cost are higher, and effectively ensuring the precision forming of a thin-walled component with an irregular shape. The integral forming method comprises the steps as follows: a parting surface is determined; blanking is carried out; in the preforming step, a plate is bent from a flat into a circular arc through a bending die or a bending machine; welding is carried out; in the hot shaping step, a hot shaping die is put in the inner part of a part that is processed through the assembly welding under the ordinary temperature, and the part is supported tightly due to the dead weight of the die and is heated in a hot shaping machine; and in addition, a pressing machine applies pressure to the hot shaping die when the part is heated until material is softened, so as to enable the part to reach the needed size. The integral forming method comprehensively utilizes the advantages of various processes, can obtain the large-sized thin-walled titanium alloy part with the irregularly-shaped curved surface through only two weld joints, and achieves higher surface quality of the part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

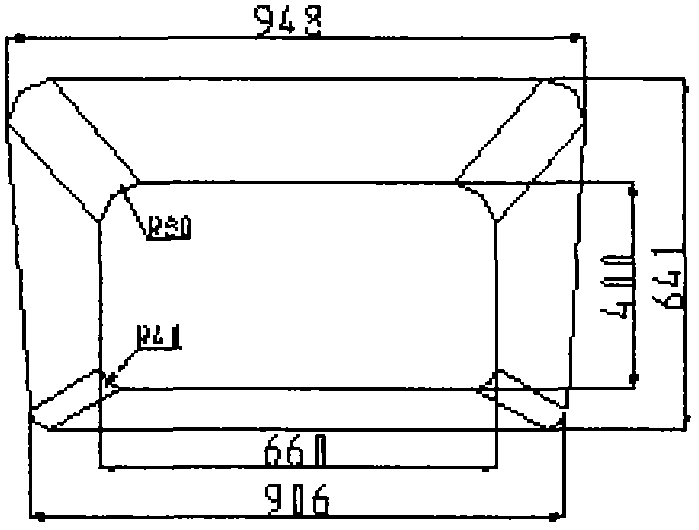

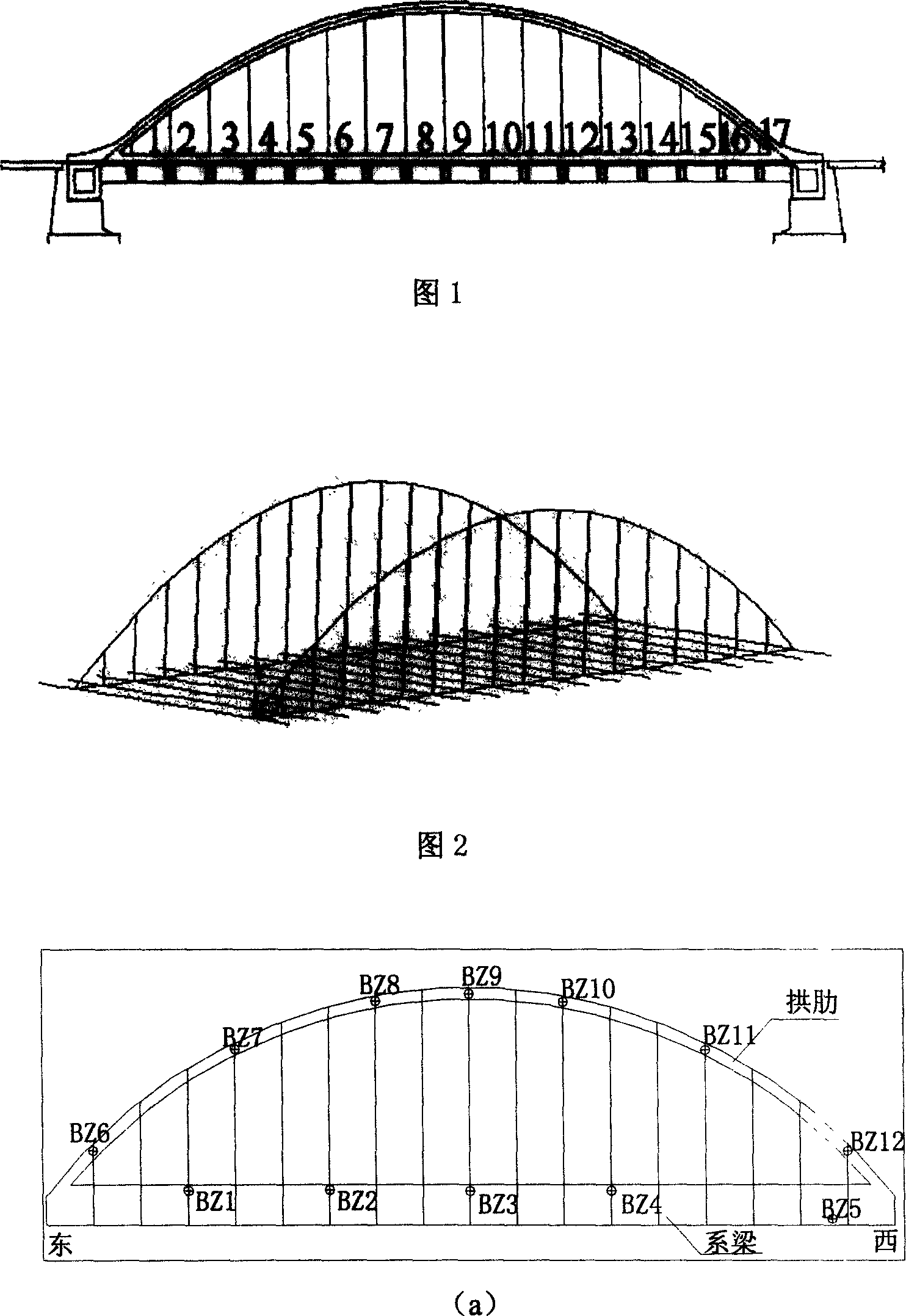

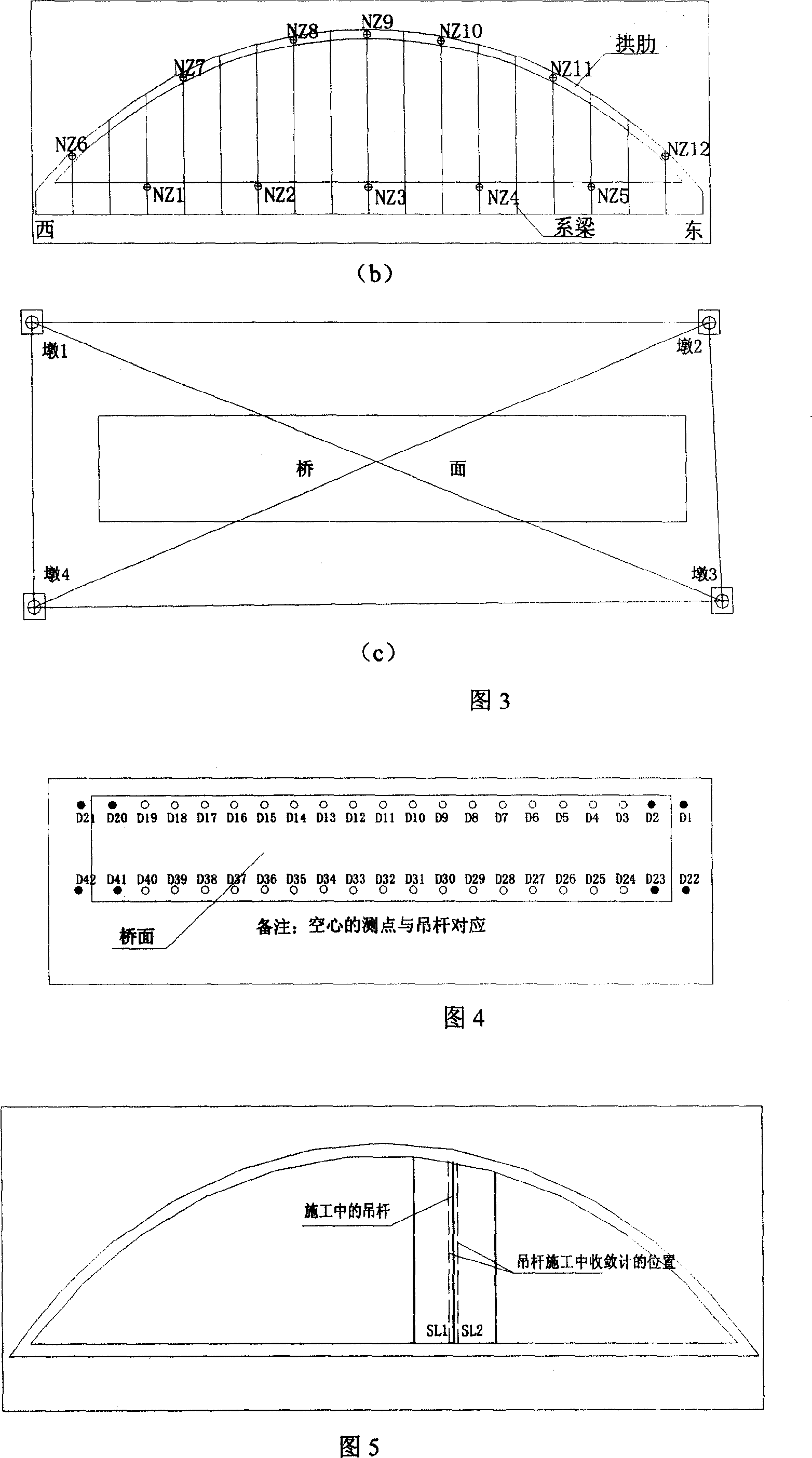

Construction monitoring method for exchanging course of half/through arch bridge suspender

InactiveCN101016728AEnhanced identification of structural parametersSmall temperature errorBridge erection/assemblyBridge strengtheningRelative displacementStructural stress

The invention relates to a construction detection used in the hanger rod exchange of middle and lower arc bridges. The invention comprises that building arc bridge spatial reference limit model, analyzing the force state of bridge, simulating the whole construction, the construction uses arc bridge three-dimension position detection, bridge sink detection, displacement detection between arc rib and beam, hanger rod force detection, structural stress detection and long-time detection, then comparing the data of detection with the reference limit model, to correct the model, to be used in next reference limit model. The invention can confirm the flexibility less than theory value and confirm the hang force in design range, to improve safety or the like.

Owner:TONGJI UNIV +1

Device and method for compensating or unloading prestressed load of anchor cable

InactiveCN102296605AGuaranteed stressGuaranteed unloadingBulkheads/pilesAnchoring boltsPre stressSpecified load

A device and method for compensating or unloading the prestressed load of an anchor cable. For an anchoring project in which the length of the steel strand at the exposed section of the anchor cable meets the tension length, the device includes: a limiting plate, a small jack and a support tube. For the anchor cable For the anchoring project where the length of the steel strand at the exposed section does not meet the tension length, the anchor cable prestress load compensation or unloading device also includes an anchor cable extension device. Anchor cable prestress load compensation or unloading methods include: install anchor cable prestress load compensation or unloading device, install tension jack and tool anchor, insert tension tool anchor clip to tighten external steel strand; start tension The jack oil pump applies the load until the working anchor is pulled and the clip of the working anchor is loosened, continue to apply the load or unload to the specified load value, and then start the small jack to load and push back to the limit plate, the clip re-cables the steel strand, and then Unloading, to complete the anchor cable stress compensation or load reduction, so as to reliably ensure the load compensation or unloading effect of the anchor cable prestress.

Owner:中铁西北科学研究院有限公司深圳南方分院

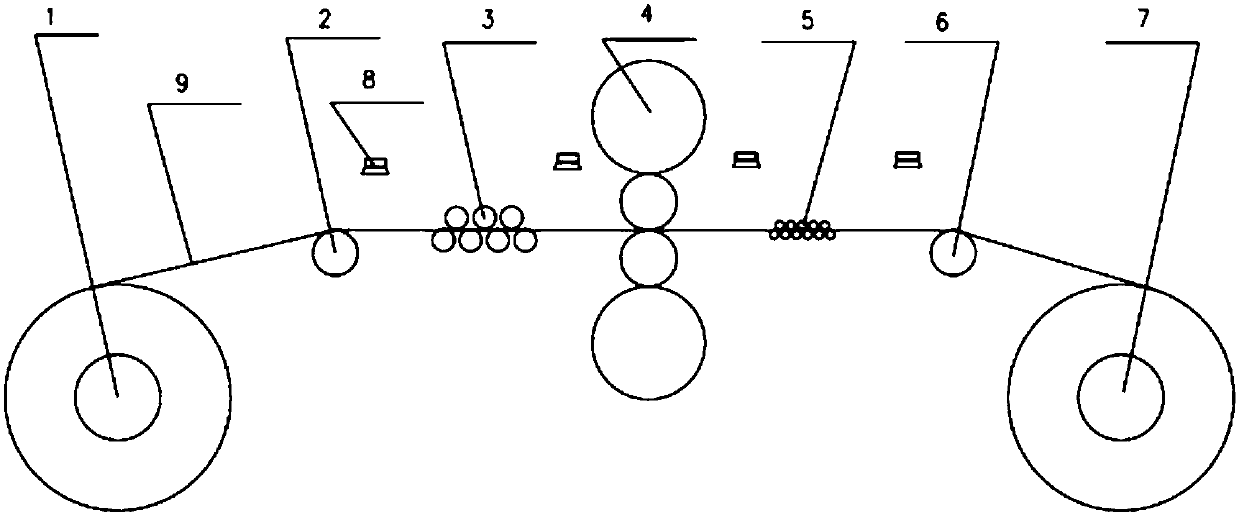

High-strength strip steel straightening, flattening and straightening process

ActiveCN107838199AReduce loadEasy to shapeProfile control deviceMetal rolling arrangementsStrip steelResidual stress

The invention discloses a high-strength strip steel straightening, flattening and straightening process. The high-strength strip steel straightening, flattening and straightening process is characterized in that a hot rolling high-strength steel plate or strip steel sequentially passes through an inlet straightening machine, a temper mill and an outlet straightening machine, and by means of the combined working procedures of straightening, flattening and straightening, the adjustment of the plate shape, the surface quality, the mechanical performance and the residual stress of the strip steelis completed; the inlet straightening machine is used for conducting rough straightening on the strip steel, on the one hand, the plate shape of the supplied material is improved, and on the other hand, the scale on the surface of the strip steel is reduced; the temper mill is used for conducting flattening on the strip steel, the plate shape of the strip steel is improved, the mechanical performance of the strip steel is adjusted, and the surface quality of the strip steel is improved; and the outlet straightening machine is used for conducting precise straightening on the strip steel, the unquenched plate shape problems and newly-generated plate shape problems in the flattening process are solved, and the unquenched residual stress and newly-generated residual stress in the flattening process are eliminated.

Owner:WISDRI ENG & RES INC LTD

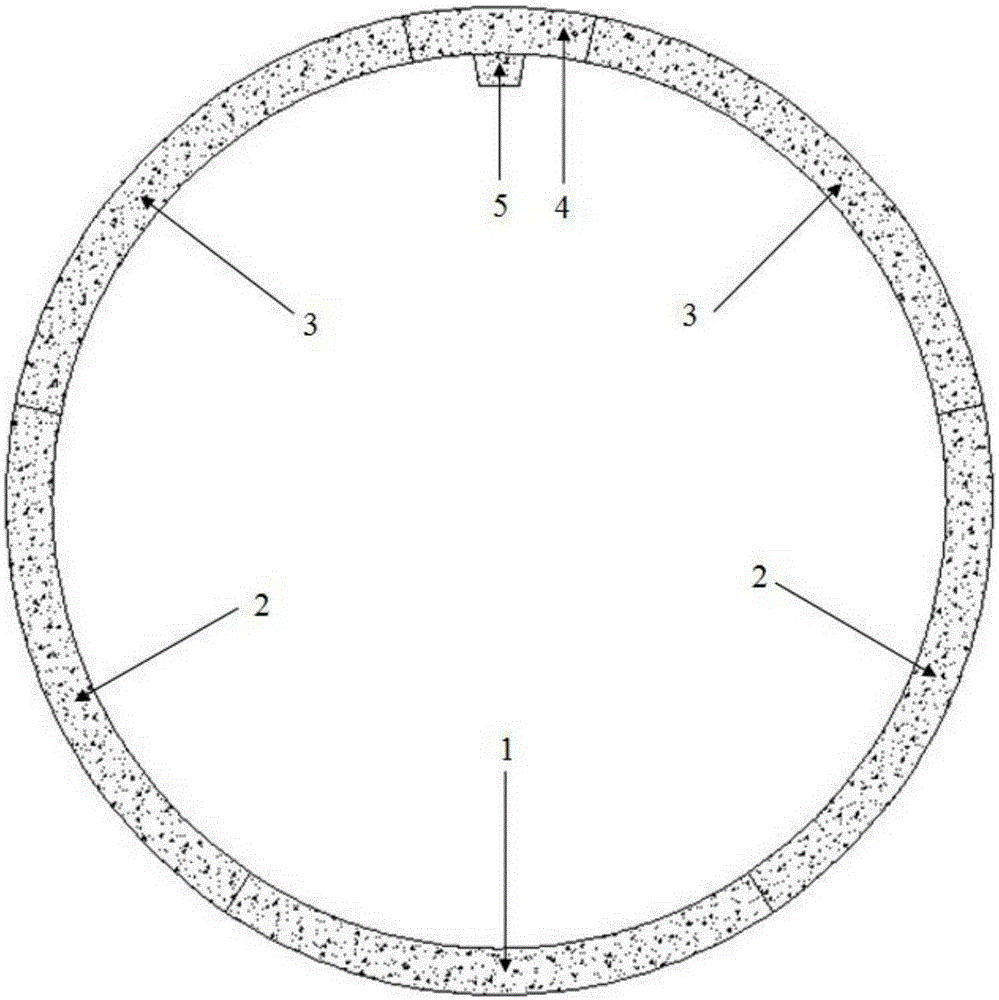

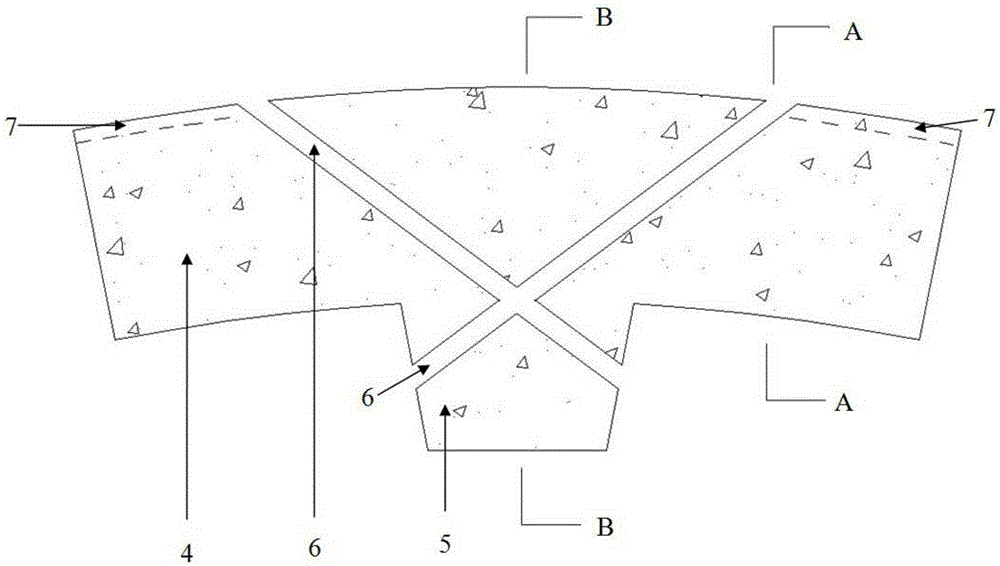

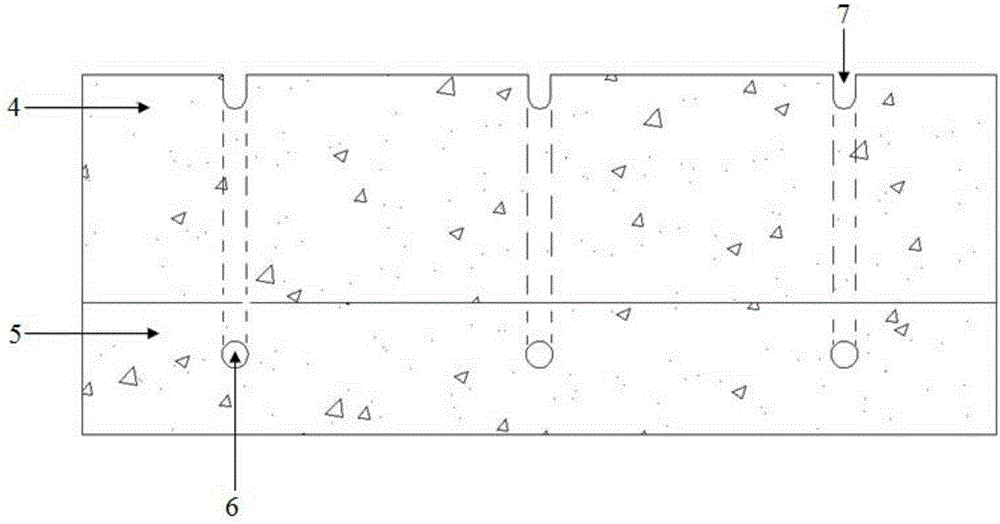

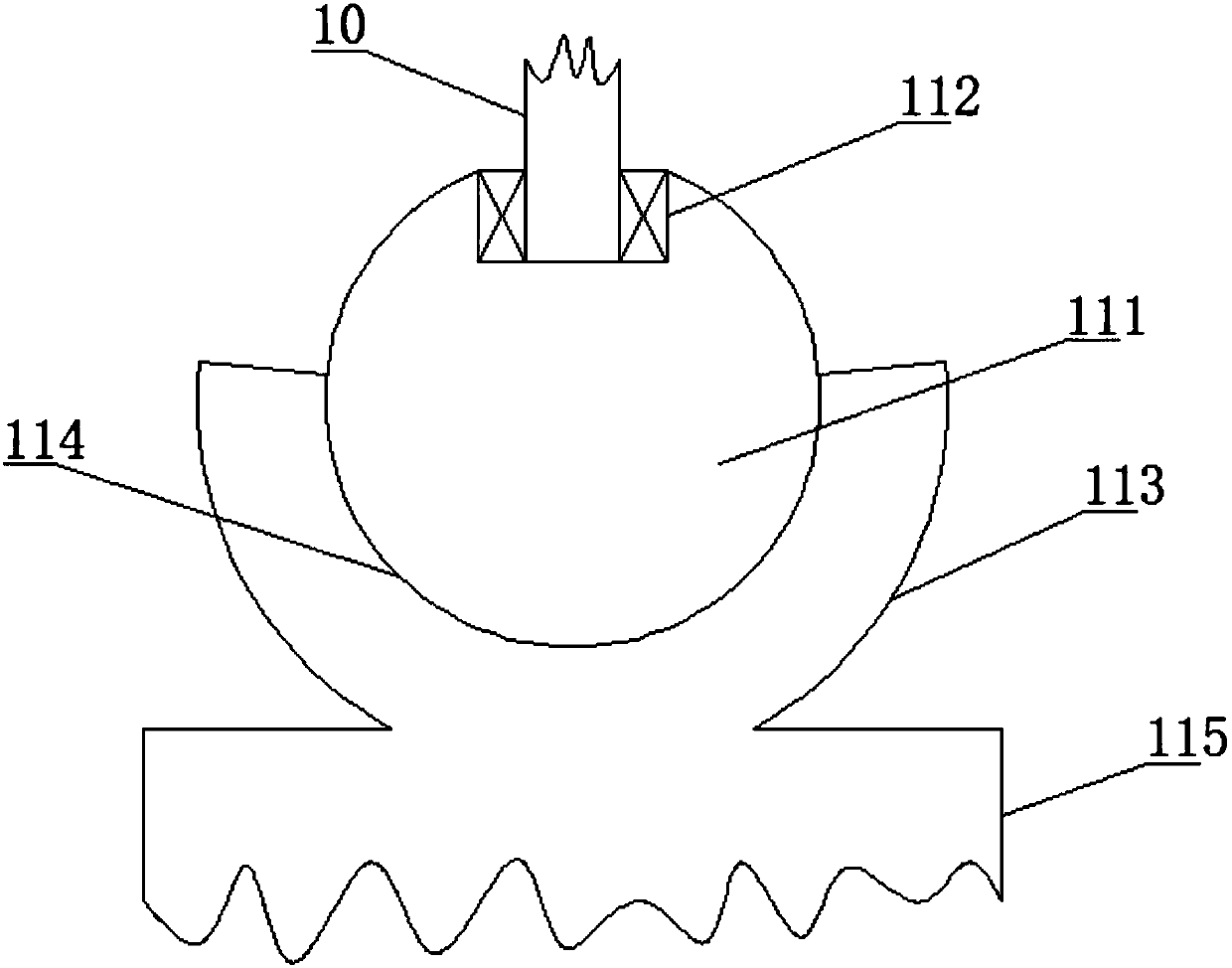

Circumferential prestress strengthening tunnel segment and manufacturing method

ActiveCN105178983AGuaranteed stressPrevent openingUnderground chambersTunnel liningPre stressEngineering

The invention relates to a circumferential prestress strengthening tunnel segment and a manufacturing method. A tunnel segment part mainly comprises an arch bottom block, wherein one adjacent block is arranged at each of two ends of the arch bottom block; a connection block clings to the end part of each adjacent block; a top sealing block is arranged between the two connection blocks; reserved grooves are formed in the outer side of the arch bottom block, the outer sides of the adjacent blocks, the outer sides of the connection blocks and the outer side of the top sealing block; reserved channels are formed in the inner part of the top sealing block; after steel strands pre-tighten the arch bottom block, the adjacent blocks, the connection blocks and the top sealing block through the reserved grooves, the end parts of the steel strands penetrate through the top sealing block and protrude out of the sealing block; each steel strand protruding out of the top sealing block is fixed by a lockset, so that the prestress application is realized; the arch bottom block, the adjacent blocks, the connection blocks and the top sealing block together form a closed cylindrical structure. Through the adoption of the tunnel segment provided by the invention, the integrality of the segment and the capability of resisting surrounding rock pressure can be effectively improved, and the manufacturing method is time-saving and material-saving.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

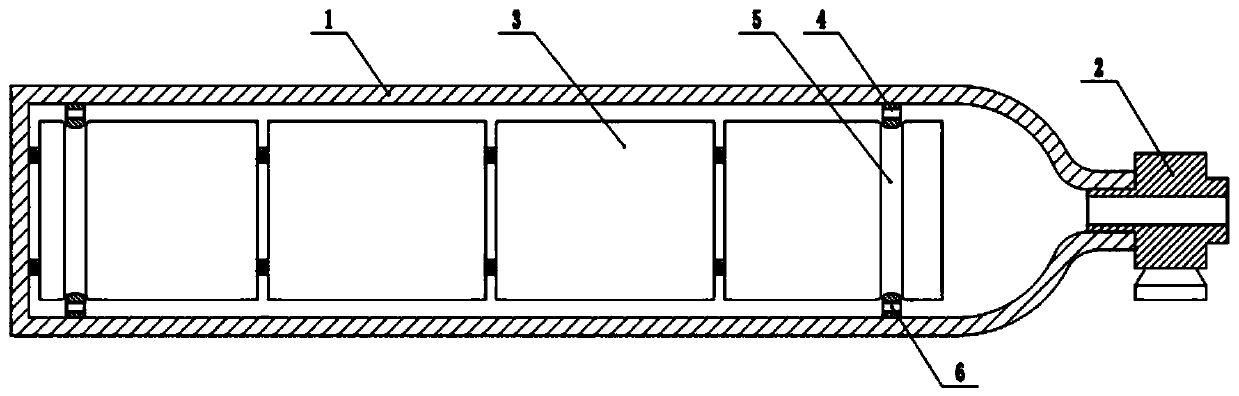

Solid-state hydrogen storage device with high heat exchange characteristics

ActiveCN111188988AEvenly dispersedAvoid damageVessel geometry/arrangement/sizeVessel wallsThermodynamicsEngineering

The invention relates to the technical field of hydrogen storage equipment, and particularly discloses a solid-state hydrogen storage device with high heat exchange characteristics. The solid-state hydrogen storage device comprises an outer tank, wherein an air inlet and outlet valve is arranged at the top of the outer tank, a plurality of hydrogen storage cylinders are fixed in the outer tank insequence, a gap of 0.5mm-3mm is formed between every two adjacent hydrogen storage cylinders, filter sheets are fixed at two ends of the hydrogen storage cylinders correspondingly, a plurality of heat-conducting partition plates are arranged in the hydrogen storage cylinders along the axial direction of the hydrogen storage cylinders, the plurality of heat-conducting partition plates divide the hydrogen storage cylinders into a plurality of hydrogen storage spaces, and the hydrogen storage spaces are filled with hydrogen storage materials. According to the solid-state hydrogen storage device,the multi-layer storage spaces are adopted, so that more rapid hydrogen absorption can be realized, and the problem of structural damage caused by uneven distribution of the hydrogen storage materialsin a hydrogen storage tank and stress concentration in the prior art is effectively solved; and in addition, the uniform distribution of the hydrogen storage materials enables the distribution of heat generated in a hydrogen absorption process to be more uniform, and the heat can be more rapidly conducted out of the hydrogen storage device.

Owner:SICHUAN UNIV

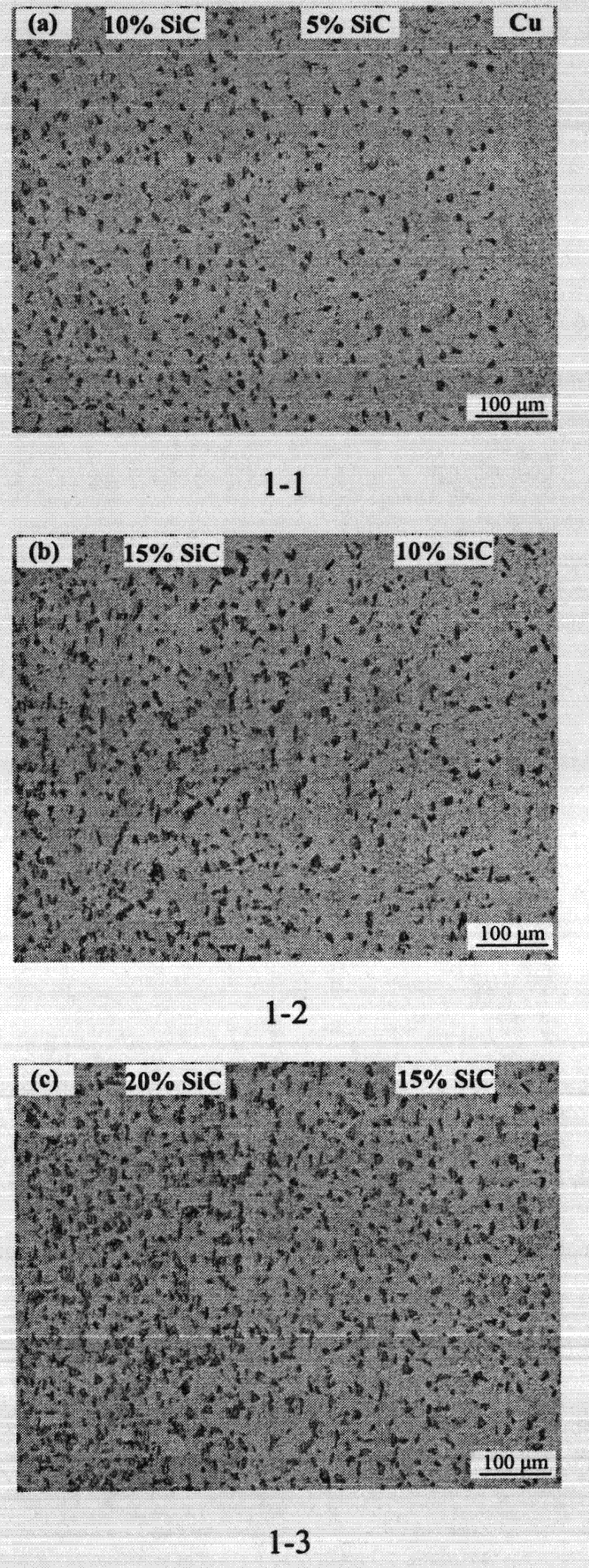

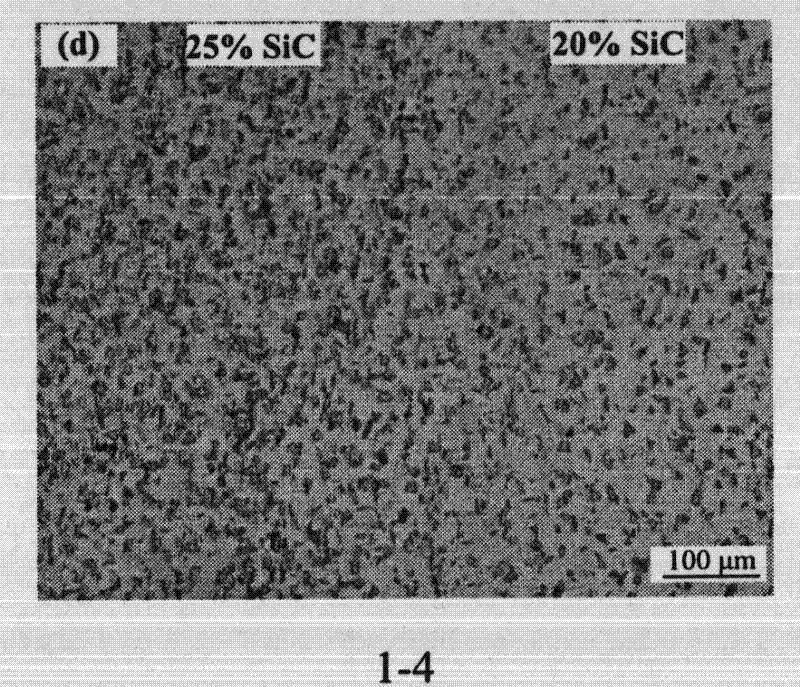

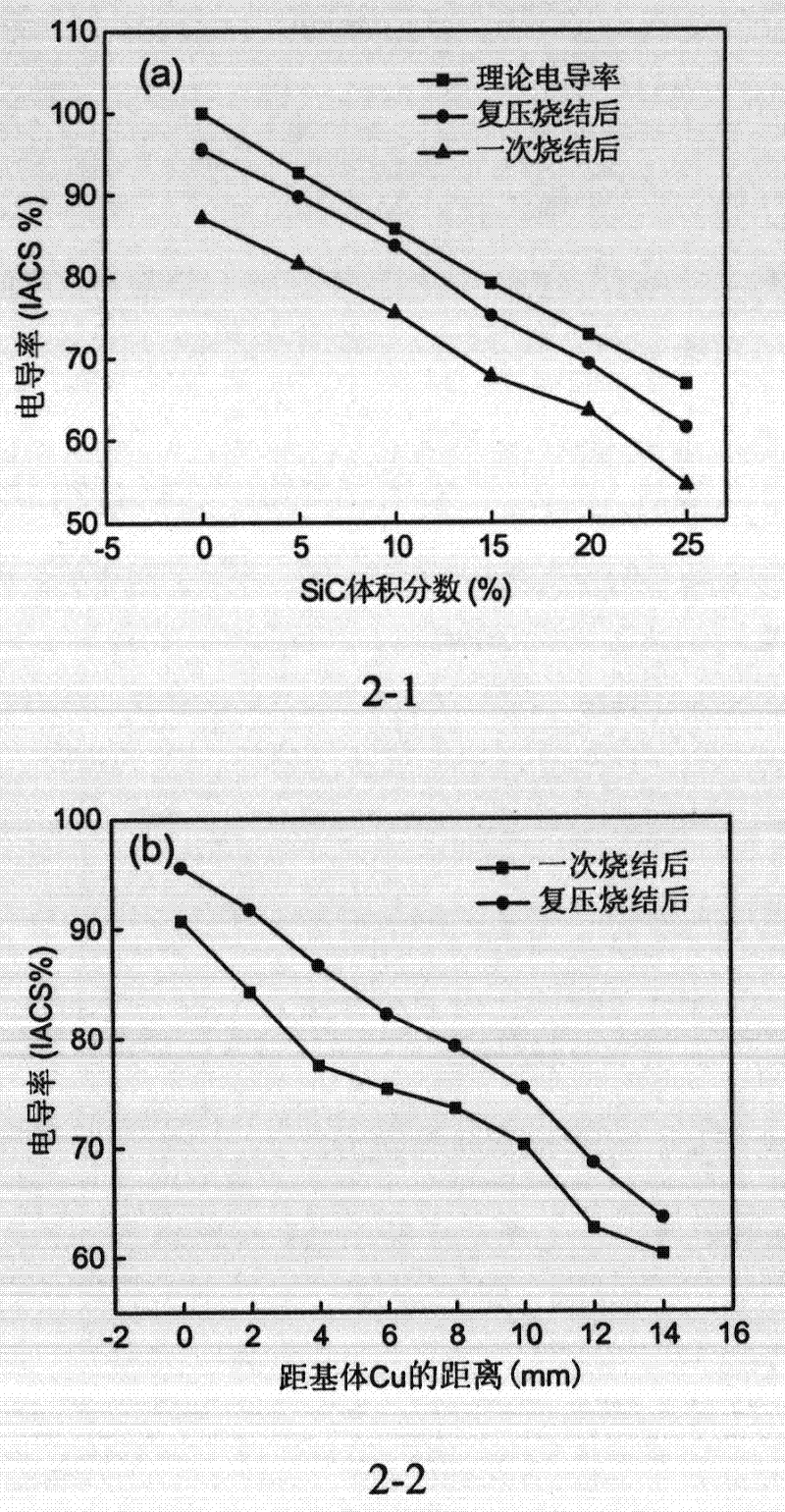

A kind of preparation method of SIC particle reinforced Cu-based gradient composite material

The invention discloses a preparation method of a SiC particle reinforced Cu-based gradient composite material, which comprises the following steps: weighing powder mixing → ball mill mixing powder for 4 hours → 400MPa billet making → vacuum degree of 10-2Pa, sintering temperature of 950°C, heating rate 10°C / min, holding time 2.5 hours for one sintering → cooling in the furnace after completion → secondary pressing at a pressure of 400MPa → vacuum degree of 10-2Pa, sintering temperature of 950°C, heating rate of 10°C / min, heat preservation The time is 2.5 hours for secondary sintering → cooling with furnace after completion → sample. It makes up for the shortcomings of uniform performance of traditional homogeneous composite materials with a certain content of reinforcing particles, thereby improving the service life of gradient composite material parts.

Owner:SHAANXI UNIV OF TECH

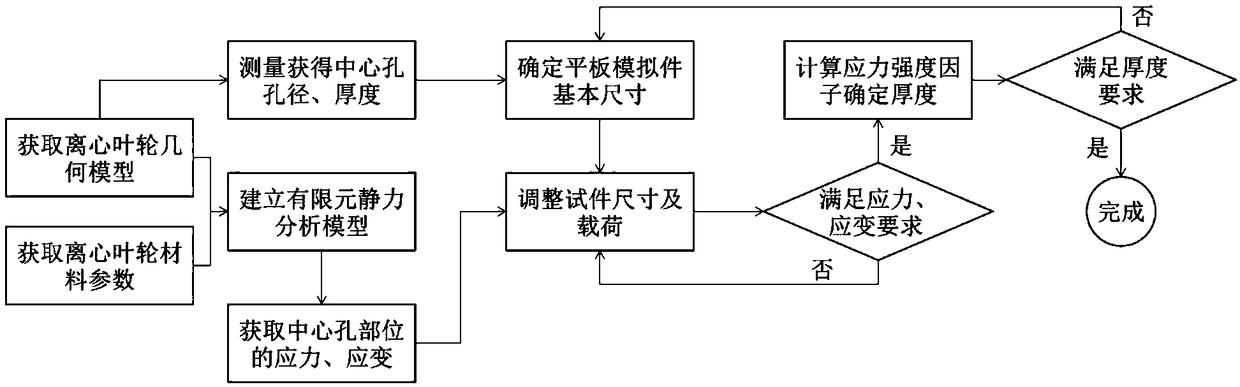

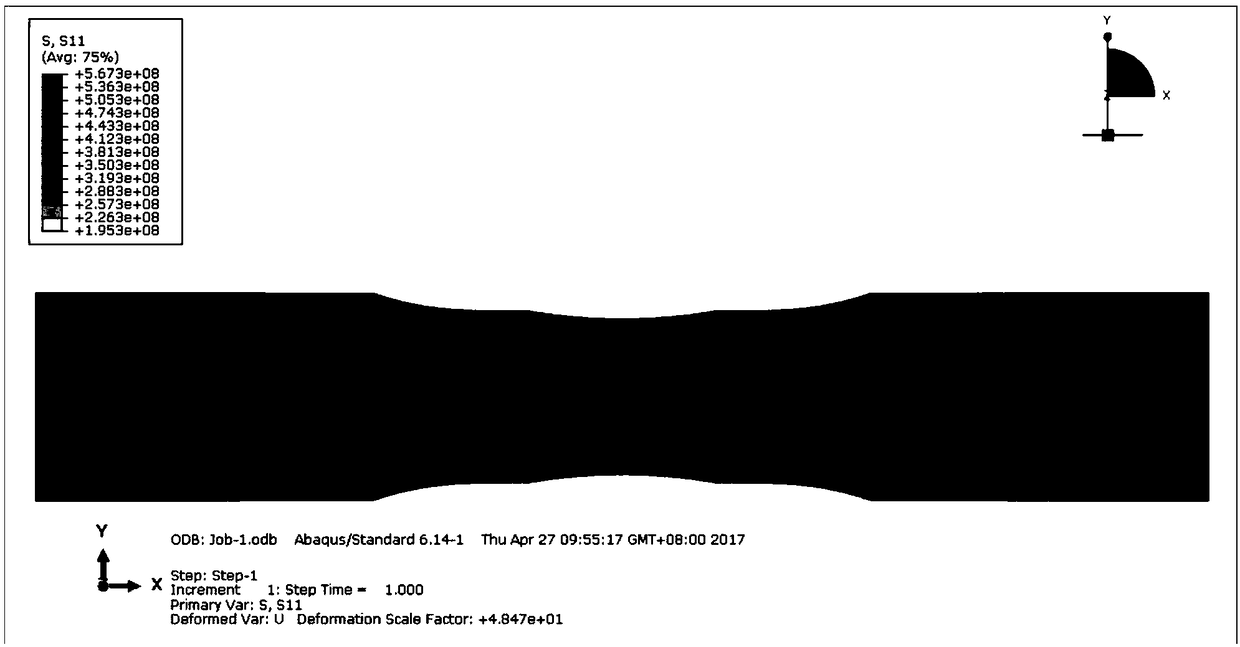

Method for designing crack propagation characteristic simulator of centrifugal impeller central hole

ActiveCN109063287AGuaranteed maximum pulling forceConsistent maximum pullGeometric CADDesign optimisation/simulationStress concentrationImpeller

A method for designing a crack propagation characteristic simulator of a central hole of a centrifugal impeller include such steps as obtaining a geometric model of that centrifugal impeller, measurea diameter and a thickness of the central hole structure, measuring the diameter and the thickness of the centrifugal impeller, measuring the diameter and the thickness of the centrifugal impeller, measuring the diameter and the thickness of the centrifugal impeller, measuring the diameter and the thickness of the centrifugal impeller, (2) obtaining the working conditions of the centrifugal impeller and the material performance parameters under the working conditions, including load, temperature, elastic modulus, yield strength and so on; (3) Establishing the finite element static analysis model of centrifugal impeller, calculating and obtaining the maximum circumferential stress point at the center hole of centrifugal impeller, and obtaining the circumferential stress value and the circumferential stress gradient of the point; (4) Based on the basic shape of the plate simulator with symmetrical circular notch, the central hole structure simulator is designed, so that the maximum stress along the direction of tensile loading on the stress concentration point of the simulator is equal to the maximum circumferential stress in the actual central hole structure, and the stress gradientis ensured to be the same; (5) Calculate the stress intensity factor of the simulator and determine the thickness of the simulator.

Owner:BEIHANG UNIV +1

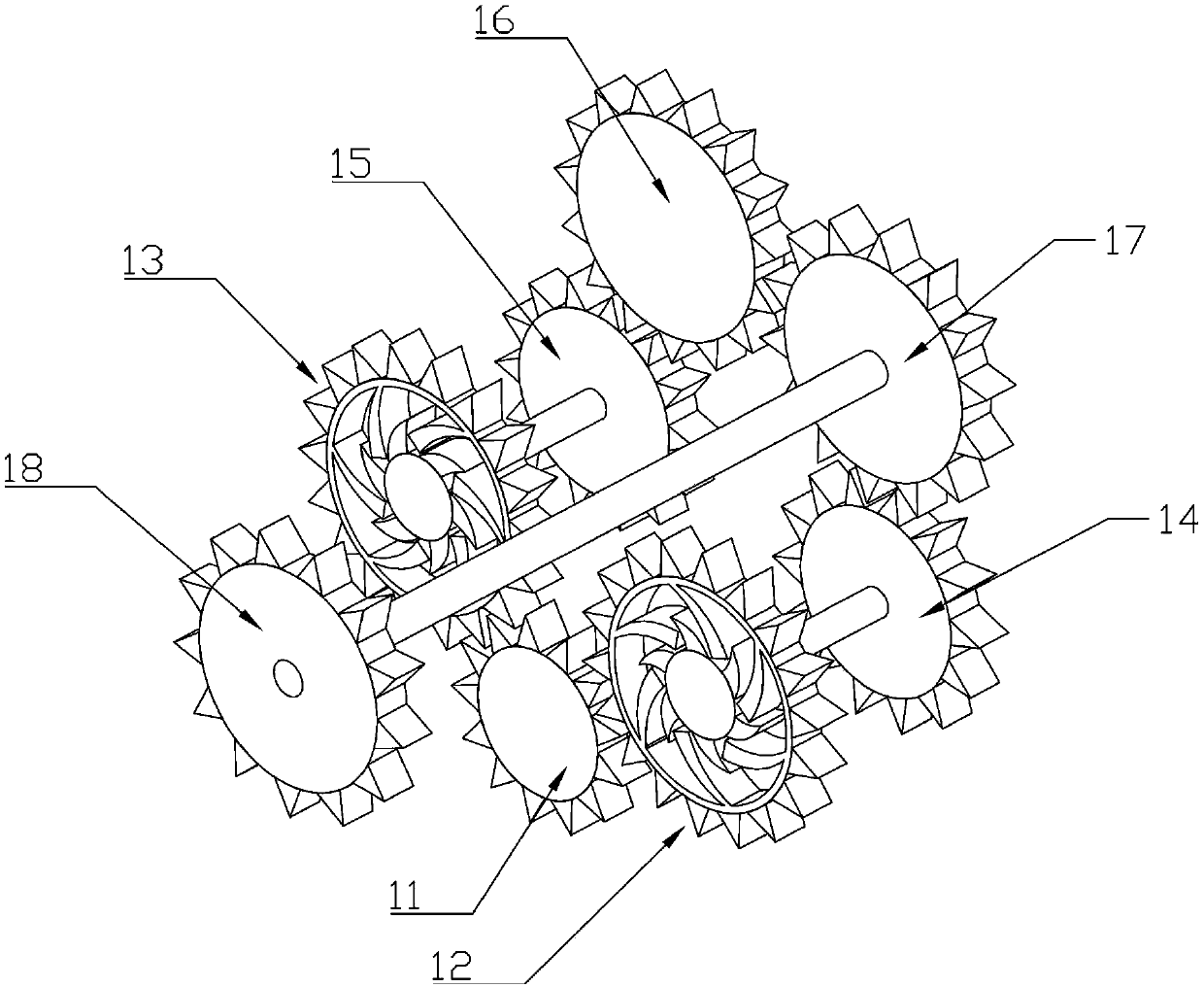

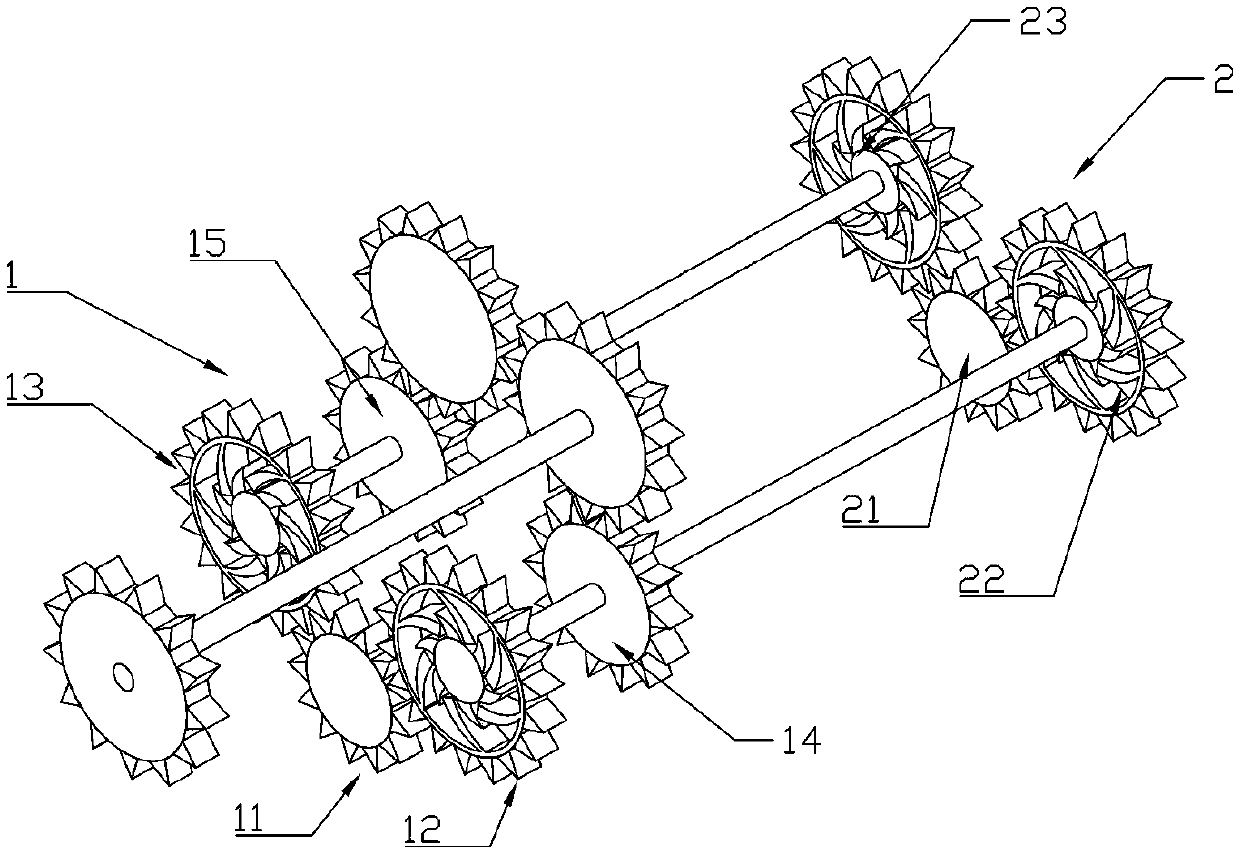

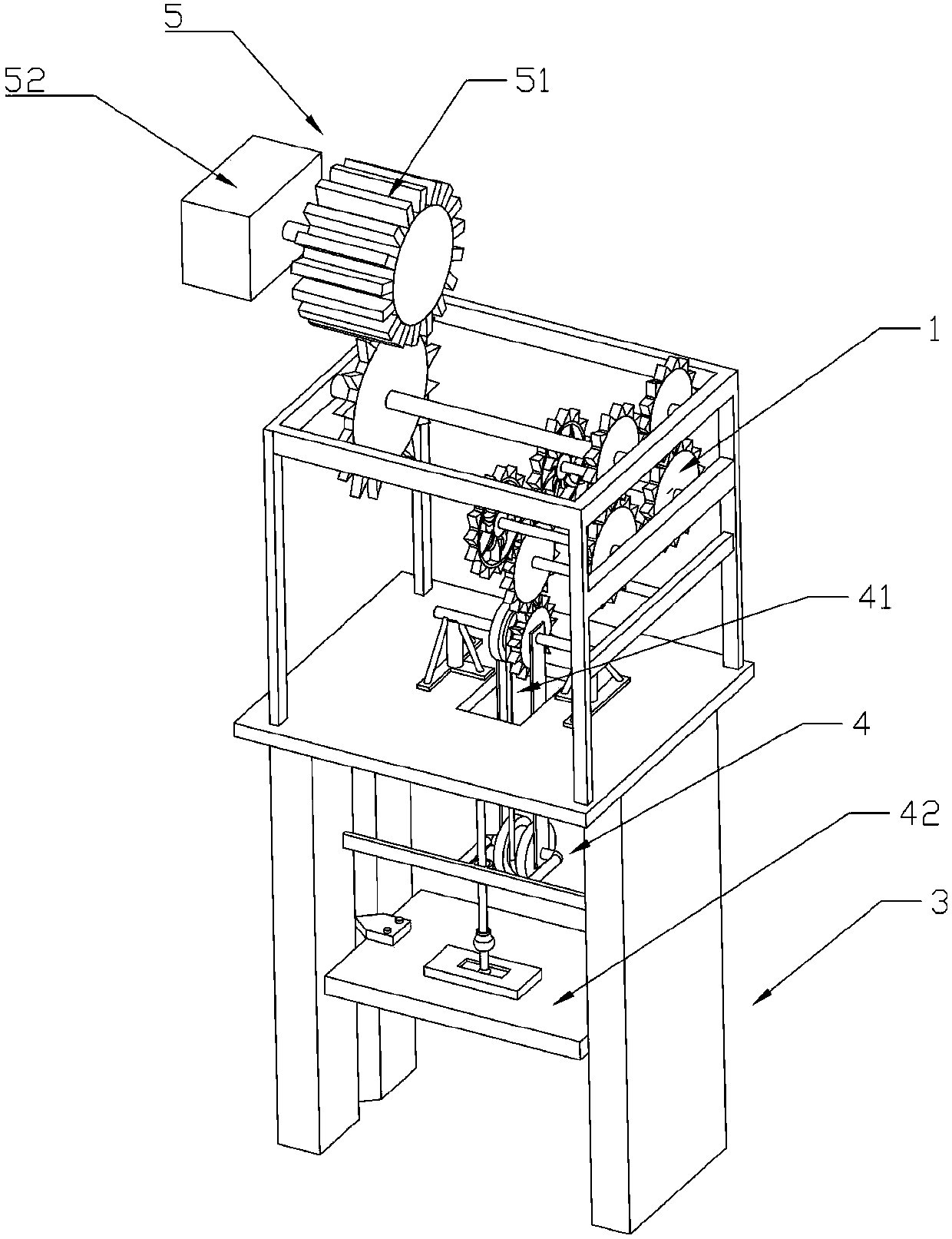

Same-direction conversion device and ocean power generation system adopting same-direction conversion device

PendingCN107829872AIncrease profitAchieve continuous power supplyHydro energy generationMachines/enginesEnergy transferMechanical energy

The invention discloses a same-direction conversion device and an ocean power generation system adopting the same-direction conversion device. The same-direction conversion device comprises a first energy conversion wheel, two unidirectional driving gears capable of achieving reverse drive, and a power wheel, wherein due to the association function in which the first unidirectional driving gear and the second unidirectional driving gear of which the driving direction is opposite to that of the first unidirectional driving gear cooperate with rotating wheels at the same time, the power wheel rotates in one direction no matter whether the first energy conversion wheel rotates anticlockwise or clockwise, and mechanical motion in different directions is converted into mechanical motion in onedirection. The same-direction conversion device is applied to the ocean power generation system, the system is equipped with energy transfer devices, main brackets and a power generation device, the energy transfer devices can convert wave energy into mechanical energy and drive the same-direction conversion device to operate, and the power wheel of the same-direction conversion device is connected with the power generation device and drives a generator to operate. According to the ocean power generation system, continuous power supply of the generator can be achieved, and power generation efficiency is improved.

Owner:杨洪彬

Preparation method of titanium alloy seamless pipe

The invention provides a preparation method of a titanium alloy seamless pipe. The preparation method comprises the following steps: step 1, smelting titanium sponge and intermediate alloy for multiple times to obtain a titanium alloy cast ingot; step 2, heating the titanium alloy cast ingot obtained by smelting, carrying out drawing forging, and carrying out multi-heating-number upsetting and drawing above the transformation temperature of the titanium alloy and below the transformation temperature of the titanium alloy in a staggered manner to obtain a titanium alloy bar blank; step 3, punching a through hole in a titanium alloy bar, and performing boring to obtain a titanium alloy hollow bar blank; step 4, coating the inner surface and the outer surface of the heated titanium alloy hollow rod blank with lubricating agent, and then extruding the titanium alloy hollow rod blank to obtain a titanium alloy extruded pipe blank; step 5, performing one-time forming precision forging on thetitanium alloy extruded pipe blank to obtain a precision forging finished pipe blank; and step 6, conducting straightening and machining after overall heat treatment to obtain the titanium alloy seamless pipe. The titanium alloy seamless pipe manufactured by the preparation method has the advantages of being adjustable in pipe outer diameter and shape, high in size precision, high in structural uniformity and the like.

Owner:湖南湘投金天科技集团有限责任公司 +1

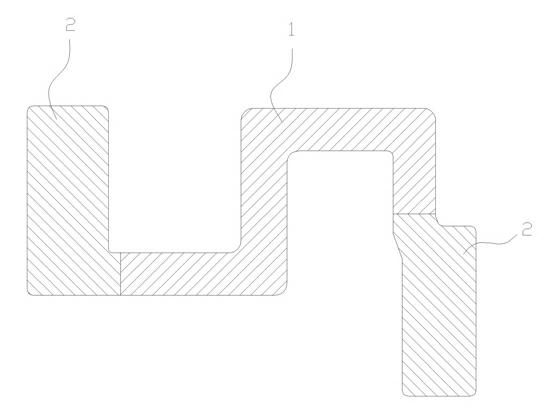

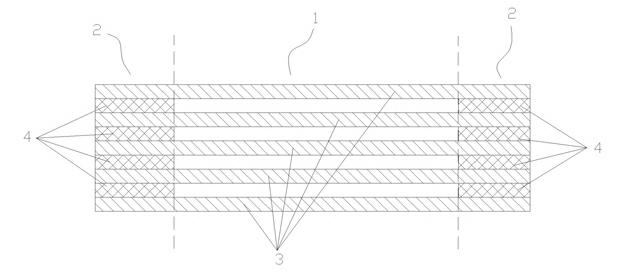

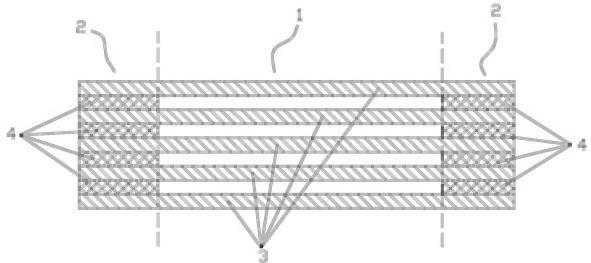

Layered FPC (flexible printed circuit) used for flip/slider phone and manufacturing method

InactiveCN102186304AImprove flex lifeReduce thicknessPrinted circuit detailsSubstation equipmentEngineeringMotherboard

The invention discloses a layered FPC (flexible printed circuit) which has simple design and can obviously improve the life of a flip or slider of a flip / slider phone and a manufacturing method. The layered FPC is connected between a phone mainboard and an upper flip / slider mainboard and comprises at least two layers of FPC single boards (3) and adhesive layers (4) arranged in the partial areas between the two adjacent layers of FPC single boards (3); the FPC single boards (3) are freely separated from each other and the adhesive layers (4) are not arranged between the two adjacent layers of FPC single boards (3) in a buckling area (1) in the middle part of the layered FPC; and the adhesive layers (4) are arranged among the FPC single boards (3) in fixed areas (2) at the two ends of the layered FPC and tightly fix the FPC single boards (3). The manufacturing method is characterized by adopting single sided boards for production, bonding the layers with adhesive films or prepregs, pre-punching the adhesive films or prepregs in the area needing to be layered and then laminating the partial punched adhesive films or prepregs with all layers of single sided boards.

Owner:ZHUHAI YUANSHENG ELECTRONICS SCI & TECH

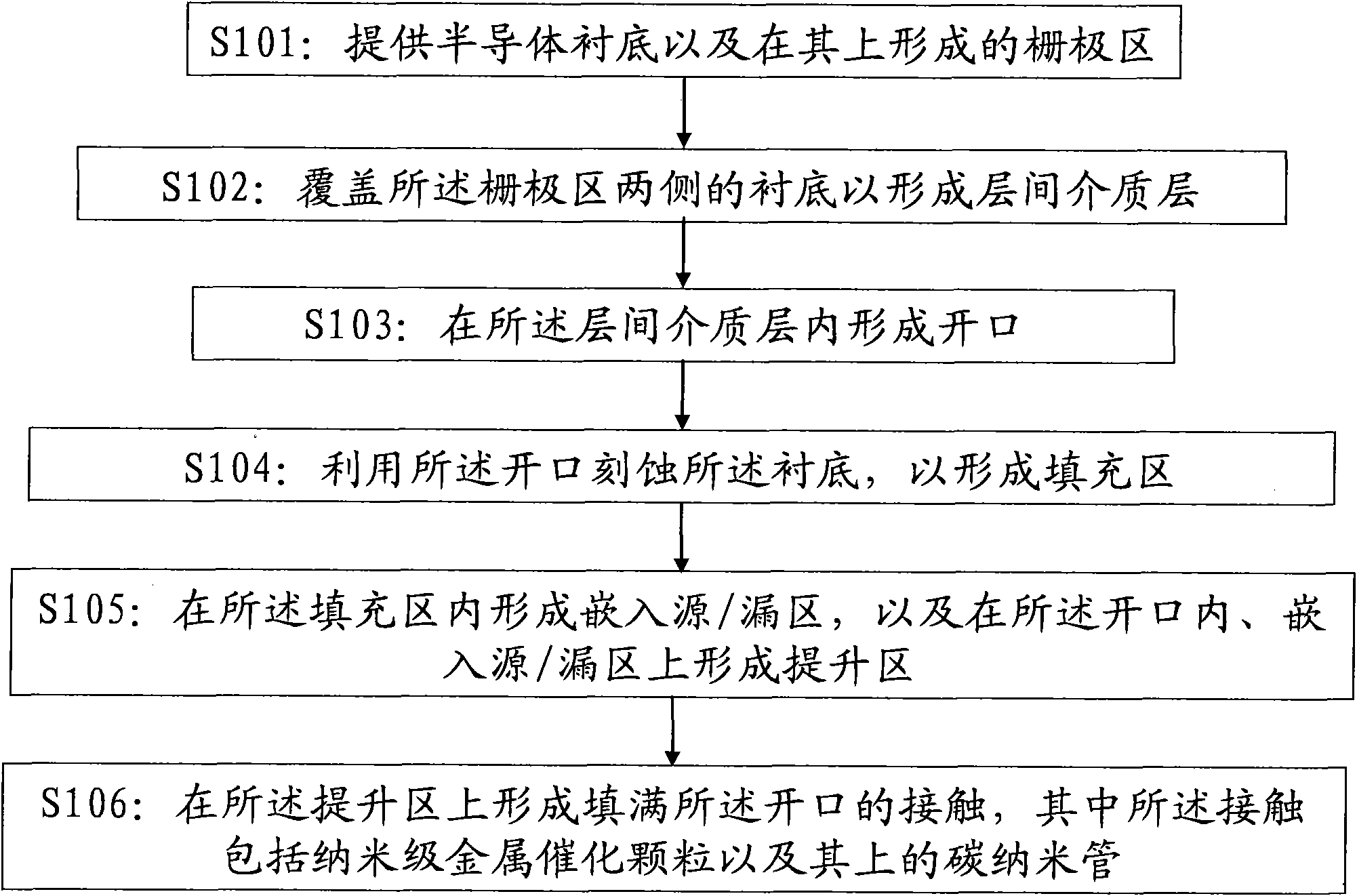

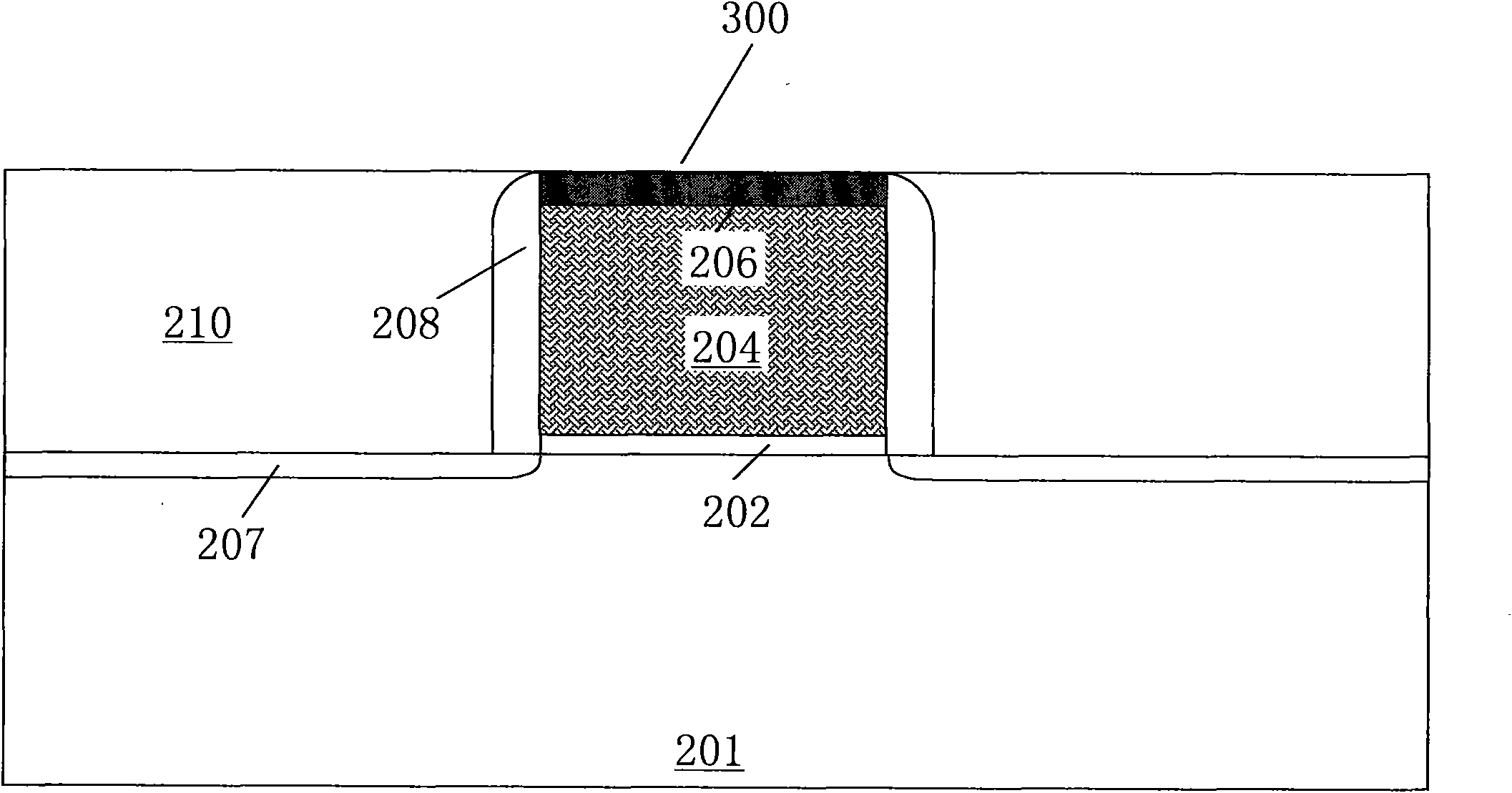

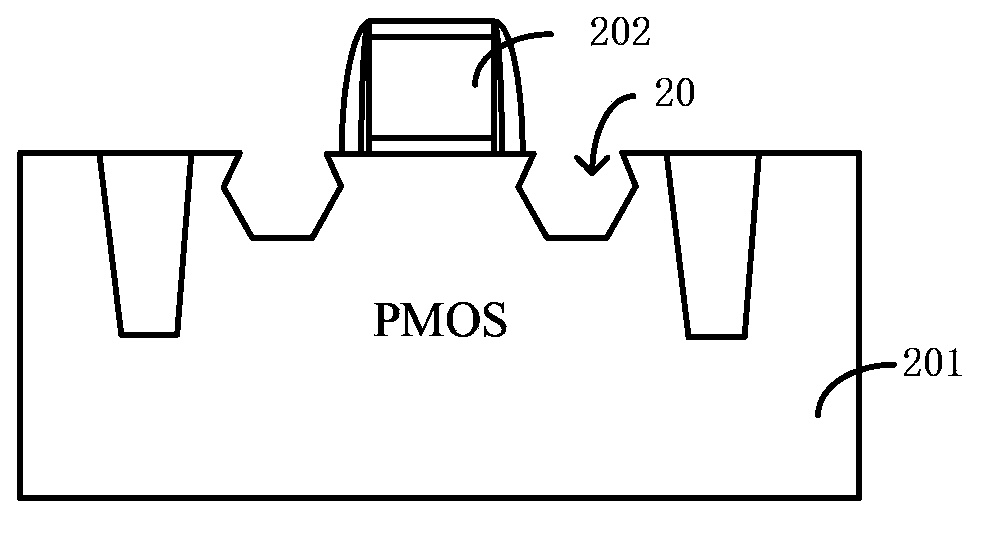

Semiconductor device and manufacturing method thereof

ActiveCN102376625AReduce contact resistanceImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeHigh conductivity

The invention discloses a semiconductor device and a manufacturing method thereof. According to the invention, after source / drain regions or lifting regions are formed, a contact plug structure containing nano-scale catalytic metal particles and carbon nanotubes on the nano-scale catalytic metal particles is formed. The nano-scale catalytic metal particles not only has an effect of inducting growth of the carbon nanotubes but also is capable of reducing contact resistances between contact plug and the source / drain regions in contact holes, so that contact resistances of the device can be reduced; moreover, the carbon nanotubes itself has high conductivity, thereby substantially reducing body resistance for contact; and thus, a parasitic resistance of the device is reduced.

Owner:锐立平芯微电子(广州)有限责任公司

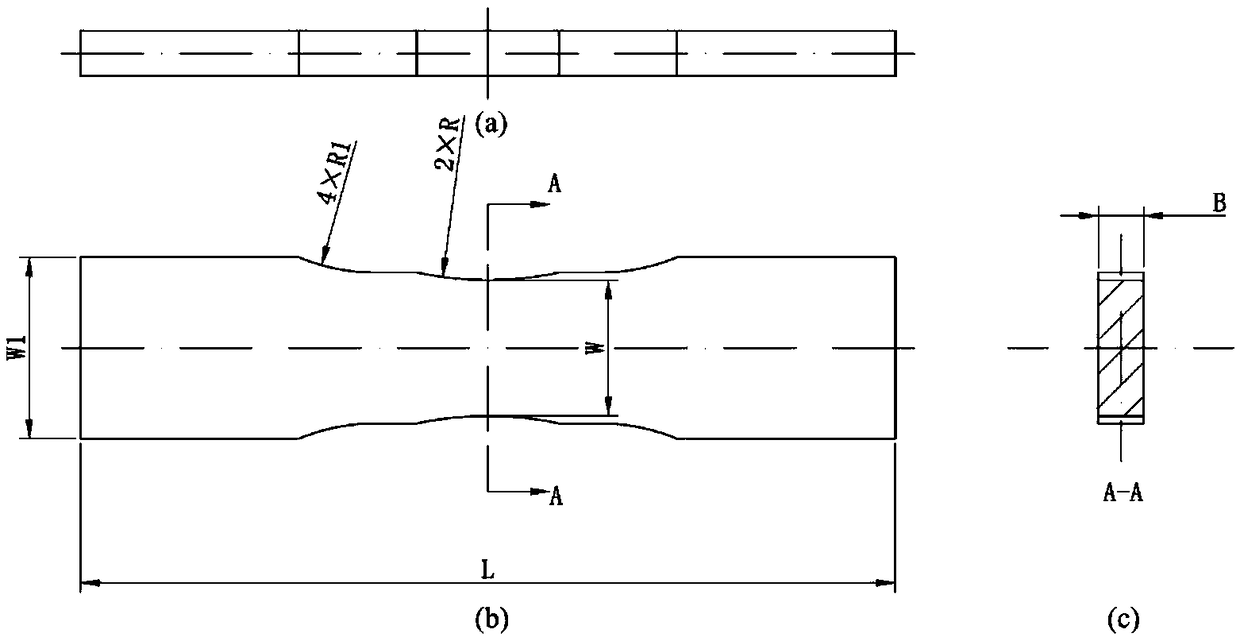

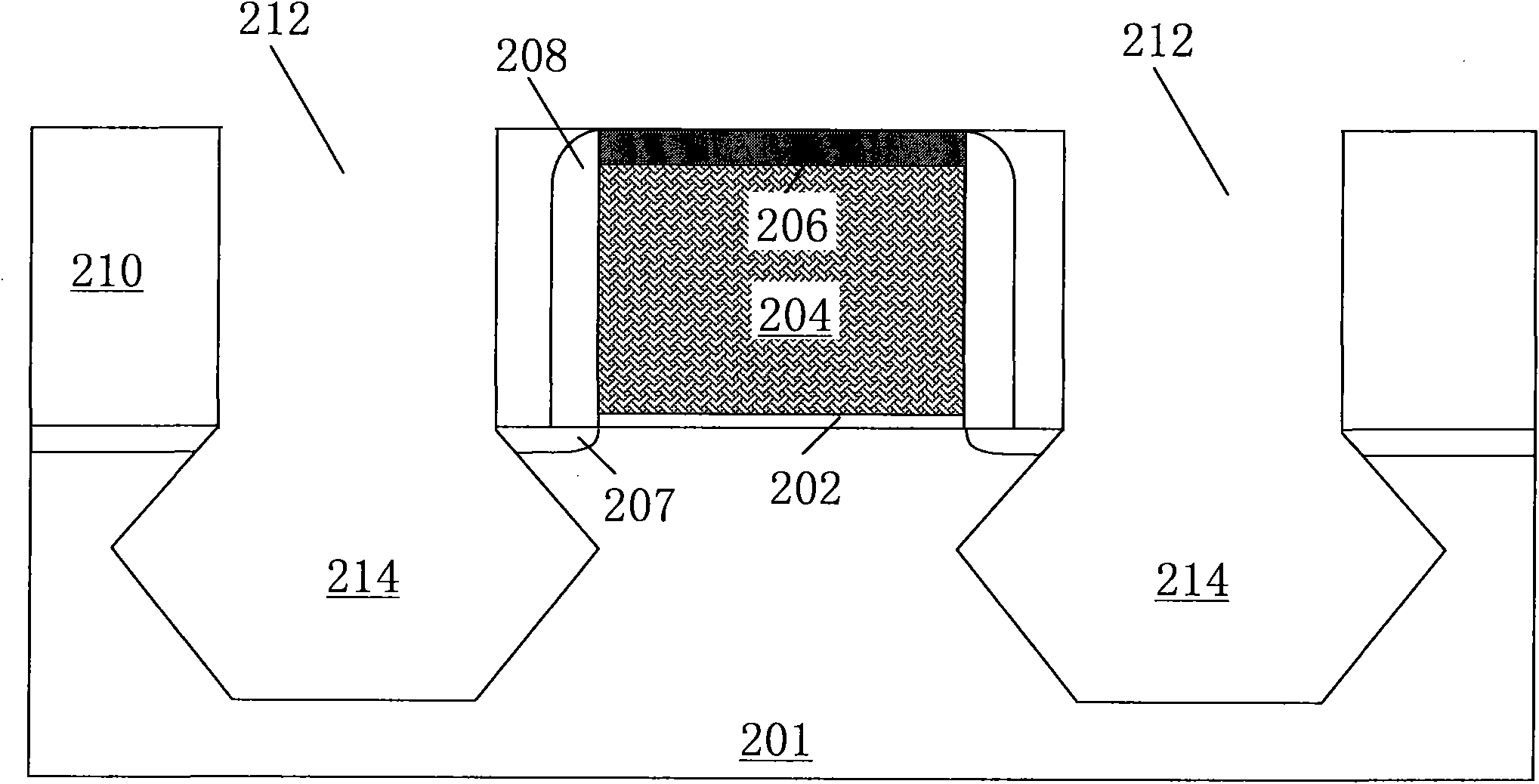

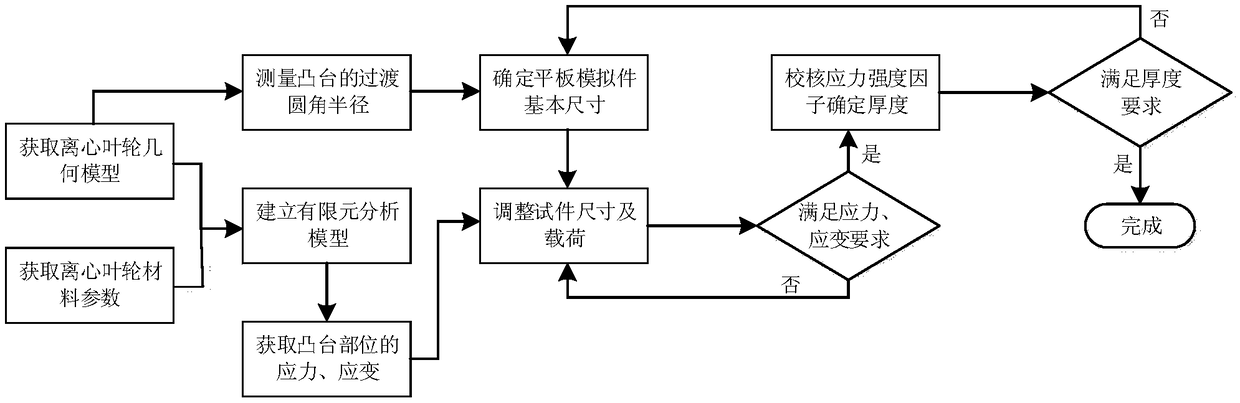

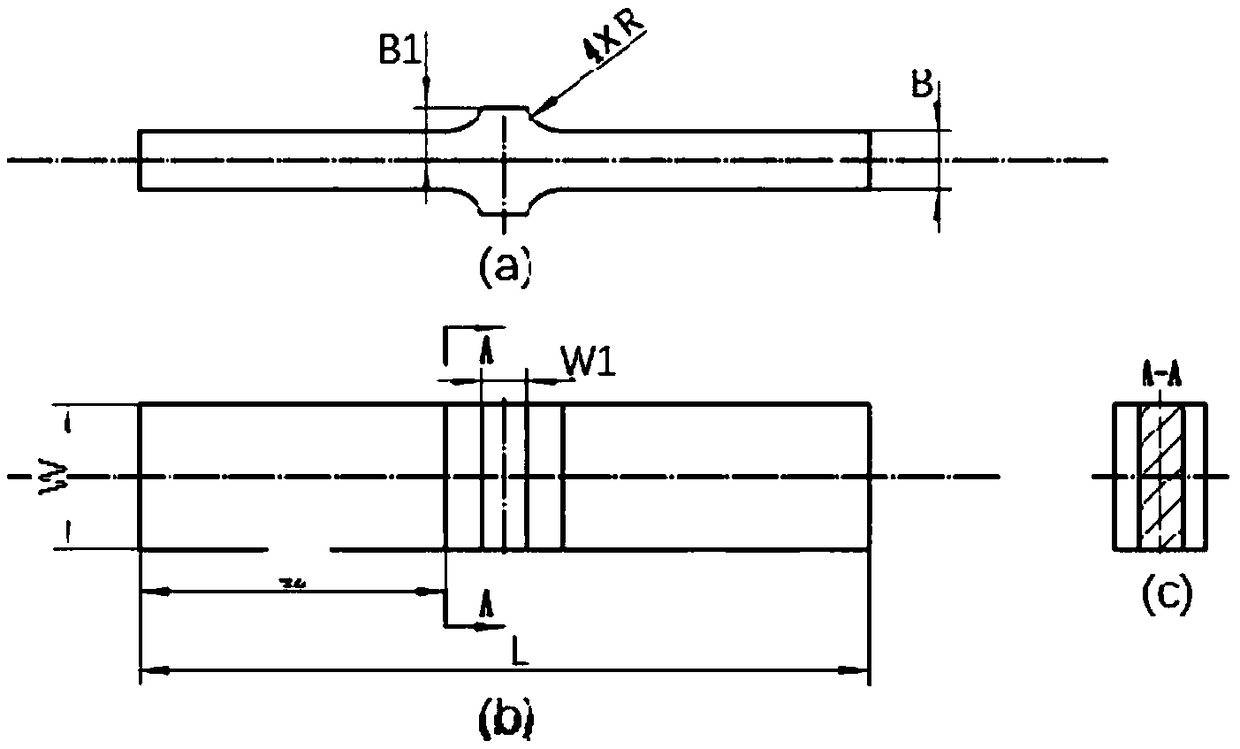

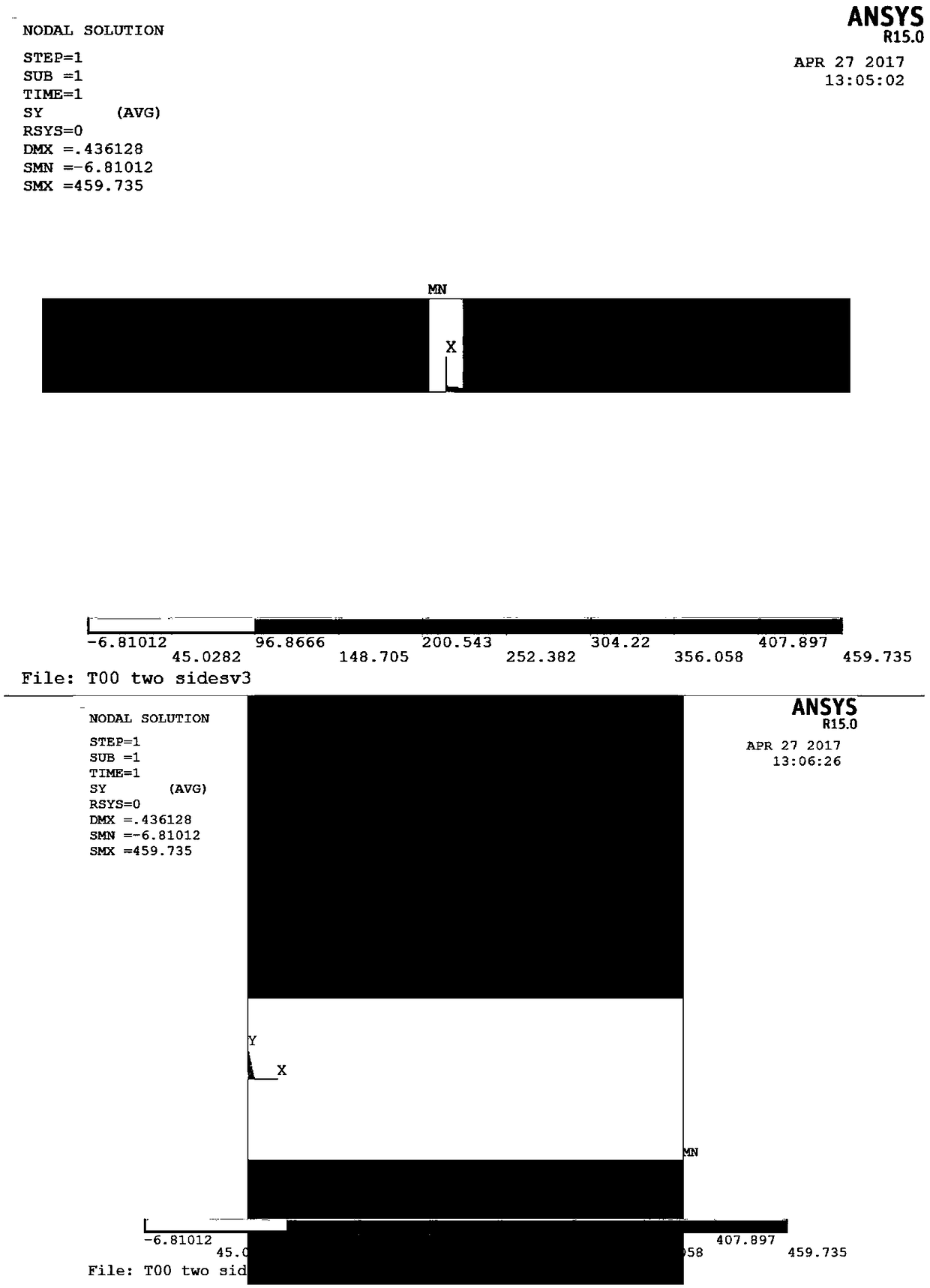

Centrifugal impeller boss crack propagation feature simulator design method

ActiveCN108763839AGuaranteed maximum pulling forceConsistent maximum pullGeometric CADDesign optimisation/simulationImpellerStress intensity factor

The invention relates to a centrifugal impeller boss crack propagation feature simulator design method. The method comprises the following steps: acquiring a geometric model of a centrifugal impeller,measuring a transition fillet semi-diameter of a boss structure and a boss radial length; acquiring a working condition of the centrifugal impeller and the material performance parameter under the working condition; establishing a centrifugal impeller finite element analysis model, computing to acquire the stress maximum point of the boss part of the centrifugal impeller; taking the rectangular slab test piece as the basic shape, wherein boss structures are arranged on symmetric locations at two sides of the slab, and the transition fillet semi-diameters of the boss and the rectangular slab and the boss radial length and the actual structure are consistent; enabling the maximum stress at the stretching direction of the simulator close to the boss location is consistent with the actual structure by adjusting the test piece length method, and guaranteeing that the stress gradient is same; checking the relation of the stress strength factor of the simulator and the test piece thickness,determining the thickness of the test piece, wherein the obtained simulator can simulate the stress strain field of the centrifugal impeller boss structure and can be used for developing crack extension test.

Owner:BEIHANG UNIV +1

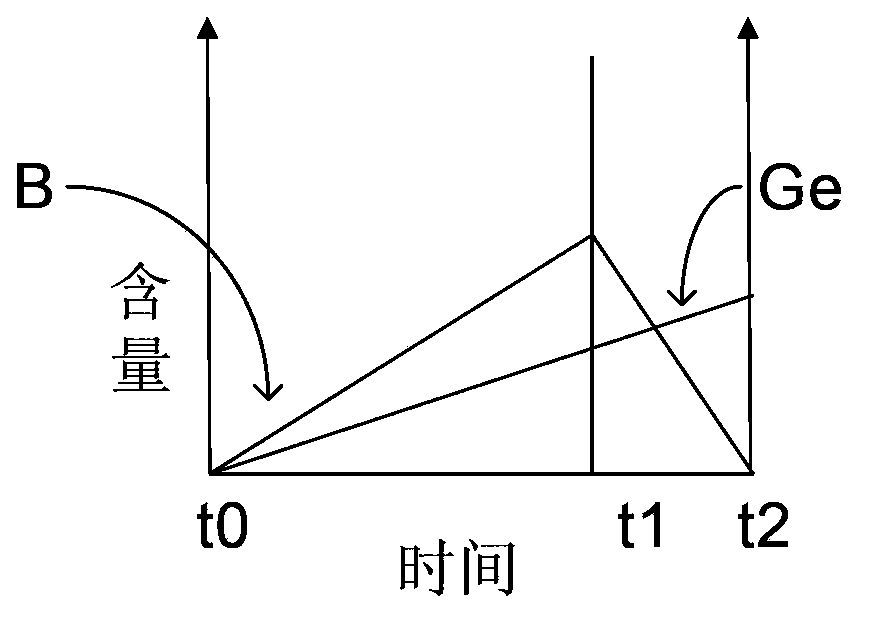

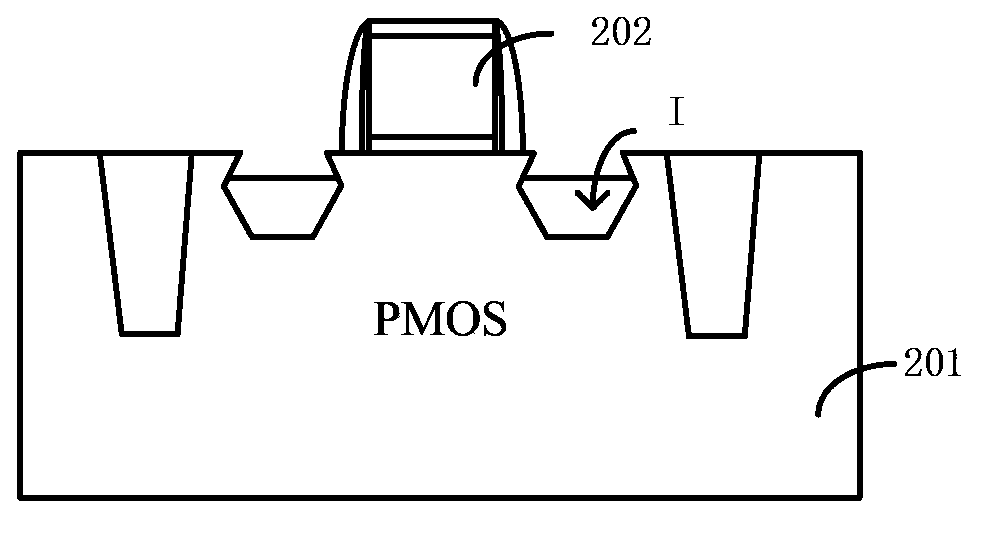

Semiconductor device preparing method

ActiveCN103779216AReduce doping concentrationGuaranteed stressSemiconductor/solid-state device manufacturingSemiconductor devicesShort-channel effectPower semiconductor device

The invention relates to a semiconductor device preparing method. The method comprises the following steps: a semiconductor substrate is provided, wherein the semiconductor substrate at least includes a gate structure; and grooves are formed in two sides of the gate and a SiGeB layer is grown in the grooves through epitaxial growth. The method is characterized in that B is doped in an in-situ manner while performing the epitaxial growth of the SiGe layer, and the epitaxial growth comprises two stages: the first stage is to increase the concentration of B in the SiGe layer to make the concentration of B in the SiGe layer reaches the peak concentration; and the second stage is to reduce the concentration of B in the SiGe layer so as to eliminate the short-channel effect. Through the method of the invention, not only a more flat doping tail contour can be acquired after the B doping process is performed so as to reduce the junction leakage phenomenon, and the method can skip the separate ion implantation process so as to make the stress in the channel region maintained; and but also the method can be used to make the doping concentration of B at channels is low so as to eliminate the short-channel effect to make prepared devices have good performances.

Owner:SEMICON MFG INT (SHANGHAI) CORP

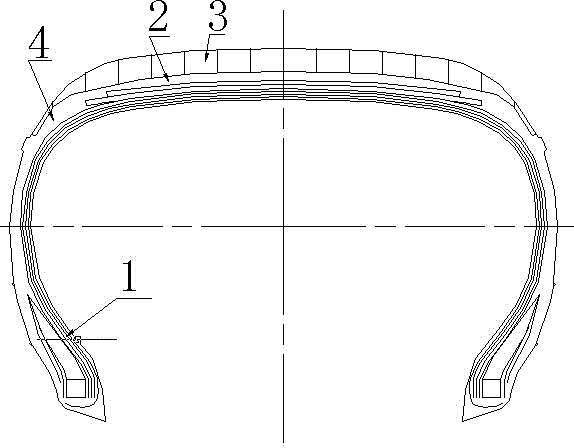

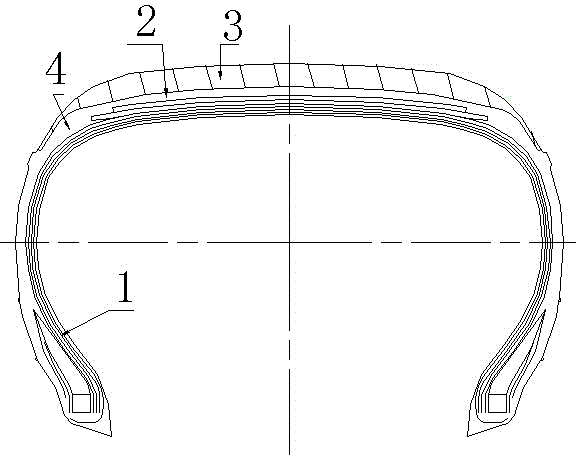

Semi-steel radial tire blank

InactiveCN104553619AImprove structural performanceImprove plasticityPneumatic tyre reinforcementsWork in processEngineering

The invention provides a semi-steel radial tire blank, which comprises a tire body, a tread and a tire side, wherein the tread is in a rubber strip wrapping structure, namely a single rubber strip is wound on the tire body from the tire side as the starting point along the peripheral direction of the tire body; the adjacent rubber strips are arranged in a clinging manner or a slant stacking manner; the tail end of each single rubber strip is located on the other surface of the tire side, and is finally vulcanized into an overall tire blank body; the width of each rubber strip can be directionally adjusted according to the technological requirements; the width of the new tread is changed by changing the width of each rubber strip; the design structure of a trapezoidal tread made from a traditional single rubber strip and a traditional cutting tread pasting process are changed; the constitutive property and the plasticity of the tire blank are enhanced; the abrasive resistance of the tread of the tire is enhanced; the technological link for manufacturing the tire blank is omitted; the technological zero distance among semi-finished product production procedures is achieved; the production quality of the process is ensured; and the potential quality hazard caused by manual intervention is avoided.

Owner:双星东风轮胎有限公司

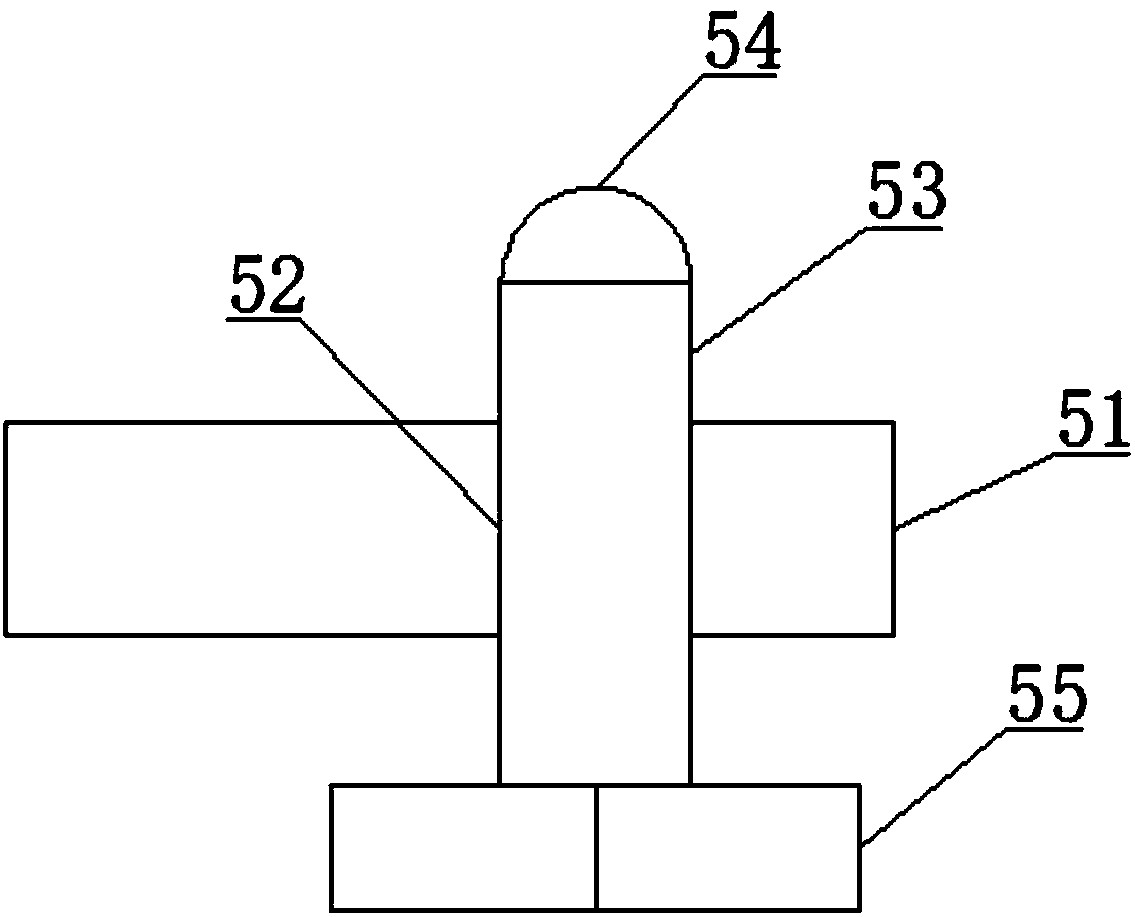

End portion balance supporting device for compartment of agricultural tractor

InactiveCN107697835AGuaranteed stressAvoid damageSafety devices for lifting equipmentsEngineeringBlock structure

The invention discloses an end portion balance supporting device for a compartment of an agricultural tractor. The device comprises a triangular block and a hollow shell; the bottom of the side face of the triangular block is provided with an insertion block structure, and the triangular block and the insertion block structure are of an integrated structure; limiting fixing mechanisms are arrangedon the two sides of one end of the insertion block structure and integrated with the insertion block structure; a rectangular insertion hole communicating with the surface of the triangular block isformed inside the center of the triangular block; a through hole structure for communicating the rectangular insertion hole and the outside is arranged inside the triangular block; and a rectangular block is inserted into the rectangular insertion hole. During working, the device can be directly inserted into a herringbone triangle position in the end portion of the compartment and is very convenient to use; in addition, the device has the function of adjusting the supporting height, when the device and a machine head are dismounted and mounted, convenience and rapidness are achieved; and besides, the device can effectively ensure the stress condition of an inner thread structure, prevents the phenomenon that threads are damaged due to stress overload and is high in practicability.

Owner:薛春红

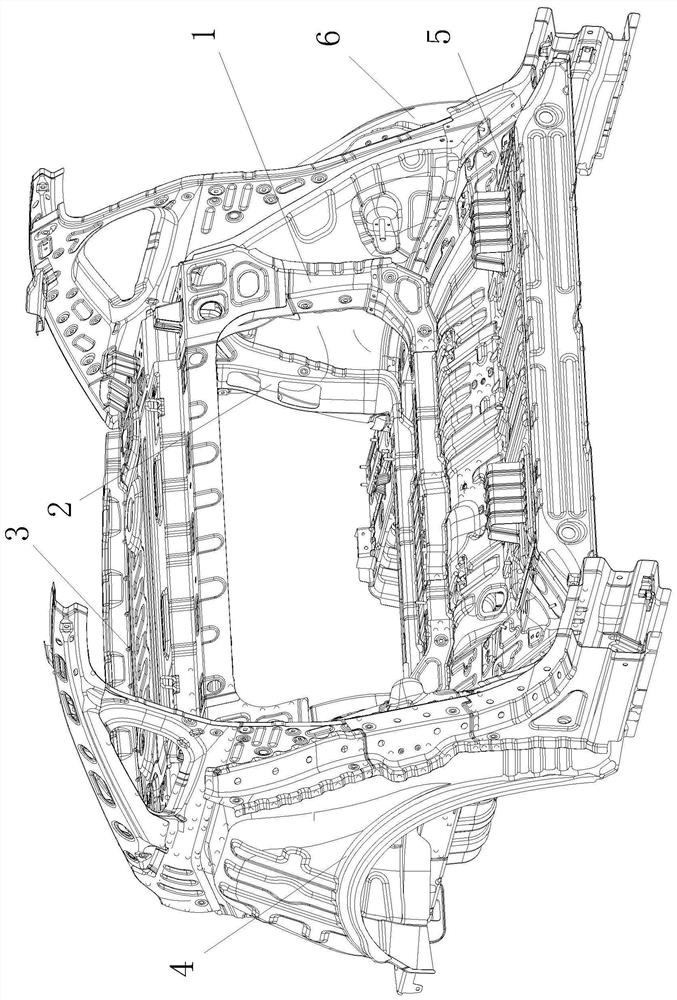

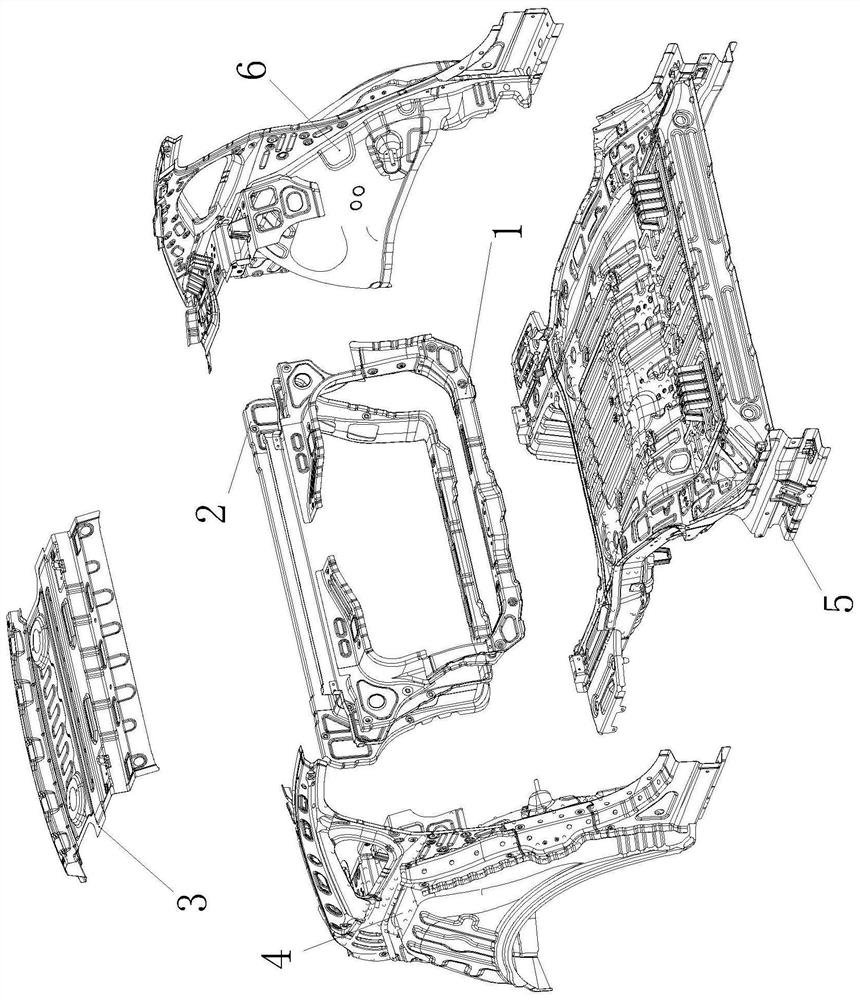

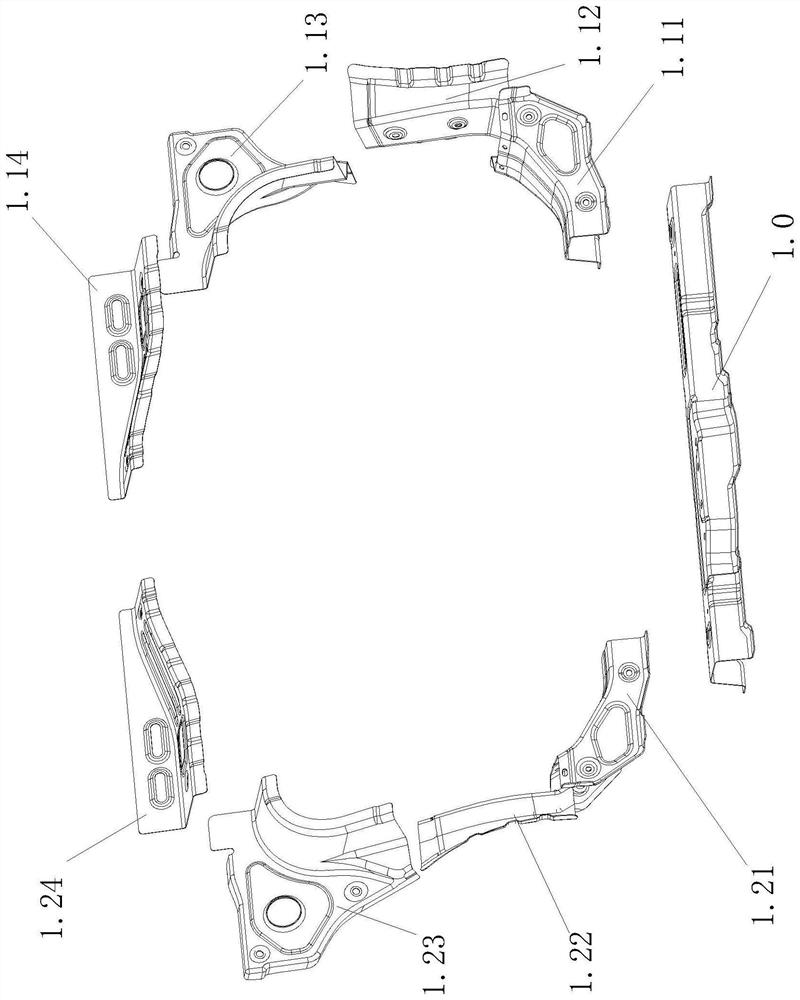

C-ring structure of new energy automobile

ActiveCN111806575AGuaranteed StrengthReduce energy consumptionSuperstructure subunitsTorsional rigidityNew energy

A C-ring structure of a new energy automobile is formed by connecting a front C-ring assembly, a rear C-ring assembly, a rear storage table assembly, a right rear wheel cover assembly, a rear floor assembly and a left rear wheel cover assembly. The front C-ring assembly is formed by connecting a front and rear floor upper cross beam assembly, a left front and rear floor upper cross beam plate, a right front and rear floor upper cross beam plate, a left wheel cover front lower plate, a right wheel cover front lower plate, a left wheel cover front plate, a right wheel cover front plate, a left rear storage table front cross beam and a right rear storage table front cross beam; and the rear C-ring assembly is formed by connecting a rear floor rear upper cross beam assembly, a left rear floorupper rear cross beam plate, a right rear floor upper rear cross beam plate, a left wheel cover rear plate, a right wheel cover rear plate and a rear storage table rear cross beam. A complete force conduction path can be constructed on one side of a shock absorber, torsional rigidity and strength of a rear side wall assembly are greatly improved, and the C-ring structure is stable in structure, light in weight and beneficial to reducing energy consumption of a new energy automobile and increasing anendurance mileage of the new energy automobile.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

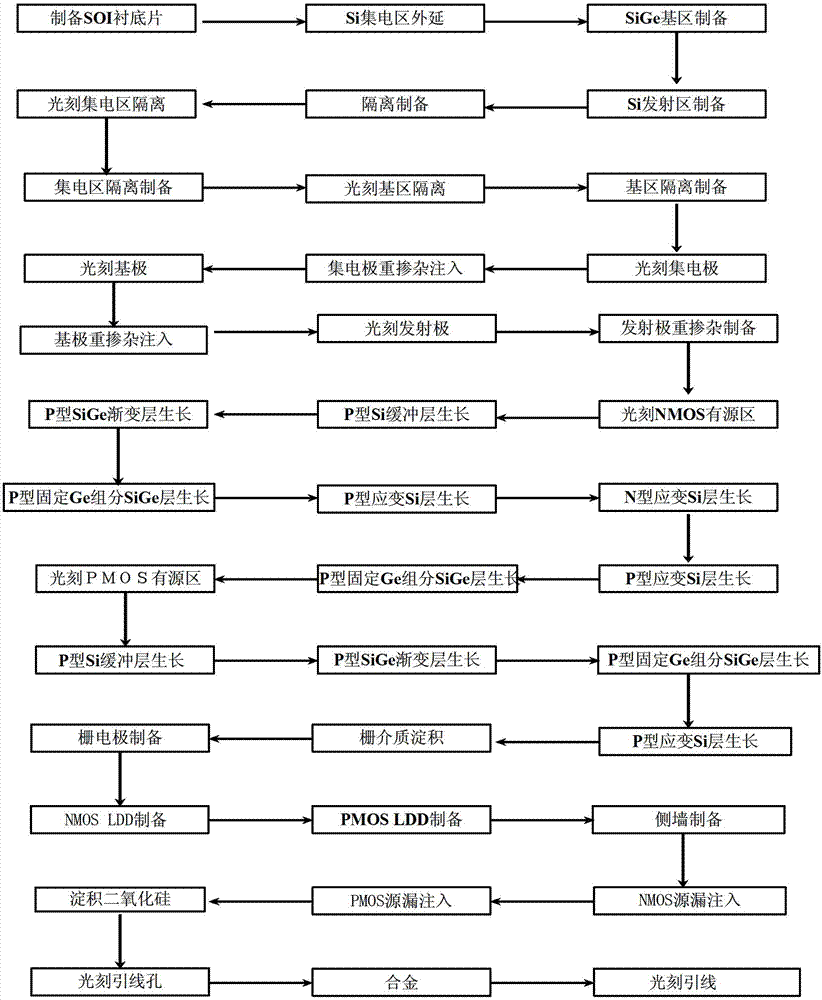

Mixed crystal plane silicon-on-insulator (SOI) bipolar complementary metal oxide semiconductor (BiCMOS) integrated device based on square channel process and preparation method

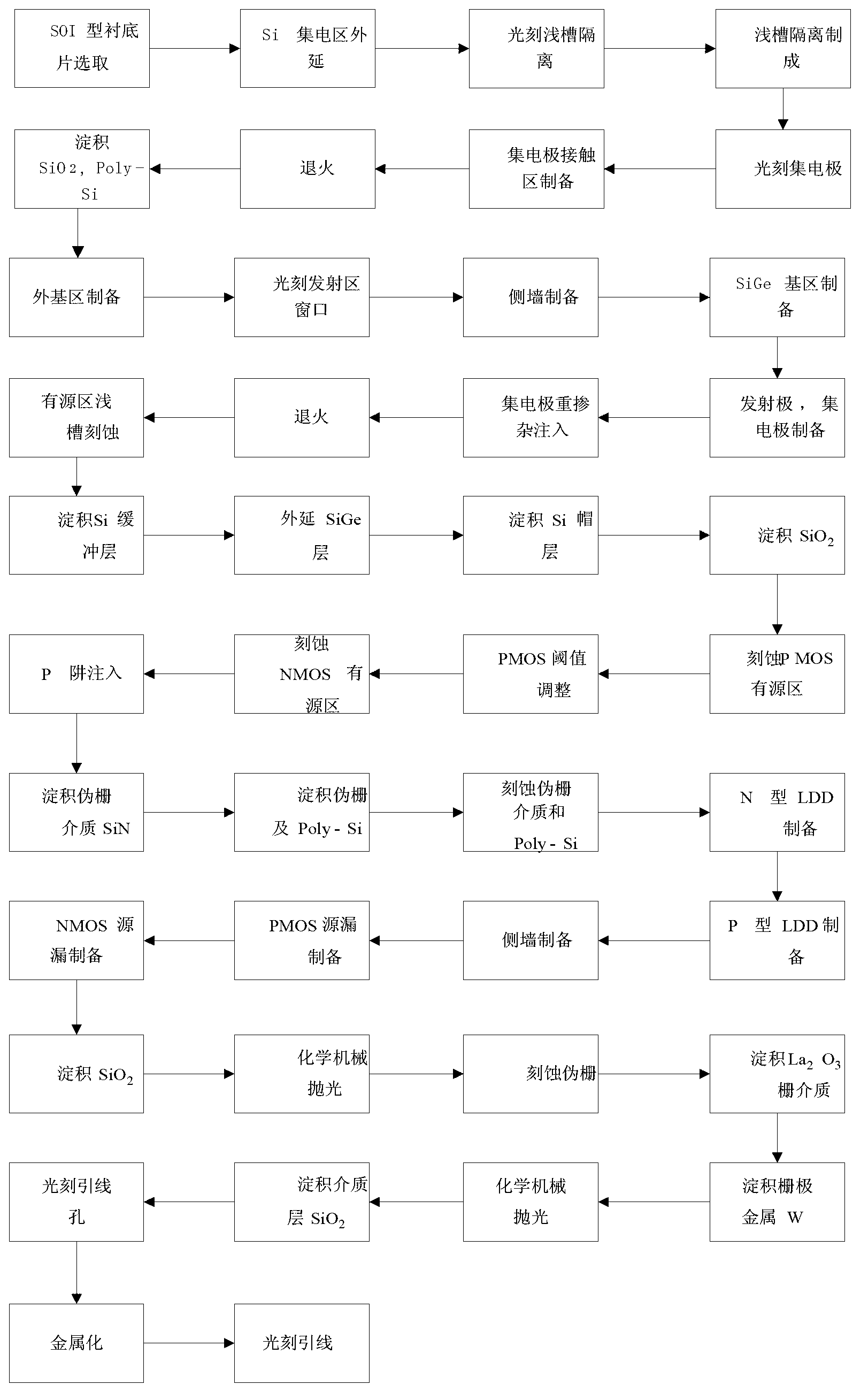

InactiveCN102738160AImprove performanceHigh hole mobilitySolid-state devicesSemiconductor/solid-state device manufacturingP channelMixed crystal

The invention discloses a mixed crystal plane silicon-on-insulator (SOI) bipolar complementary metal oxide semiconductor (BiCMOS) integrated device based on a square channel process and a preparation method. The method comprises the following steps of: preparing an SOI substrate, continuously growing N-Si, P-SiGe and N-Si layers on the SOI substrate, preparing an deep groove isolator, forming a collector, a base and an emitter contact area, and forming a SiGe heterojunction bipolar transistor (HBT) device; photo-etching an active area of a p-channel metal oxide semiconductor (PMOS) device, continuously growing 7 layers of materials in the active area, preparing a drain and a grid, and forming the PMOS device; photo-etching a groove of an active area of an n-channel metal oxide semiconductor (NMOS) device, continuously growing 4 layers of materials in the active area, preparing a grid dielectric layer and grid polycrystalline, and forming the NMOS device; and photo-etching lead holes, alloying, photo-etching leads, and thus forming the mixed crystal plane SOI BiCMOS integrated device and a mixed crystal plane SOI BiCMOS integrated circuit of which CMOS conductive channels are 22 to 45 nanometers based on the square channel process. By fully using the characteristic of mobility anisotropy of a strain Si material, the mixed crystal plane SOI BiCMOS integrated circuit with enhanced performance is prepared at the temperature between 600 and 800 DEG C.

Owner:XIDIAN UNIV

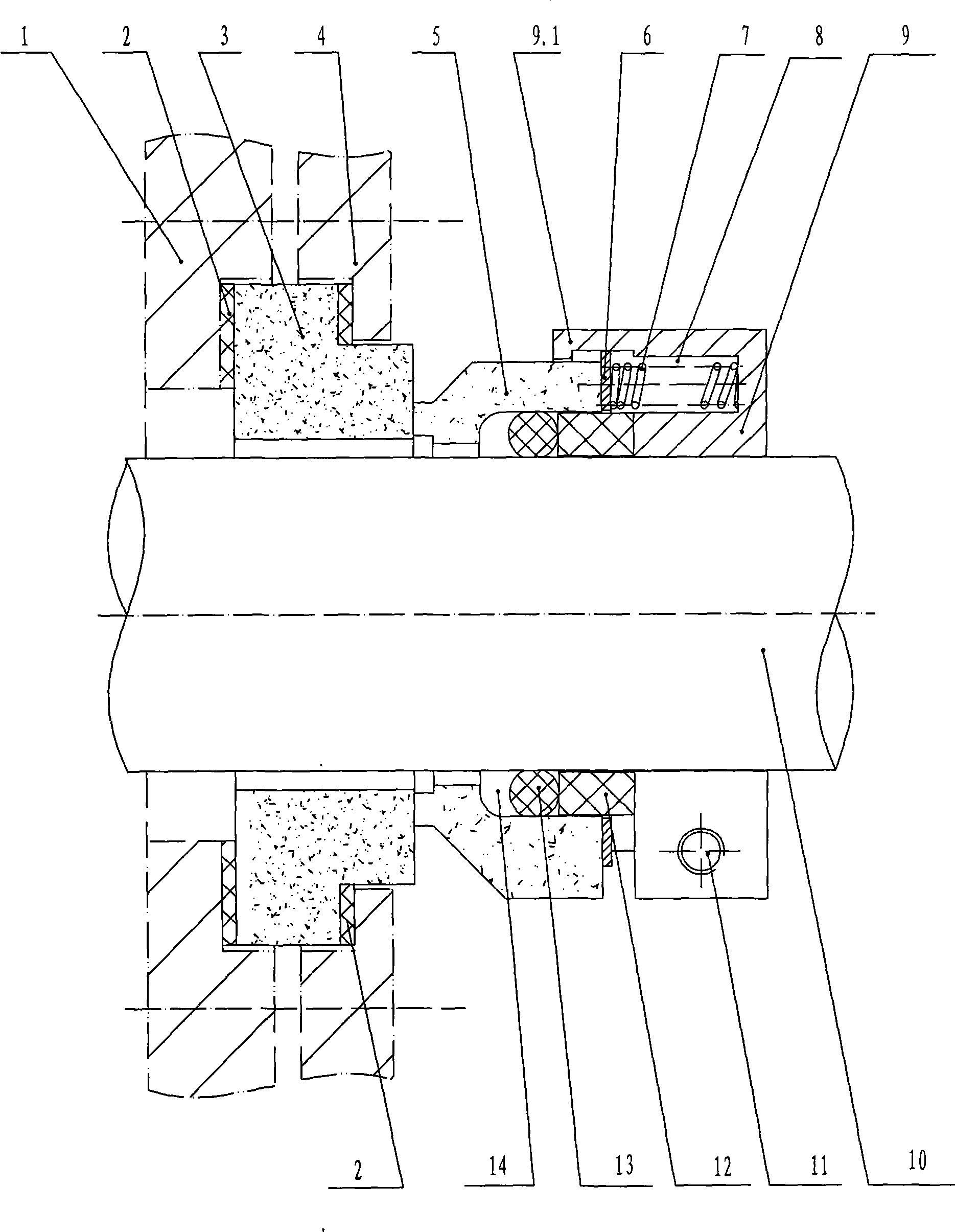

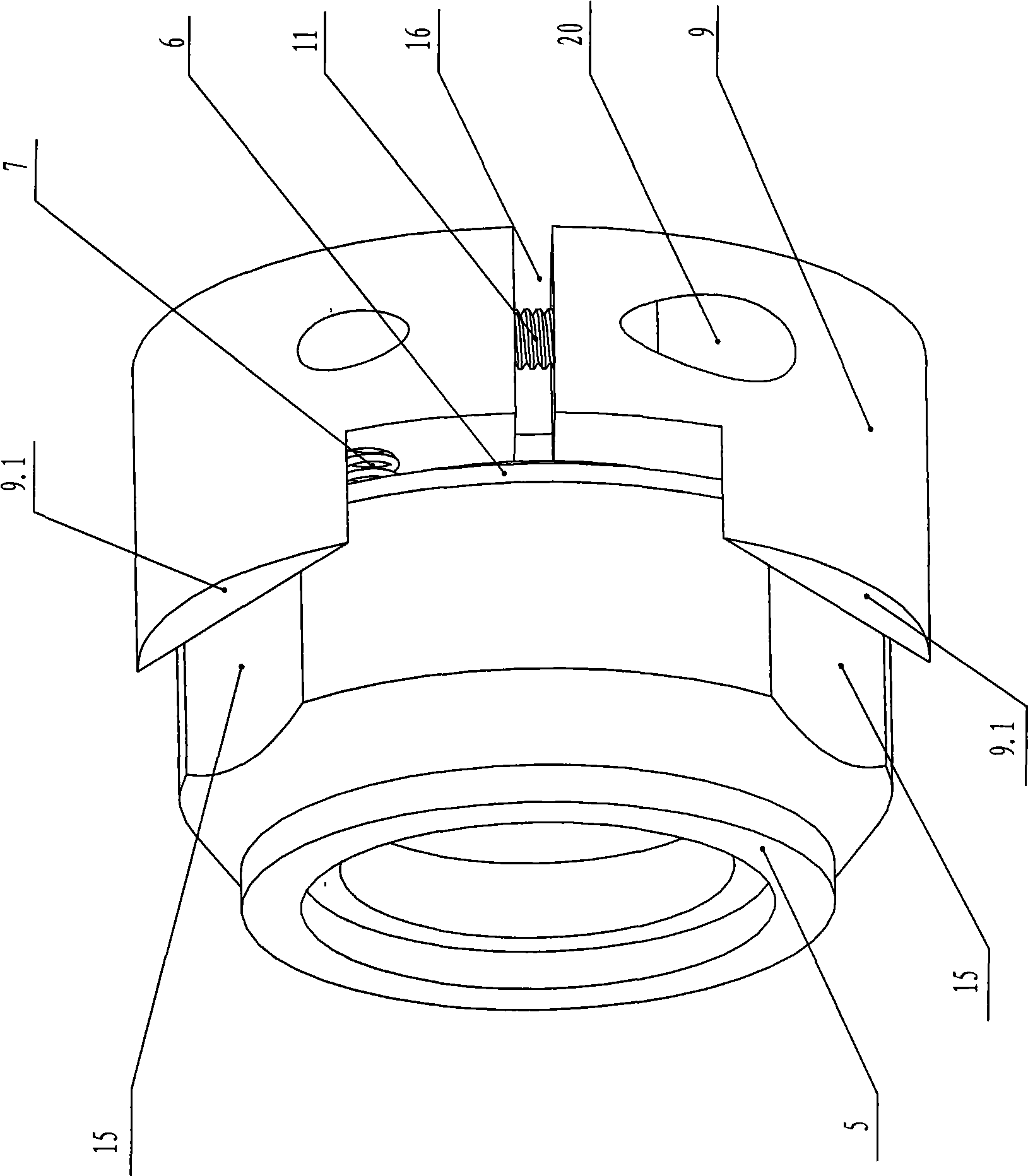

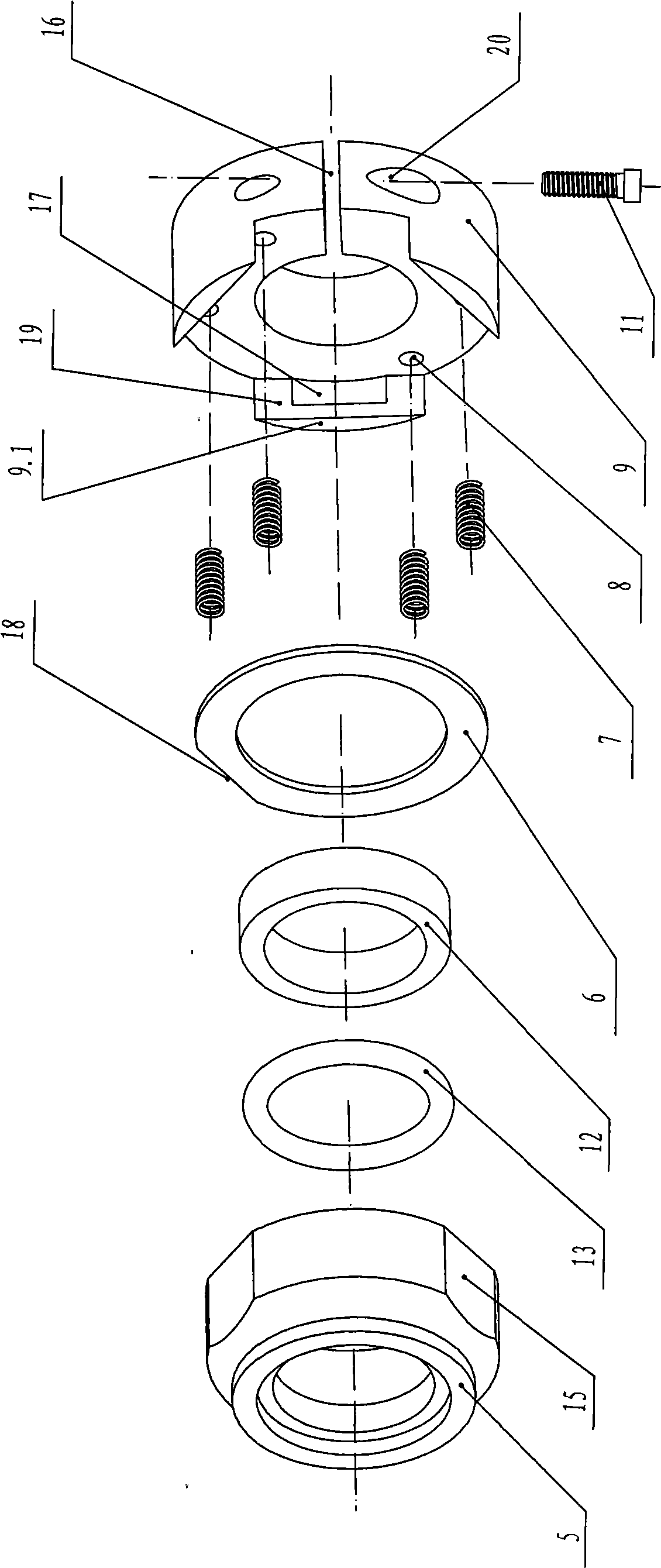

Self-balanced mechanical seal

The invention discloses a self-balanced mechanical seal, wherein a moving ring component comprises a sealing ring (13), a spring (7), a transmission seat (9) connected with a shaft (10) and a moving ring (5); a spring groove (8) is arranged on the transmission seat (9); two ends of the spring (7) respectively abut between a spring pad (6) and the spring groove (8); three planes I (15) are uniformly distributed on circumference external surface of the moving ring (5); three convex edges (9.1) are uniformly distributed on a left end of the transmission seat (9); inner side of the convex edges (9.1) is a plane II (19) matched with the planes I (15); an arc-shaped groove (17) is arranged on the plane II (19); a straight line loss edge (18) is arranged on outer circumference of the spring seat (6); a step bore is arranged at a right end of the moving ring (5); and a moving sealing ring (13) is arranged in the step bore in an interference fit manner. The invention has long service life, stable transmission and small bearing stress for the moving ring, can make disassembling of the moving ring simple and convenient, and can prevent the moving ring from wearing in disassembling process.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

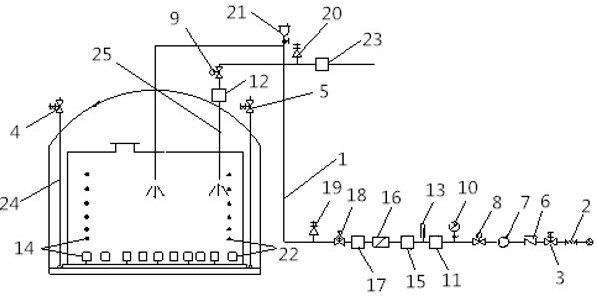

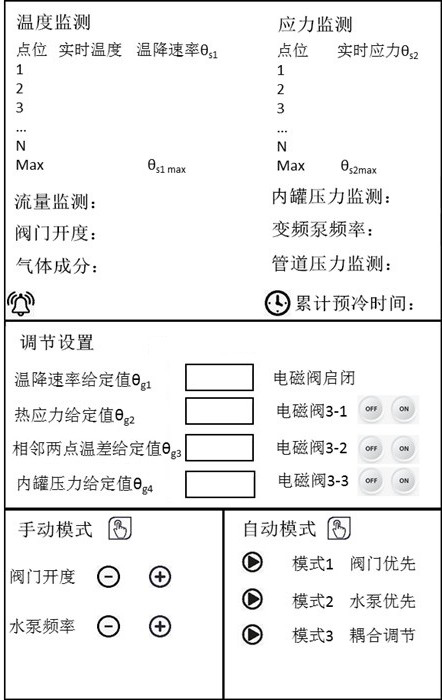

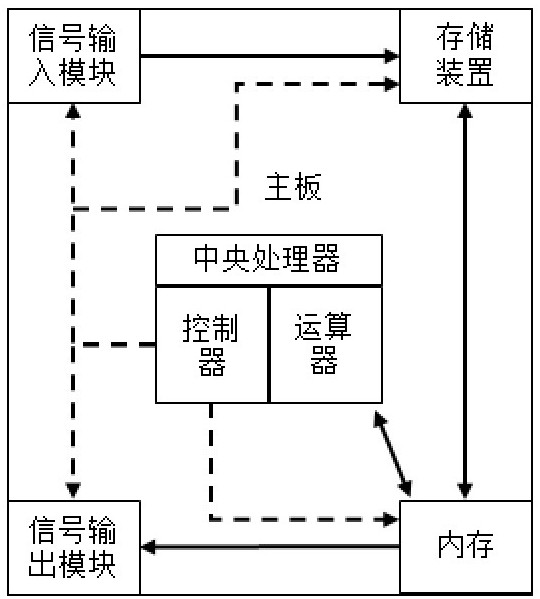

LNG storage tank automatic pre-cooling system based on efficient communication and pre-cooling method

ActiveCN113339695ASolve blindnessImprove pre-cooling effectFluid handling accessoriesContainer discharging methodsMaterial resourcesElectric control

The invention provides an LNG storage tank automatic pre-cooling system based on efficient communication and a pre-cooling method. A CFD numerical simulation module is used for conducting pre-cooling process simulation, and initial flow parameters are provided for the pre-cooling process; and the point positions are installed on a storage tank in a modularized manner, and signal transmission between all sensors in the pre-cooling system and an integrated operation platform is achieved through 5G technology. According to the LNG storage tank automatic pre-cooling system and the pre-cooling method, limit values of parameters such as temperature drop rate, thermal stress, temperature difference between two adjacent points, inner tank pressure and the like are set on the basis of the integrated operation platform, monitoring results and the limit values are compared and analyzed, and then an electric control valve module and a variable frequency pump module are automatically adjusted, so that the conveying flow of a pre-cooling medium is adjusted, and it is guaranteed that the pre-cooling process is stably and safely carried out. According to the LNG storage tank automatic pre-cooling system and method, automatic, integrated and integrated control over the pre-cooling process can be achieved, monitoring personnel do not need to be arranged at monitoring points for a long time, potential safety hazards are avoided, manpower and material resources are saved, pre-cooling control is more accurate, and the pre-cooling efficiency is high.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

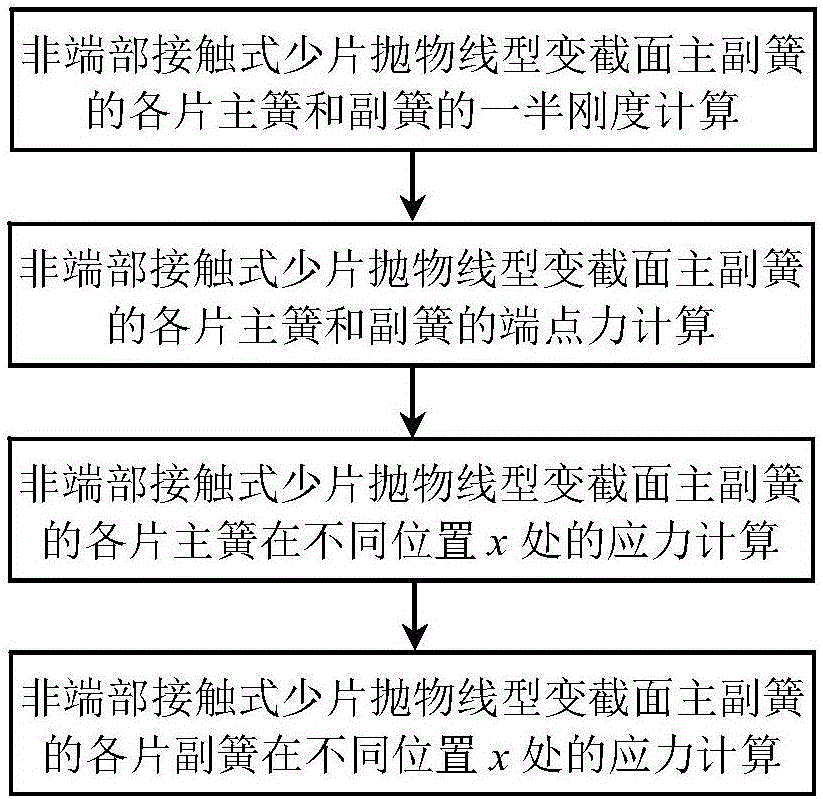

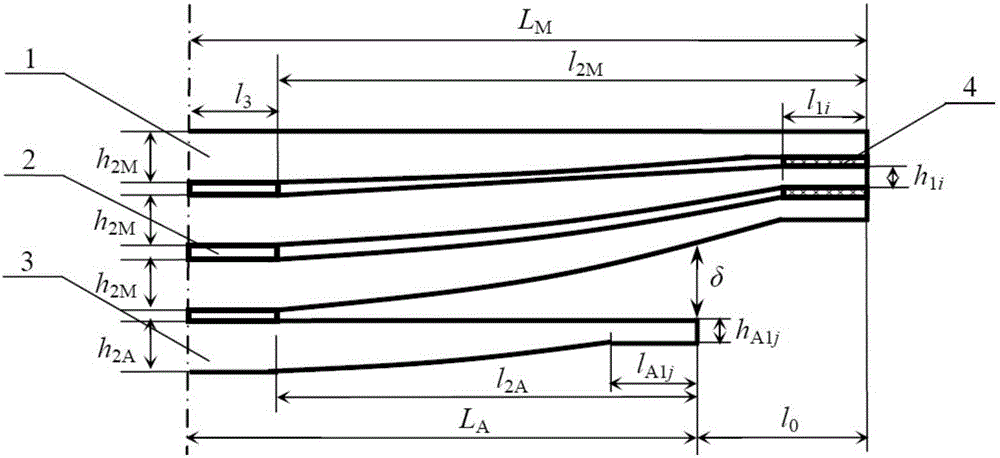

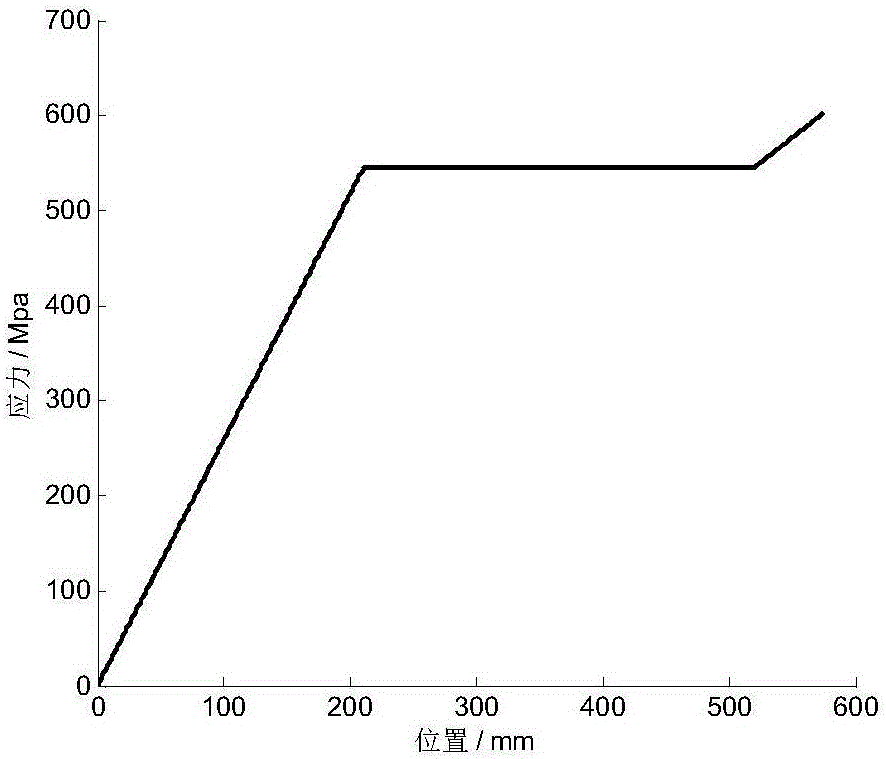

Stress calculating method of each spring of non-end contact type few-leaf parabola main-auxiliary spring

ActiveCN105912794AImprove the design levelImprove ride comfortGeometric CADSpecial data processing applicationsEngineeringContact type

The invention relates to a stress calculating method of each spring of a non-end contact type few-leaf parabola main-auxiliary spring, and belongs to the hang rack steel plate spring technical field; according to structure parameters, elasticity modulus, auxiliary spring useful load and main-auxiliary spring bearing load of each main spring and each auxiliary spring of the non-end contact type few-leaf parabola variable cross-section main-auxiliary spring, the method can calculate the stress of each main spring and each auxiliary spring in a random position; through embodiments and ANSYS emulation proof, the method can obtain accurate and reliable stress calculation values of each main spring and each auxiliary spring in a random position, thus providing accurate calculation method for the stress values of each main spring and each auxiliary spring in a random position of the non-end contact type few-leaf parabola variable cross-section main-auxiliary spring, improving design level, performance and life of the product, improving vehicle driving smoothness, reducing product design and test cost, and accelerating product develop speed.

Owner:山东双力板簧有限公司

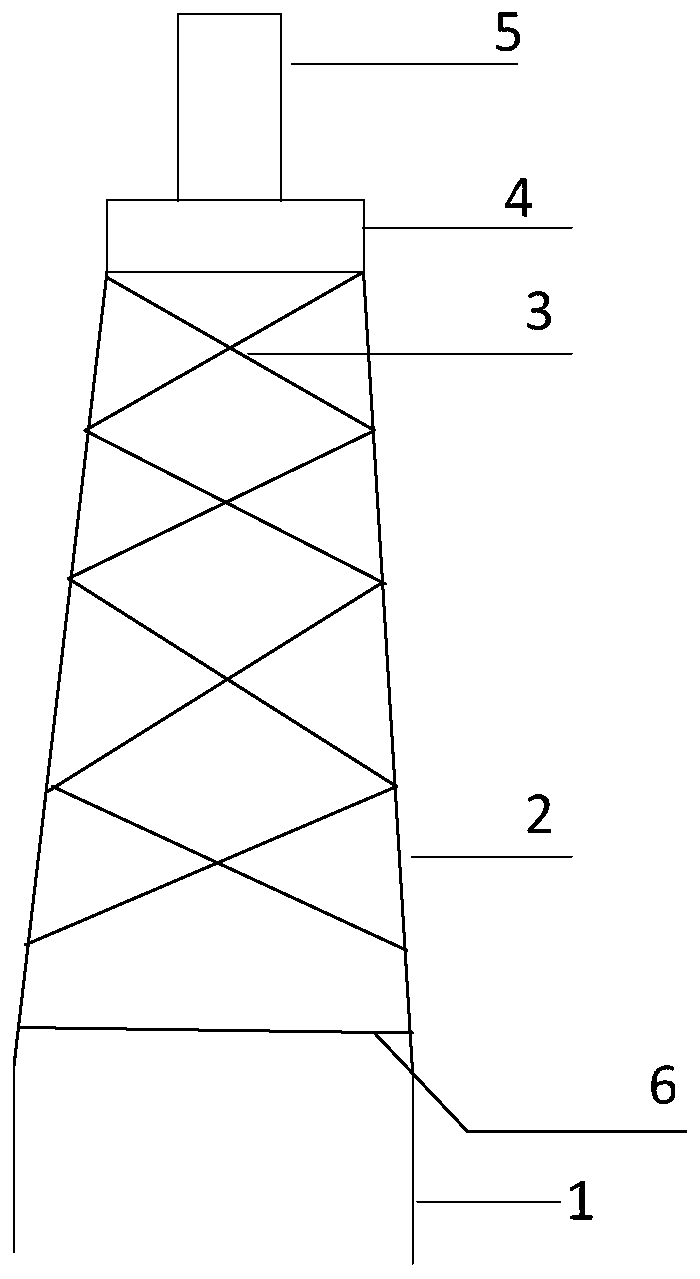

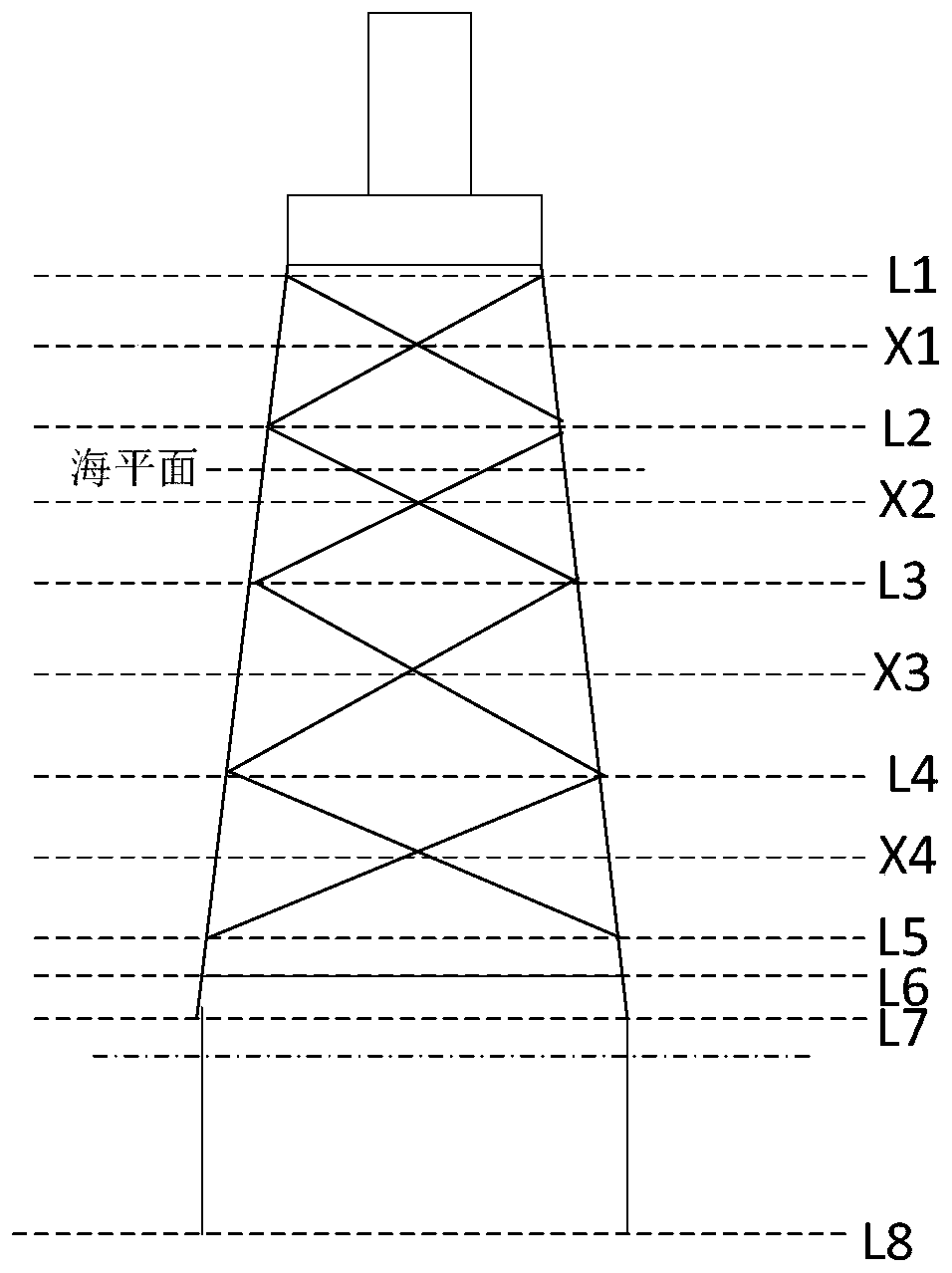

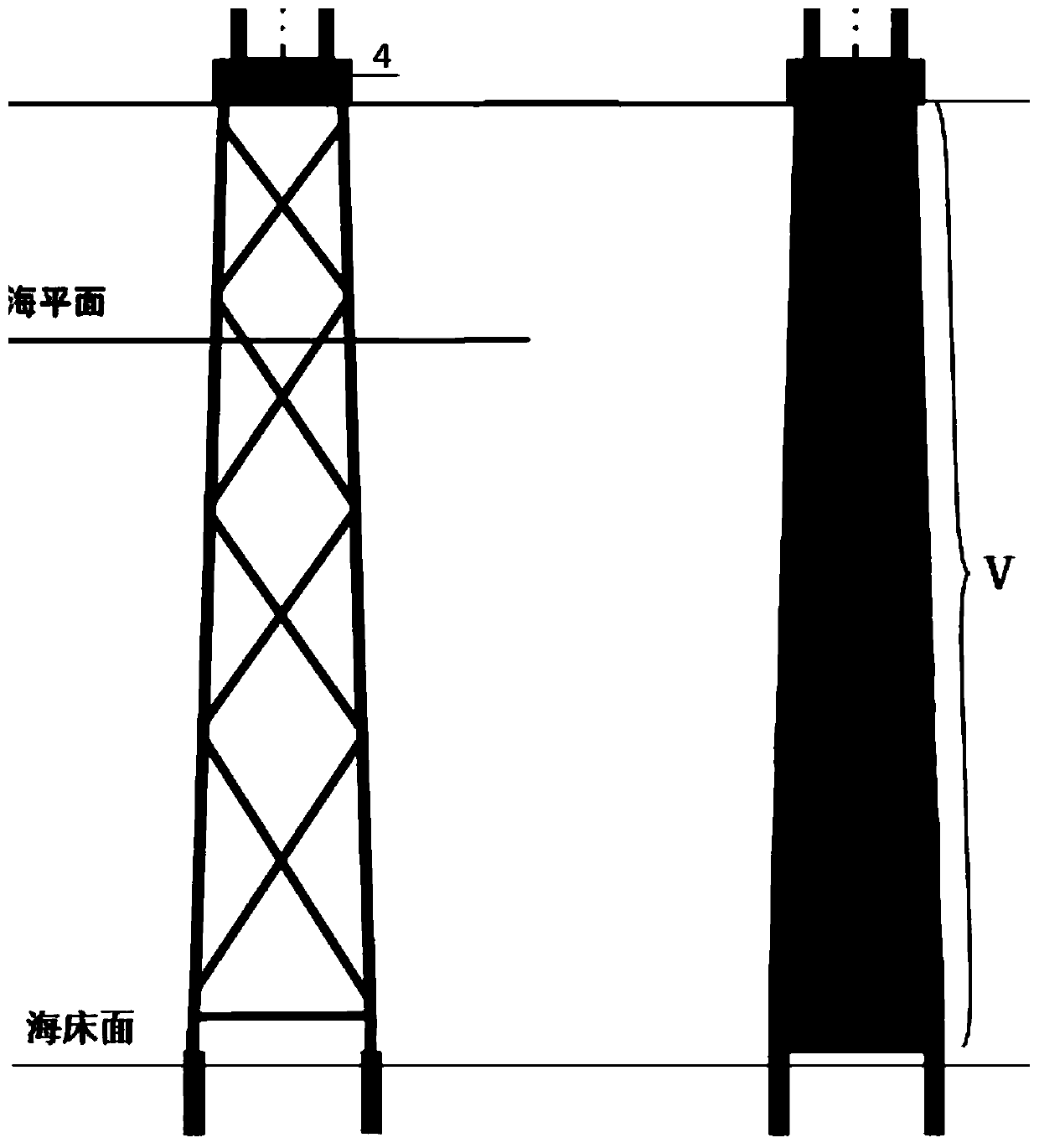

Offshore wind turbine foundation structure and lightweight design method

PendingCN110847210AReduce weightUniform stress distributionGeometric CADWind motor supports/mountsMarine engineeringStructural engineering

The invention discloses an offshore wind turbine foundation structure and a lightweight design method. The offshore wind turbine foundation structure comprises a jacket; the bottom of the jacket is fixed to four piles, the top of the jacket is provided with a transition block, and a wind turbine tower is arranged on the transition block; the jacket comprises four pile legs and a cross structure; and the cross structure is arranged among the pile legs and comprises five layers, including X-shaped structures and K-shaped structures. The offshore wind turbine foundation structure has the advantages that a traditional installation structure of the jacket is changed, a continuum structure is directly optimized by establishing a continuum model, a reasonable truss-type structure with a reasonable force transfer path is obtained, the overall stress is more uniform while the structural weight of the jacket is reduced, and the working safety coefficient is improved.

Owner:OCEAN UNIV OF CHINA

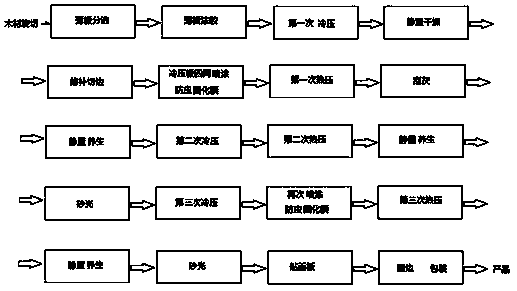

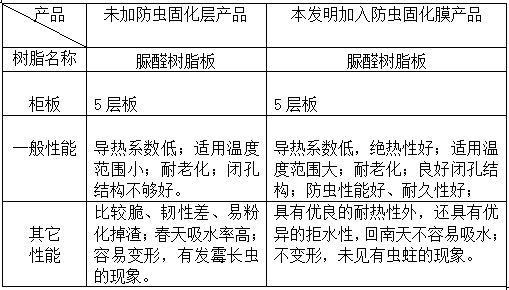

Insect-proof multi-layer eucalyptus wood board and production method thereof

InactiveCN110871477AImprove textureGood dimensional stabilityOther plywood/veneer working apparatusLamination ancillary operationsAdhesive glueSingle plate

The invention provides an insect-proof multi-layer eucalyptus wood board and a production method thereof. The production method of the multi-layer board comprises the steps of single plate thin platesorting, thin plate glue applying, cold pressing, hot pressing, standing curing, dust scraping, sanding, repair, trimming and plate pasting, and is characterized in that a layer of insect-proof curedfilm is sprayed at the peripheral surface, the upper surface and the lower surface of a slab before first hot pressing and final hot pressing to prevents glue from being dried too quickly during the hot pressing process and maintain stress inside the multi-layer board, the urea-formaldehyde glue can be fully reacted completely, the formed multi-layer board is not prone to mildewing, in the use process of a user, volatile formaldehyde is also reduced, and after hot pressing, the board is subjected to standing curing, sanding and plate pasting, so that the insect-proof multi-layer eucalyptus wood board product can be obtained by edge sawing and packaging.

Owner:广西横县正林木业有限公司

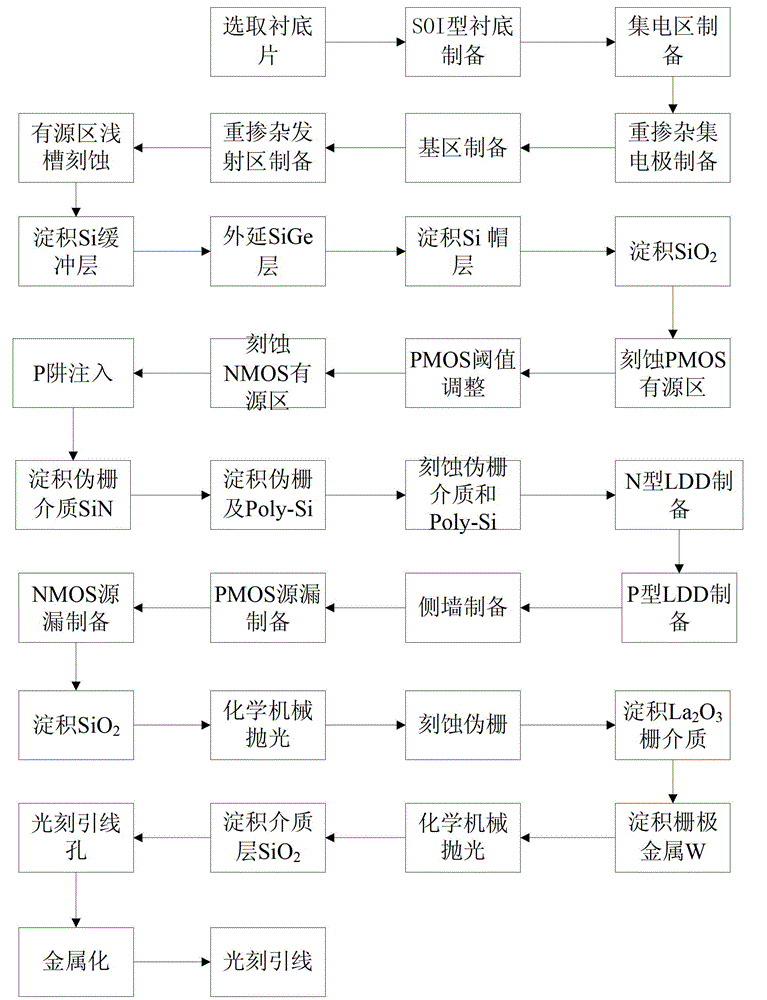

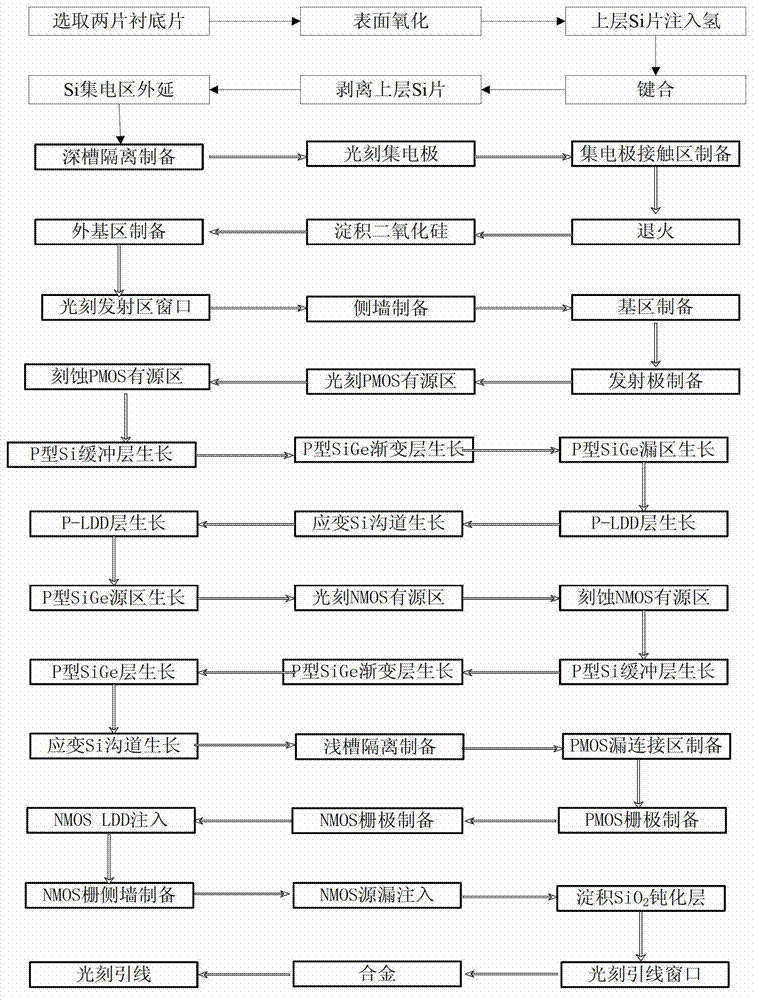

SOI (Silicon On Insulator) strain SiGe Bi CMOS (Complementary Metal-Oxide-Semiconductor) integrated device and preparation method thereof

InactiveCN102723337AInhibition effectHigh frequencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringP channel

The invention discloses a method for preparing an SOI (Silicon On Insulator) strain SiGe Bi CMOS (Complementary Metal-Oxide-Semiconductor) integrated device and a circuit. The preparation method comprises the steps of manufacturing an SOI bipolar transistor in bipolar device area in an SOI substrate; and conducting photoetching on an MOS (Metal Oxide Semiconductor) active region in the SOI substrate, growing strain SiGe material on the active region to respectively form NMOS (N-Channel Metal Oxide Semiconductor) active region and a PMOS (P-channel Metal Oxide Semiconductor) active region, then depositing SiO2 and polycrystalline silicon in the NMOS active region and the PMOS active region, etching a virtual gird with the length being 22-350nm, conducting self alignment to generate a source-drain region of the MOS by applying a self alignment process, removing the virtual grid, preparing a grid medium and preparing wolfram (W) to be a grid electrode, conducting photoetching on a lead wire to form the integrated device with the length being 22-350nm and the circuit of the MOS device. According to the integrated device prepared by the invention, a lightly doped source drain (LDD) structure is adopted, so that the influence on the performance of the device caused by hot carriers can be inhibited effectively; and a quantum well structure is adopted in a PMOS structure, so that a hole can be limited in a SiGe layer effectively, the interface scattering is reduced, and the electric properties of frequency, current driving capability and the like of the device are improved.

Owner:XIDIAN UNIV

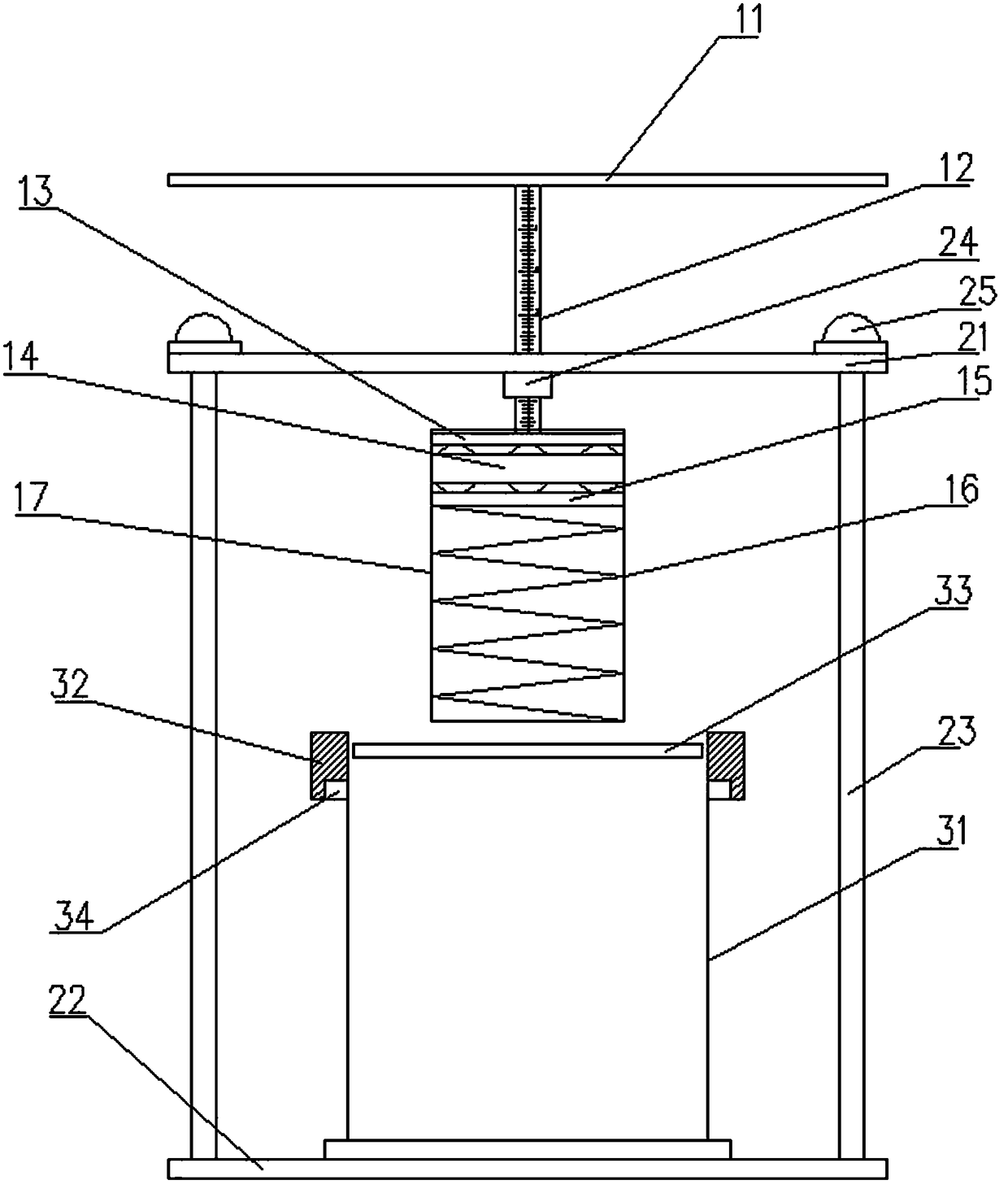

Pervious concrete test piece forming device and forming method thereof

PendingCN108760428ARealize pressure-vibration combined moldingSimple structurePreparing sample for investigationSurface stressOperability

The invention discloses a pervious concrete test piece forming device and a forming method thereof. The pervious concrete test piece forming device comprises a force application assembly, a counterforce frame and a test mould and can achieve compression-vibration combined forming of a previous concrete test piece; furthermore, in a concrete vibration process, force can be continuously applied to acushion plate above concrete through the force application assembly, so that the phenomenon that cavities partially appear after the pervious concrete test piece is formed is effectively avoided. According to the forming method, a body of the test mold is filled with green concrete twice, many times of vibrating falling operation is performed respectively, so that the green concrete filled into the body of the test mold has very good compactness, and the settling volume of the concrete in the vibration process is effectively reduced; furthermore, pressure on the cushion plate above the concrete can be accurately calculated out by a dividing ruler on a screw, and the settling volume of the green concrete can be compensated in time in the vibration process; thus, surface stress of the greenconcrete is ensured, the forming method has the advantages of simpleness and high operability, and a test piece forming effect is good.

Owner:中交绿建(厦门)科技有限公司 +2

Silicon on insulator (SOI) SiGe bipolar complementary metal oxide semiconductor (BiCMOS) integrated device and preparation method thereof

InactiveCN102800681AInhibition effectHigh frequencySolid-state devicesSemiconductor/solid-state device manufacturingEtchingGate dielectric

The invention discloses a silicon on insulator (SOI) SiGe bipolar complementary metal oxide semiconductor (BiCMOS) integrated device and a preparation method of the SOI SiGe BiCMOS integrated device. The method comprises the following steps of: growing an N-type Si epitaxial layer on an SOI substrate, preparing shallow-trench isolation, forming a collector contact region, etching to form a side wall, performing wet etching to form a base region window, selectively growing a SiGe base region, photoetching a collector window, depositing an N-type Poly-Si, removing the Poly-Si, and forming a SiGe HBT device; growing a strain SiGe material on the substrate, isolating an active region of the device, photoetching an active region of an N-channel metal oxide semiconductor (NMOS) device, performing P-type ion implantation, preparing a pseudo grid, self-aligning to grow a source drain region of a metal oxide semiconductor (MOS) device, removing the pseudo grid, preparing a lanthanum oxide material to form gate dielectric and preparing metal tungsten to form a gate in a stamping groove at the pseudo grid, photoetching a lead, and preparing the integrated device and the circuit. According to the method, the characteristics of SiGe are fully utilized, and due to the prepared integrated circuit, the performance of the conventional analog and digital / analog mixed integrated circuit is greatly improved.

Owner:XIDIAN UNIV

Vertical-channel mixed-lattice-strain BiCMOS (bipolar complementary metal oxide semiconductor) integrated device and preparation method

InactiveCN102738154AImprove performanceHigh electron mobilitySolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricP channel

The invention discloses a vertical-channel mixed-lattice-strain BiCMOS integrated device and a preparation method. The preparation method comprises preparing an SOI (silicon on insulator) substrate, epitaxially growing a Si layer on the substrate as a collector region, preparing deep trench isolation, and preparing a double-polysilicon SiGe HBT (heterojunction bipolar transistor) device on the active region of the bipolar device by self-alignment process; etching an active region of a PMOS (p-channel metal oxide semiconductor) device by lithography, continuously growing seven material layers on the active region, andpreparing a drain and a gate to obtain the PMOS device; etching a trench in the active region of an NMOS (n-channel metal oxide semiconductor) device by lithography, continuously growing four material layers on the active region, preparing a gate dielectric layer and gate polysilicon to obtain the NMOS device, etching lead holes by lithography, alloying, and etching leads by lithography to obtain the vertical-channel mixed-lattice-strain BiCMOS integrated device and circuit with a CMOS conductive channel of 22 to 45nm. The preparation method provided by the invention can prepare the performance-enhanced vertical-channel mixed-lattice-strain BiCMOS integrated device at 600 to 800 DEG C by fully utilizing the characteristics of mobility anisotropy of the tensile strained Si material.

Owner:XIDIAN UNIV

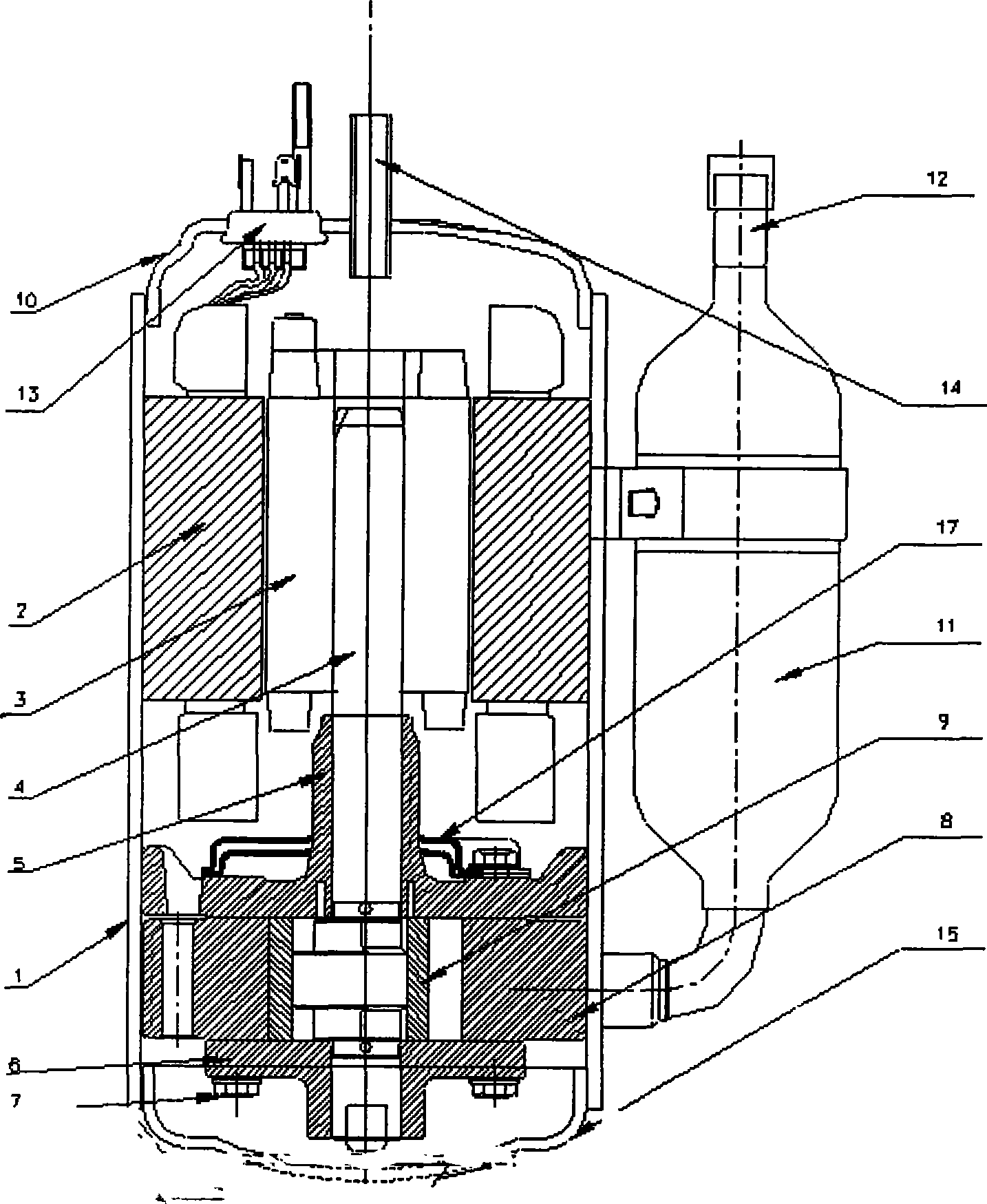

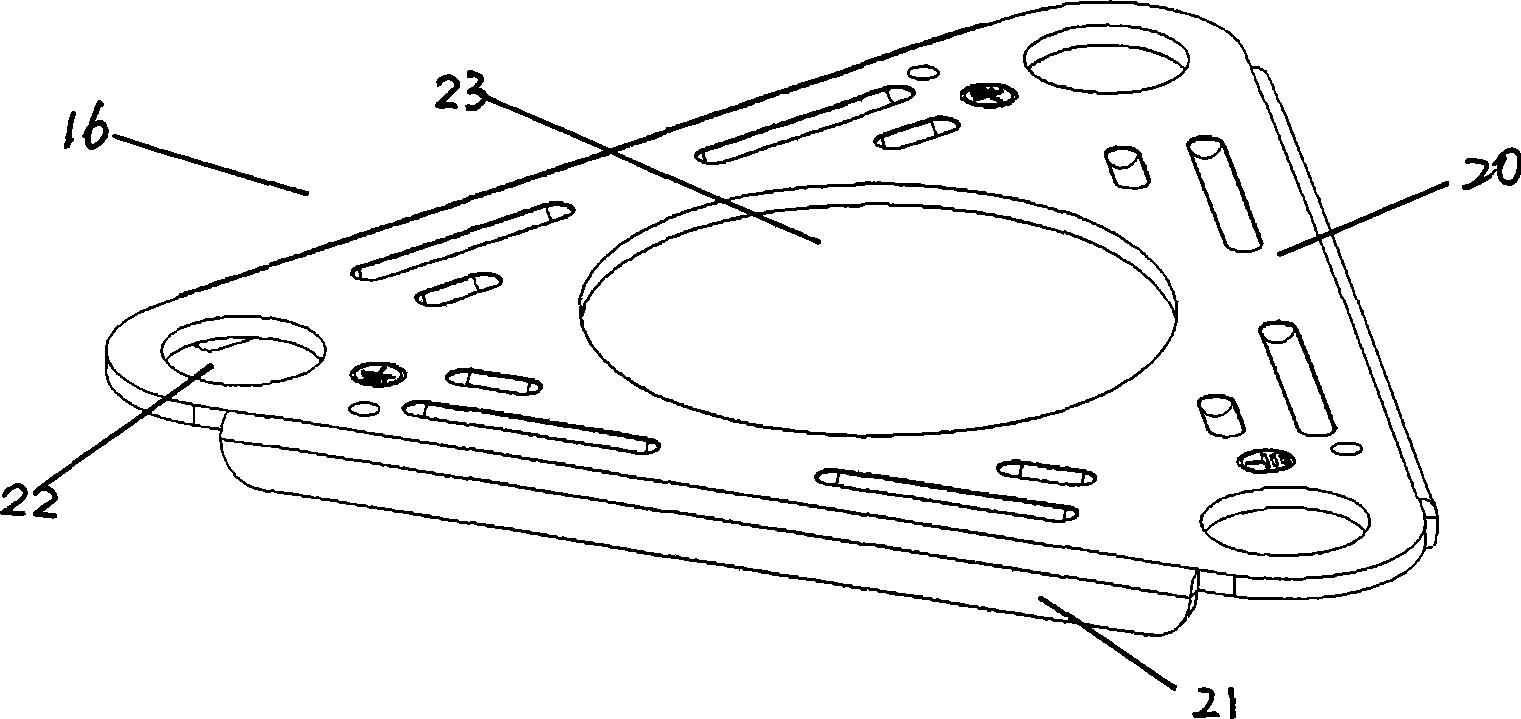

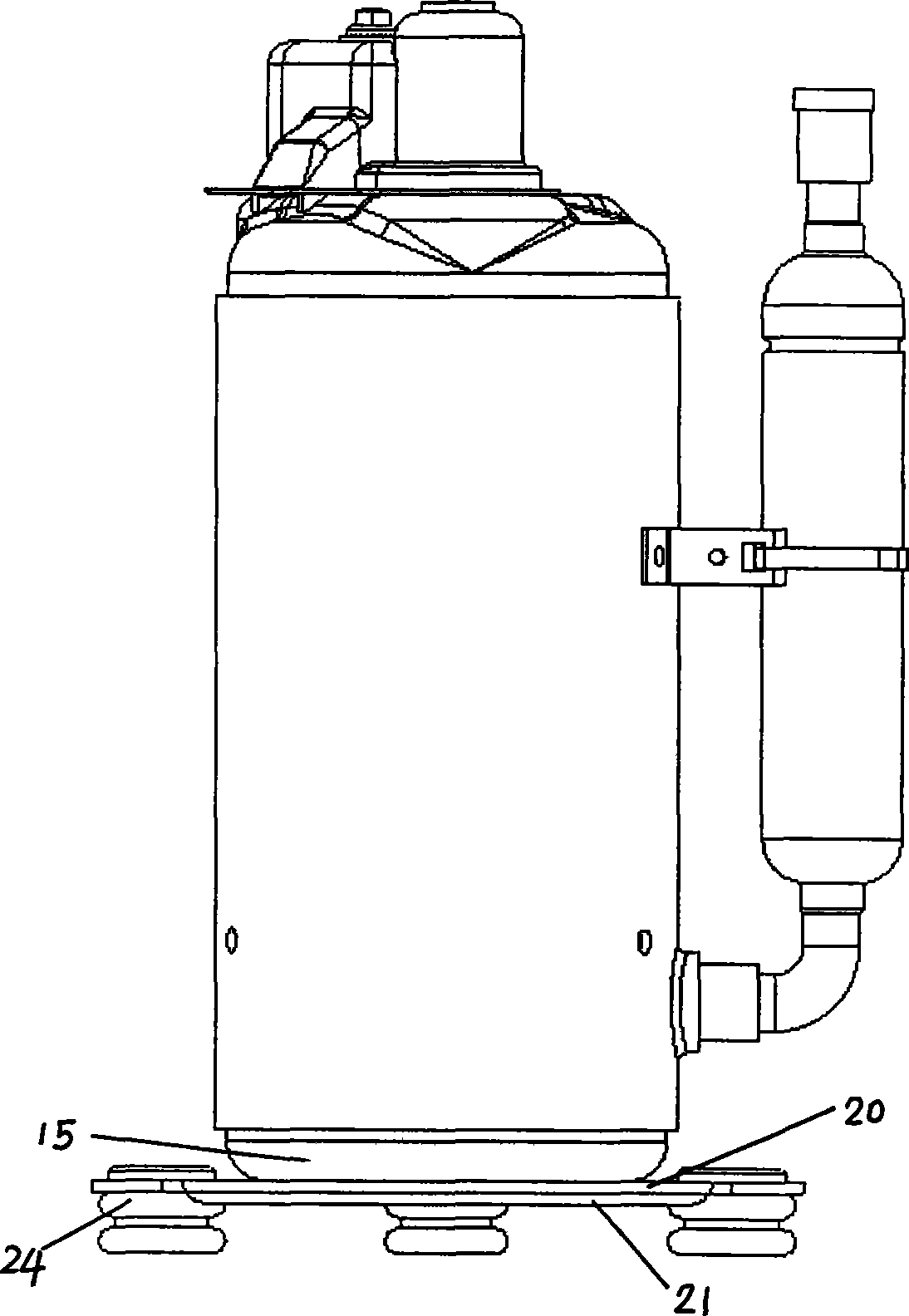

Base corner of rotary compressor

InactiveCN101372971AGuaranteed stressDesign Die Size ImprovementRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringChassis

The invention discloses a base angle of a rotary compressor, which comprises a plane part, a support rib, a through hole and a mounting hole, wherein the support rib is positioned below the plane part along each side thereof; the through hole for mounting the bottom cover of the compressor is arranged at the center of the plane part; the penetrating mounting hole which is used for mounting the compressor on a chassis through the base angle and inserted into a rubber gasket is arranged on the top angle of the plane part; and the support rib adopts a strip structure provided with a plurality of penetrating notches. Each notch is into a shape of a trapezoid with the narrow top and the wide bottom, and the upper bottom of the trapezoid coincides with the lower surface of the plane part. The base angle has the beneficial effects that on the premise of ensuring the stress of a bending edge, the base angle is improved by designing die size; materials are saved after improvement; and a part of bending edge is punched out on the premise of ensuring the stress.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

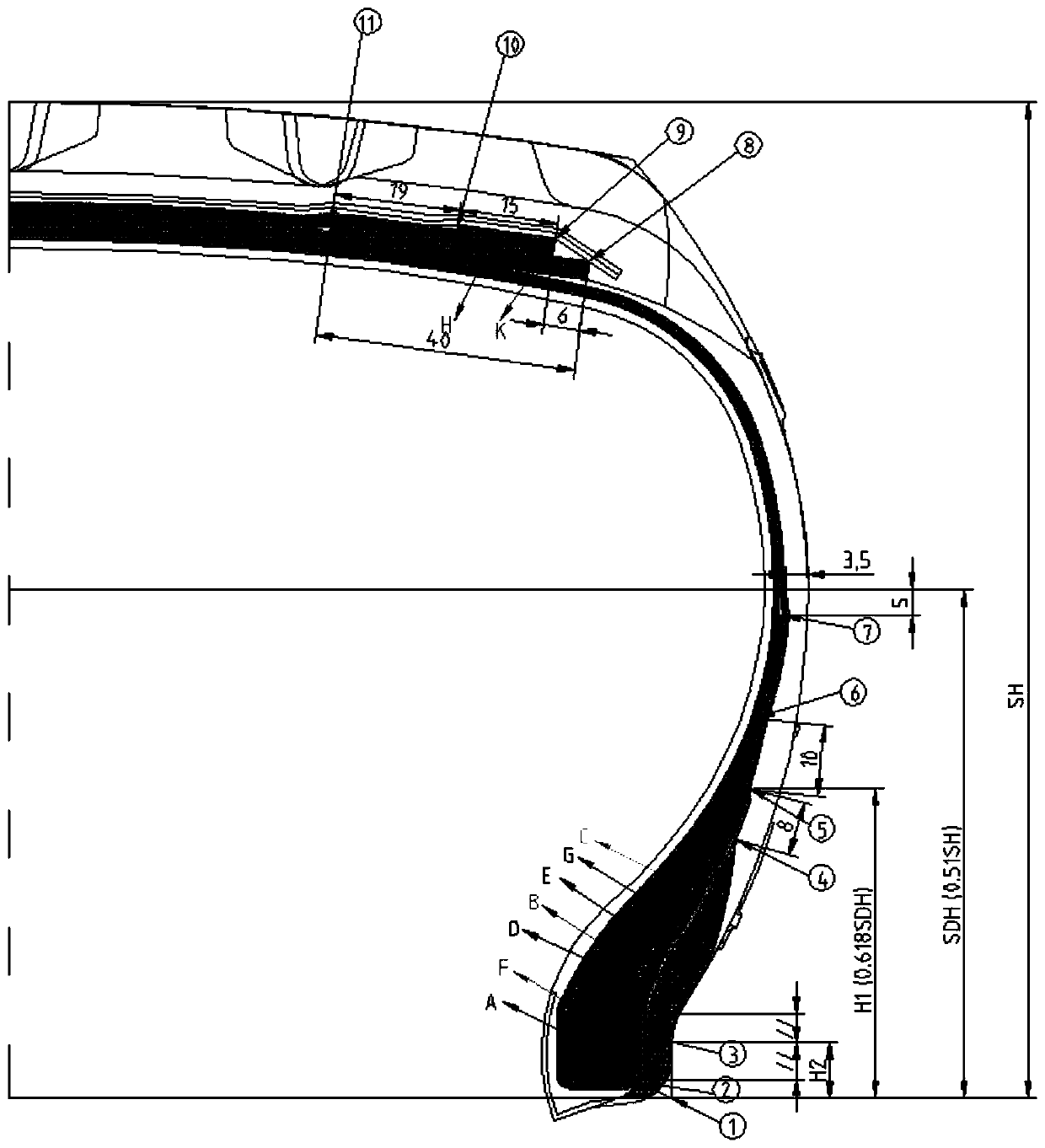

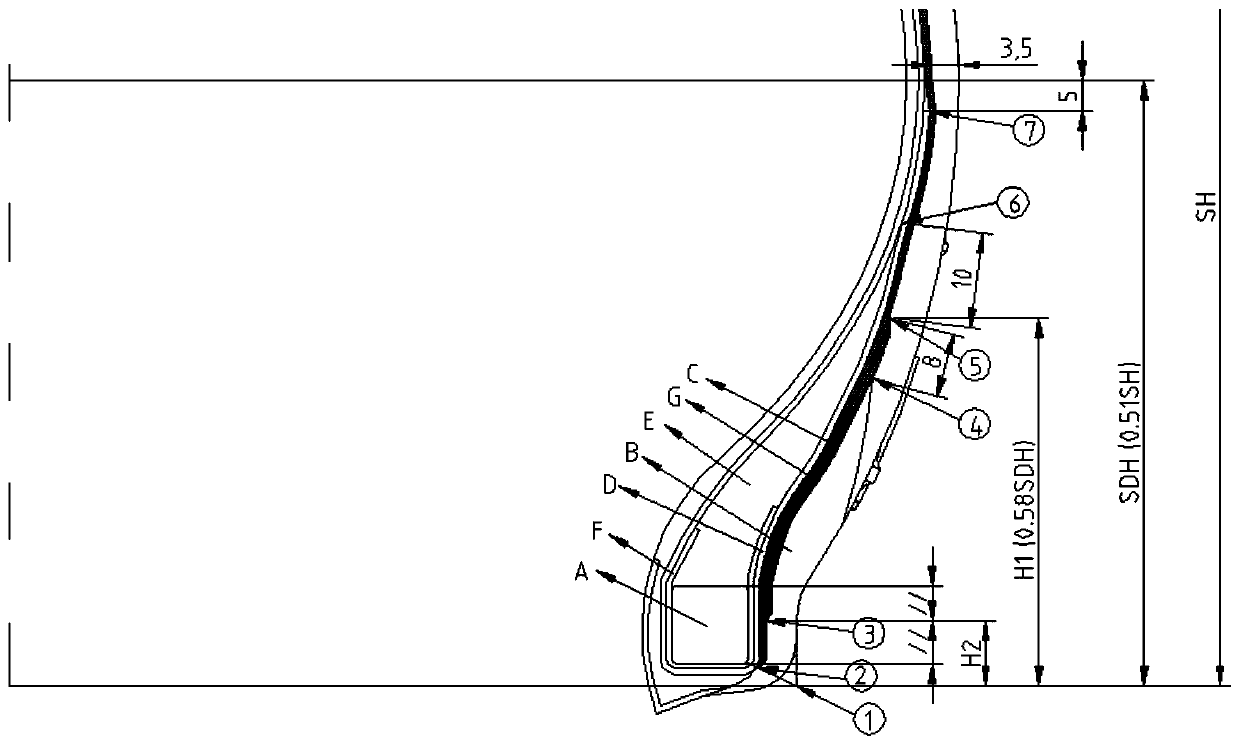

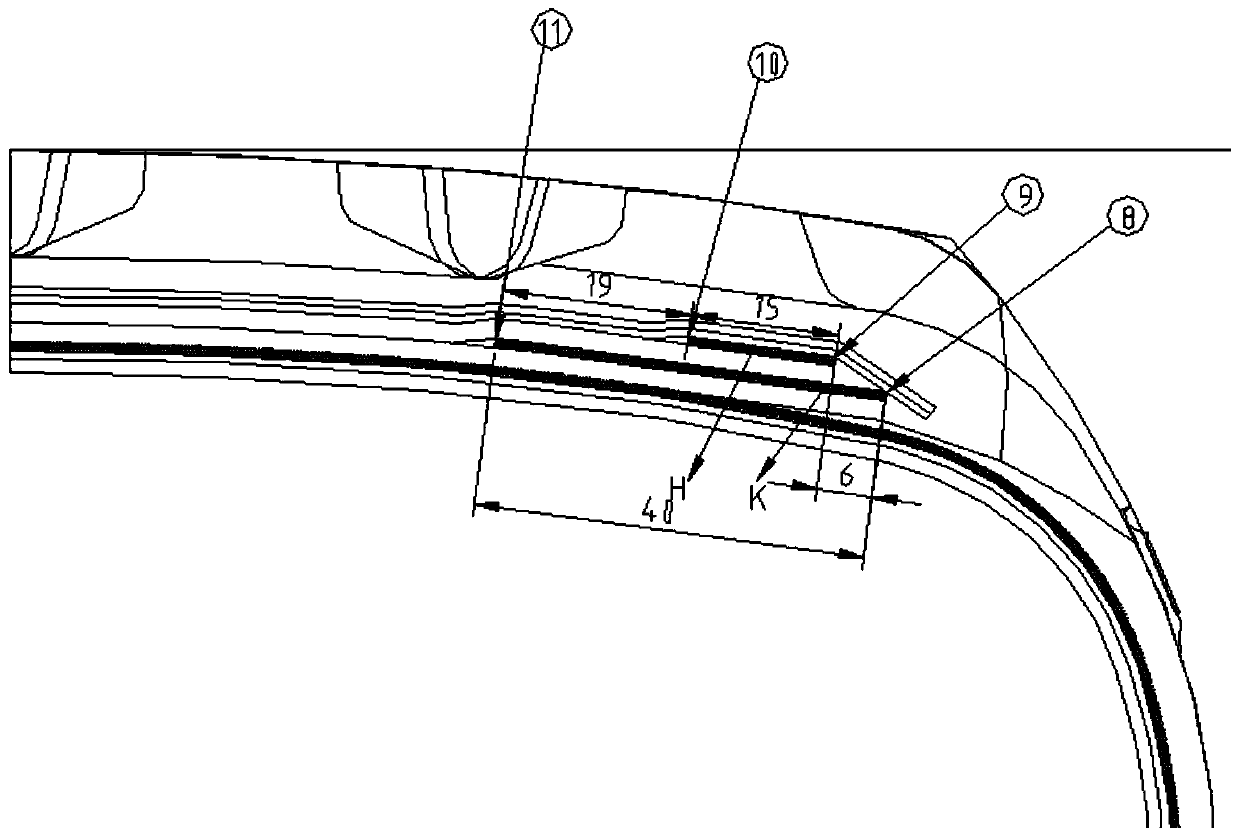

A Pneumatic Radial Tire with Improved Endurance Performance

ActiveCN107415591BReinforcement is less effectiveCan't reach the reinforcing effectPneumatic tyre reinforcementsTyre beadsTire beadReinforced rubber

The invention provides a pneumatic radial tire with improved endurance performance, which includes a carcass, the carcass is divided into a carcass layer, a shoulder part, a sidewall part and a bead part, and the carcass layer is wound from the inside to the bead core. The outside includes a turn-up layer and a layer of over-wrap, the bead core and apex rubber are placed in the turn-up layer, and the slit protection rubber is placed outside the over-wrap in the tire axial direction; the turn-up Between the axially outer side of the layer and the axially inner side of the spigot cover, a layer is set along the turn-up layer from 30% to 34% of the tire section height to 4% to 7% of the tire section height Sidewall adhesive reinforcing rubber strips, the side edges of the belt layers are provided with edge rubber for preventing creeping between the belt layers. On the basis of maintaining the formula and pattern without changing and ensuring excellent load-carrying performance, the present invention limits the size and size of each component at the same time by increasing the belt edge glue, the positive bag structure and the sidewall adhesive reinforcing strip structure. Relative position to improve the durability performance of the tire.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com