High-strength strip steel straightening, flattening and straightening process

A strip steel and leveling technology, applied in the field of high-strength strip steel leveling and leveling technology, can solve the problems of difficult finishing of high-strength steel, insufficient leveling ability, and affecting the production capacity of the unit, so as to achieve good coiling quality, good product quality, and good Effect of shape and residual stress level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

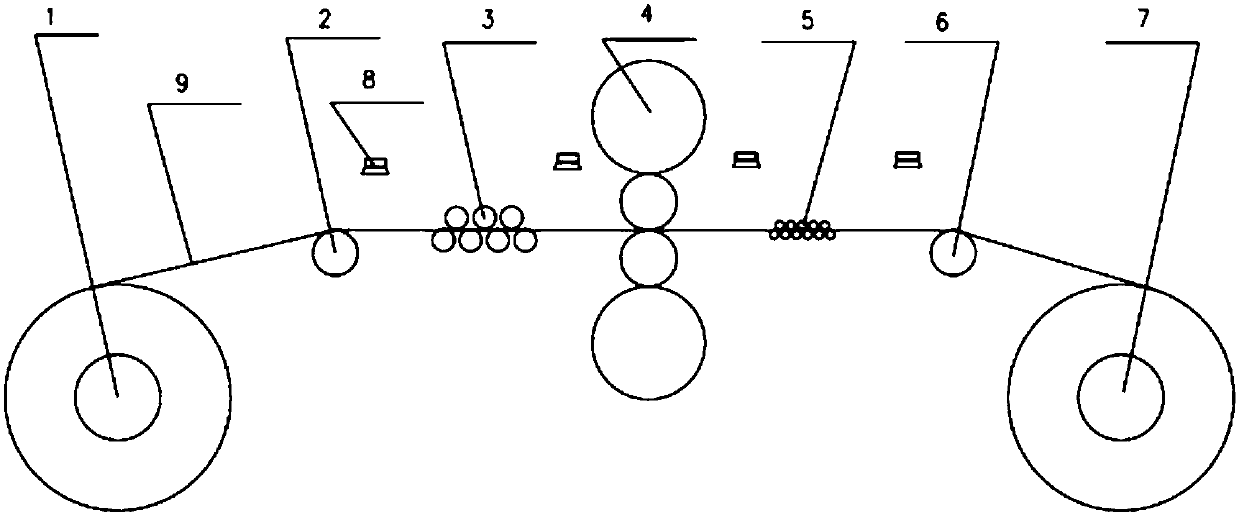

[0029] Such as figure 1 Shown is the high-strength strip steel leveling and leveling process implemented according to the present invention, the high-strength steel is produced by the leveling and leveling process, and the hot-rolled high-strength steel plate or strip steel 9 sequentially passes through the entrance leveler 3, the tempering machine 4, and the exit leveler 5. Complete the adjustment of strip steel 9 plate shape, surface quality, mechanical properties and residual stress.

[0030] The entrance straightening machine 3, the tempering machine 4, and the exit straightening machine 5 are respectively equipped with encoders or laser speedometers 8 to measure the elongation of the steel plate or strip, and are used to measure the elongation value of the strip 9 at each stage and the total elongation value.

[0031] Further, an uncoiler 1 is arranged in front of the entrance straightener 3, and a coiler 7 is arranged behind the exit straightener 5; an entrance turning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com