Calculation of equivalent modulus of composite laminates and strength verification under given load

A composite material layer and equivalent modulus technology, applied in calculation, design optimization/simulation, special data processing applications, etc., can solve the problem that the finite element analysis results cannot correctly and intuitively reflect the stress of the laminated board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

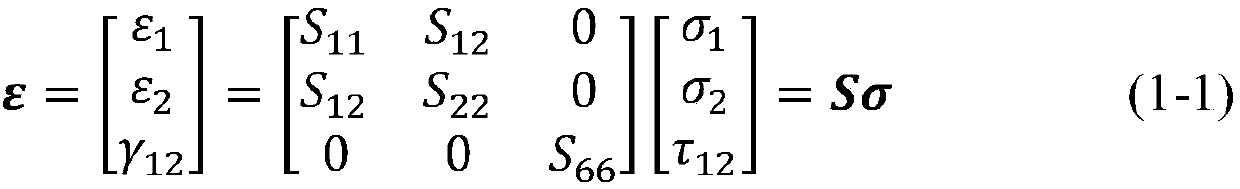

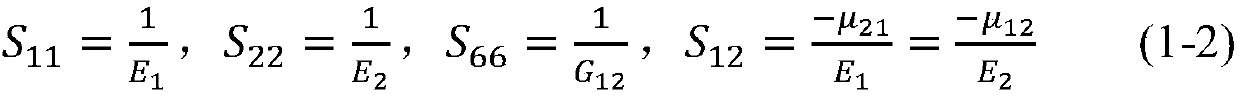

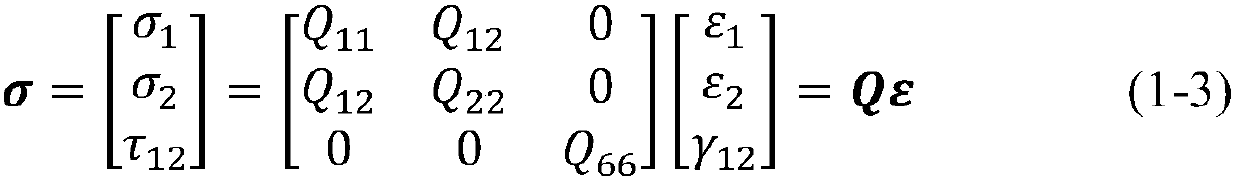

[0060] Embodiment 1: It includes an information input module, an operation module and an information output module. After the data is input and run, the calculation program will first calculate the stiffness matrix of each single layer according to the data input in the information input module, and then integrate the laminate stiffness matrix according to the ply information. From the laminate stiffness matrix, the equivalent modulus and equivalent stiffness matrix of the laminate under pure in-plane load and pure bending torsional load can be calculated, and the overall strain can be obtained by combining the load information, and further combined with the ply information to obtain the According to the maximum stress criterion, the Tsai-Hill failure criterion and the Tsai-Wu failure criterion, it is judged whether the laminate fails under the specified load.

[0061] In the equivalent modulus and strength check calculation program, the information included in the information...

Embodiment 2

[0114] Embodiment 2: on the basis described in embodiment 1, in order to satisfy the situation that part has requirement to structural rigidity, increase output structural rigidity data, include:

[0115] a. Tensile stiffness EA:

[0116]

[0117] Among them, EA is the tensile stiffness, E is the modulus of elasticity, A is the cross-sectional area; F is the tensile force, l is the length of the rod, and ΔL is the elongation of the rod.

[0118] b. Bending stiffness EI:

[0119]

[0120] Where EI is the bending stiffness, E is the modulus of elasticity, I is the moment of inertia of the section about the rotation axis; F is the concentrated force at the rod end of the cantilever, l is the length of the rod, and ω is the deflection of the rod end.

[0121] c. Torsional stiffness GI p :

[0122]

[0123] where GI p is the torsional stiffness, G is the shear modulus, I p is the polar moment of inertia; T is the torque, l is the length of the member, is the relativ...

Embodiment 3

[0125] Embodiment 3: On the basis described in Embodiment 2, in order to facilitate professional computing personnel to check the calculation details, increase the output A, D, B matrix information, the stress-strain information σ under the x-y coordinates of each layup and the 1-2 coordinates x , σ y , τ xy , σ 1 , σ 2 , τ 12 . However, it should be noted that due to the data type in the calculation process, only 4 digits after the decimal point are reserved for the short type, so the corresponding calculation results will produce data deviations, and the data 0 will often be calculated as 10 -10 Numbers below the order of magnitude.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com