Patents

Literature

165 results about "Specified load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In civil engineering, specified loads are the best estimate of the actual loads a structure is expected to carry. These loads come in many different forms, such as people, equipment, vehicles, wind, rain, snow, earthquakes, the building materials themselves, etc. Specified Loads also known as Characteristic loads in many cases.

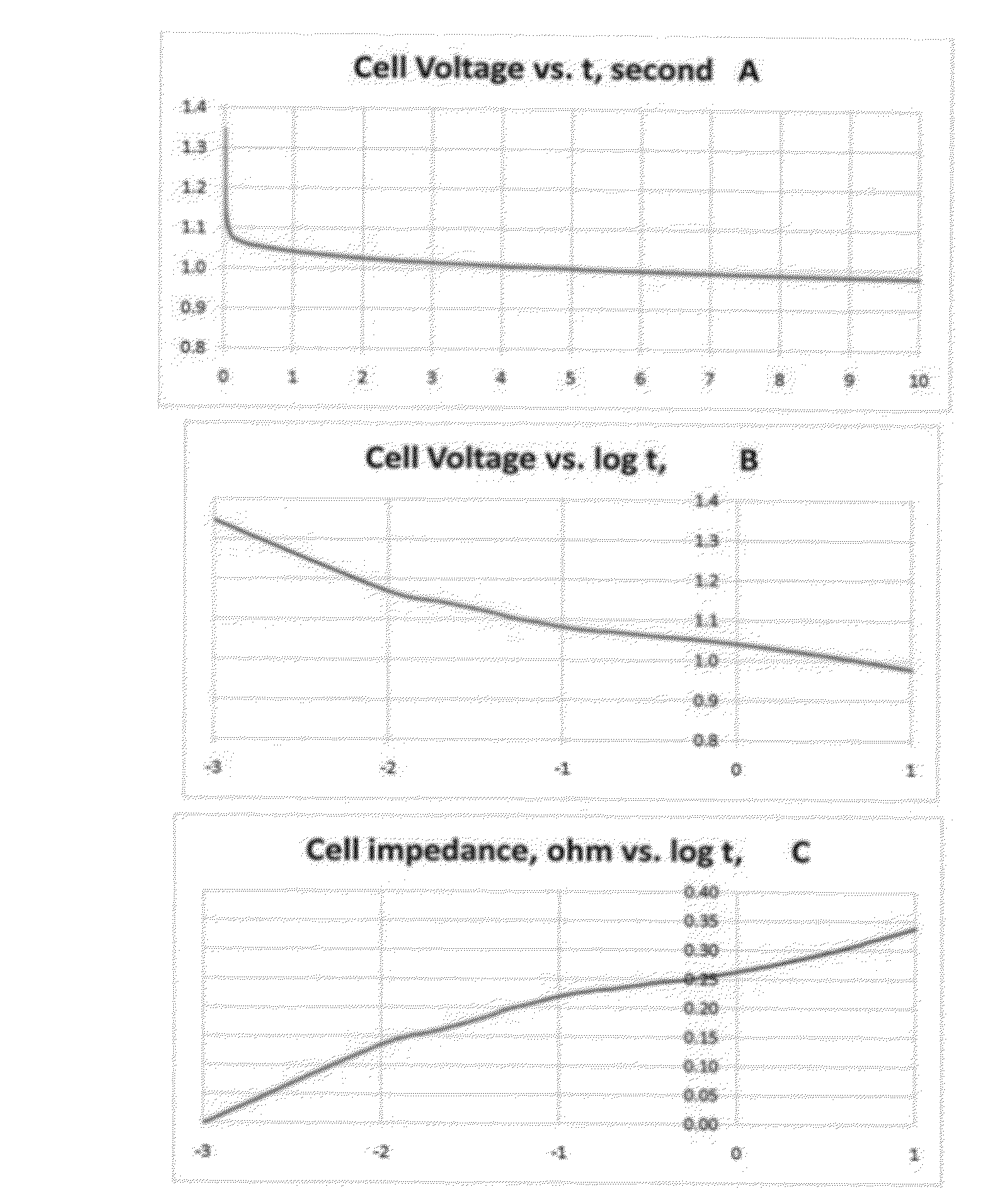

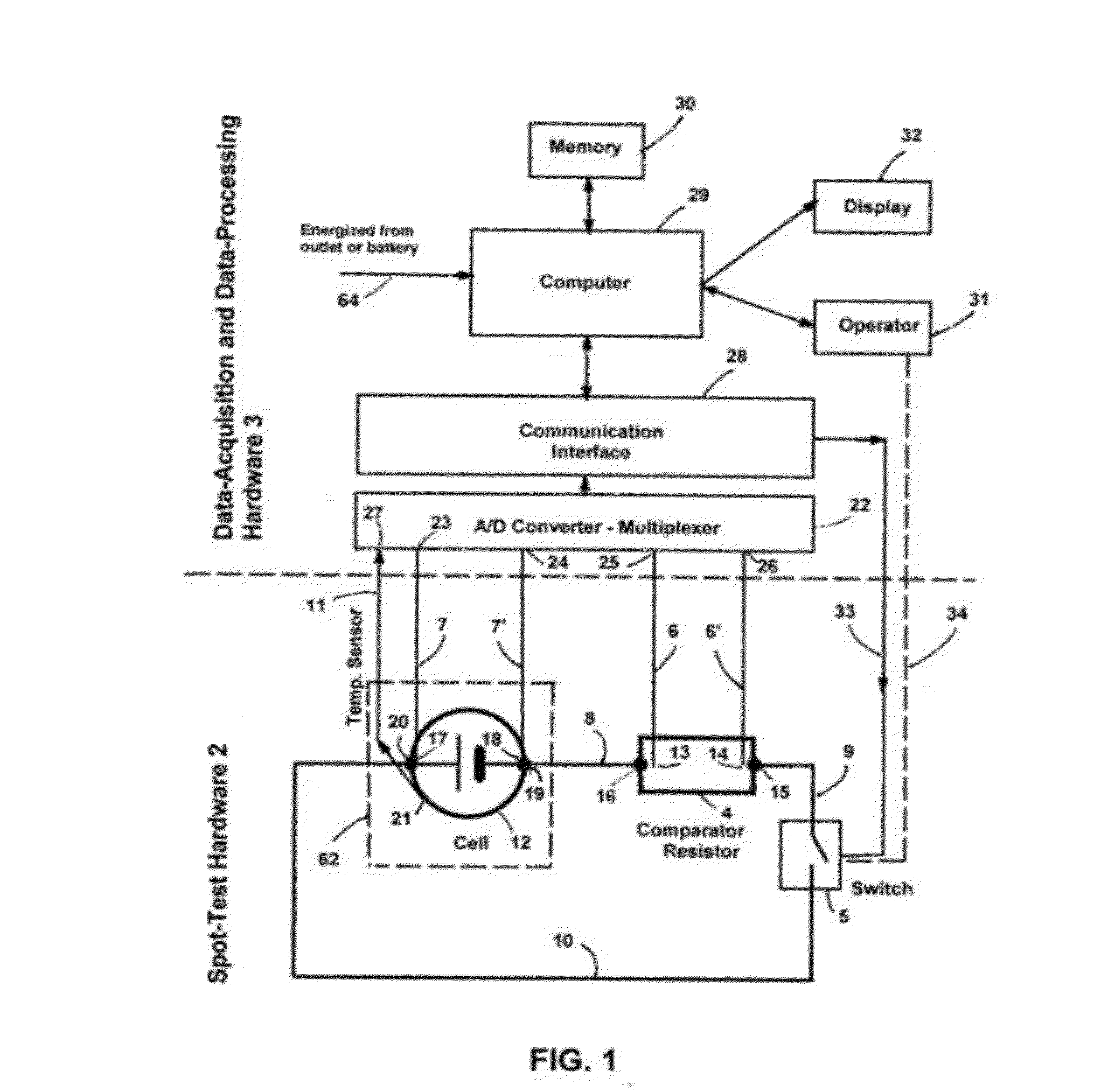

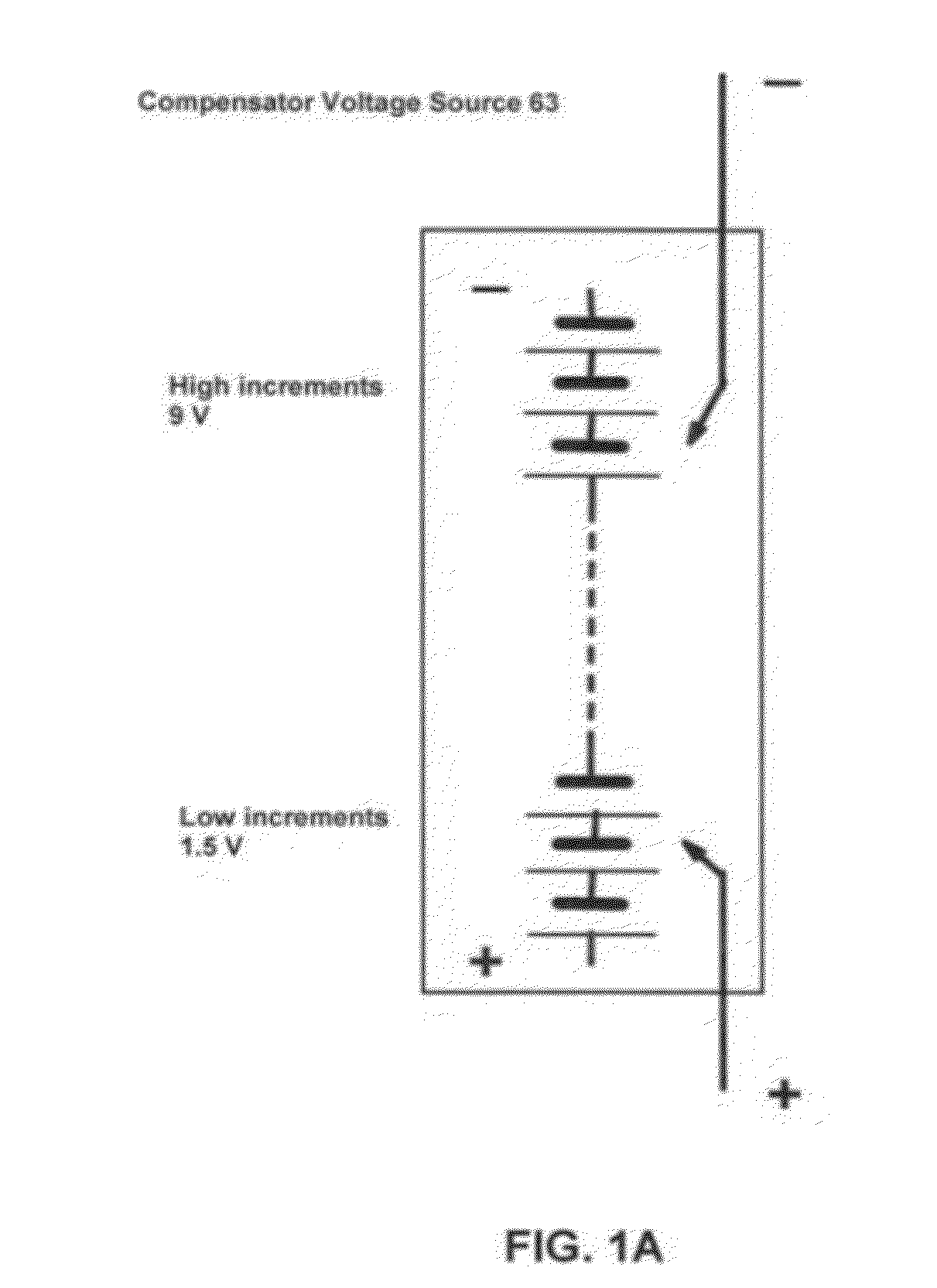

Apparatus and method for determining battery/cell's performance, age, and health

InactiveUS20120310565A1Quick and concise evaluationReliable estimateMaterial analysis by electric/magnetic meansElectrical testingTime domainVoltage response

A self-energized measuring system for determining primary and secondary battery / cell's performance, age, and health by measuring and recording battery / cell's voltage response to a specified load-changing perturbation spot-test event. The cell's voltage response is compared to a synchronously measured voltage signal of a comparator resistor. The relationship between the two voltage signals is analyzed on logarithmic time scale to determine performance parameters such as cell impedance and power and their variation in the time domain. The cell temperature is also measured for impedance and power normalization for 20 centigrade. Results are compared to a previously generated master data tabulation characteristic of a similar, new cell of perfect health condition. The time-domain performance parameters are related to the performance, age and health of the cell at any particular instant. The evaluation method can be easily adjusted to various battery chemistries, types.

Owner:REDEY LASZLO

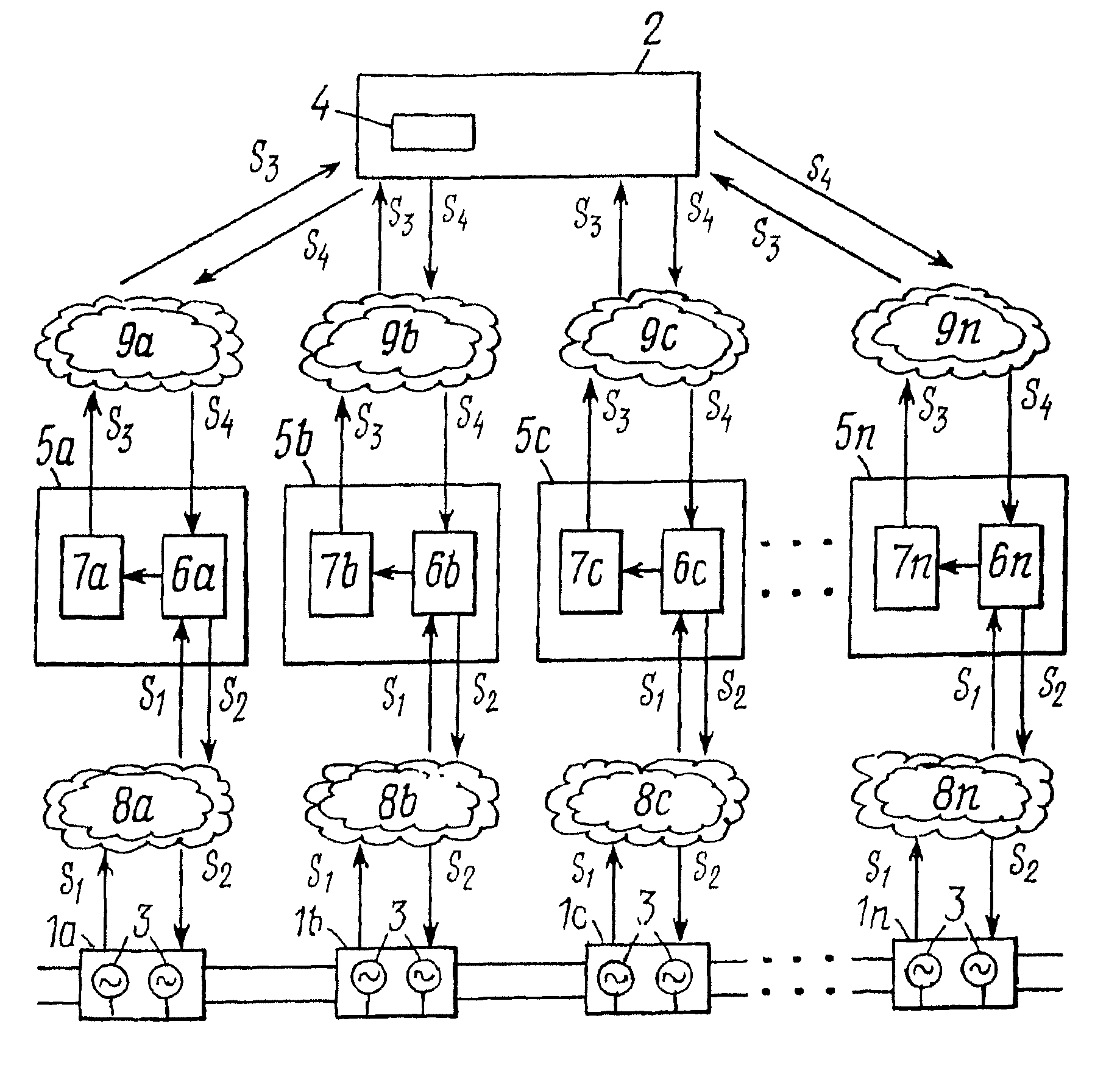

System for dispatching and controlling of generation in large-scale electric power systems

InactiveUS7489989B2Lower the volumeHigh speedLevel controlSpecial tariff metersPower stationControl system

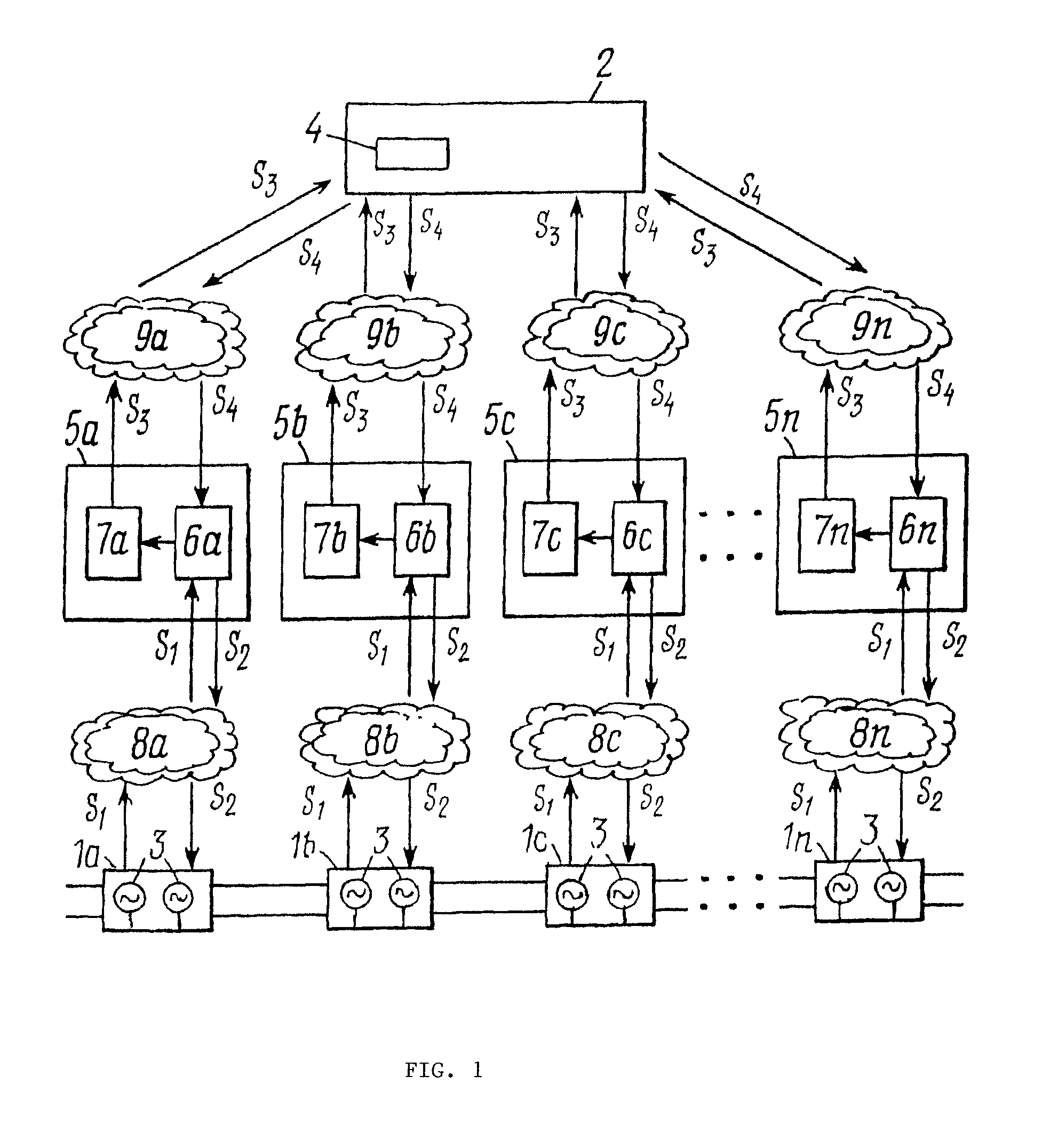

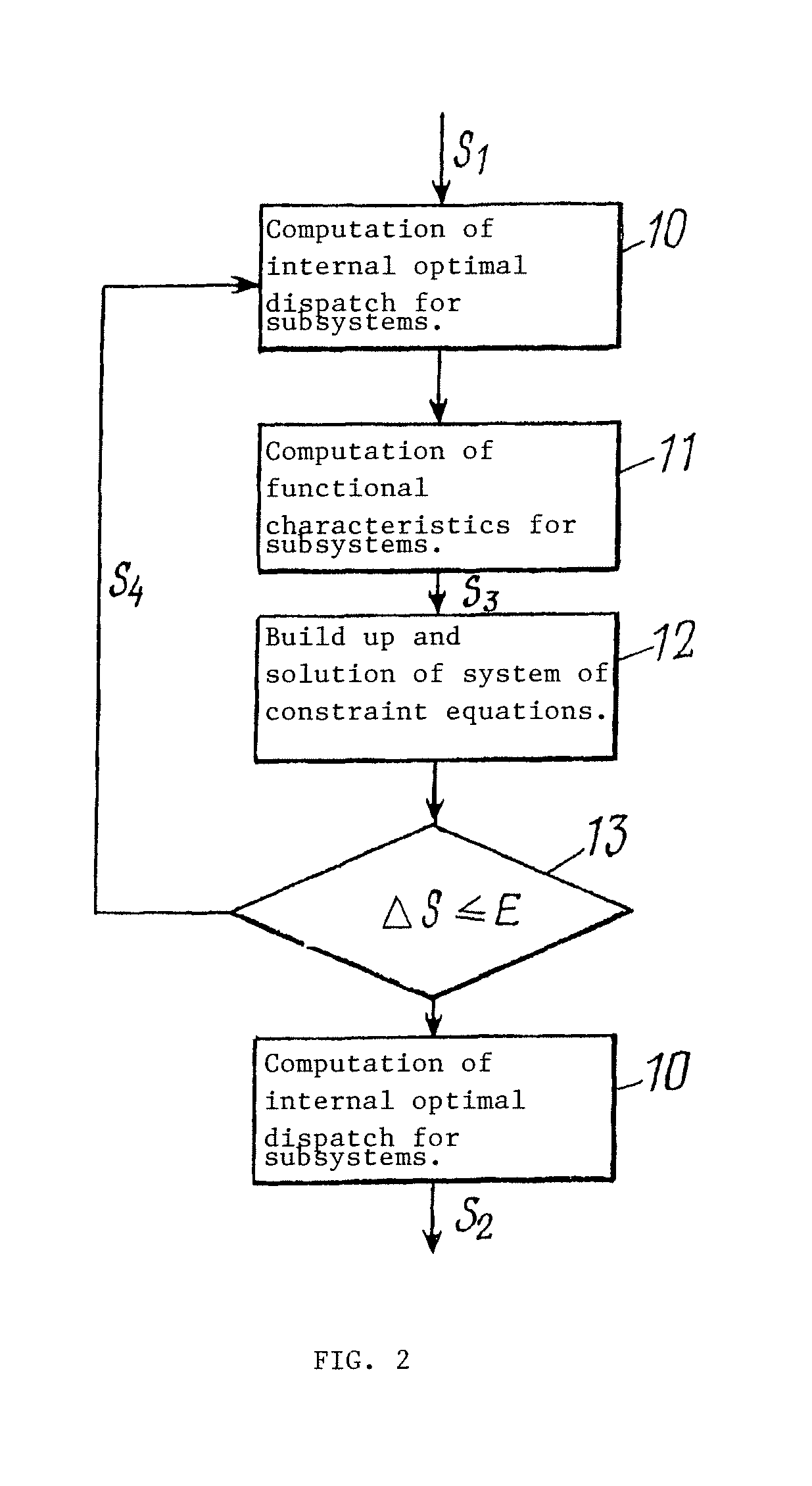

A system for dispatching and controlling generation in an electric power system consisting of a plurality of power units comprises a computer with dispatching optimization module connected by communications means to the power units. According to the invention, in the electric power system consisting of a plurality of subsystems each comprising a plurality of power plants provided with power units, said computer is a higher-layer computer and the specified load dispatching optimization module is designed to determine parameters for an optimal interchange of power and energy between subsystems. The inventive controlling system further comprises a plurality of computers according to a number of subsystems, said computers being lower-layer computers each comprising a specified subsystem dispatching optimization module designed to determine parameters for an optimal allocation of generation between power plants within a subsystem, and a unit for computation of functional characteristics for each subsystem, wherein each lower-layer computer is connected by lower-layer communications means to respective power plants of respective subsystems. The inventive controlling system also comprises higher-layer communications means, wherein the lower-layer computers are connected to a higher-layer computer via the higher-layer communications means.

Owner:SUKHANOV OLEG ALEXEEVICH +2

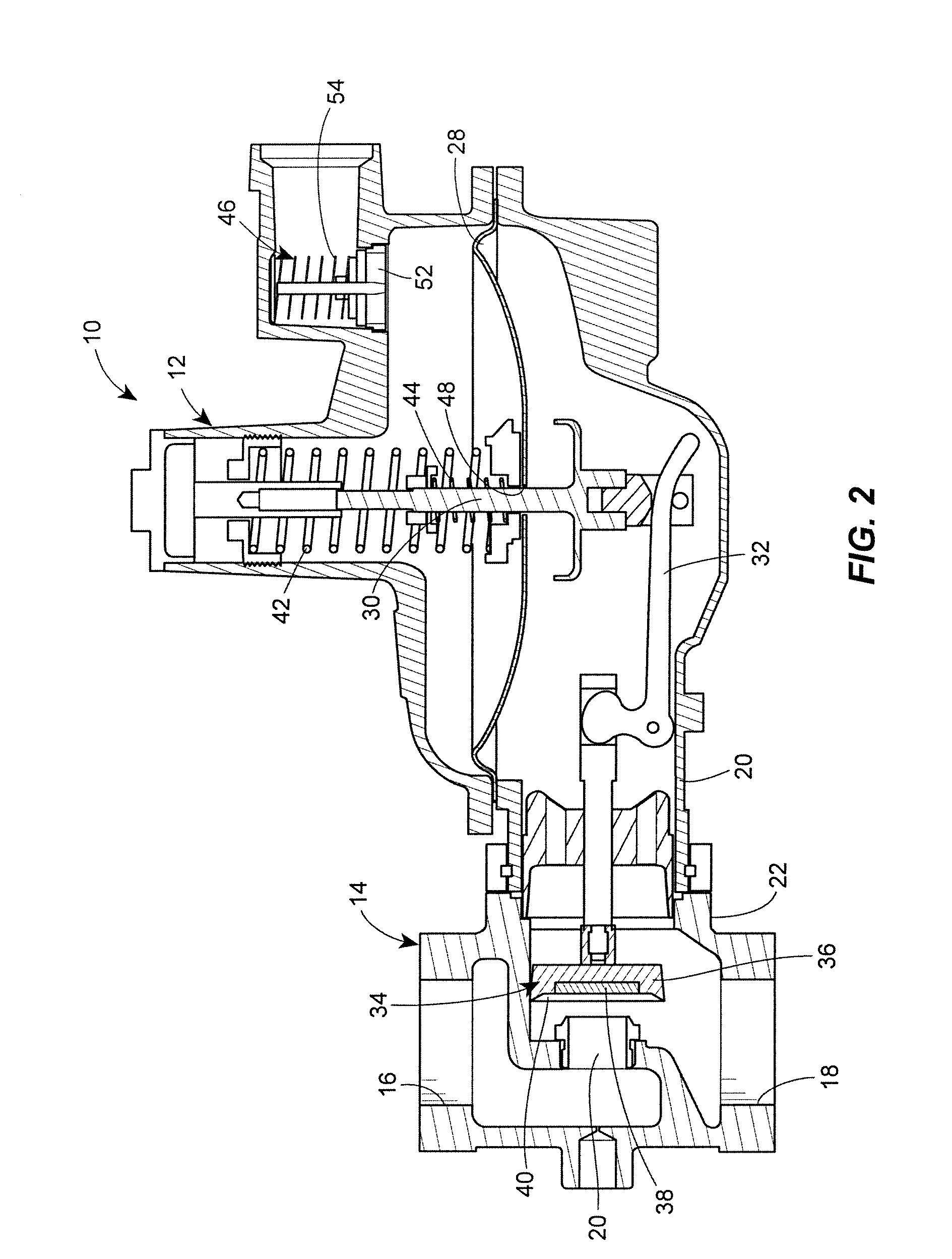

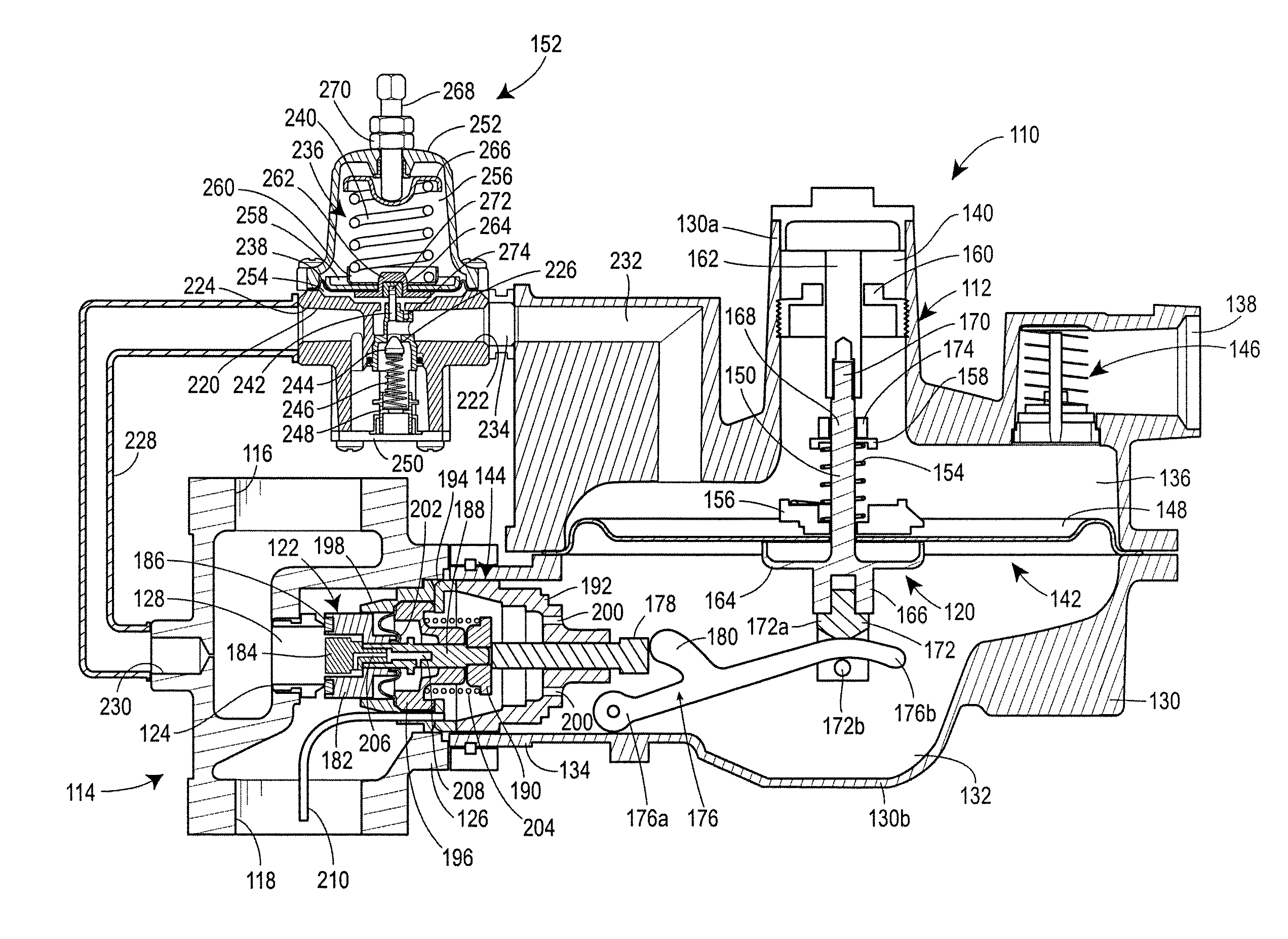

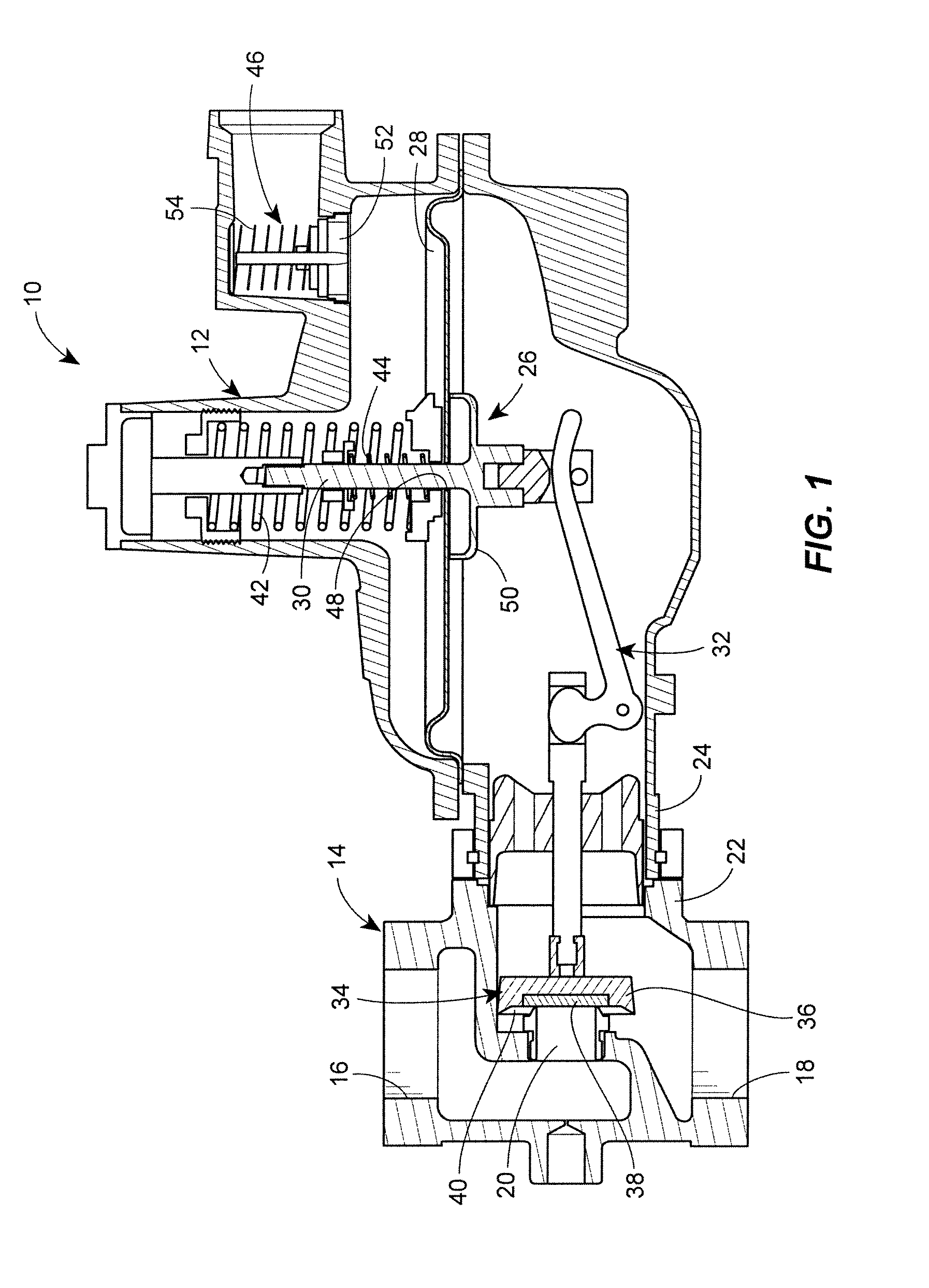

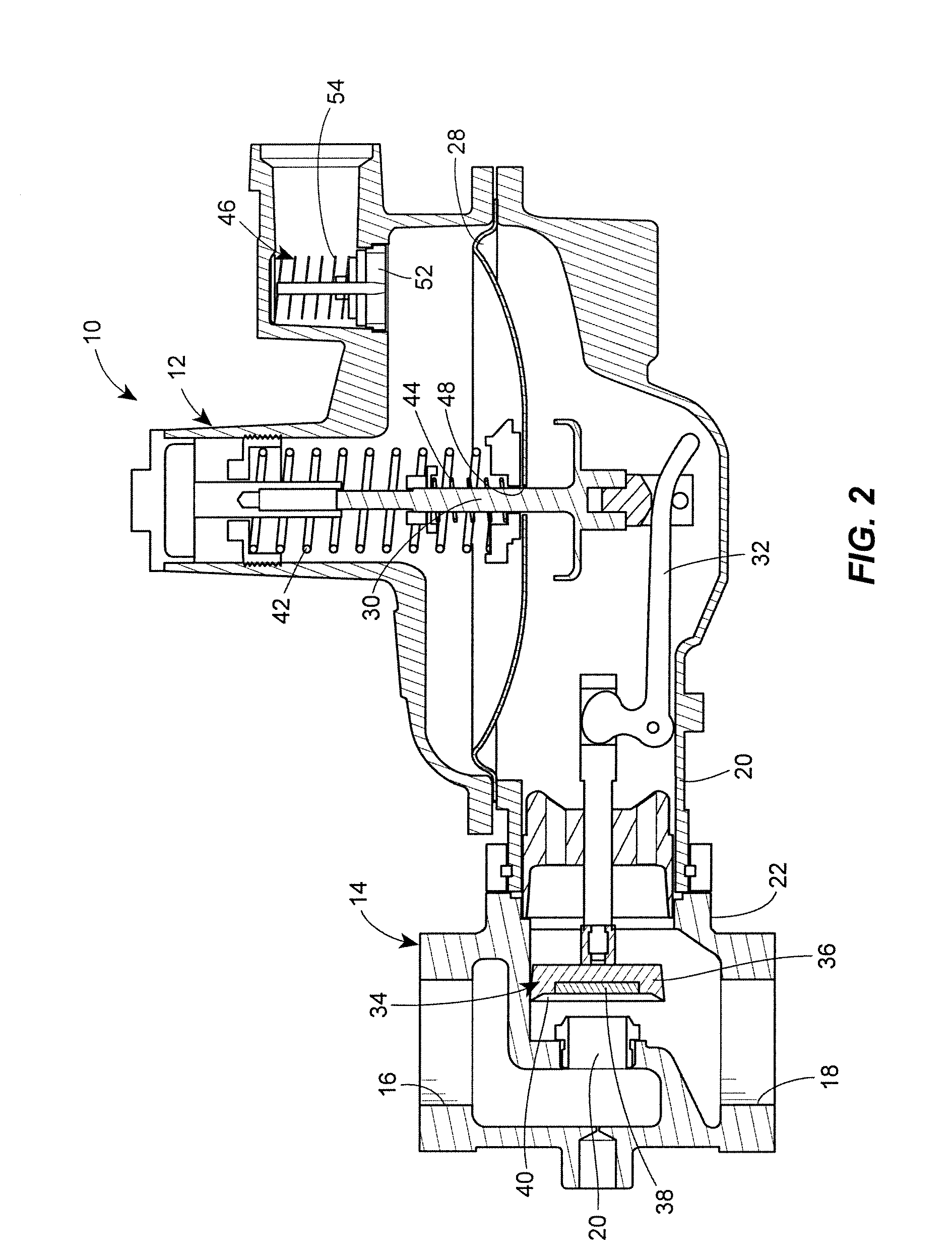

Pressure Loaded Service Regulator with Pressure Balanced Trim

ActiveUS20100071786A1Operating means/releasing devices for valvesEqualizing valvesPressure balanceActuator

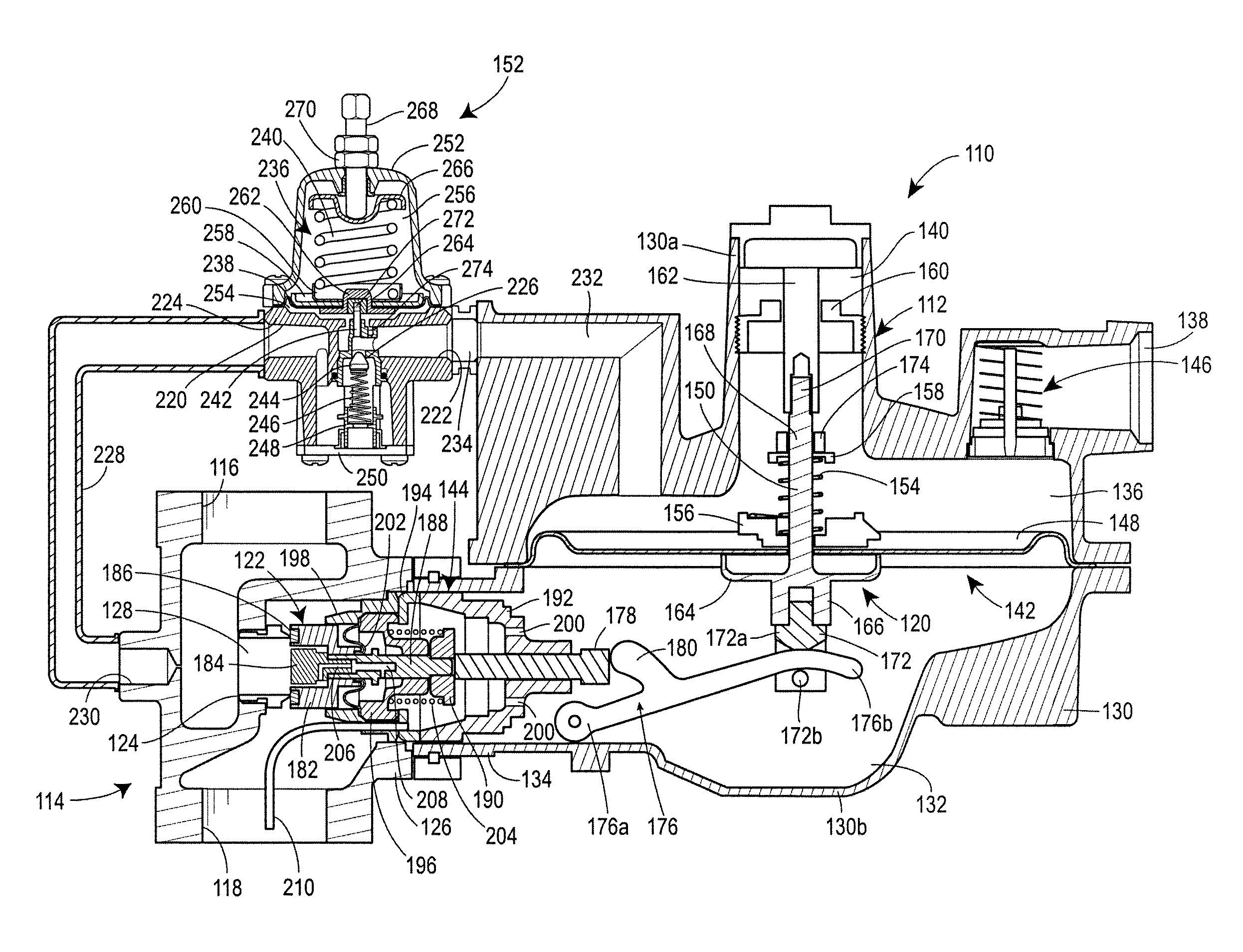

A gas regulator includes an actuator, a regulator valve, and pressure loading device. The pressure loading device provides a pressure load to a surface of a diaphragm of the actuator to act against a downstream pressure being applied to the opposite surface of the diaphragm and being controlled by the regulator. As the downstream pressure varies and the diaphragm displaces to move a control element to regulate the downstream pressure, the pressure loading device maintains a specified load pressure. The regulator may further include a balanced trim applying a balancing force to offset a force of an upstream pressure on the control element.

Owner:IRIDEX CORP +1

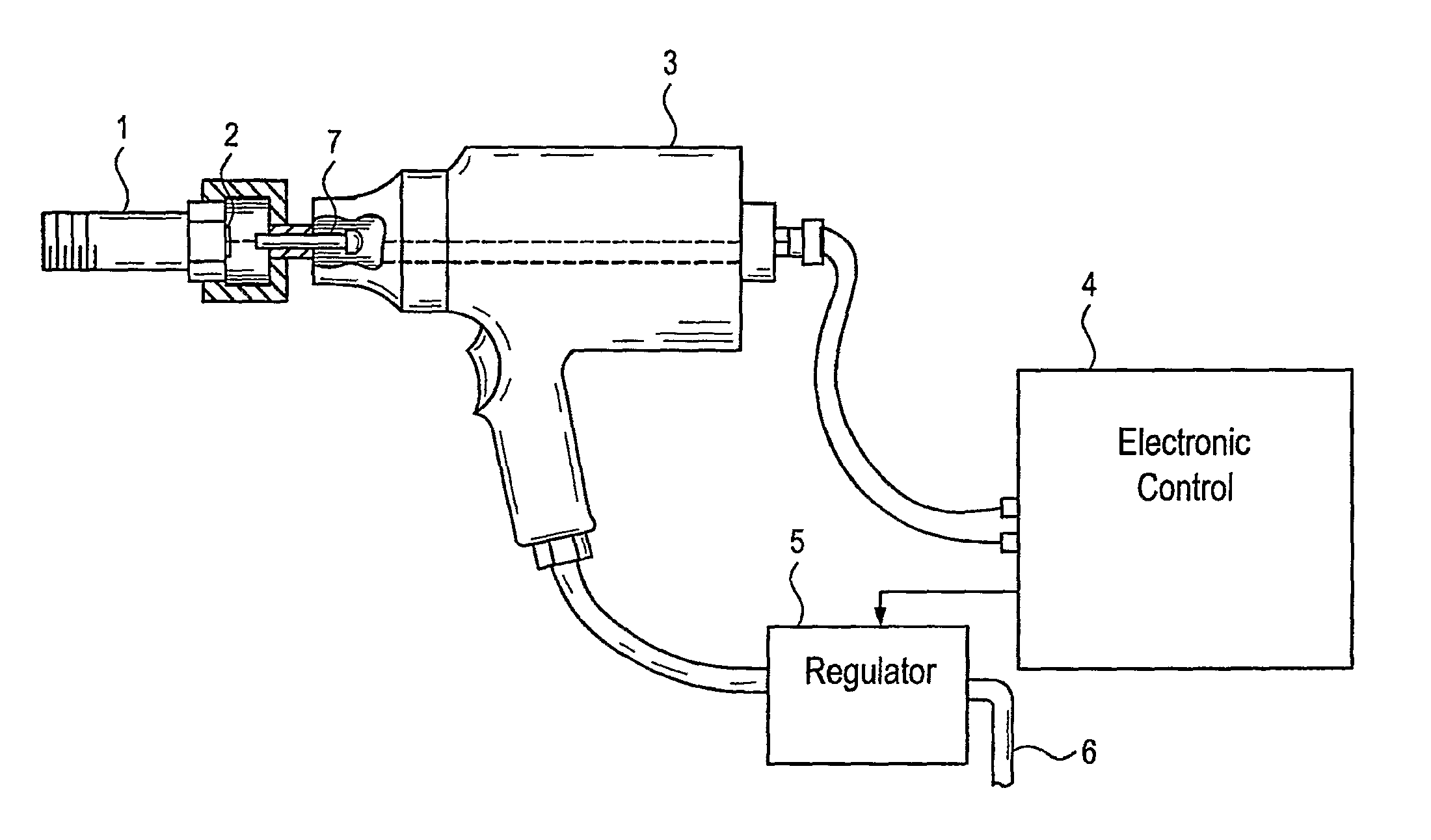

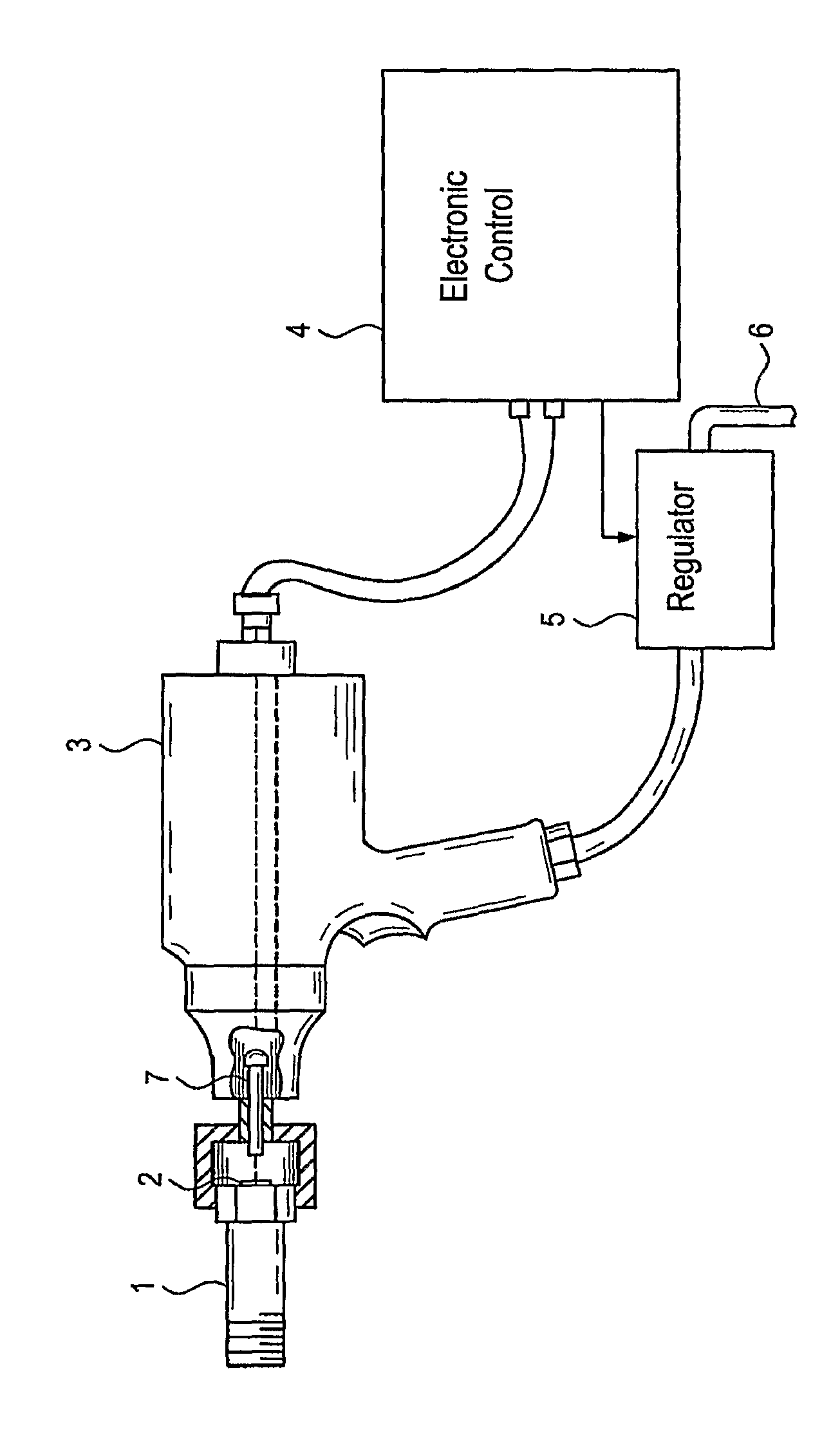

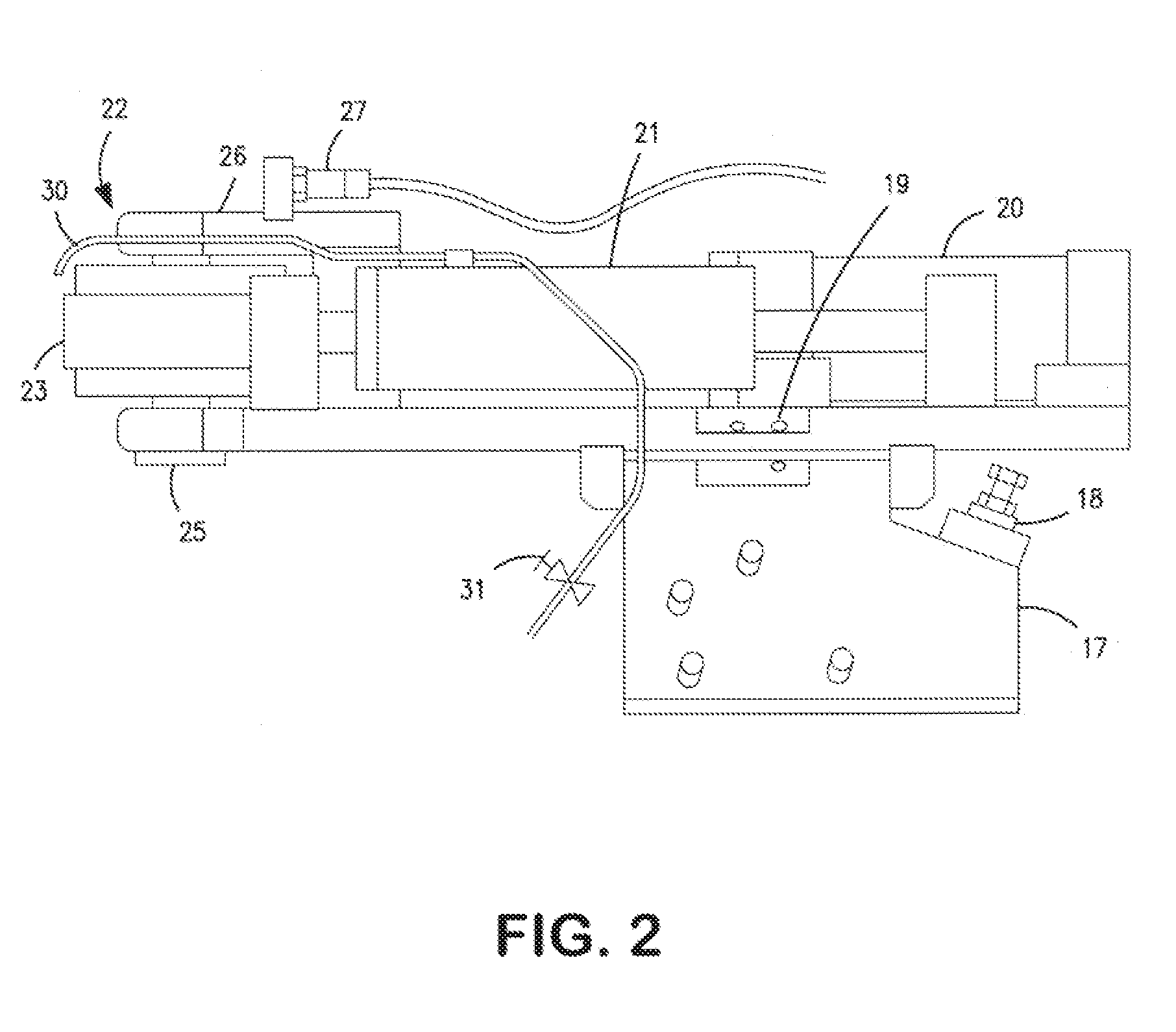

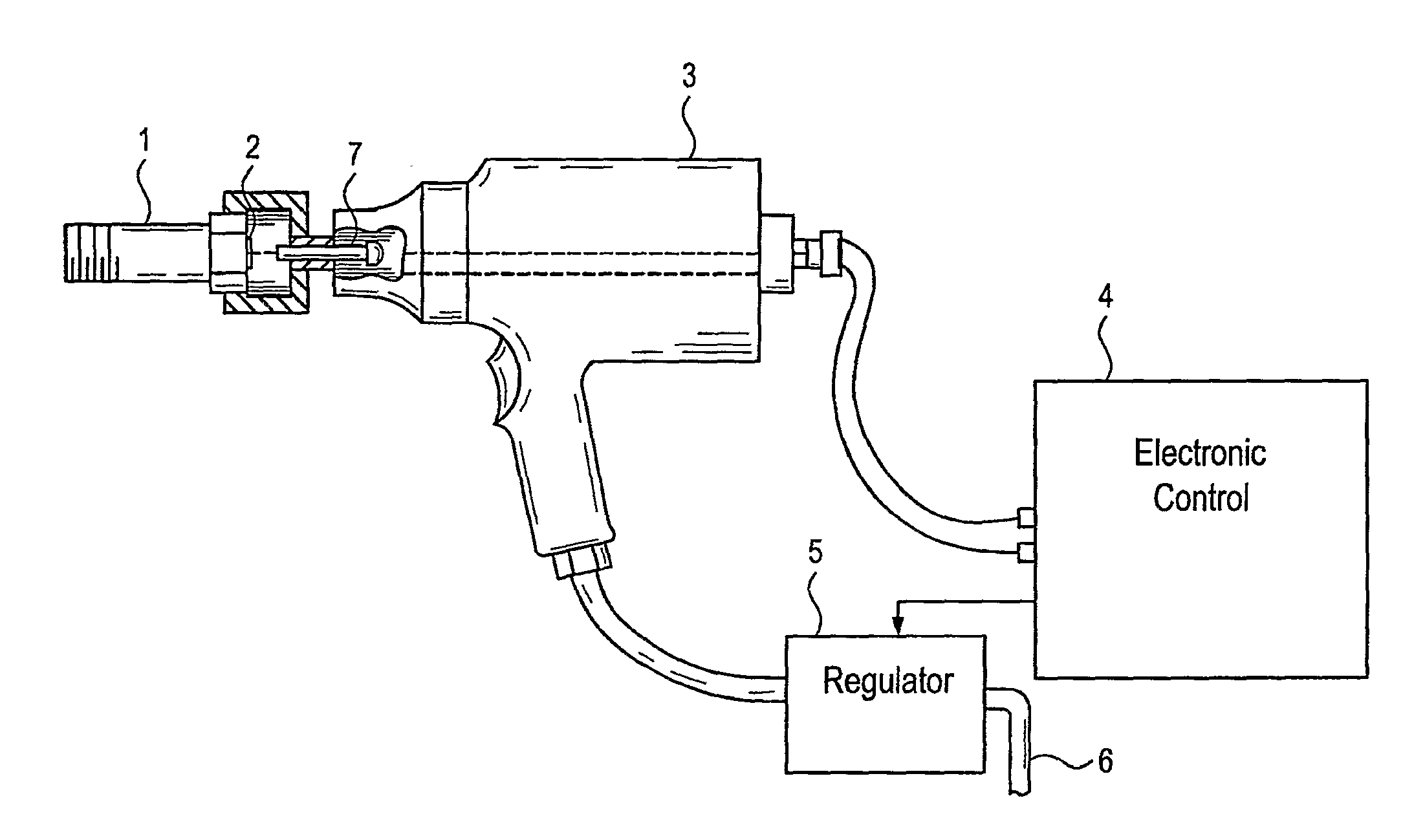

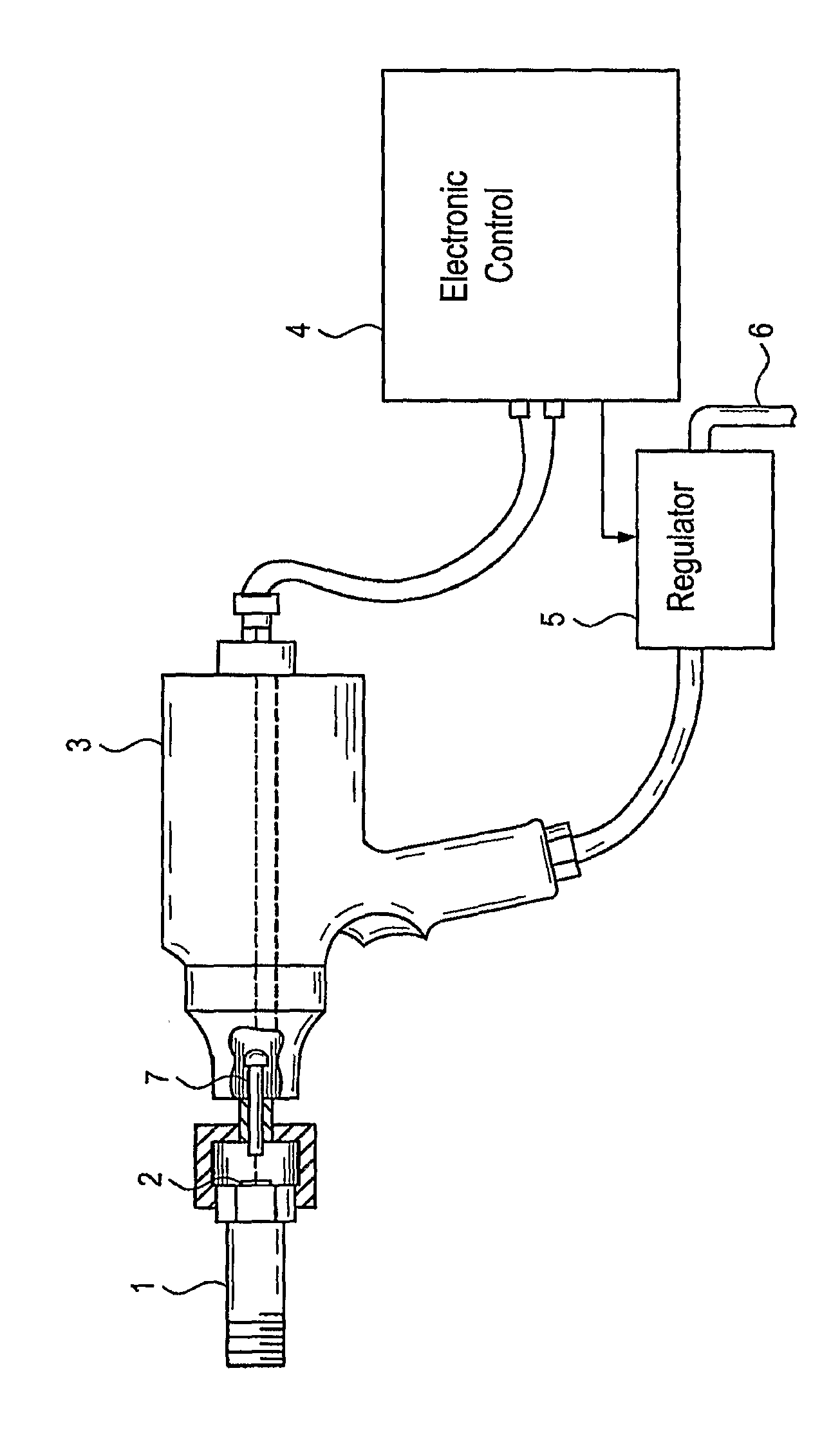

System for dynamically controlling the torque output of a pneumatic tool

ActiveUS7823458B2Reduce probabilityStop preciseDerricks/mastsTemperatue controlRotation velocityHeating effect

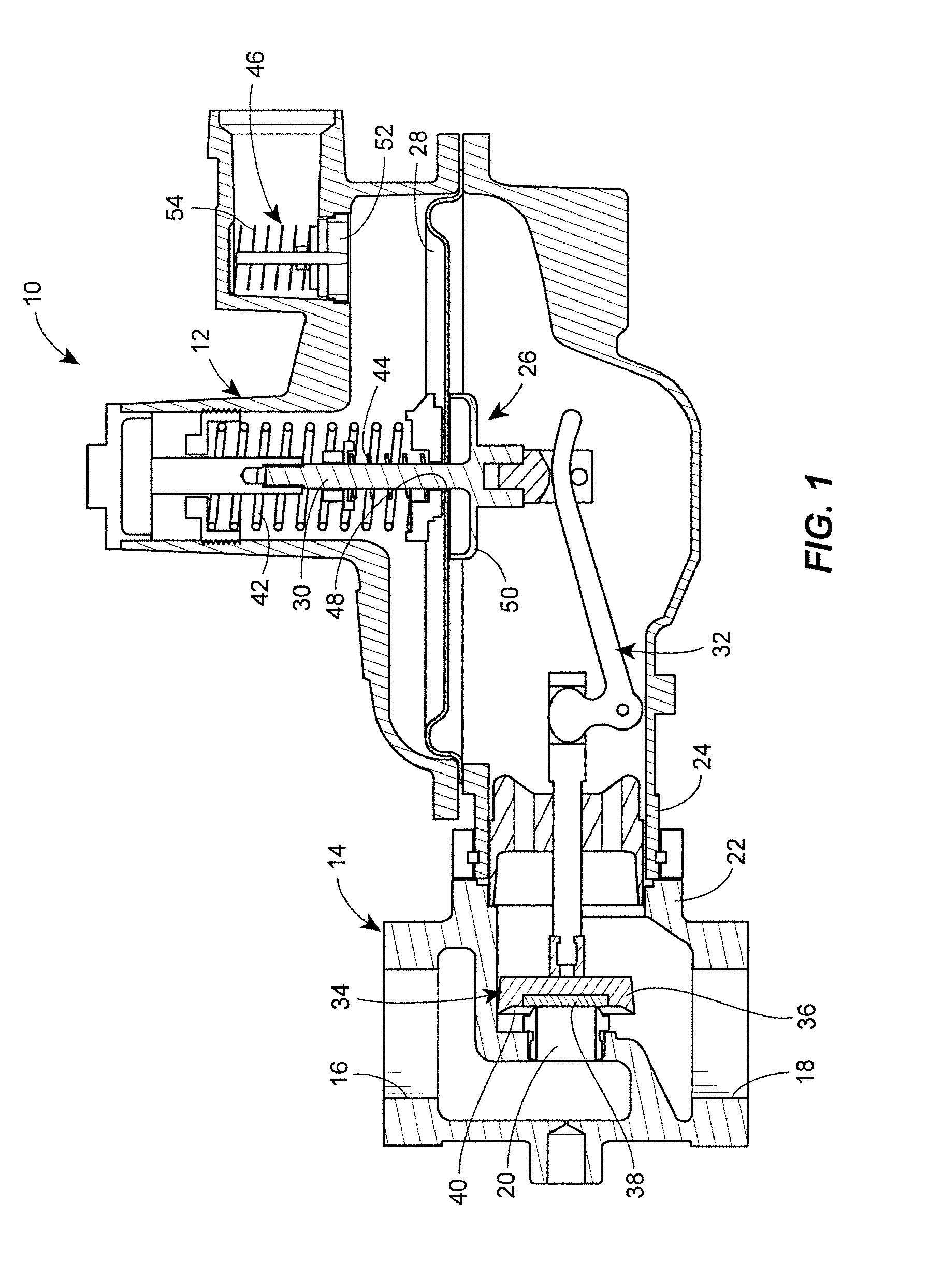

Pneumatic tightening tools can be used for high speed assembly of critical bolts to precise loads by dynamically controlling the output power of the pneumatic tool during a tightening cycle using an electronically controlled air pressure regulator to reduce the tightening rate, or the load increase per impact for impact or impulse tools, to enable the tool to be stopped precisely at a specified stopping load or torque. For prevailing torque fasteners, the output power of the pneumatic tool is dynamically controlled to minimize the speed of rotation during rundown, to minimize the heating effects associated with such torque fasteners, and to then increase the power from the tool, as required, to provide the torque to reach the specified stopping load or torque. The maximum air pressure supplied to the pneumatic tool can be limited, depending on the expected torque required to tighten the fastener to the specified load or torque.

Owner:INNOVATION PLUS LLC

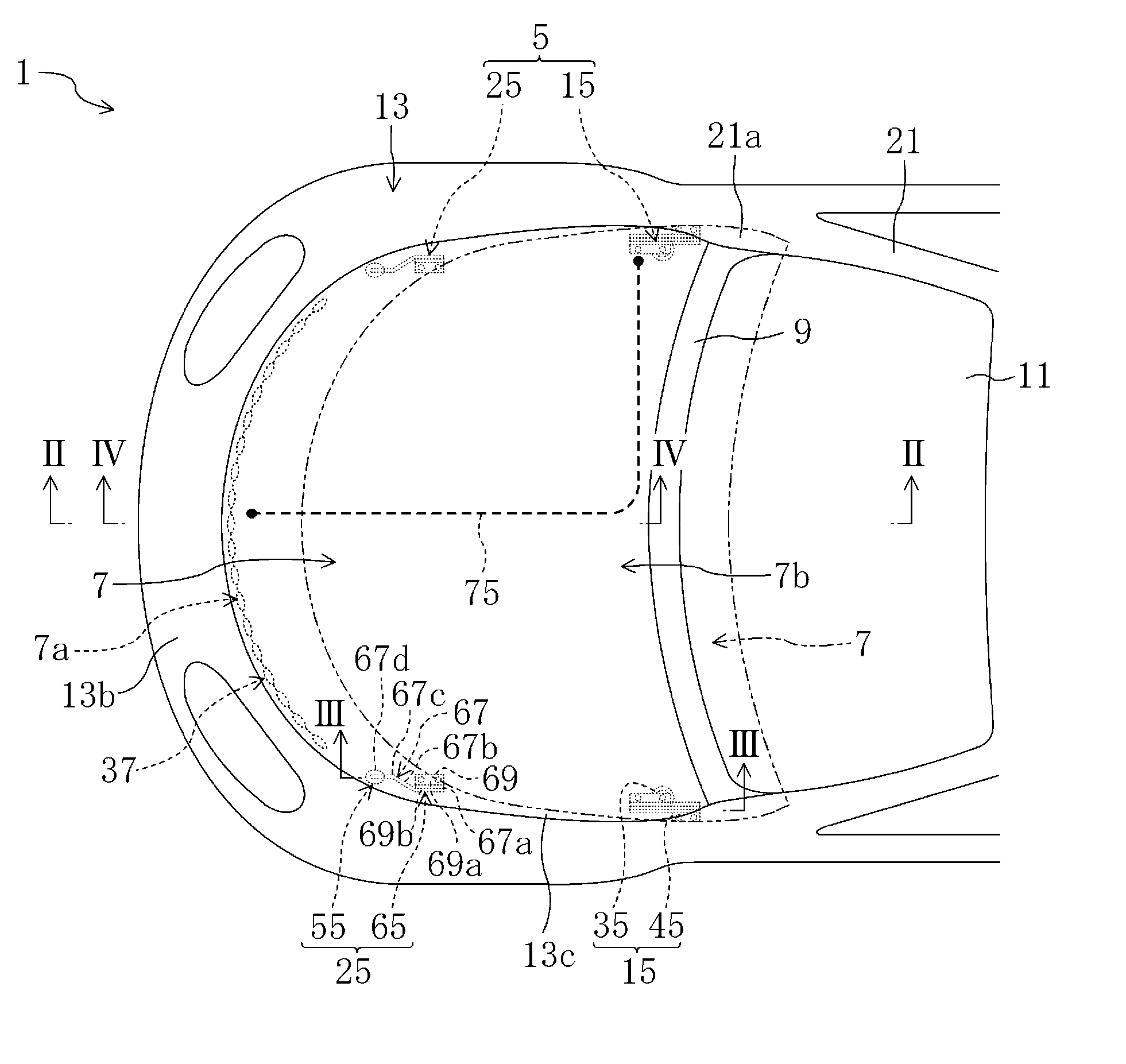

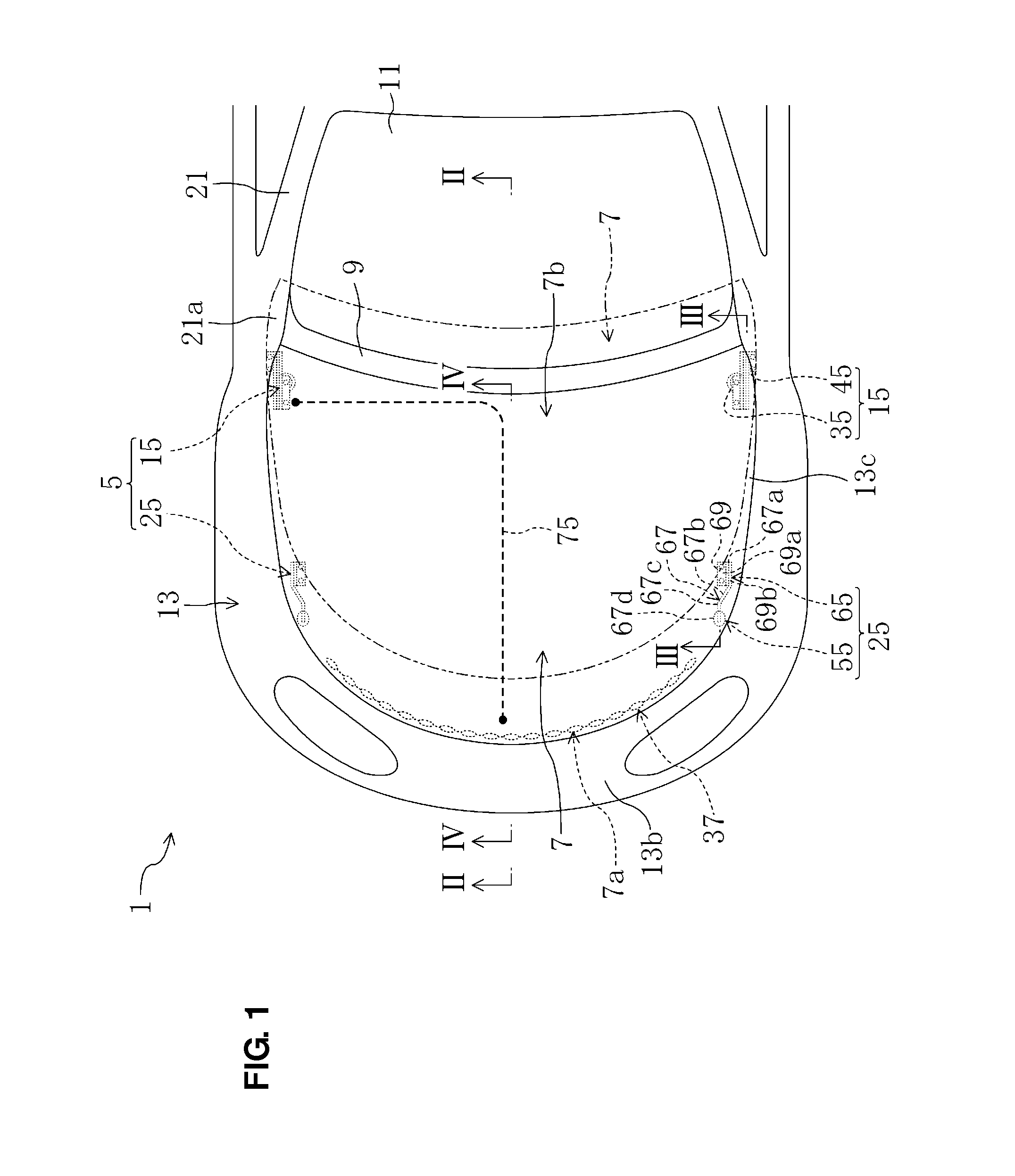

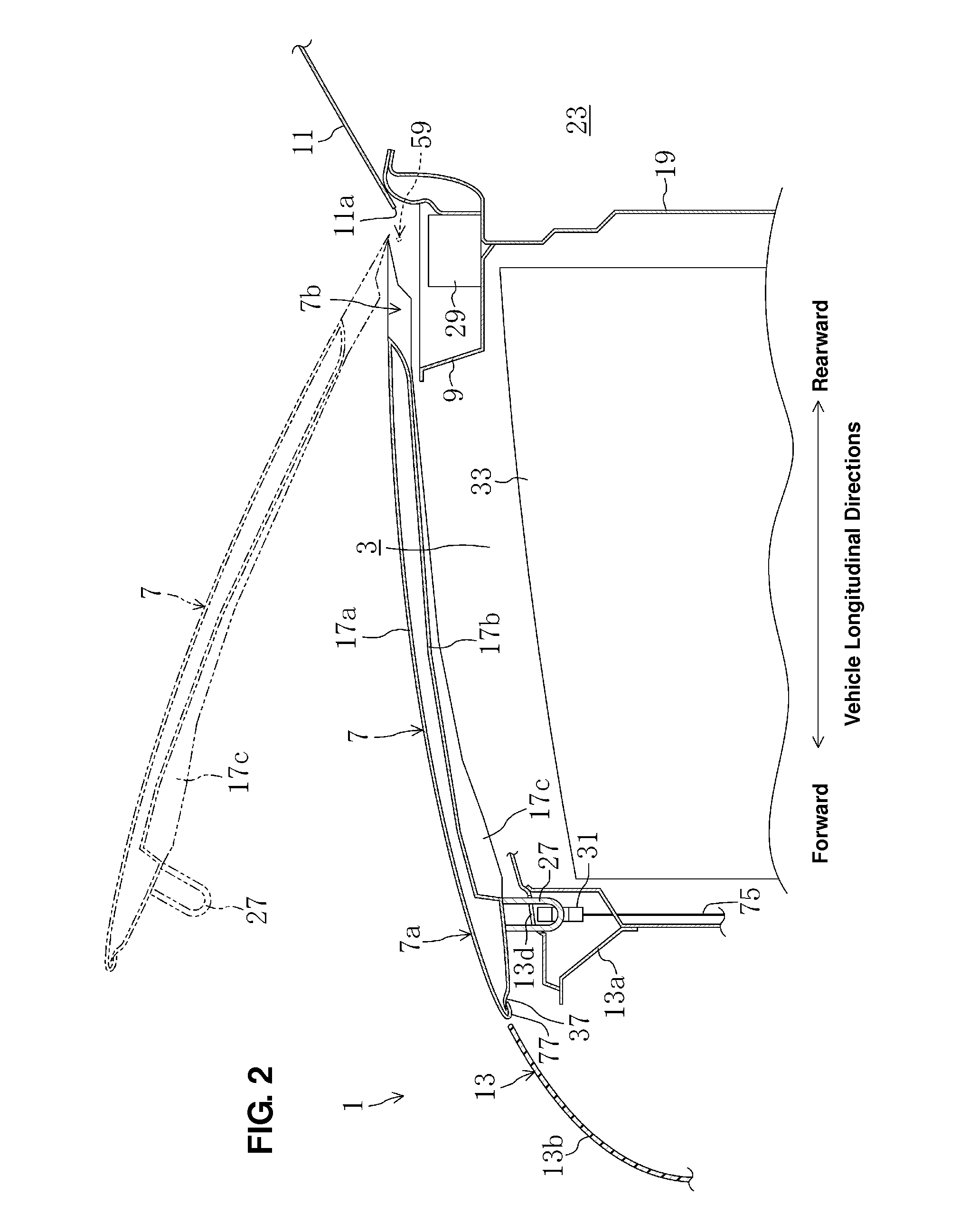

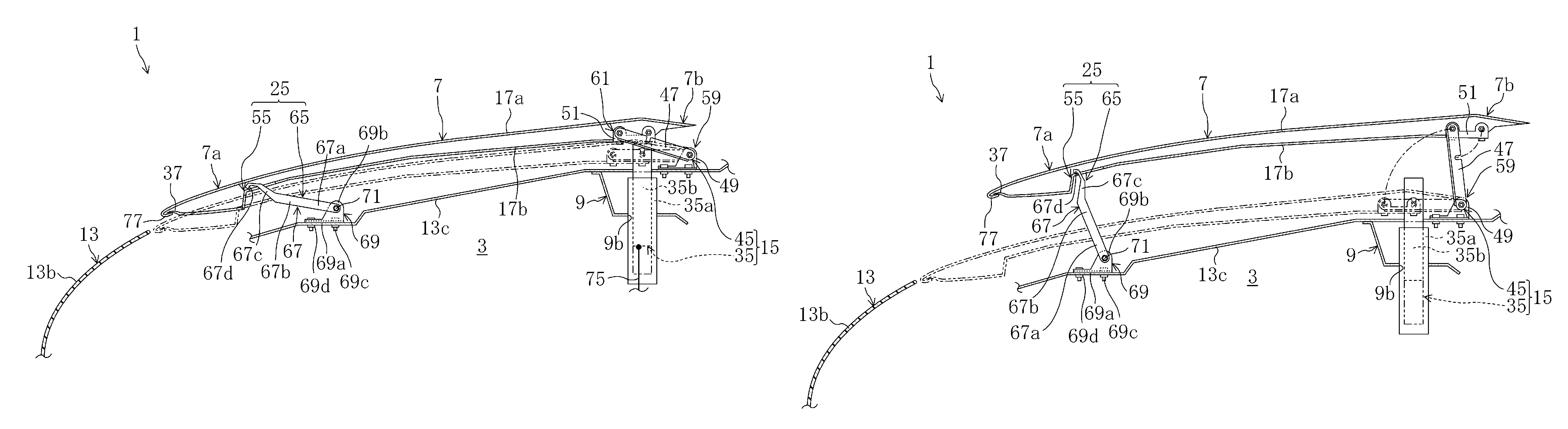

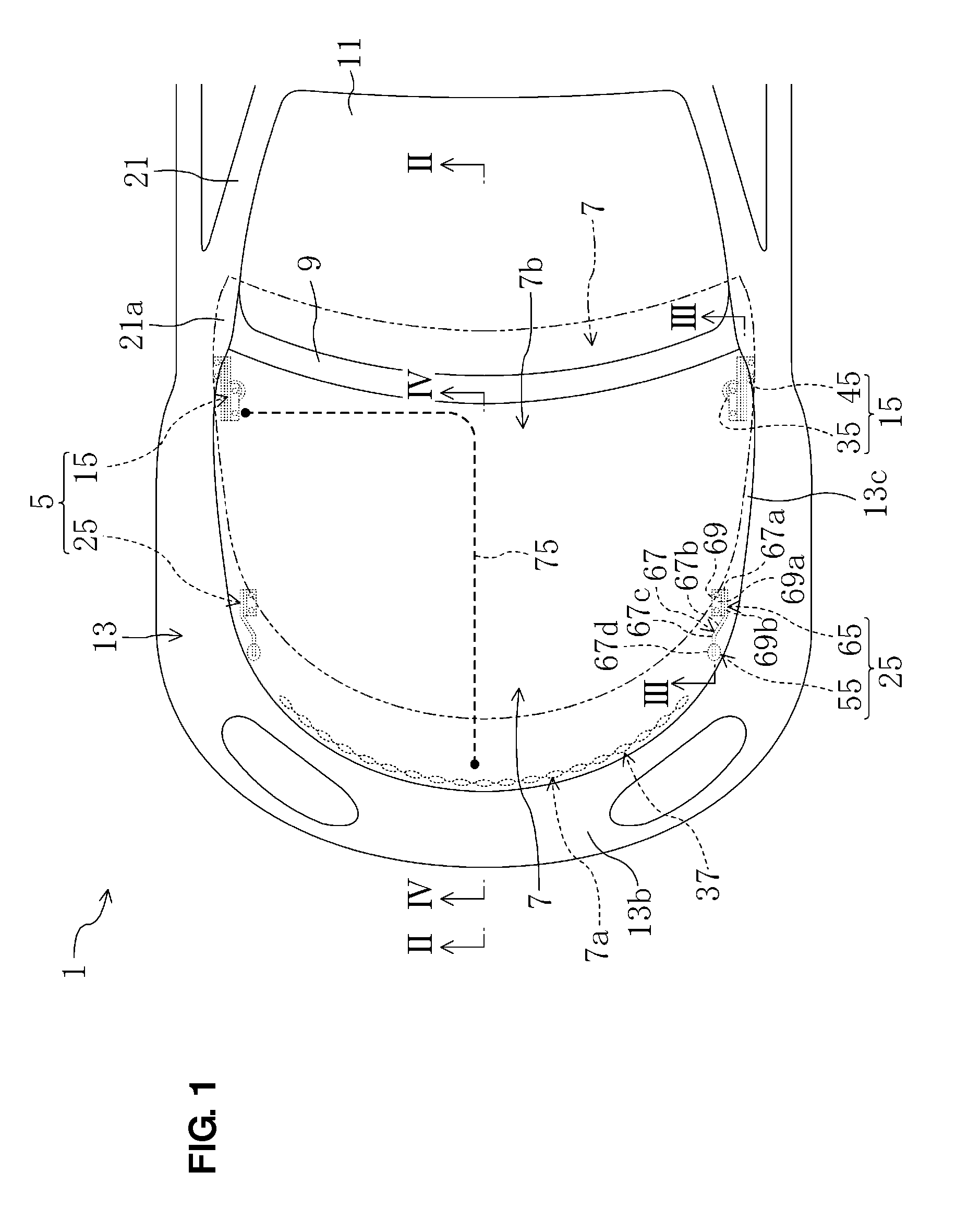

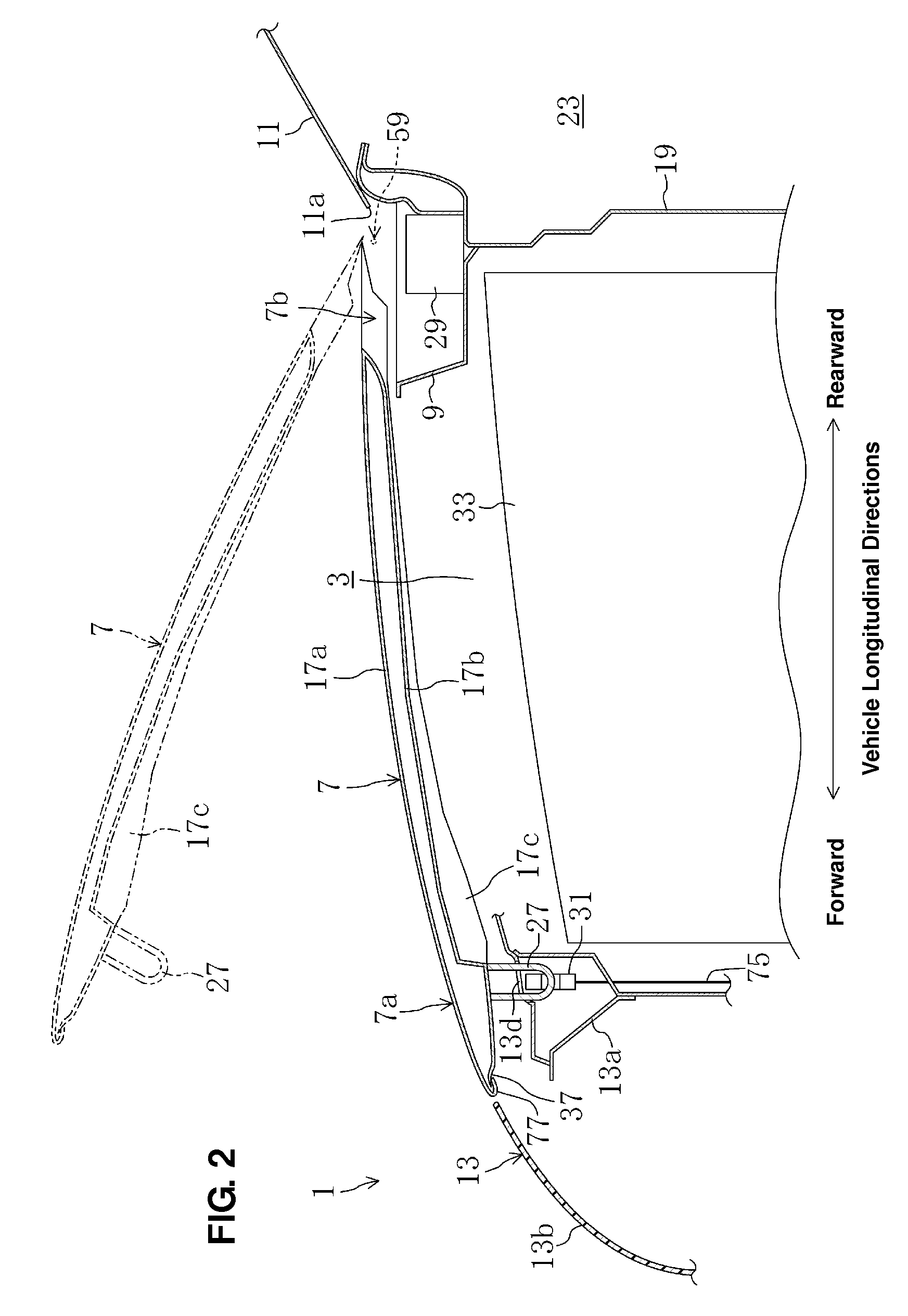

Pedestrian protection device for vehicle

ActiveUS20100244484A1Reduce the impactReduce impactVehicle seatsPedestrian/occupant safety arrangementEngineeringSpecified load

A pedestrian protection device for a vehicle is provided at a vehicle-body front portion which comprises an engine room, a cowl box provided at an upper portion of a dash panel and extending in a vehicle width direction, and an engine hood pivotally supported at the vehicle body via a first hinge provided at a rear end portion so as to cover over the engine room. An engine-hood guide mechanism guides the engine hood upwardly and rearwardly so as to cover at least part of the cowl box when a collision of a pedestrian against a front bumper face is detected or predicted, and lowers the engine hood downwardly when a load acting on the engine hood exceeds a specified load.

Owner:MAZDA MOTOR CORP

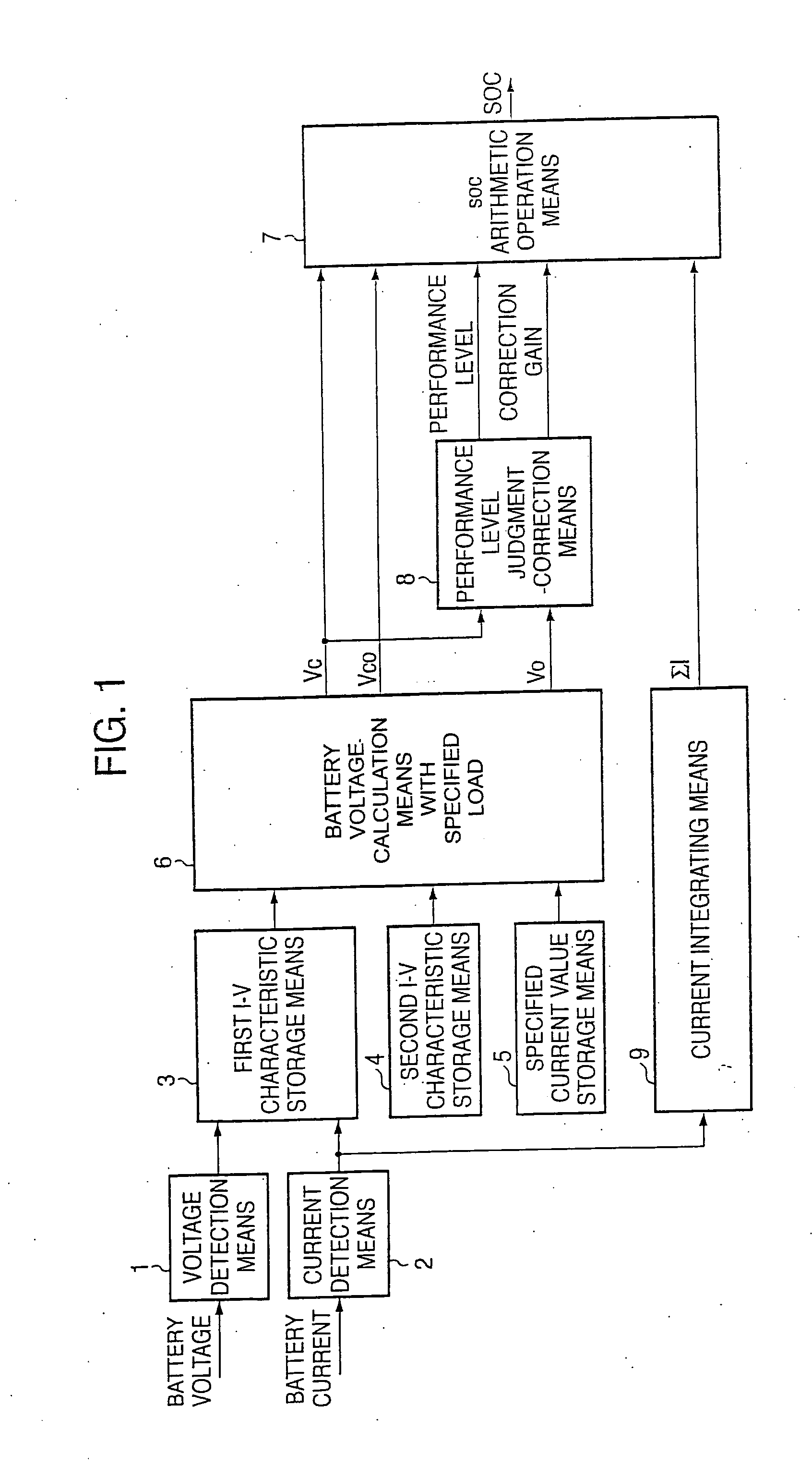

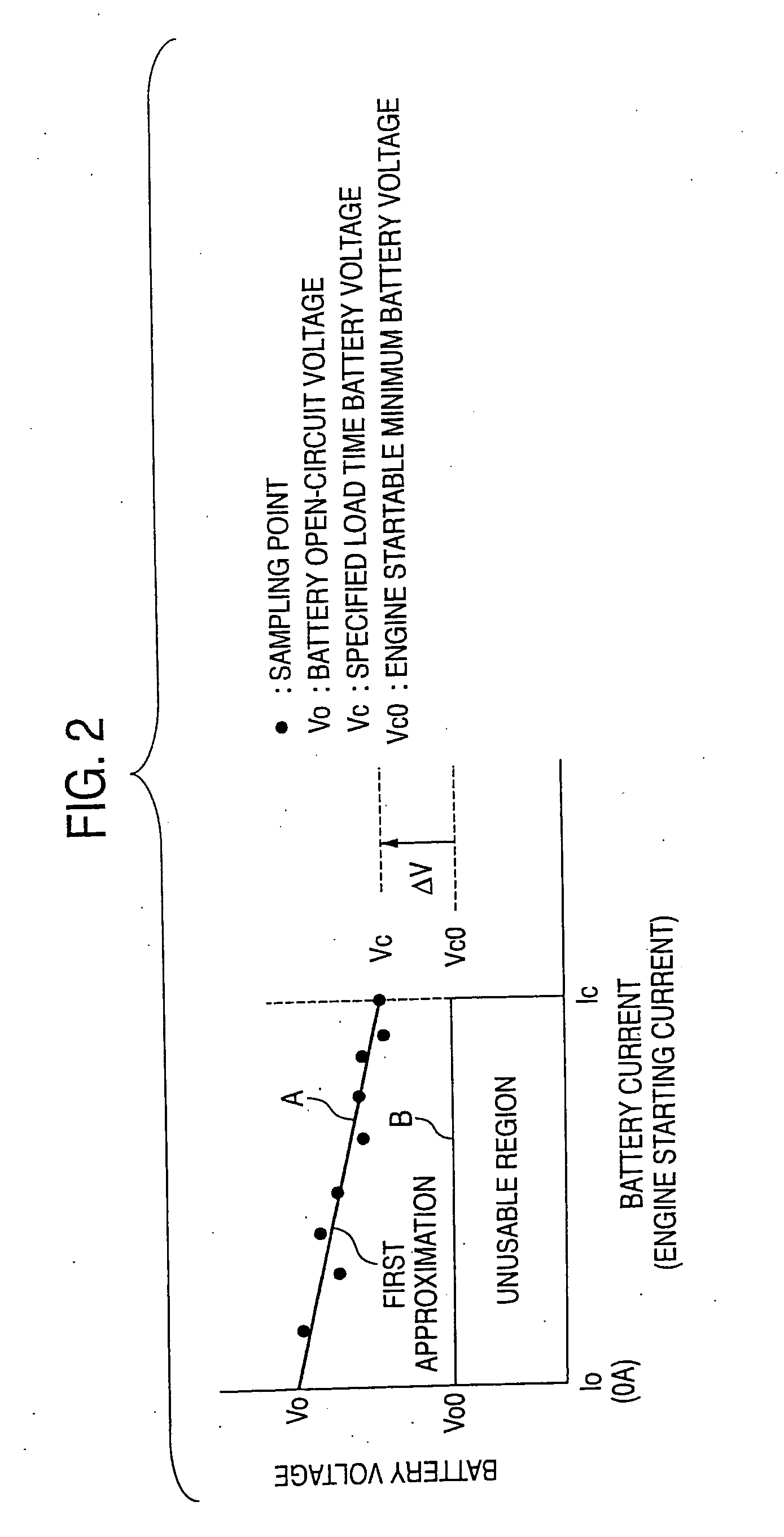

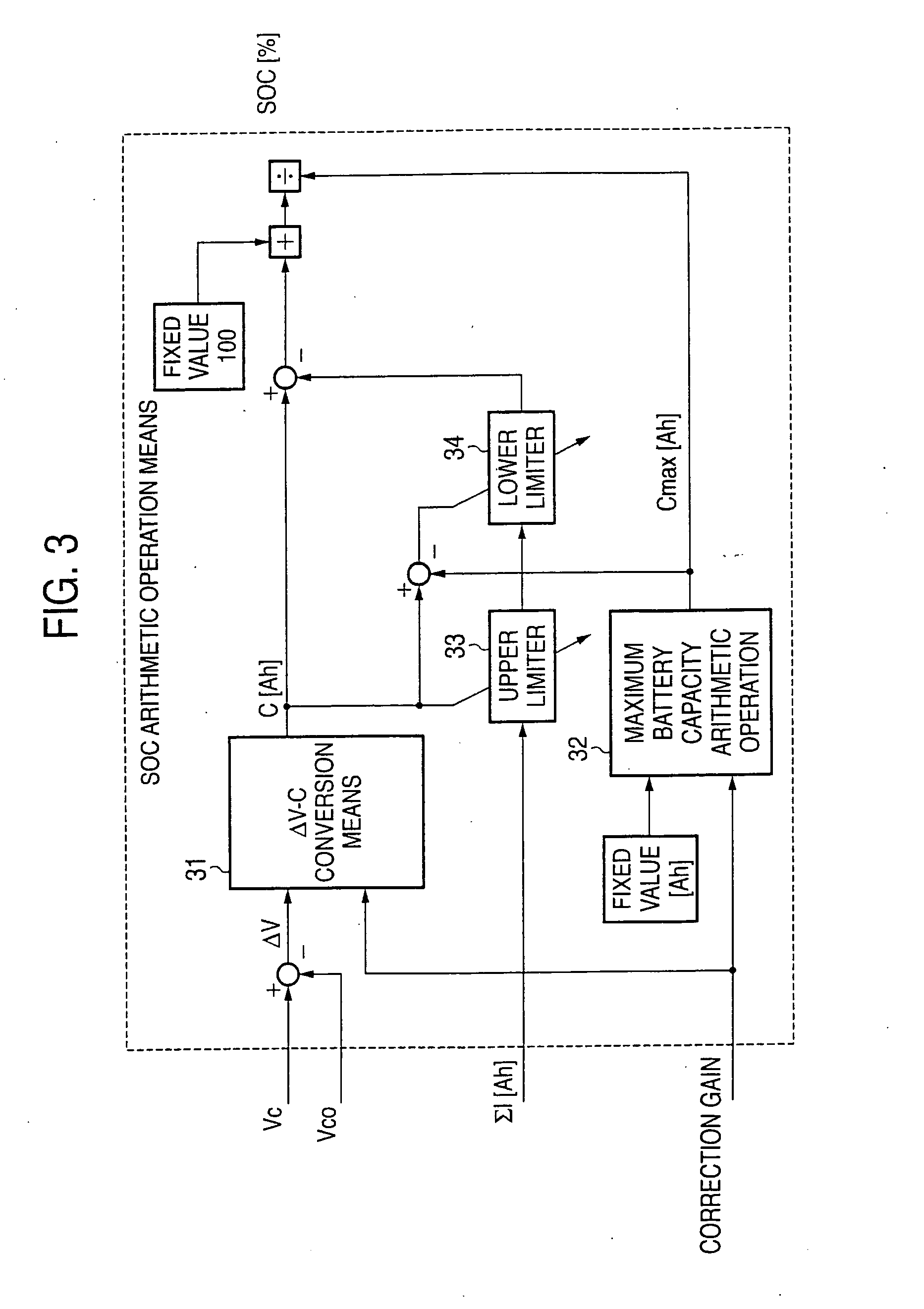

Battery charged condition computing device and battery charged condition computing method

InactiveUS20060055374A1Easy to judgeShort timeBatteries circuit arrangementsTesting electric installations on transportBattery state of chargeBattery charge

In order to provide a battery charging state arithmetic operation device which can judge a charging state of a battery currently being used easily and in a short time, there are provided battery voltage calculation means 6 with specified load for calculating a first and a second battery voltages when a battery current is at a specified load current value from a first I-V characteristic of the battery which is in a first state as a currently used state and is stored in first I-V characteristic storage means 3 and a second I-V characteristic which is in a second state where the amount of remaining energy is small and is stored in second I-V characteristic storage means 4, and SOC arithmetic operation means 7 for calculating an SOC (charging state) of the battery in the first state by using the first and the second battery voltages calculated.

Owner:MITSUBISHI ELECTRIC CORP +1

Pedestrian protection device for vehicle

ActiveUS8534410B2Reduce impactVehicle seatsPedestrian/occupant safety arrangementEngineeringSpecified load

Owner:MAZDA MOTOR CORP

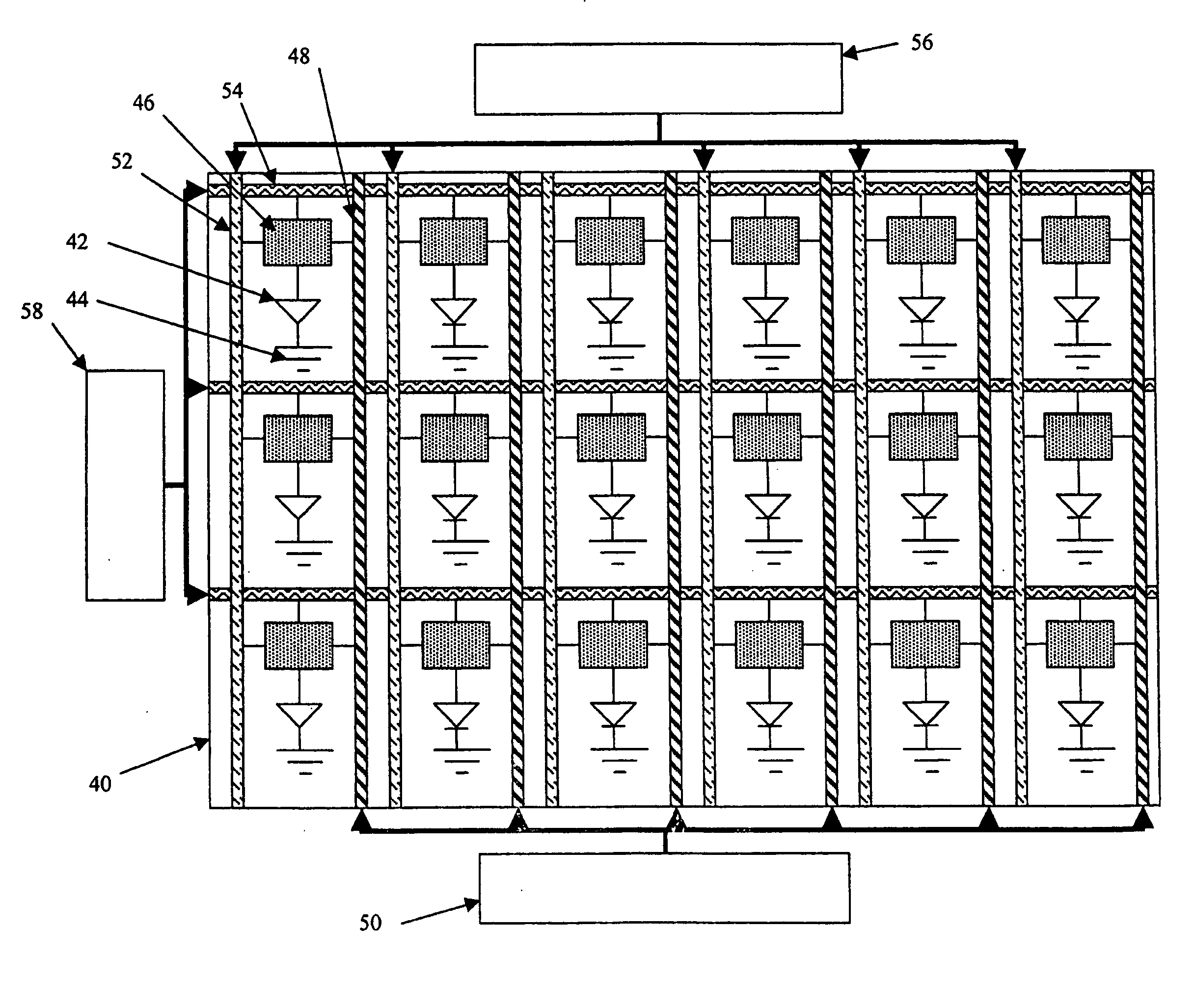

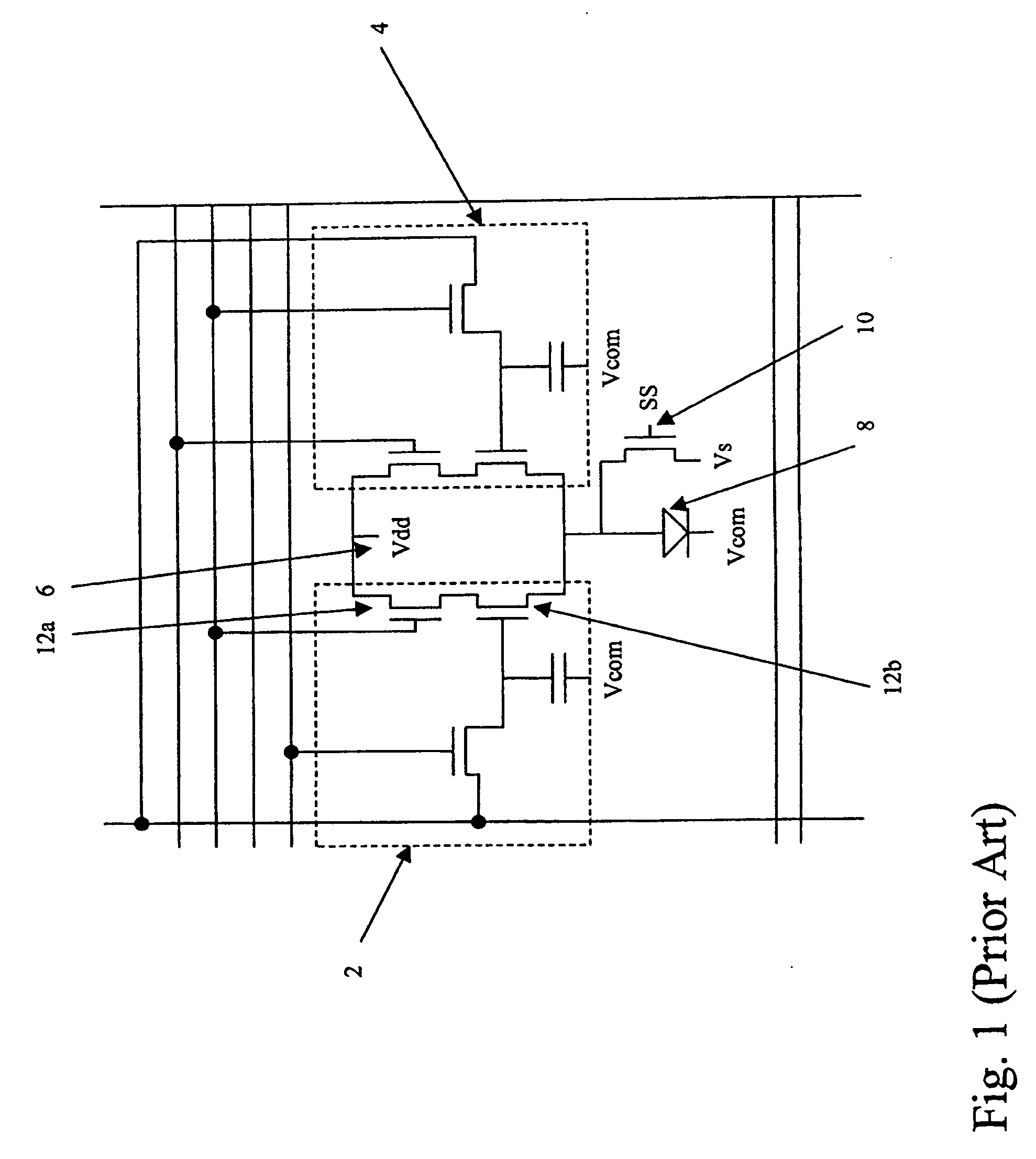

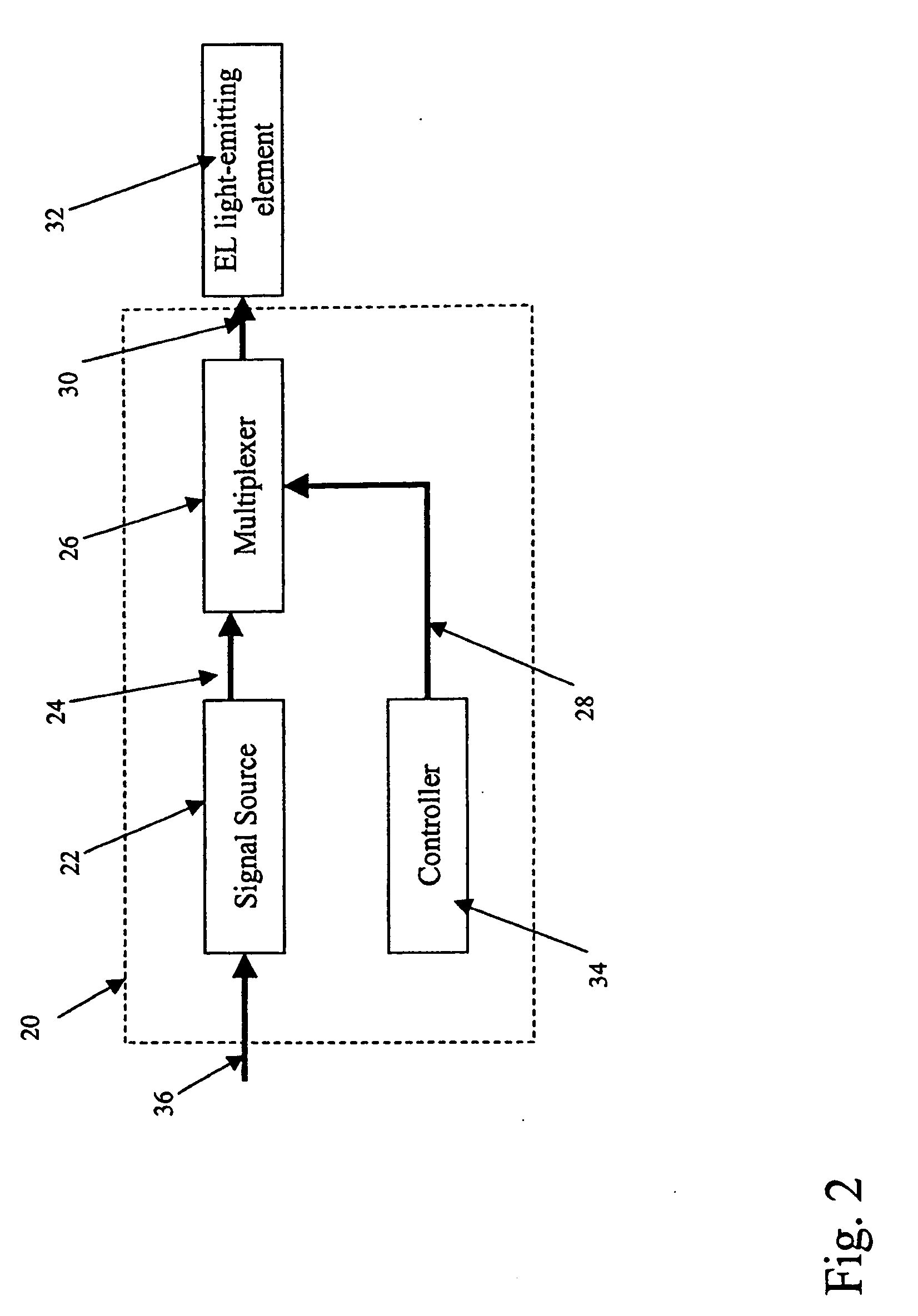

Drive circuit and electro-luminescent display system

A drive circuit for rapidly interleaving image data displayed on an EL device is disclosed. The drive circuit includes a signal source that provides a image data signals. Each image data signal is provided for a specified load period. A multiplexer receives the image data signals, and in response to a selection signal selects one of the image data signals to provide a control signal that directs the EL device to emit light. Additionally, a controller causes interleaving of the image data during multiple display periods; each display period is shorter than the load period.

Owner:GLOBAL OLED TECH

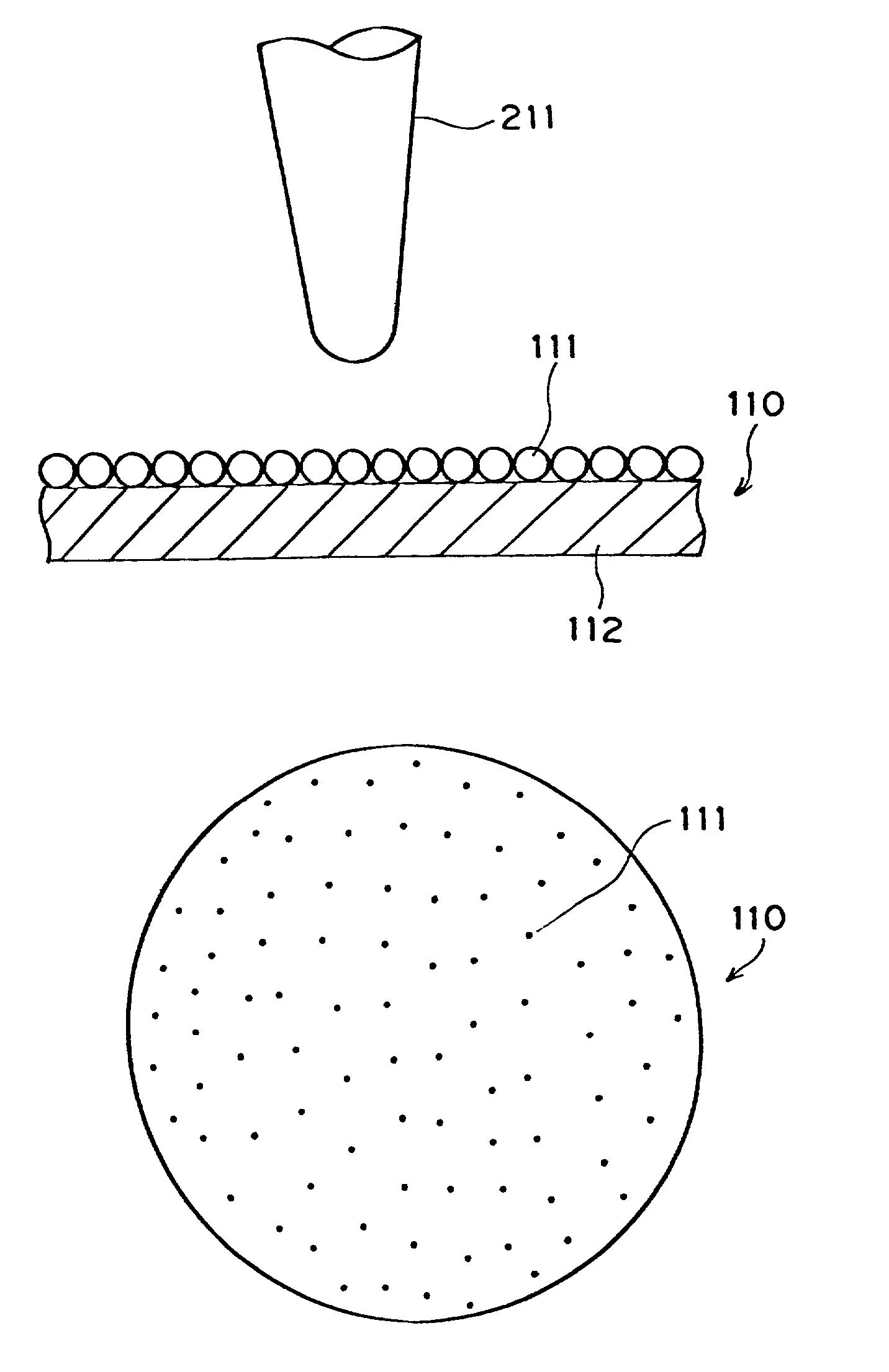

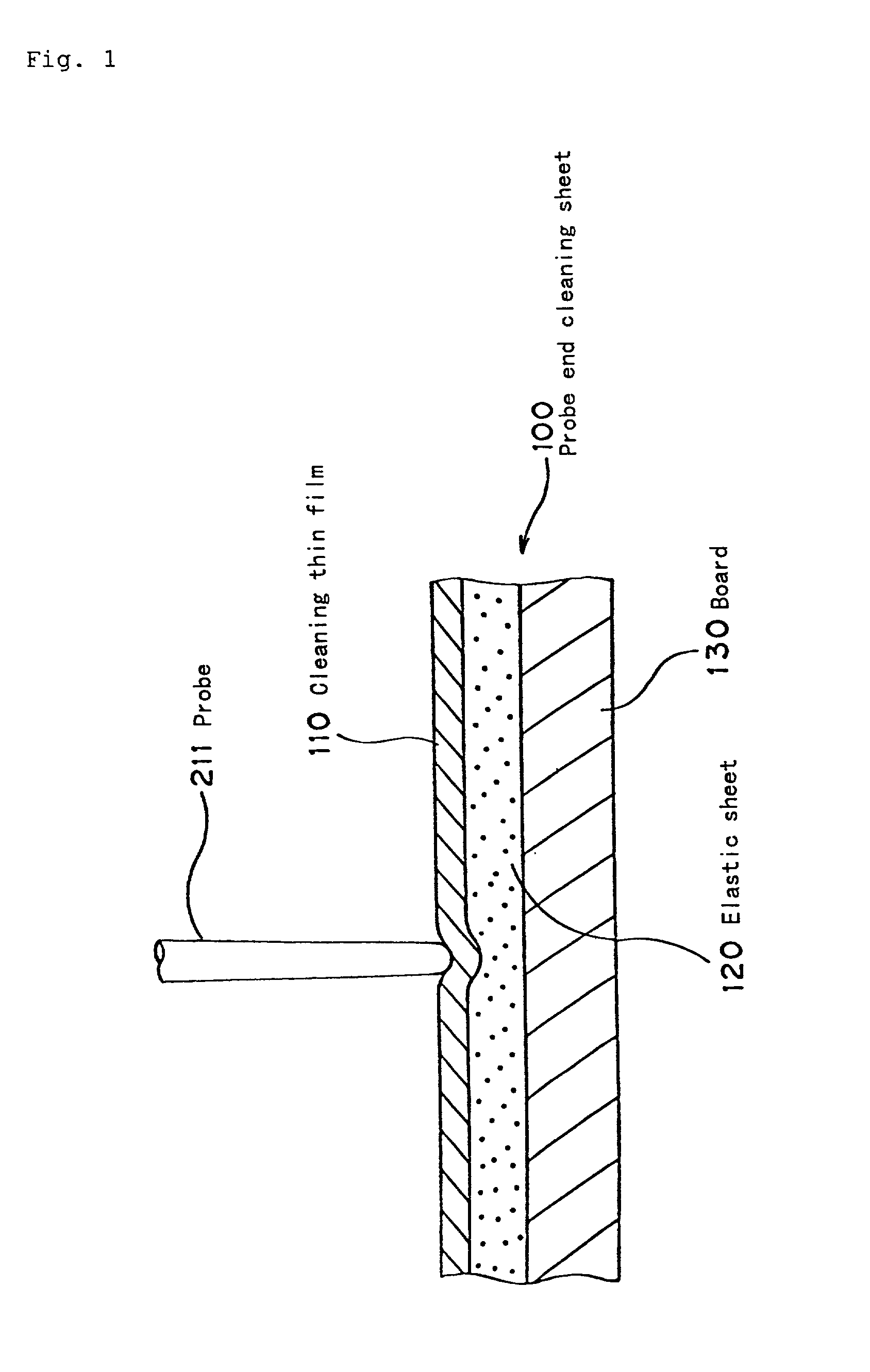

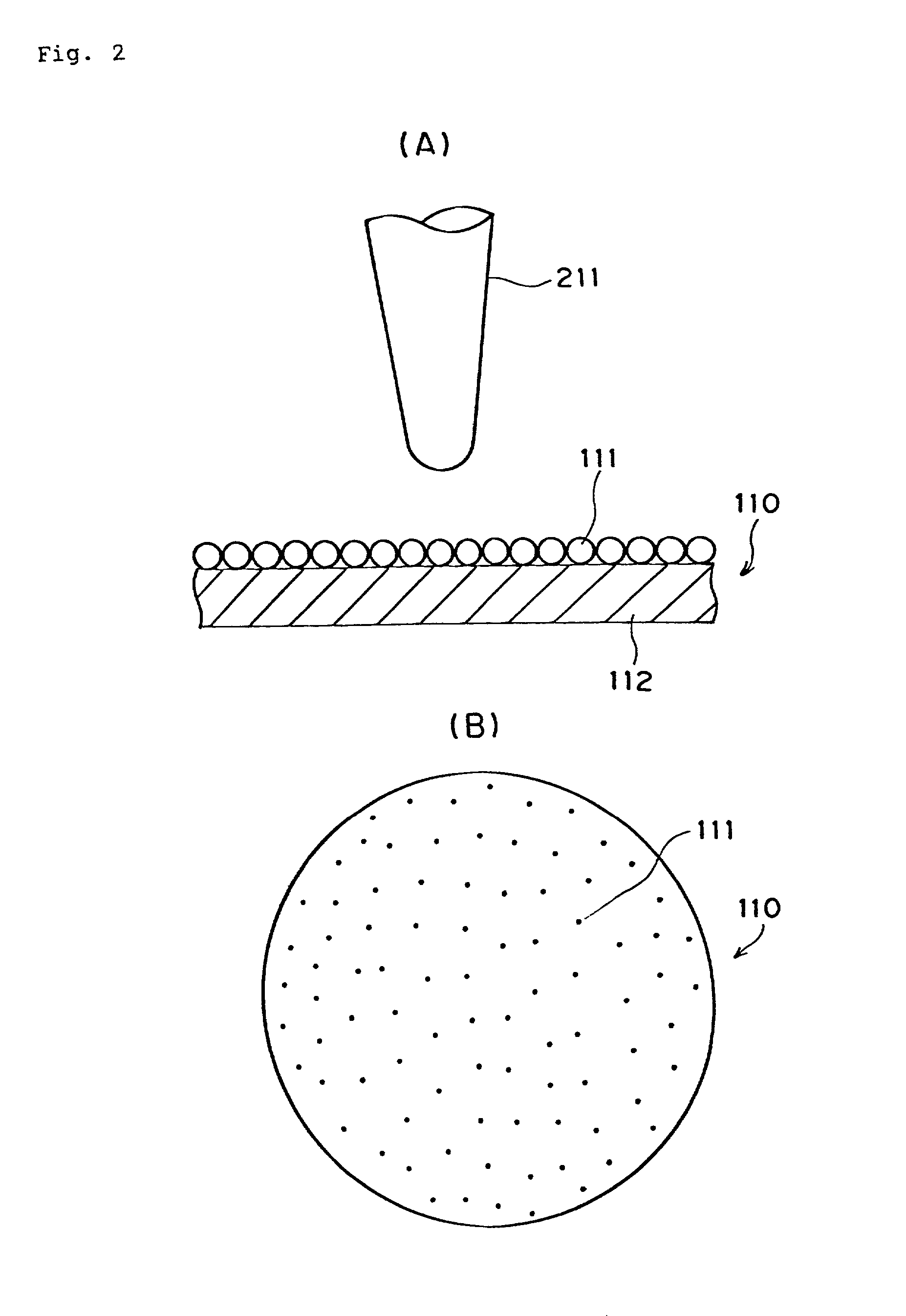

Probe end cleaning sheet

InactiveUS20020028641A1Polishing machinesSemiconductor/solid-state device testing/measurementForeign matterSpecified load

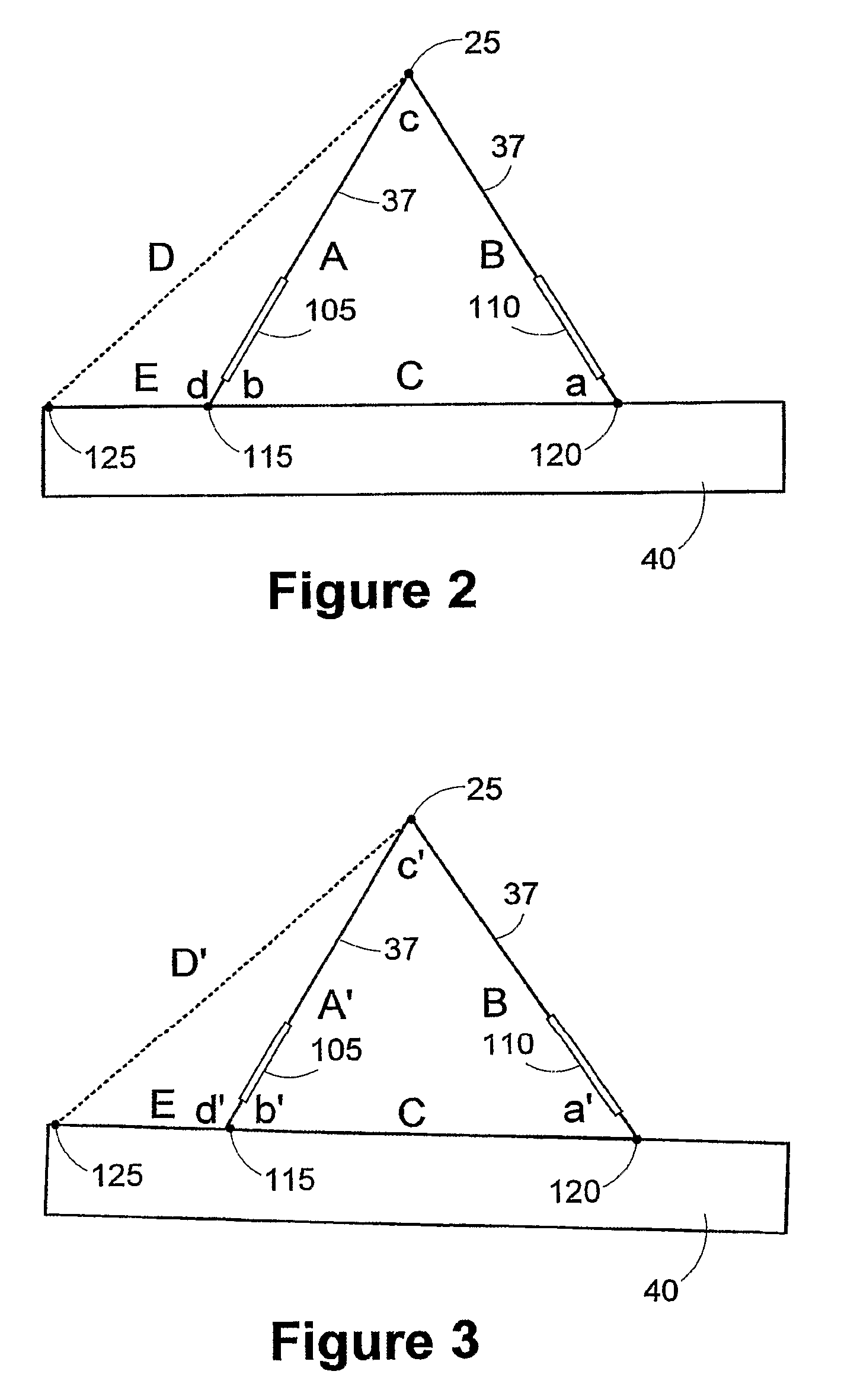

To remove foreign matter without deforming the end of a probe, and prevent new foreign matter from adhering to the end of a probe. A probe end cleaning sheet for removing foreign matter adhered to the end of a probe 211, comprising a cleaning thin film 110 having fine abrasive powder applied on the surface, an elastic sheet 120 provided in a lower layer of the cleaning thin film 110 and having an elasticity, and a board 130 provided in a lower layer of the elastic sheet 120, in which the cleaning thin film 110 is made of a material which is dented when the end of the probe 211 is pressed with a specified load but is not torn by the end of the probe 211, and the elastic sheet 120 is made of a material which is dented in the pressed portion by the end of the probe 211 when the end of the probe 211 is pressed to the cleaning thin film 110 with the specified load.

Owner:NIHON DENSHIZAIRYO

Roller fatigue test apparatus

InactiveUS20080168823A1Duplicating the rolling action of a cam lobeSimulation is accurateUsing mechanical meansInvestigating abrasion/wear resistanceSpecified loadTorque sensor

Owner:GENTEK TECH MARKETING

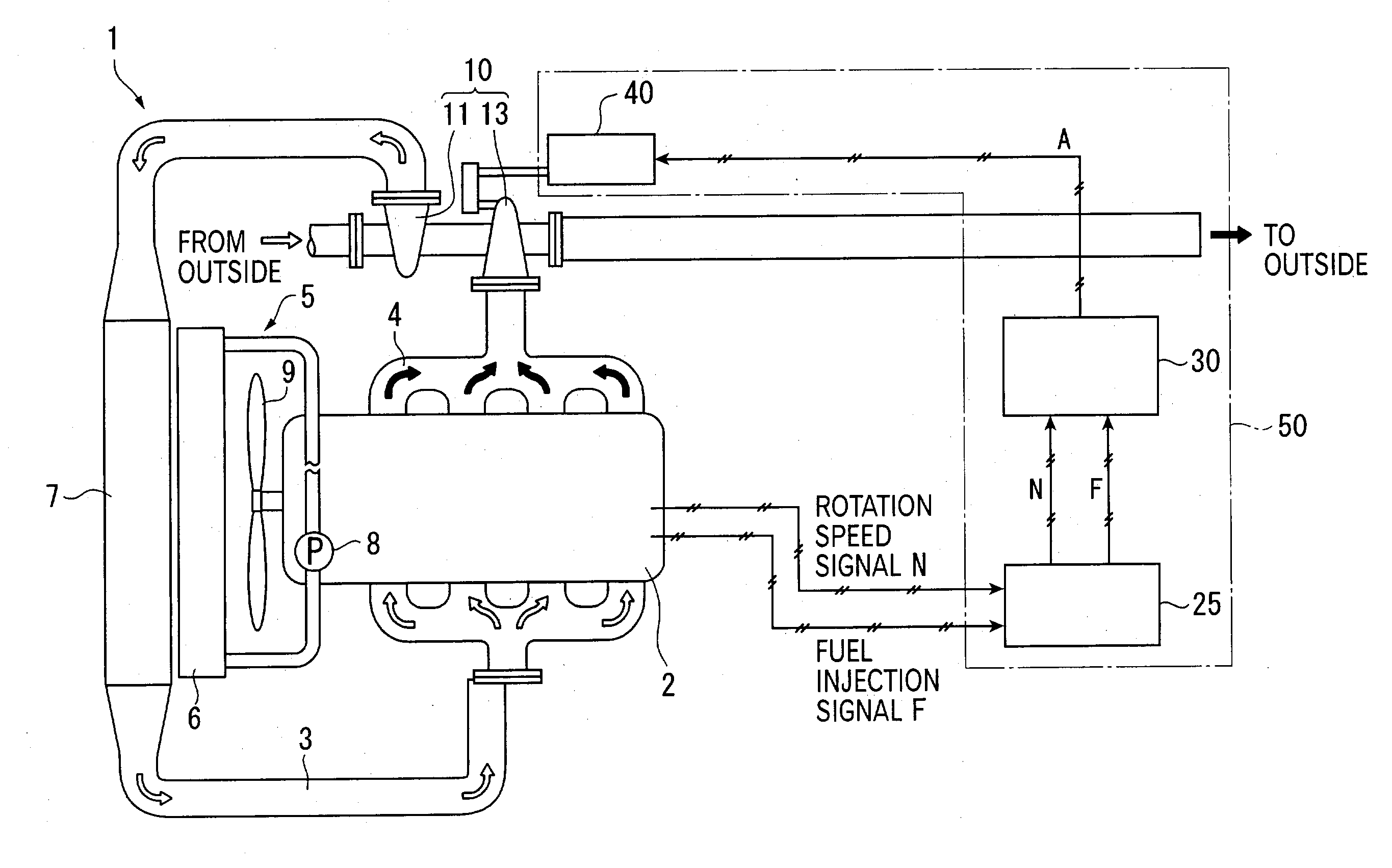

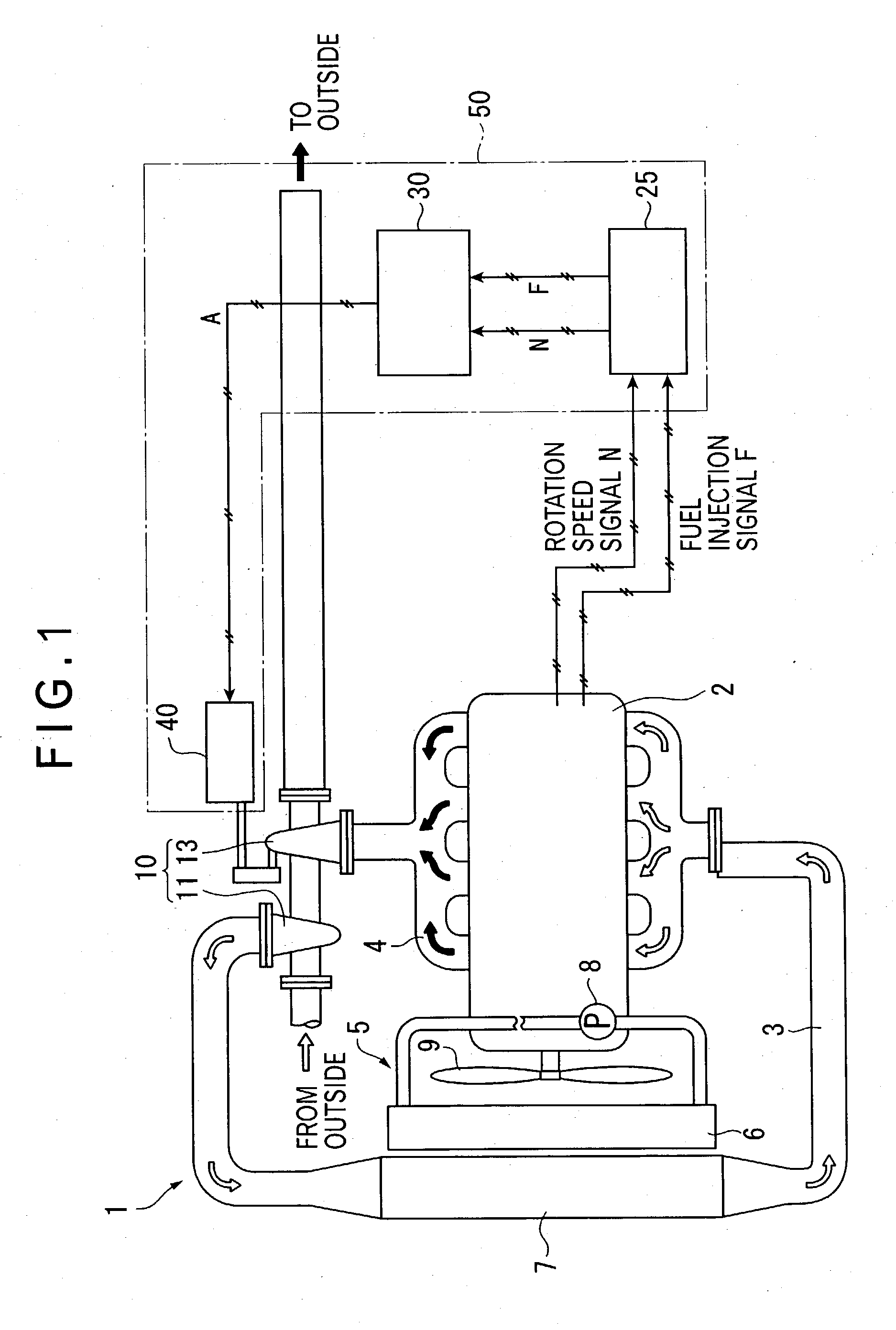

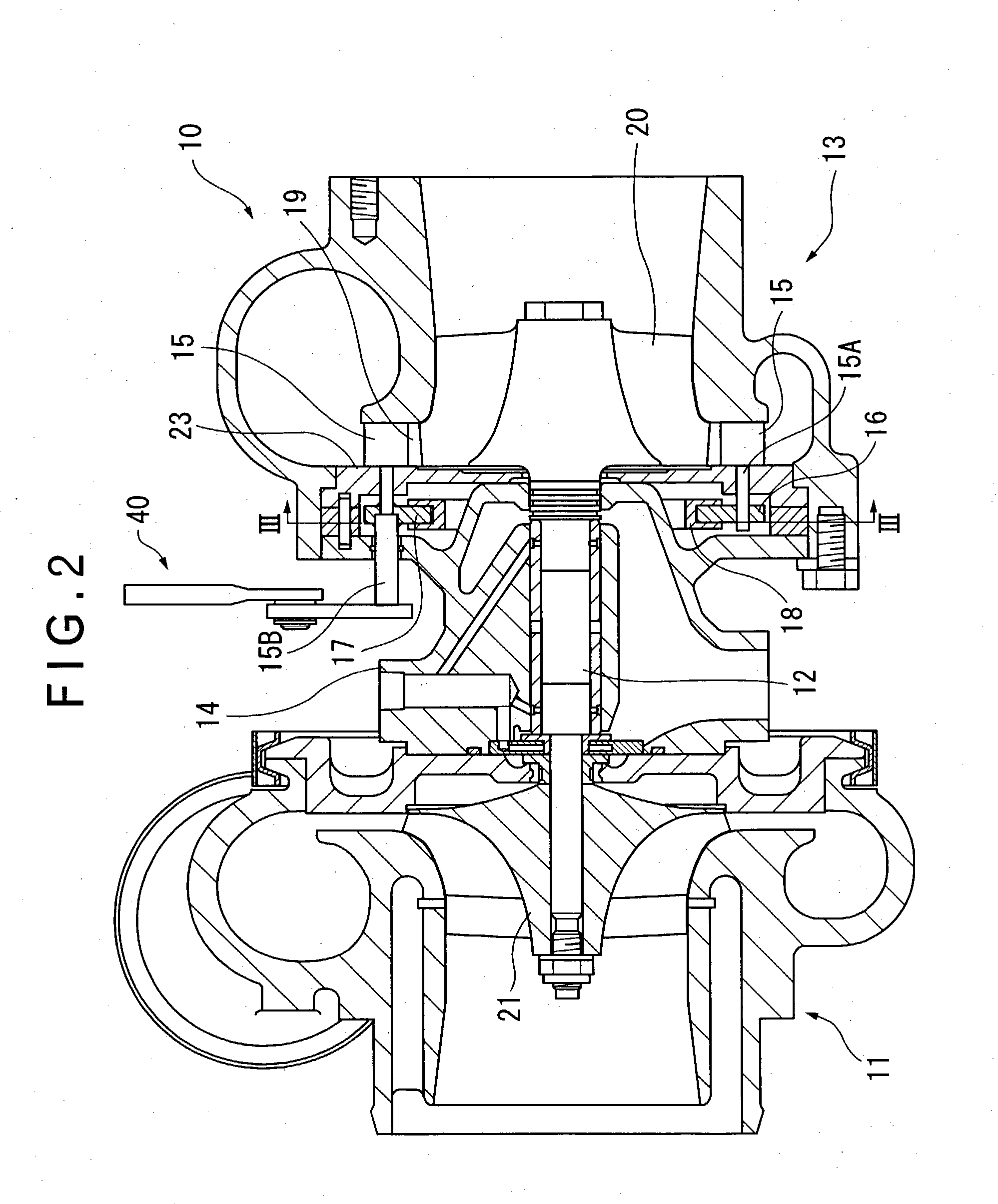

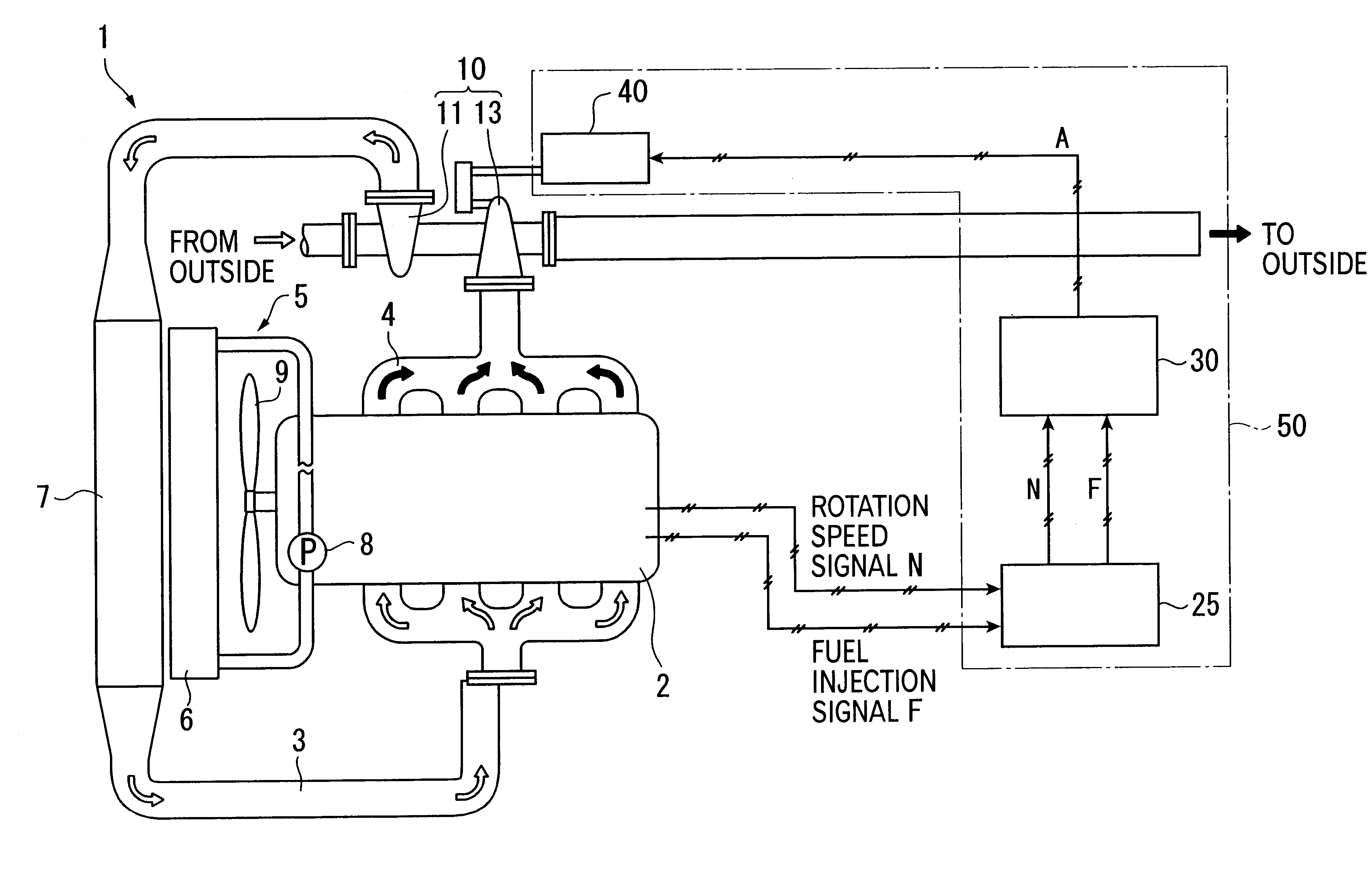

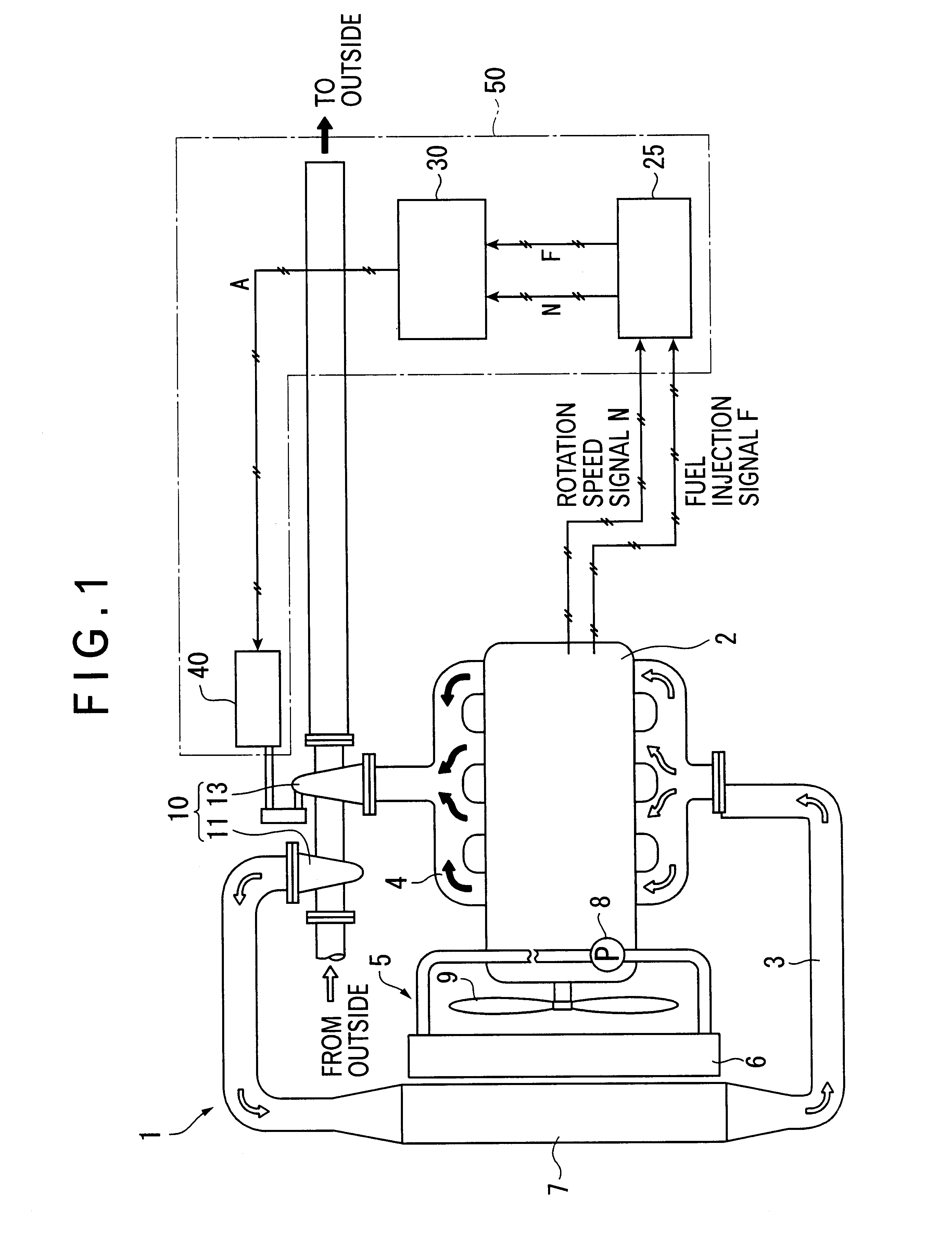

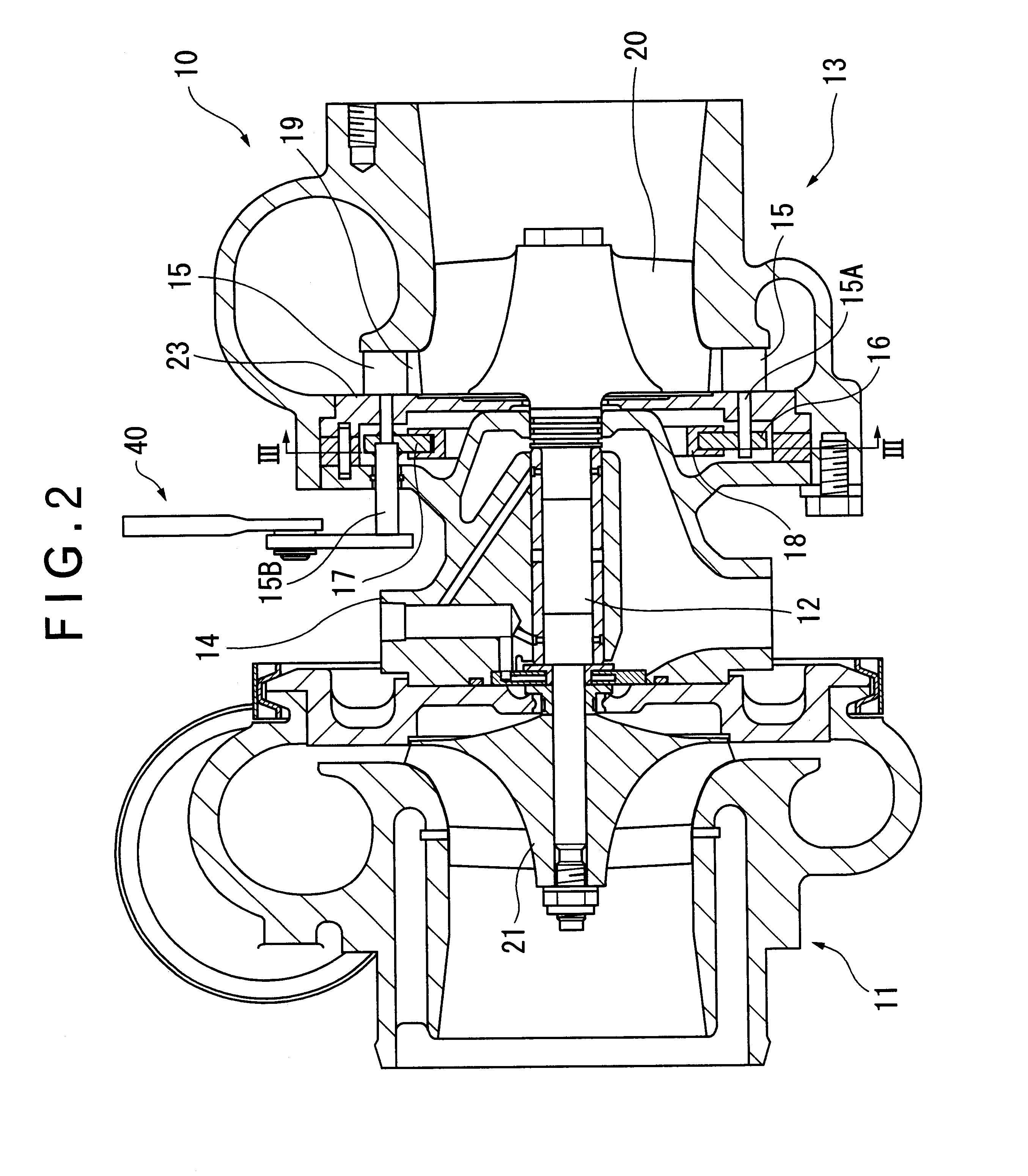

Variable nozzle opening control system for an exhaust turbine supercharger

InactiveUS20030182940A1Reduce openingDegradation of combustionElectrical controlInternal combustion piston enginesLow speedControl system

The present invention provides a variable nozzle opening control unit insuring a low fuel consumption rate and excellent response speed in the low load mode for an exhaust turbine supercharger. To achieve the purpose described above, an opening of the variable nozzle of the exhaust turbine supercharger 10 is set to and maintained at the maximum value in the constant operating state when the load is not more than a prespecified load level, and also the opening is gradually made smaller, when the load is not less than the specified load level, as the load becomes higher. When the load shifts from the high load region to the low load region, the variable nozzle is more closed or maintained at the original opening. Further when the operating state may get close to the surging limit, the variable nozzle is more opened. When shifting from the low load region to the high load region, or when sifting from the low speed to the high speed, the variable nozzle is once opened more, and then closed more to return to the constant operating state.

Owner:KOMATSU LTD

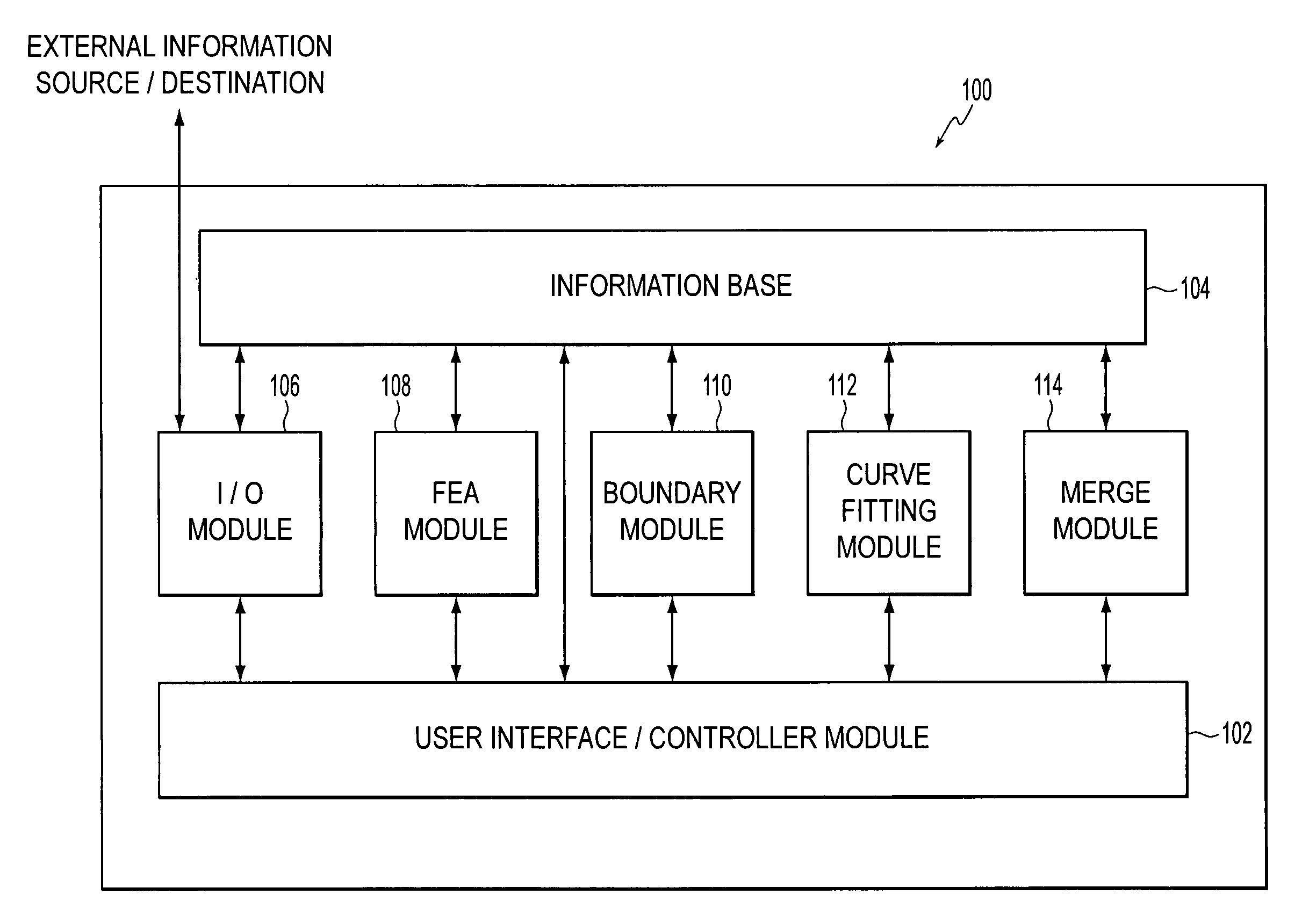

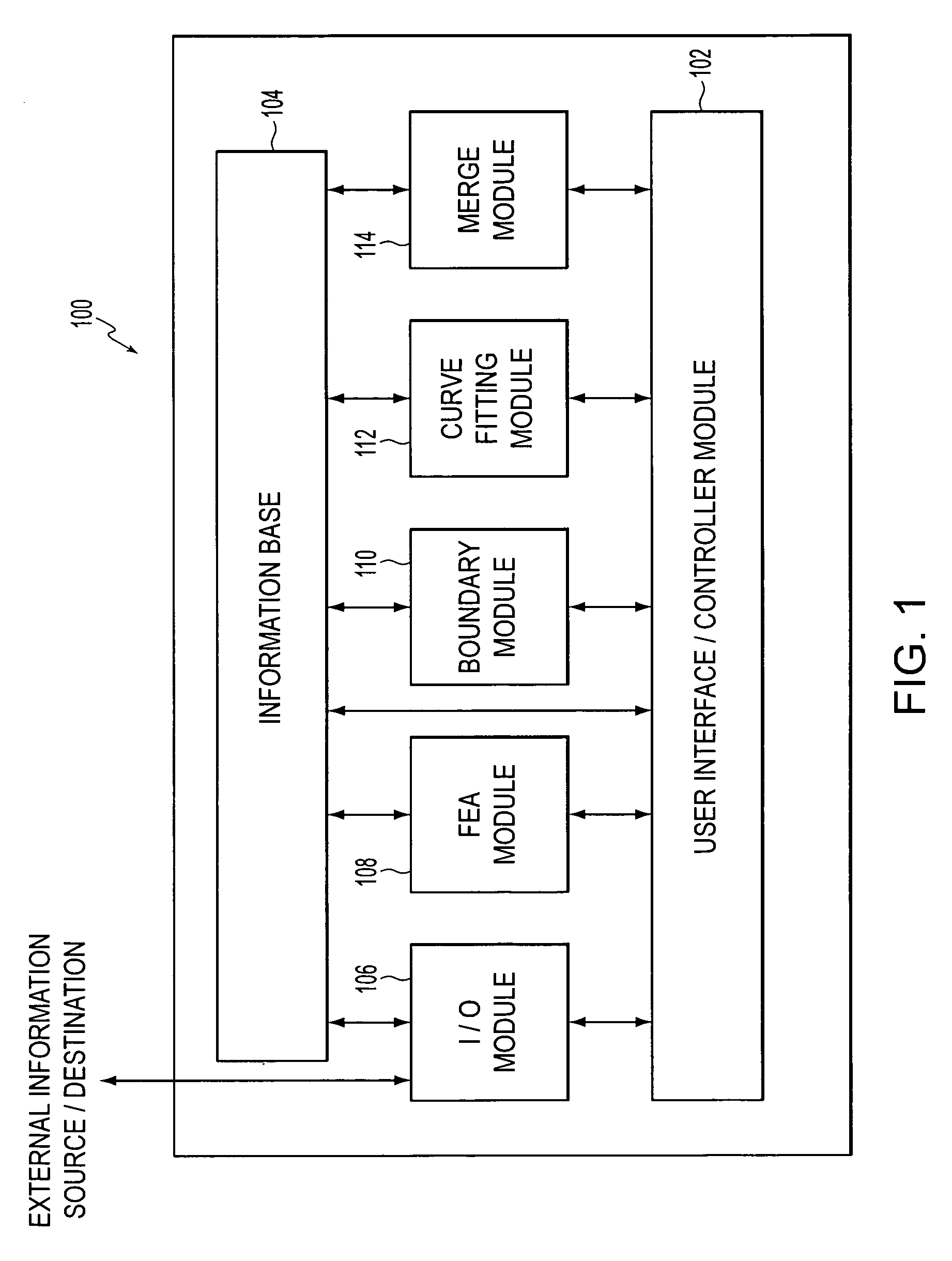

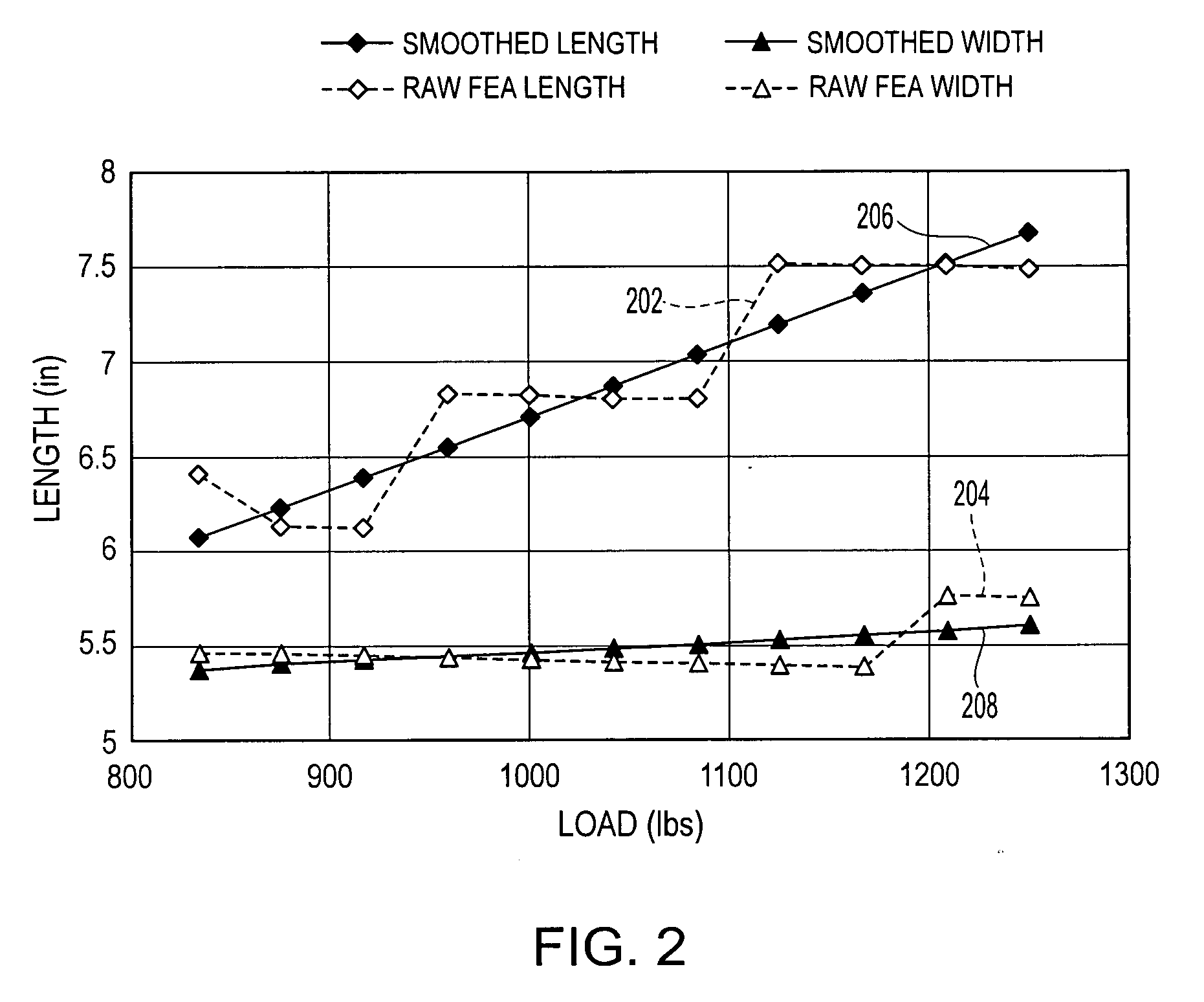

Finite element analysis tire footprint smoothing algorithm using multiple load cases

InactiveUS20060031046A1Improve accuracyImprove resolutionGeometric CADComputation using non-denominational number representationElement modelImage resolution

A method and apparatus for predicting the shape of a contact region of a finite element model deformed against a contact surface. The contact surface may be a rigid body or another finite element model. The shape of a contact region is dictated by the node / element distribution in response to a simulated load. This procedure uses curve fitting to predict the boundary of a contact region for a specified load condition based upon an analysis of contact region shapes generated by finite element analysis for each load within a range of simulated loads. In this manner, the discrete nature of the contact region boundary associated with finite element analysis results at a single load is overcome using information derived from previous load simulations. The approach improves the accuracy and resolution of simulated contact shape boundaries without a corresponding increase in processing resources.

Owner:BRIDGESTONE FIRESTONE NORTH AMERICAN TIRE

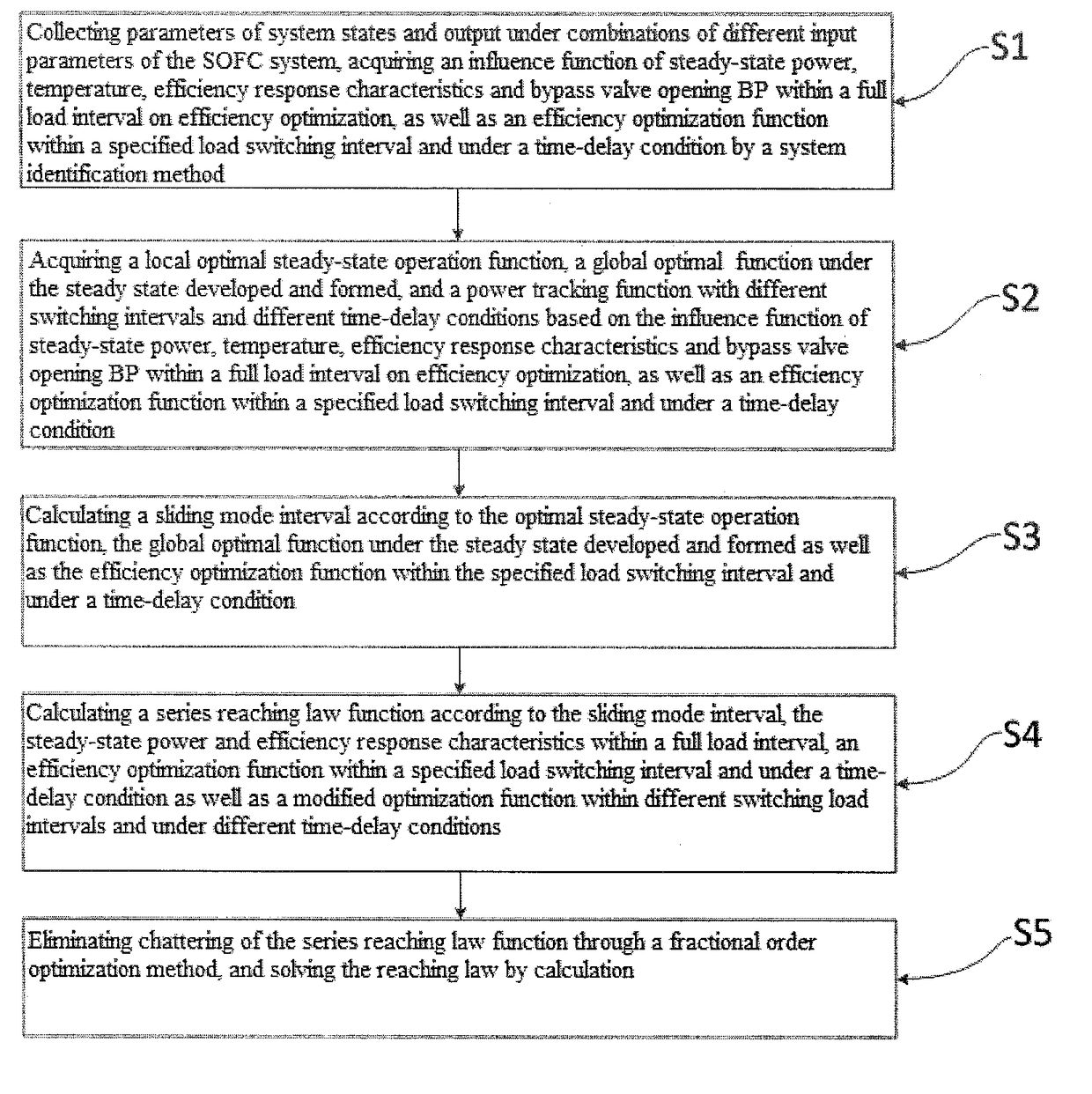

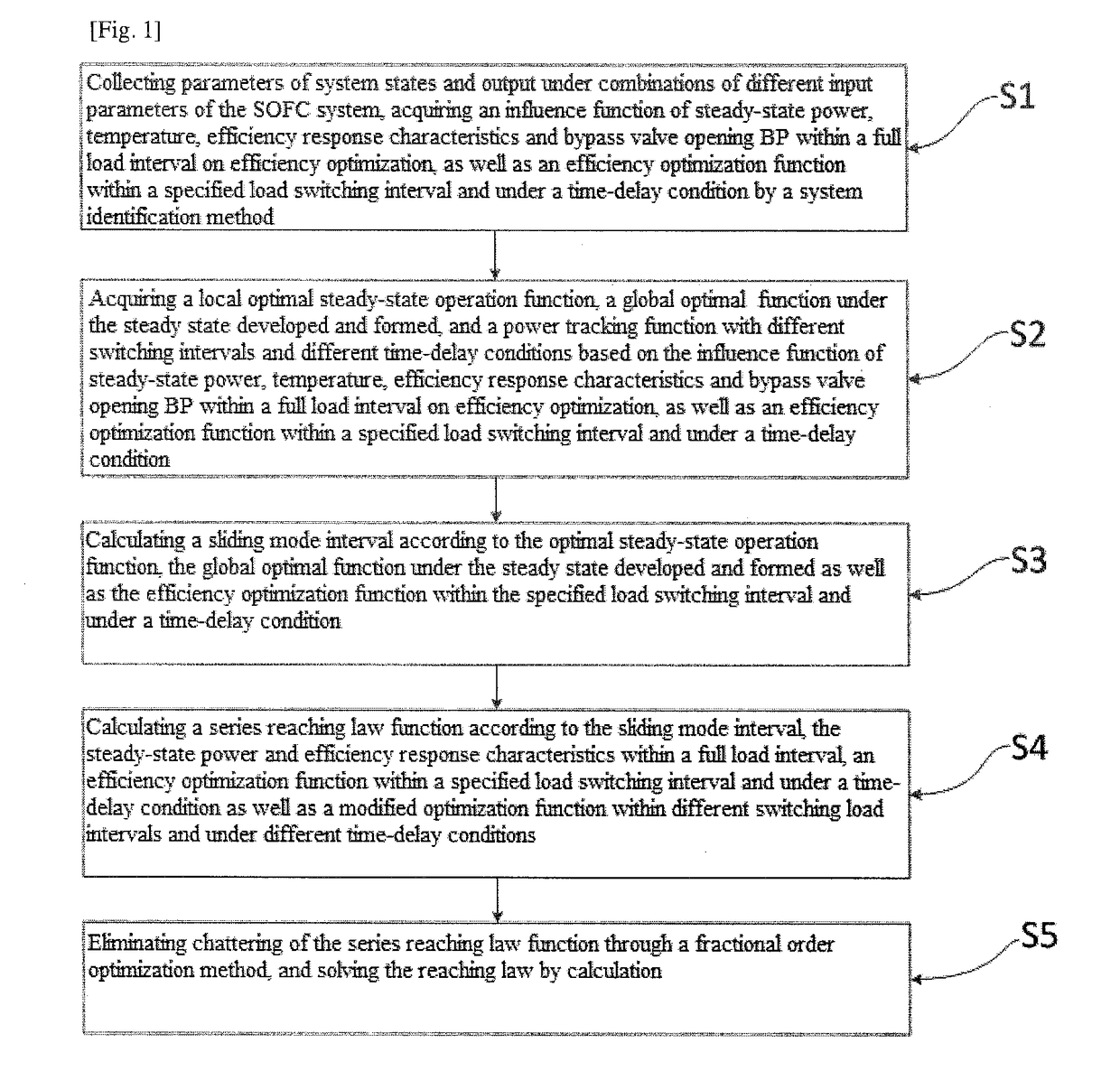

Thermoelectric cooperative control method for sofc system based on fractional order sliding mode variable structure

ActiveUS20180131021A1Precise and flexible and stable controlSpeed up the switching processElectric controllersFuel cellsLocal optimumPresent method

The present invention provides a thermoelectric cooperative control method for the SOFC system based on fractional order sliding mode variable structure, comprising the following steps: S1, collecting parameters of system states and output under combinations of different input parameters of the SOFC system, acquiring an influence function of steady-state power, temperature, efficiency response characteristics and bypass valve opening BP within a full load interval on efficiency optimization, as well as an efficiency optimization function within a specified load switching interval and under a time-delay condition; S2, acquiring a local optimal steady-state operation function, a global optimal function under the steady state developed and formed, and a power tracking function with different switching intervals and different time-delay conditions; S3, calculating a sliding mode interval; S4, calculating a series reaching law function according to optimization functions; S5, eliminating chattering of the series reaching law function through a fractional order optimization method, and solving the reaching law by calculation. The present method can provide precise, flexible and stable control, greatly speed up the switch process, overcome time-delay feature of the great inertia of the SOFC system, and realize fast load switching.

Owner:HUAZHONG UNIV OF SCI & TECH

System for Dynamically Controlling the Torque Output of a Pneumatic Tool

ActiveUS20090055028A1Reduce probabilityStop preciseDerricks/mastsTemperatue controlPneumatic toolHeating effect

Pneumatic tightening tools can be used for high speed assembly of critical bolts to precise loads by dynamically controlling the output power of the pneumatic tool during a tightening cycle using an electronically controlled air pressure regulator to reduce the tightening rate, or the load increase per impact for impact or impulse tools, to enable the tool to be stopped precisely at a specified stopping load or torque. For prevailing torque fasteners, the output power of the pneumatic tool is dynamically controlled to minimize the speed of rotation during rundown, to minimize the heating effects associated with such torque fasteners, and to then increase the power from the tool, as required, to provide the torque to reach the specified stopping load or torque. The maximum air pressure supplied to the pneumatic tool can be limited, depending on the expected torque required to tighten the fastener to the specified load or torque.

Owner:INNOVATION PLUS

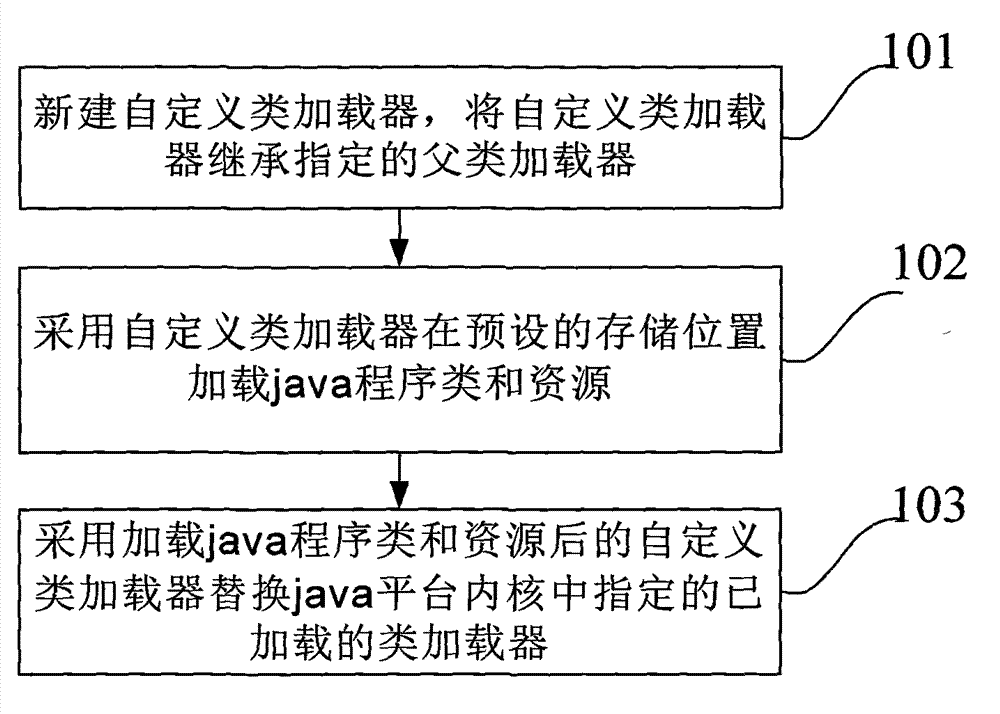

Java-platform-based web service support method and device

ActiveCN102929597ARealize dynamic upgradeImprove performance qualitySpecial data processing applicationsSpecific program execution arrangementsApplication serverWeb service

The embodiment of the invention discloses a java-platform-based web service support method and a java-platform-based web service support device, and belongs to the field of computers. The method comprises the following steps of: newly building a custom class loader, and allowing the custom class loader to inherit a specified parent class loader; loading a java program class and a resource at a preset storage position by using the custom class loader; and replacing a specified loaded class loader in a java platform kernel with the custom class loader loaded with the java program class and the resource. Management personnel only need to load a java file at a specified position by using the custom class loader, an application server and a service system are separated, the possibility that the service system is not compatible with the application server is avoided, and new functions are sustainably added; and maintenance cost is minimized under the condition of requirement change, and the performance and service quality of the web service system are improved.

Owner:MOCHA SOFTWARE TIANJIN

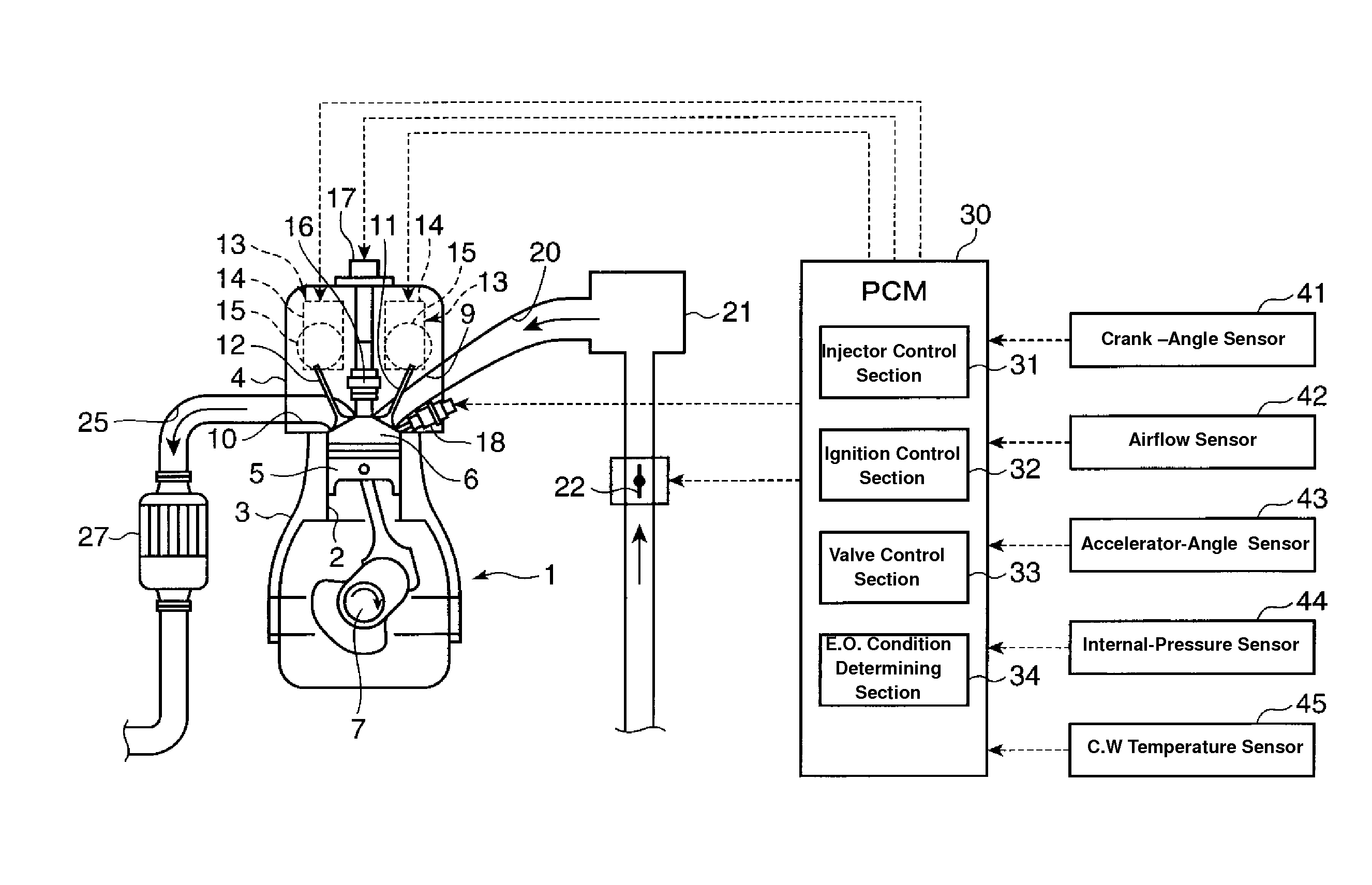

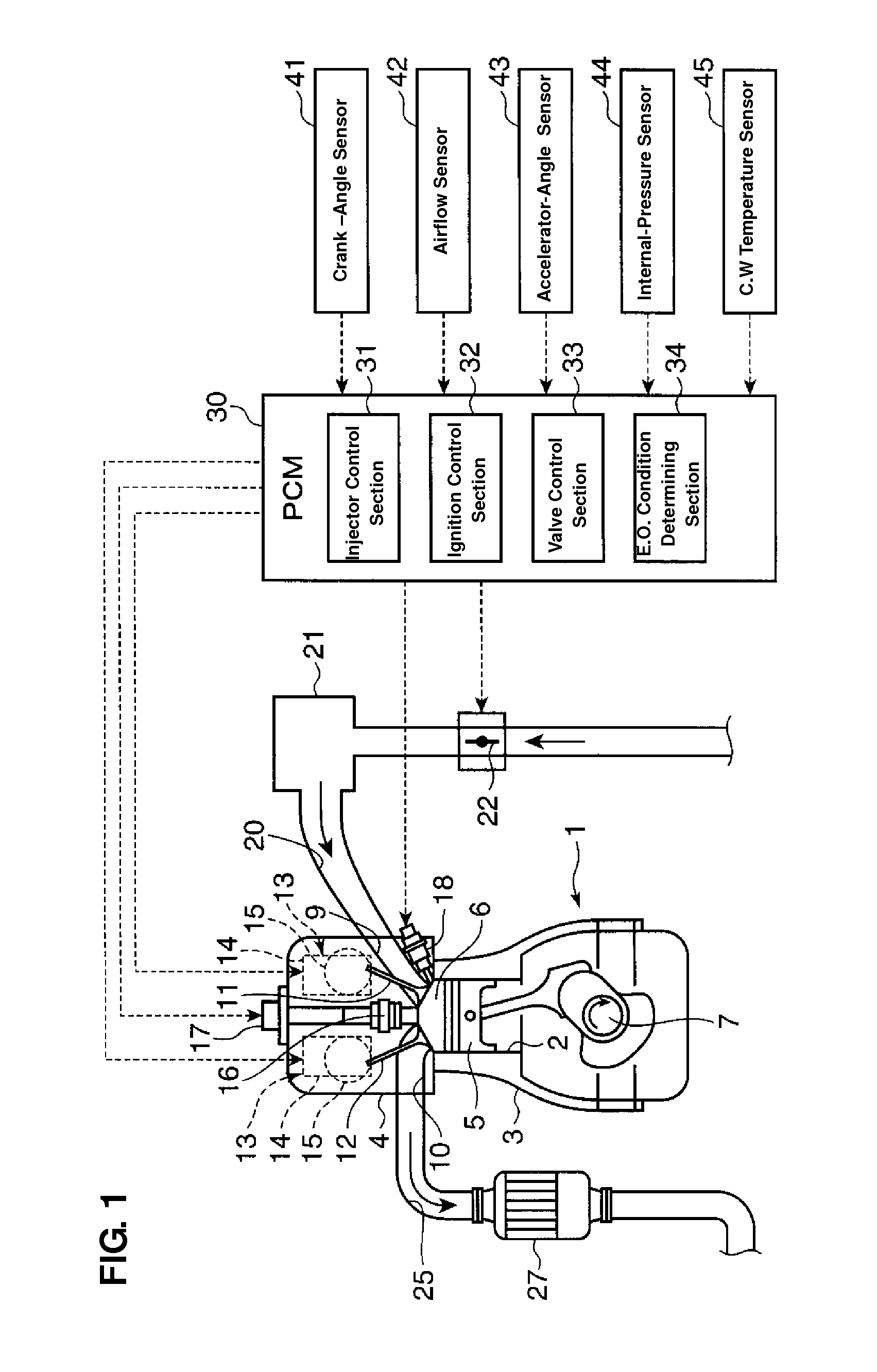

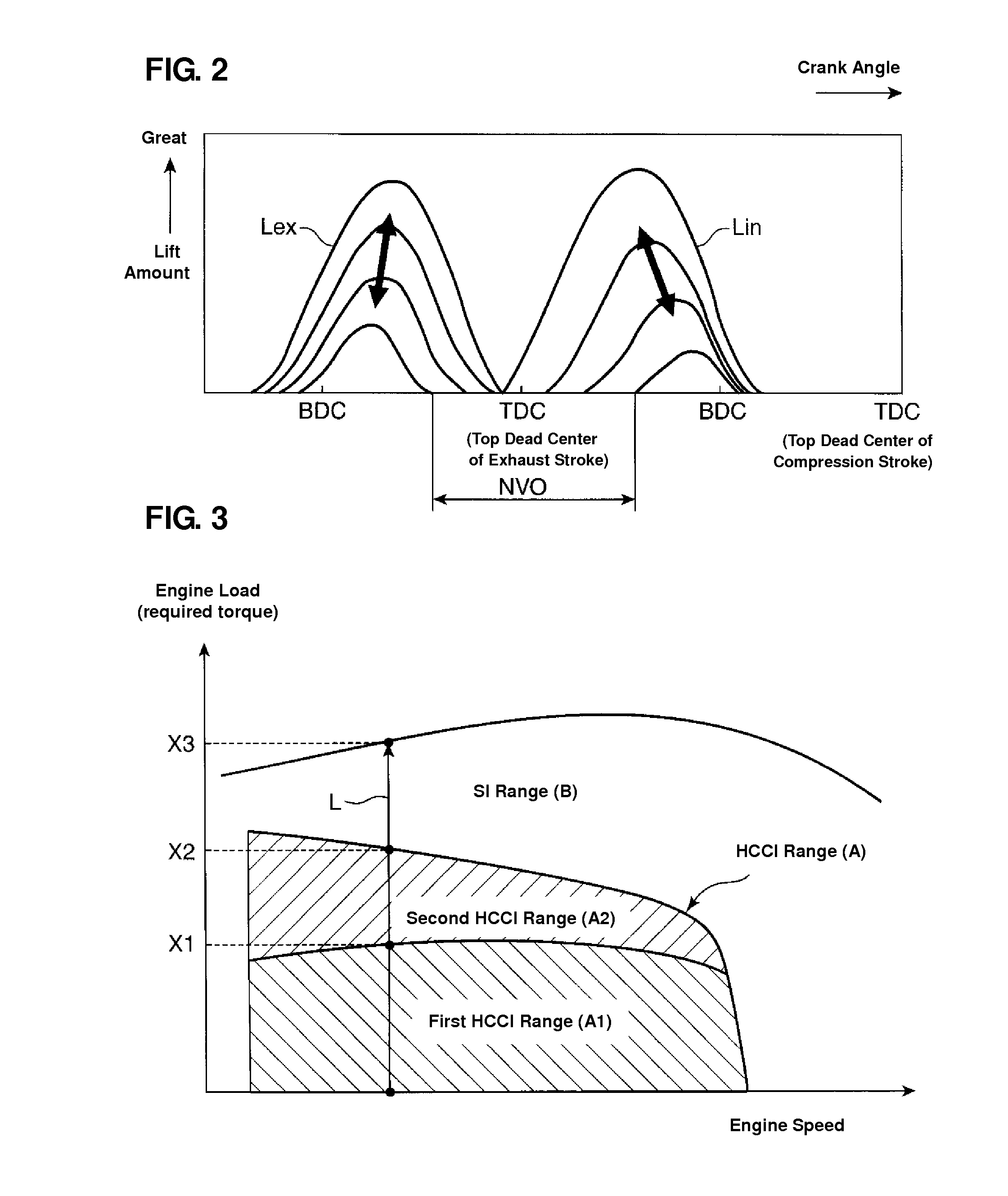

Control method and system of engine

InactiveUS20100312455A1Improper detonationImproper of emissionElectrical controlInternal combustion piston enginesInternal pressureExhaust valve

When it is determined that an engine operating condition is in a high-engine load HCCI range (A2) where an engine load is higher than a specified load X1 within a HCCI range A where a compression self combustion is performed, an after-TDC injection F2s is executed at a point T1 when an internal pressure of a combustion chamber drops below a specified pressure Y after the top dead center of an exhaust stroke during a minus valve overlap period NVO during which intake and exhaust valves are both closed. Then, a main injection F2m as a main injection is executed. Accordingly, any improper detonation or deterioration of NOx emission which may be caused by the compression self-ignition combustion in the range where the engine load is relatively high can be prevented.

Owner:MAZDA MOTOR CORP

Device and method for compensating or unloading prestressed load of anchor cable

InactiveCN102296605AGuaranteed stressGuaranteed unloadingBulkheads/pilesAnchoring boltsPre stressSpecified load

A device and method for compensating or unloading the prestressed load of an anchor cable. For an anchoring project in which the length of the steel strand at the exposed section of the anchor cable meets the tension length, the device includes: a limiting plate, a small jack and a support tube. For the anchor cable For the anchoring project where the length of the steel strand at the exposed section does not meet the tension length, the anchor cable prestress load compensation or unloading device also includes an anchor cable extension device. Anchor cable prestress load compensation or unloading methods include: install anchor cable prestress load compensation or unloading device, install tension jack and tool anchor, insert tension tool anchor clip to tighten external steel strand; start tension The jack oil pump applies the load until the working anchor is pulled and the clip of the working anchor is loosened, continue to apply the load or unload to the specified load value, and then start the small jack to load and push back to the limit plate, the clip re-cables the steel strand, and then Unloading, to complete the anchor cable stress compensation or load reduction, so as to reliably ensure the load compensation or unloading effect of the anchor cable prestress.

Owner:中铁西北科学研究院有限公司深圳南方分院

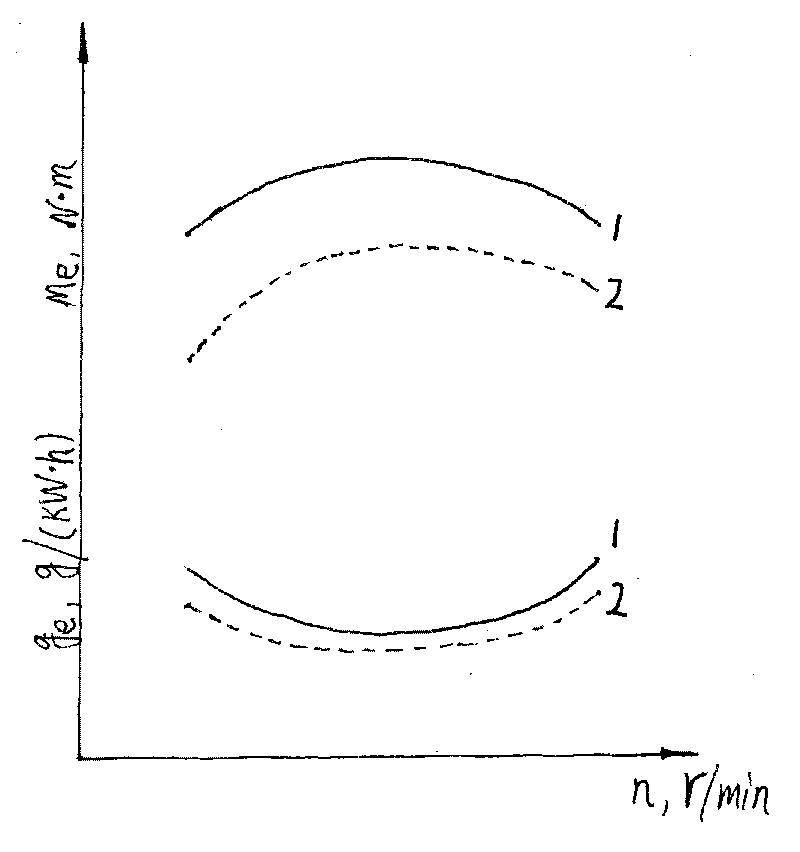

Automobile constant speed engine given load detection method

ActiveCN101718629AImprove detection accuracyAvoid damageInternal-combustion engine testingConstant forceOperability

The invention relates to an automobile constant speed engine specified load detection method, which defines the rotating speed range of the automobile speed under the engine rated torque and the full-load minimum fuel consumption rate when the high speed gear is engaged in a gearbox on a chassis dynamometer by an automobile, after the test and the calculation, the load constant force value of a power absorbing device of the engine defined load is determined at the defined automobile speed point, when the load working condition is defined by the engine delta rated torque, the load is controlled by the constant force of the power absorbing device, the accelerator is adjusted and stabilized, and the vehicular dynamic property and fuel economy are detected in the constant speed at the defined automobile speed point, the method has good accuracy, validity and operability, meanwhile, the method can avoid the damages to the in-use vehicles or engines with worse technology condition, thereby increasing the detection safety.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

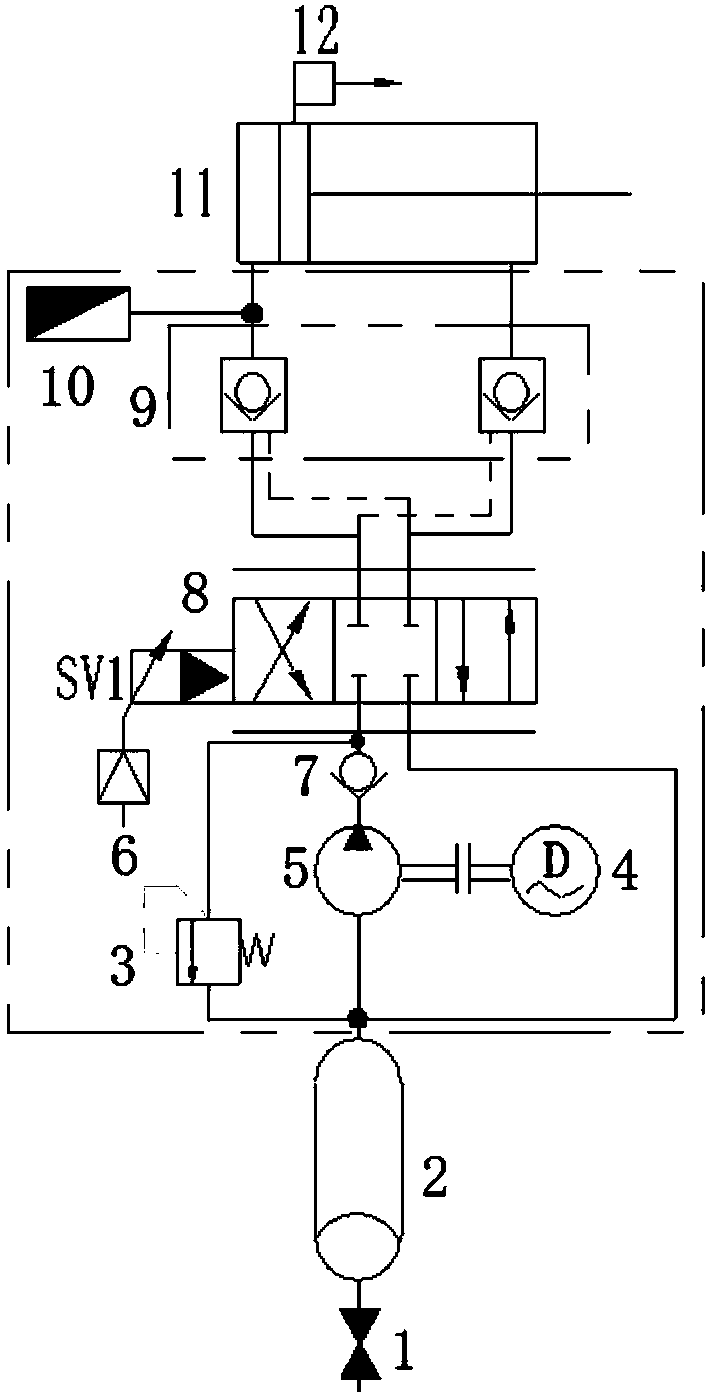

Hydraulic servo buffer capable of achieving active control

ActiveCN107816505ASimple structureRealize automatic controlSpringsSprings/dampers design characteristicsHydraulic cylinderEngineering

The invention discloses a hydraulic servo buffer capable of achieving active control. The hydraulic servo buffer is characterized in that a low-pressure energy accumulator with a switch valve is connected with a hydraulic constant delivery pump with a motor, the hydraulic constant delivery pump is connected with an inlet of a one-way valve, an outlet of the one-way valve is connected with an oil inlet of a hydraulic servo valve with a hydraulic servo amplifier, an oil return port of the hydraulic servo valve is connected with an oil outlet of the low-pressure energy accumulator, two ports of an oil outlet of the hydraulic servo valve are connected with two oil inlets of a hydraulic lock, oil outlets of the hydraulic lock are connected with a rodless cavity and a rod cavity of a hydraulic cylinder respectively, and a pressure sensor is arranged on a pipeline which enables the hydraulic lock and the rodless cavity to be connected; and a displacement sensor is arranged on a piston rod inthe hydraulic cylinder, the outer end of the piston rod of the hydraulic cylinder is hinged to a sliding block through a spherical hinge, and the sliding block is arranged on a guide rail corresponding to the sliding block. According to the hydraulic servo buffer capable of achieving active control, the responding speed and the control precision are high, specified loads are applied to a system, and then the requirements of some high-grade, precision and advanced special occasions on load reducing are achieved.

Owner:YANSHAN UNIV

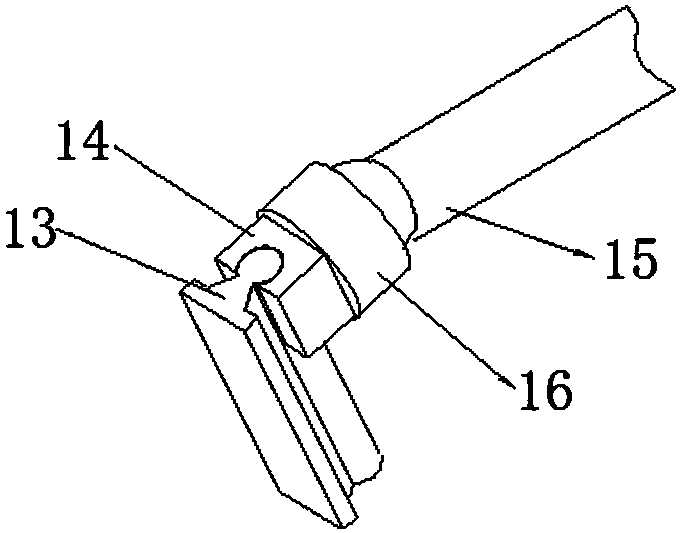

Cold roll milling technology for rotor blade and stator blade of high pressure compressor for GH150 alloy

The invention relates to a process for carrying out cold rolling on a moving blade and a stationary blade of a GH150 alloy high-pressure compressor. The process comprises a flow of a predominant process and a heat-treatment process: a semi-precision forging piece is subjected to solid solution and oil cooling; subsequently, a rabbet is machined and a root part of a blade body is milled; subsequently, the blade body is leveled and is subjected to primary cold rolling, argon charging and cold solid solution treatment in vacuum and secondary cold rolling till the blade body is rolled to have no residue; the blade body is charged with argon in a vacuum furnace and is subjected to the treatment of cold solid solution and cold sizing; and the rabbet and the gas inlet and exhaust edge of the blade body are subjected to polishing, fine machining, primary aging in the vacuum furnace, argon protection, secondary aging treatment and vibrating burnishing. The process has the advantages that engineering application research on a cold rolling technology of the blade is carried out, successfully working blades and rectifying blades with thirteen levels of the high-pressure compressor of an engine are developed; and the blade passes a cyclic vibration fatigue test under specified load and a long-term trial-run test of the engine.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Pressure loaded service regulator with pressure balanced trim

A gas regulator includes an actuator, a regulator valve, and pressure loading device. The pressure loading device provides a pressure load to a surface of a diaphragm of the actuator to act against a downstream pressure being applied to the opposite surface of the diaphragm and being controlled by the regulator. As the downstream pressure varies and the diaphragm displaces to move a control element to regulate the downstream pressure, the pressure loading device maintains a specified load pressure. The regulator may further include a balanced trim applying a balancing force to offset a force of an upstream pressure on the control element.

Owner:IRIDEX CORP +1

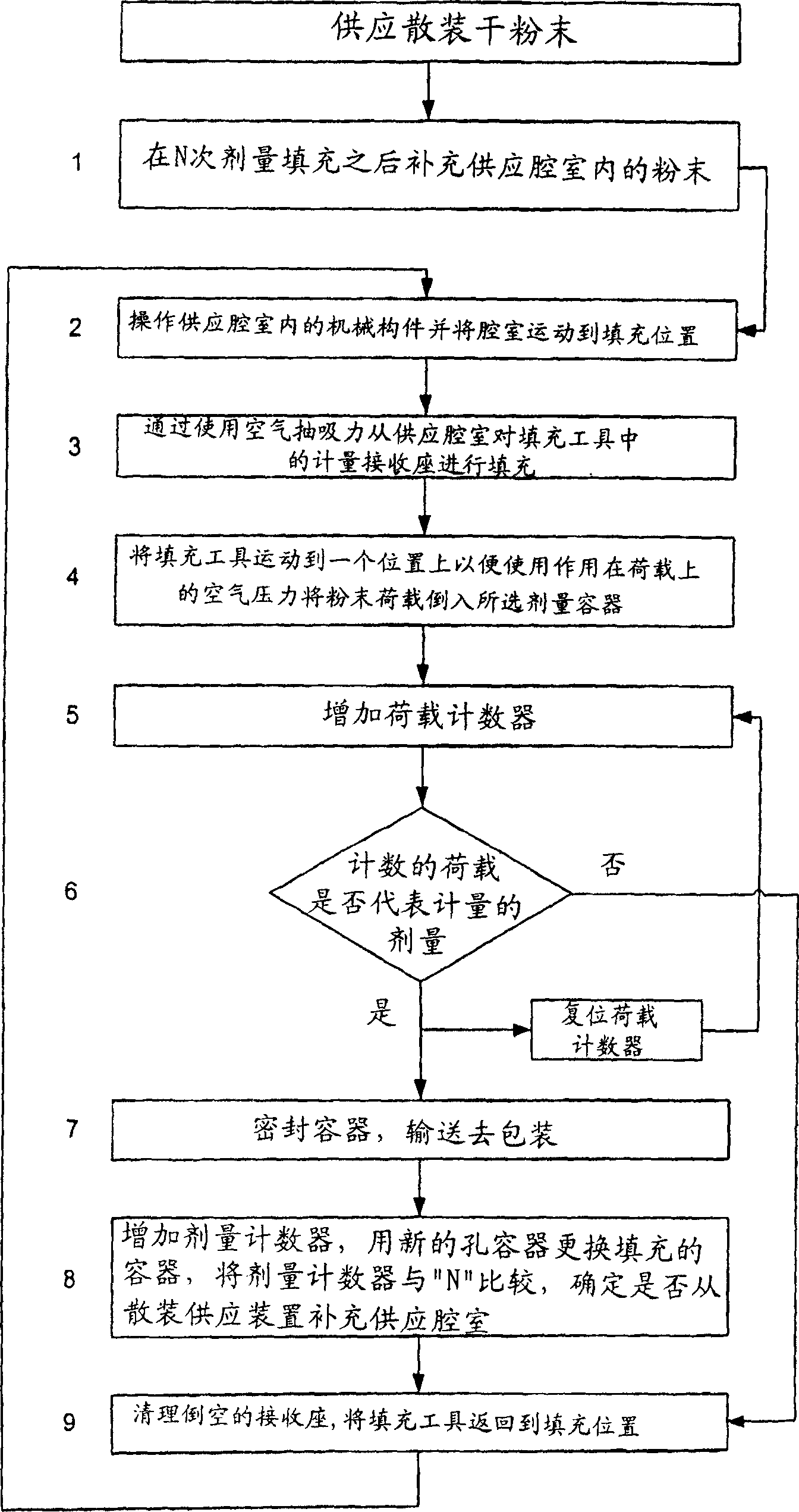

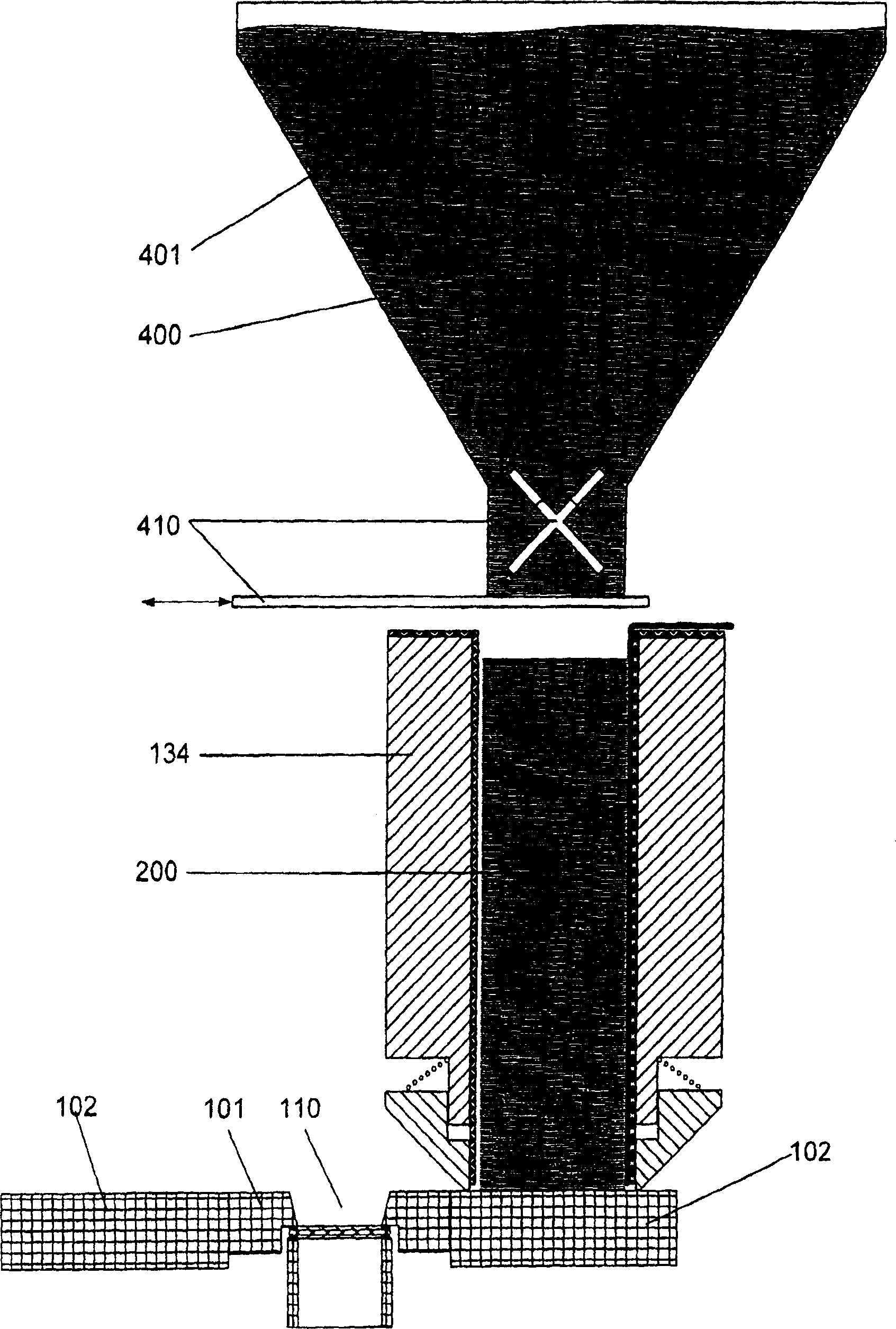

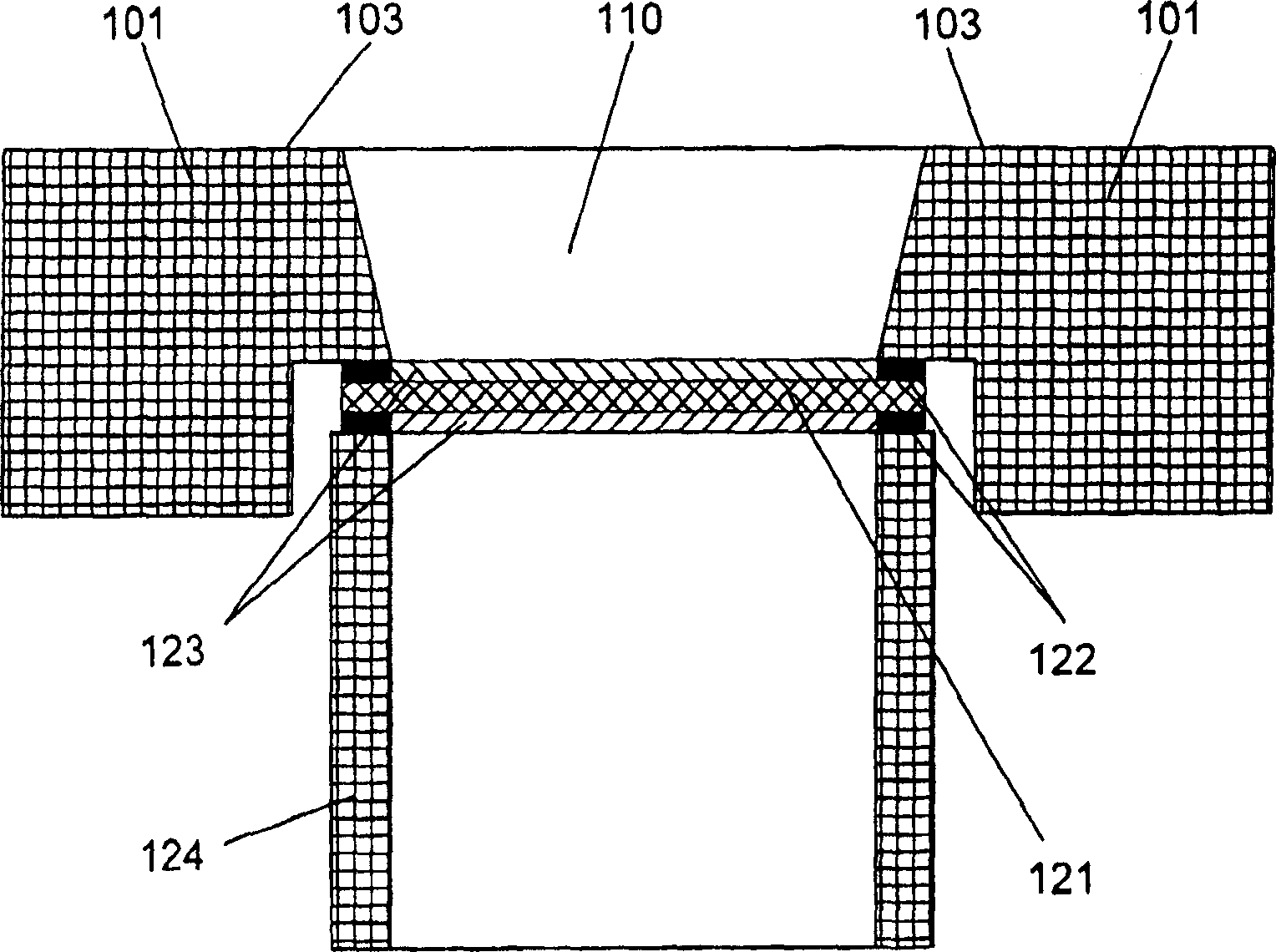

A feeding chamber, an apparatus and a method for production of doses of dry powder, a method for controlling particle segregation in dry powder during filling

InactiveCN1918035AImprove accuracyHigh precisionBurnersLiquid surface applicatorsPowder InhalerSpecified load

The invention discloses a method and an apparatus for exact metering and volumetric filling of dry powder medicament doses into preformed containers, which are adapted for administration by means of a dry powder inhaler (DPI). The filling apparatus of the invention includes at least a bulk powder source (401), a feeding chamber (134) and a receptacle (110) providing the volume for a specified load mass (202) of dry powder. The bulk powder source releases a portion of powder discontinuously to the feeding chamber, but is disconnected from the feeding chamber and receptacle during the filling operation. The filling apparatus further presents a plane surface (103) in contact with the movable feeding chamber and provides a hard-wearing, low friction coating for reducing dynamic friction and powder retention.

Owner:MEDERIO AG

Variable nozzle opening control system for an exhaust turbine supercharger

InactiveUS6769255B2Reduce openingDegradation of combustionElectrical controlInternal combustion piston enginesLow speedLow load

An opening of the variable nozzle of the exhaust turbine supercharger is set to and maintained at the maximum value in the constant operating state when the load is not more than a prespecified load level. The opening is gradually made smaller, when the load is not less than the specified load level, as the load becomes greater. When the load shifts from the high load region to the low load region, the variable nozzle is mere closed or maintained at the original opening, and when the operating state get close to the surging limit, the variable nozzle is more opened. When shifting from the low load region to the high load region, or when sifting from low speed to high speed, the variable nozzle is opened mace, and then closed to return to the constant operating state.

Owner:KOMATSU LTD

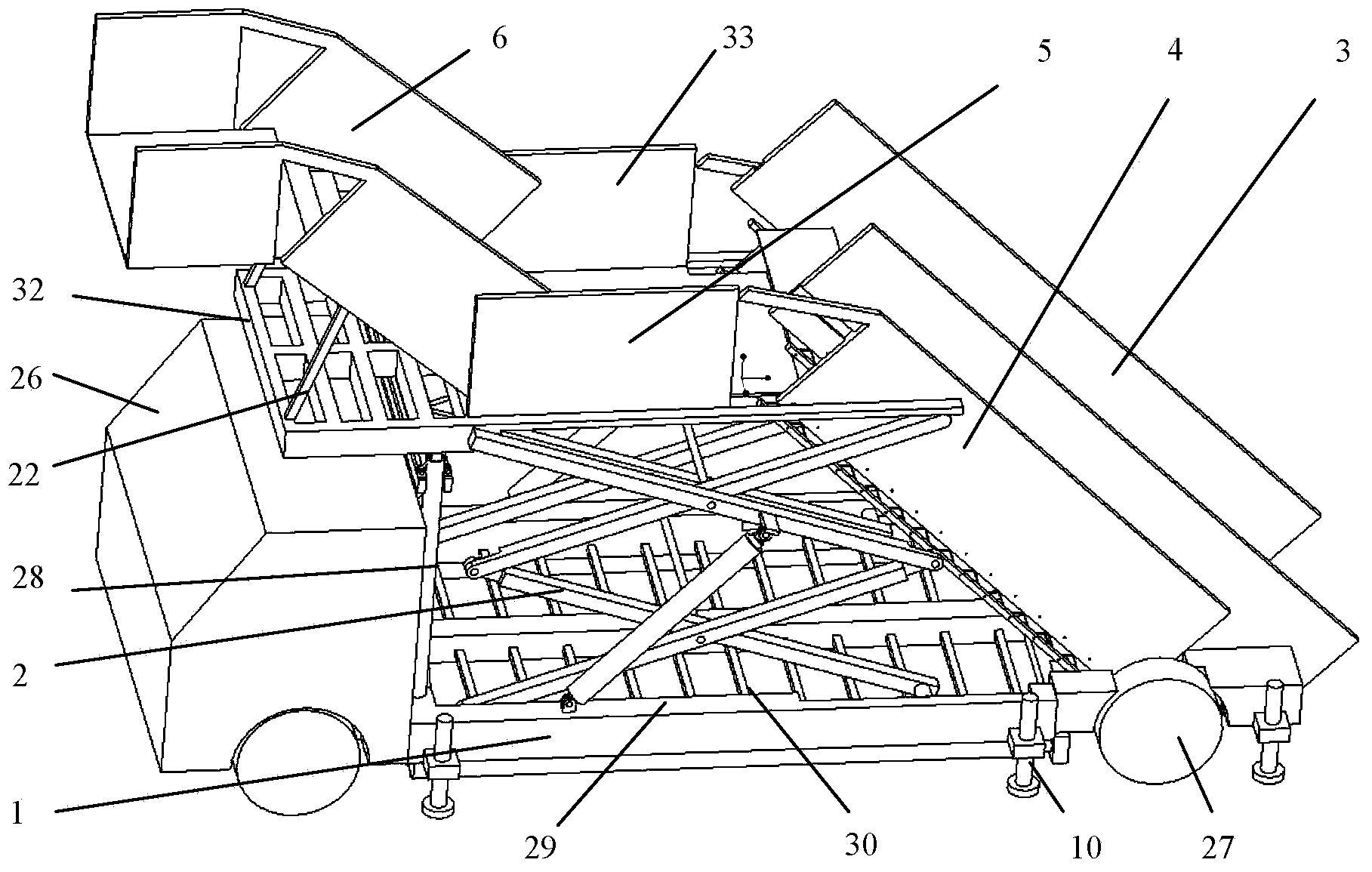

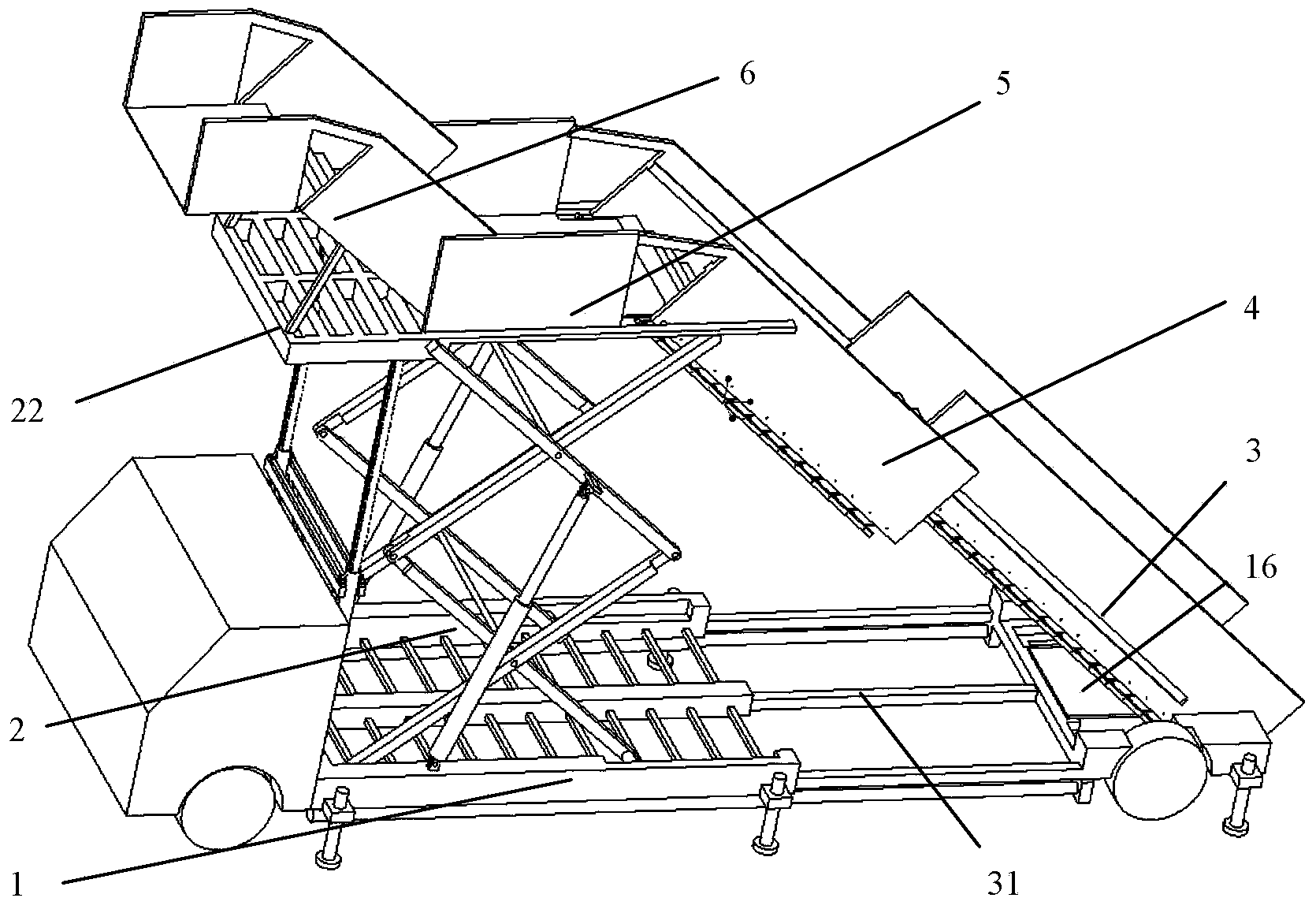

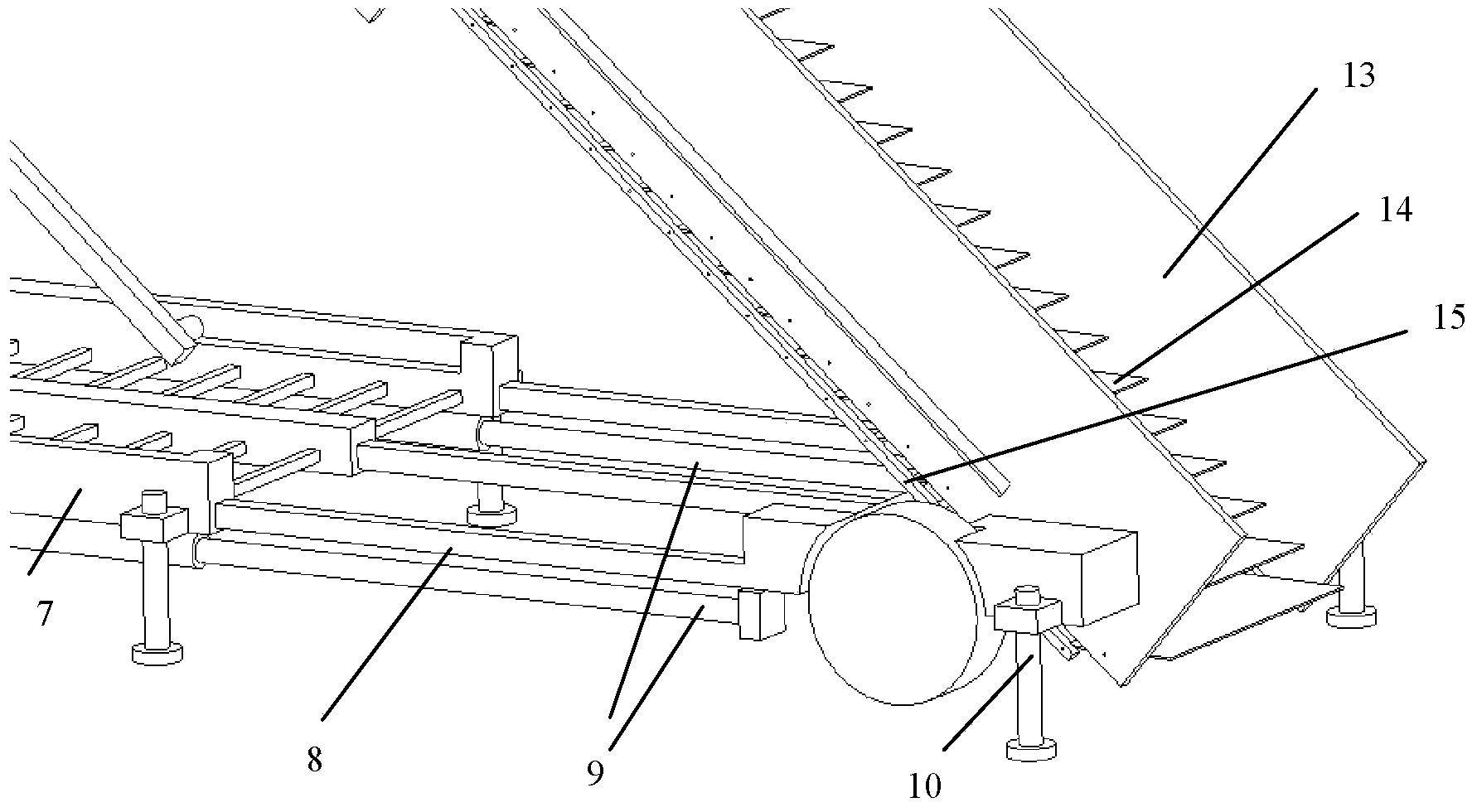

Wheel-base-changeable passenger lift vehicle

InactiveCN104163249ASmall footprintImprove stabilityUnderstructuresGround installationsSpecified loadWork status

The invention provides a wheel-base-changeable passenger lift vehicle. The wheel-base-changeable passenger lift vehicle mainly comprises a vehicle head, a plurality of wheels, a telescopic chassis, a scissor-shaped frame lifting mechanism, a rotating ladder, a sliding ladder, a transition platform and a butt joint platform. According to the wheel-base-changeable passenger lift vehicle, the telescopic chassis which can move relatively is adopted to guarantee stability of the passenger lift vehicle under the specified load, the telescopic chassis can be in the contraction state when the vehicle is in the stored state or in the running state, and thus the space occupied by the passenger lift vehicle can be reduced. When the vehicle is in the working state, the telescopic chassis can be in the extending state so that it can be guaranteed that the center of the gravity of the overall passenger lift vehicle is still within the safety range, and thus stability and safety of the passenger lift vehicle are improved. The wheel-base-changeable passenger lift vehicle is suitable for boarding of all types of airplanes and wide in application prospect.

Owner:CIVIL AVIATION UNIV OF CHINA

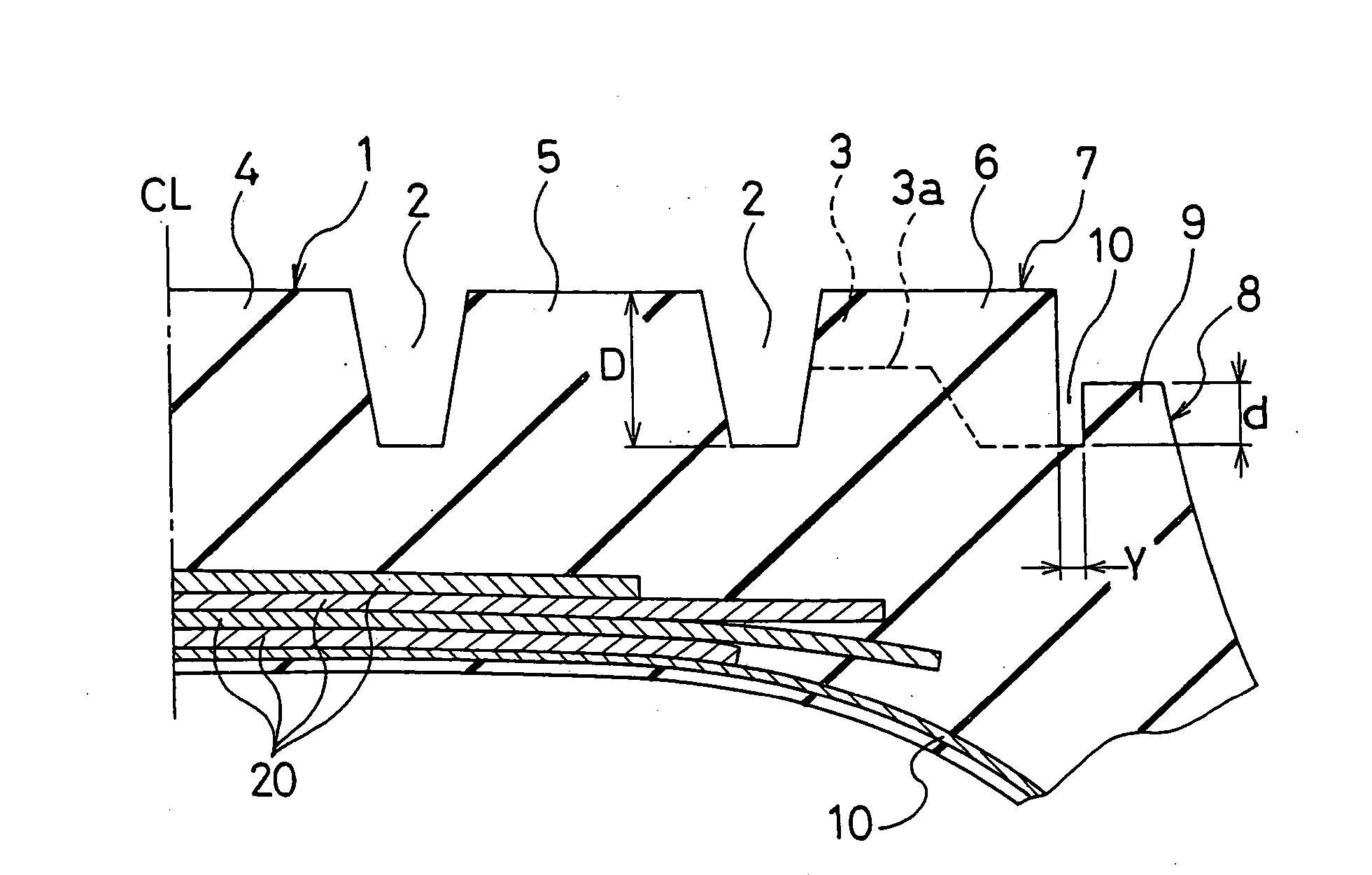

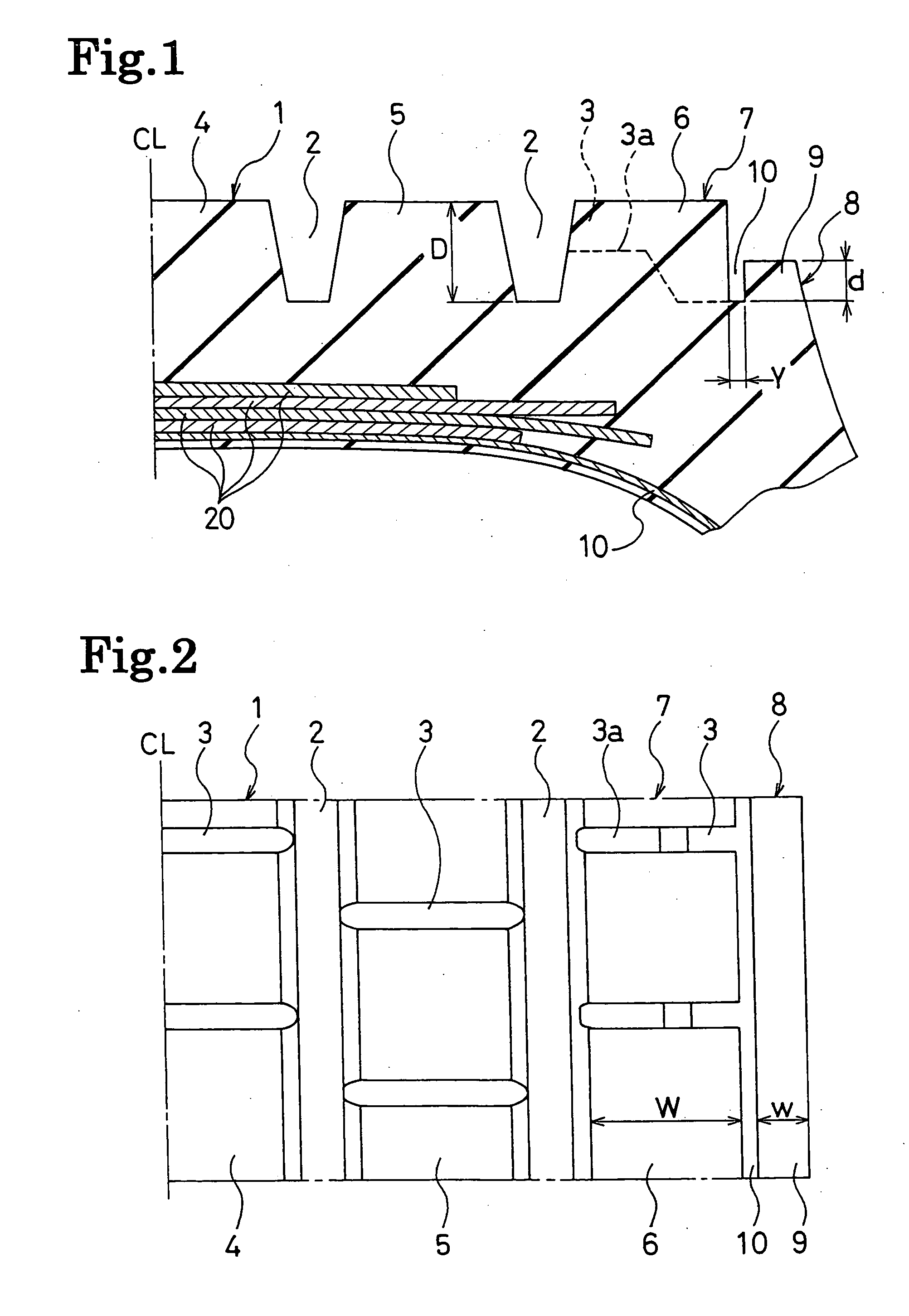

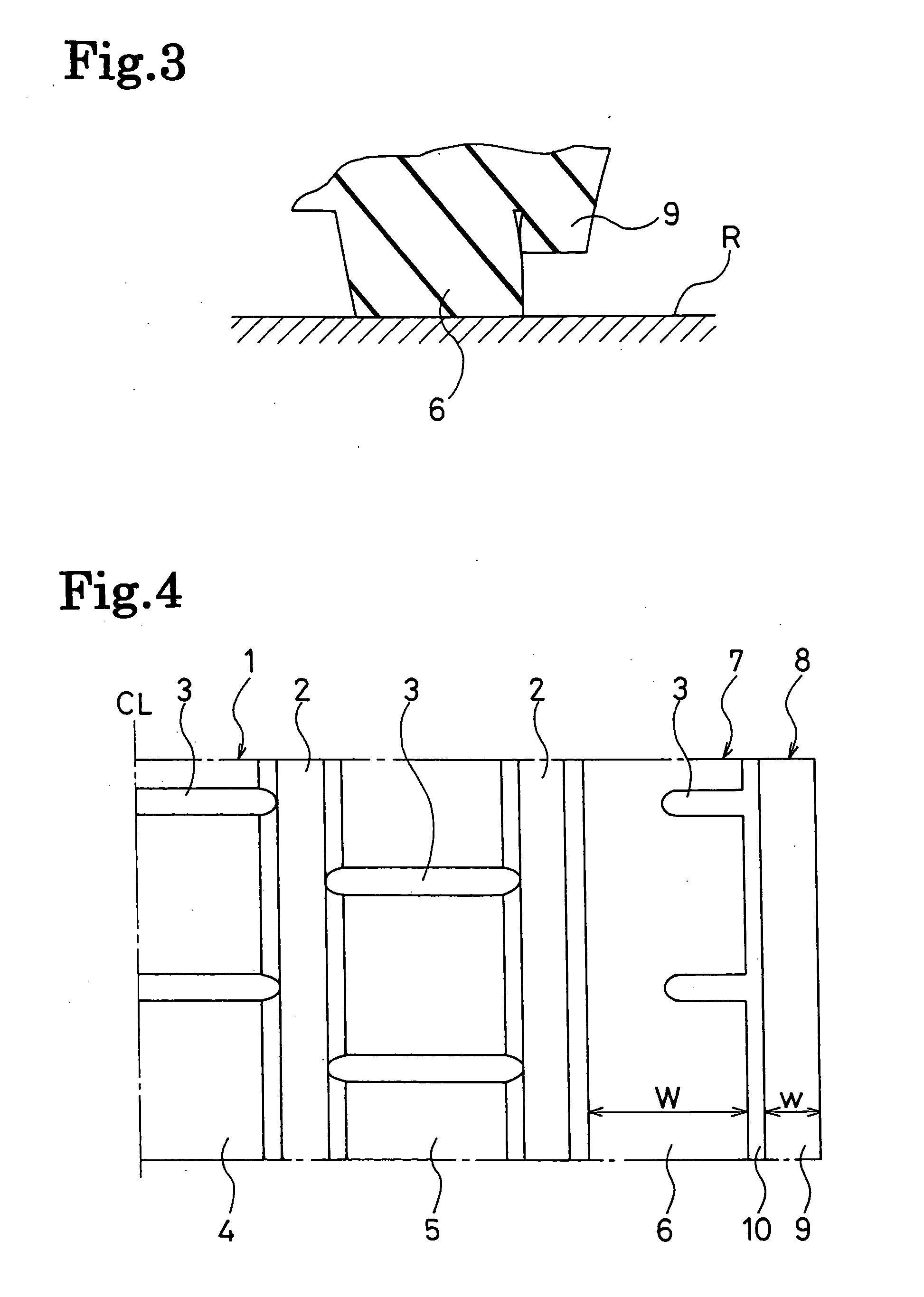

Heavy-duty pneumatic tire

ActiveUS20050006016A1InhibitionImprove drainage performanceTyre tread bands/patternsNon-skid devicesGround contactHeel-and-toe

A heavy-duty pneumatic tire designed to suppress the occurrence of heel-and-toe wear in the shoulder blocks while maintaining good drainage and traction performance through the final stage of the wear life. In this heavy-duty pneumatic tire, whose shoulder portion is divided into a plurality of shoulder blocks in the tire circumferential direction, and wherein the depth of the lug groove between each two adjacent of the shoulder blocks is set to be equal to the depth of main the grooves, a non-contact rib is provided, in a serial configuration in the tire circumferential direction, to a buttress portion outside a ground contact width, so as to come into contact with the side faces of the shoulder blocks in the state that the tire is in contact with the ground with a specified inflation pressure and a specified load.

Owner:YOKOHAMA RUBBER CO LTD

Organic electrolyte battery

InactiveUS7445870B2Large capacityDecreasing electrode volumeHybrid capacitor electrolytesNon-aqueous electrolyte accumulatorsPulse loadVoltage drop

The organic electrolyte cell that is suitable for application of direct current backup of pulse load with load width on the order of milliseconds and has higher backup capability than the conventional design is achieved by setting the product R·C of an impedance R (Ω) at 1 kHz and a capacity C (F) is in a range from 0.00002 to 0.05, and improving the balance of voltage drop during discharge over a specified load width on the order of milliseconds.

Owner:TAIYO YUDEN KK

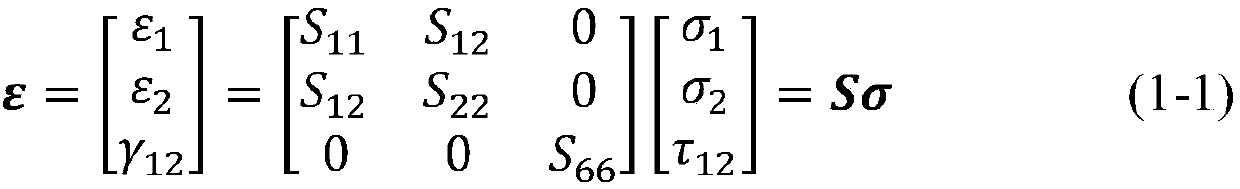

Calculation of equivalent modulus of composite laminates and strength verification under given load

ActiveCN108984841AFast resultsHigh precisionSustainable transportationDesign optimisation/simulationIn planeMaterial Design

The invention relates to the field of composite material design, in particular to calculation of equivalent modulus of composite laminates and strength verification under a given load. The invention comprises an information input module, an operation module and an information output module. Material property information, laminating information and load data information are input into the information input module. Three stiffness matrices A, D, B of composite laminates are calculated according to the input data by a computing program, and the equivalent modulus and stiffness matrices of composite laminates under pure in-plane load and pure bending-torsion load are calculated according to the matrix A and matrix D. At the same time, according to the stiffness matrix and load information, theoverall strain and deflection rate of the laminate can be calculated, and the stress and strain information of each single layer can be obtained. Through adoption of three composite failure criteria,whether the laminate meets the strength requirements under the specified load can be checked. The invention greatly improves the calculation speed, and the accurate numerical solution of stress and strain can be directly and quickly obtained for the analysis of the laminated plate under the simple stress condition, and the design efficiency is improved.

Owner:WEIHAI GUANGWEI COMPOSITES

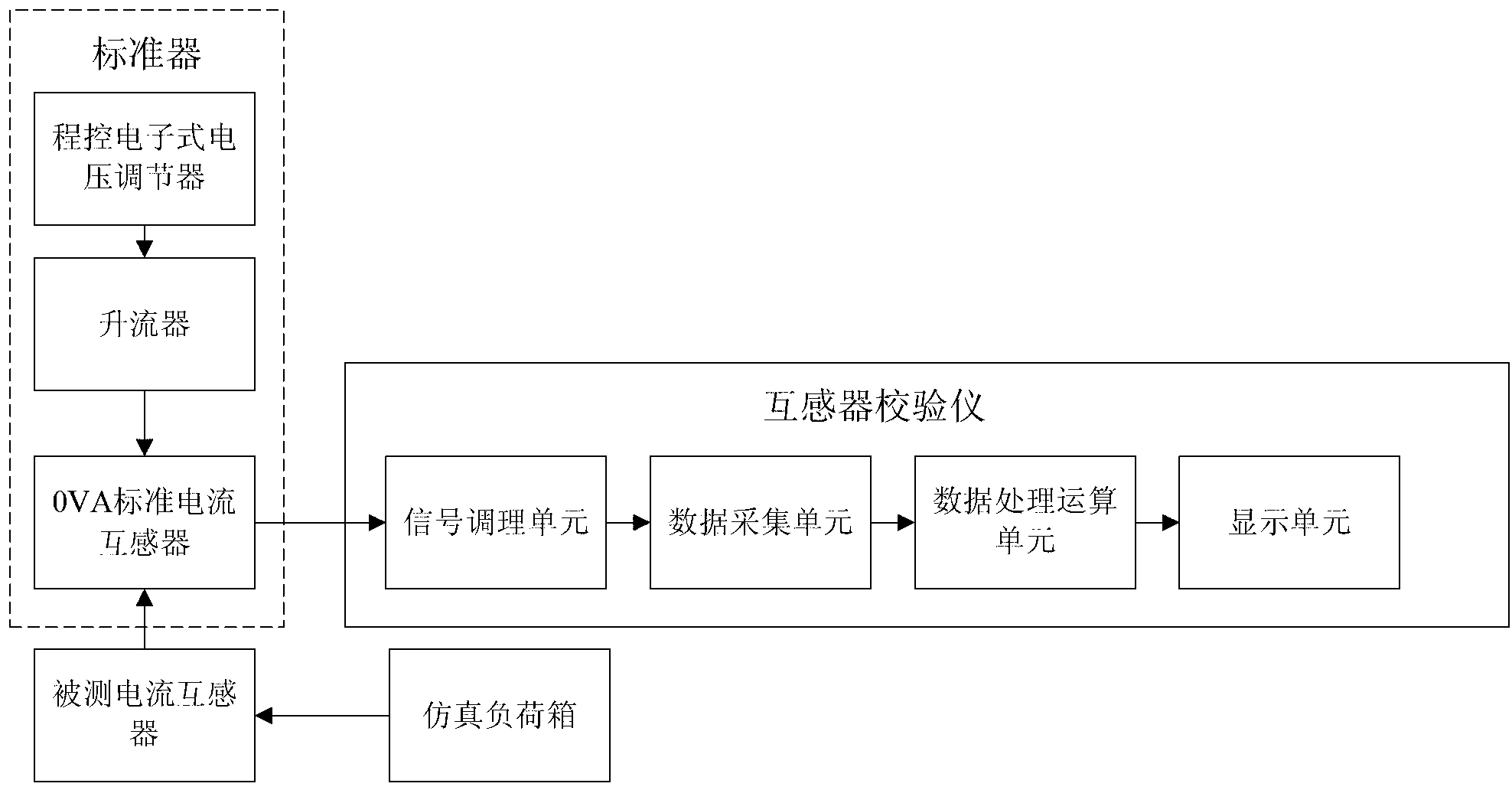

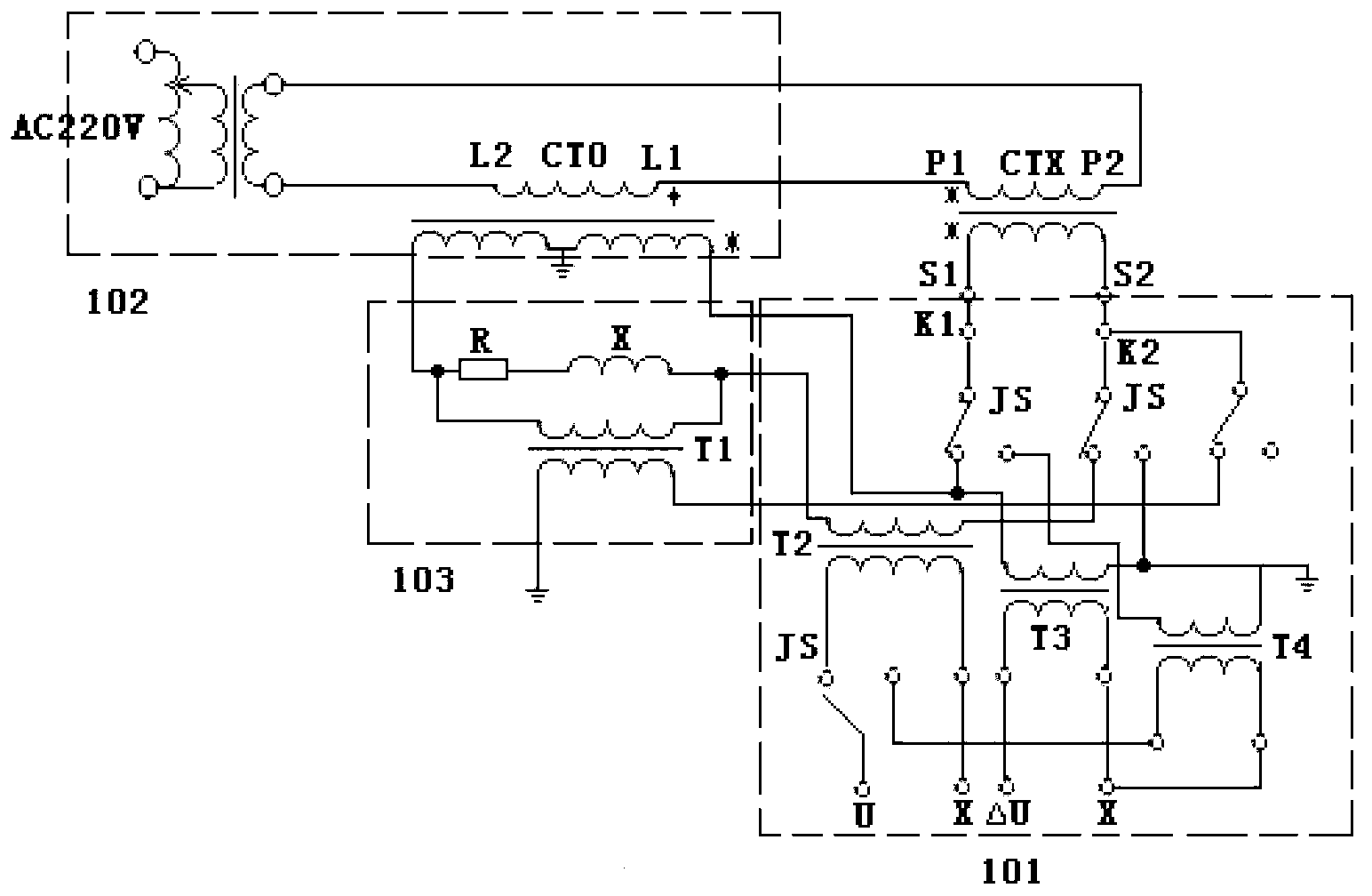

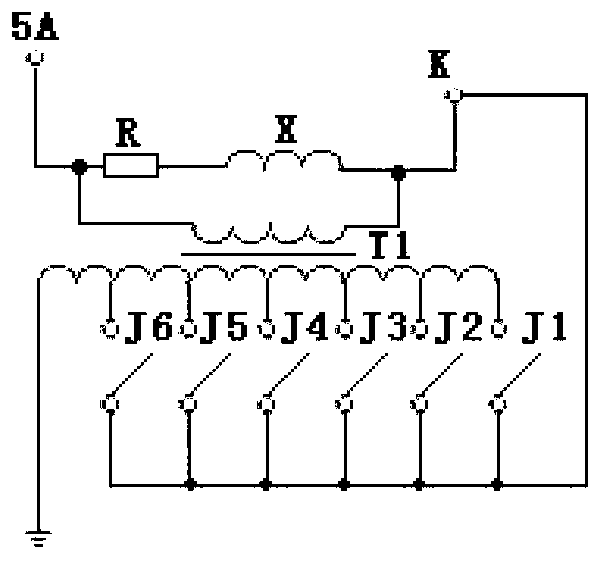

On-site current transformer comprehensive detector and testing method thereof

The invention discloses an on-site current transformer comprehensive detector and a testing method thereof. The on-site current transformer comprehensive detector comprises a transformer calibrator, a standard instrument and an artificial load box which are connected with a to-be-tested current transformer. The standard instrument is compared with the secondary side of the to-be-tested current transformer and transmits differential current signals and standard secondary signals both acquired through comparison to the transformer calibrator. The transformer calibrator performs calibration, data collection and data processing calculation on input signals of a to-be-tested device. The artificial load box is used for providing specified loads to the to-be-tested device. Errors and related parameters of the to-be-tested current transformer are actually measured under low power frequency currents, errors under rated currents are extrapolated on the basis of a low current test, and then overall transformer performance indexes including magnetic saturation margin, volt-ampere characteristics, magnetic properties and security coefficients of the to-be-tested transformer are measured. The problems of difficulty in connecting of a high-current transformer and inability of accurate verification are solved, labor intensity of workers is lowered, and working efficiency is improved.

Owner:STATE GRID CORP OF CHINA +3

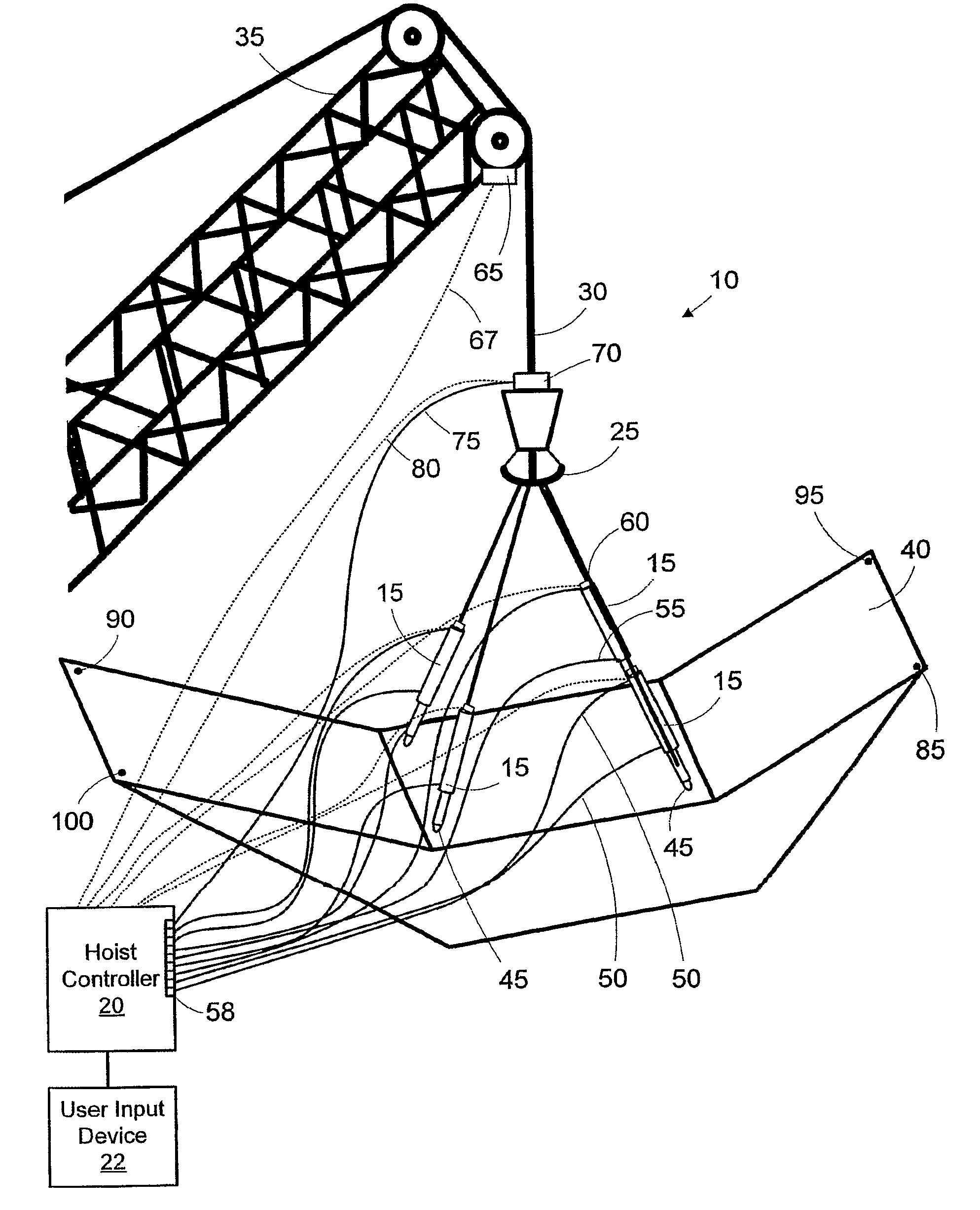

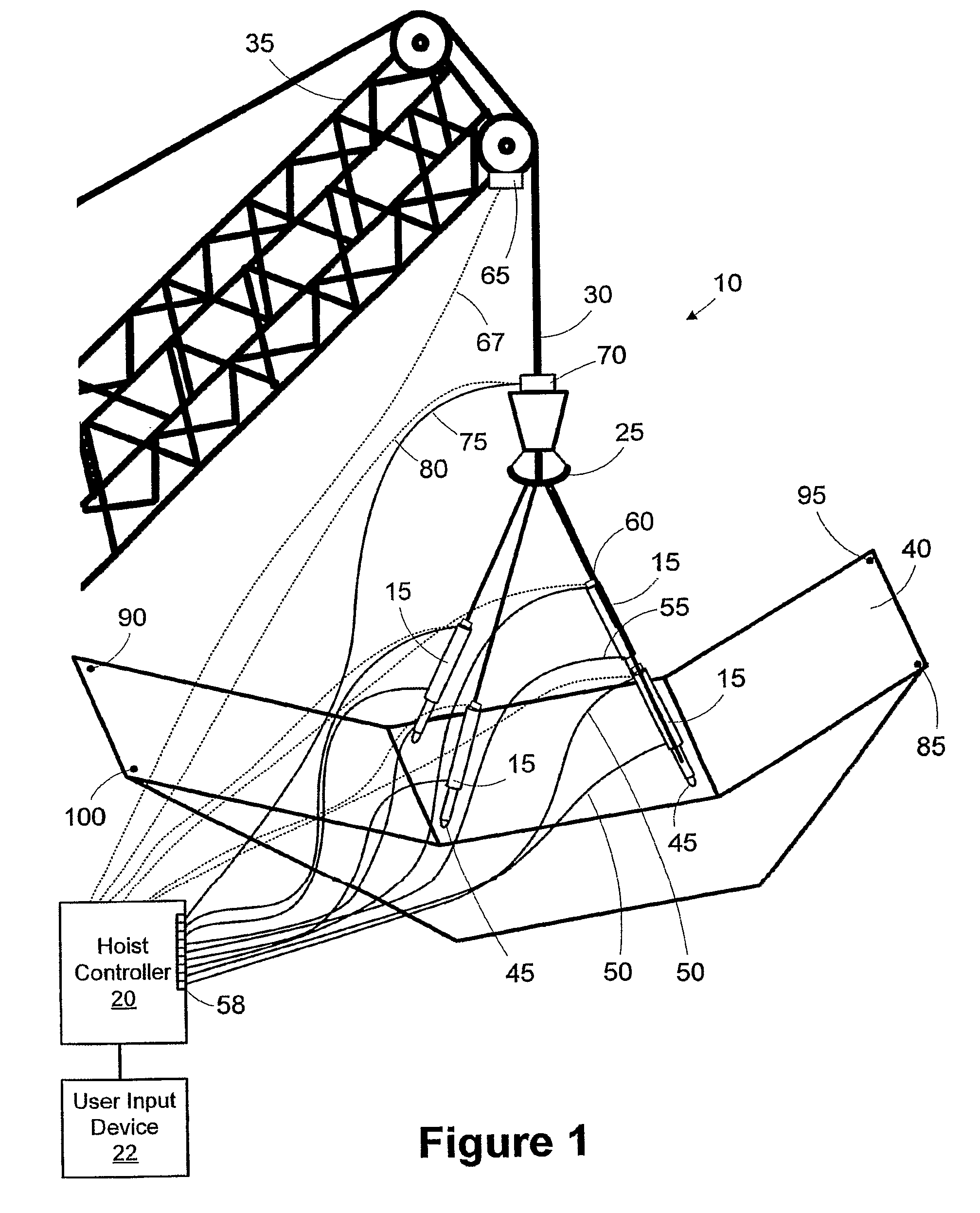

Hydraulic auxiliary hoist and crane control for high precision load positioning

A hoist for positioning a load (40) includes a plurality of lift cylinders (15), a plurality of position sensors, a plurality of electronically controlled valves, a user input device (22), and a hoist controller (20). Each of the hydraulic hoist cylinders is coupled at one end to the hoist and at an opposite end to the load at a lifting point (45). Each of the position sensors is associated with one of the hoist cylinders and operable to provide position data for the associated hoist cylinder. The electronically controlled valves are hydraulically coupled to the hoist cylinders for extending and retracting the associated hoist cylinders. The user input device is operable by a user to specify load data. The hoist controller is operable to receive the load data from the input device and the position data from the position sensors and in response thereto to control the electronically controlled valves so as to position the load according to the load data.

Owner:ENERPAC TOOL GRP CORP

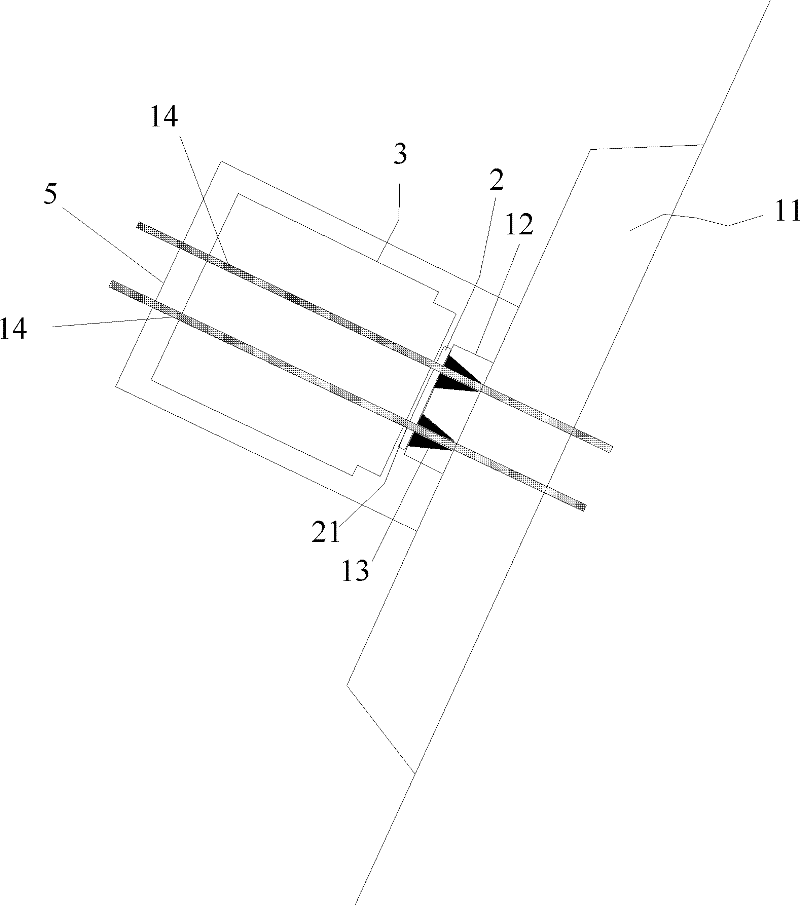

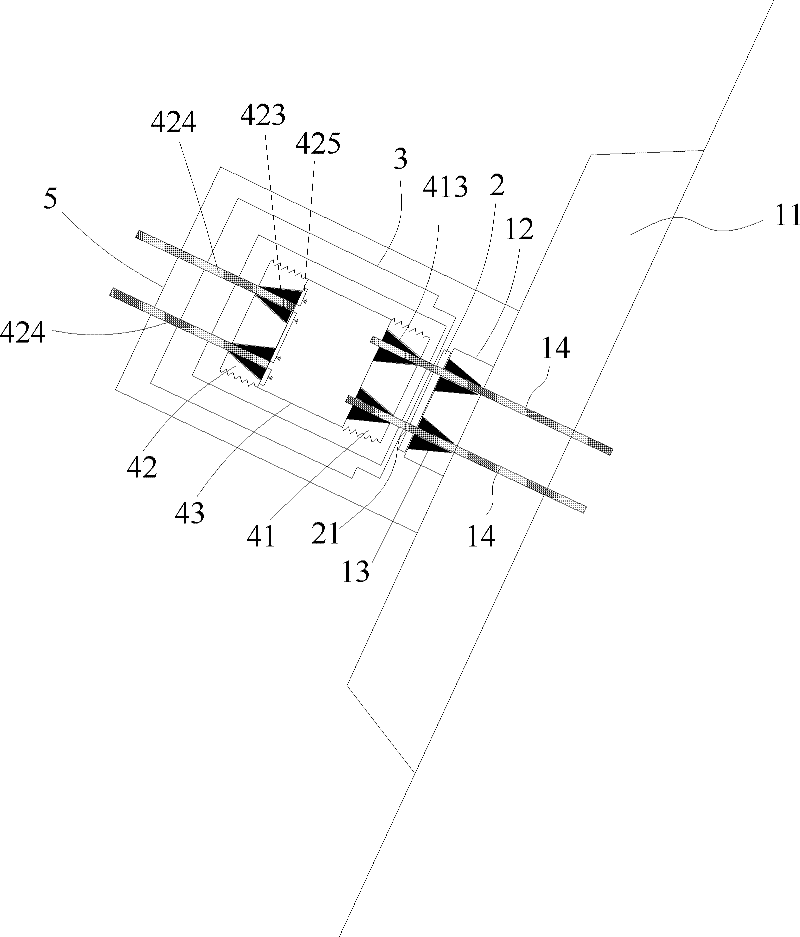

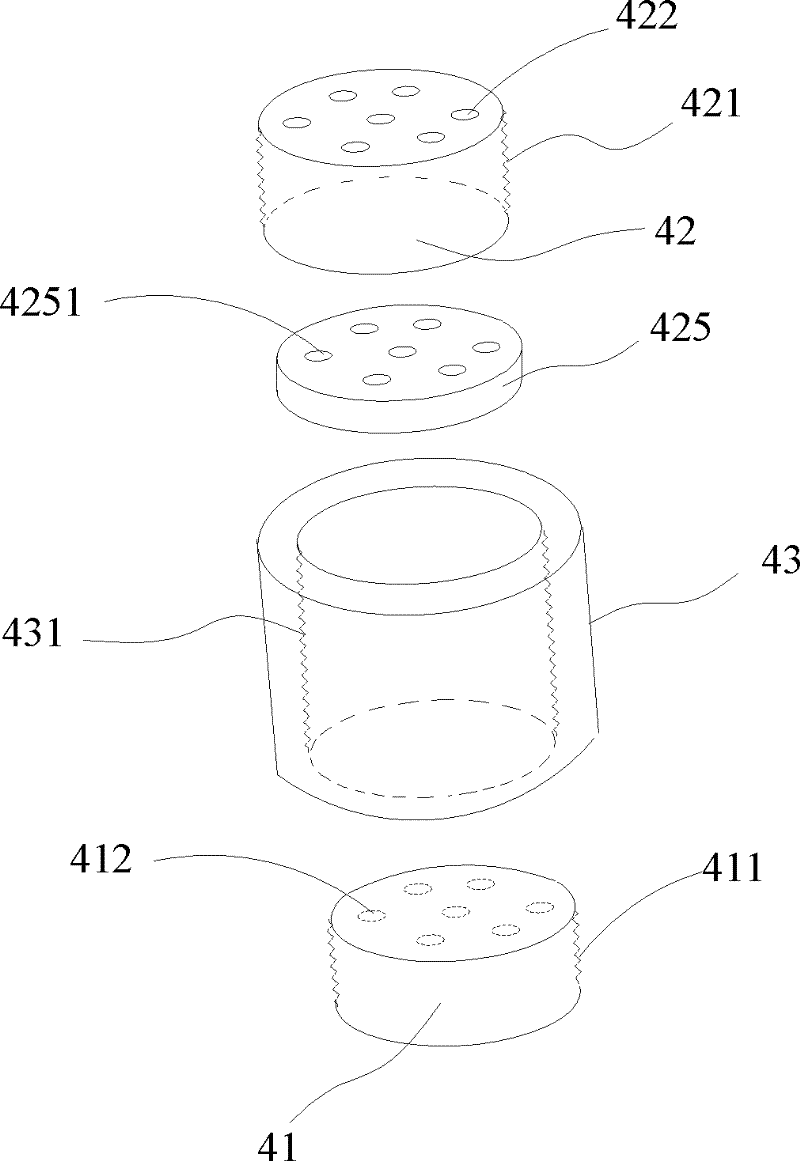

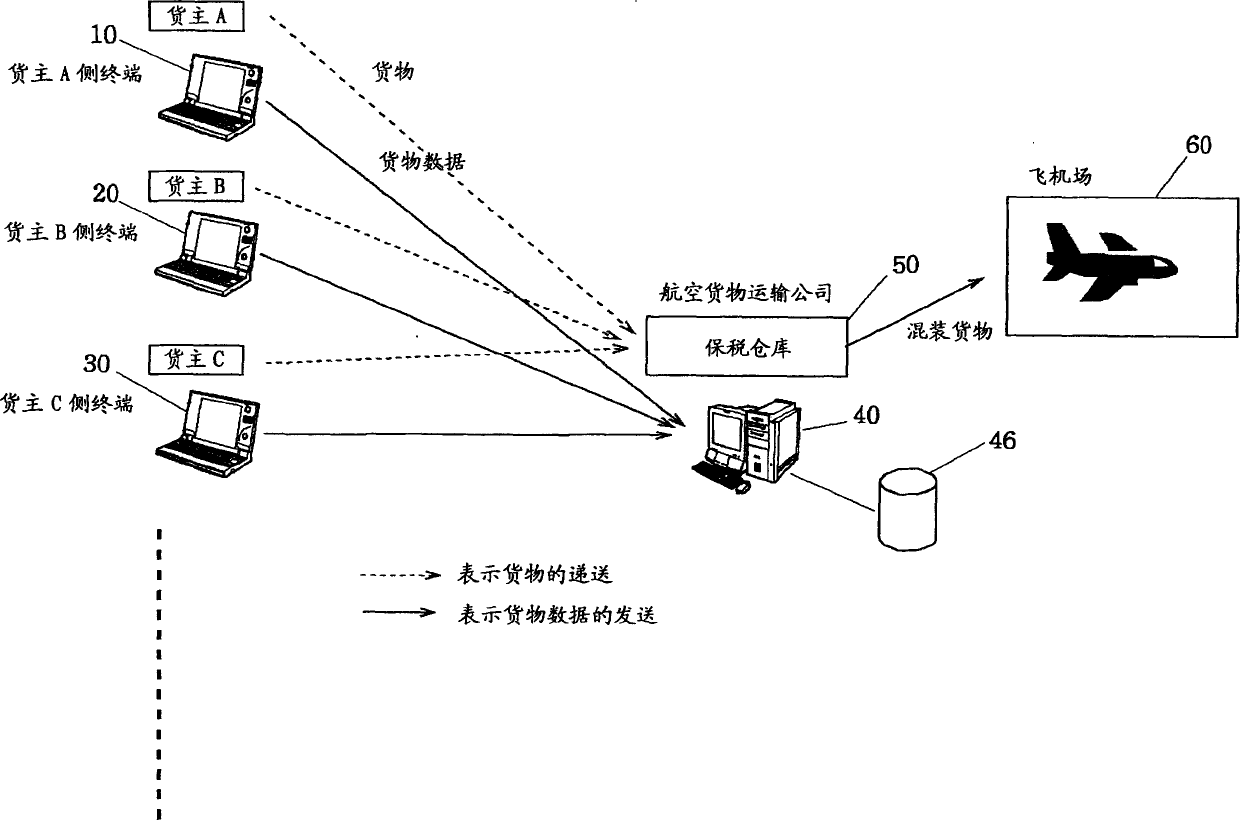

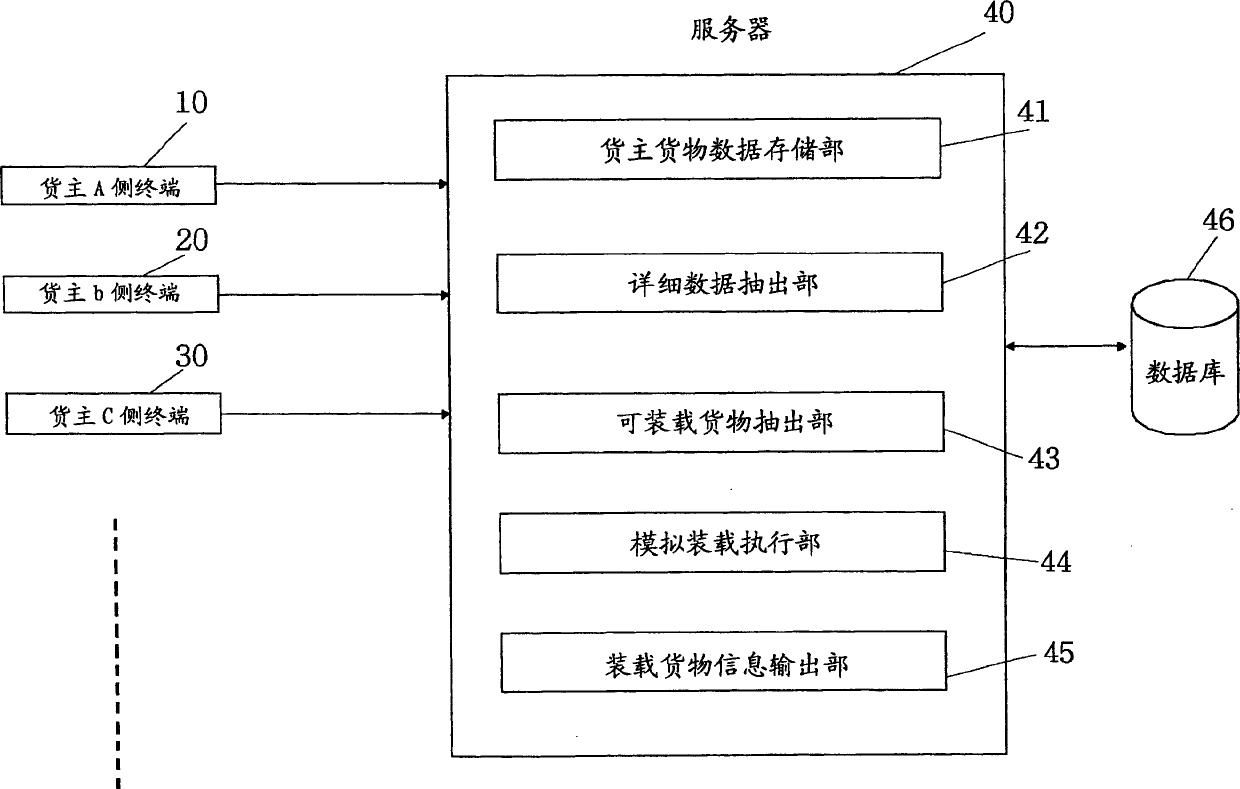

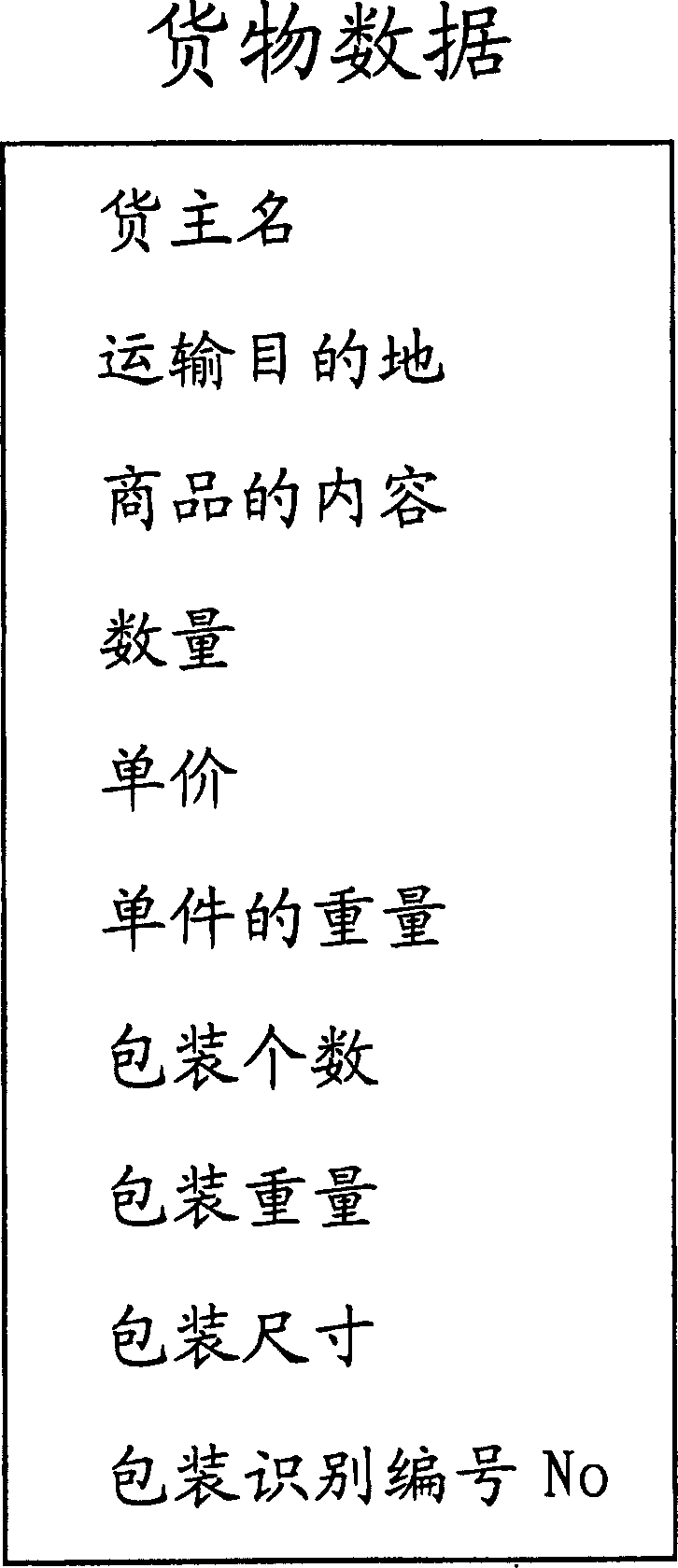

Consolidated air cargo management system

[Object] The invention makes it possible to easily and accurately perform the work of loading consolidated cargo without requiring skill and experience, and makes it possible to reduce the transport cost for each small cargo load. [Means Solve] The invention comprises: a terminal 10 on the side of a cargo owner A, a terminal 20 on the side of a cargo owner B and a terminal 30 on the side of a cargo owner C that have the function of sending cargo data related to a plurality of small cargo loads; a server 40 on the side of a business that handles air cargo and that is connected to these terminals, and that has a function of extracting small cargo loads based on the cargo data that will match the specified load amount of the a pallet 70; and a database 46 that stores basic data that gives the types of pallets 70, the specified load amounts that specify the load weight and dimensions for each air carrier, and the unit fee.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com