A feeding chamber, an apparatus and a method for production of doses of dry powder, a method for controlling particle segregation in dry powder during filling

A technology of powder particles and chambers, applied in the field of supply chambers, equipment for manufacturing dry powder medicaments and controlling the separation of particles in dry powders during filling, which can solve the difficulties of medicament metering, powder bulk density changes, filling medicaments container and other issues, to achieve the effect of controllable particle separation and low particle separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

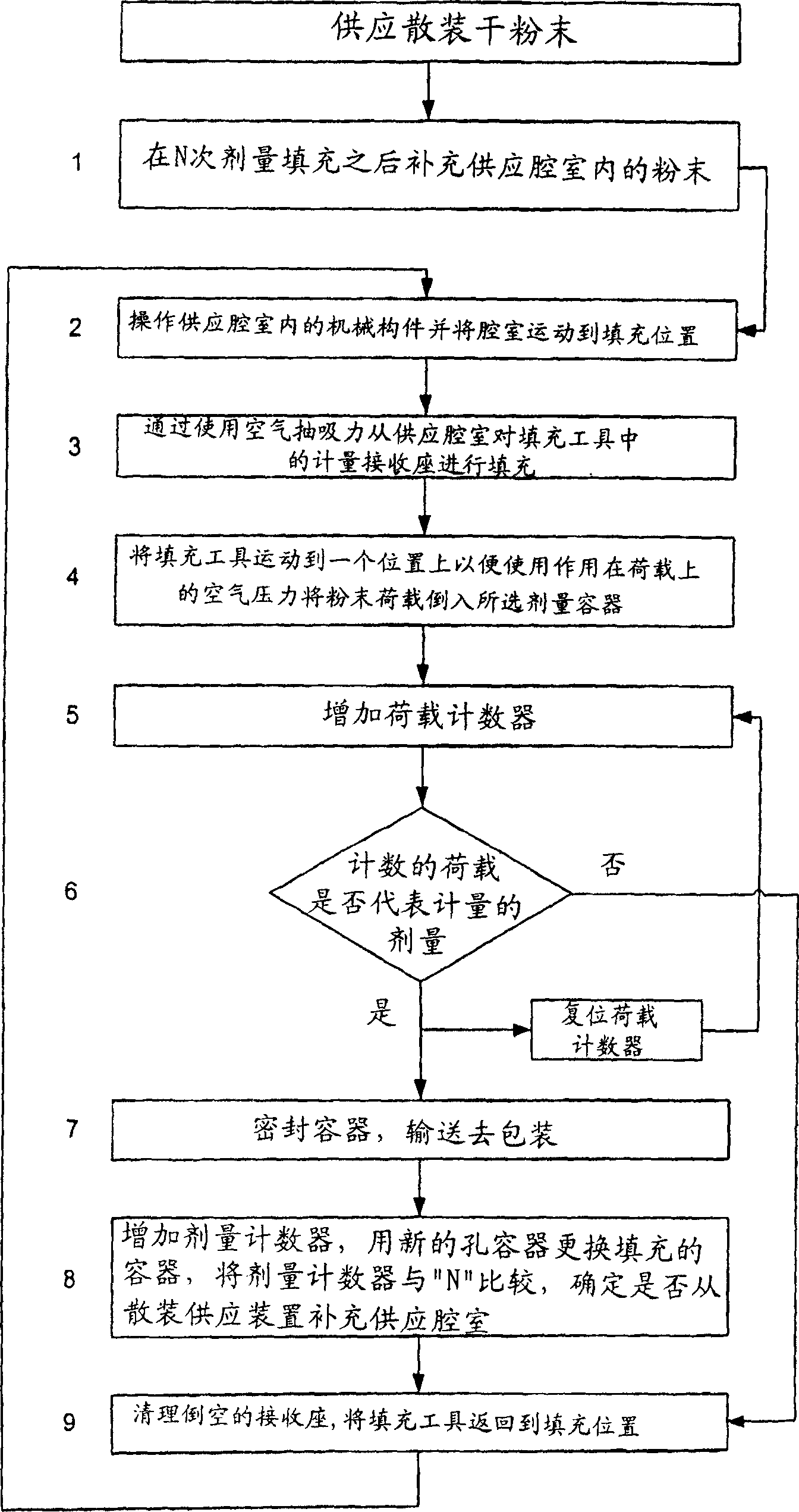

[0032] The present invention discloses apparatus and apparatus for accurately metering and volumetric filling of dry powder pharmaceutical medicaments into preformed containers, wherein the medicaments and containers are suitable for administration by inhalation using a dry powder inhaler (DPI). The method of the present invention is expressed in figure 1 in the flow chart.

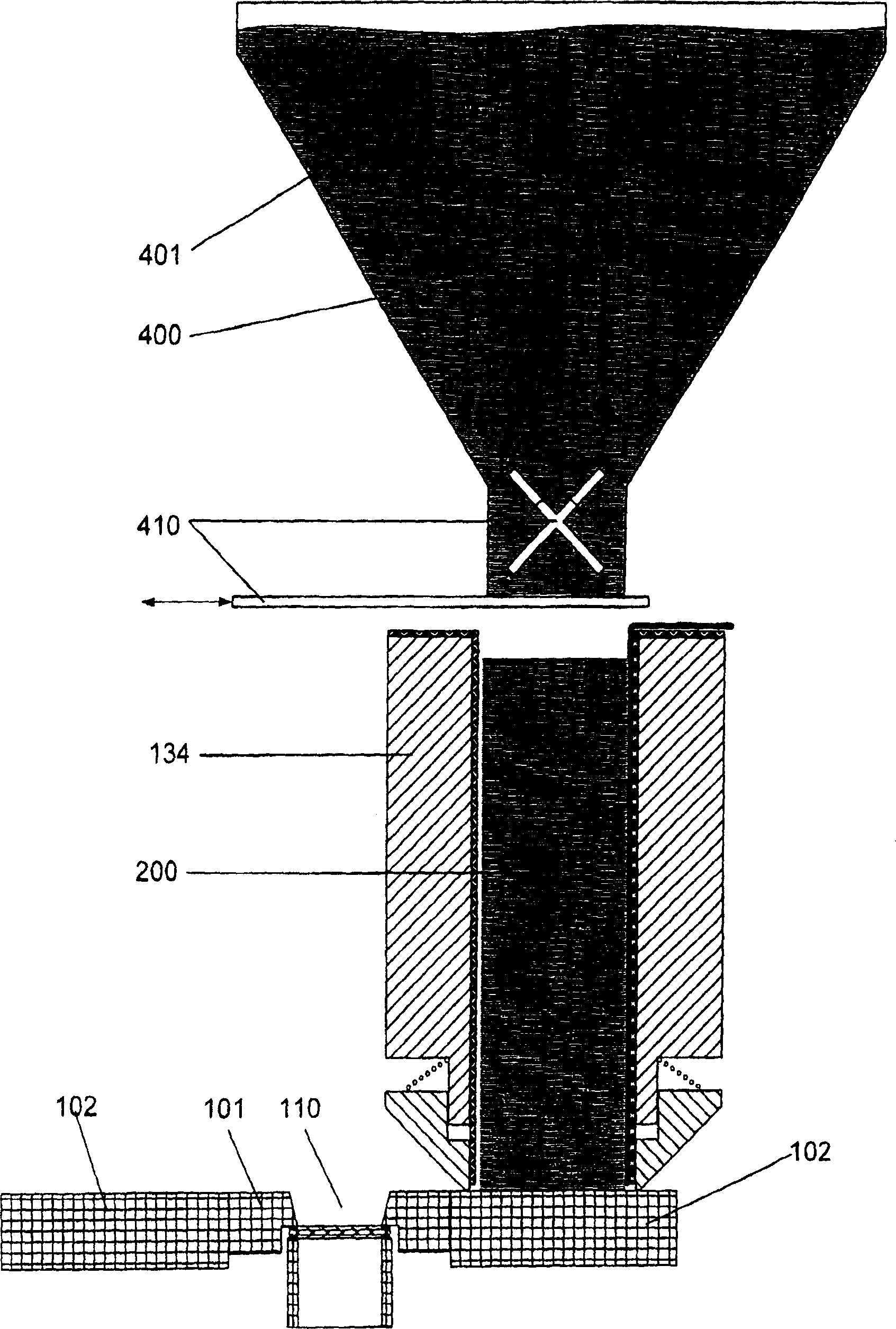

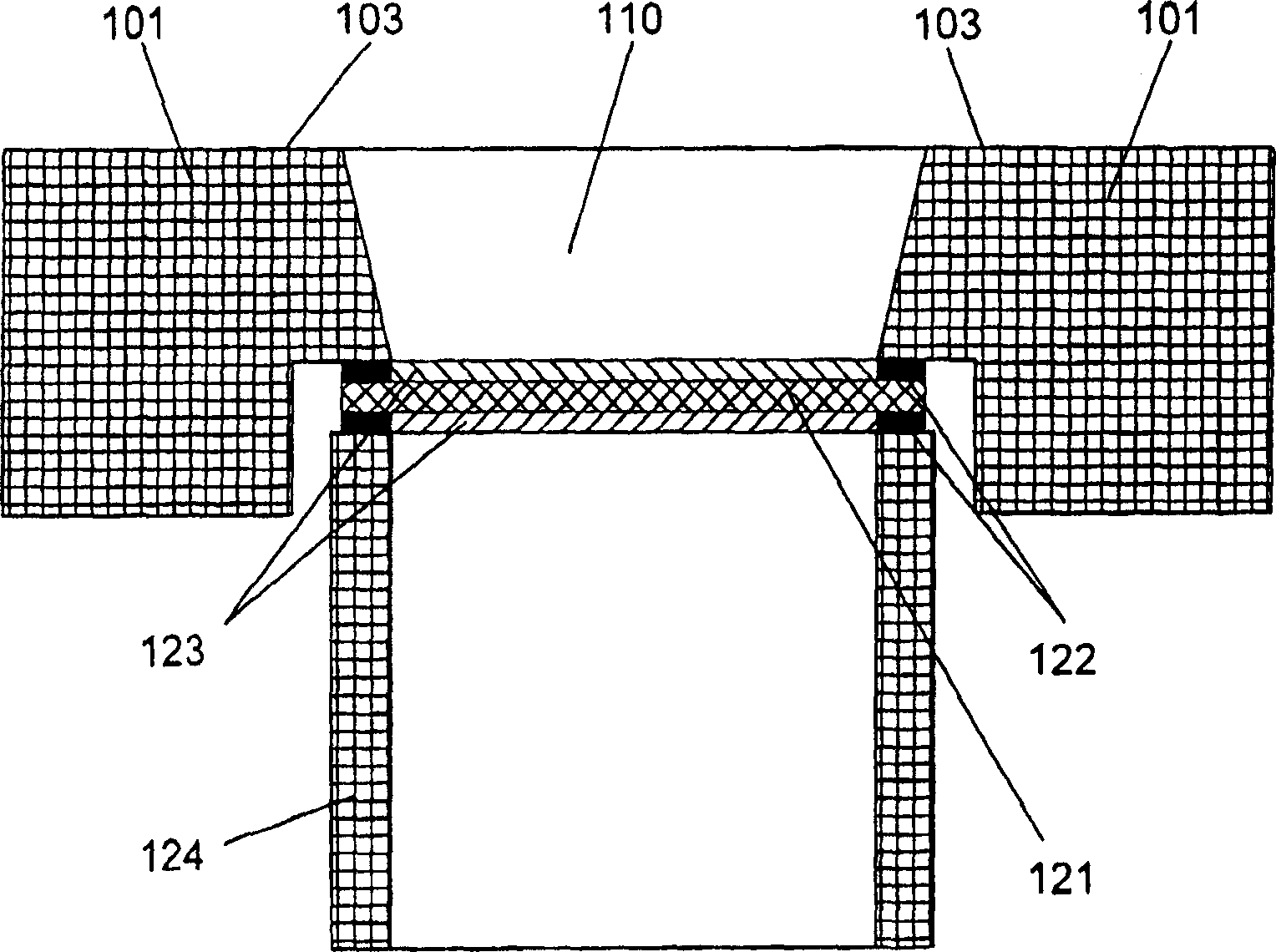

[0033] Prior art methods and apparatus use a primarily cylindrical filling tool having a plurality of generally conical metering cavities, receptacles that are filled from a bulk powder source that holds the bulk powder. The cylindrical filling tool is then rotated to an emptying position where the filled receptacle is emptied into the appropriate package. However, since the filling process affects the amount of powder involved in the filling process, a considerable fine particle portion of the powder is filled into the receptacle, and the amount of powder filled into the receptacle varies with time. En...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com