Patents

Literature

61results about How to "Improve pre-cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automotive air-conditioning apparatus

InactiveUS6158225AImprove cooling effectEfficient use ofAir-treating devicesVehicle heating/cooling devicesAtmospheric temperatureSolar battery

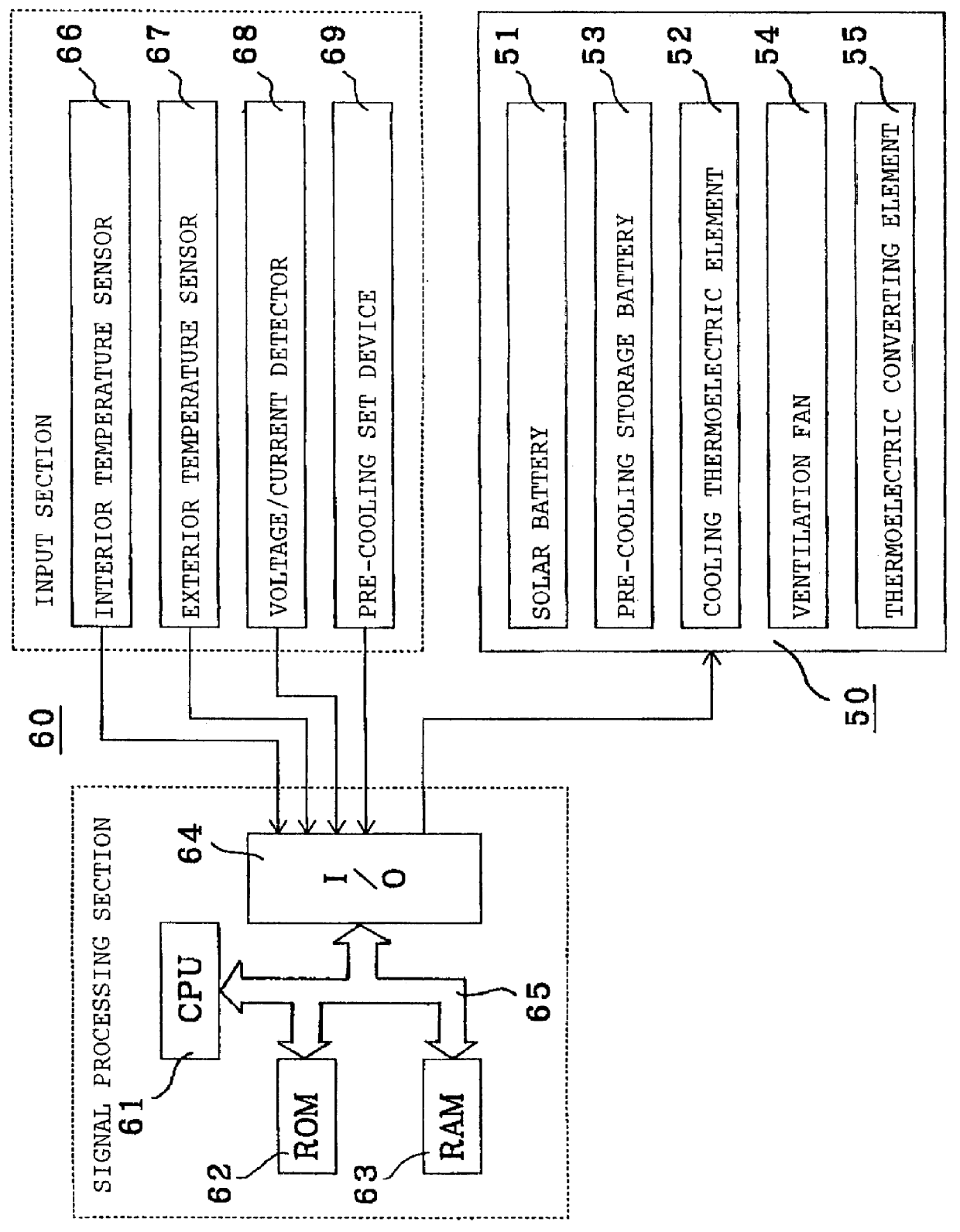

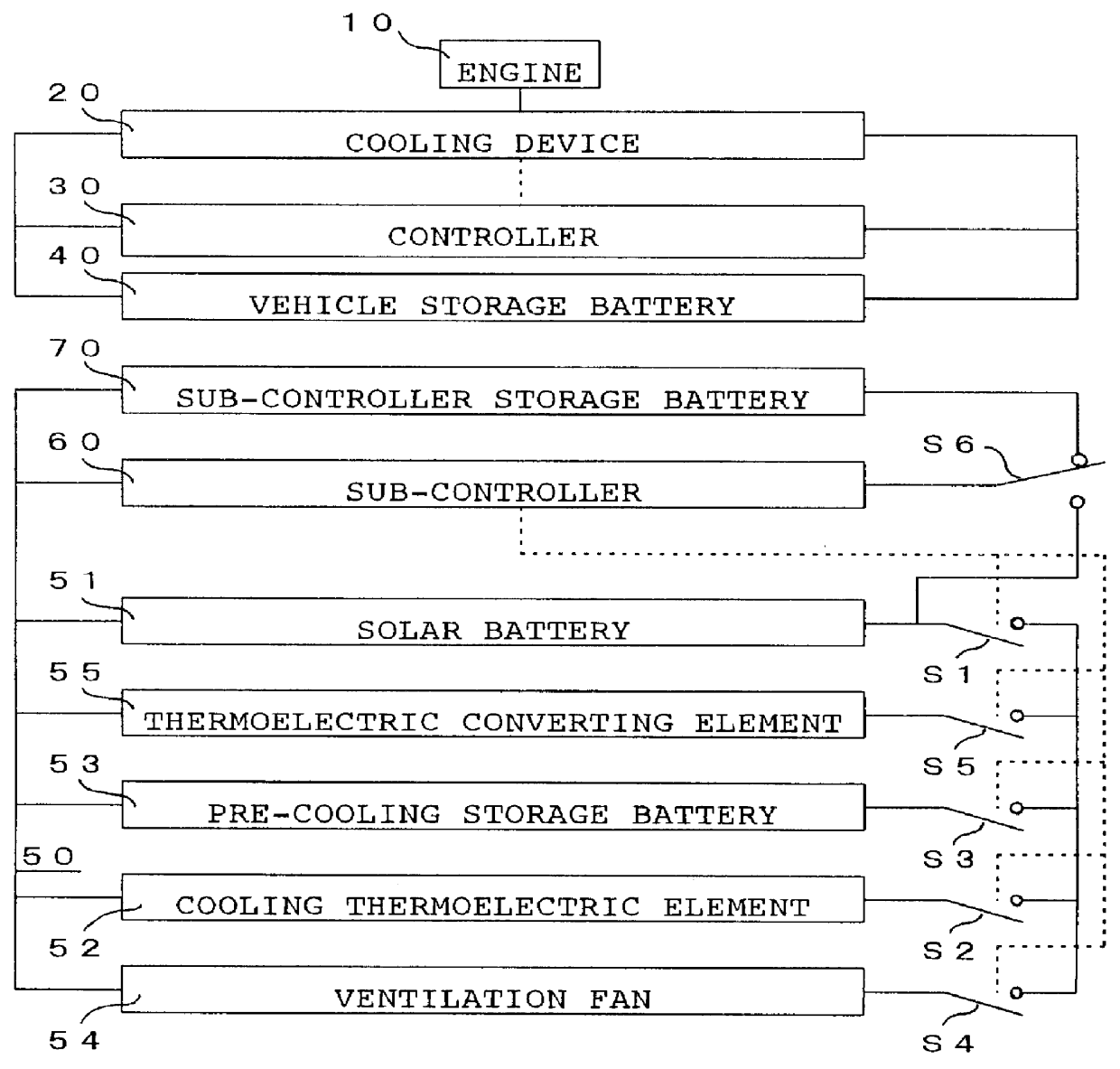

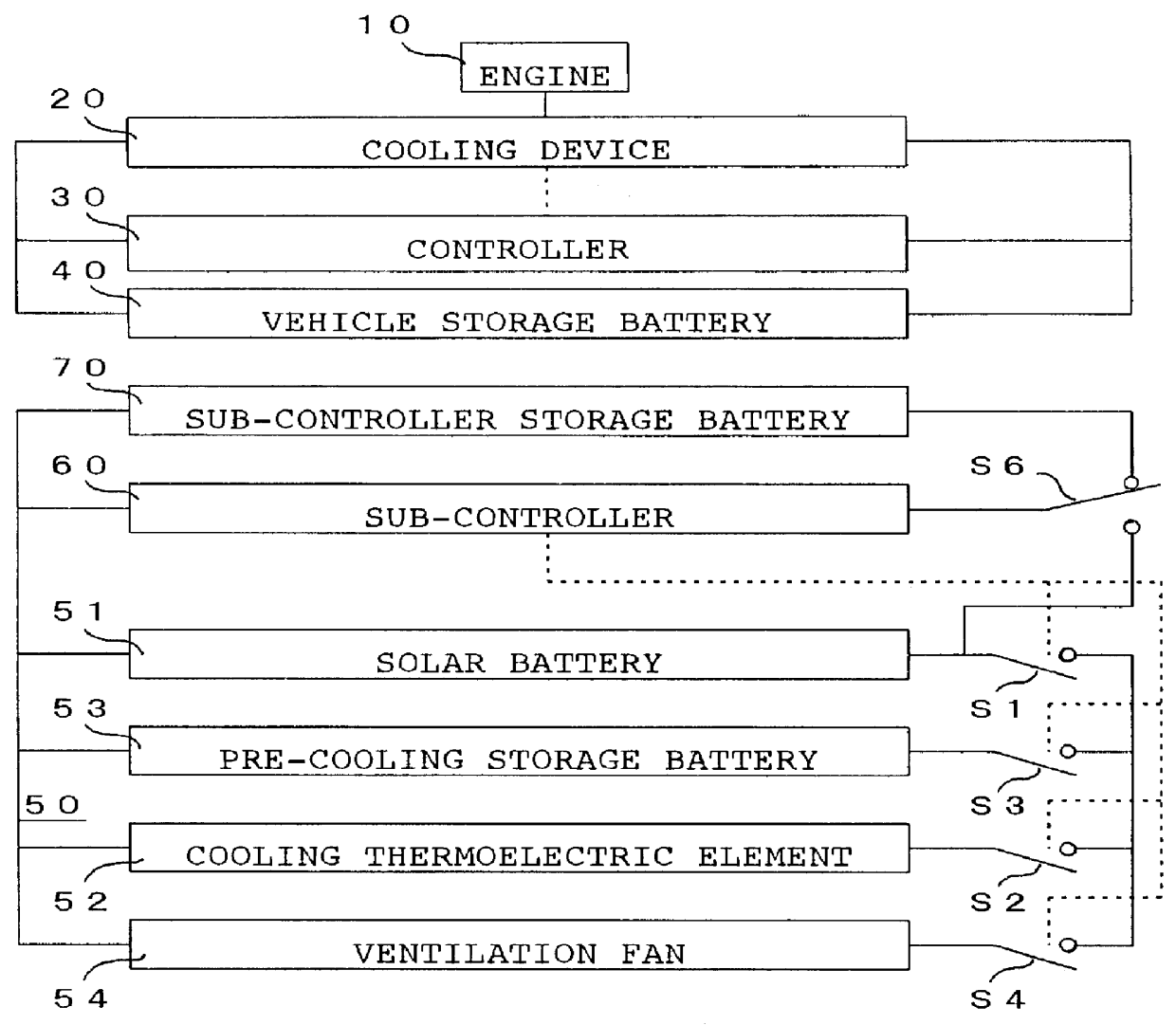

To keep a temperature of an interior of an automotive vehicle at least at a level of an external atmospheric temperature even if the vehicle is parked with an engine being stopped for a long time, an automotive air-conditioning apparatus is composed of a cooling device 12 to be controlled by a controller 13, a pre-cooling device 20 for pre-cooling the interior of the vehicle, and a sub-controller 18 for controlling the pre-cooling device. The pre-cooling device is composed of a cooling thermoelectric element module 22, a ventilation fan 23, a solar battery 21 and a pre-cooling storage battery 24 charged by the solar battery. The sub-controller always operates the pre-cooling device 20 while the vehicle is stopped with the engine being stopped and starts the pre-cooling device 20, for example, one hour prior to a time when the vehicle starts to movement during parking for a long time in an interior parking lot or the like with the engine being stopped so that the temperature of the interior of the vehicle is kept at a temperature that does not so much exceed a set temperature, i.e., at least at the level of the external atmospheric temperature, until the engine is started.

Owner:SEIKO INSTR INC

Pasteurization machine

InactiveCN103622130AImprove liquiditySpeed up the flowFood preservationWater temperatureWaste management

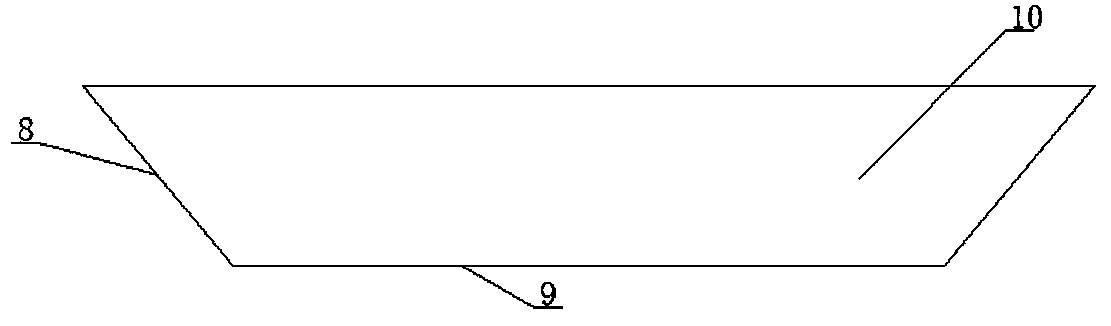

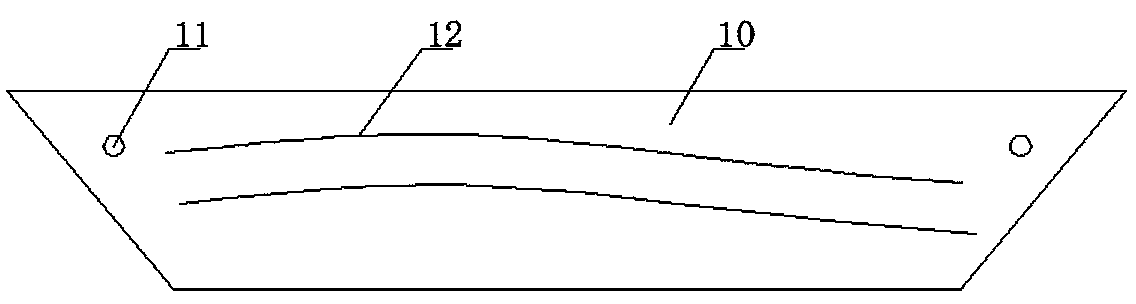

The invention discloses a pasteurization machine which is used for solving the problems that the incongruous water temperature in a sterilization tank in the prior art influences the sterilization effect. The pasteurization machine comprises a rack, wherein a sterilization tank and a cooling tank are arranged sequentially on the rack and are provided with a conveyer belt; the sterilization tank consists of a base plate, two side plates and two inclined plates which are connected with one other; a temperature sensor is arranged in the sterilization tank; the two side plates are provided with at least two inclined baffles; the baffles and the side plates form a channel; the baffle on the front section of the side plates is higher than the baffle on the rear section of the side plates. Due to the adoption of the pasteurization machine, water in the sterilization tank is driven to circulate, the consistent water temperature of all parts in the sterilization tank is guaranteed, and the temperature sensor can detect the water temperature in the sterilization tank accurately so as to guarantee the sterilization effect; the pasteurization machine has the characteristics of simple structure and high practicability.

Owner:CHENGDU FANXINJIA TECH

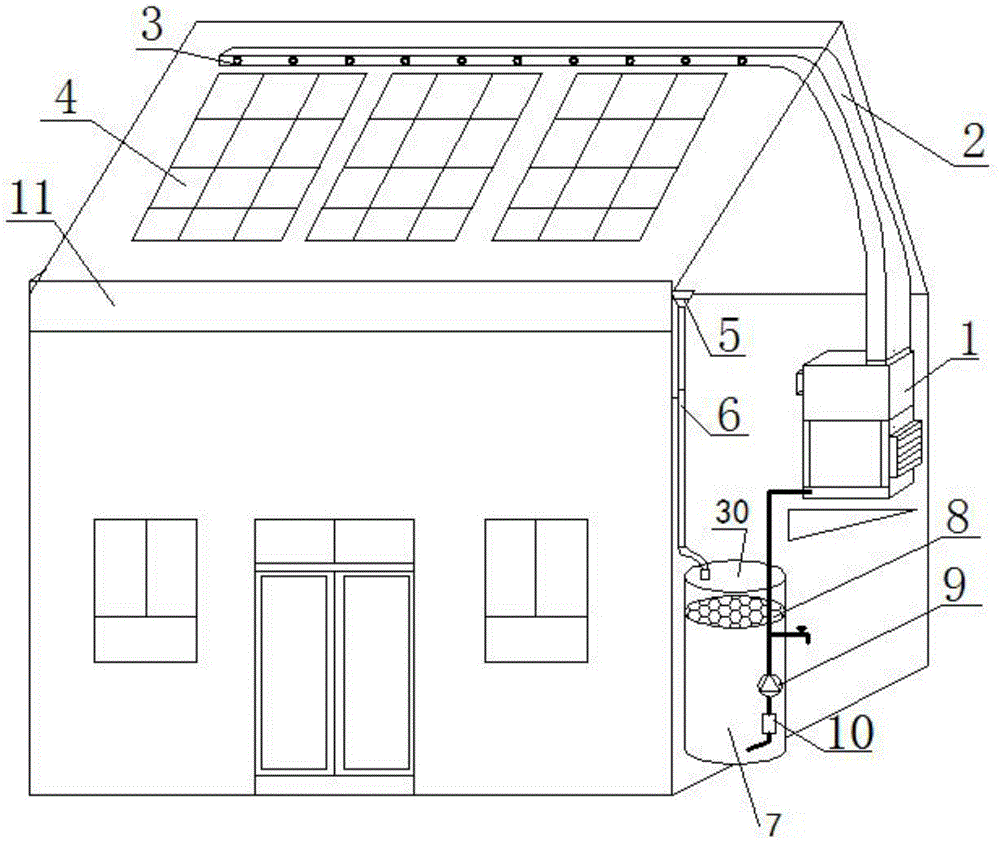

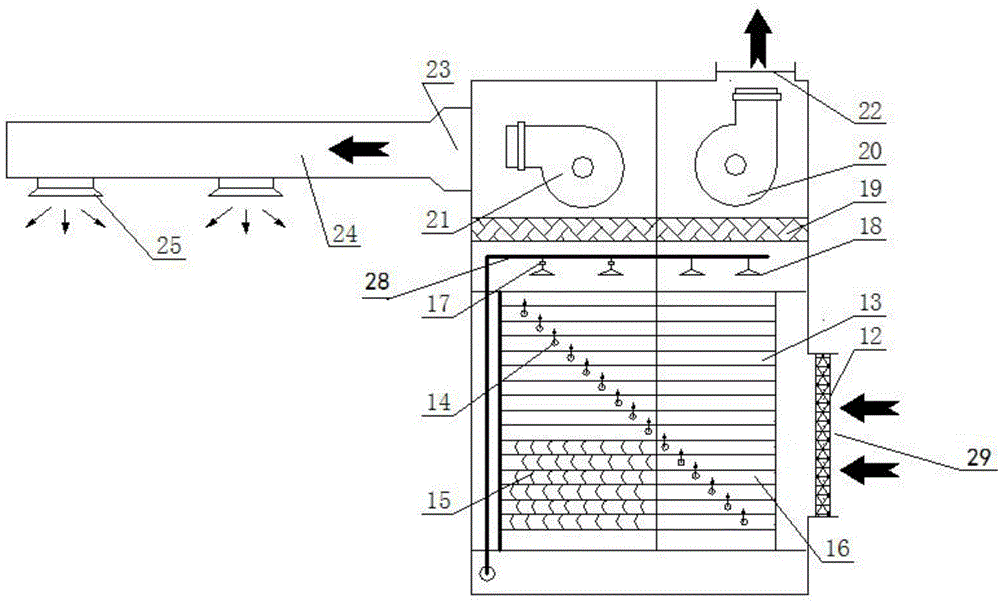

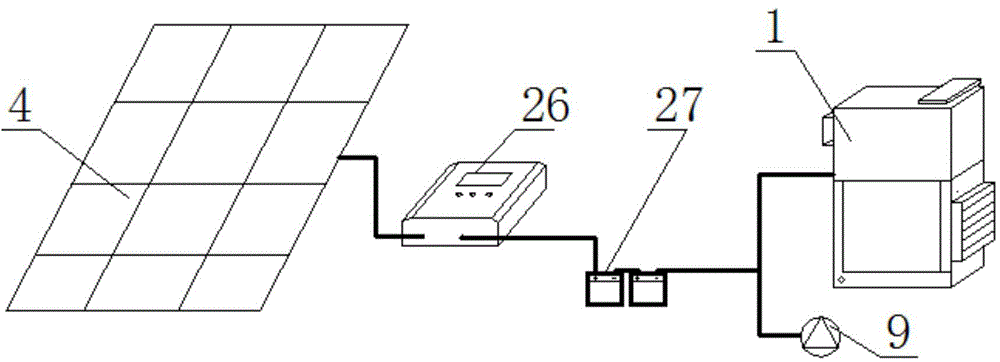

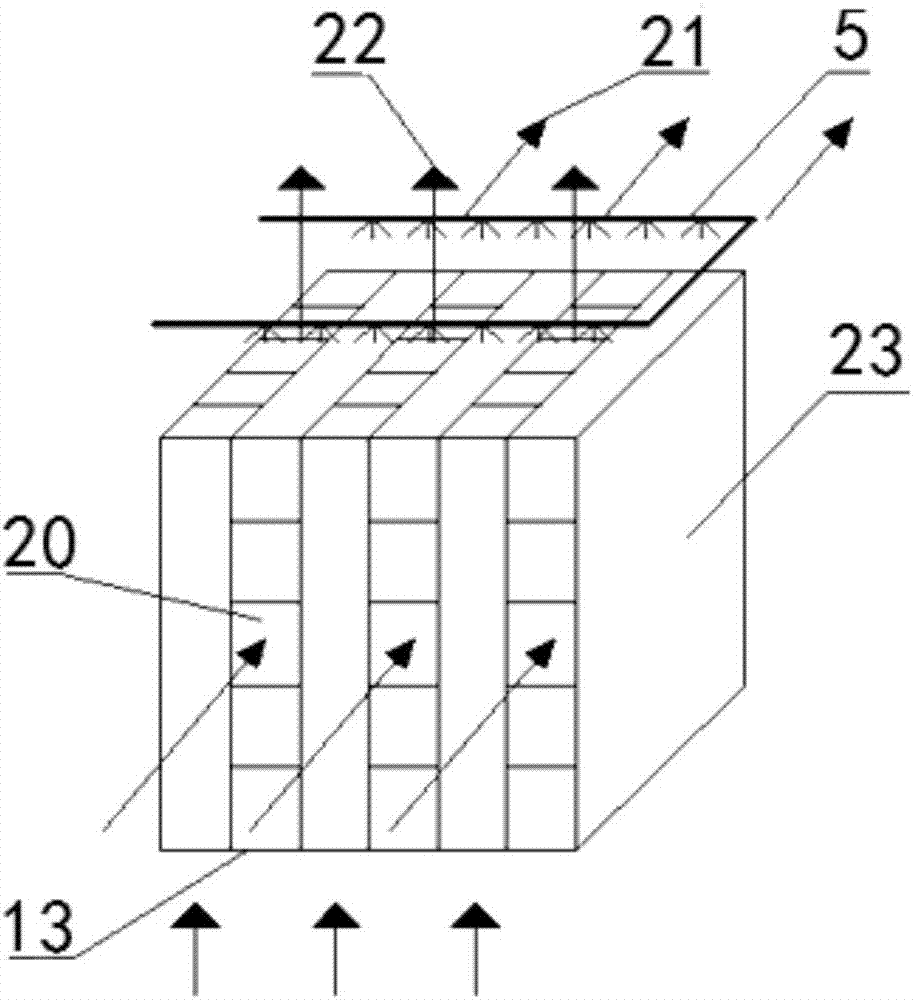

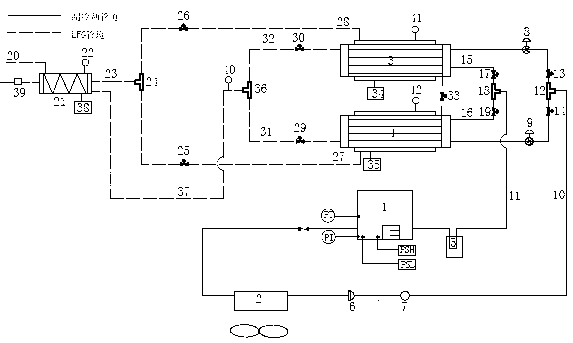

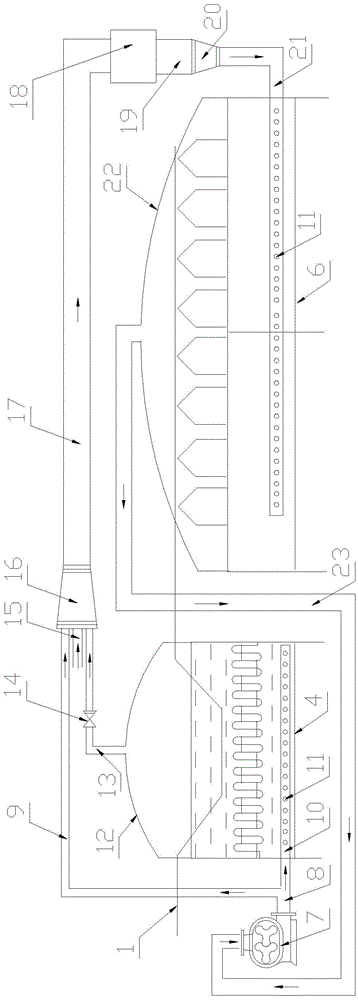

Photovoltaic-drive evaporation cooling air conditioner system integrating recycling of rain water

InactiveCN104566711AImprove pre-cooling effectRealize cascade utilizationDucting arrangementsLighting and heating apparatusElectricityEvaporation

The invention discloses a photovoltaic-drive evaporation cooling air conditioner system integrating recycling of rain water. The photovoltaic-drive evaporation cooling air conditioner system comprises a combined type evaporation cooling air conditioner, wherein the combined type evaporation cooling air conditioner is respectively connected with a rain water recycling use system and a photovoltaic power generation system. According to the photovoltaic-drive evaporation cooling air conditioner system integrating the recycling of the rain water, the solar energy and rain water can be adequately utilized, the water and electricity can be effectively saved, and a good refrigerating effect can be achieved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

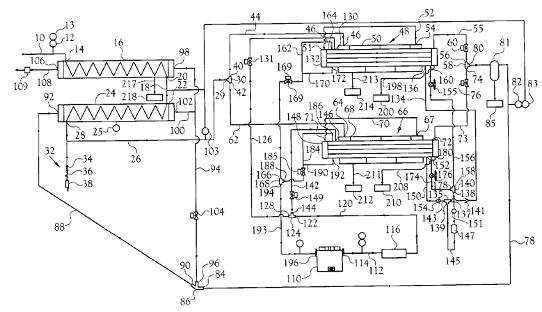

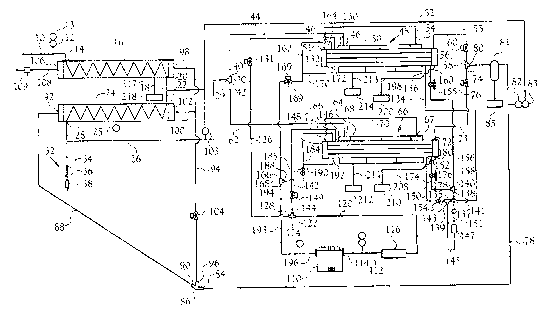

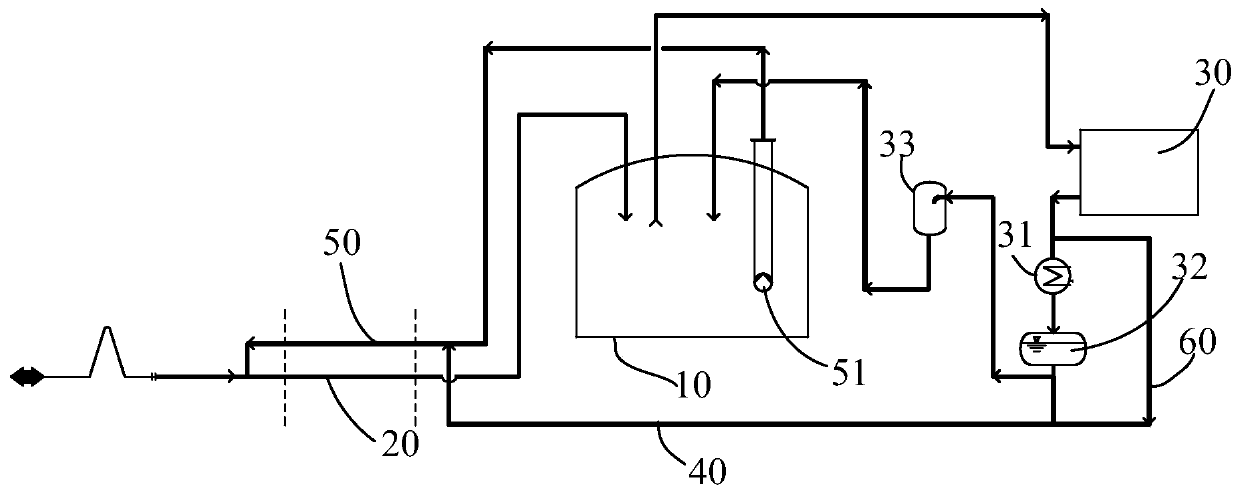

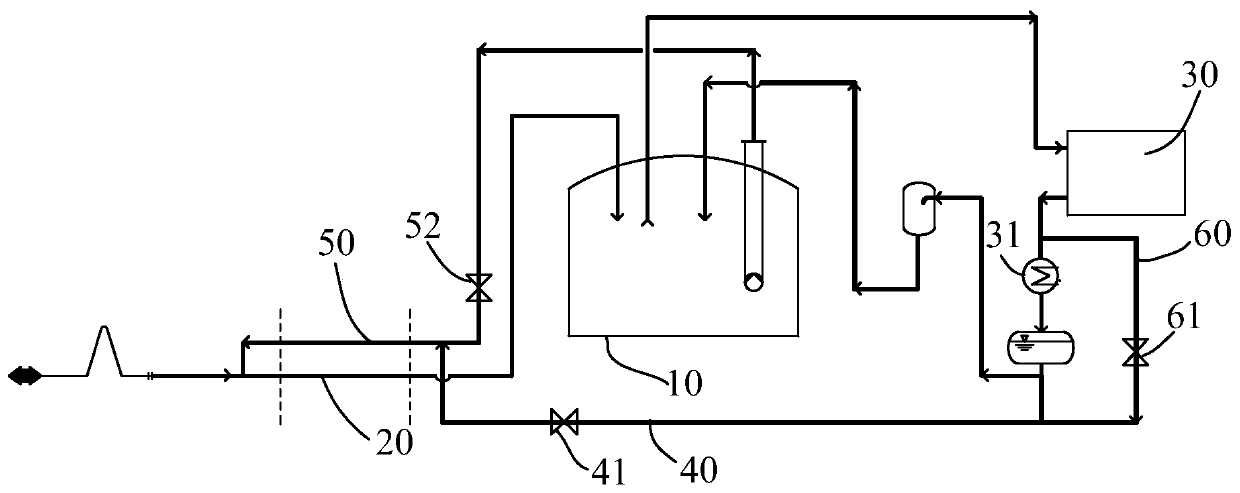

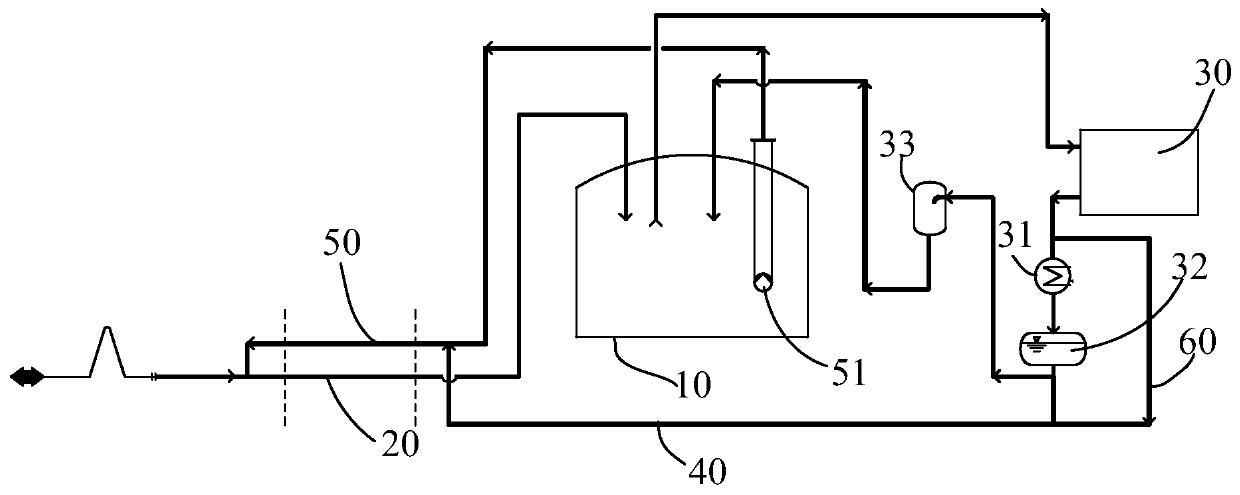

Device capable of removing siloxane in combustible gas stably and continuously

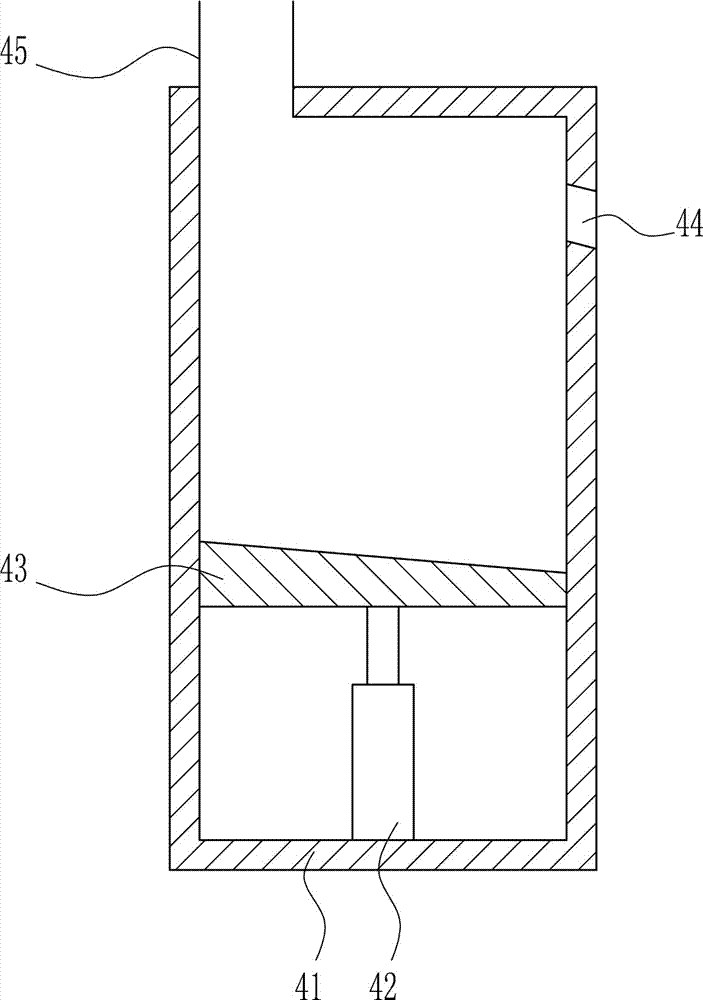

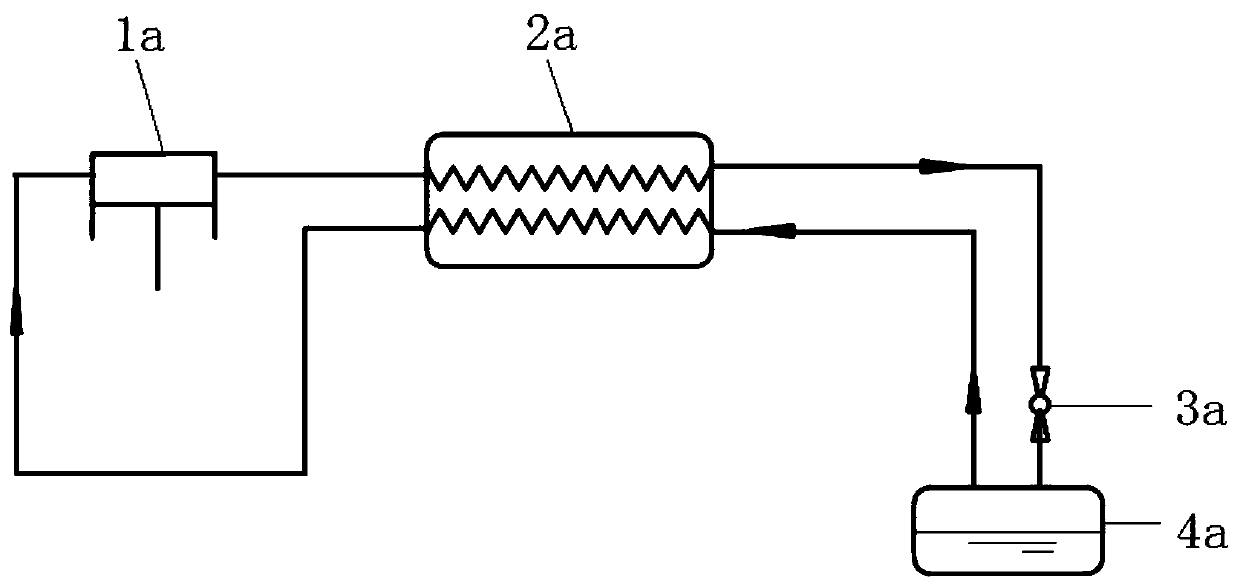

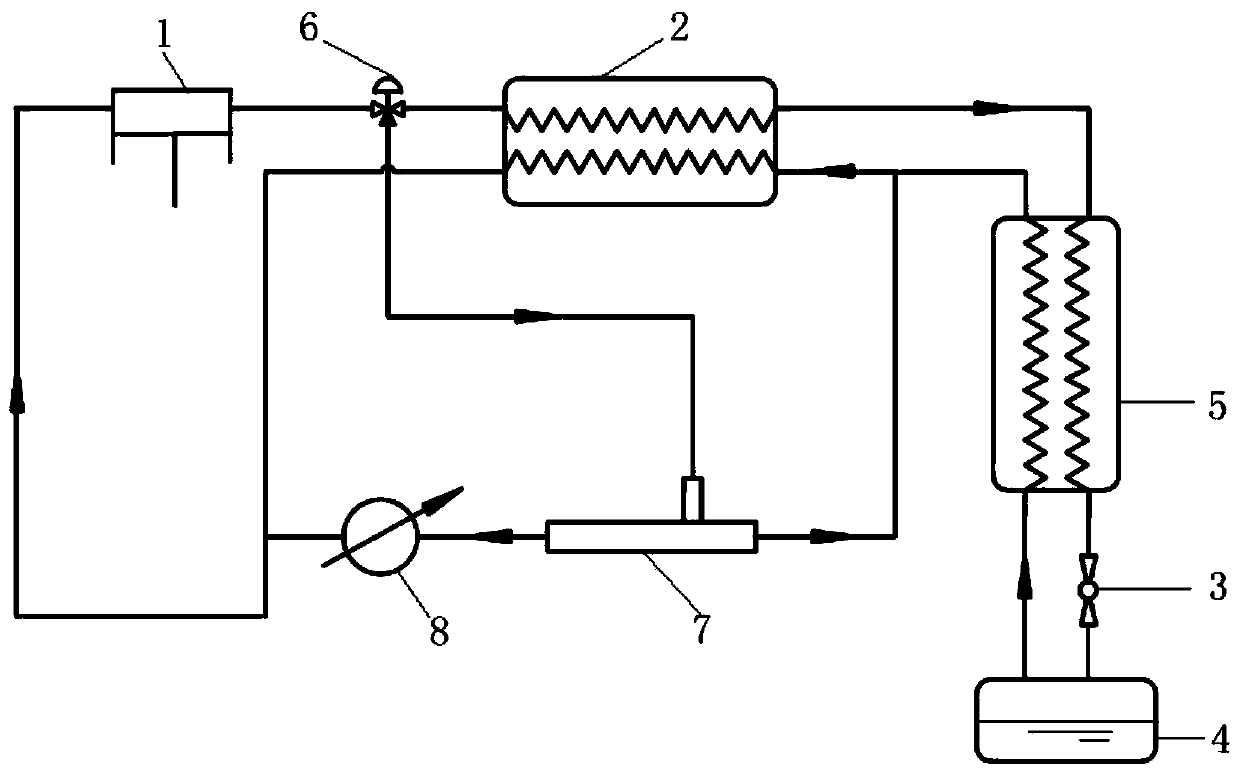

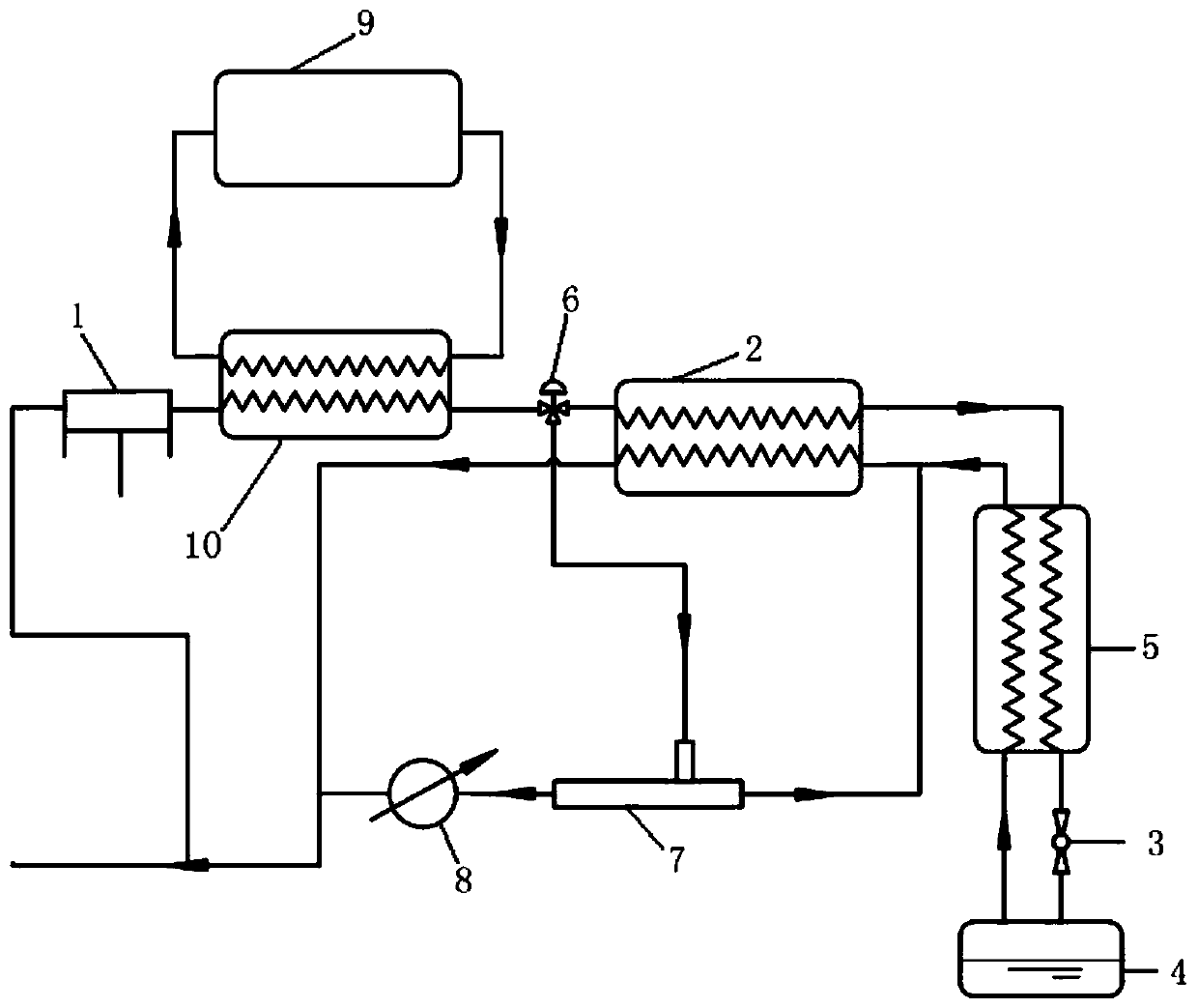

InactiveCN102382701AGood pre-cooling effectImprove defrosting effectGaseous fuelsWaste based fuelPre coolingSewage discharge

The invention discloses a device capable of removing siloxane in combustible gas stably and continuously, which belongs to the field of utilization and purification of renewable energy sources. The device comprises a refrigeration cycle, a landfill gas circulation system and a monitoring and control system, and particularly comprises a compressor, a gas-liquid separator, a condenser, two evaporators in parallel connection, an expansion valve, a drying filter, a liquid viewer, a pre-cooling heat exchanger, a sewage discharging device, a temperature sensing device, a pressure gauge, a pluralityof valves and pipelines. A novel defrosting method of self-defrosting of incoming gas is provided, refrigeration and defrosting can be operated independently and simultaneously, and effective defrosting is achieved while stable operation of the refrigeration system can be guaranteed. Meanwhile, due to the precise control system, the temperature of the landfill gas can be kept within a set temperature in the whole treatment process, and impurities such as siloxane, water and the like in the landfill gas can be removed stably, continuously and effectively.

Owner:NANJING NORMAL UNIVERSITY +1

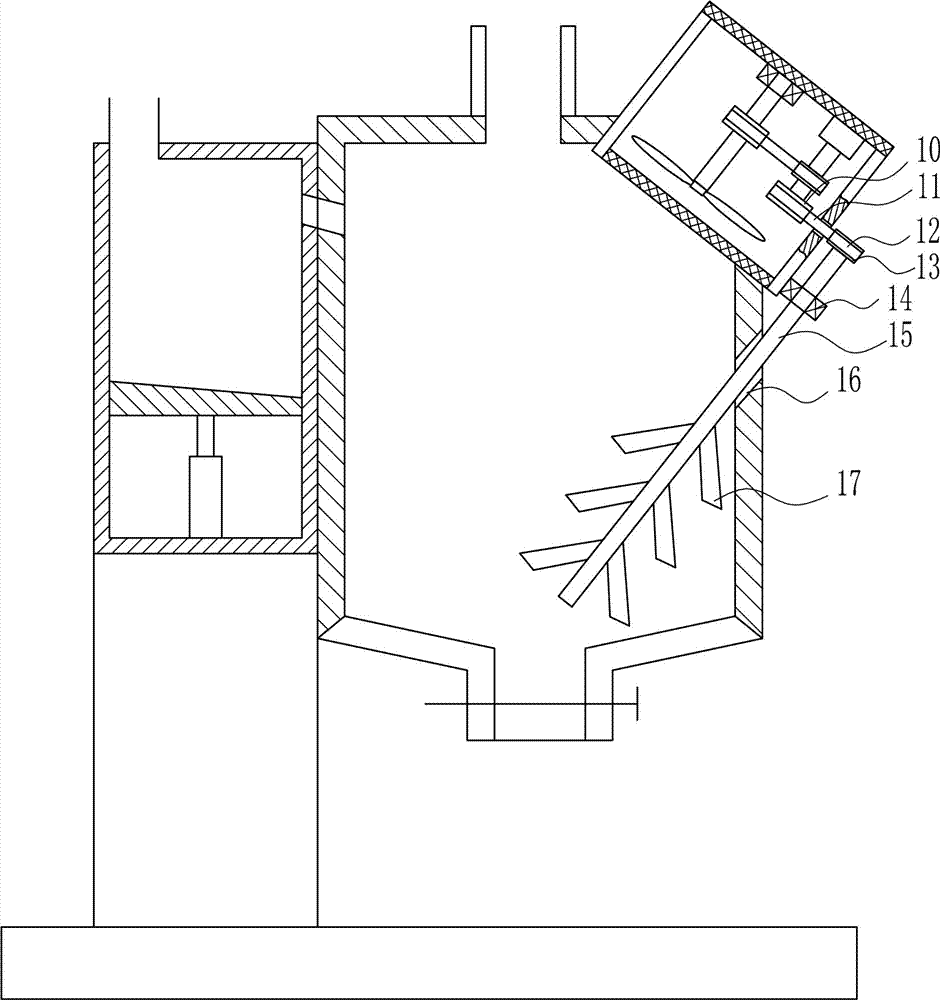

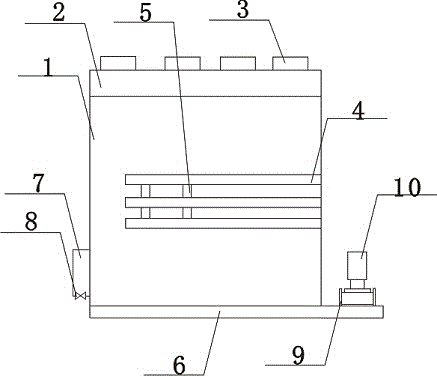

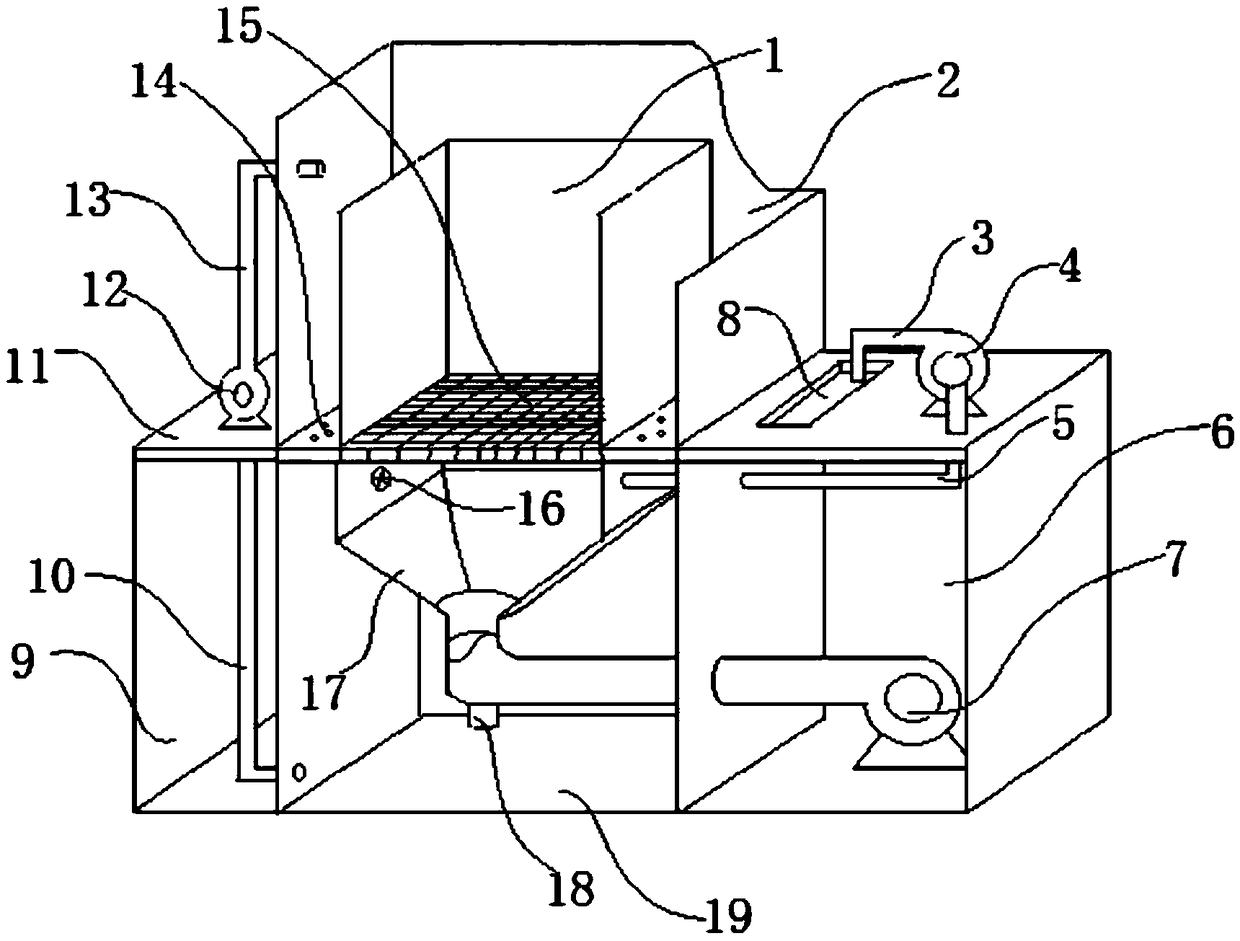

Concrete aggregate precooling device

The invention relates to a precooling device, in particular to a concrete aggregate precooling device, and aims to provide a concrete aggregate precooling device. In order to solve the technical problem, the invention provides the concrete aggregate precooling device. The concrete aggregate precooling device comprises a pedestal, a bracket, a cooling tank, an ice cooling device, a blow cooling device and the like, wherein the bracket is arranged on the left side of the top of the pedestal; the ice cooling device is arranged at the top of the bracket; the cooling tank is arranged on the right side of the ice cooling device; a first material feeding hopper is arranged at the middle of the cooling tank; a first opening is formed in the left wall of the cooling tank; the blow cooling device is arranged at the upper part of the right wall of the cooling tank; a material discharging hopper is arranged at the bottom of the cooling tank; and a valve is arranged on the material discharging hopper. The concrete aggregate precooling device achieves effects of maximizing the concrete aggregate cooling efficiency with various modes and cyclically using water. The device is high in practicability, obvious in precooling effect and worthy of being popularized.

Owner:中山市三和混凝土有限公司

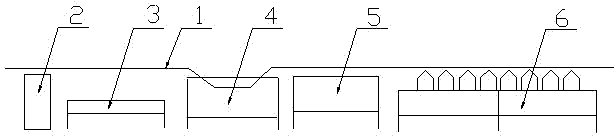

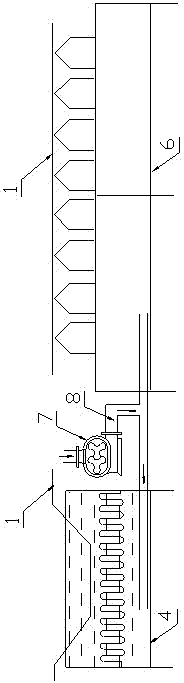

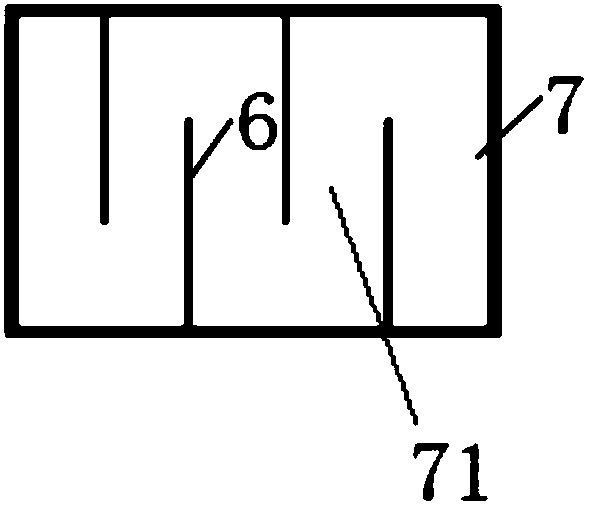

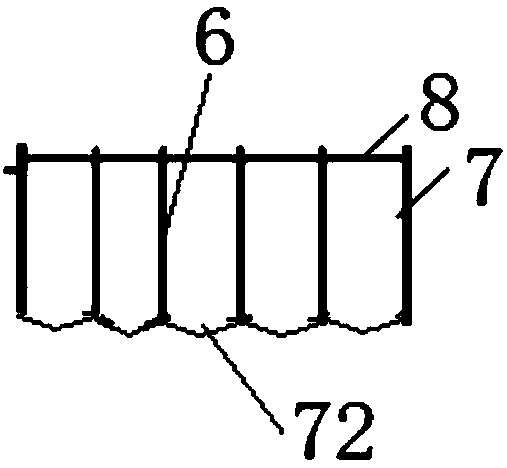

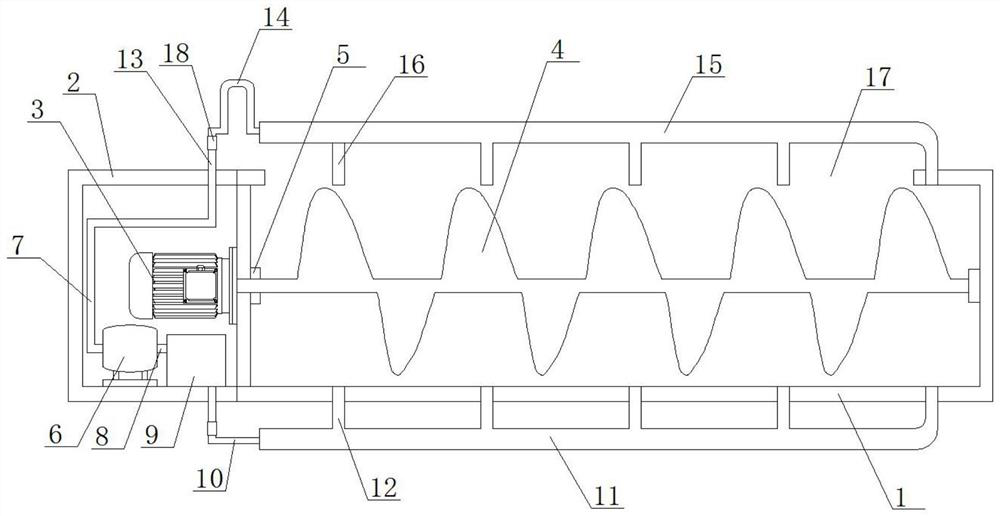

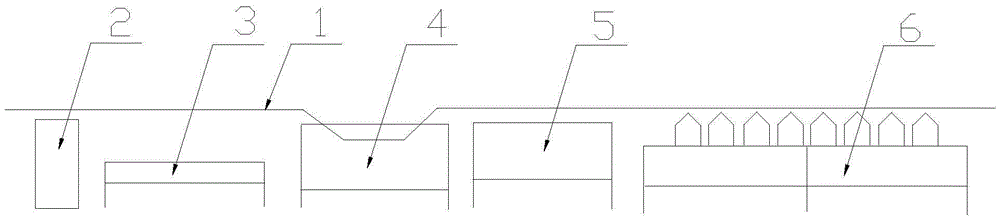

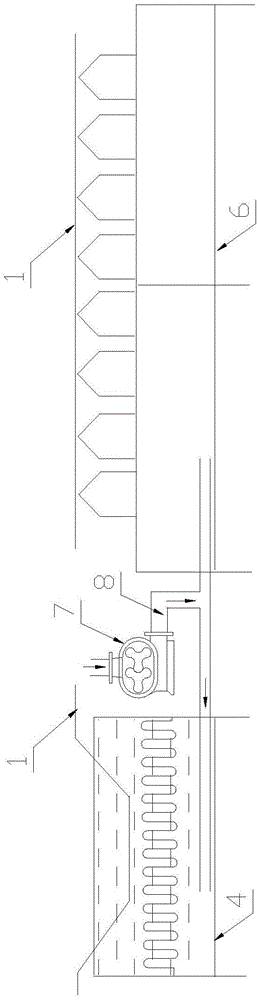

Roots blower slaughtering production line

ActiveCN104705381AFast gas flowEasy to inhalePoultry processingProduction lineAgricultural engineering

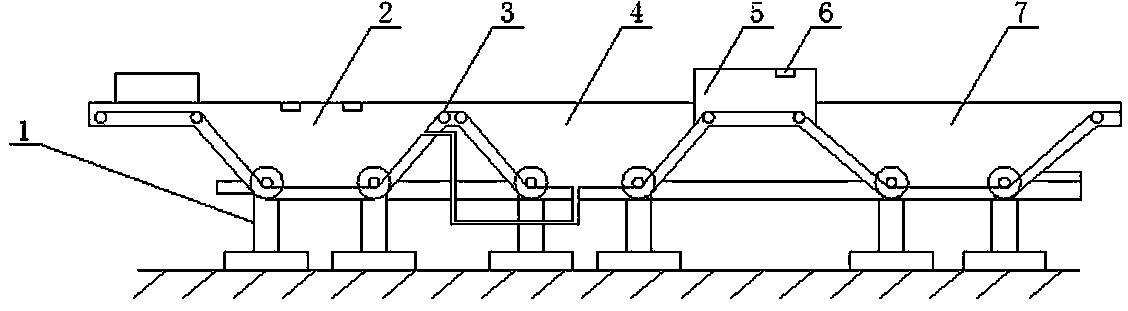

The invention discloses a roots blower slaughtering production line which comprises a suspension conveying line (1), wherein an electrical stunning machine (2), a bloodletting groove (3), a livestock scalding tank (4), a depilator (5) and a spiral precooling machine (6) are sequentially arranged on the suspension conveying line (1); a roots blower (7) is adopted to blow wind to the livestock scalding tank (4) and a first diameter variable connector (16) respectively; returned air of the livestock scalding tank (4) and the fresh air of a fourth air tube (15) are gathered through the first diameter variable connector (16), are fed into a refrigerating device (18) for cooling, and are further conveyed to the spiral precooling machine (6); returned air of the spiral precooling machine (6) is collected through the roots blower (7) by using a return air tube (23). The roots blower (7) is adopted to replace a plurality of spiral air pumps, so that the cost and time for equipment maintenance can be reduced, the roots blower (7) is long in service life, the air can be prevented from flowing back but is completely conveyed to areas requesting air, and the consumption caused by small pressure of the spiral air pump can be reduced.

Owner:SHANDONG ZHANGQIU HUADONG BLOWER

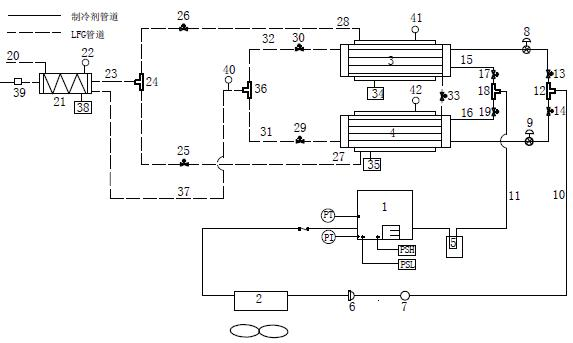

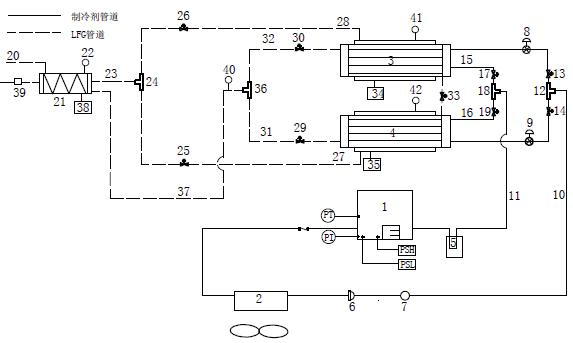

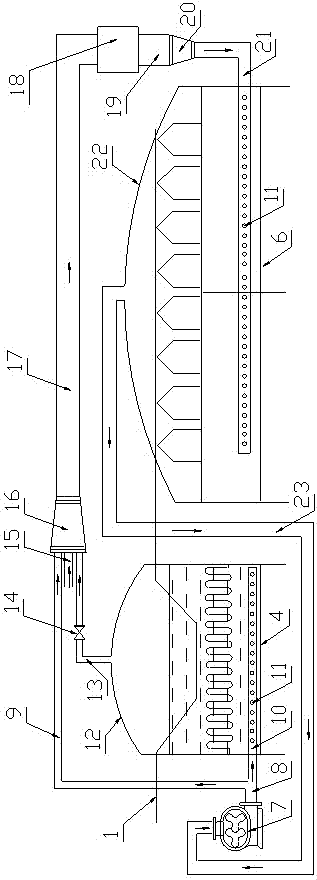

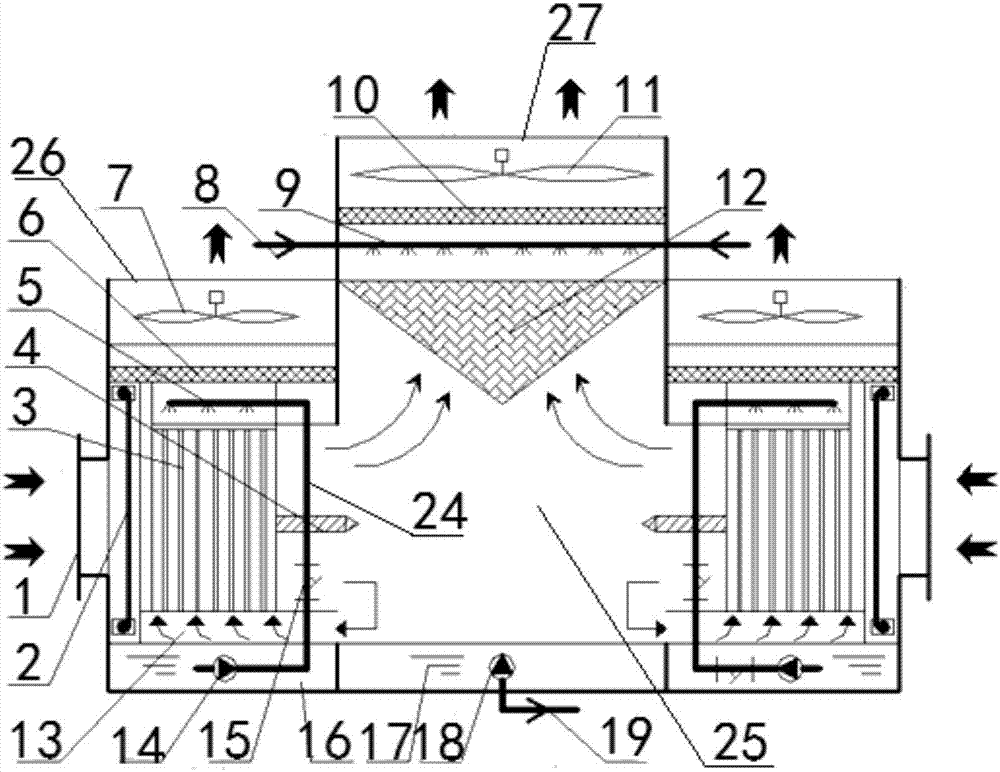

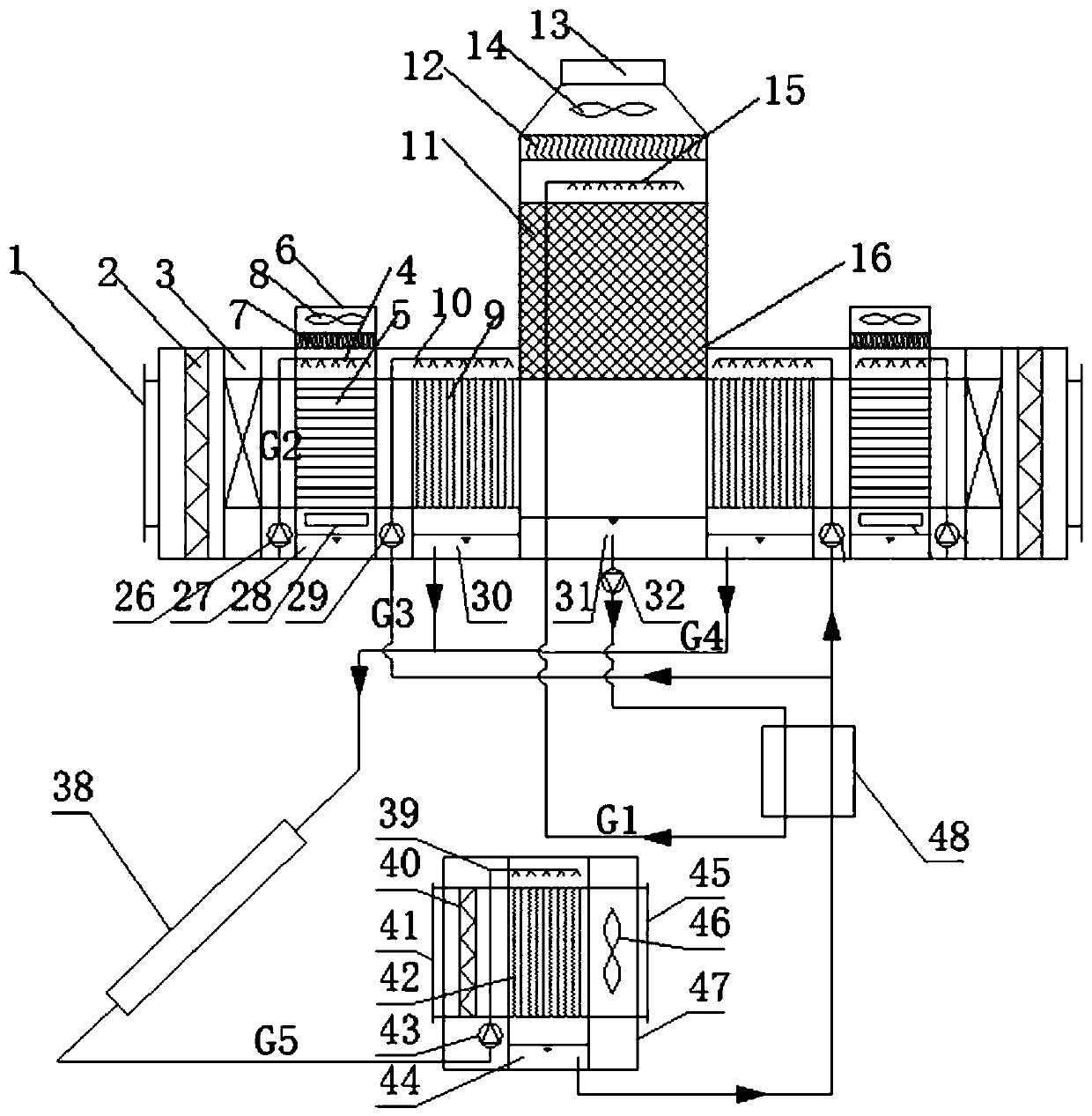

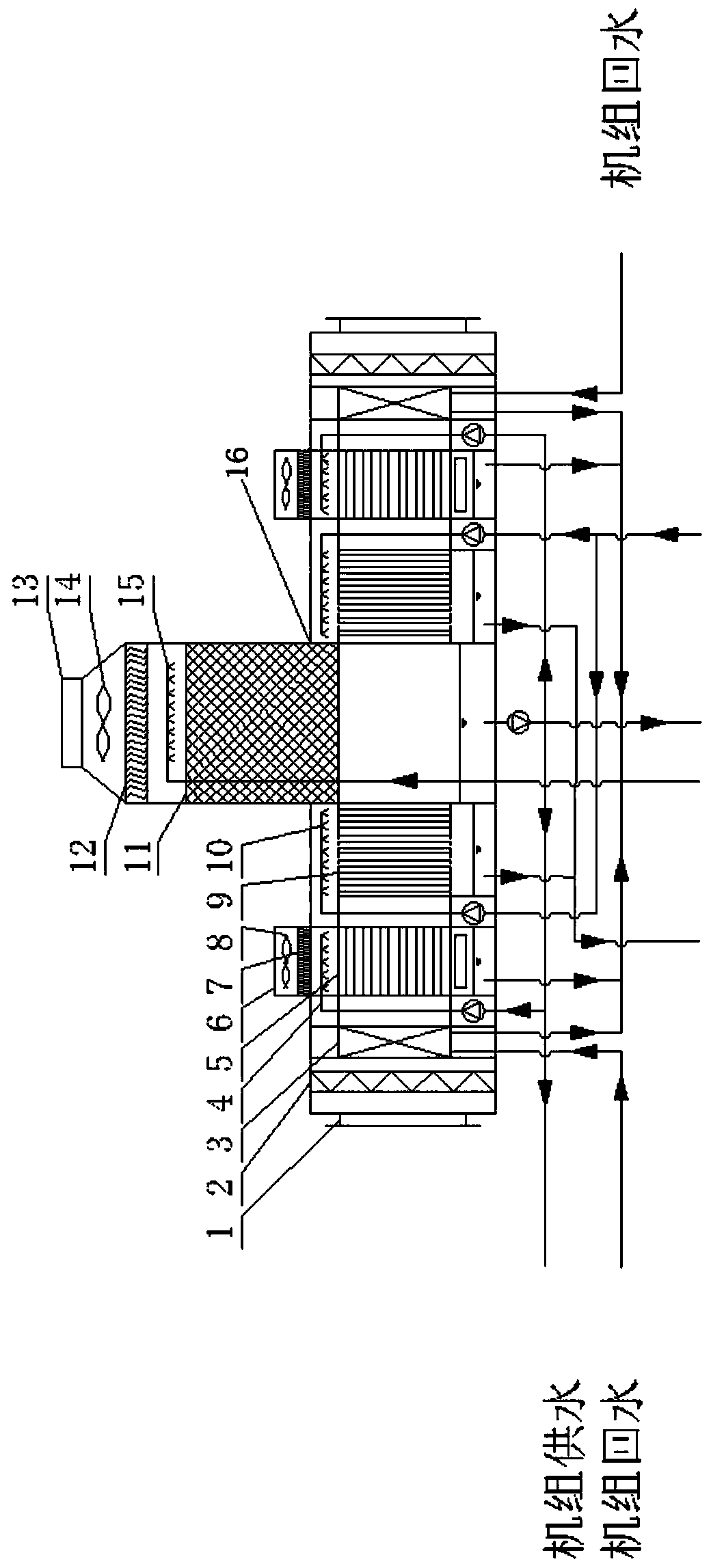

Evaporative cooling water-chilling unit applying plate-fin indirect evaporative coolers

ActiveCN107543264ACompact structureReduce weightLighting and heating apparatusSpace heating and ventilation detailsEvaporative coolerEngineering

The invention discloses an evaporative cooling water-chilling unit applying plate-fin indirect evaporative coolers. The evaporative cooling water-chilling unit comprises a unit shell body, wherein a fresh air inlet port is formed in the two opposite sidewalls of the unit shell body separately, a packed tower is arranged at the centre in the unit shell body, one plate-fin indirect evaporative cooler is arranged between the packed tower and one fresh air inlet port, and one plate-fin indirect evaporative cooler is also arranged between the packed tower and the other fresh air inlet port; an airexhaust port b is formed in the corresponding top of the unit shell body above the packed tower; and an air exhaust port a is formed in a part corresponding to each plate-fin indirect evaporative cooler, on the top wall of the unit shell body. The evaporative cooling water-chilling unit disclosed by the invention has the characteristics of being good in heat exchange effect, small in size and notliable to scale in use.

Owner:ZHEJIANG JINLING REFRIGERATION ENG

Device capable of removing siloxane in combustible gas stably and continuously

InactiveCN102382701BImprove pre-cooling effectImprove defrosting effectGaseous fuelsWaste based fuelPre coolingSewage discharge

The invention discloses a device capable of removing siloxane in combustible gas stably and continuously, which belongs to the field of utilization and purification of renewable energy sources. The device comprises a refrigeration cycle, a landfill gas circulation system and a monitoring and control system, and particularly comprises a compressor, a gas-liquid separator, a condenser, two evaporators in parallel connection, an expansion valve, a drying filter, a liquid viewer, a pre-cooling heat exchanger, a sewage discharging device, a temperature sensing device, a pressure gauge, a plurality of valves and pipelines. A novel defrosting method of self-defrosting of incoming gas is provided, refrigeration and defrosting can be operated independently and simultaneously, and effective defrosting is achieved while stable operation of the refrigeration system can be guaranteed. Meanwhile, due to the precise control system, the temperature of the landfill gas can be kept within a set temperature in the whole treatment process, and impurities such as siloxane, water and the like in the landfill gas can be removed stably, continuously and effectively.

Owner:NANJING NORMAL UNIVERSITY +1

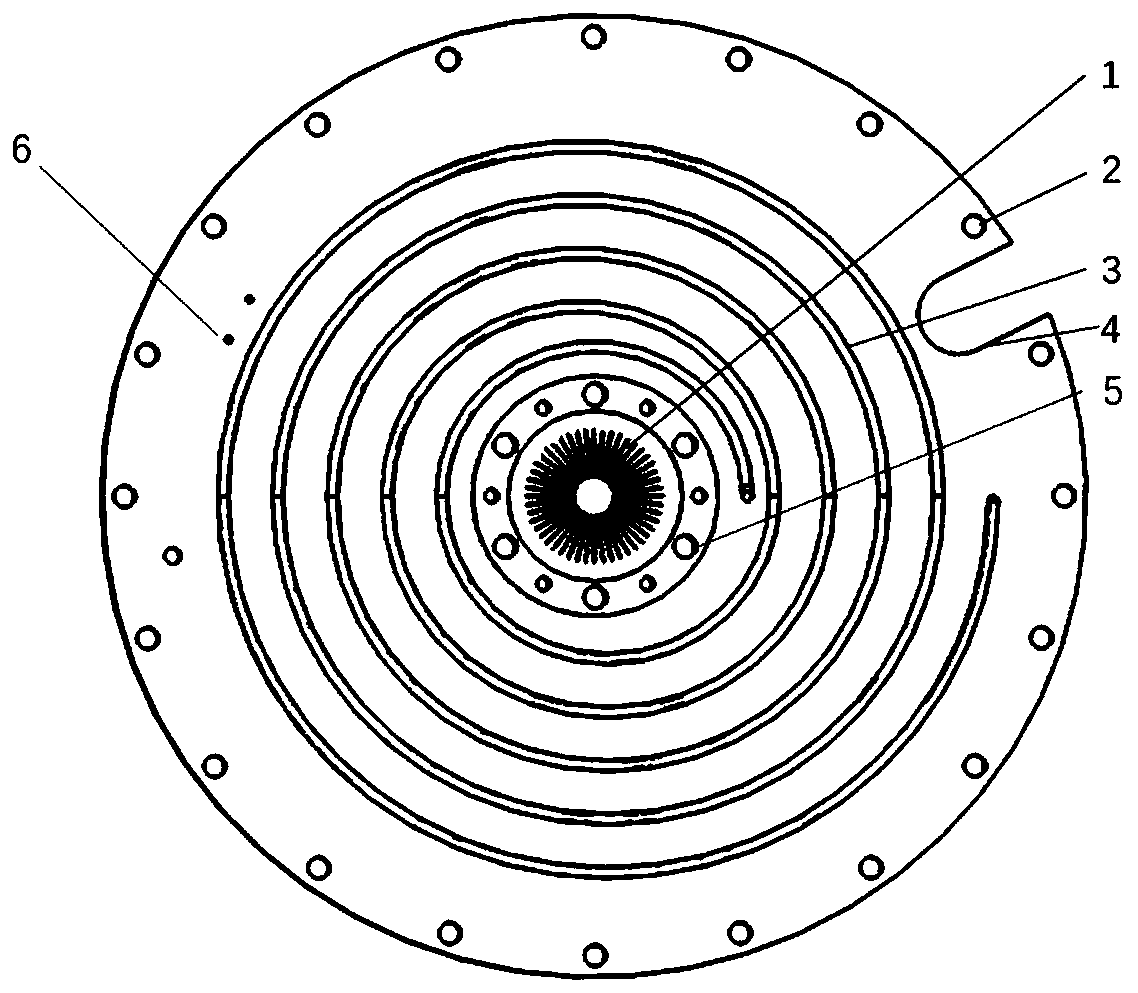

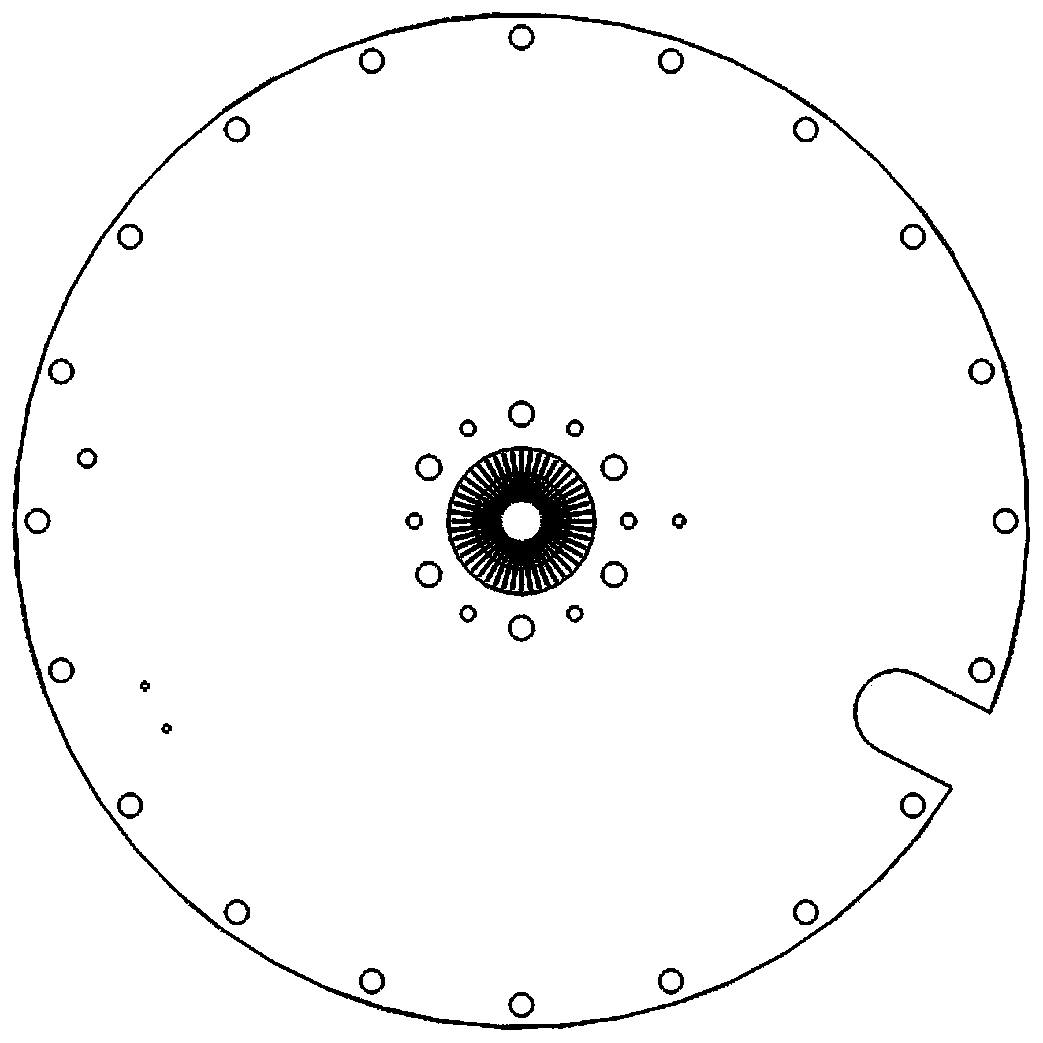

Multifunctional low-temperature scroll plate pre-cooling heat exchanger

PendingCN110749115AIncrease the heat exchange areaConvenient ArrangementCompression machinesRadiation leakageCooling effect

The invention discloses a multifunctional low-temperature scroll plate pre-cooling heat exchanger. The multifunctional low-temperature scroll plate pre-cooling heat exchanger includes an intermediateslit structure, a threaded hole, a spiral groove, a U-shaped groove, a fixing hole and a temperature measuring and heating threaded hole. The heat exchanger is applied to a pre-cooling unit of a pre-cooling type JT refrigerator for a liquid helium temperature zone and a room temperature zone. The heat exchanger can not only directly replace a cold head of a pre-cooler, but also can be used as a supporting bottom plate of a cold screen. The intermediate slit structure increases the heat exchange area, so that the pre-cooling efficiency is greatly improved. The spiral groove is in interference fit with a high-pressure pipeline to pre-cool high-pressure and high-temperature helium. The surface of the heat exchanger is plated with a micron-level thin gold layer to reduce radiation leakage heatloss. The U-shaped groove facilitates the arrangement of pipelines and wires, and can further be used as heat sink of the wires from the liquid helium temperature zone to the room temperature zone. The multiple functions of the cold head of the pre-cooler, the support of the cold screen, the pre-cooling of high-pressure fluid and the heat sink of the wires are integrated, the structure is compact, the contact thermal resistance between the pre-cooler and the heat exchanger is reduced, the pre-cooling effect of a refrigerator is enhanced, and the pre-cooling efficiency is improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

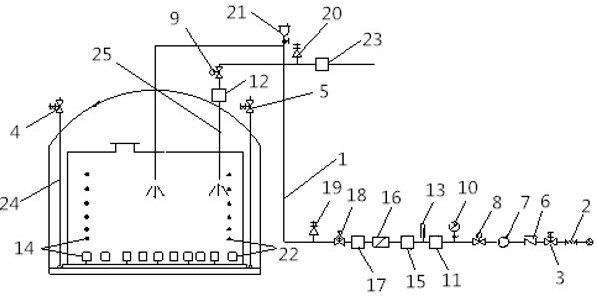

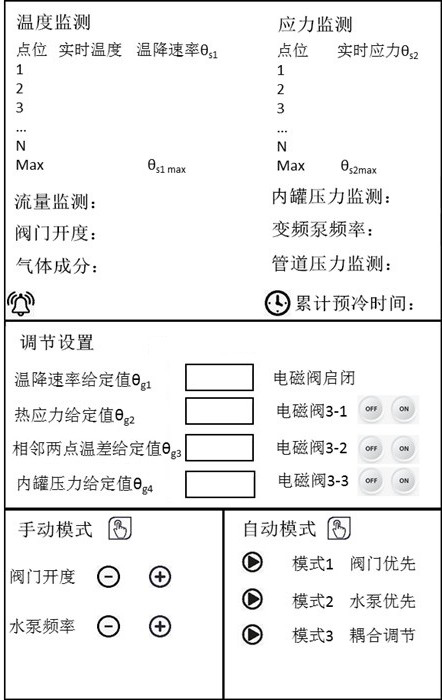

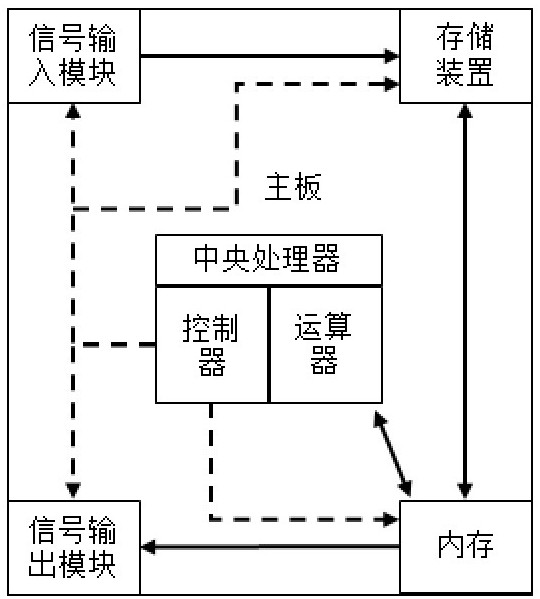

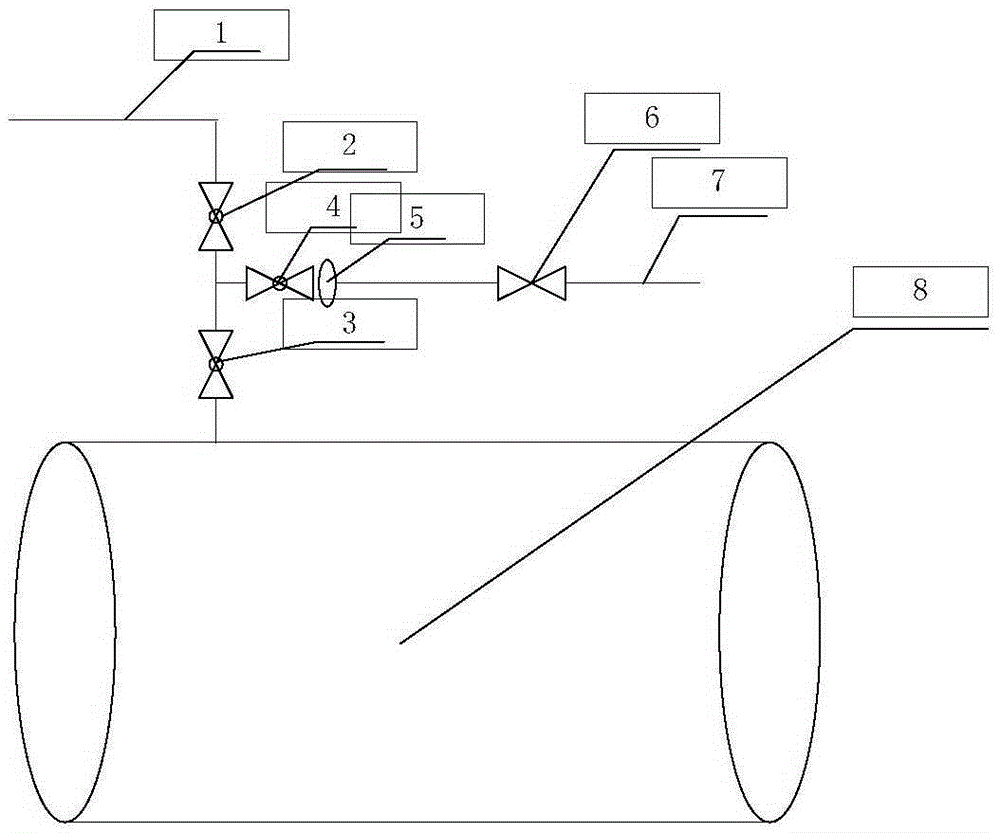

LNG storage tank automatic pre-cooling system based on efficient communication and pre-cooling method

ActiveCN113339695ASolve blindnessImprove pre-cooling effectFluid handling accessoriesContainer discharging methodsMaterial resourcesElectric control

The invention provides an LNG storage tank automatic pre-cooling system based on efficient communication and a pre-cooling method. A CFD numerical simulation module is used for conducting pre-cooling process simulation, and initial flow parameters are provided for the pre-cooling process; and the point positions are installed on a storage tank in a modularized manner, and signal transmission between all sensors in the pre-cooling system and an integrated operation platform is achieved through 5G technology. According to the LNG storage tank automatic pre-cooling system and the pre-cooling method, limit values of parameters such as temperature drop rate, thermal stress, temperature difference between two adjacent points, inner tank pressure and the like are set on the basis of the integrated operation platform, monitoring results and the limit values are compared and analyzed, and then an electric control valve module and a variable frequency pump module are automatically adjusted, so that the conveying flow of a pre-cooling medium is adjusted, and it is guaranteed that the pre-cooling process is stably and safely carried out. According to the LNG storage tank automatic pre-cooling system and method, automatic, integrated and integrated control over the pre-cooling process can be achieved, monitoring personnel do not need to be arranged at monitoring points for a long time, potential safety hazards are avoided, manpower and material resources are saved, pre-cooling control is more accurate, and the pre-cooling efficiency is high.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

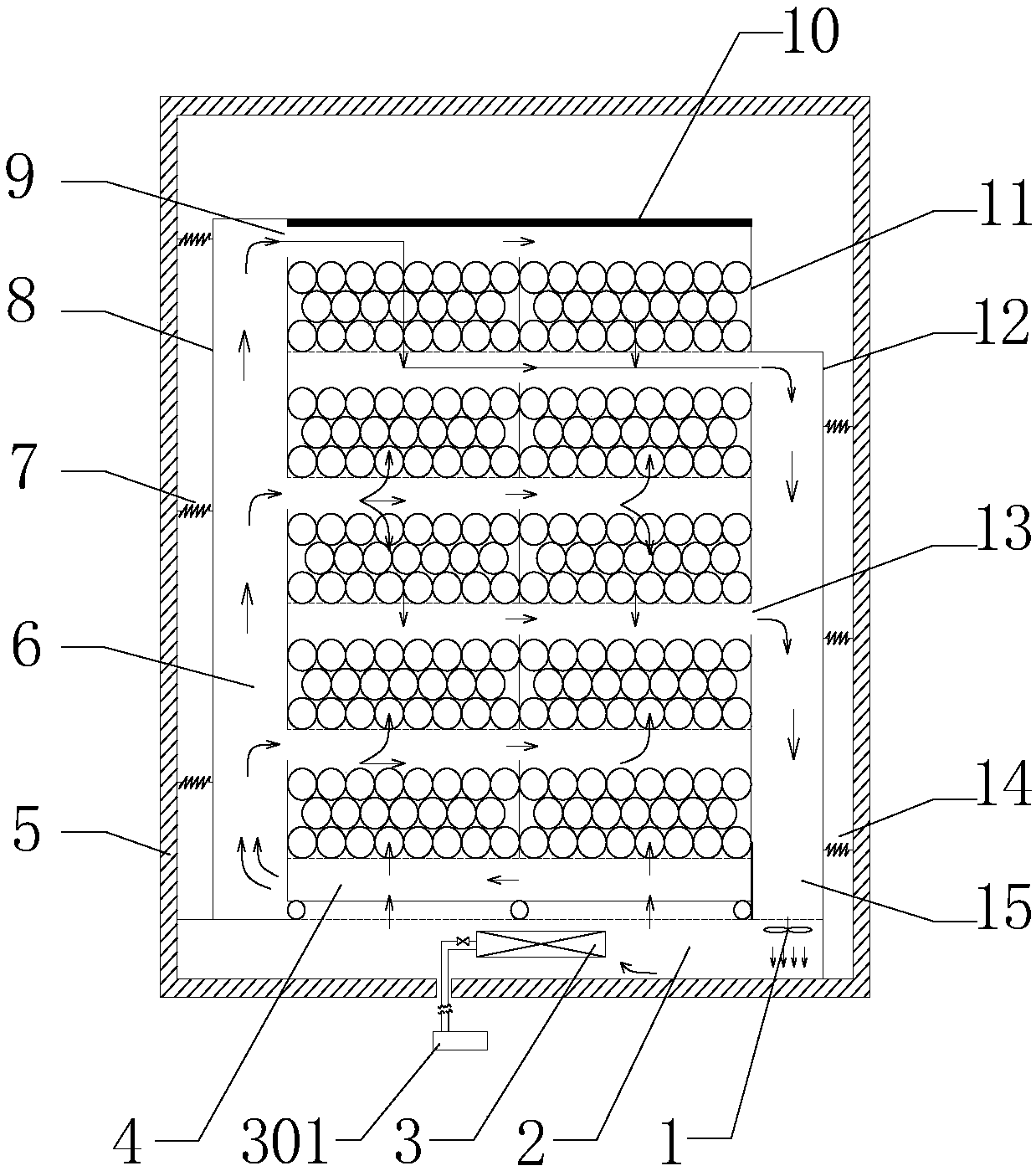

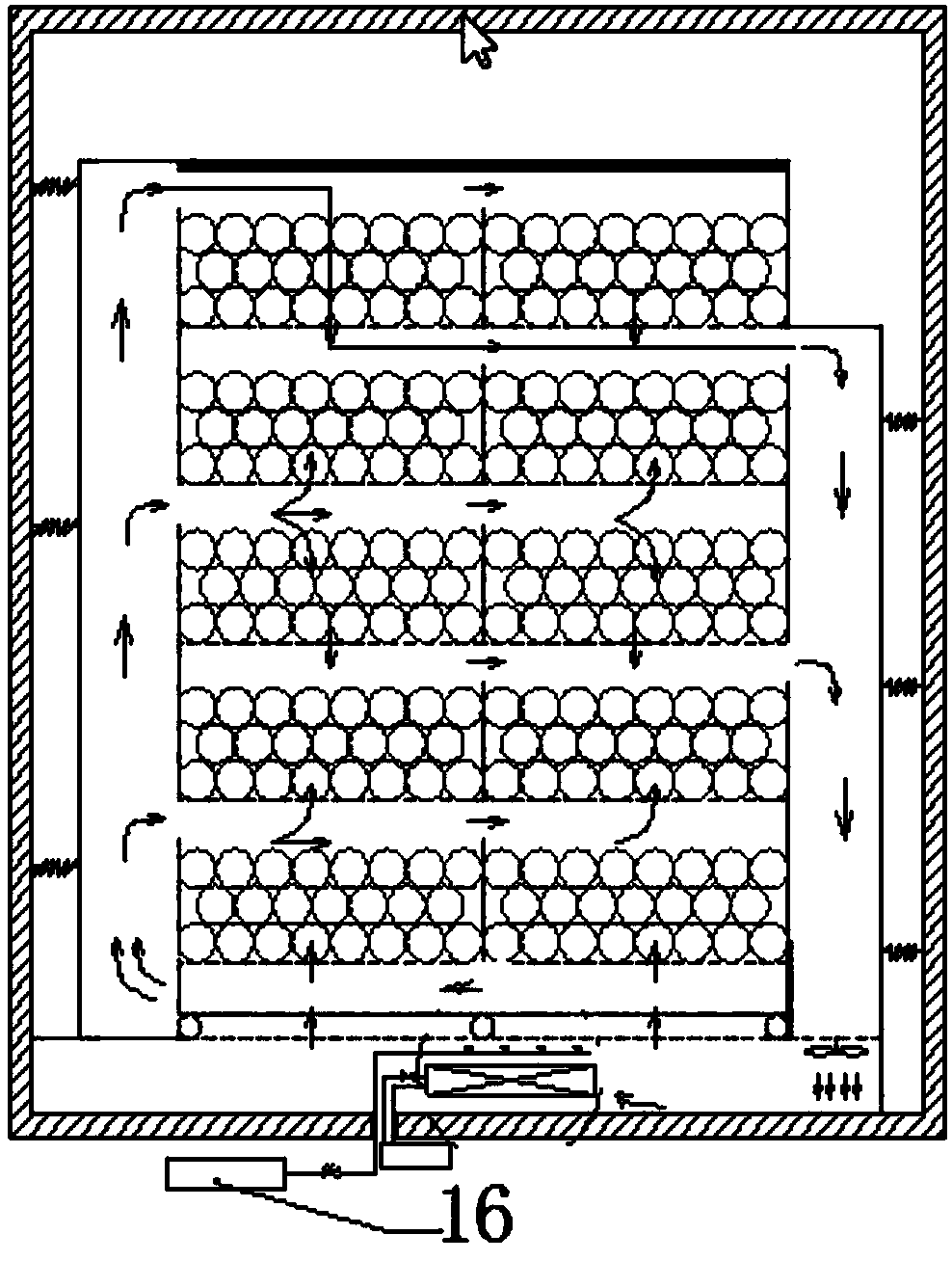

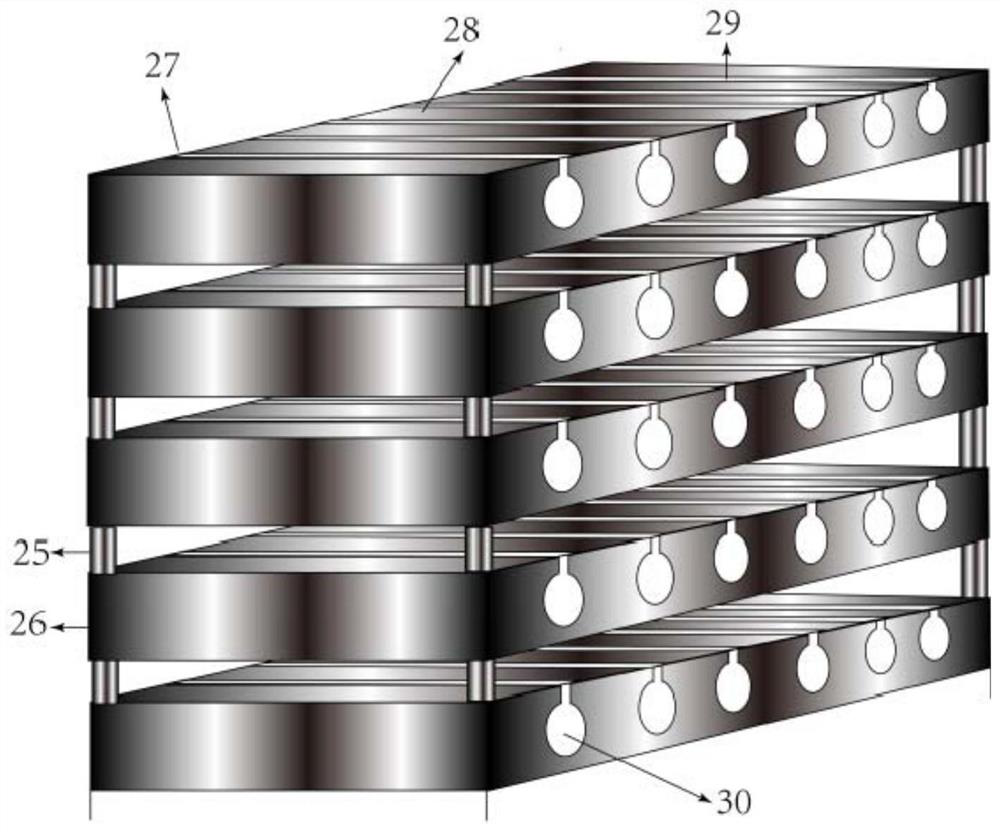

Vertical ventilation differential pressure pre-cooling device for fruits and vegetables

PendingCN108391721AOvercome air short circuitOvercome uniformity issuesFruits/vegetable preservation by freezing/coolingCold airDifferential pressure

The invention discloses a vertical ventilation differential pressure pre-cooling device for fruits and vegetables. The device comprises a refrigeration unit module and a fruit-vegetable pre-cooling module. The refrigeration system module is used for cooling air inside the fruit-vegetable pre-cooling module; and the fruit-vegetable pre-cooling module can perform batch pre-cooling operation on fruits and vegetables. The device can be conveniently installed on a container transportation vehicle and transported to farming area or near a refrigeration house for carrying out pre-cooling work on fruits and vegetables before warehousing, and can carry out movable pre-cooling in transit. With a split-level Z-shaped pre-cooling air channel with sending layers and returning layers, cold air can vertically pass through the fruits and vegetables in a pre-cooling turnover box so as to improve the pre-cooling uniformity, and to avoid the problems of short circuit of air supply and low pre-cooling efficiency. The device is beneficial to reducing the cost of fruit and vegetable fresh-keeping, is beneficial to the wide popularization and application, and has significant production practice significance.

Owner:TIANJIN UNIV OF COMMERCE

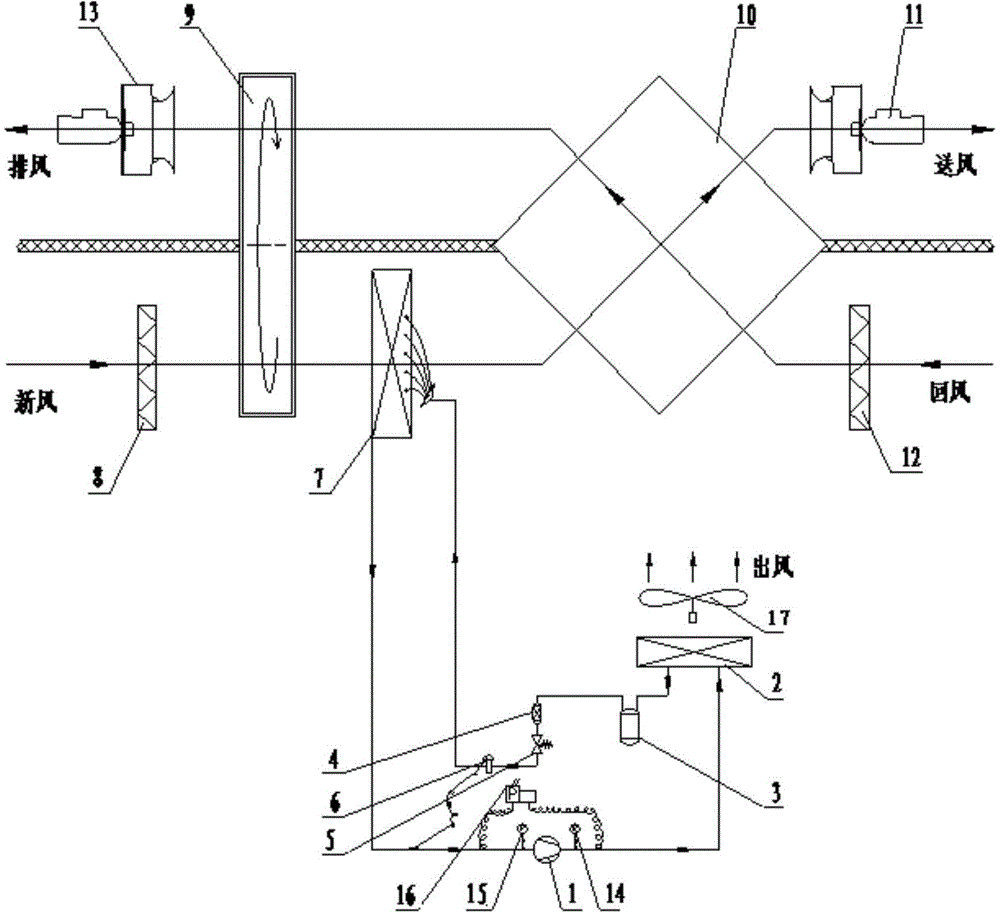

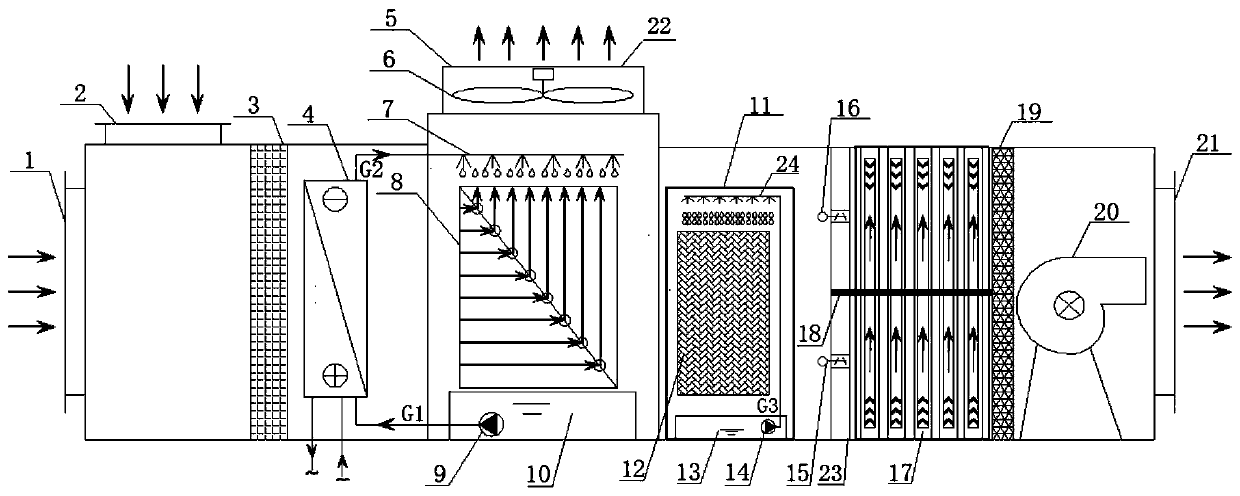

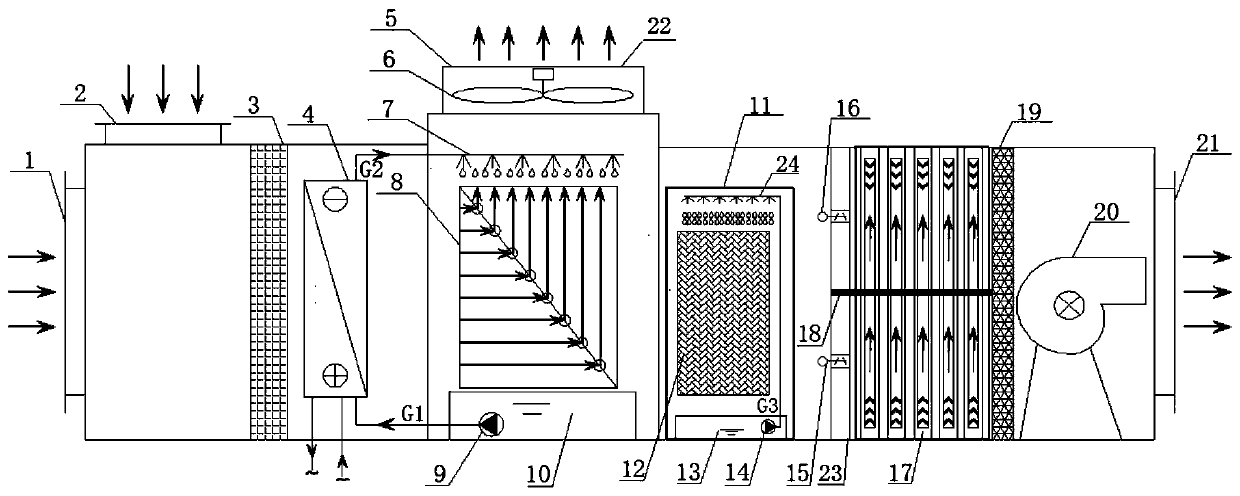

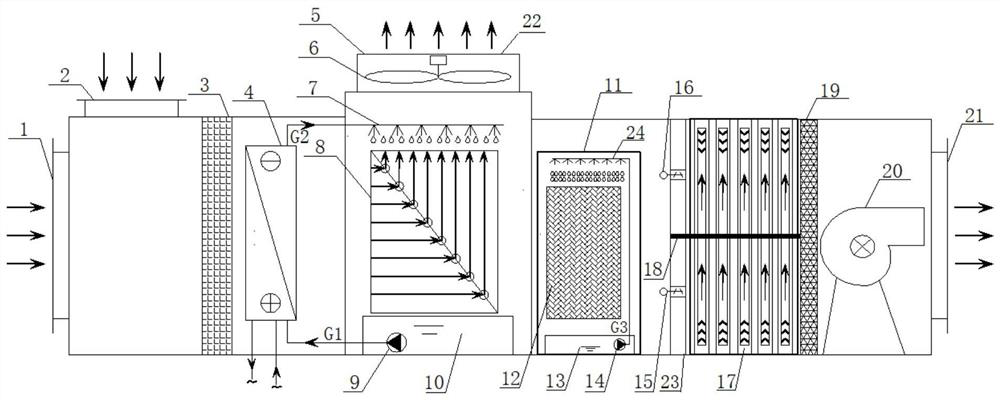

Double-effect energy-saving type roof type air-conditioning unit

ActiveCN104676781AImprove pre-cooling effectReduce loadEnergy recovery in ventilation and heatingMechanical apparatusScale unitFresh air

The invention discloses a double-effect energy-saving type roof type air-conditioning unit, comprising a compressor, a condenser, a liquid reservoir, a drying filter, an electromagnet, a thermostatic expansion valve and an evaporator; the evaporator is connected with the compressor. The double-effect energy-saving type roof type air-conditioning unit not only satisfies the requirement of fresh air treatment, but sufficiently utilizes two energy recycling devices to recycle the energy of exhausted air and plays roles in energy conservation and emission reduction. The double-effect energy-saving type roof type air-conditioning unit can be applied to various commercial or civil buildings such as office buildings, high-grade residential buildings, restaurants and hospitals; and the large-scale unit can be applied to fresh air pretreatment of a central air-conditioner.

Owner:NANJING WUZHOU REFRIGERATION GRP

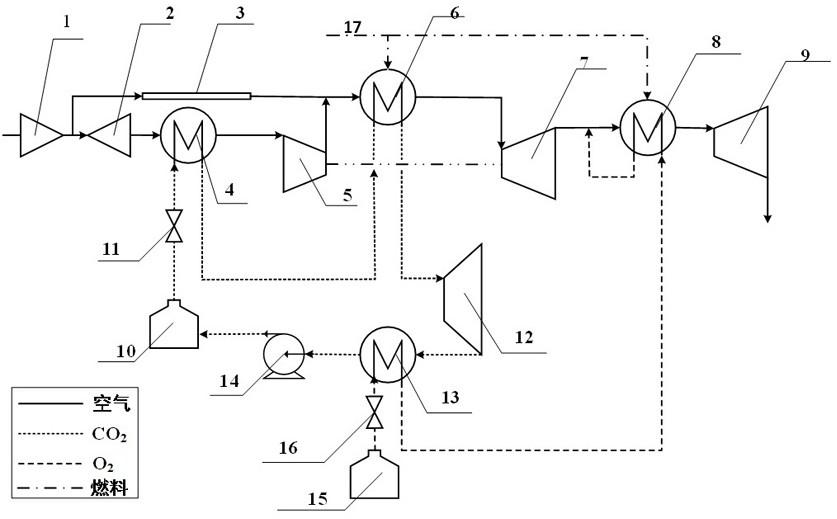

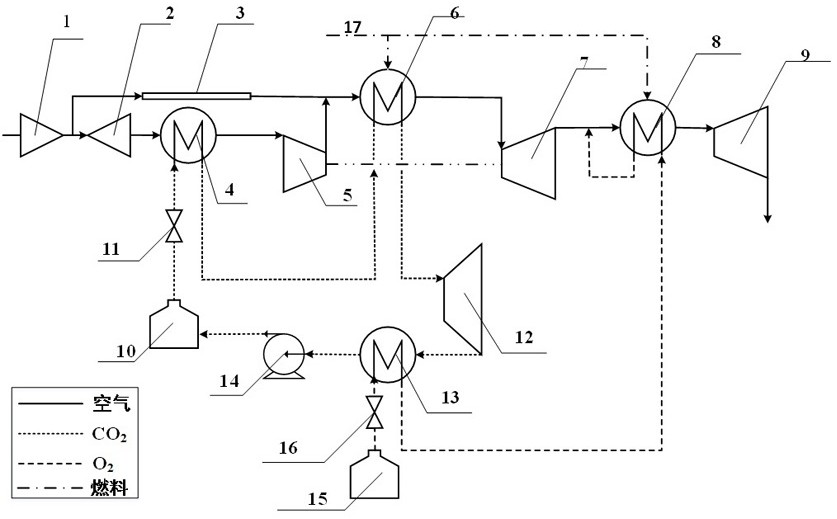

Multi-mode combined power cycle system based on transcritical CO2 and method

ActiveCN113236426AImprove pre-cooling effectEasy to carry and storeTurbine/propulsion engine coolingGas turbine plantsFlight vehicleSystem structure

The invention discloses a multi-mode combined power cycle system based on transcritical CO2 and a method, and belongs to the field of aviation power propulsion. According to the multi-mode combined power cycle system based on transcritical CO2 and the method, a turbine engine, a ramjet and the supercritical CO2 Brayton cycle are coupled, so that a hypersonic aircraft can be switched in multiple modes, and therefore the purpose of wider-range work is achieved. The system comprises an air inlet channel (1), an inner duct (2), an outer duct (3), a precooler (4), a compressor (5), a main combustion chamber (6), an air turbine (7), an afterburner (8), a spray pipe (9), a CO2 turbine (12), a condenser (13), a pump (14), a liquid CO2 tank (10), a liquid oxygen tank (15), a first switch (11) and a second switch (16). According to the combined power cycle, transcritical CO2 closed heat energy gradient recovery Brayton cycle is adopted in a super-precooling flight mode, and liquid oxygen is utilized for condensation, so that the energy utilization of the system is maximized; and in addition, supercritical CO2 is adopted as a pre-cooling working medium to replace traditional helium, the system structure is more compact, the thrust is larger, and the wider-range working requirement can be rapidly met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

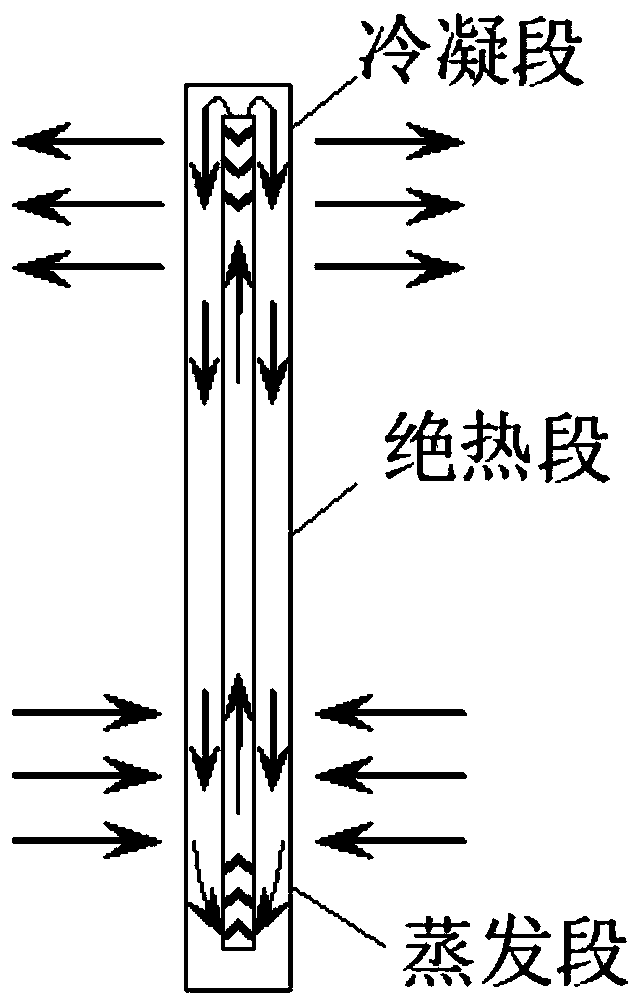

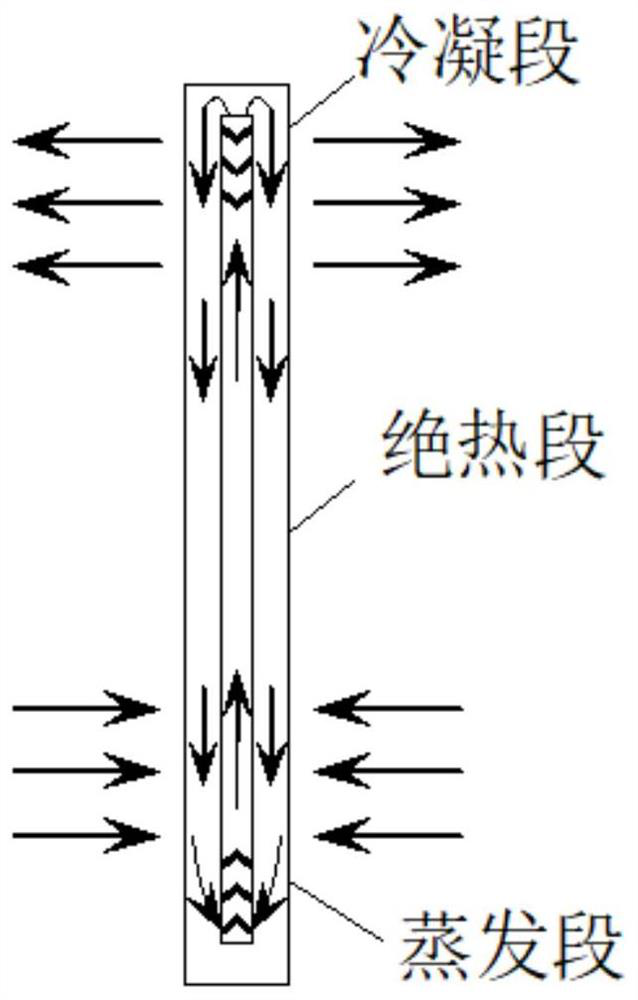

Air conditioner unit with gravity heat pipe and dew point indirect evaporative cooler combined

ActiveCN109990413ASimple structureEasy to processMechanical apparatusIndirect heat exchangersEvaporative coolerChiller

The invention discloses an air conditioner unit with a gravity heat pipe and a dew point indirect evaporative cooler combined. The air conditioner unit comprises a unit shell. A fresh air opening andan air supply opening are formed in the opposite two side walls of the unit shell correspondingly. A coarse effect filtering section, a coil pipe, a dew point indirect evaporative cooling section, a gravity heat pipe section and a centrifugal draught fan are sequentially arranged in the unit shell according to the flowing direction after air enters the unit shell. The coil pipe is connected with the dew point indirect evaporative cooling section and is further connected with a municipal hot water pipe network. An air return opening is formed in the position, between the coarse effect filteringsection and the fresh air opening, on the top wall of the unit shell, and an exhaust opening is formed in the position, corresponding to the upper portion of the dew point indirect evaporative cooling section, on the top wall of the unit shell. Compared with an existing mechanical refrigerating combined air conditioner unit, the air conditioner unit reduces the equipment electric energy consumption, and meanwhile, for different outdoor weather conditions, different working modes can be selectively started for meeting various indoor environment requirements.

Owner:XI'AN POLYTECHNIC UNIVERSITY

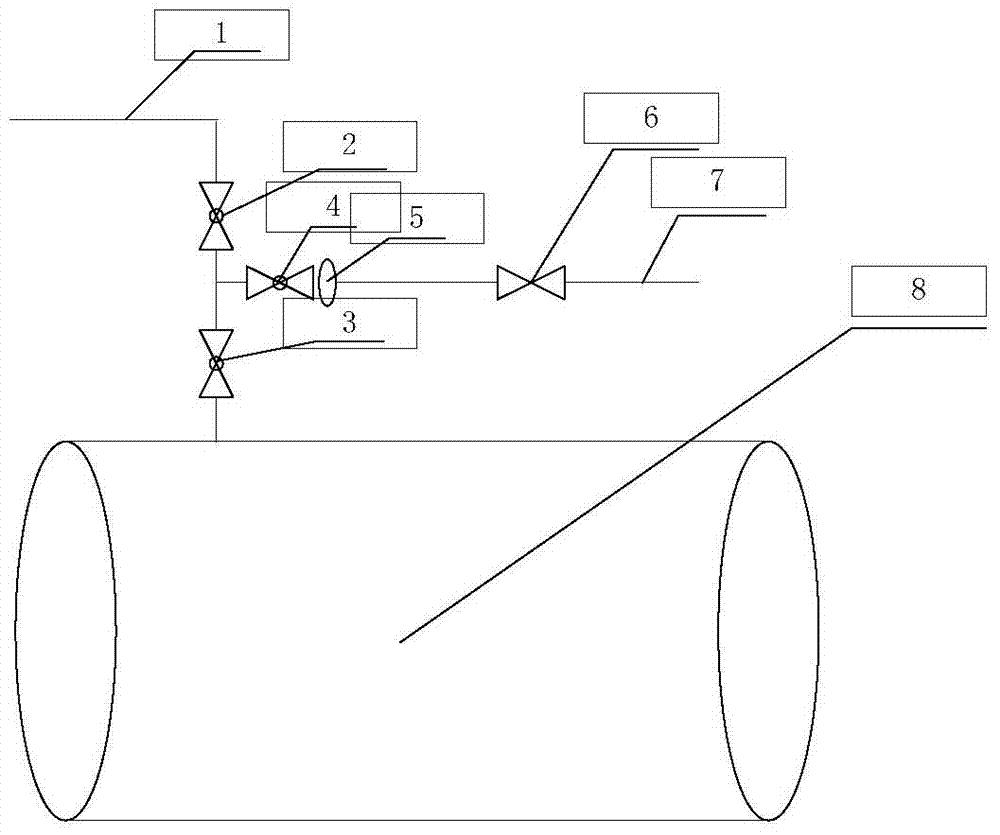

System for cooling pipeline through boil off gas (BOG)

InactiveCN105351662APrevent the effects of pre-coolingReduce risk of coolingPipe heating/coolingGas phaseMechanical engineering

The invention relates to a system for cooling a pipeline through boil off gas (BOG). The system comprises the cooled pipeline, a liquefied natural gas (LNG) pipeline and a BOG gas-phase pipeline, wherein a first valve is arranged on the top of the cooled pipeline; the LNG pipeline and the BOG gas-phase pipeline are located above the first valve and are communicated with the cooled pipe through the first valve; the LNG pipeline is provided with a pore plate. By utilization of the system for cooling the pipeline through the BOG, influences on precooling of the pipeline by heavy component gathering are prevented, the cost is reduced, the pipeline cooling risks are reduced, and the precooling effect is improved.

Owner:中海福建天然气有限责任公司

A low-temperature refrigeration system with one-time throttling for precooling by utilizing the energy separation effect of vortex tubes

ActiveCN108050722BSimple structureLarge expansion coefficientMechanical apparatusCompression machinesEngineeringRefrigeration

A throttling low-temperature refrigeration system for precooling using the energy separation effect of a vortex tube, comprising a compressor, a regenerator, a throttle valve and an evaporator, characterized in that the regenerator includes a first regenerator and a second regenerator The heater also includes a three-way flow regulating valve and a vortex tube, the outlet of the compressor is connected with the inlet of the three-way flow regulating valve, and the first outlet of the three-way flow regulating valve is connected with the hot end inlet of the first regenerator , the second outlet is connected with the inlet of the vortex tube, the outlet of the cold end of the vortex tube is merged with the outlet of the hot end of the second regenerator, and then connected with the inlet of the cold end of the first regenerator, the first regenerator The outlet of the hot end of the compressor is connected with the inlet of the compressor. The one-throttle low-temperature refrigeration system precooled by the energy separation effect of the vortex tube has a simple structure, can adopt internal precooling, and has high refrigeration efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Cooling spray tower

InactiveCN105043128AImprove stabilityImprove pre-cooling effectTrickle coolersCooling towerAtmospheric air

The invention discloses a cooling spray tower. The cooling spray tower comprises a cooling tower body. An air inlet device is arranged at the position, close to the top, of the cooling tower body and is fixed to the cooling tower body. The upper surface of the air inlet device is connected with more than one air inlet pipe. The air inlet pipes are evenly arranged on the air inlet device. The air inlet pipes are detachably connected with the air inlet device. Pre-cooling layers are arranged in the cooling tower body. One end of each pre-cooling layer is fixed to the inner wall of the cooling tower body. Shifting pieces are connected to the pre-cooling layers. The shifting pieces are connected with the pre-cooling layers in a sliding manner. A water collection tank is arranged at the bottom of the cooling tower body. The cooling tower body and the water collection tank are communicated and connected. By means of the cooling spray tower, the stability of air flow entering the tower can be better improved; the influences of the wind force of the atmosphere on the cooling tower can be effectively avoided; the air inlet resistance is small; the air flow is smooth; the cooling efficiency is greatly improved; pre-cooling can be conveniently conducted; the pre-cooling effect is quite good; and therefore the cooling efficiency is greatly improved, and energy is effectively saved to a certain extent.

Owner:CHENGDU JIAMEIJIA SCI & TECH

An air conditioning unit combined with a gravity heat pipe and a dew point indirect evaporative cooler

ActiveCN109990413BVarious operating modesImprove energy efficiencyMechanical apparatusIndirect heat exchangersEvaporative coolerFresh air

The invention discloses an air-conditioning unit combined with a gravity heat pipe and a dew point indirect evaporative cooler, which includes an organic unit casing. The opposite side walls of the unit casing are respectively provided with fresh air outlets and air supply outlets. In the direction of flow, there are coarse filter section, coil, dew point indirect evaporative cooling section, gravity heat pipe section and centrifugal fan. The coil is connected to the dew point indirect evaporative cooling section, and the coil is also connected to the municipal hot water pipe network. An air return port is provided on the top wall of the unit housing between the filter section and the fresh air outlet, and an air exhaust port is provided on the top wall of the unit housing corresponding to the dew point indirect evaporative cooling section. Compared with the existing mechanical refrigeration combined air conditioning unit, the air conditioning unit of the present invention reduces the power consumption of the equipment, and at the same time, it can selectively open different working modes for different outdoor weather conditions to meet the requirements of various indoor environments .

Owner:AOLAN FUJIAN IND

Fruit differential-pressure rapid precooling technology

InactiveCN102860353AGood effectShort pre-cooling timeFruits/vegetable preservation by freezing/coolingProcess engineeringCold air

The invention discloses a fruit differential-pressure rapid precooling technology. A differential-pressure refrigeration storage is arranged in a high-temperature refrigeration storage, a sealing door, an exhaust pump, a pressure gauge and a gas inlet are arranged on the differential-pressure refrigeration storage, and a humidifier is arranged inside the differential-pressure refrigeration storage; and a rapid differential-pressure precooling process includes that the exhaust pump is started, gas is discharged out of the storage, a negative pressure state in the storage in achieved, heat caused by fruits enter the storage is discharge out of the storage rapidly, when the negative pressure in the storage reaches a low value, the exhaust stops discharging gas, the gas inlet is opened, cold air in the high-temperature refrigeration storage is led into the differential-pressure refrigeration storage by using differential pressure, the fruits are cooled down rapidly, when the inner differential pressure and the outer differential pressure of the differential-pressure refrigeration storage are balanced, the exhaust pipe is started and discharges gas outwards, 'discharging and leading' are performed, a circulation is achieved every three or five minutes for 2-3 hours, and the temperature of the fruits is reduced to the lowest. The fruit differential-pressure rapid precooling technology has the advantages of being fast in precooling, good in effect, low in water loss rate and capable of saving electrical power. Internal tissue cells of the fruits can not be damaged, and the storage and conveying quality and time of the fruits also can not be affected.

Owner:XINJIANG XINJIYUAN AGRI & ANIMAL HUSBANDRY DEV

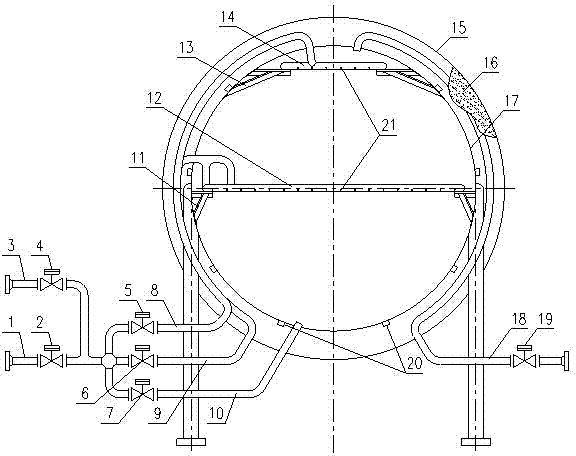

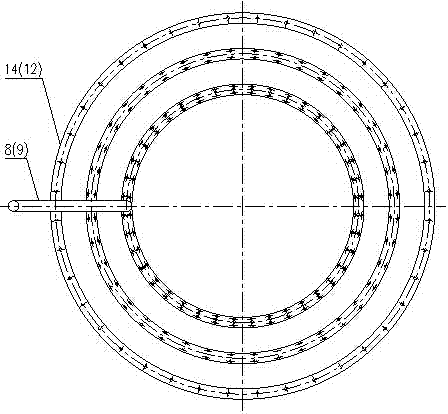

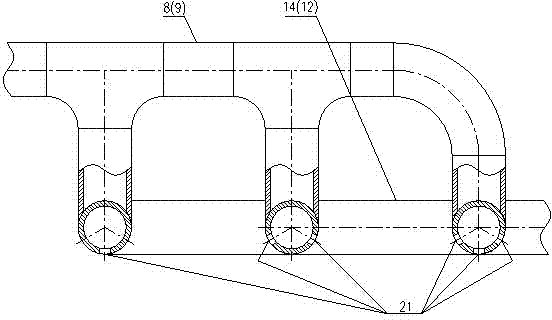

Low-temperature double-ball spherical tank liquid distribution system and precooling method

ActiveCN104747900AReduce stressIncrease temperatureContainer filling methodsPressure vesselsThermodynamicsDistribution system

The invention provides a low-temperature double-ball spherical tank liquid distribution system which comprises an upper inlet liquid distributor and a lower liquid inlet pipe, wherein the upper inlet liquid distributor and the lower liquid inlet pipe are arranged at the top and lower part of an inner spherical tank; the liquid distribution system comprises a middle inlet distributor arranged at the middle of the inner spherical tank; the middle inlet liquid distributor consists of a middle liquid inlet pipe and a middle liquid distributor; the middle liquid inlet pipe is guided from the bottom of an outer spherical tank, is guided to the middle of the inner spherical tank along an interlayer and penetrates through the inner spherical tank so as to be connected with the middle liquid distributor in an equatorial plane of the inner spherical tank. A precooling method of the low-temperature dual-ball spherical tank is realized by virtue of preparation before precoling, a front-stage precooling stage, a middle-stage precooling stage and a rear-stage precooling stage. By virtue of matched use of the upper inlet liquid distributor and the middle inlet liquid distributor, large-range uniform liquid distribution in a precooling process is realized, the wall temperature distribution of the inner spherical tank in the precooling process is effectively improved, the temperature stress is reduced, and the structural safety of the low-temperature dual-ball spherical tank in the precooling process is greatly improved.

Owner:GANSU LANPEC TECH +2

Plastic forming and processing workshop cooling water recycling system and treatment process thereof

PendingCN108328776AReduce pollutionPlay a cooling roleFatty/oily/floating substances removal devicesTreatment involving filtrationWater sourceWaste management

The invention discloses a plastic forming and processing workshop cooling water recycling system and a treatment process thereof and belongs to the technical field of cooling water recycling. The recycling system comprises a plastic forming and processing device, a circulating pond, a water supply subsystem, a water return subsystem and a purification subsystem, the purification subsystem comprises a cooling and purification pond, and a plurality of roundabout tanks in sequential communication are arranged in the cooling and purification tank; a cooling water internal recycling device is arranged in the plastic forming and processing device, a water inlet of the cooling water internal recycling device is externally connected with the water supply subsystem while a water outlet of the sameis externally connected with the water return subsystem, the water return subsystem is communicated with a water incoming end of the cooling and purification pond, and the cooling and purification pond discharges water to the circulating pond which serves as a water source of the water supply subsystem. The problem of cooling and purifying the plastic forming and processing workshop cooling waterin an energy-saving manner is solved.

Owner:马鞍山顾地塑胶有限公司

Water-air combined pre-cooling and film forming device for plum fruits

PendingCN109042856AImprove pre-cooling effectReduce the temperatureFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingWater storageSpray nozzle

The invention relates to the technical field of film-forming fresh keeping of fruits and in particular relates to a water-air combined pre-cooling and film forming device for plum fruits. According tothe water-air combined pre-cooling and film forming device, a water storage cavity, a fruit box and a liquid storage groove are combined, and an air homogenizing cabin is arranged at the bottom of the fruit box; a spraying nozzle is arranged in the air homogenizing cabin; the spraying nozzle is communicated with the liquid storage groove, so that liquid containing a fresh-keeping agent, which issprayed through the spraying nozzle, is blown into the fruit box in an air conveying process of the air homogenizing cabin; the liquid is in contact with the fruits in the fruit box from bottom to topat an atomized state, and a film is formed on the surfaces of the fruits, so that atomization and film formation are realized and the fresh-keeping effect of the pre-cooled fruits is improved.

Owner:沿河蛟坝权新种养殖有限公司

Evaporative cooling water chilling unit achieving dehumidifying through solution dehumidifying humidity-permeable film

PendingCN111256257ALower the water temperatureAvoid the risk of liquid carryLighting and heating apparatusSpace heating and ventilation detailsThermodynamicsWater vapor

The invention discloses an evaporative cooling water chilling unit achieving dehumidifying through a solution dehumidifying humidity-permeable film. The evaporative cooling water chilling unit comprises a cold water production unit and a dehumidifying solution regeneration unit which are mutually connected; and the cold water production unit comprises a unit shell, a direct evaporative cooling section is arranged in the unit shell, the internal structures of the portions, on the two sides of the direct evaporative cooling section, of the unit shell are symmetrical and same and each comprise aunit air inlet, and filters, surface coolers, plate tube indirect evaporative cooling units, dehumidifying sections and the direct evaporative cooling section are sequentially arranged in the unit airinlets in the air flowing direction. According to the evaporative cooling water chilling unit, outdoor fresh air is precooled and subjected to dehumidifying treatment through dry air energy and a solution dehumidifying technology based on the film, air and a dehumidifying solution can be isolated from a polymer film with the high permselectivity through solution dehumidifying humidity-permeable film packing, the dehumidifying solution does not directly make contact with the air, water molecules are only allowed to be transmitted through permeation under driving of partial pressure differenceof water steam, and passing of germs and the dehumidifying solution is isolated.

Owner:XI'AN POLYTECHNIC UNIVERSITY

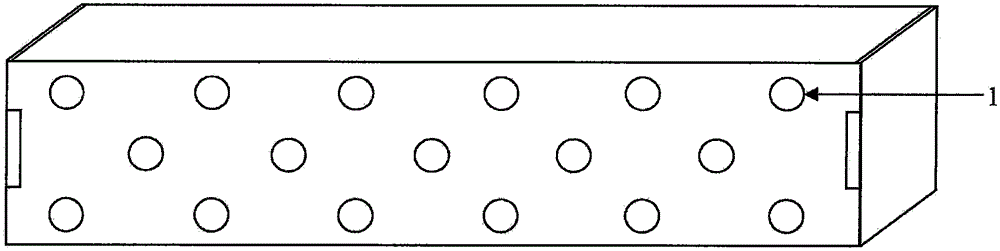

Conveying device for chrysanthemum cutting seedlings

InactiveCN105398640AShorten pre-cooling timeUniform temperatureLiving organism packagingRigid containersPulp and paper industrySeedling

The invention discloses a conveying device for chrysanthemum cutting seedlings. Seventheen air holes are formed in the bottom of a corrugated paper box. The length, the width and the height of the corrugated paper box are respectively 50*15.5*10.5 cm; the diameter of the air holes is 1.5 cm; the air holes are arrayed in a manner of 6:5:6; and distances between transverse and vertical air holes and the four sides at the bottom are all 3 cm. The conveying device is good in precooling treatment, simple in structure, low in cost, convenient to operate and especially suitable for application in large-scale production.

Owner:刘进池

Transcritical based co 2 Multi-modal combined power cycle system and method

ActiveCN113236426BMake up for the defect of low densityImprove availabilityTurbine/propulsion engine coolingGas turbine plantsAviationCombustion chamber

A transcritical CO2 multi-mode combined power cycle system and method, belonging to the field of aerodynamic propulsion. The invention couples the turbine engine, the ramjet engine and the supercritical CO2 Brayton cycle, so that the hypersonic aircraft can be switched in multiple modes, so as to achieve the purpose of working in a wider area. The system includes intake duct (1), inner duct (2), outer duct (3), precooler (4), compressor (5), main combustion chamber (6), air turbine (7), afterburner Combustor (8), nozzle (9), CO2 turbine (12), condenser (13), pump (14), liquid CO2 tank (10), liquid oxygen tank (15), first switch (11) and Second switch (16). The combined power cycle proposed by the present invention adopts a transcritical CO2 closed-type thermal energy cascade recovery Brayton cycle in the super-precooling flight mode, and uses liquid oxygen to condense, so that the energy utilization of the system is maximized. In addition, the present invention uses supercritical CO2 as the pre-cooling working fluid to replace traditional helium, the system structure is more compact, the thrust is greater, and it can quickly realize the working requirements in a wider area.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

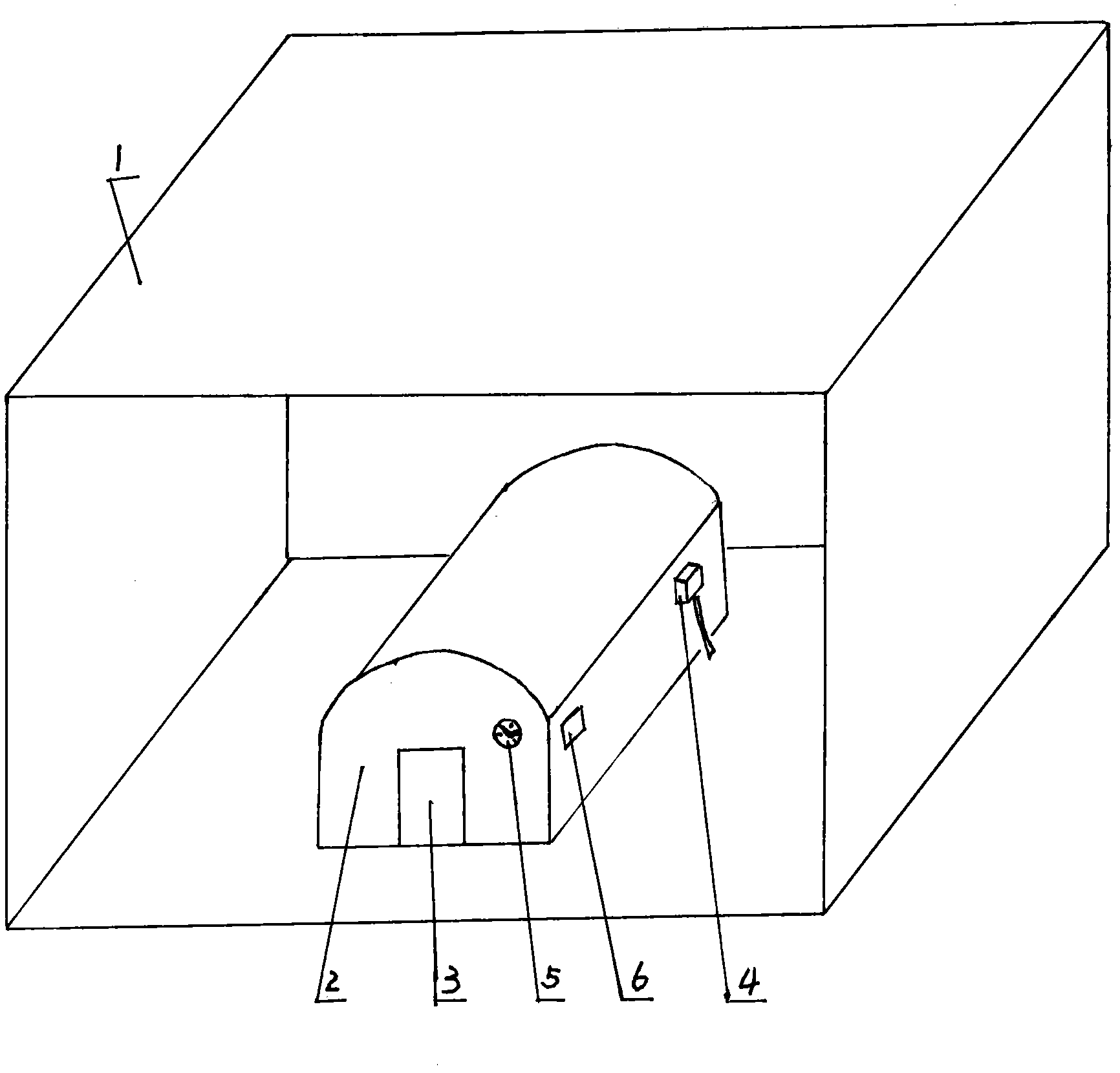

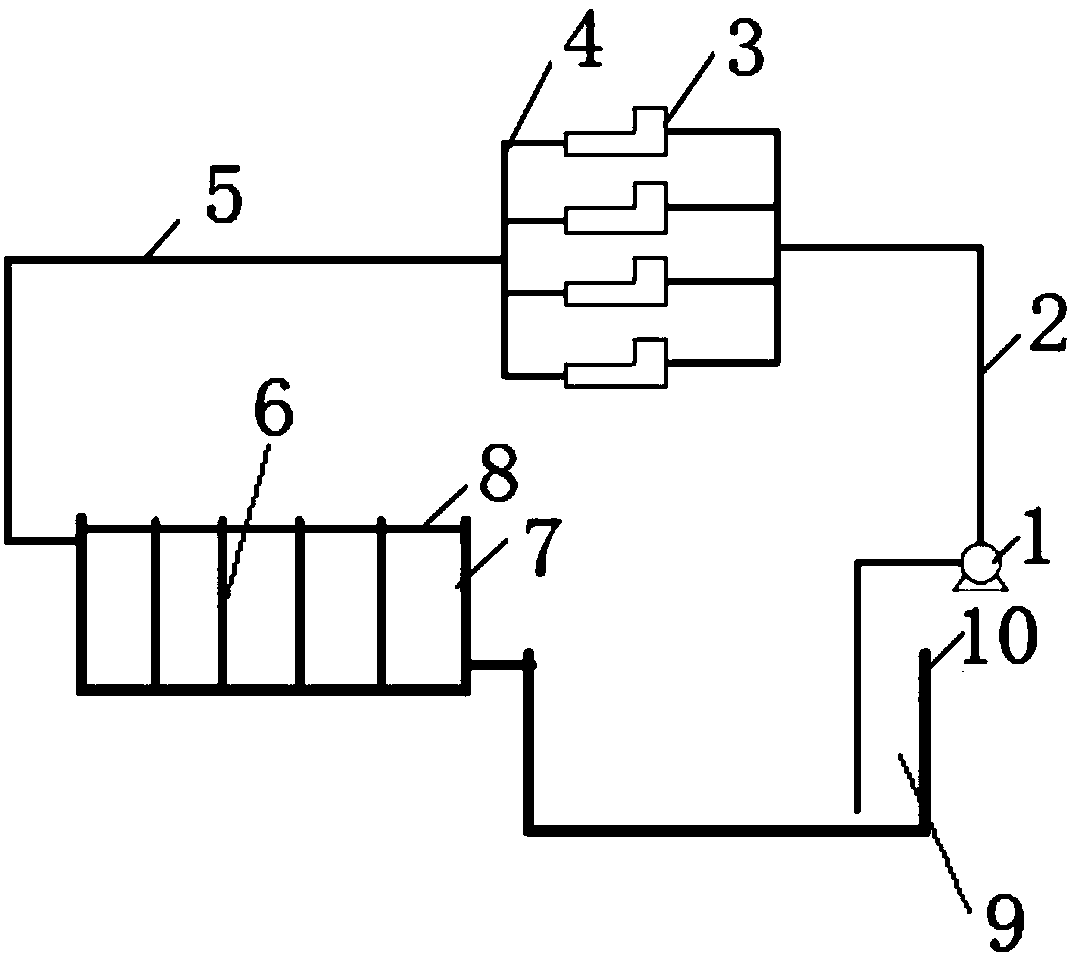

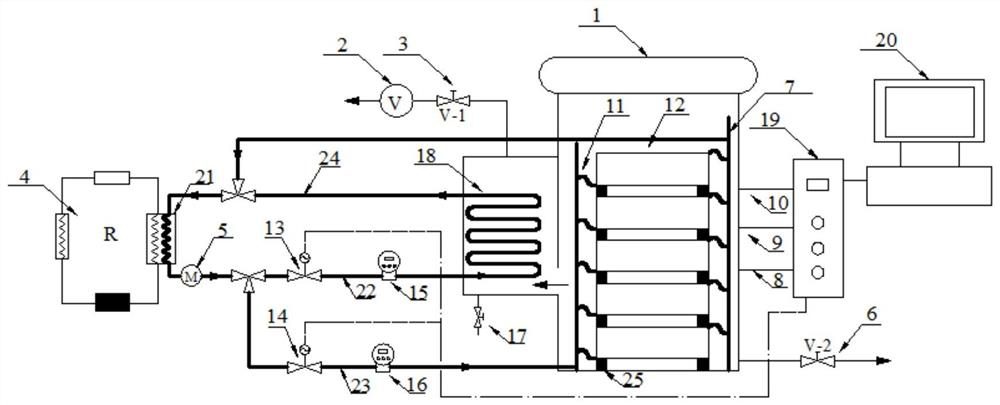

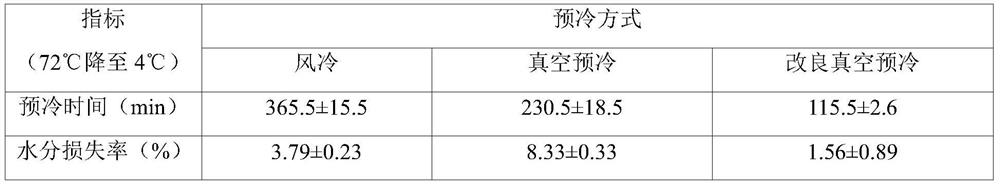

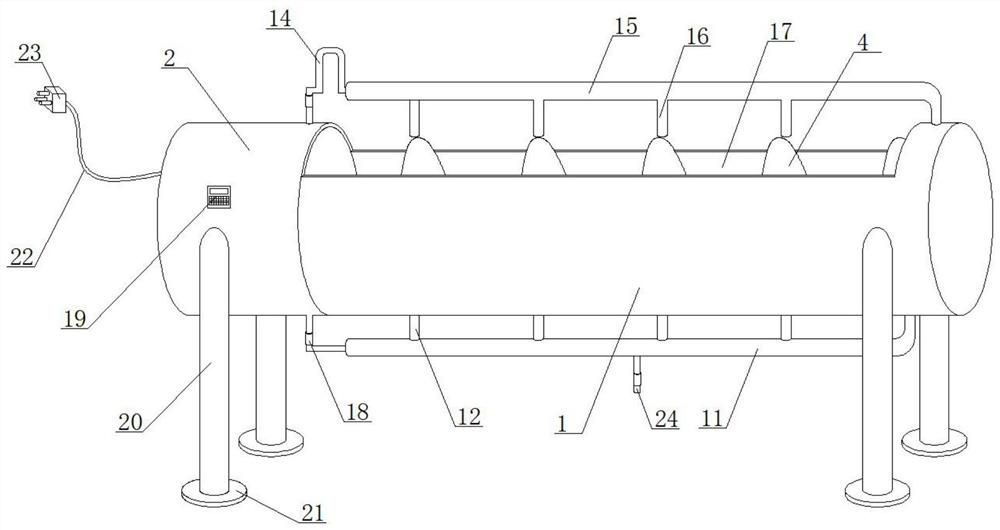

An improved vacuum precooling method for low-temperature cooked meat products

ActiveCN109393304BReduce lossesInhibit outward evaporationFood ingredient as colourBiotechnologyTemperature control

The invention belongs to the field of processing low-temperature cooked meat products, and relates to an improved vacuum precooling treatment method for low-temperature cooked meat products. Before the vacuum precooling of low-temperature cooked meat products, the refrigeration unit (4), the low-temperature liquid circulation pump (5) and the electric valve (13, 14) are turned on, and the auxiliary device group (7) and the condenser are connected through the heat exchanger (21). The temperature of (18) drops to the set temperature; put the cooked low-temperature cooked meat products into the auxiliary device group (7) at the same time, turn on the vacuum pump (2) and control the pressure drop rate, according to the position of the low-temperature cooked meat products In different temperature sections, adjust the opening of the electric valves (13, 14) to control the flow of the corresponding branch pipelines I and II, so that the temperature control of the auxiliary device group (7) and the condenser (18) can be realized. The invention can not only obtain high cooling rate and low water loss for low-temperature cooked meat products, but also maintain high color and luster quality of low-temperature cooked meat products, and has simple operation and low energy consumption.

Owner:SHAOGUAN COLLEGE

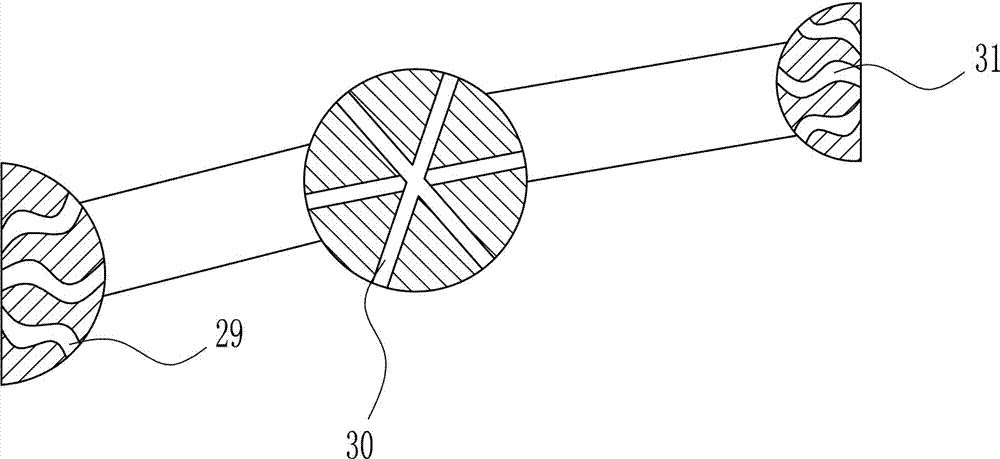

Spiral pre-cooling trough used for goose processing

InactiveCN112762648AImprove pre-cooling effectIncrease contact timeLighting and heating apparatusRefrigeration devicesFisheryCooling effect

The invention provides a spiral pre-cooling trough used for goose processing. The spiral pre-cooling trough comprises a cooling tank and a motor box, the motor box is fixedly mounted at one end of the cooling tank, a motor is fixedly mounted on the inner side wall of one side of the motor box, a bearing is fixedly embedded in the inner side wall of one side of the cooling tank, and a spiral stirring rod is connected to the inner side wall of the other side of the cooling tank through a rotating shaft. The spiral pre-cooling trough used for goose processing is reasonable in design, a mixed cooling pipe is installed at the bottom of the cooling tank, when water in the cooling tank is cooled, the water enters the mixed cooling pipe firstly, on one hand, the contact time of the water and cooling gas can be prolonged, and the cooling effect can be improved; and on the other hand, in the process of introducing the cooling gas, the water in the mixed cooling pipe can continuously flow into the cooling tank, the cooling uniformity can be effectively improved, and therefore the goose pre-cooling effect is improved, and practicability is high.

Owner:贾炳侠

Pipeline pre-cooling system

PendingCN109915682AImprove pre-cooling effectEnables pre-cooled transfer linesPipe heating/coolingEngineeringPre cooling

The invention provides a pipeline pre-cooling system. The pipeline pre-cooling system comprises a low-temperature storage tank, a transferring pipeline, a compressor and a pressurizing pipeline; one end of the transferring pipeline communicates with a containing cavity of the low-temperature storage tank, and the other end of the transferring pipeline is used for being connected with external equipment; the compressor is provided with an air inlet end, the air inlet end communicates with the containing cavity, and the compressor is used for compressing a gaseous first medium input from the airinlet end to form a second medium; and one end of the pressurizing pipeline is connected with the compressor, the other end of the pressurizing pipeline communicates with the transferring pipeline, and the pressurizing pipeline is used for transferring the second medium into the transferring pipeline for pre-cooling of the transferring pipeline. When the high-pressure second medium is introducedinto the transferring pipeline, the second medium can be vaporized rapidly, strong driving force is generated in the transferring pipeline to overcome the resistance caused by pipeline routes and liquid plugging in the pipelines, and thus the purpose of pre-cooling of the transferring pipeline is realized.

Owner:CIMC ENRIC ENGINEERING TECHNOLOGY CO LTD

A system utilizing bog to cool pipes

InactiveCN105351662BPrevent the effects of pre-coolingReduce risk of coolingPipe heating/coolingGas phaseEngineering

The invention relates to a system for cooling a pipeline through boil off gas (BOG). The system comprises the cooled pipeline, a liquefied natural gas (LNG) pipeline and a BOG gas-phase pipeline, wherein a first valve is arranged on the top of the cooled pipeline; the LNG pipeline and the BOG gas-phase pipeline are located above the first valve and are communicated with the cooled pipe through the first valve; the LNG pipeline is provided with a pore plate. By utilization of the system for cooling the pipeline through the BOG, influences on precooling of the pipeline by heavy component gathering are prevented, the cost is reduced, the pipeline cooling risks are reduced, and the precooling effect is improved.

Owner:中海福建天然气有限责任公司

A Roots Blower Slaughter Production Line

ActiveCN104705381BReduce squeeze contactImprove pre-cooling effectPoultry processingProduction lineAgricultural engineering

The invention discloses a roots blower slaughtering production line which comprises a suspension conveying line (1), wherein an electrical stunning machine (2), a bloodletting groove (3), a livestock scalding tank (4), a depilator (5) and a spiral precooling machine (6) are sequentially arranged on the suspension conveying line (1); a roots blower (7) is adopted to blow wind to the livestock scalding tank (4) and a first diameter variable connector (16) respectively; returned air of the livestock scalding tank (4) and the fresh air of a fourth air tube (15) are gathered through the first diameter variable connector (16), are fed into a refrigerating device (18) for cooling, and are further conveyed to the spiral precooling machine (6); returned air of the spiral precooling machine (6) is collected through the roots blower (7) by using a return air tube (23). The roots blower (7) is adopted to replace a plurality of spiral air pumps, so that the cost and time for equipment maintenance can be reduced, the roots blower (7) is long in service life, the air can be prevented from flowing back but is completely conveyed to areas requesting air, and the consumption caused by small pressure of the spiral air pump can be reduced.

Owner:SHANDONG ZHANGQIU HUADONG BLOWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com