Hydraulic servo buffer capable of achieving active control

A hydraulic servo and active control technology, applied in the field of hydraulic buffers, can solve the problems of long recovery time, complex mechanical structure, low control precision, etc., and achieve the effect of high automatic control precision, simple structure and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

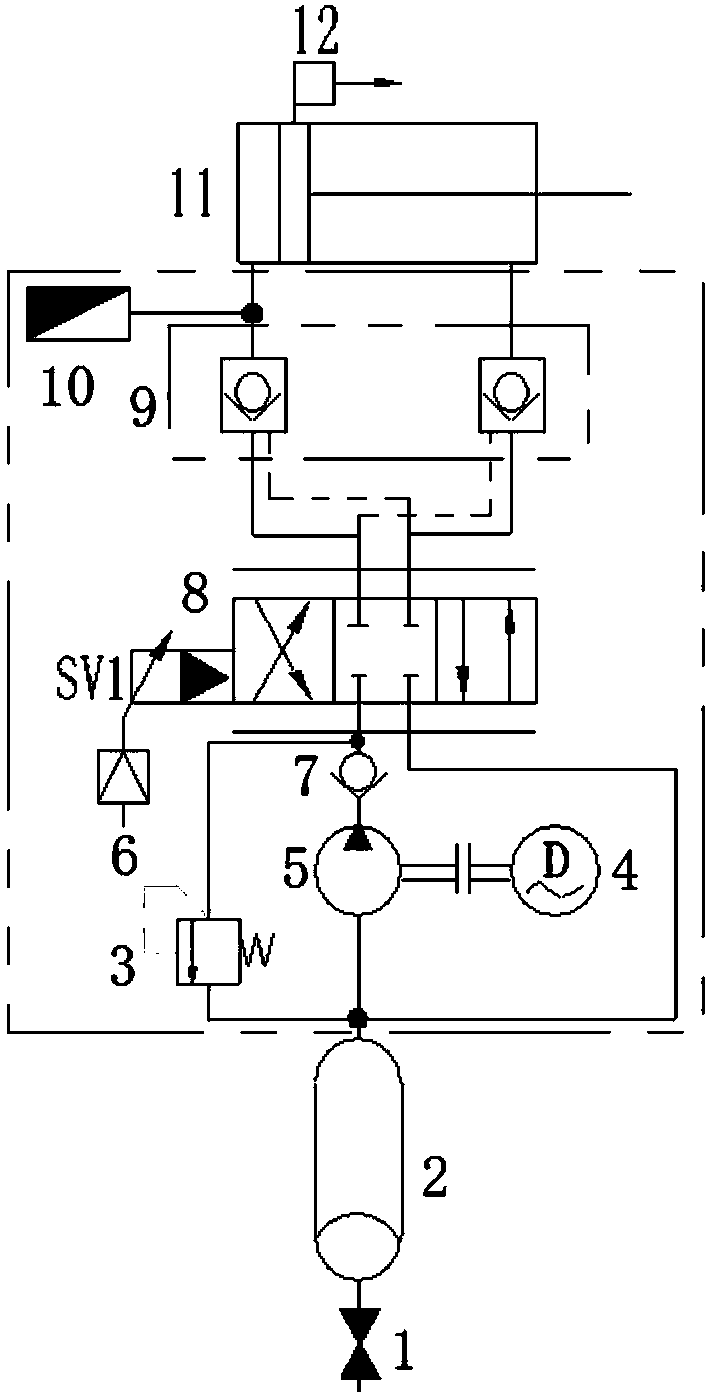

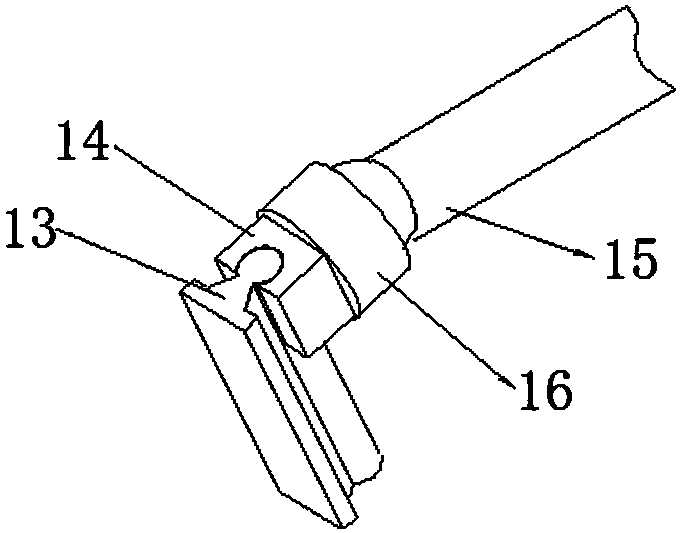

[0014] exist figure 1 with figure 2 In the active control hydraulic servo buffer shown, the low-pressure accumulator 2 is connected to the normally closed switch valve 1, said low-pressure accumulator is connected to the hydraulic quantitative pump 5 equipped with the electric motor 4, and the hydraulic quantitative pump is connected to the non-return valve 7 is connected to the inlet, the outlet of the one-way valve 7 is connected to the oil inlet of the hydraulic servo valve 8, and the oil return port of the hydraulic servo valve is connected to the outlet of the low-pressure accumulator. The outlet of the one-way valve 7 is connected with the inlet of the safety valve 3, the safety valve 3 is a direct-acting relief valve, and the outlet of the safety valve 3 is connected with the outlet of the low-pressure accumulator. The hydraulic servo valve is a three-position four-way hydraulic servo valve, which is provided with a servo amplifier 6 and an electromagnet sv1. The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com