Base corner of rotary compressor

A rotary compressor and compressor technology, applied in the field of compressors, can solve the problems of waste of materials, waste of material support stress, etc., and achieve the effect of improving the die size and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

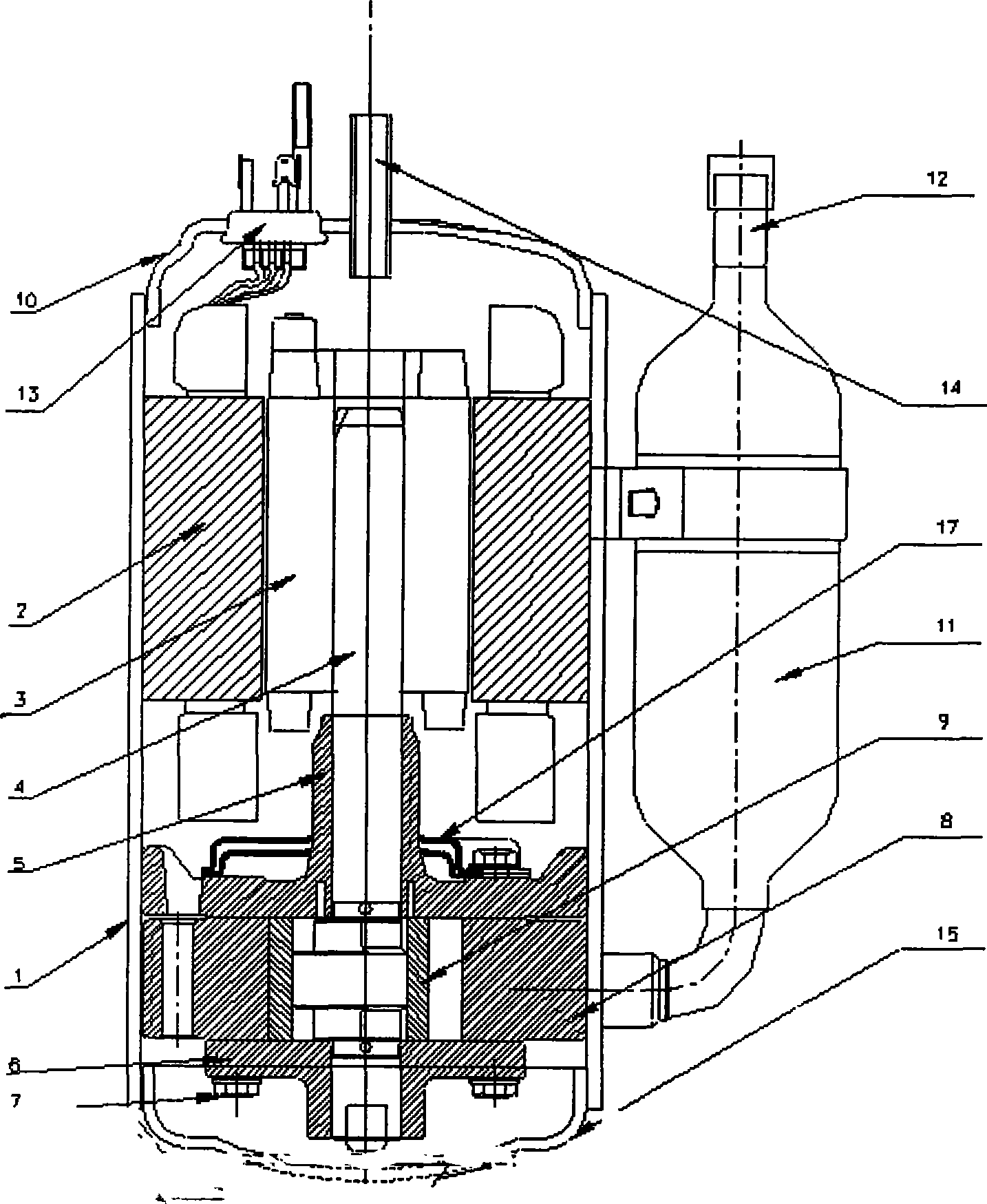

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] The working principle of the rotary compressor of the present invention is the same as that of the prior art, and the prior art can be referred to, so it will not be described again. The difference between the present invention and the prior art is the bottom angle of the rotary compressor, which will be described in detail below instruction of:

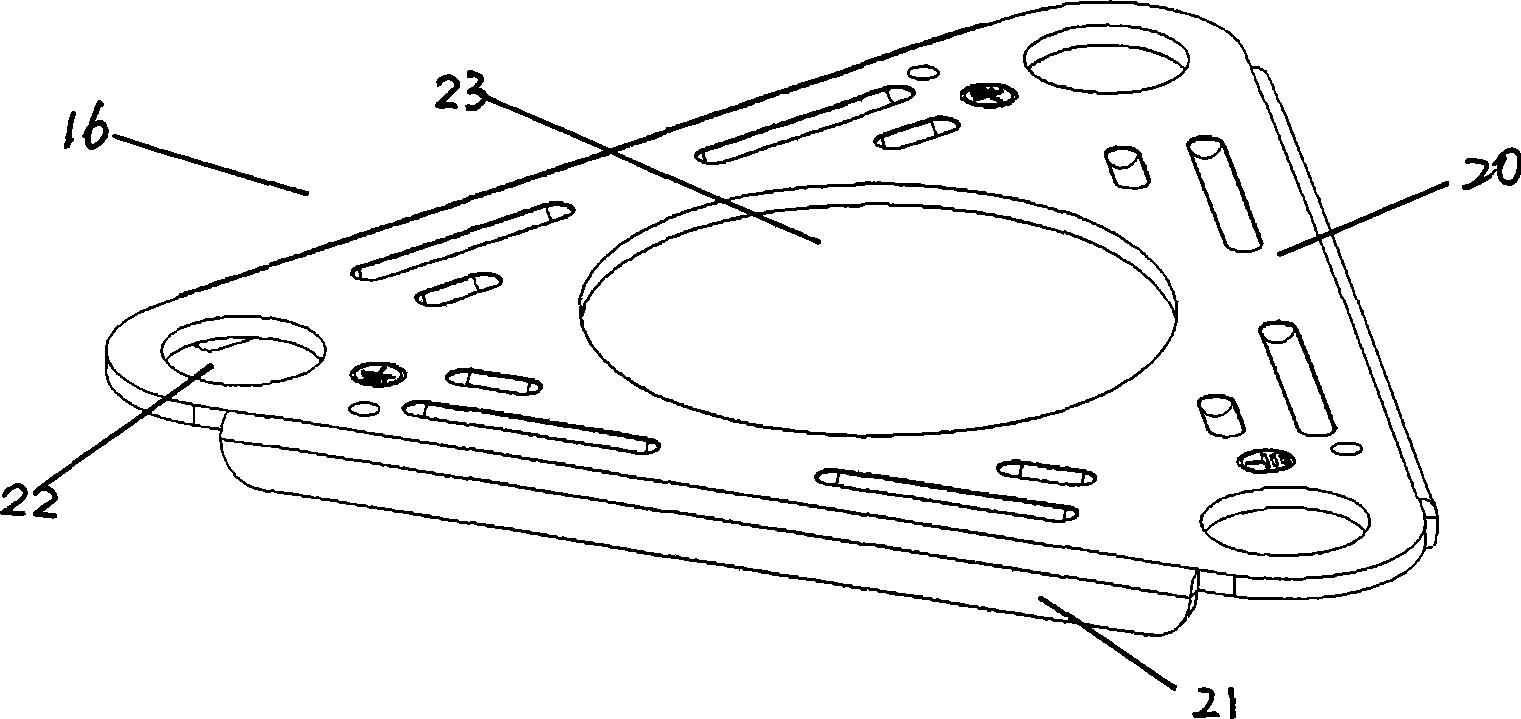

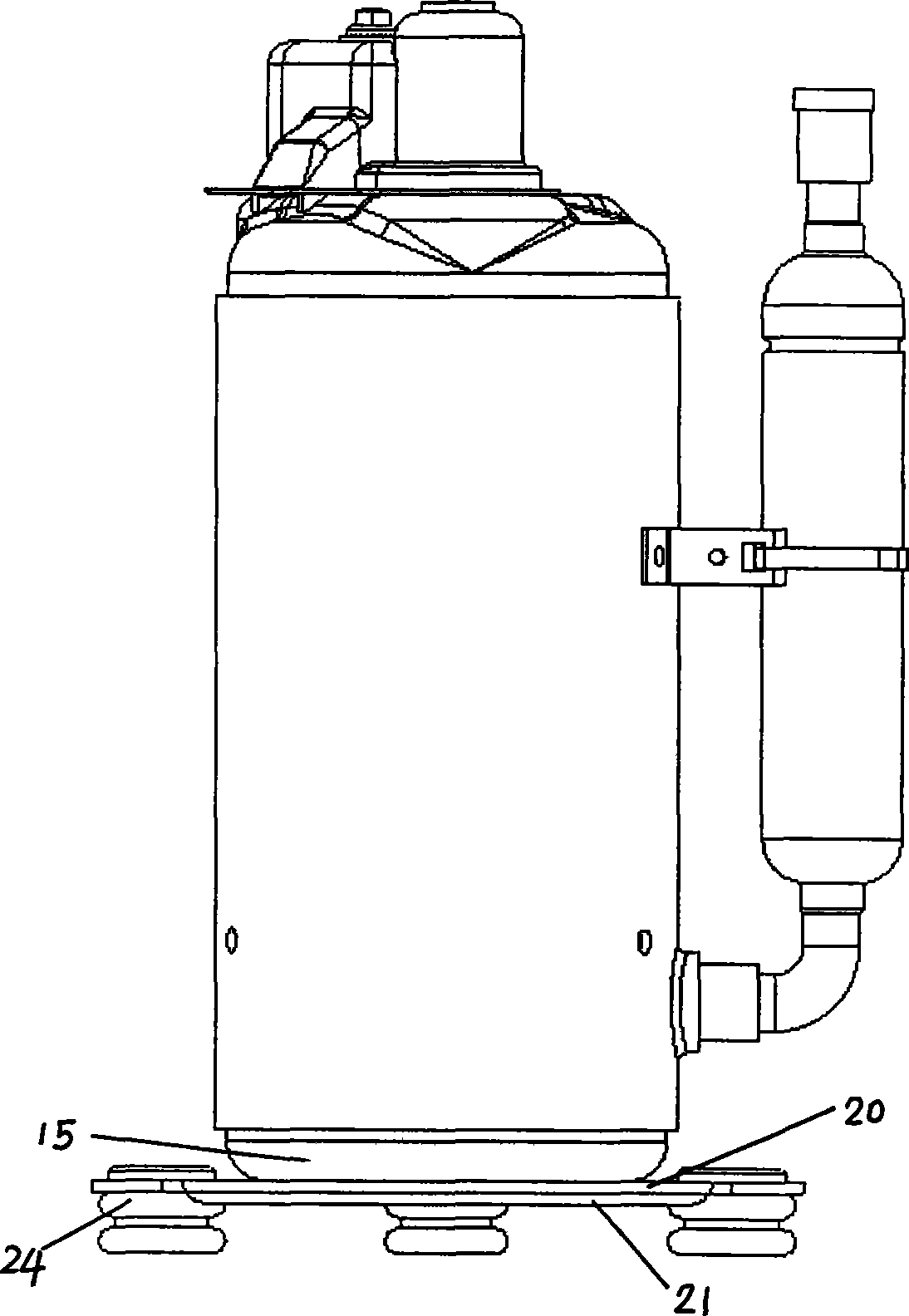

[0026] As shown in Figures 4 and 5, the base angle 26 of the present invention consists of a triangular planar portion 20 and three support ribs 31 positioned below the planar portion 20 along each side of the triangle. The through hole 23 has three mounting holes 22 through the three corners of the triangular planar portion 20 for installing the compressor to the chassis through the bottom angle 26 and inserting the rubber gasket 24. The supporting rib 31 is a long sheet structure with three t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com