Probe end cleaning sheet

a technology of end-of-probe cleaning and end-of-probe, which is applied in the direction of measuring lead/probe, semiconductor/solid-state device testing/measurement, manufacturing tools, etc., can solve the problems of poor electrical contact and inability to measure accurate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiments

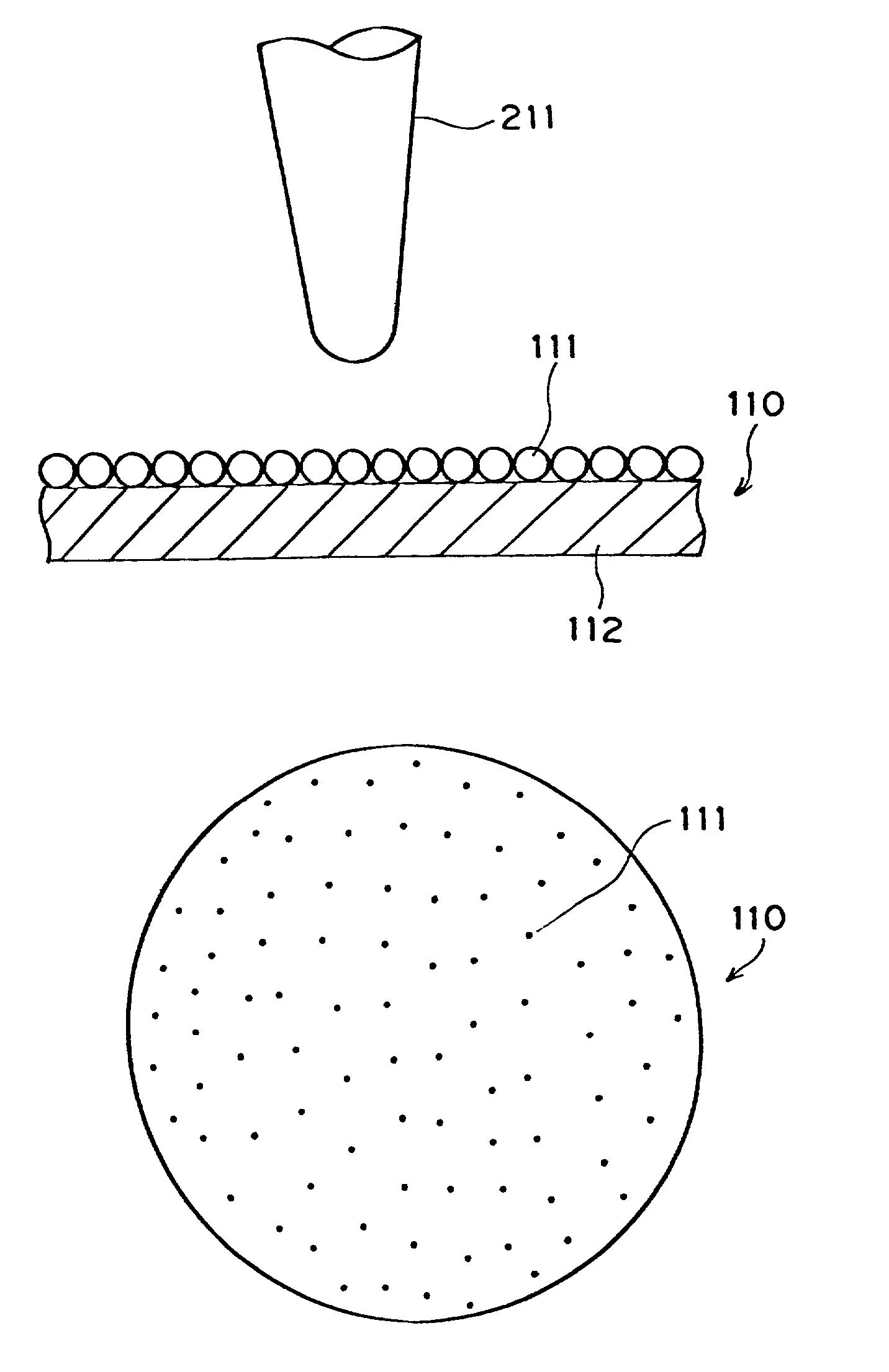

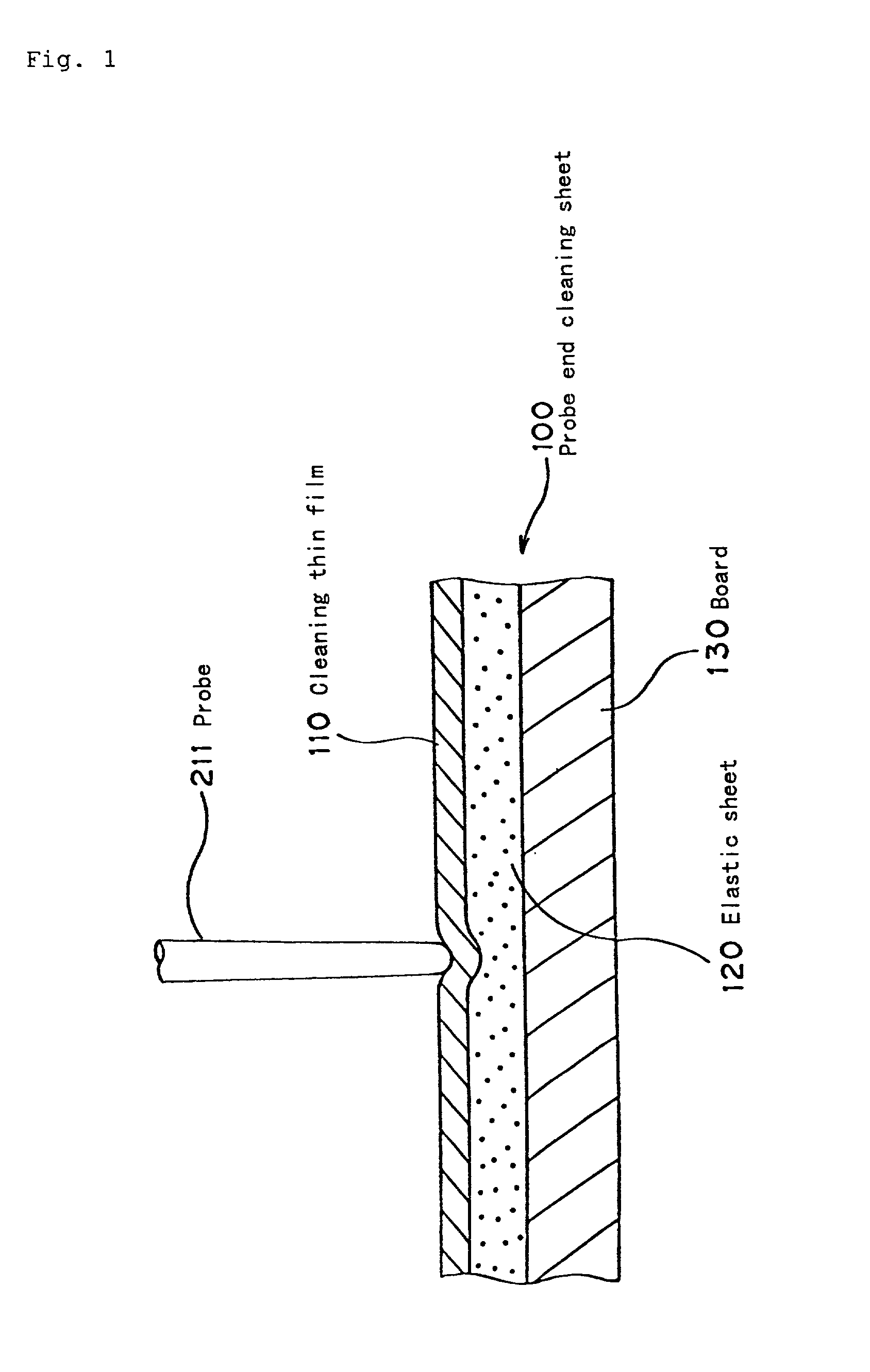

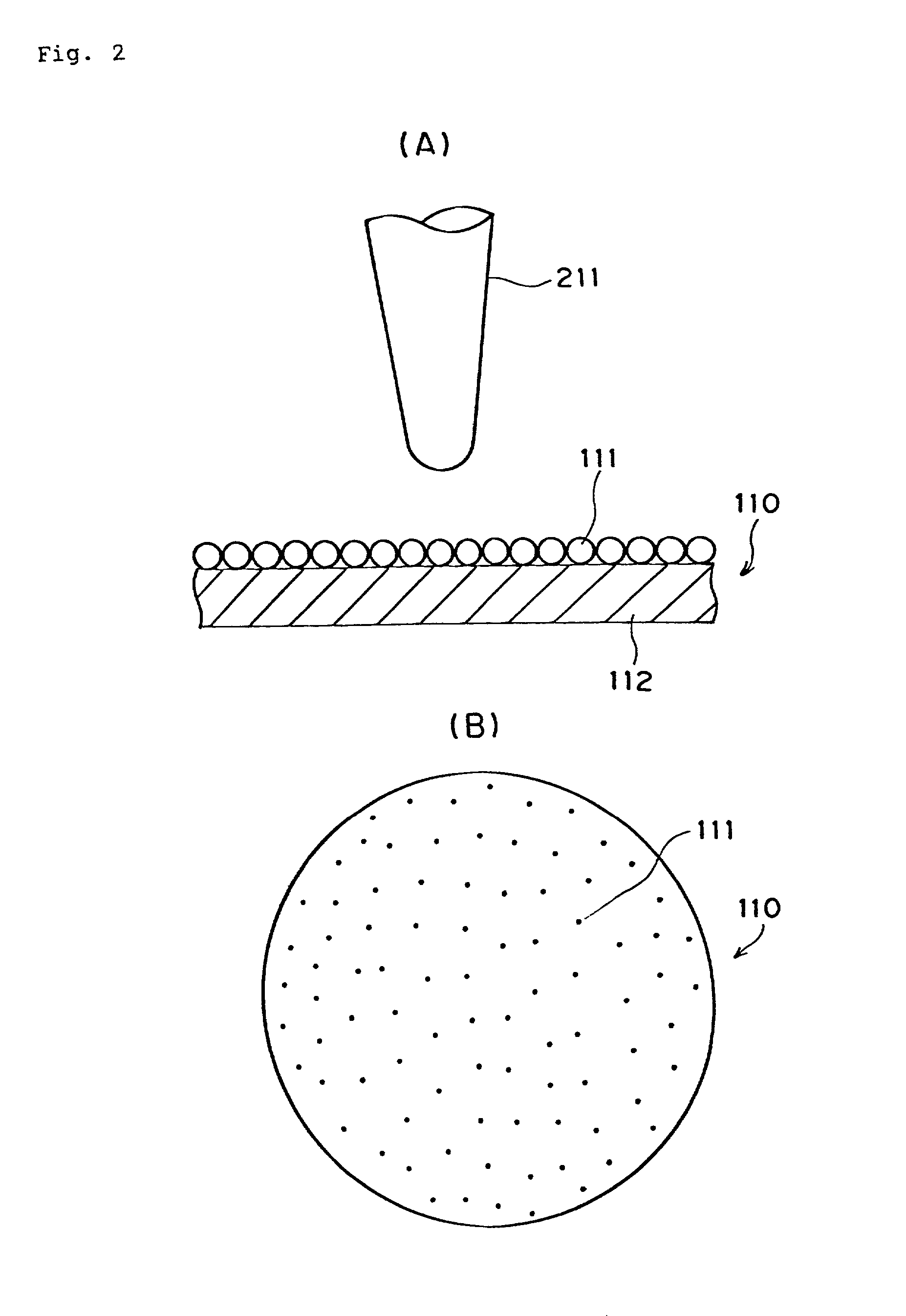

[0026] FIG. 1 is a schematic explanatory diagram of cleaning of a probe using a probe end cleaning sheet according to an embodiment of the invention, FIG. 2 is a drawing of the probe end cleaning sheet in the embodiment of the invention, (A) being a schematic magnified sectional view, (B) being a schematic plan view, FIG. 3 is a schematic structural view for explaining cleaning of the probe using the probe end cleaning sheet in the embodiment of the invention, FIG. 4 is a drawing of a probe end cleaning sheet in other embodiment of the invention, (A) being a schematic magnified sectional view, (B) being a schematic plan view, FIG. 5 is a schematic structural view for explaining cleaning of the probe using the probe end cleaning sheet in the embodiment of the invention, and FIG. 6 is a schematic explanatory diagram showing the shape of the end of the probe cleaned by the probe end cleaning sheet in the embodiment of the invention. In the drawings, meanwhile, the ratio of dimensions o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com