Insect-proof multi-layer eucalyptus wood board and production method thereof

A production method and wood board technology, applied in insect-proof multi-layer eucalyptus board and its production field, can solve the problems of easy deformation, unevenness, cracking and other problems of products, and achieve reduction of volatile formaldehyde, low dry shrinkage and wet expansion rate, good dimensional stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

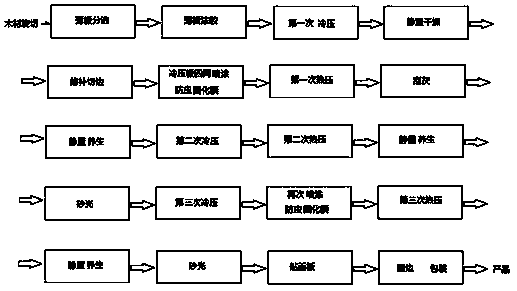

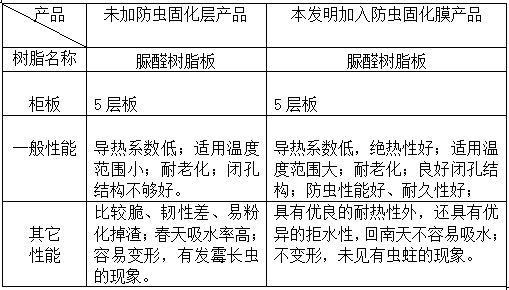

[0051] A method for producing an insect-proof multi-layer eucalyptus wood board, the production method of the multi-layer board includes veneer veneer sorting, veneer gluing, three times of cold pressing, three times of hot pressing, two times of static health preservation and dust scraping, sanding, repairing, The step of trimming and veneering is characterized in that before the first cold pressing, trimming, the first hot pressing and the last hot pressing, a layer of insect-proof curing film is sprayed around and up and down the surface of the slab to protect and prevent The glue dries too quickly during the hot pressing process and maintains the internal stress of the multi-layer board. It can also make the urea-formaldehyde glue fully react, so that the formed multi-layer board has high strength and insect resistance; the user reduces volatile formaldehyde during use. After the third hot pressing, the boards are left to stand for health preservation, sanded and veneered, ...

Embodiment 2

[0060] A method for producing an insect-proof multi-layer eucalyptus wood board, the production method of the multi-layer board includes veneer veneer sorting, veneer gluing, three times of cold pressing, three times of hot pressing, two times of static health preservation and dust scraping, sanding, repairing, The step of trimming and veneering is characterized in that before the first cold pressing, trimming, the first hot pressing and the last hot pressing, a layer of insect-proof curing film is sprayed around and up and down the surface of the slab to protect and prevent The glue dries too quickly during the hot pressing process and maintains the internal stress of the multilayer board. It can also make the urea-formaldehyde glue fully react, so that the strength of the multilayer board after molding is high, and the volatile formaldehyde is reduced during the user's use. The third After the first hot pressing, the boards are left to stand for health preservation, sanded an...

Embodiment 3

[0069] A method for producing an insect-proof multi-layer eucalyptus wood board, the production method of the multi-layer board includes veneer veneer sorting, veneer gluing, three times of cold pressing, three times of hot pressing, two times of static health preservation and dust scraping, sanding, repairing, The step of trimming and veneering is characterized in that before the first cold pressing, trimming, the first hot pressing and the last hot pressing, a layer of insect-proof curing film is sprayed around and up and down the surface of the slab to protect and prevent The glue dries too quickly during the hot pressing process and maintains the internal stress of the multilayer board. It can also make the urea-formaldehyde glue fully react, so that the strength of the multilayer board after molding is high, and the volatile formaldehyde is reduced during the user's use. The third After the first hot pressing, the boards are left to stand for health preservation, sanded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com