Layered FPC (flexible printed circuit) used for flip/slider phone and manufacturing method

A slide mobile phone and the technology of its manufacturing method, which are applied in the fields of multi-layer circuit manufacturing, branch office equipment, telephone communication, etc., can solve the problems that stress cannot be eliminated, product hardness increases, and bending is difficult, etc., so as to increase the bending life and flip the life. The effect of increasing and decreasing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

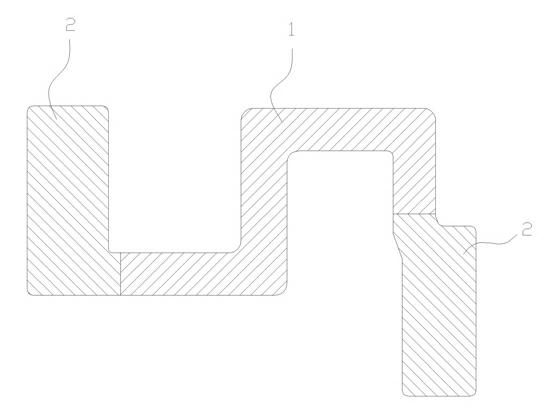

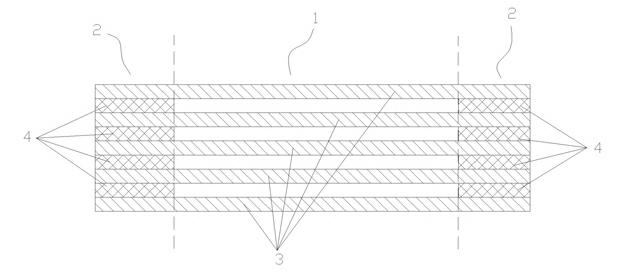

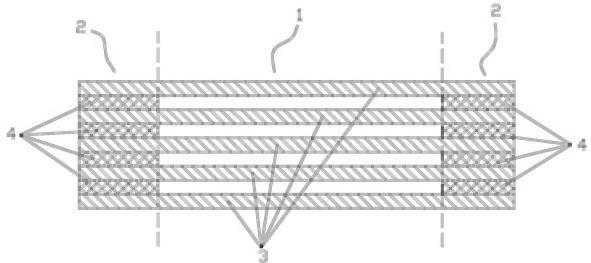

[0022] Such as figure 1 , figure 2 As shown, the present embodiment takes a flip phone as an example, and a slide phone is similar to it. The invention relates to a layered FPC for moving around the rotating shaft of a clamshell mobile phone. Data between the motherboard on the flip cover. The layered FPC is a multi-layer board, including at least two layers of FPC veneers 3 and an adhesive layer 4 arranged in a partial area between two adjacent layers of FPC veneers 3, and the adhesive layer 4 is a prepreg or adhesive Adhesive film, the number of layers of FPC veneer 3 is generally designed to be 2 to 8 layers; in the bending area 1 in the middle part of the layered FPC, each layer of FPC veneer 3 is freely separated, and the FPC of two adjacent layers There is no adhesive layer 4 between the veneers 3; the adhesive layer 4 is arranged between the FPC veneers 3 of each layer in the fixed area 2 at both ends of the layered FPC and fixed tightly, and the fixed Area 2 is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com