Offshore wind turbine foundation structure and lightweight design method

A lightweight design, offshore wind turbine technology, applied in infrastructure engineering, design optimization/simulation, installation/support configuration of wind turbines, etc. and displacement, stress distribution uniform, to meet the effect of lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

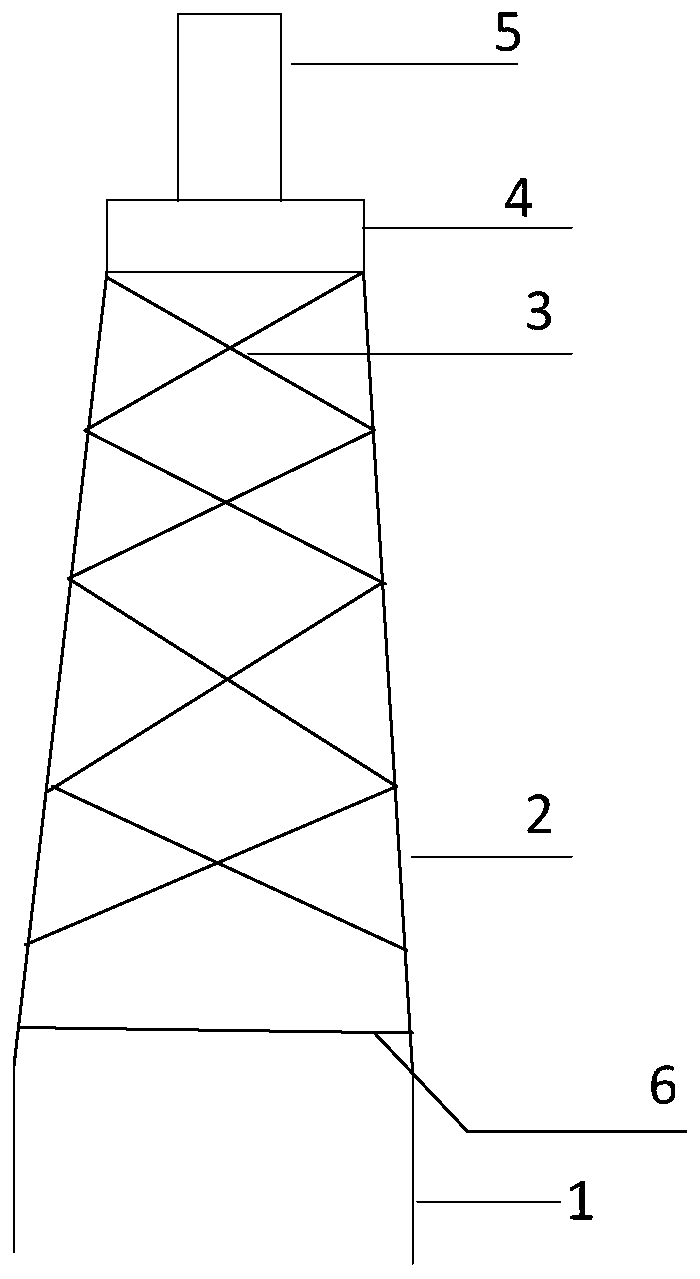

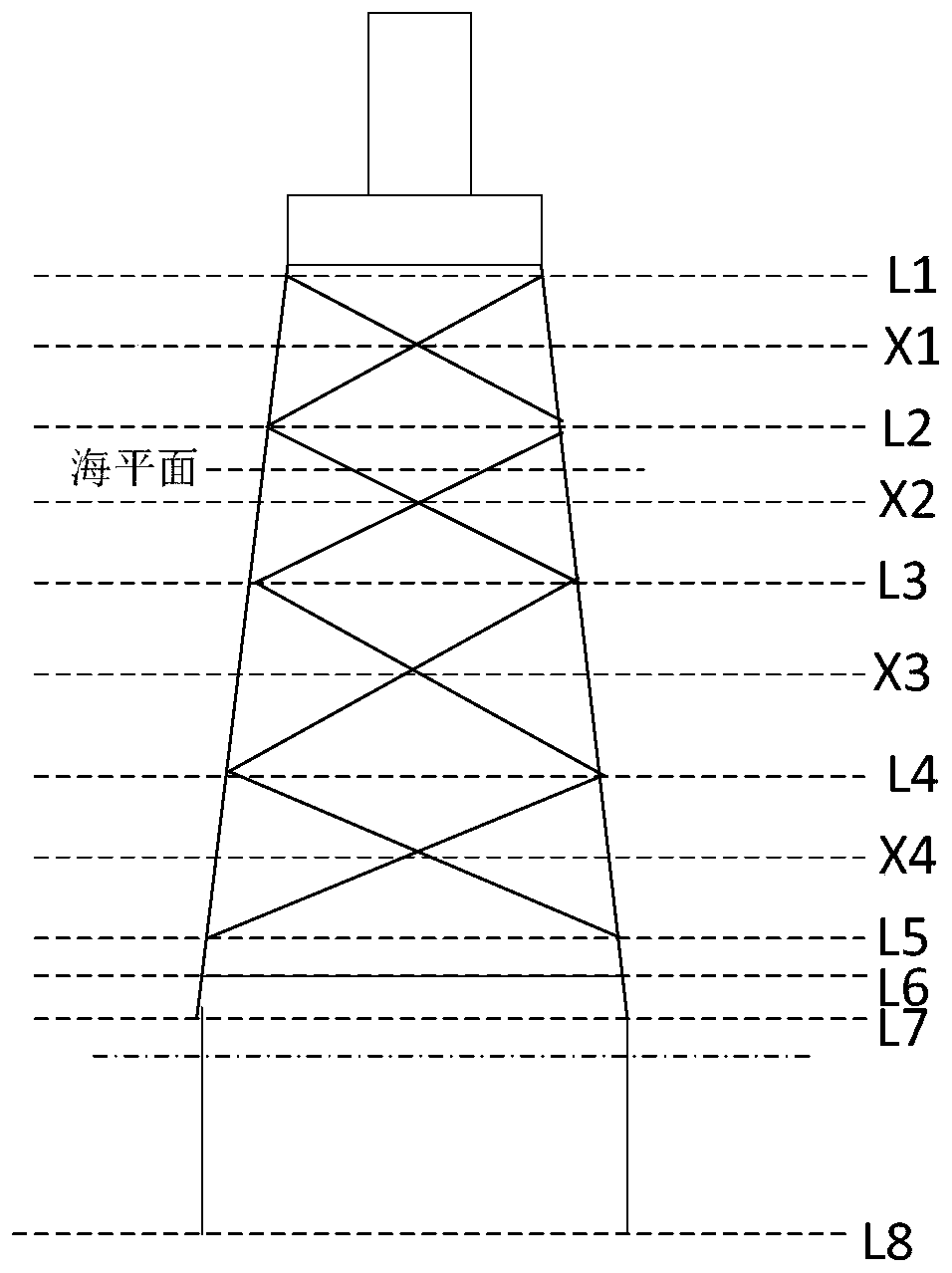

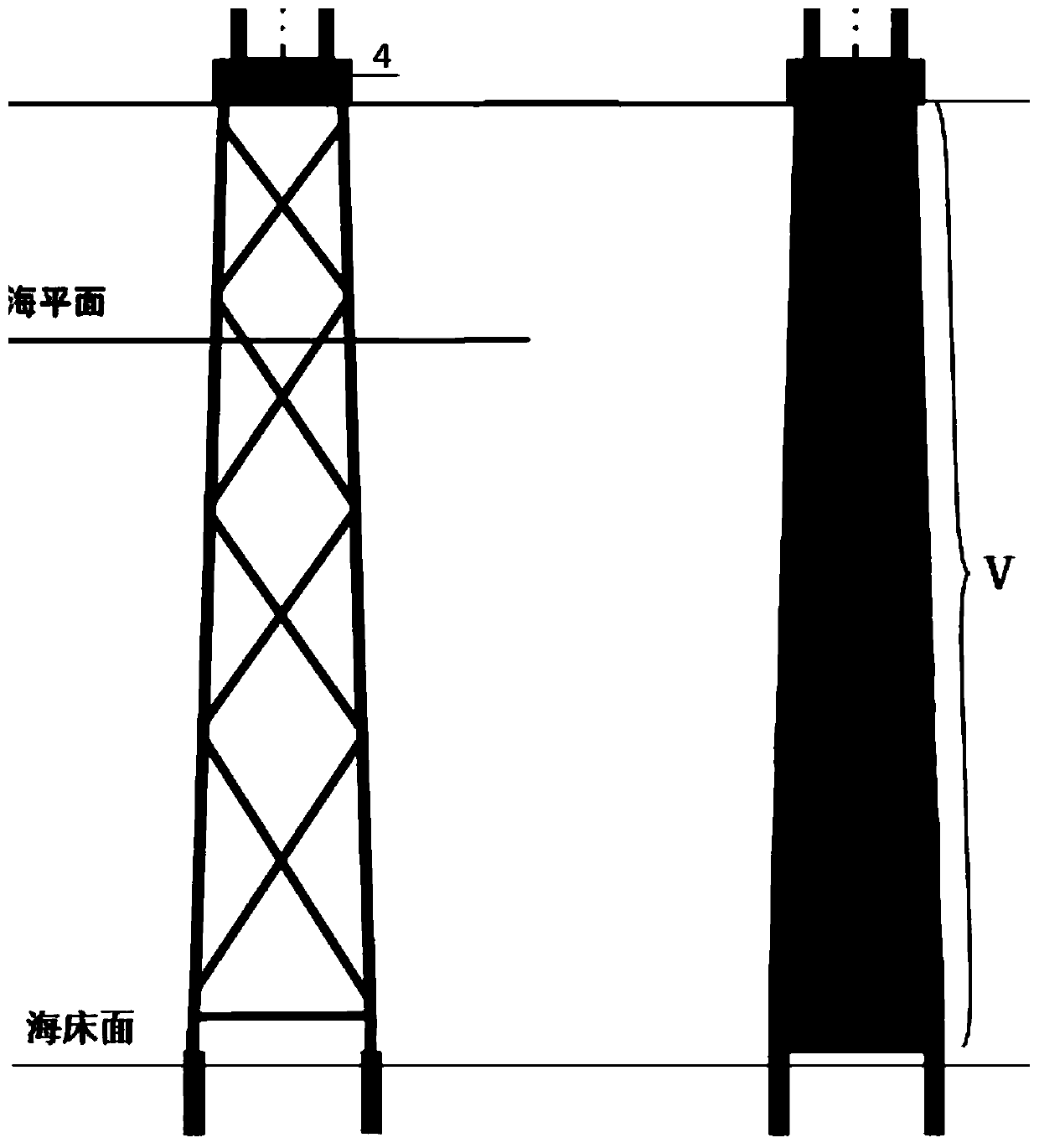

[0058]An offshore fan foundation structure, comprising a jacket, the bottom of the jacket is fixed on four piles 1, a transition block 4 is arranged on the top, and a fan tower 5 is arranged on the transition block 4; a cross brace 6 is arranged at the bottom of the jacket, and the conduit The frame includes four support legs 2 that form a tapered structure, and a cross structure 3 is arranged between the support legs 2. The cross structure 3 includes a first layer of cross structures 31, a second layer of cross structures 32, The third layer of intersecting structure 33, the fourth layer of intersecting structure 34 and the fifth layer of intersecting structure 35, their structural shapes are successively X-shaped, K-shaped, X-shaped, X-shaped and X-shaped structures; The middle point of the shape structure is located lower than the intersection point of X.

[0059] Support leg 2 comprises first support leg 21, second support leg 22, the 3rd support leg 23, the 4th support le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com