Multifunctional low-temperature scroll plate pre-cooling heat exchanger

A technology of pre-cooling heat exchangers and heat exchangers, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of life limitation, launch cost increase, etc., and achieve reduced contact thermal resistance, compact structure, The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

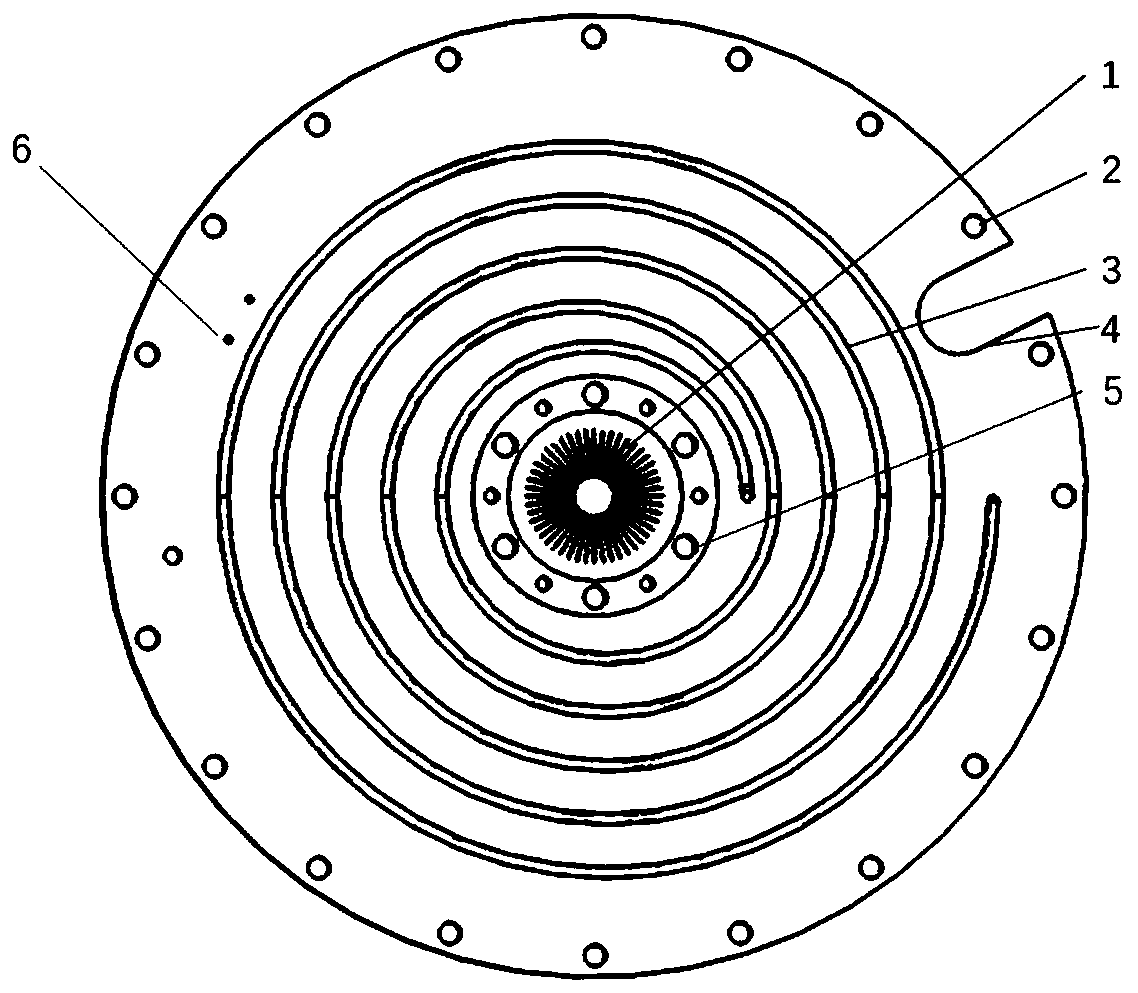

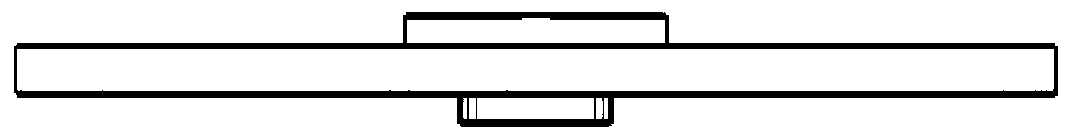

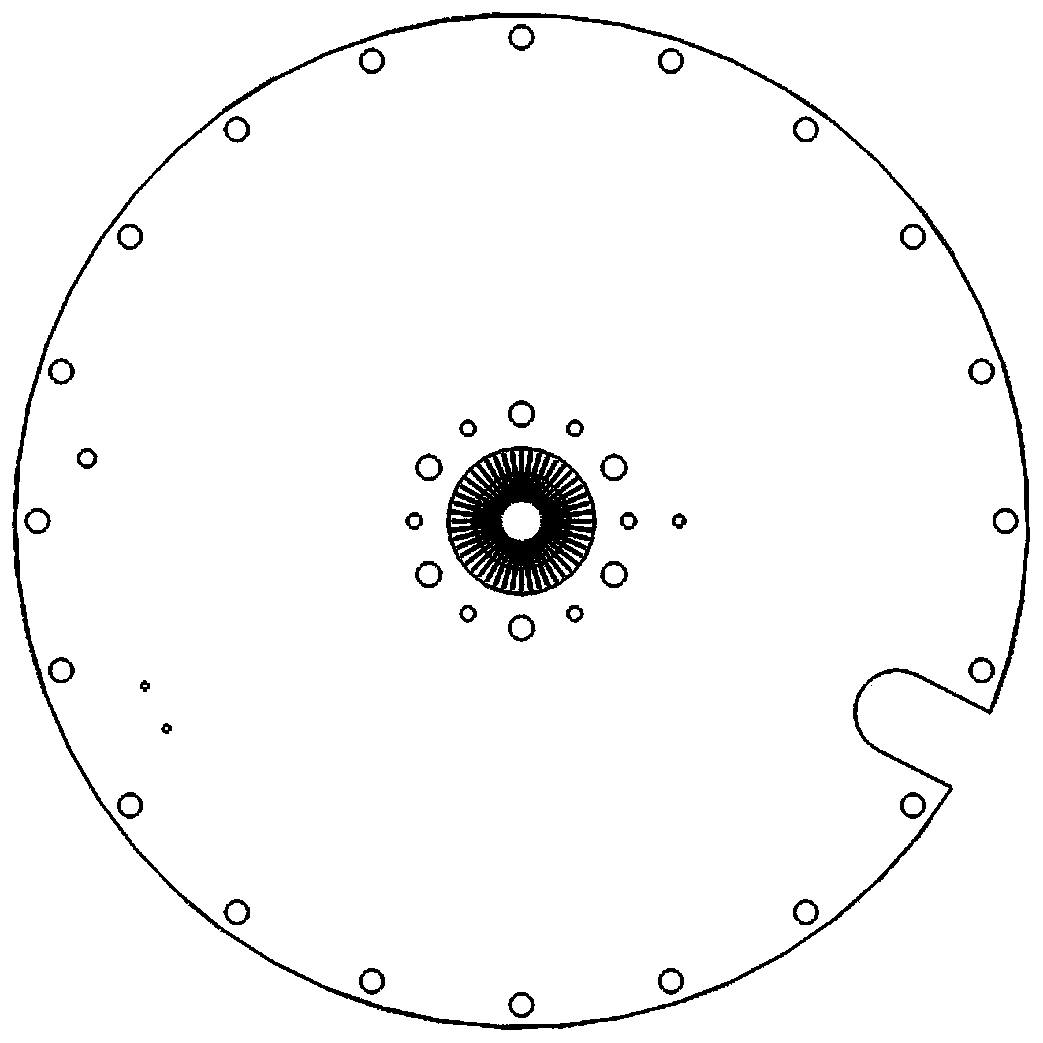

[0012] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a multi-functional low temperature vortex coil precooling heat exchanger, which is applied to liquid helium and lower temperature zone precooling type JT refrigerators. It includes a middle slit structure 1, a threaded hole 2, a spiral groove 3, a U-shaped groove 4, a fixing hole 5, and a temperature measuring and heating threaded hole 6. The heat exchanger is made of oxygen-free copper material into a circular structure, and the entire surface of the heat exchanger is plated with a micron-sized gold layer to reduce the radiation heat loss of the entire multi-functional low-temperature vortex coil pre-cooling heat exchanger, and the surface is left The temperature sensor and the heating plate fixing screw port 6 are used to test the working temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com