Patents

Literature

31results about How to "Improve pre-cooling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

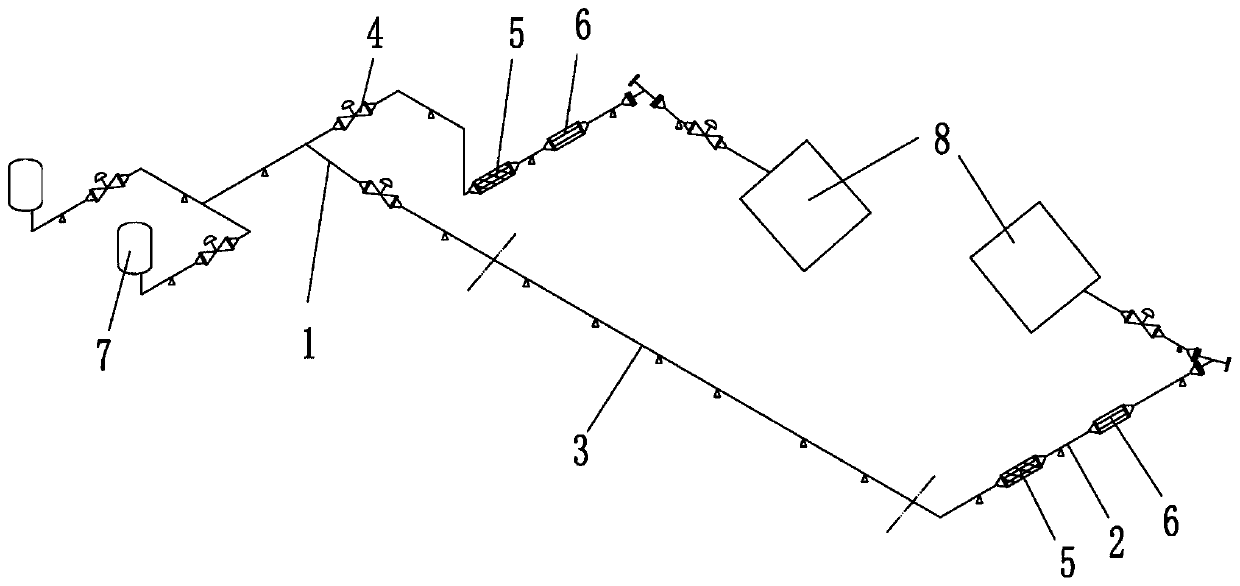

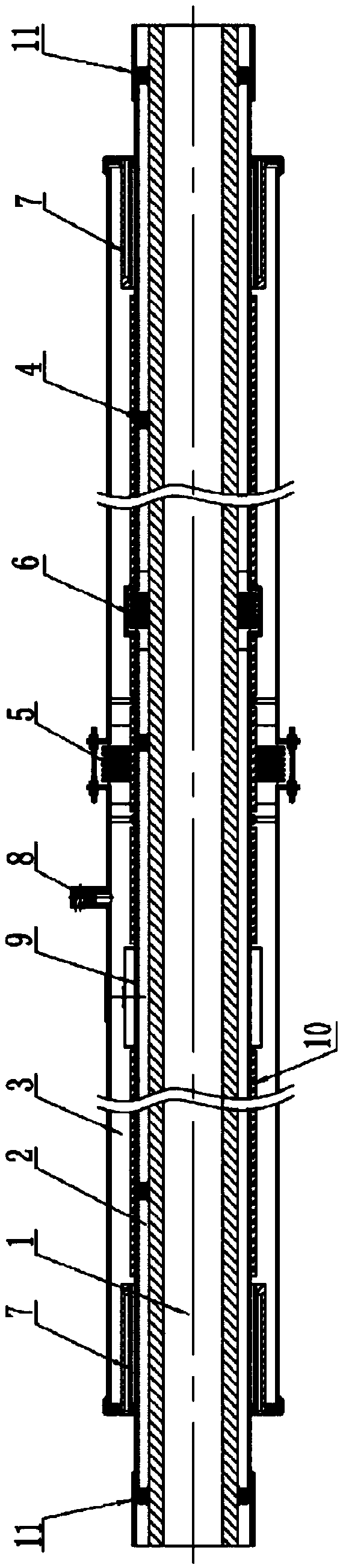

Low temperature pipeline system

ActiveCN109707946AImprove cooling effectReduce usageThermal insulationPipe heating/coolingEngineeringHigh pressure

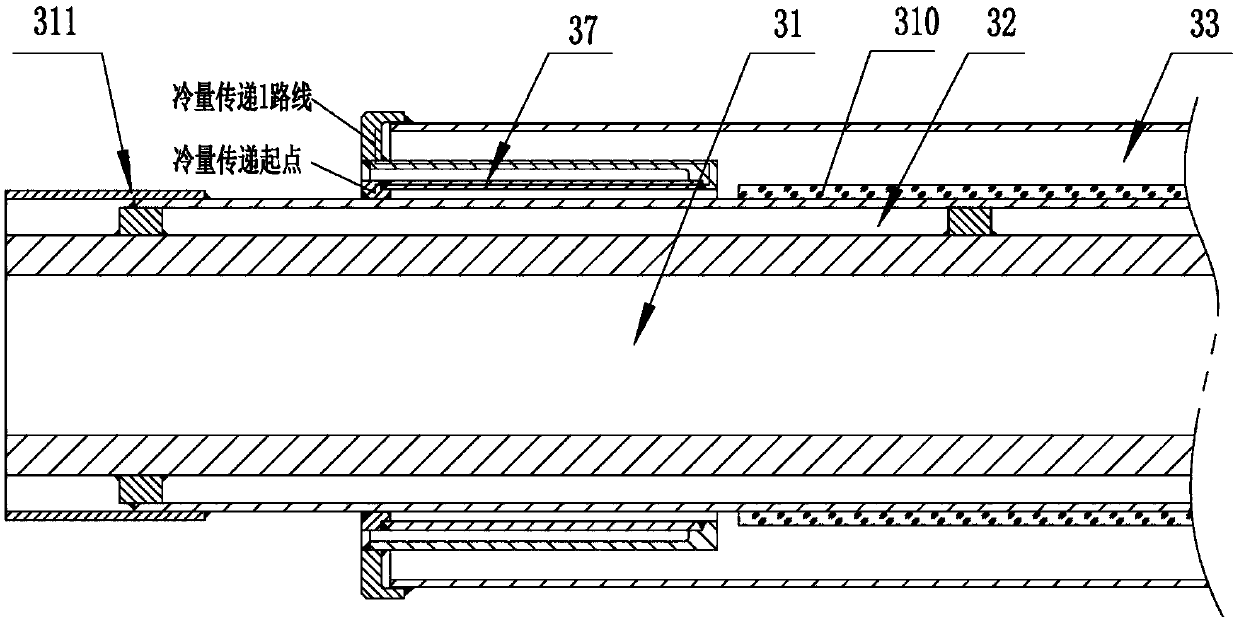

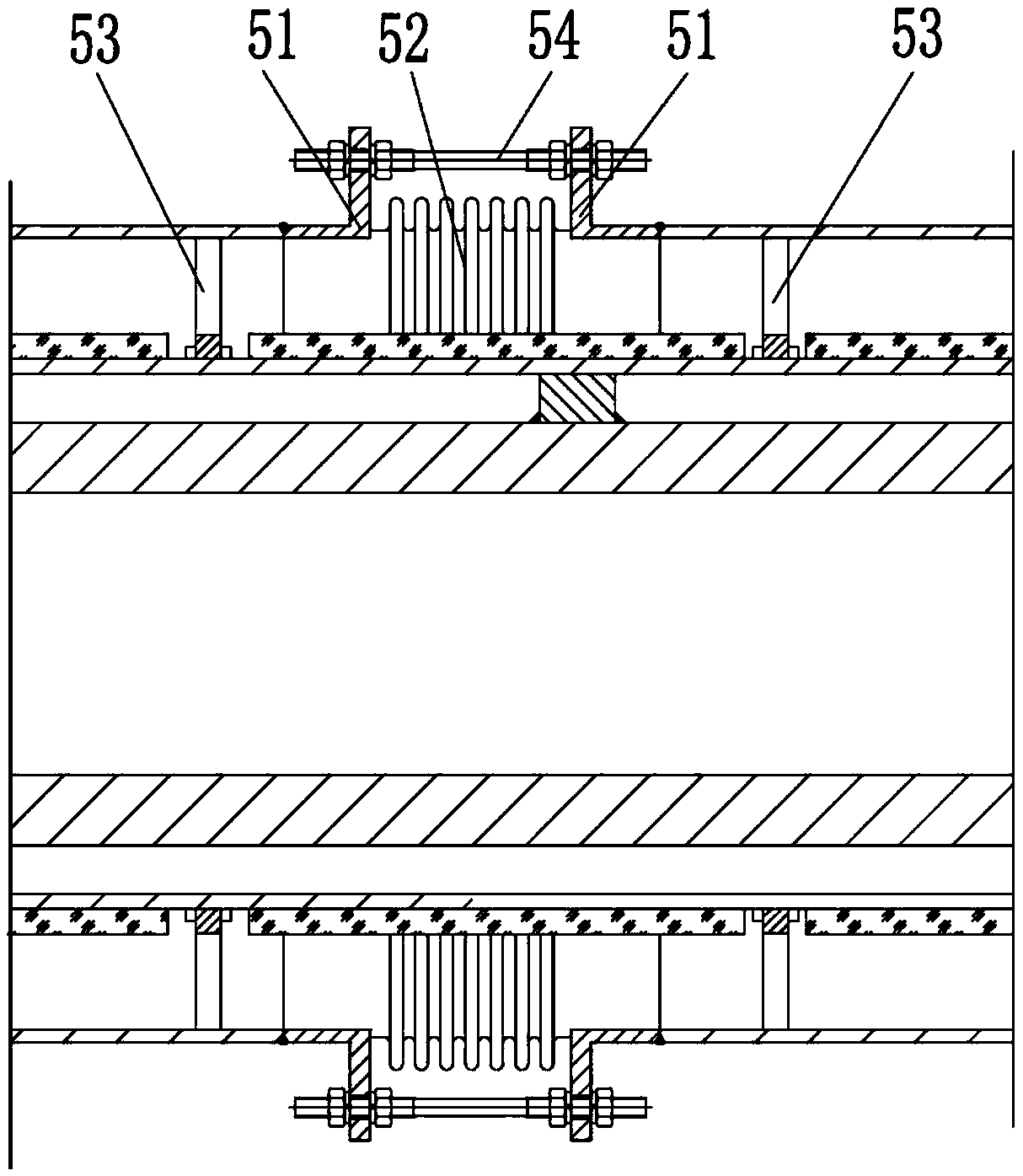

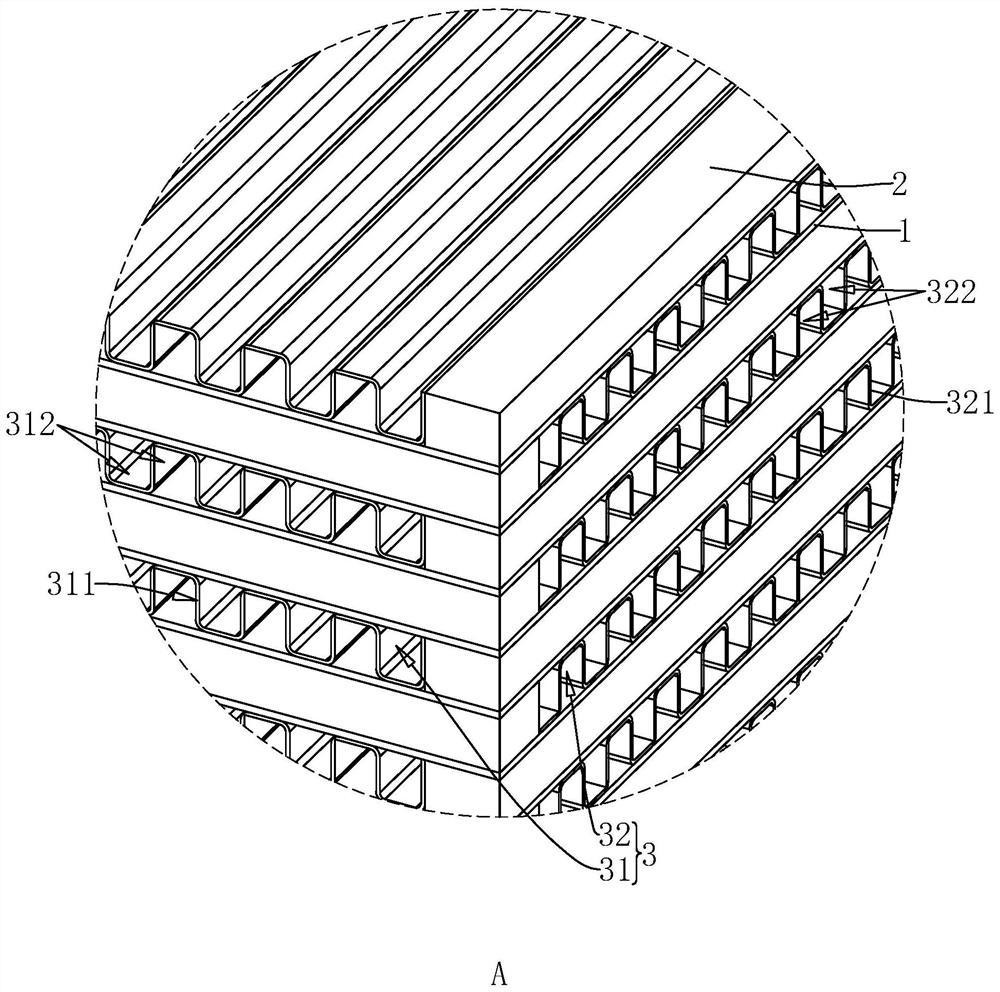

The invention relates to a low temperature pipeline system. The problems that during pipeline precooling of existing pipeline systems, resources are wasted, and safety accidents are liable to occur are solved. The system comprises a high-pressure interlayer pipeline unit and a high-pressure vacuum pipeline; the high-pressure interlayer pipeline unit comprises a first high-pressure interlayer pipeline, a second high-pressure interlayer pipeline, a valve, a flow meter and a filter; one end of the first high-pressure interlayer pipeline is connected with a high-pressure storage tank; the other end of the first high-pressure interlayer pipeline is connected with one end of the high-pressure vacuum pipeline and testing equipment; the other end of the high-pressure vacuum pipeline is connected with the testing equipment through the second high-pressure interlayer pipeline; the high-pressure vacuum pipeline comprises an inner layer conveying pipe, a middle precooling pipe, an outer layer vacuum heat insulation pipe, a first support frame, a first flexible connection assembly and a second flexible connection assembly; and the first high-pressure interlayer pipeline and the second high-pressure interlayer pipeline are of the same structure and each comprise an inner conveying pipe, a middle precooling pipe, an outer cladding layer, a third support frame and a third flexible connection assembly.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

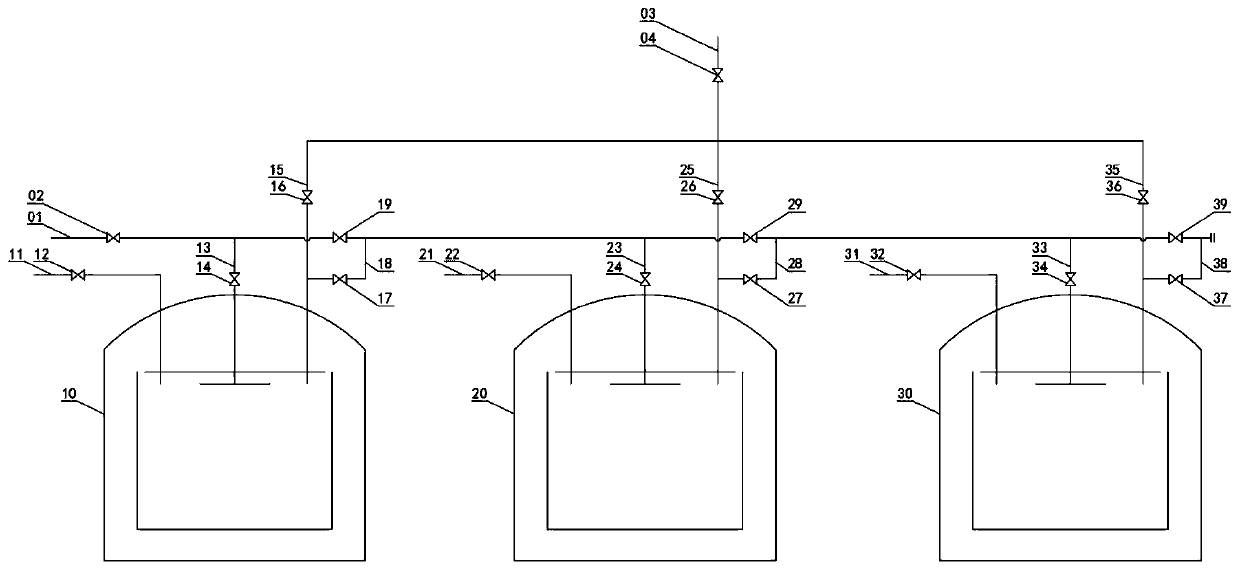

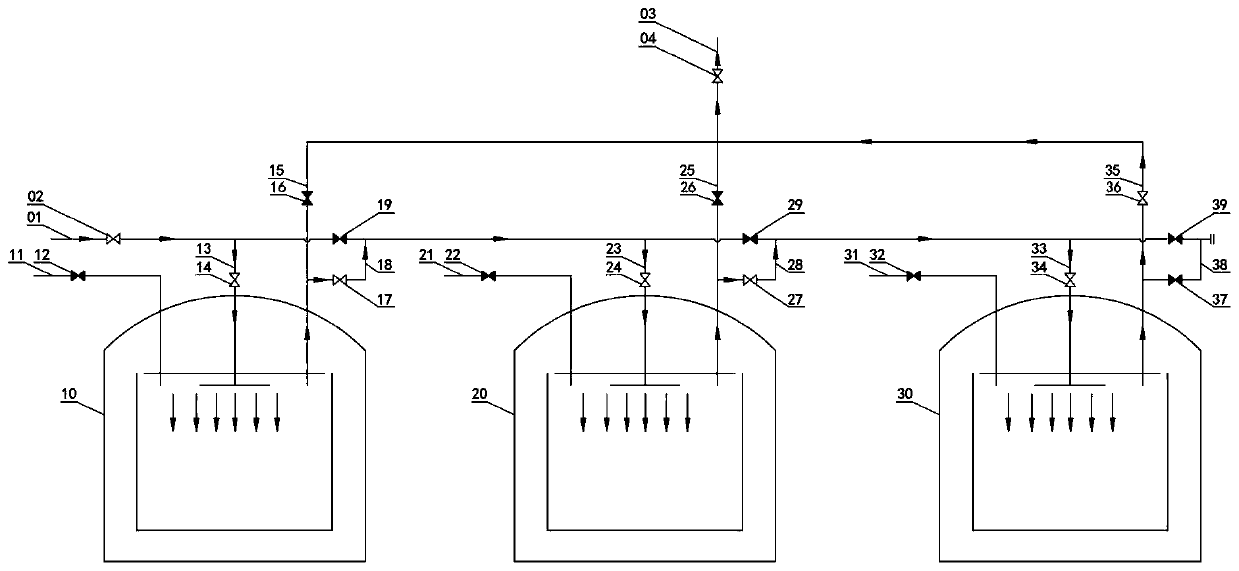

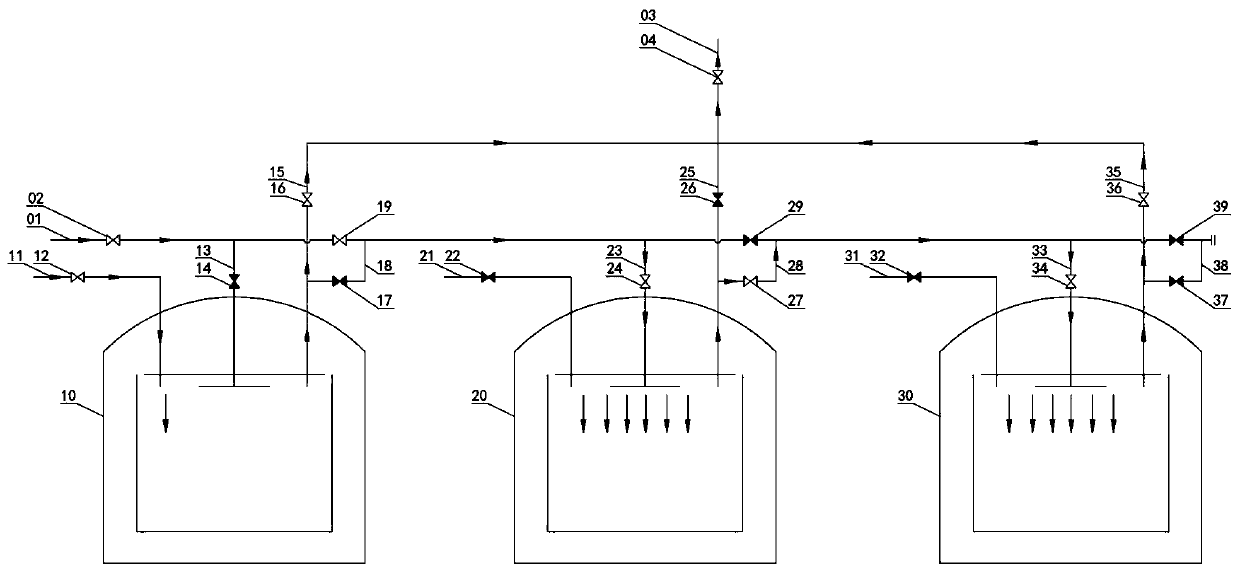

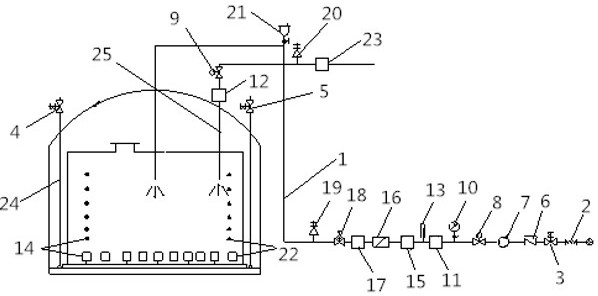

Low-temperature storage tank pre-cooling system and pre-cooling method

ActiveCN110145684AIncrease profitImprove pre-cooling efficiencyContainer filling methodsPipeline systemsGas phaseProcess engineering

The invention discloses a low temperature storage tank pre-cooling system. The low temperature storage tank pre-cooling system comprises a low temperature storage tank No. 1, a low temperature storagetank No. 2, a low temperature storage tank No. 3, a pre-cooling main pipe and a gas phase external transportation main pipe, wherein a pre-cooling main pipe valve is arranged on the pre-cooling mainpipe; and a gas phase external transportation main pipe valve is arranged on the gas phase external transportation main pipe. The low temperature storage tank pre-cooling system has the beneficial effects that the low temperature storage tank pre-cooling system is simple and convenient to operate; the utilization rate of the cold energy of a liquid phase low temperature medium is high; the pre-cooling efficiency is high; the problem that when a low temperature storage tank is pre-cooled, the cold energy is largely wasted, and the pre-cooling cost is high, is solved; meanwhile the efficiency ofsimultaneously pre-cooling multiple low temperature storage tanks in a tank field is improved; the pre-cooling time is saved; and the investment of owners in the pre-cooling of the storage tanks is greatly reduced.

Owner:CHINA NAT AIR SEPARATION ENG CO LTD

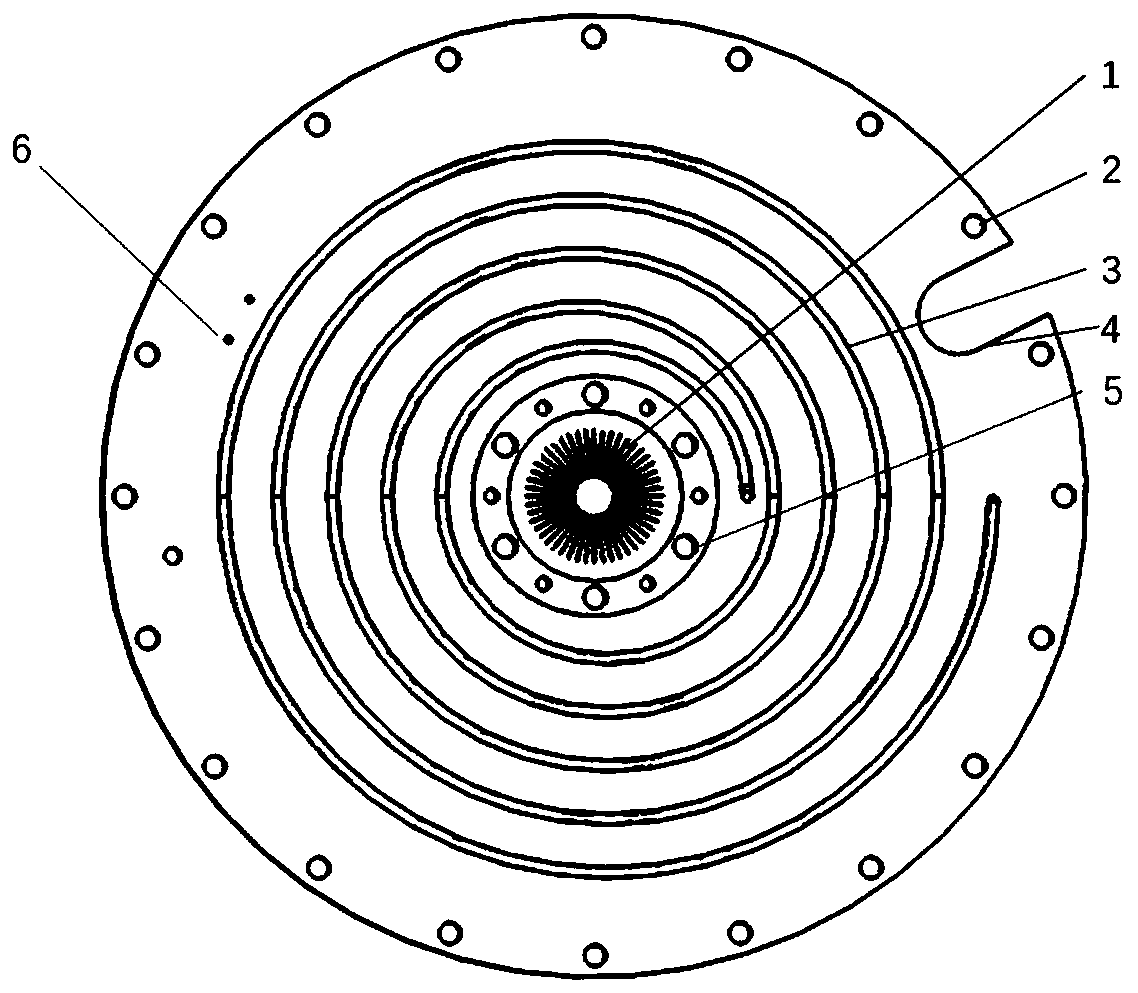

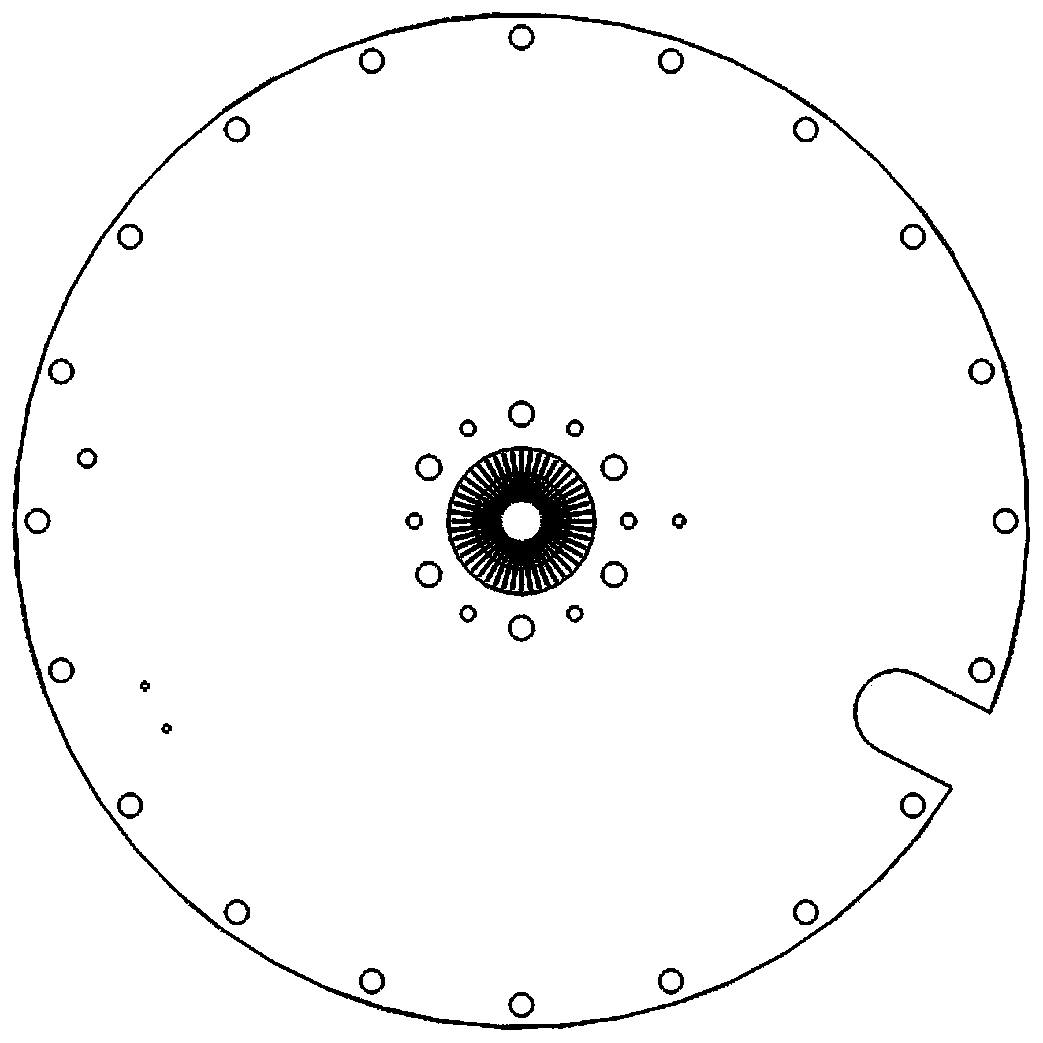

Multifunctional low-temperature scroll plate pre-cooling heat exchanger

PendingCN110749115AIncrease the heat exchange areaConvenient ArrangementCompression machinesRadiation leakageCooling effect

The invention discloses a multifunctional low-temperature scroll plate pre-cooling heat exchanger. The multifunctional low-temperature scroll plate pre-cooling heat exchanger includes an intermediateslit structure, a threaded hole, a spiral groove, a U-shaped groove, a fixing hole and a temperature measuring and heating threaded hole. The heat exchanger is applied to a pre-cooling unit of a pre-cooling type JT refrigerator for a liquid helium temperature zone and a room temperature zone. The heat exchanger can not only directly replace a cold head of a pre-cooler, but also can be used as a supporting bottom plate of a cold screen. The intermediate slit structure increases the heat exchange area, so that the pre-cooling efficiency is greatly improved. The spiral groove is in interference fit with a high-pressure pipeline to pre-cool high-pressure and high-temperature helium. The surface of the heat exchanger is plated with a micron-level thin gold layer to reduce radiation leakage heatloss. The U-shaped groove facilitates the arrangement of pipelines and wires, and can further be used as heat sink of the wires from the liquid helium temperature zone to the room temperature zone. The multiple functions of the cold head of the pre-cooler, the support of the cold screen, the pre-cooling of high-pressure fluid and the heat sink of the wires are integrated, the structure is compact, the contact thermal resistance between the pre-cooler and the heat exchanger is reduced, the pre-cooling effect of a refrigerator is enhanced, and the pre-cooling efficiency is improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

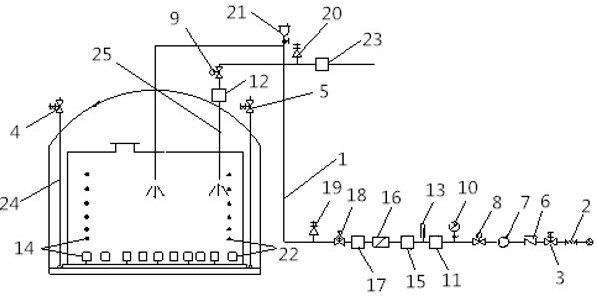

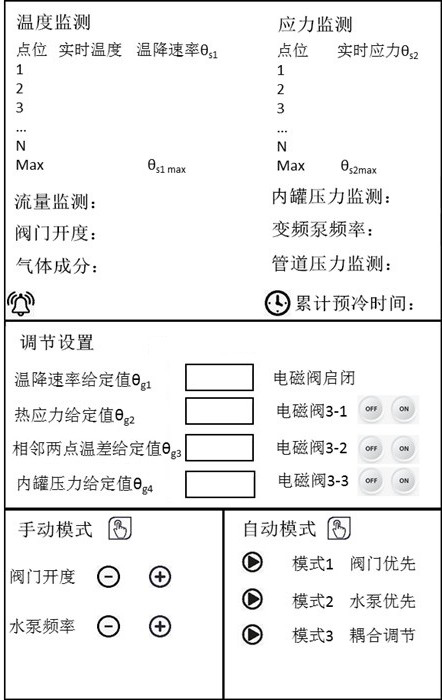

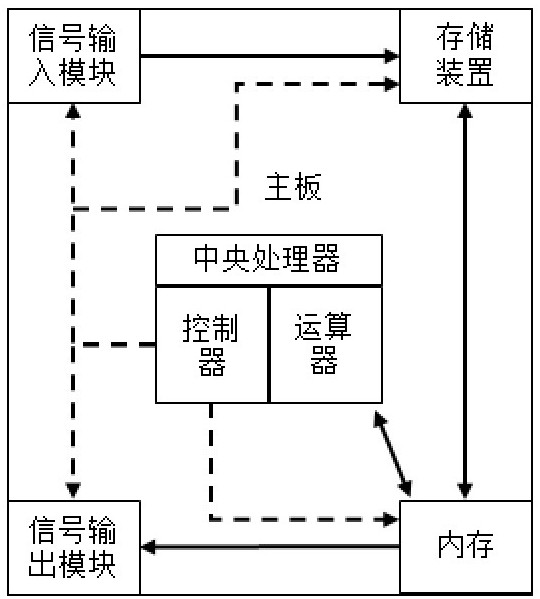

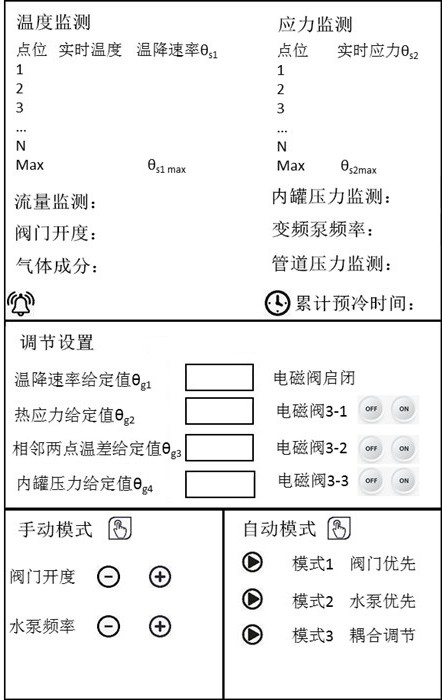

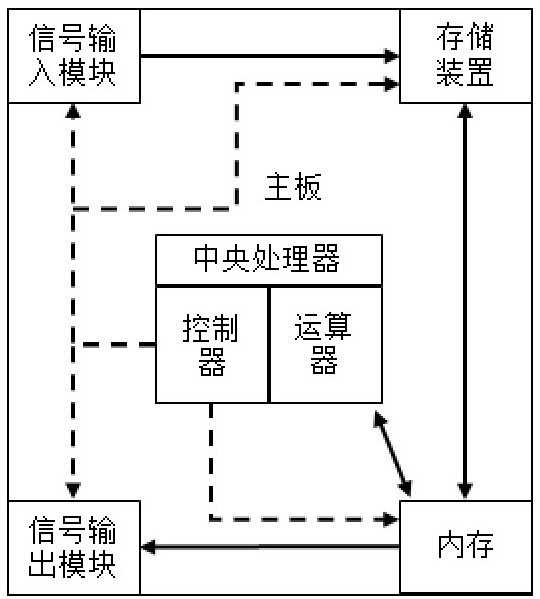

LNG storage tank automatic pre-cooling system based on efficient communication and pre-cooling method

ActiveCN113339695ASolve blindnessImprove pre-cooling effectFluid handling accessoriesContainer discharging methodsMaterial resourcesElectric control

The invention provides an LNG storage tank automatic pre-cooling system based on efficient communication and a pre-cooling method. A CFD numerical simulation module is used for conducting pre-cooling process simulation, and initial flow parameters are provided for the pre-cooling process; and the point positions are installed on a storage tank in a modularized manner, and signal transmission between all sensors in the pre-cooling system and an integrated operation platform is achieved through 5G technology. According to the LNG storage tank automatic pre-cooling system and the pre-cooling method, limit values of parameters such as temperature drop rate, thermal stress, temperature difference between two adjacent points, inner tank pressure and the like are set on the basis of the integrated operation platform, monitoring results and the limit values are compared and analyzed, and then an electric control valve module and a variable frequency pump module are automatically adjusted, so that the conveying flow of a pre-cooling medium is adjusted, and it is guaranteed that the pre-cooling process is stably and safely carried out. According to the LNG storage tank automatic pre-cooling system and method, automatic, integrated and integrated control over the pre-cooling process can be achieved, monitoring personnel do not need to be arranged at monitoring points for a long time, potential safety hazards are avoided, manpower and material resources are saved, pre-cooling control is more accurate, and the pre-cooling efficiency is high.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

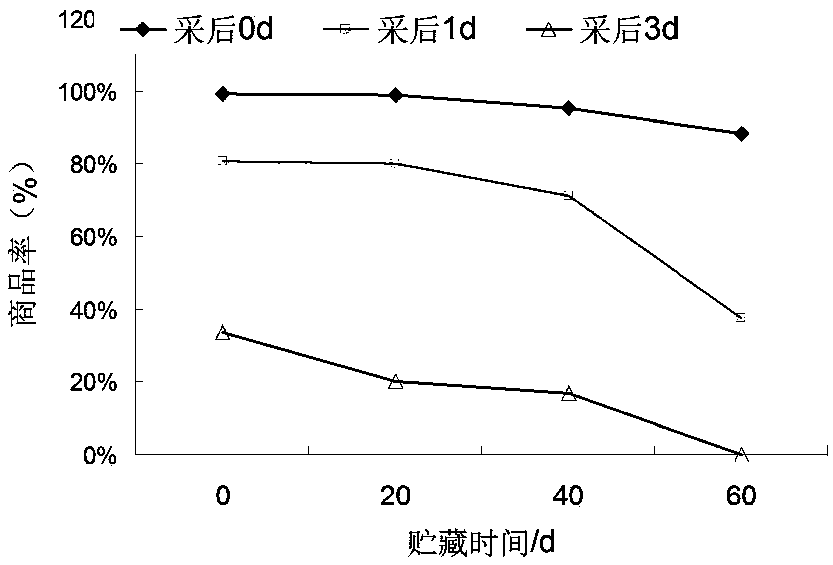

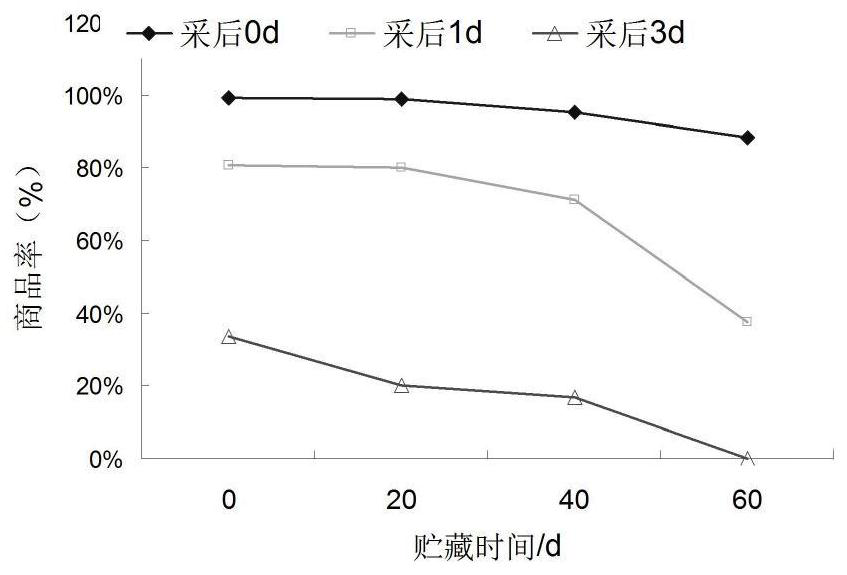

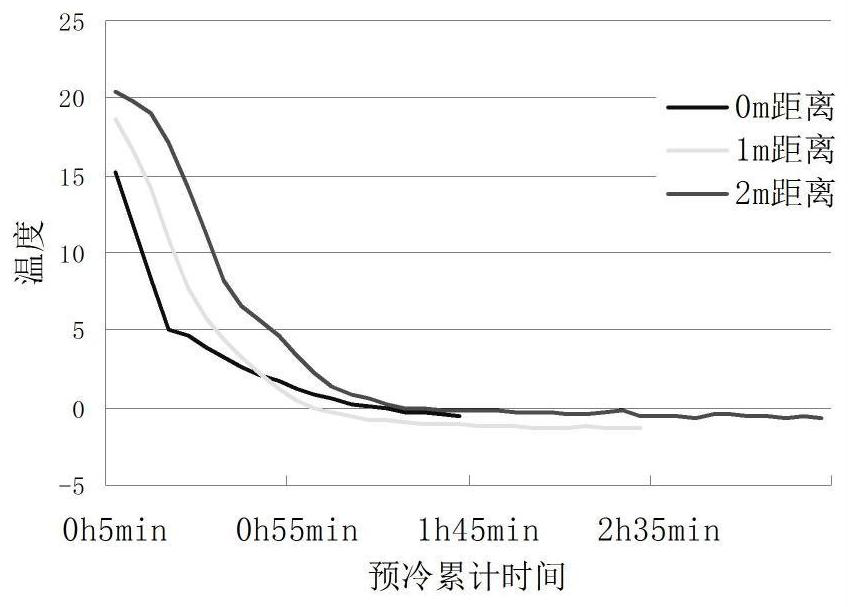

Gradient pre-cooling method suitable for red globe grapes

ActiveCN108041155AImprove pre-cooling efficiencyReduce morbidityFruits/vegetable preservation by freezing/coolingChemistryPhases of clinical research

The present invention discloses a gradient pre-cooling method suitable for red globe grapes. An orthogonal experiment method is used to optimize processes, and pre-cooling efficiency is improved by atwo-stage gradient differential pressure pre-cooling method. Wind temperature is -3 DEG C and differential pressure wind speed is 1.0 m / s in a rapid pre-cooling stage, and a center temperature of grape fruit granules is pre-cooled to 3 DEG C. The differential pressure effect is even, an interaction between the differential pressure pre-cooling wind temperature and wind speed is obvious, a coolingrate can be increased by 1.23-1.75 times; no cold damage occurs in the pre-cooling period, and green color fading and dry shrinkage of ear stalks and fruit stalks are not obvious in the pre-cooling period; and temperature fluctuations of the fruit ears of the red globe grapes are small, and respiratory intensity and humidity fluctuations are relatively stable in the pre-cooling treatment. The gradient pre-cooling method solves a problem that the red globe grapes are easy to rot caused by improper pro-cooling preservation after the red globe grapes are picked, and has wide practicality and development value in the field of preservation of fruits and vegetables.

Owner:新疆农业科学院农产品贮藏加工研究所

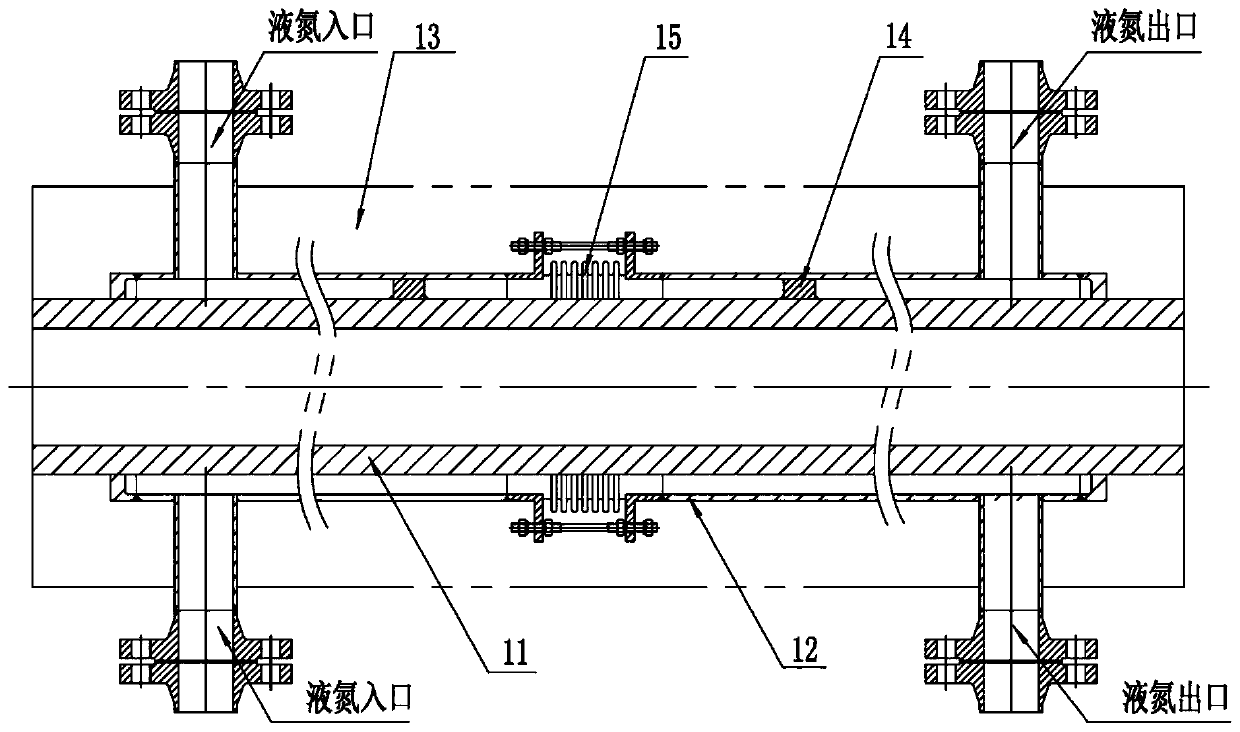

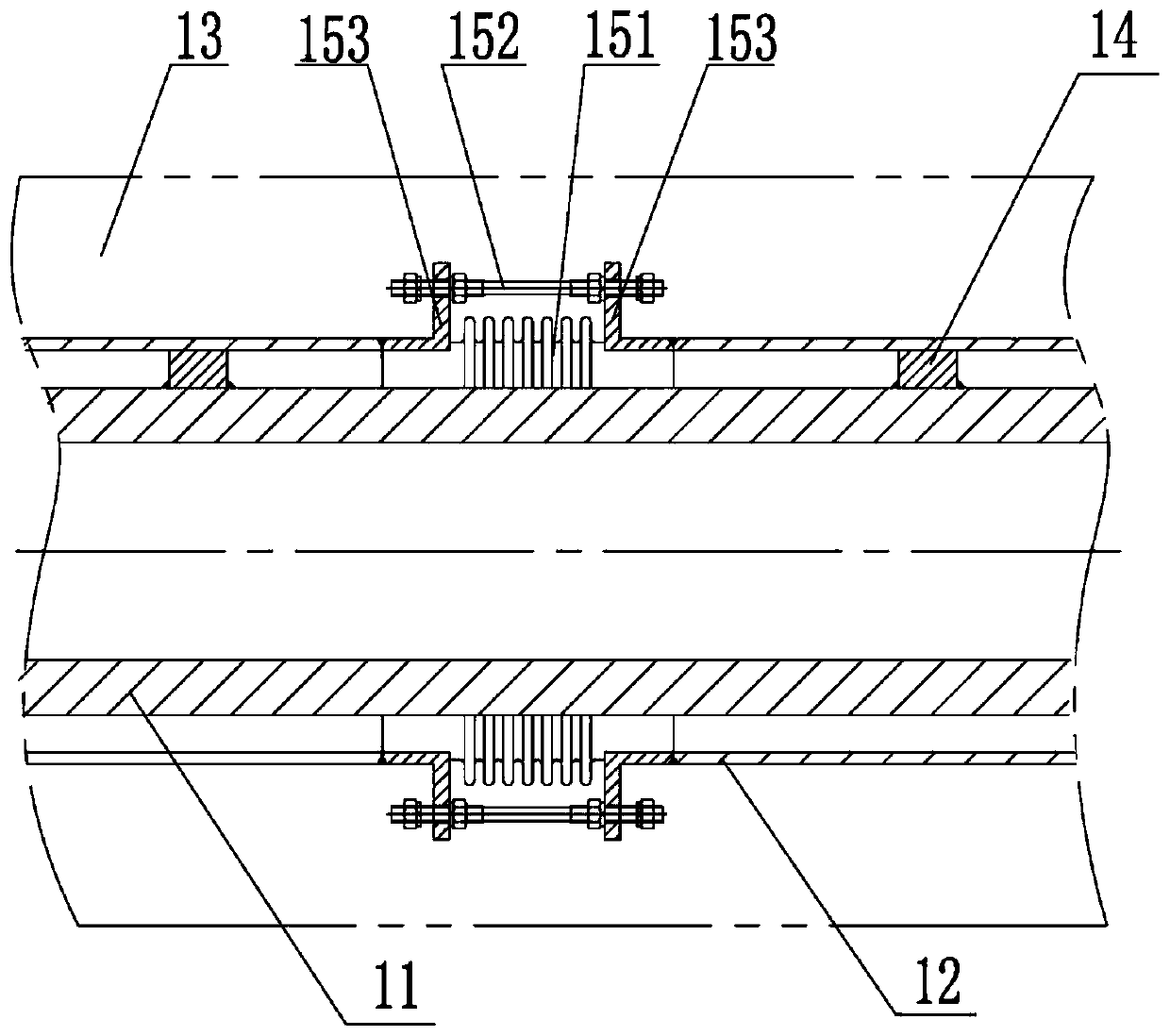

High-pressure vacuum sandwich pipeline

InactiveCN109668007ALarge pre-cooling contact areaEnergy savingThermal insulationPipe protection by thermal insulationMolecular sieveHigh pressure

The invention relates to a high-pressure vacuum sandwich pipeline, and the problems of resource waste and safety risk caused by a vacuum interlayer pipeline are solved. The high-pressure vacuum sandwich pipeline comprises an inner-layer conveying pipe, intermediate pre-cooling pipes, external vacuum heat insulation pipes, first supporting frames, first flexible connecting assemblies and second flexible connecting assemblies, wherein pre-cooling medium is arranged in the intermediate pre-cooling pipes; the inner-layer conveying pipe, the intermediate pre-cooling pipes and the external vacuum heat insulation pipes are sequentially arranged from inside to outside and are coaxial, the plurality of external vacuum heat insulation pipes are connected through the first flexible connection assemblies, and the plurality of intermediate pre-cooling pipes are connected through second flexible connecting assemblies; the first supporting frames are multiple, a plurality of first supporting frames are arranged between the intermediate pre-cooling pipes and the inner-layer conveying pipe and are provided with overflowing holes; a heat bridge is arranged at the two ends of the external vacuum heatinsulation pipes, and the heat bridge is of a multi-layer snake-shaped pipe structure; and a vacuumizing connector is arranged on the external vacuum heat insulation pipes, and molecular sieve filling cavities are formed in an inner cavity and are used for filling molecular sieves.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

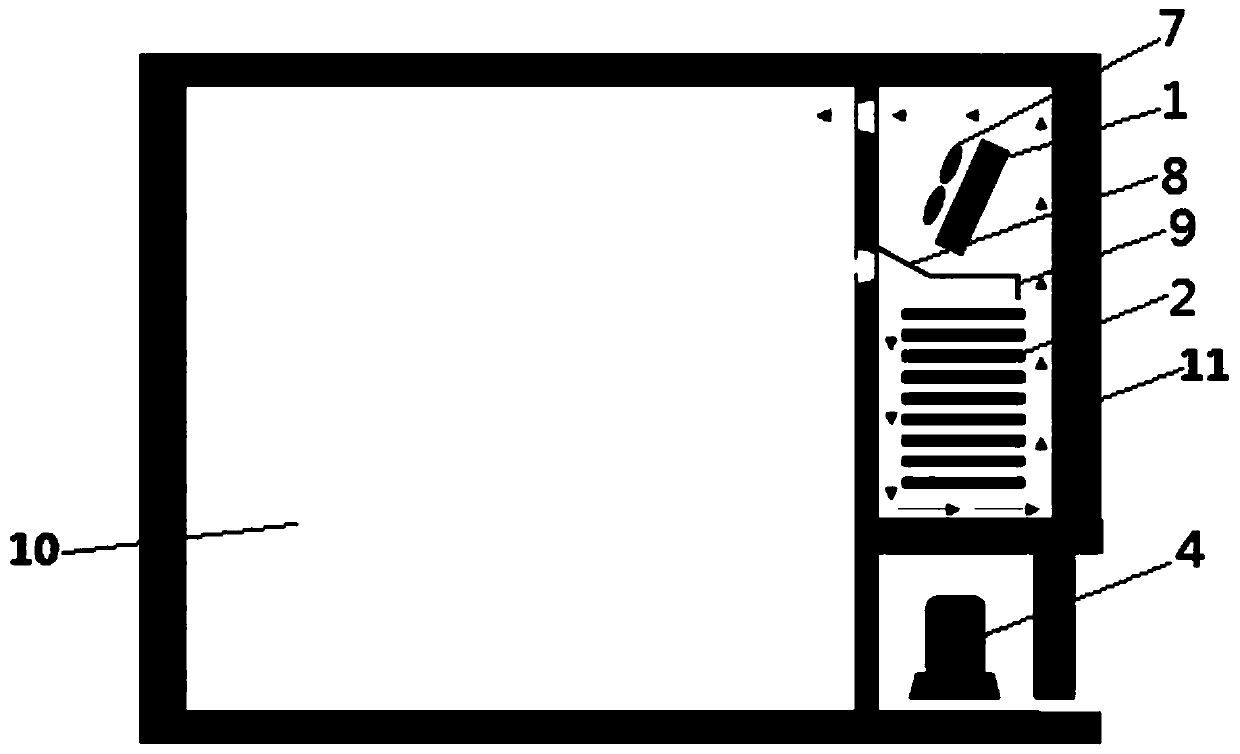

Cold chain unit distribution box with independent cold storage space

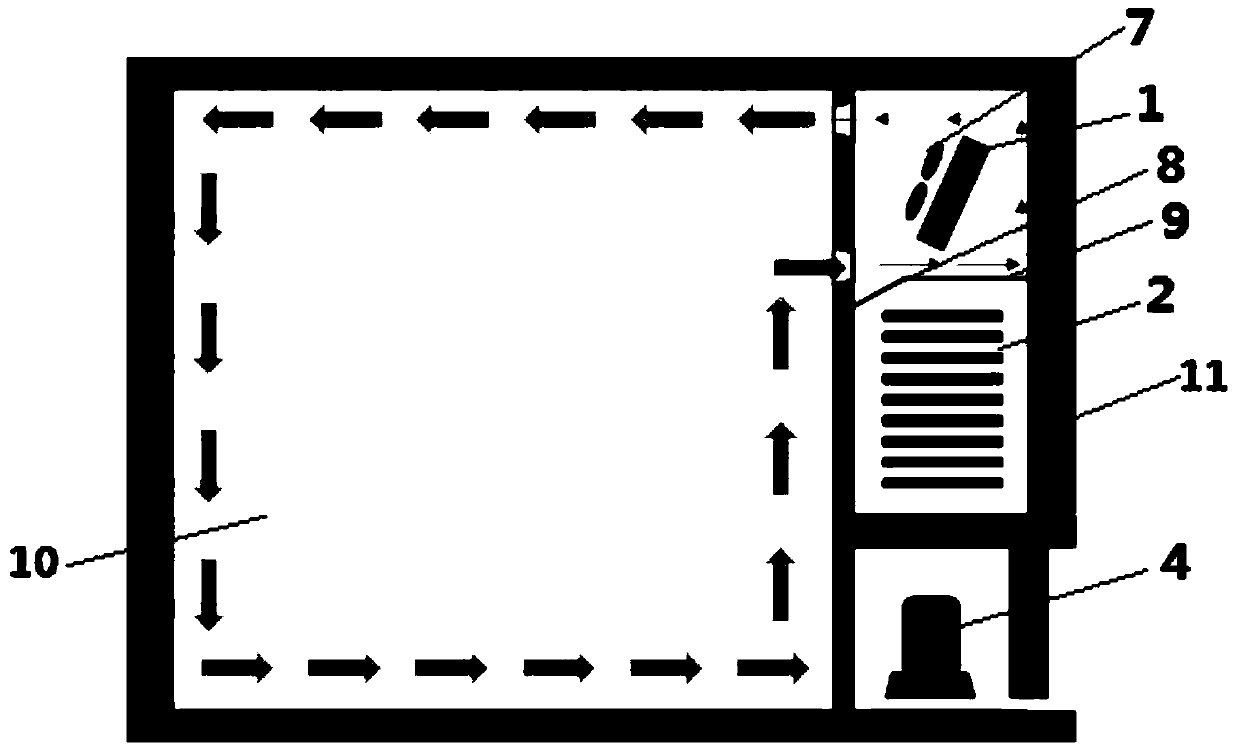

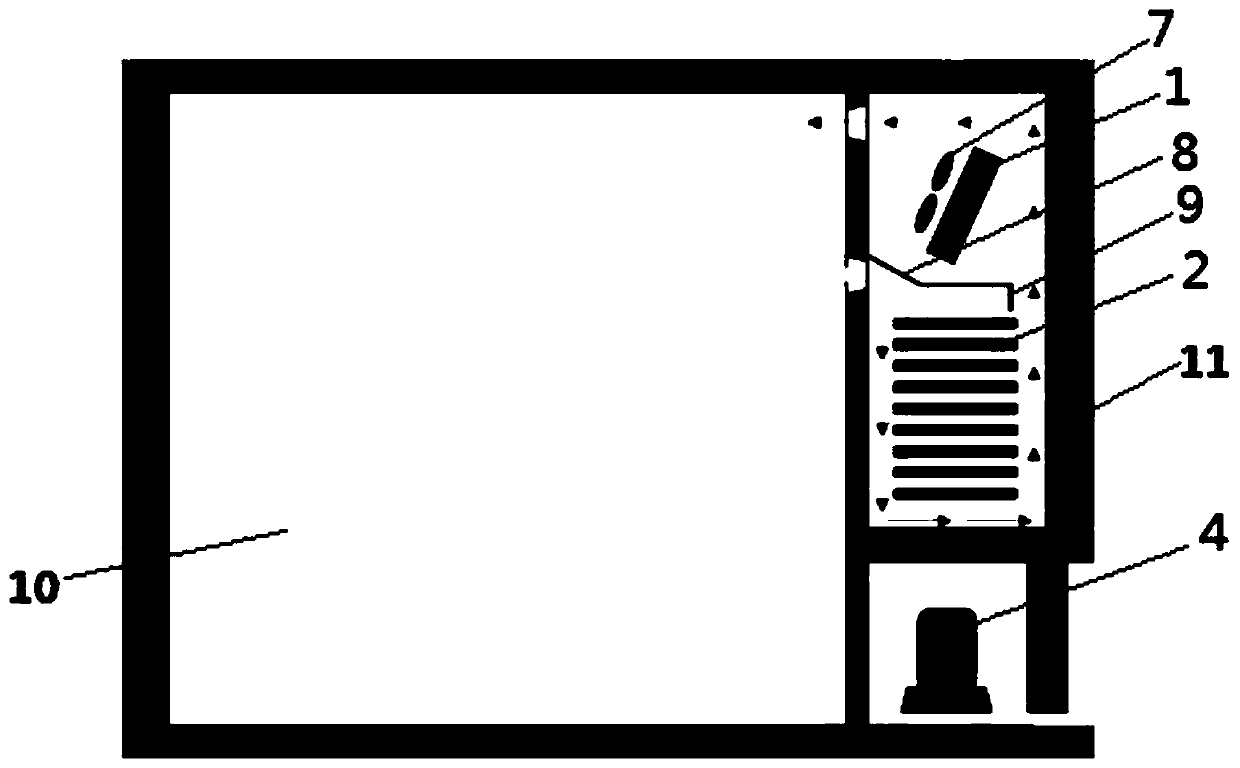

PendingCN110758924APrevent frostbiteGuaranteed temperature managementLarge containersTank wagonsCold chainTemperature control

The invention discloses a cold chain unit distribution box with independent cold storage space. The cold chain unit distribution box comprises a machine box body, and cold storage space arranged in the machine box body; a cold storage device is arranged in the cold storage space; and an evaporator with a fan is arranged in the machine box body. The cold chain unit distribution box further comprises a compressor connected to the cold storage device and an outlet end of the evaporator with the fan, and a condenser connected to an outlet end of the compressor; and a refrigerant outlet end of thecondenser is connected to an expansion valve. The cold chain unit distribution box can preferably guarantee the temperature management of goods space, prevents the risk of no temperature control of cold chain goods by failures of an air cooler system, preferably retains a cooling plate to achieve more exquisite capacity of temperature difference control and temperature maintenance, prevents the problem of higher temperature difference in the temperature control process due to refrigeration and temperature maintenance always by the air cooler, and can meet the distribution demands with more exquisite temperature requirements.

Owner:ZHEJIANG XUEBOLAN TECH CO LTD

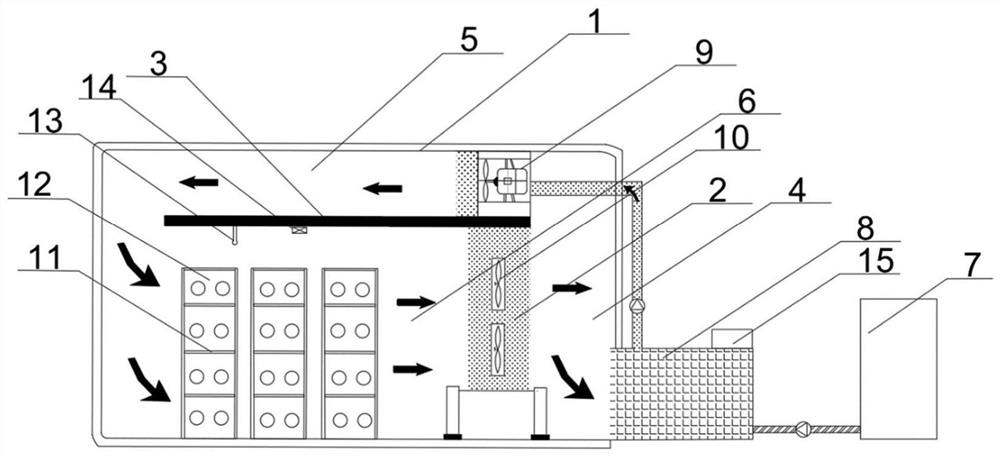

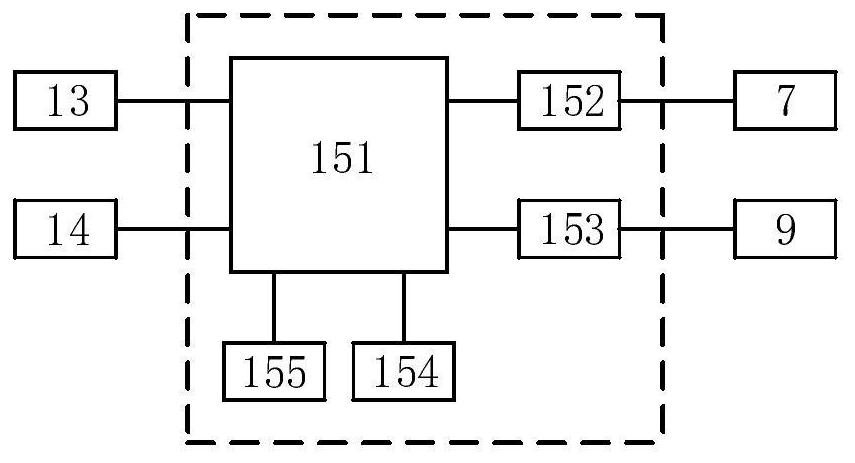

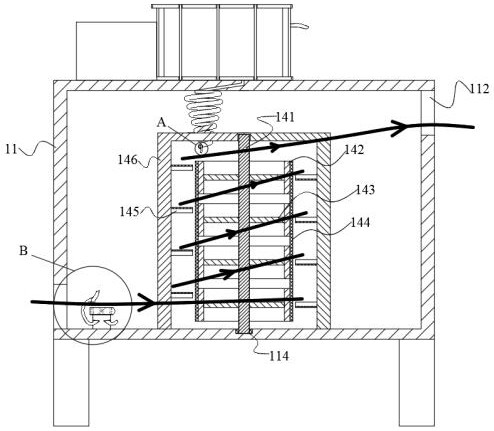

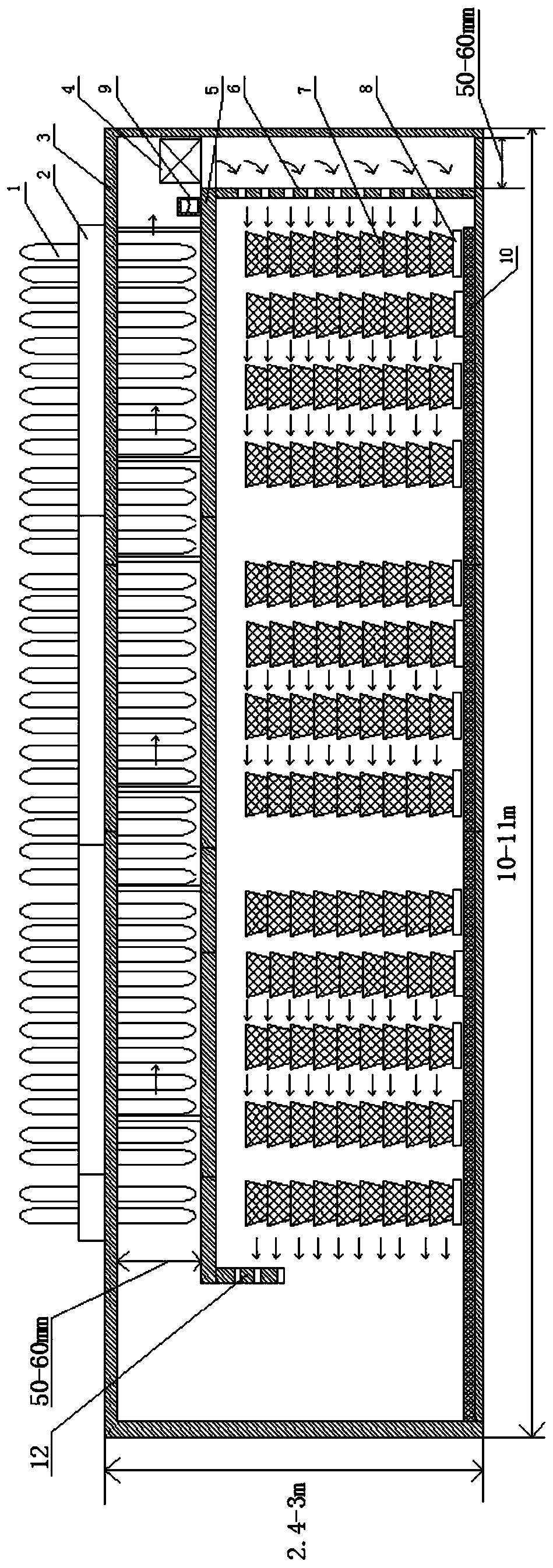

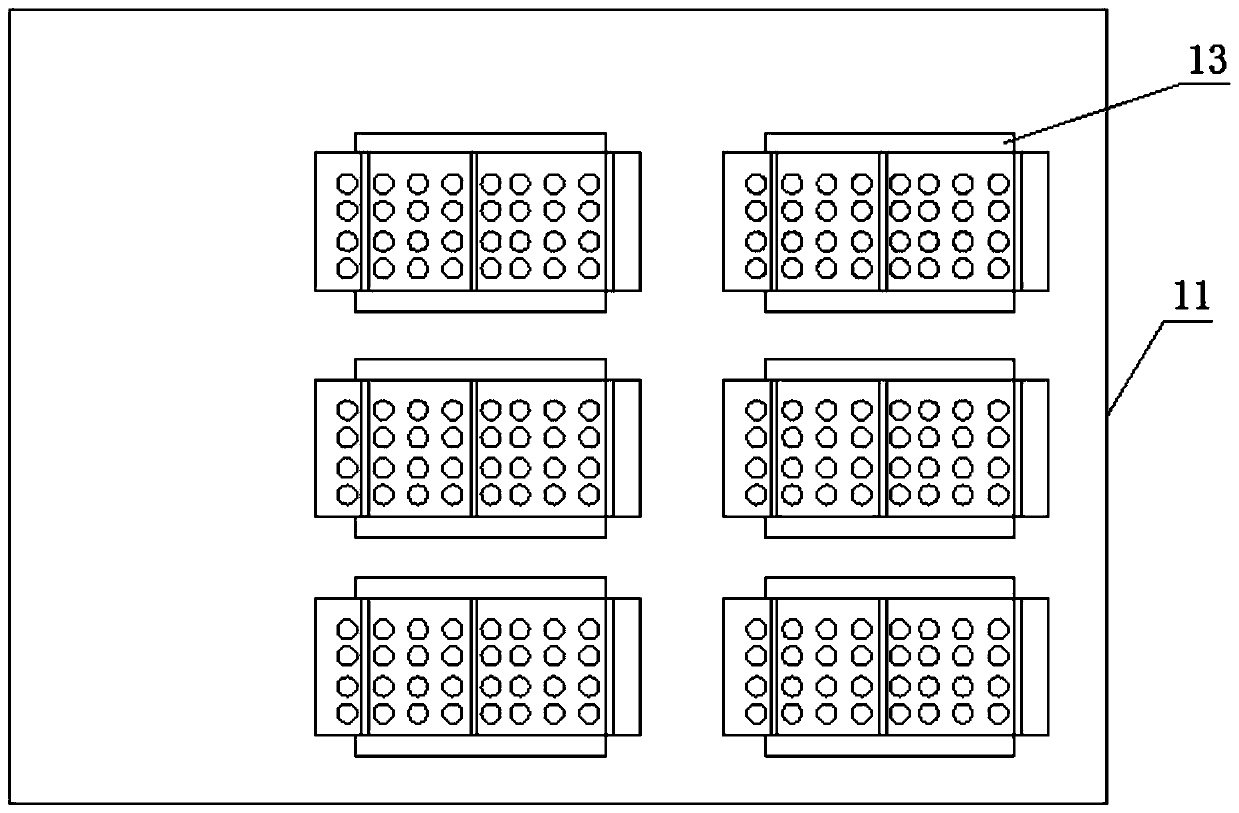

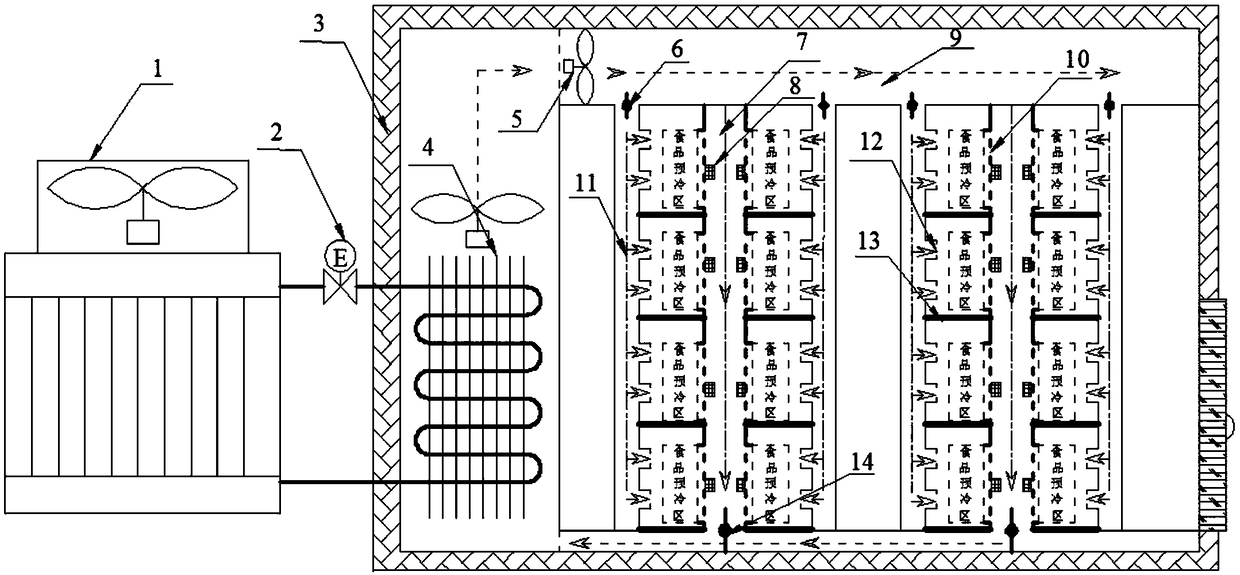

Intelligent agricultural product differential pressure precooling system adopting ice slurry

PendingCN114111147AAdd controlImprove reliabilityLighting and heating apparatusCooling fluid circulationAir pumpEngineering

The invention discloses an intelligent agricultural product differential pressure precooling system adopting ice slurry. The interior of the refrigeration house is divided into an air inlet area, a pre-cooling area and an air return area through a vertical partition and a transverse partition. An air inlet of the heat exchanger is communicated with the lower portion of the air return area, an air outlet of the heat exchanger is connected with the air cooler, and the ice slurry generator is connected with the heat exchanger through a pipeline. And a plurality of exhaust fans are embedded on the vertical partition of the air return area to form pressure difference. A goods shelf and a pre-cooling box are arranged in the pre-cooling area, and a temperature sensor and a humidity sensor are arranged in the pre-cooling area. And the temperature sensor, the humidity sensor, the ice slurry generator and the air cooler are connected with the control device. The air pumped into the air return area still has certain moisture and low temperature, is not directly discharged to the outside, but enters the heat exchanger for circulating heat exchange, and the problem of water loss in the traditional differential pressure precooling process is effectively solved. The problem that an existing pressure difference pre-cooling technology cannot be automatically and intelligently adjusted is solved, and the refrigeration efficiency is improved.

Owner:HANGZHOU DIANZI UNIV

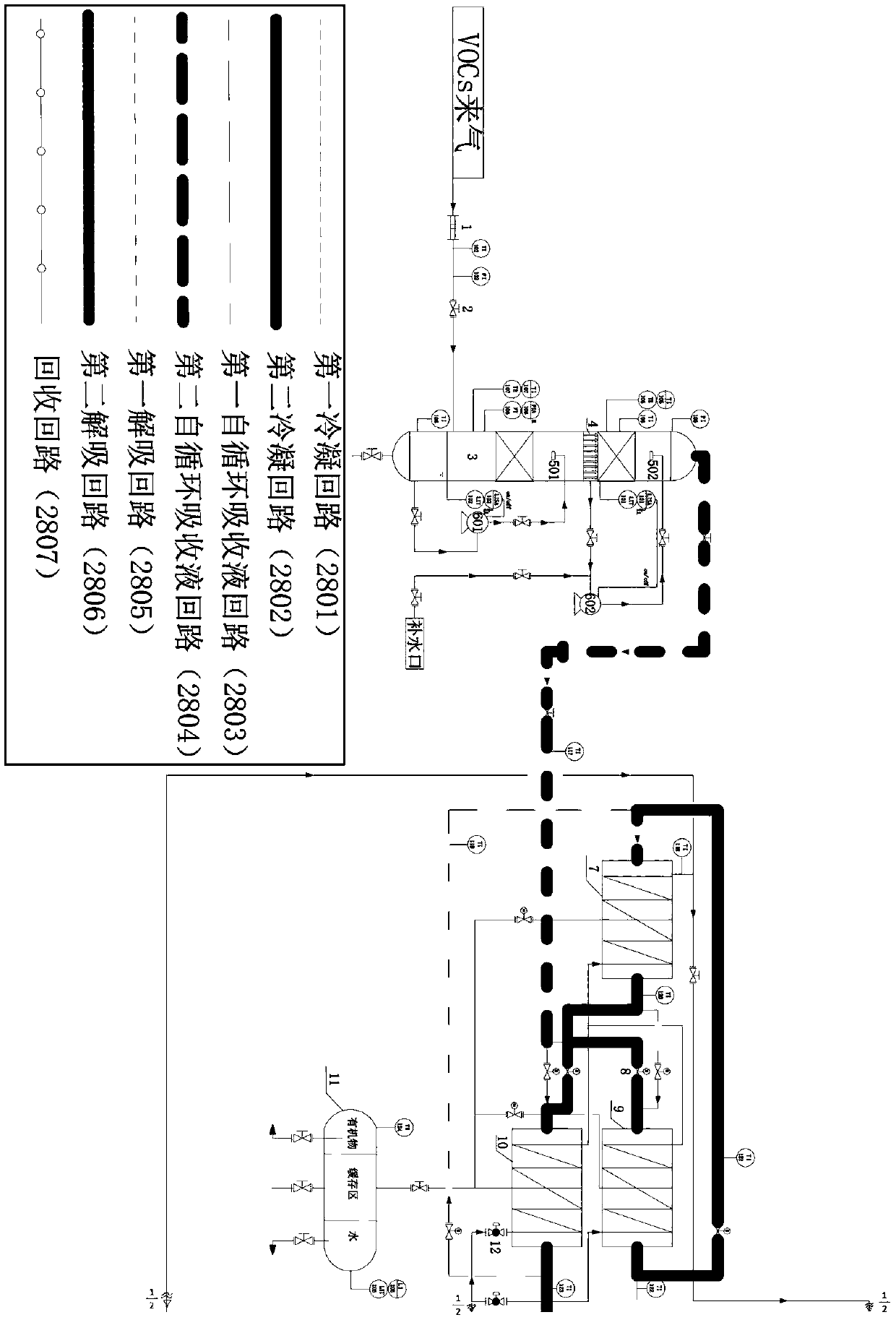

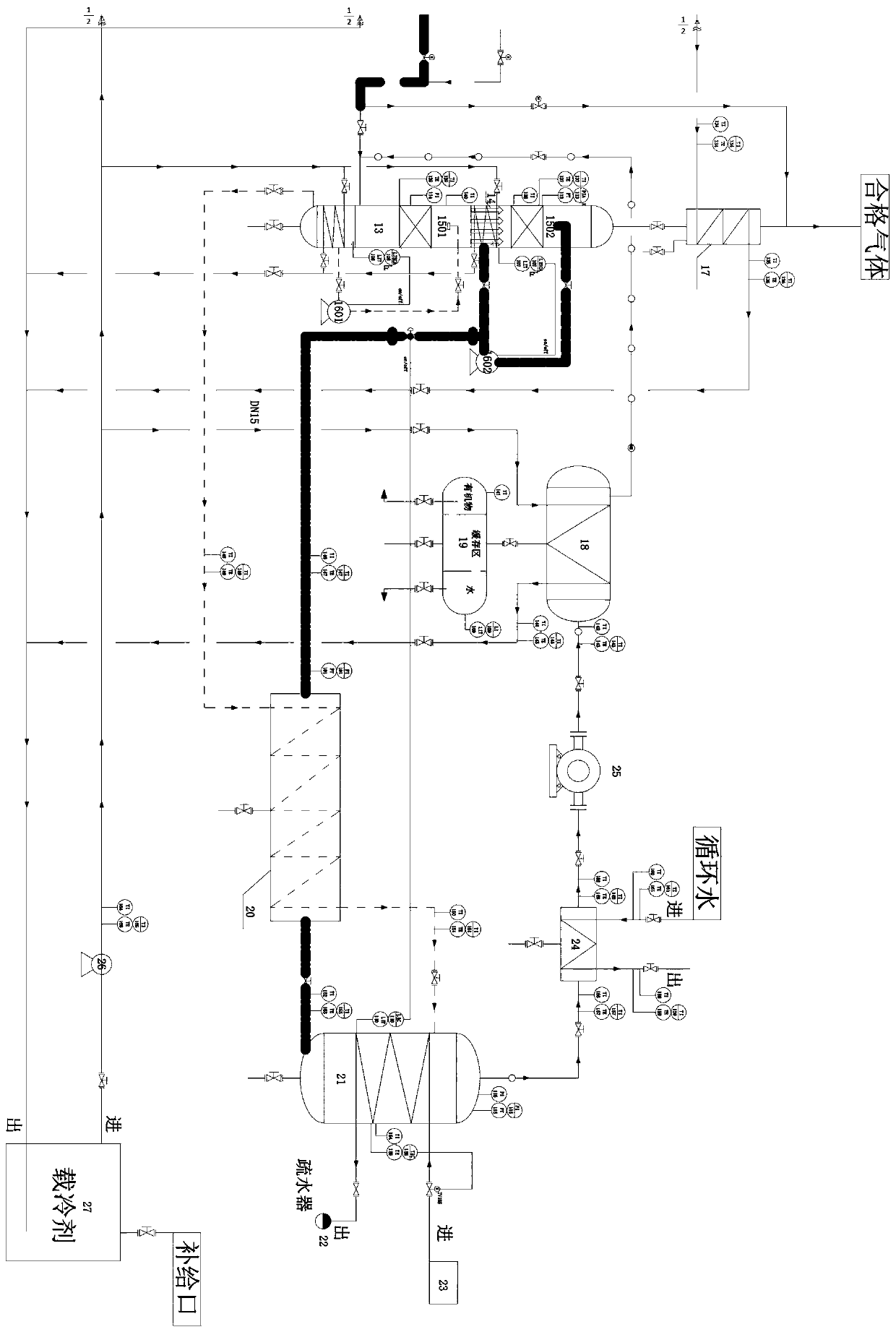

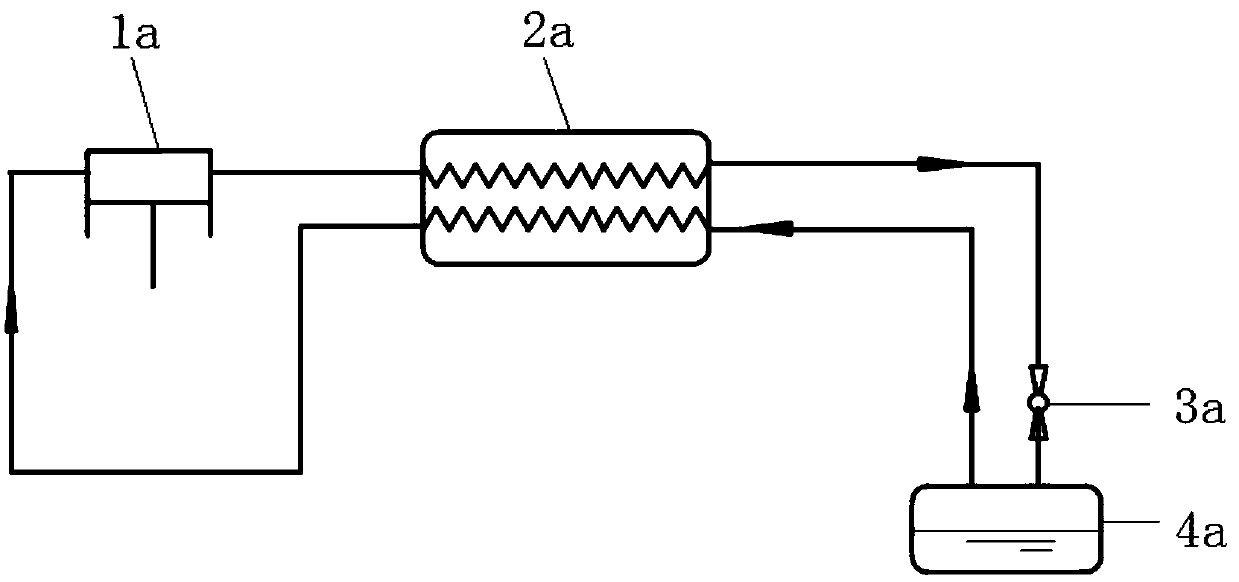

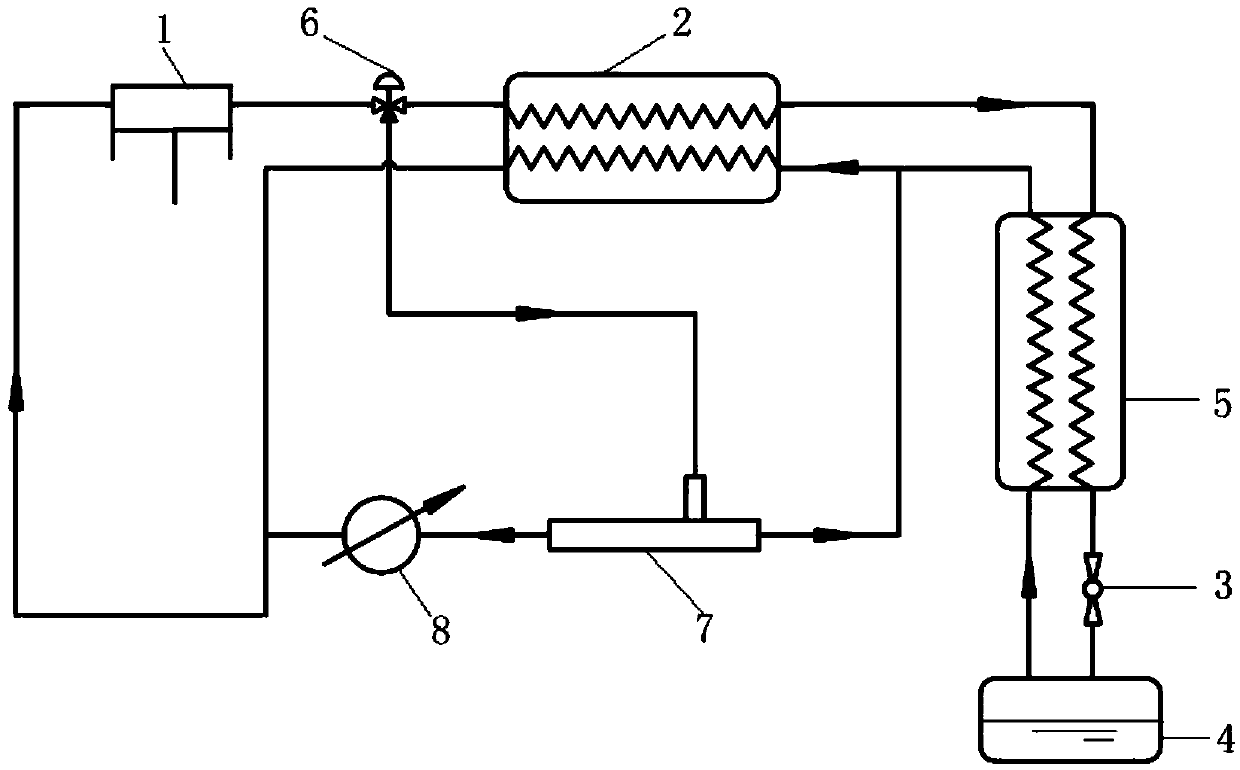

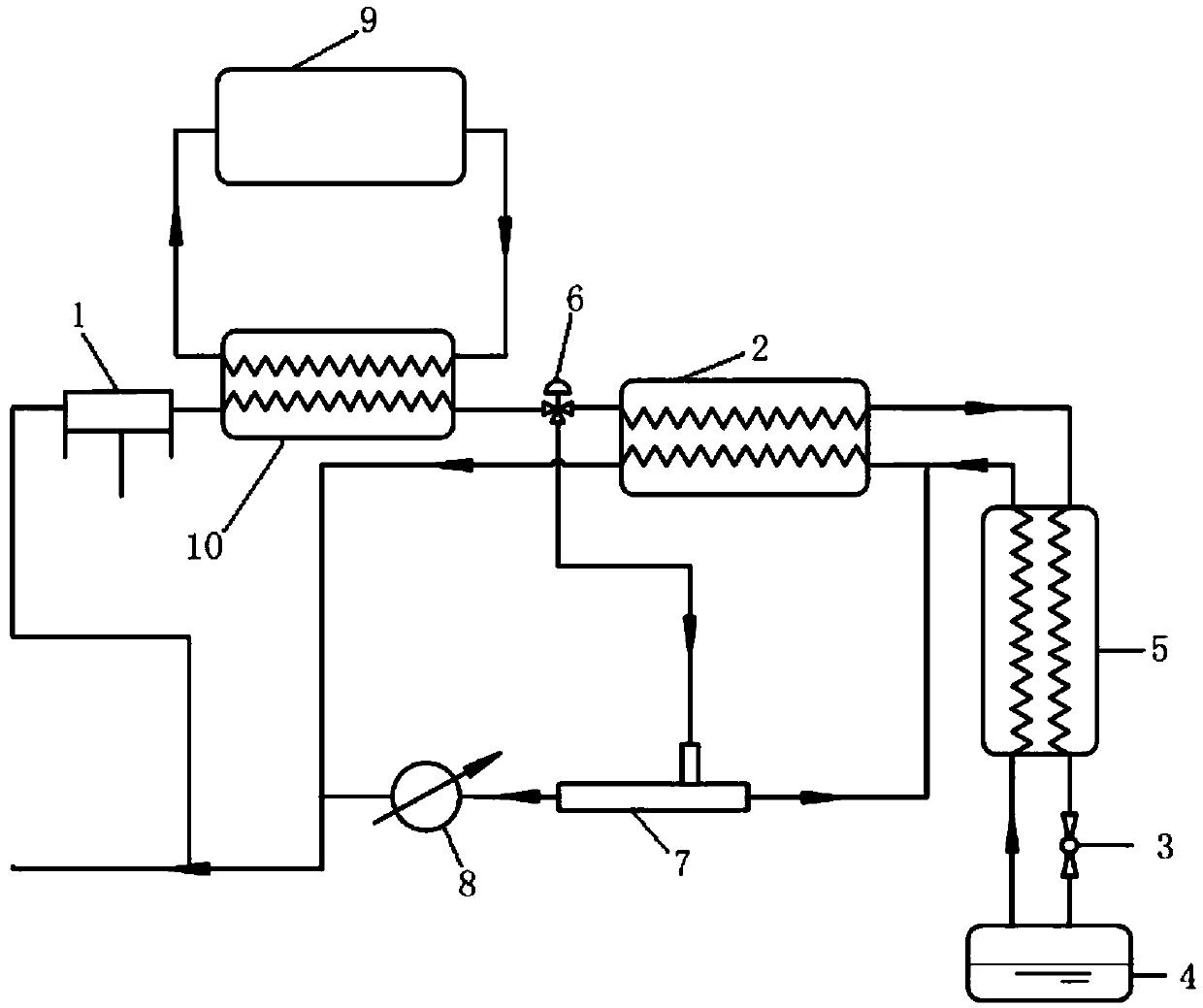

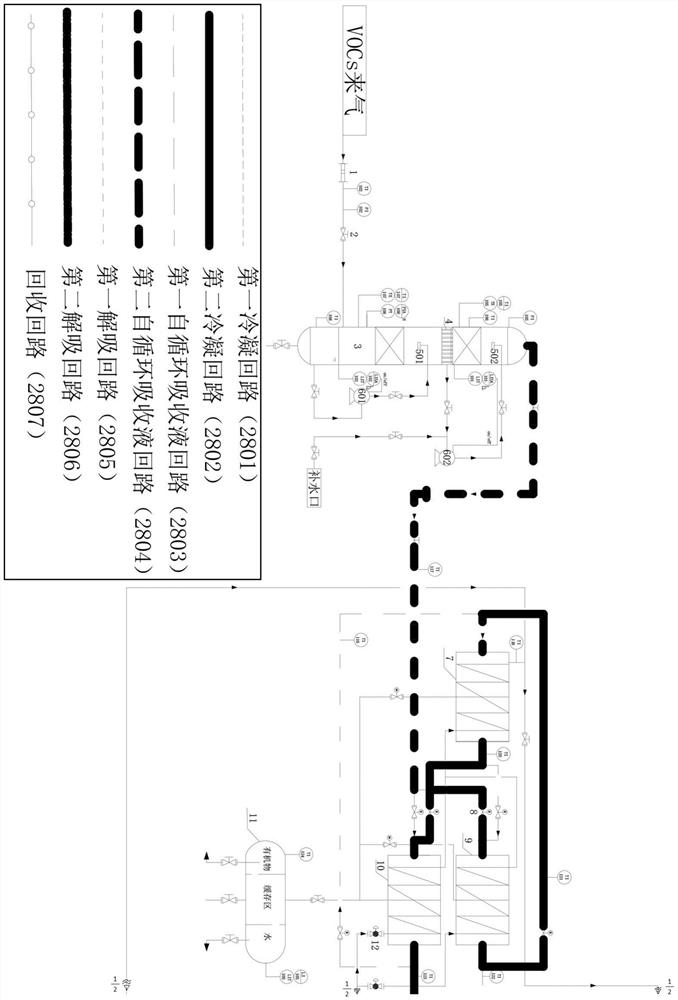

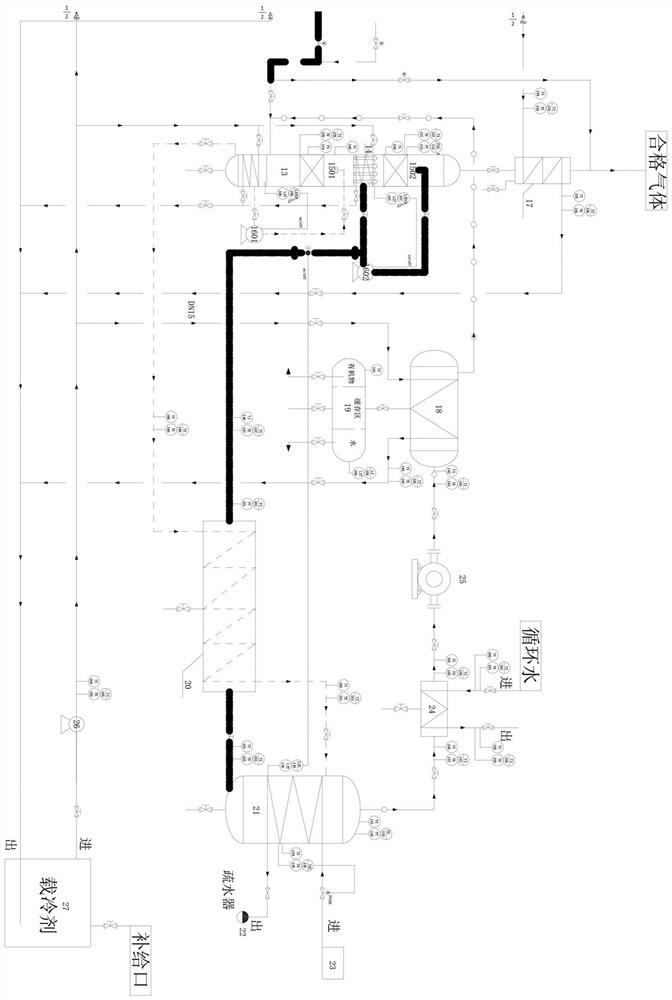

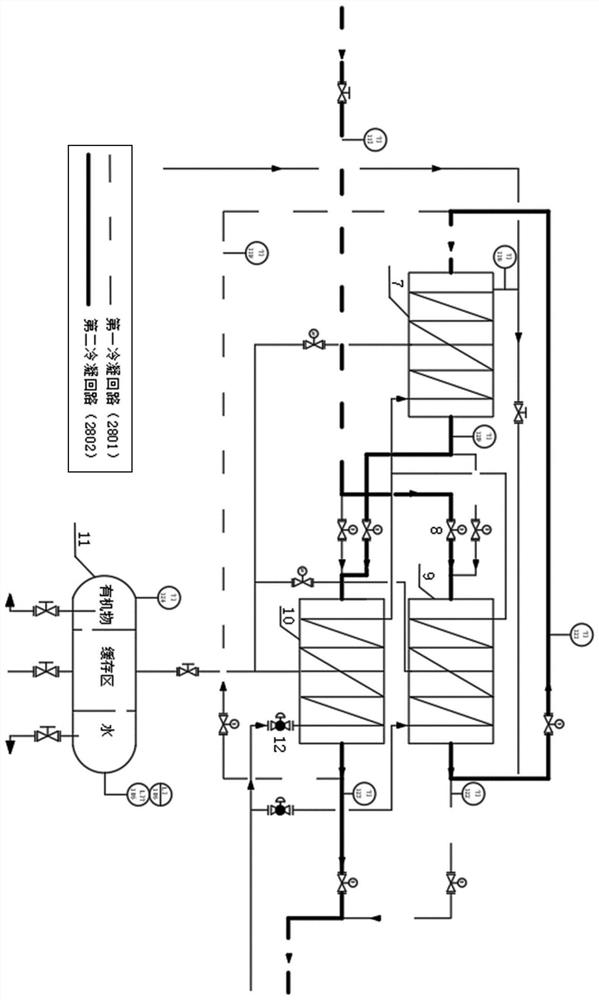

Absorption, desorption and recovery integrated VOCs recovery system and absorption, desorption and recovery integrated VOCs recovery method

ActiveCN111036041AAchieve recyclingReduce energy costsGas treatmentDispersed particle separationEnvironmental engineeringWaste management

The invention discloses an absorption, desorption and recovery integrated VOCs recovery system and an absorption, desorption and recovery integrated VOCs recovery method. The recovery system comprises: a water washing unit connected with a self-coupling pre-cooling unit and used for carrying out water washing on VOCs inlet gas; the self-coupling pre-cooling unit connected to a low-temperature absorption unit and used for condensing the washed VOCs gas; the low-temperature absorption unit connected to a high-temperature desorption unit through a heat exchanger II and used for absorbing the condensed VOCs gas; the high-temperature desorption unit connected to a low-temperature recovery unit through a heat exchanger III and used for desorbing the VOCs gas subjected to low-temperature absorption; and the low-temperature recovery unit connected to the low-temperature absorption unit and used for recovering the liquefied VOCs and conveying the non-liquefied VOCs to the low-temperature absorption unit again so as to be treated. The recovery system disclosed by the invention is highly energy-saving, and realizes cyclic utilization of the absorption liquid.

Owner:CHANGZHOU UNIV

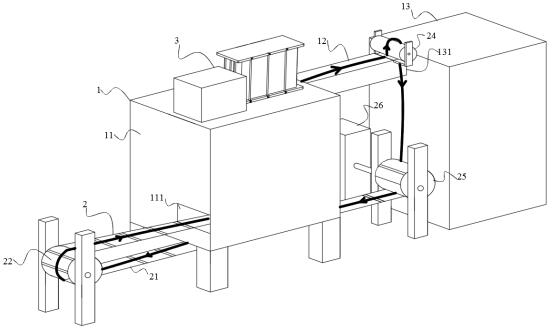

Gradient freezing storage device with double-helix quick-freezing diversion function

ActiveCN113959142APrevent leakageInstantaneous speed increaseLighting and heating apparatusDomestic refrigeratorsFrozen storageEngineering

The invention discloses a gradient freezing storage device with a double-helix quick-freezing diversion function. The gradient freezing storage device comprises a fixing device, a transmission device, a quick-freezing device and a pre-cooling device, the transmission device is movably connected with the fixing device, the fixing device comprises a freezing chamber, a connecting pipe and a storage tank, and the freezing chamber is connected with the storage tank through the connecting pipe. The quick-freezing device is connected with the freezing chamber, the freezing chamber is provided with a freezing cavity, the pre-cooling device is connected with the freezing chamber in a fastened mode, one side of the freezing cavity is provided with a conveying outlet, the freezing cavity communicates with the conveying outlet, the storage tank is provided with a feeding port, the two ends of the connecting pipe communicate with the conveying outlet and the feeding port respectively, the storage tank is provided with a storage cavity, the feeding port communicates with the storage cavity, and the conveying outlet is located at the upper end of one side of the freezing cavity. The side, away from the conveying outlet, of the freezing cavity is provided with a conveying inlet, and the conveying inlet is located at the lower end of one side of the freezing cavity.

Owner:杰欧(江苏)冷链装备有限公司

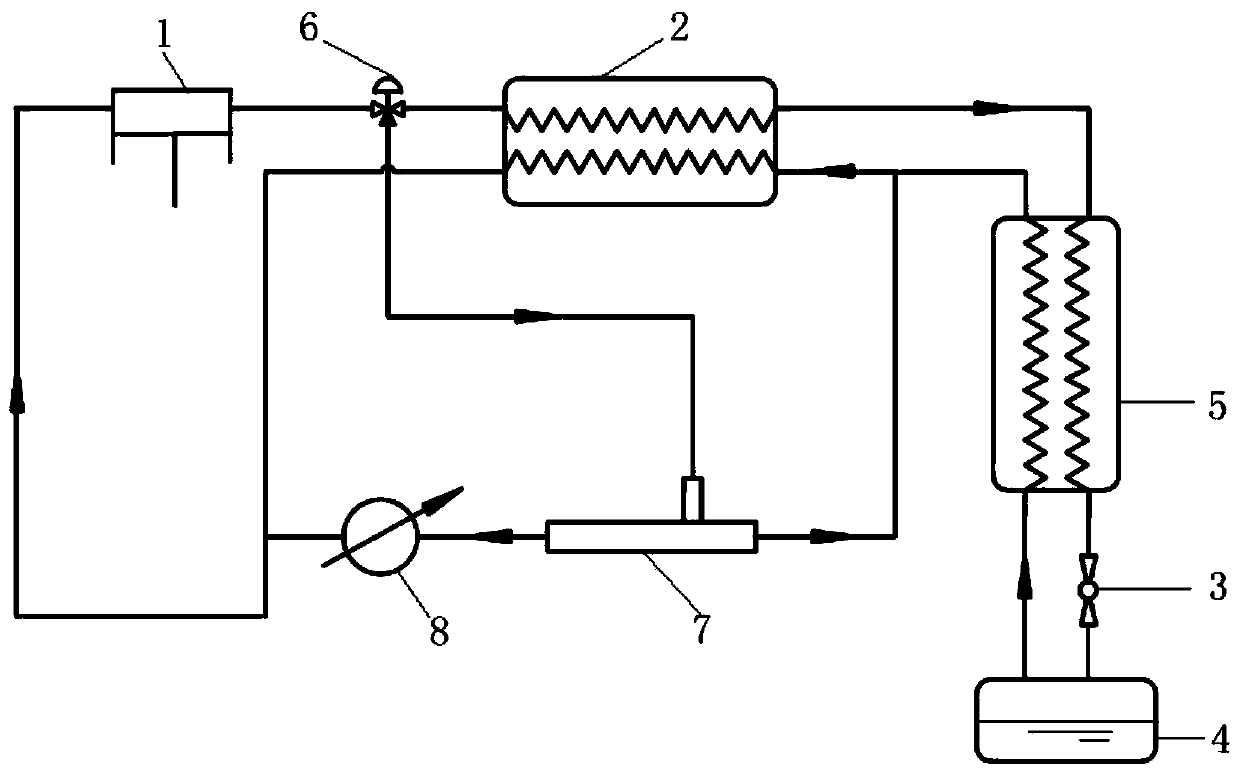

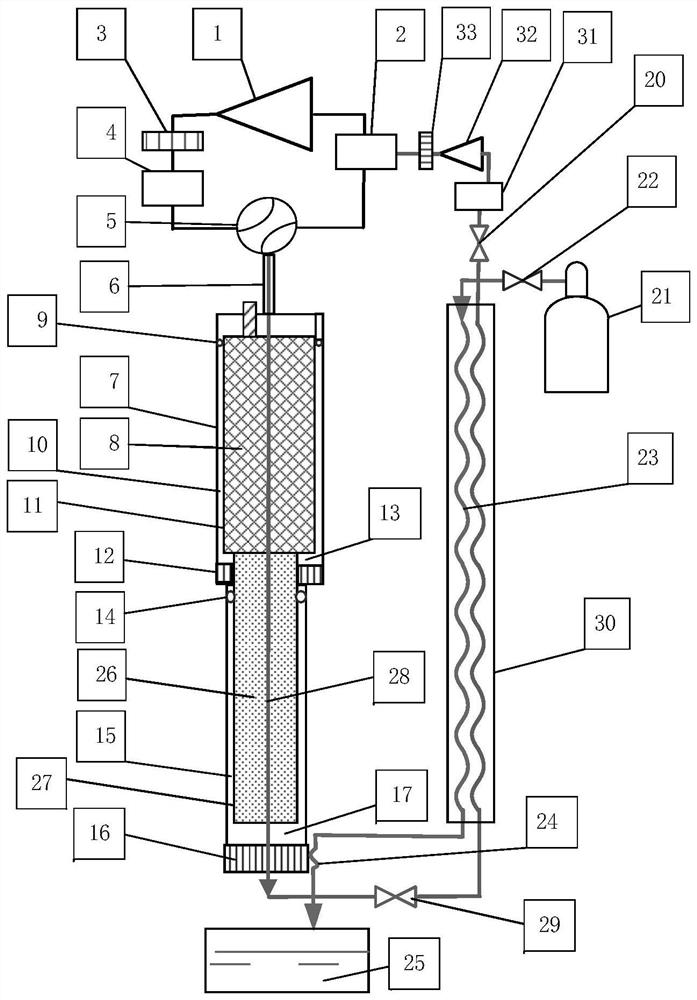

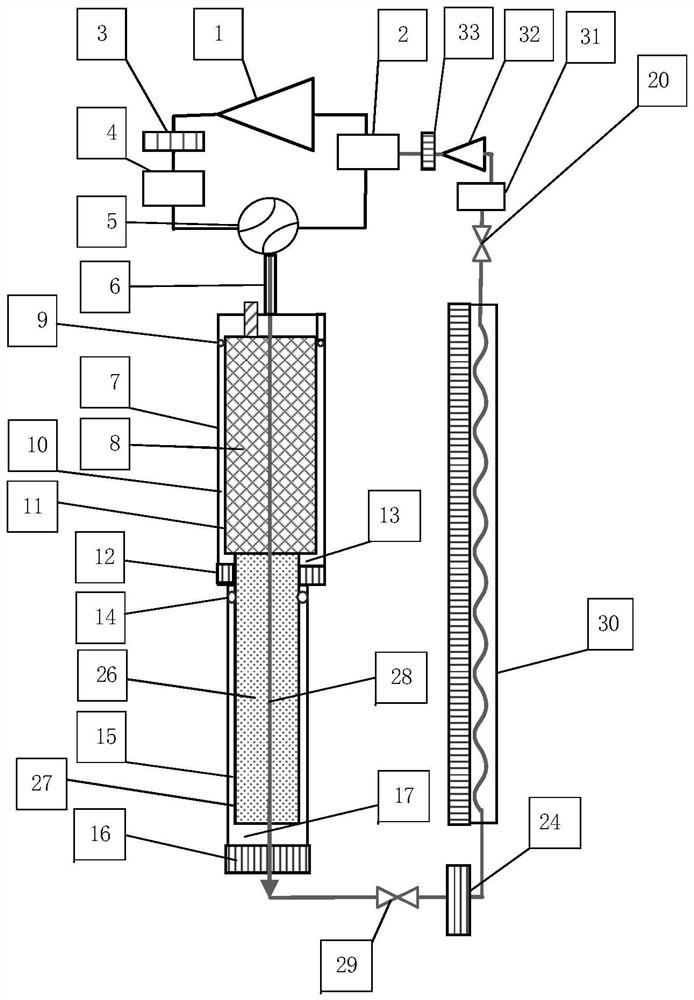

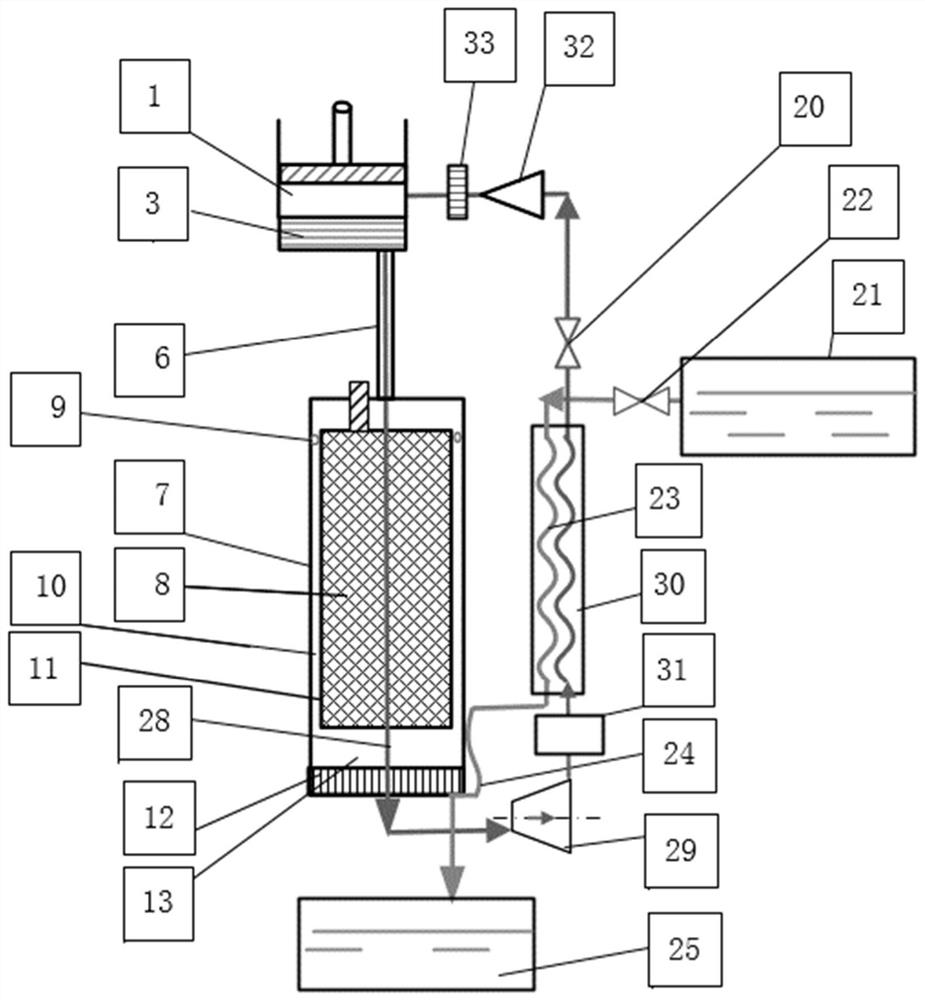

A low-temperature refrigeration system with one-time throttling for precooling by utilizing the energy separation effect of vortex tubes

ActiveCN108050722BSimple structureLarge expansion coefficientMechanical apparatusCompression machinesEngineeringRefrigeration

A throttling low-temperature refrigeration system for precooling using the energy separation effect of a vortex tube, comprising a compressor, a regenerator, a throttle valve and an evaporator, characterized in that the regenerator includes a first regenerator and a second regenerator The heater also includes a three-way flow regulating valve and a vortex tube, the outlet of the compressor is connected with the inlet of the three-way flow regulating valve, and the first outlet of the three-way flow regulating valve is connected with the hot end inlet of the first regenerator , the second outlet is connected with the inlet of the vortex tube, the outlet of the cold end of the vortex tube is merged with the outlet of the hot end of the second regenerator, and then connected with the inlet of the cold end of the first regenerator, the first regenerator The outlet of the hot end of the compressor is connected with the inlet of the compressor. The one-throttle low-temperature refrigeration system precooled by the energy separation effect of the vortex tube has a simple structure, can adopt internal precooling, and has high refrigeration efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

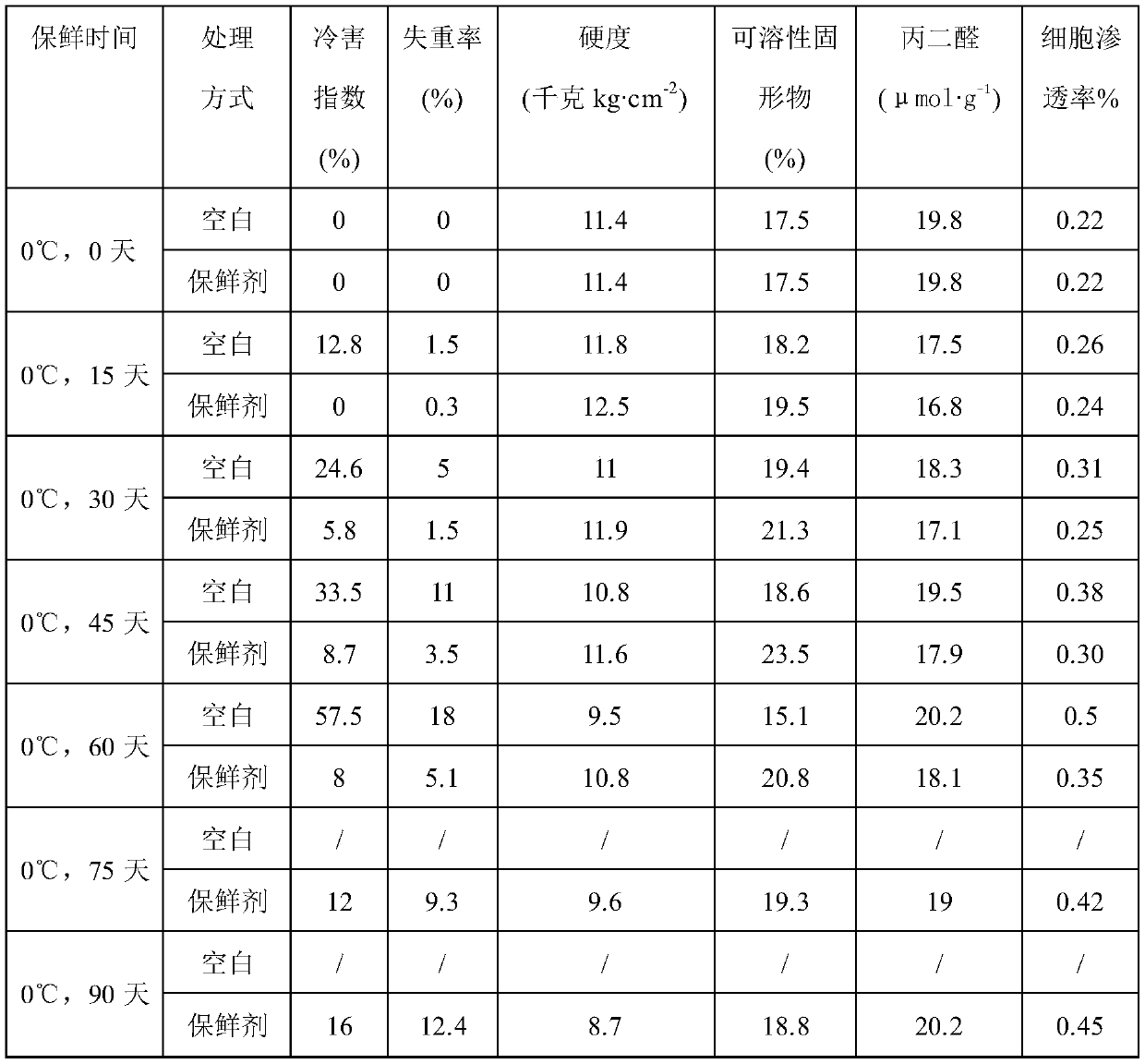

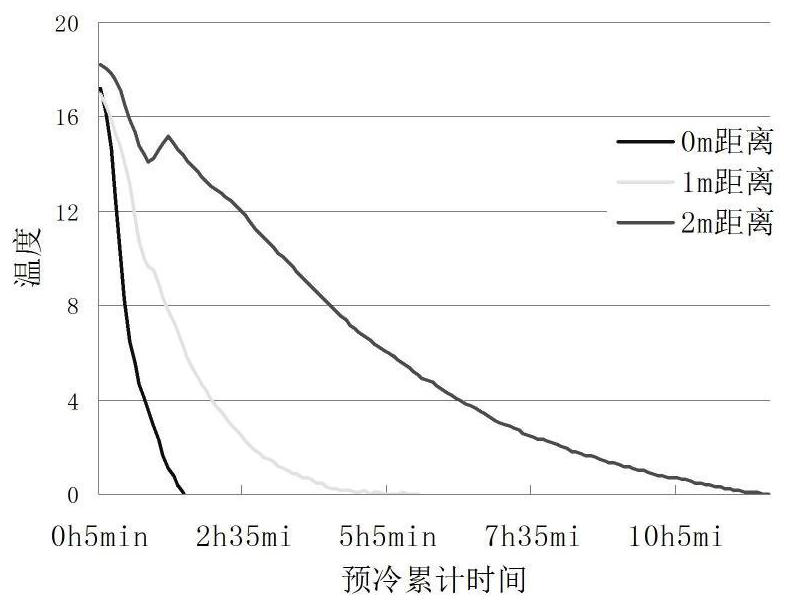

Pre-cooling Method of Lingwu Changzao Against Chilling Injury and Spot Spot Disease

ActiveCN107242290BReduce churnReduce lossFruits/vegetable preservation by freezing/coolingDiseaseThermodynamics

The invention relates to a Lingwu long jujube precooling method used for preventing cold injury and surface dot piting. According to the Lingwu long jujube precooling method, harvested Lingwu long jujubes without damage are delivered into a differential pressure precooling device provided with high efficiency tunnel differential pressure atmosphere controlled precooling equipment, gradient cooling is adopted for precooling, the temperature is reduced to 5 DEG C from 25 to 30 DEG C at a uniform speed in 6 to 10h, and then is reduced to 0 DEG C at a temperature reducing speed of 1 DEG C per 24h. According to the Lingwu long jujube precooling method, gradient cooling is adopted, fruit low temperature impact resistance is improved, on one hand dissipation of a large amount of filed heat is realized quickly, one the other hand fruit callusing is accelerated, and in addition fruit defensive system is activated, it is beneficial for improving of fruit cold resistance and reducing later period cold injury.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

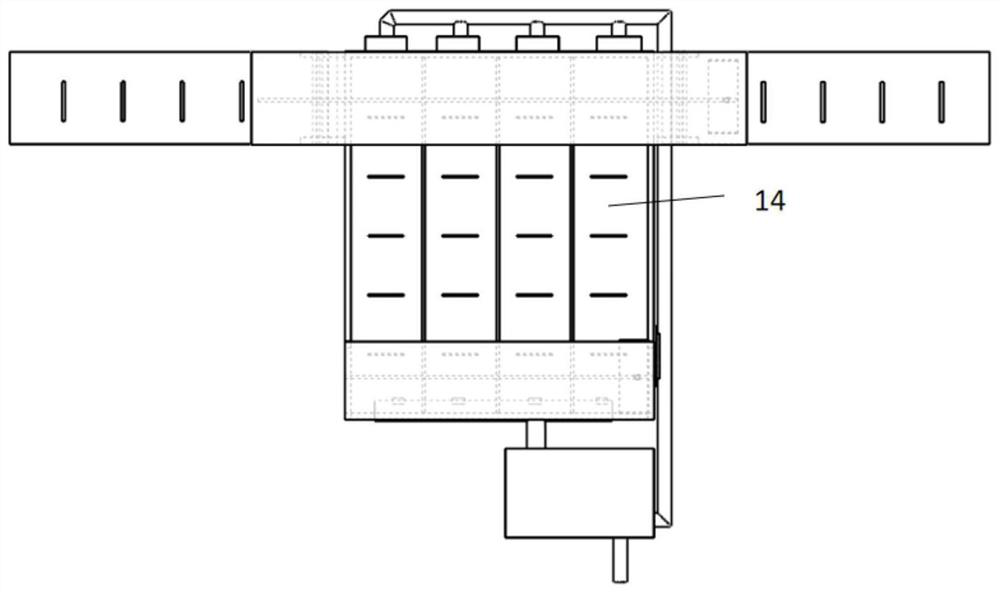

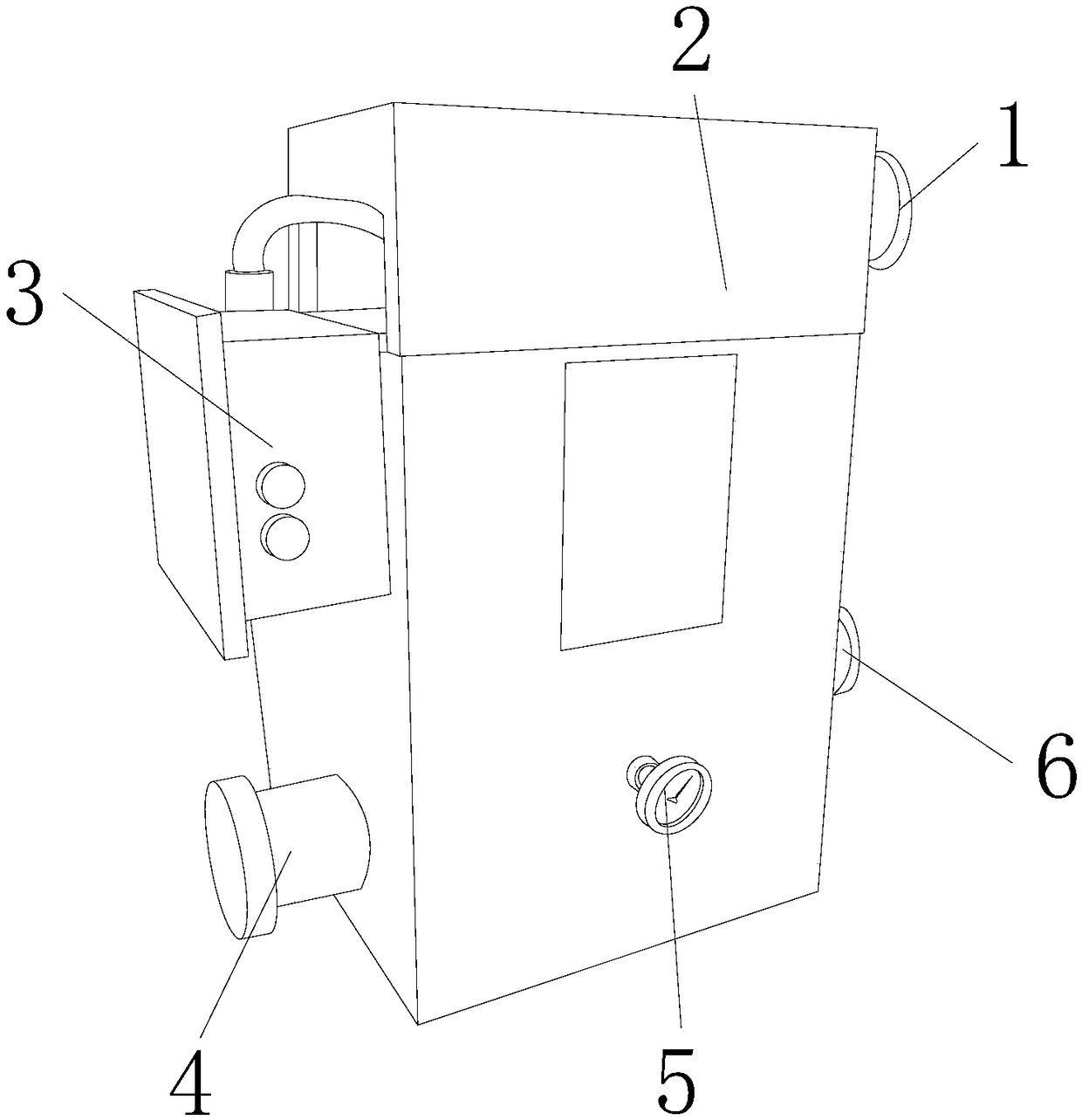

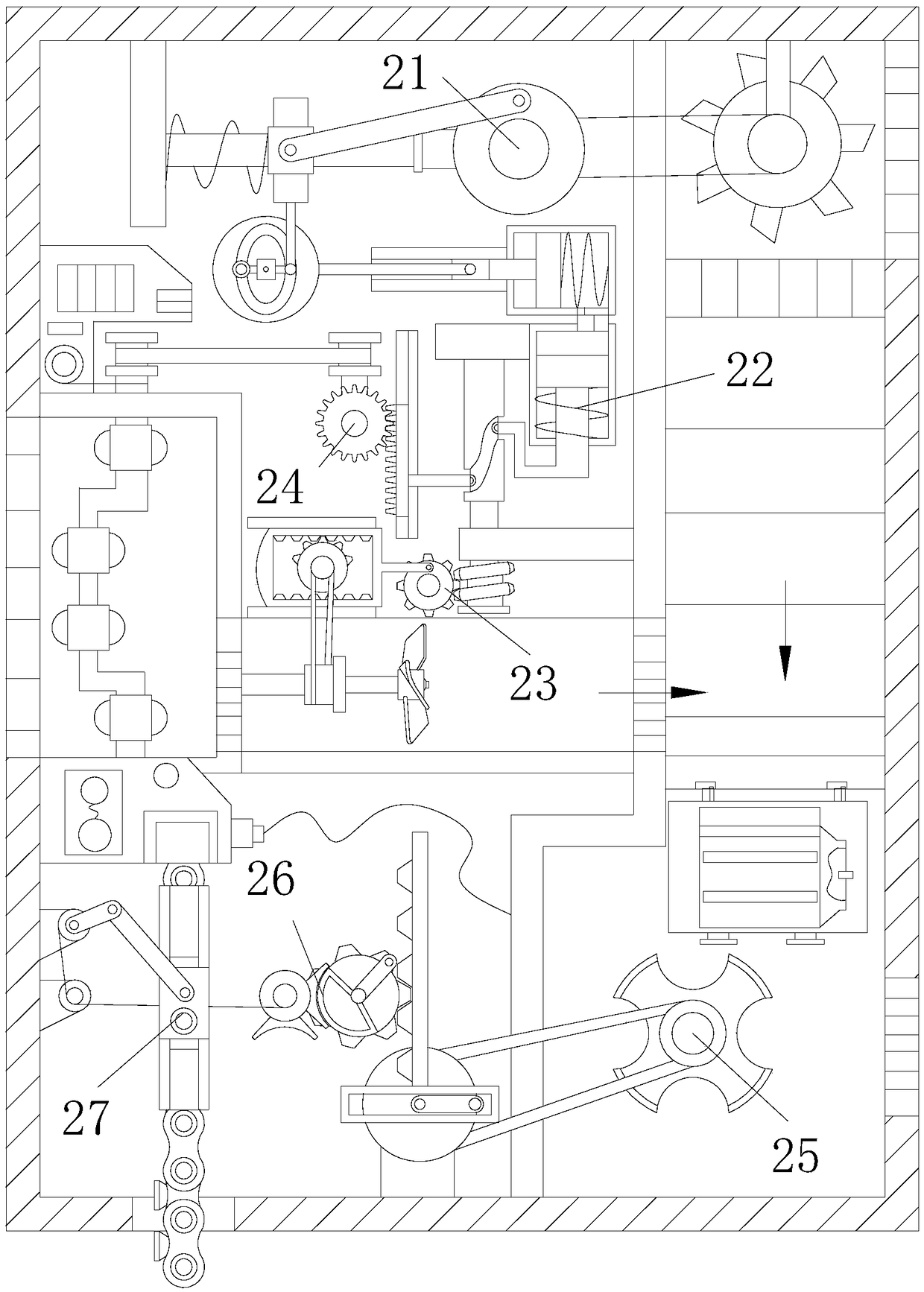

A classification precooling device for deep-sea fish and its application

ActiveCN113970222BAvoid wastingAvoid damageLighting and heating apparatusIce productionThermal insulationCooling chamber

The invention discloses a classification and pre-cooling device for pelagic fish catches and an application thereof. The grading and pre-cooling device for pelagic fish includes a pre-cooling chamber with thermal insulation performance and a fluid ice making equipment; The extraction equipment is connected to the pre-cooling cabin through the flow ice output pipeline; the two ends of the pre-cooling cabin are respectively provided with circulation components for the transport of fish catches, and the cabin is divided into a plurality of compartments by partitions, and each compartment is divided into several compartments. The bottom of each compartment is provided with a transmission device; the fluid ice making equipment transports fluid ice to each compartment of the pre-cooling chamber through the fluid ice output pipeline; the present invention performs overall control through the electronic control module, The rapid cooling of the fish body is achieved by grading pre-cooling in different compartments of the cabin. The grading pre-cooling in different compartments can effectively shorten the pre-cooling time by 1 / 3, and improve the overall quality of deep-sea fishing. Freshness efficiency. In addition, the catches in the cabin are stacked and pre-cooled, which avoids squeezing and damage between the fish bodies and ensures the quality of the fish bodies.

Owner:ZHEJIANG UNIV OF TECH

Liquefied natural gas pre-cooling device

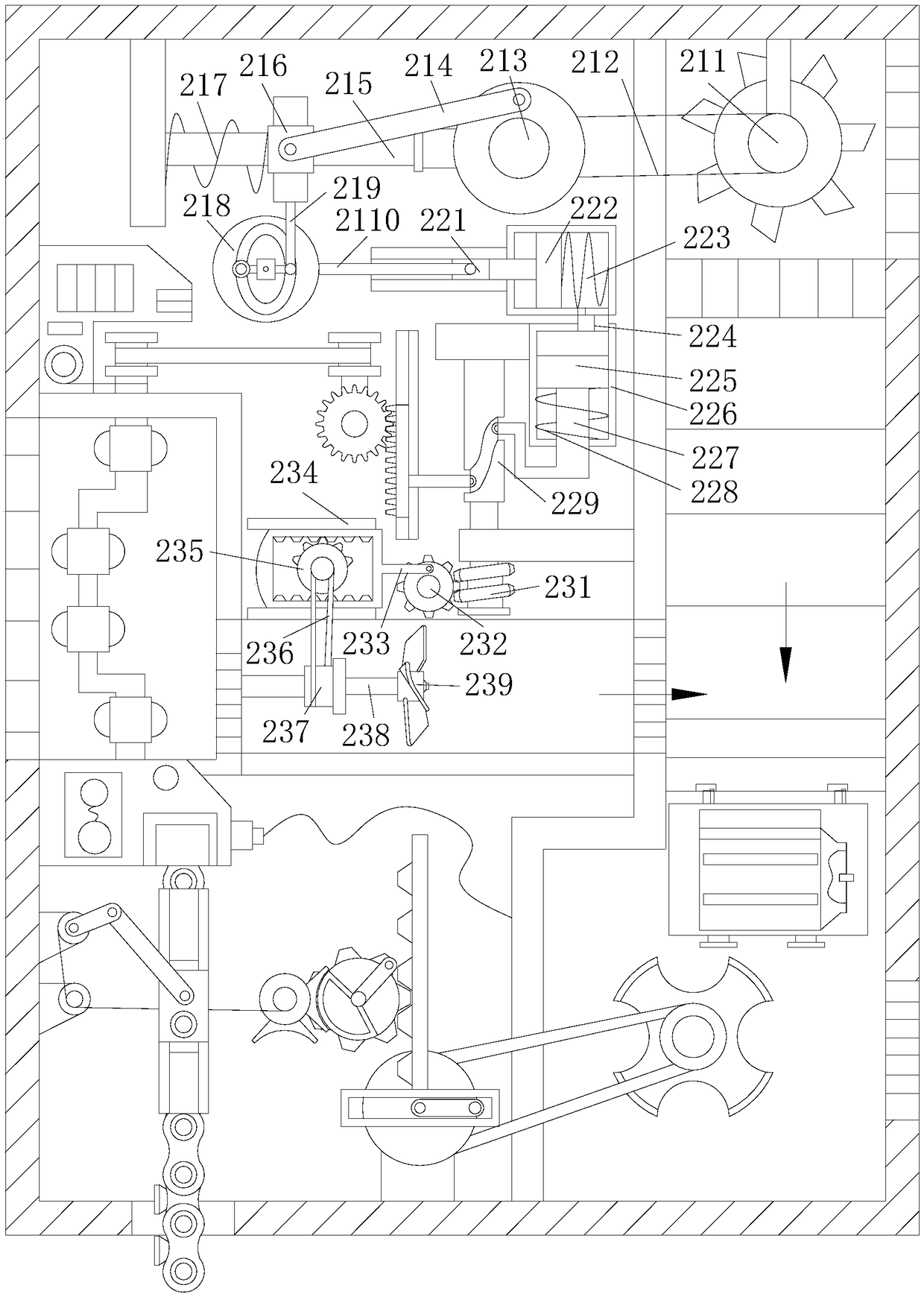

InactiveCN108826828ARealize the ability to retractSpeed up coolingSolidificationLiquefactionElectricityProcess engineering

The invention discloses a liquefied natural gas pre-cooling device. The liquefied natural gas pre-cooling device structurally comprises a gas inlet pipe, an anti-static pre-cooling device, a controller, a protector, a pressure gauge and a liquid discharge pipe; and the left end of the gas inlet pipe is welded with the right upper part of the anti-static pre-cooling device, the left surface of theanti-static pre-cooling device is attached to the right surface of the controller and is fixed through screws, and the protector is arranged below the controller and is electrically connected to the controller through wires. According to device, the anti-static pre-cooling device comprises a gas flow driving device, a transmission mechanism, a uniform cooling device, a rapid condensation device, aliquid flow starting device, a timing rotating mechanism and an anti-static device; and when liquefied natural gas is pre-cooled, the pre-cooling of the liquefied natural gas can be more uniform, thepre-cooling efficiency is improved, static electricity generated by friction between the liquefied natural gas and the inner wall of the device can be led outside, sparks are prevented from being generated inside the device, so that the safety capability is improved.

Owner:杨永红

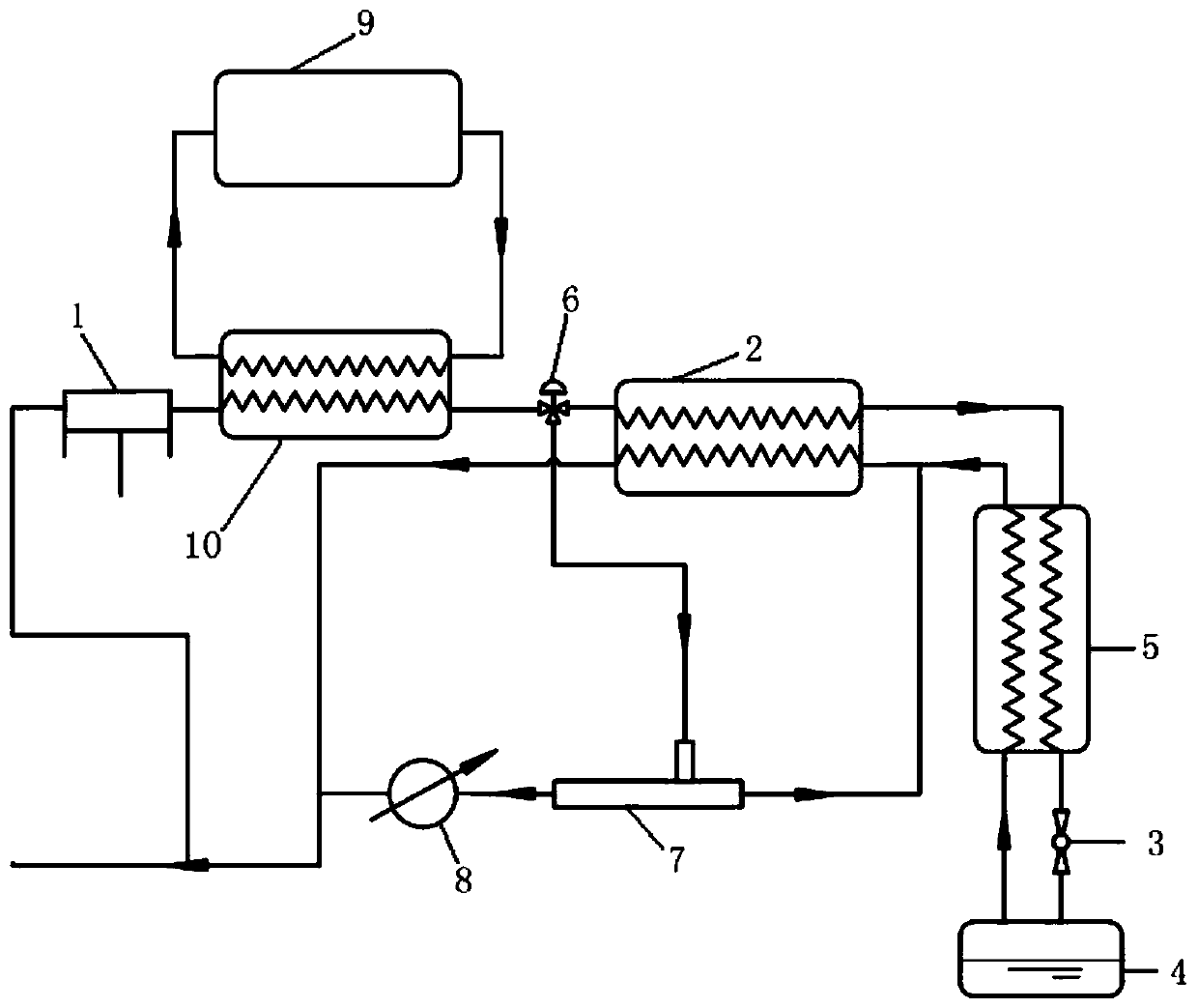

Efficient pre-cooling and liquefying system coupled with expansion mechanism and regenerative refrigerator

PendingCN114353366AIncrease the cooling capacity of the cold endImprove pre-cooling efficiencySolidificationLiquefactionProcess engineeringEngineering

The invention relates to an efficient pre-cooling and liquefying system of a coupling expansion mechanism and a regenerative refrigerating machine. The efficient pre-cooling and liquefying system comprises a regenerative refrigerating module, an expansion and compression module and a pre-cooling and liquefying module. The regenerative refrigeration module comprises a regenerative refrigerator unit and a direct-current external circulation unit; the regenerative refrigerator unit comprises a compressor device, a regenerator and a cold end heat exchanger which are connected in sequence; in the direct-current external circulation unit, direct current is led out of the refrigerator unit from any position, passes through a plurality of channels and then returns to the heat regenerator, and direct-current circulation is completed. And a direct-current control valve is arranged in the direct-current external circulation unit so as to control the direct-current flow. Compared with the prior art, the direct current led out is subjected to expansion depressurization, the expansion refrigeration effect is improved, the pressure similar to that of the to-be-precooled material is obtained, the specific heat capacity of the to-be-precooled material is similar, more to-be-precooled materials can be precooled and liquefied through the equivalent led-out direct current, and therefore the precooling and liquefying efficiency is improved.

Owner:TONGJI UNIV

Primary throttling low-temperature refrigeration system pre-cooled by utilizing the vortex tube energy separation effect

ActiveCN108050722ASimple structureLarge expansion coefficientMechanical apparatusCompression machinesEngineeringSystem structure

The invention discloses a primary throttling low-temperature refrigeration system pre-cooled by utilizing the vortex tube energy separation effect. The system comprises a compressor, heat regenerators, a throttling valve and an evaporator, and is characterized in that the heat regenerator comprises a first heat regenerator and a second heat regenerator; the system further comprises a three-way flow regulating valve and a vortex tube; an outlet of the compressor communicates with an inlet of the three-way flow regulating valve, a first outlet of the three-way flow regulating valve communicateswith a hot end inlet of the first heat regenerator, and a second outlet of the three-way flow regulating valve communicates with an inlet of the vortex tube; a cold end outlet of the vortex tube and ahot end outlet of the second heat regenerator are combined into one path to communicate with a cold end inlet of the first heat regenerator; and a hot end outlet of the first heat regenerator communicates with an inlet of the compressor. The primary throttling low-temperature refrigeration system pre-cooled by utilizing the vortex tube energy separation effect has the advantages that structure issimple, internal pre-cooling can be adopted, and the refrigerating efficiency is high.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

A vocs recovery system and method integrating absorption, desorption and recovery

ActiveCN111036041BAchieve recyclingReduce energy costsGas treatmentDispersed particle separationHigh energyProcess engineering

The invention discloses a VOCs recovery system and method that integrates absorption, desorption and recovery. The recovery system includes a water washing unit: connected to a self-coupling pre-cooling unit, used to wash VOCs intake air; a self-coupling pre-cooling unit: connected to To the low-temperature absorption unit, used to condense the VOCs gas after washing; the low-temperature absorption unit: connected to the high-temperature desorption unit through the second heat exchanger, used to absorb the condensed VOCs gas; the high-temperature desorption unit: through the heat exchanger 3. Connected to the low-temperature recovery unit for desorption of VOCs gas after low-temperature absorption; low-temperature recovery unit: connected to the low-temperature absorption unit for recovery of liquefied VOCs, and retransmitting unliquefied VOCs to the low-temperature absorption unit for processing . The recovery system of the invention not only has high energy saving, but also realizes the recycling of the absorption liquid.

Owner:CHANGZHOU UNIV

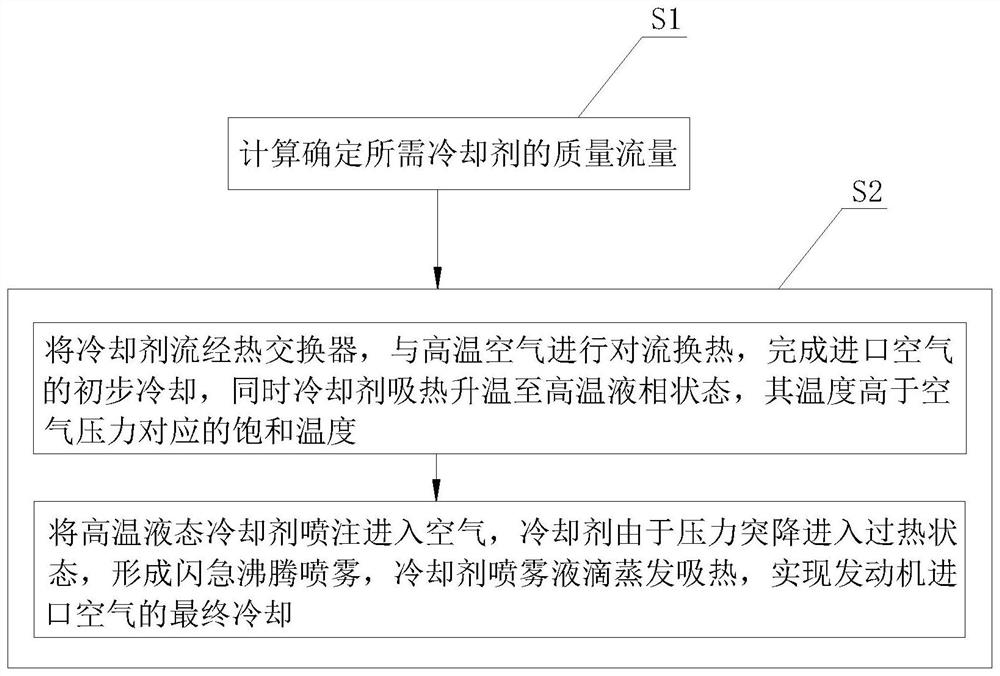

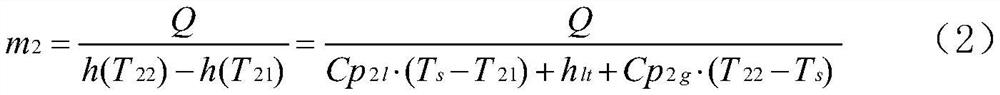

Engine inlet air cooling method

PendingCN114151188AImprove pre-cooling efficiencyIncrease evaporation rateInternal combustion piston enginesCoolant flowLiquid state

The invention discloses an engine inlet air cooling method, and relates to the technical field of aerospace power, and the technical scheme is characterized in that S1, the flow of a required coolant is determined; s2, enabling a coolant to flow through a heat exchanger, enabling the coolant to perform convection heat exchange with air at an inlet of the engine, completing primary cooling of the air, and meanwhile, enabling the coolant to absorb heat to be heated to a high-temperature liquid-phase state and enabling the temperature to be higher than saturation temperature corresponding to inlet air pressure; a high-temperature liquid coolant is sprayed into air, spray droplets evaporate and absorb heat in the air, and final cooling of the air at the inlet of the engine is achieved. Coolant flows into the heat exchanger and performs convective heat exchange with inlet air, so that the coolant absorbs heat and is heated and then sprayed into the air, the viscosity and the surface tension of the coolant are reduced along with temperature rise, meanwhile, the coolant enters an overheating state due to sudden pressure drop to form flash boiling spray, and the size of spray liquid drops is greatly reduced; therefore, coolant evaporation rate is improved, evaporation distance is shortened, and air cooling efficiency is improved.

Owner:中国空气动力研究与发展中心空天技术研究所

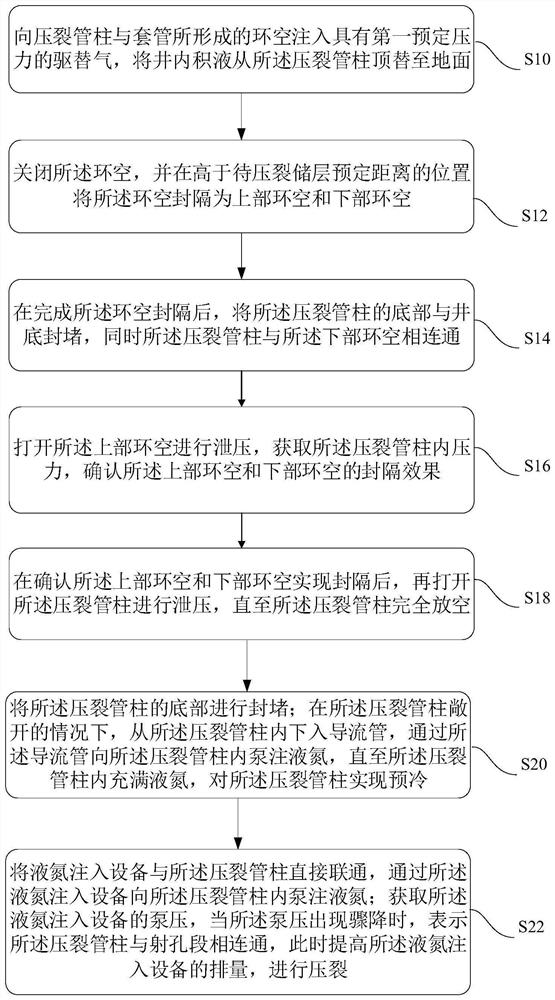

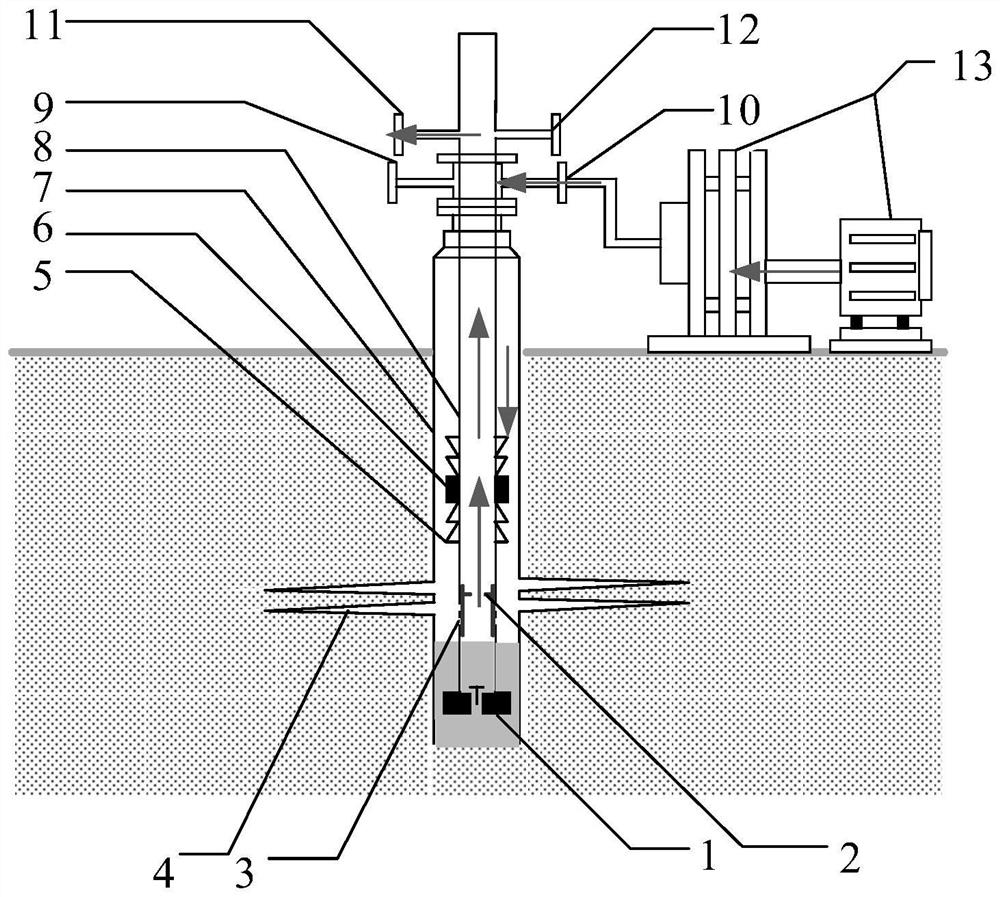

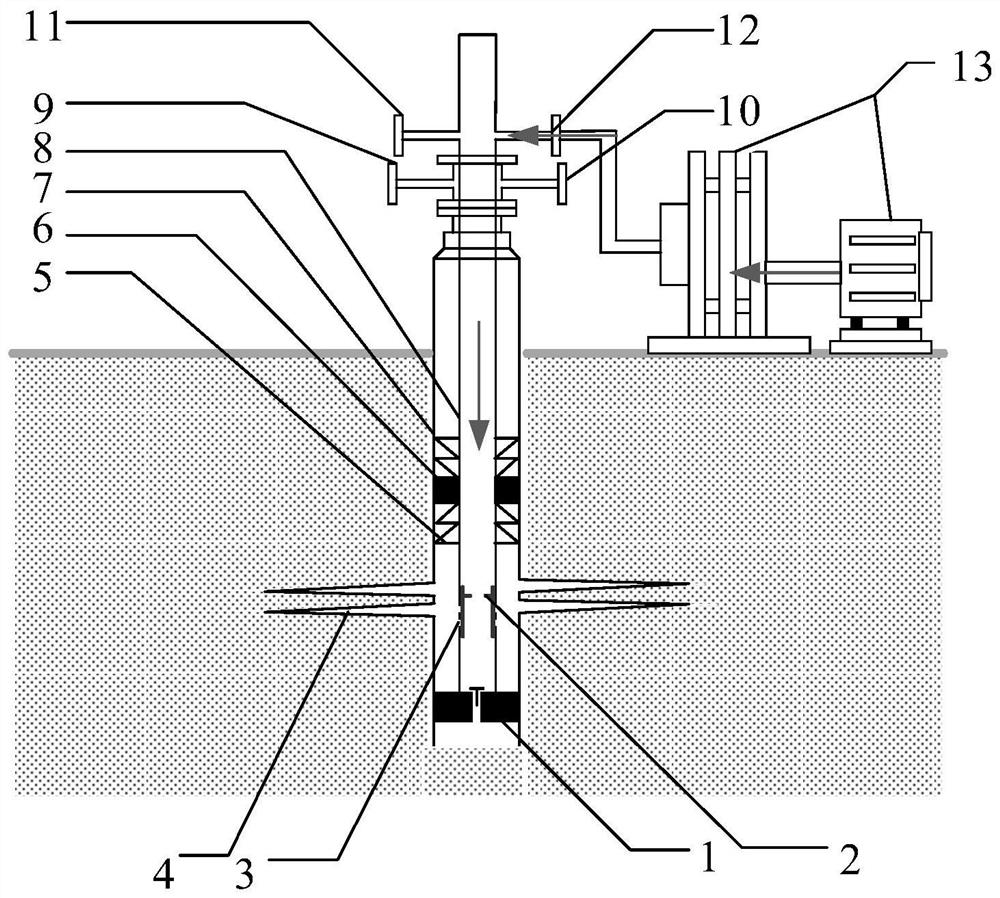

Liquid nitrogen fracturing process

InactiveCN111271036BReduce delivery efficiencyImprove pre-cooling efficiencyFluid removalMechanicsPetroleum engineering

The invention discloses a liquid nitrogen fracturing process method. The method comprises the steps that replacing accumulated fluid in a well to the ground from a fracturing pipe column; at the position higher than a reservoir to be fractured by the reserved distance, packing an annulus into an upper annulus and a lower annulus; blocking the bottom of the fracturing pipe column and the well bottom, and meanwhile enabling the fracturing pipe column to communicate with the lower annulus; opening the upper annulus for pressure relief, obtaining pressure in the fracturing pipe column, and after confirming that the upper annulus and the lower annulus are packed, opening the fracturing pipe column for pressure relief; blocking the bottom of the fracturing pipe column; under the condition of opening the pressuring pipe column, lowering a flow guide pipe from the fracturing pipe column, and pumping and injecting liquid nitrogen into the fracturing pipe column through the flow guide pipe untilthe interior of the fracturing pipe column is full of the liquid nitrogen, and achieving precooling of the fracturing pipe column; communicating a liquid nitrogen injection device with the fracturingpipe column, and pumping and injecting the liquid nitrogen; and when the fracturing pipe column communicates with a perforation segment, increasing the displacement to carry out fracturing. It can beensured that the low-temperature liquid nitrogen has the higher conveying efficiency and better heat preservation effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

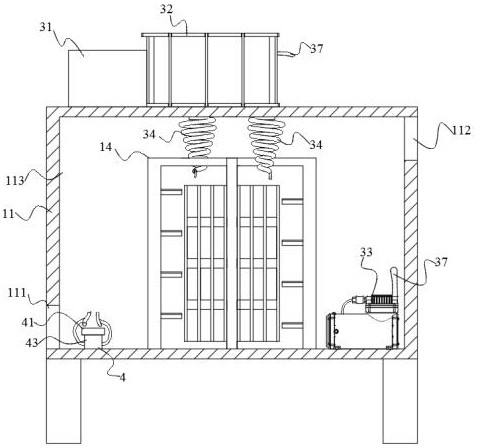

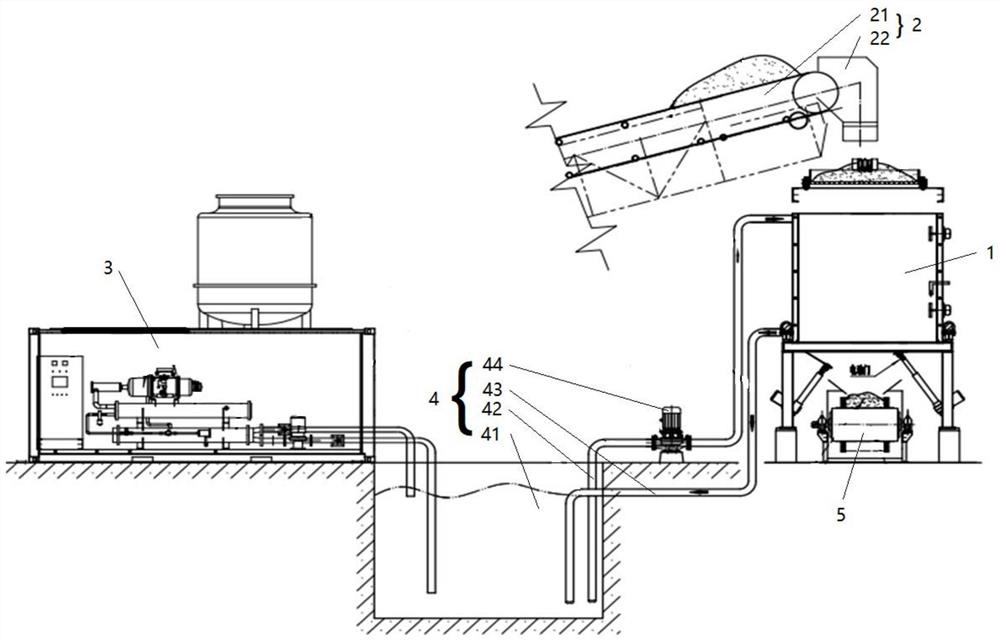

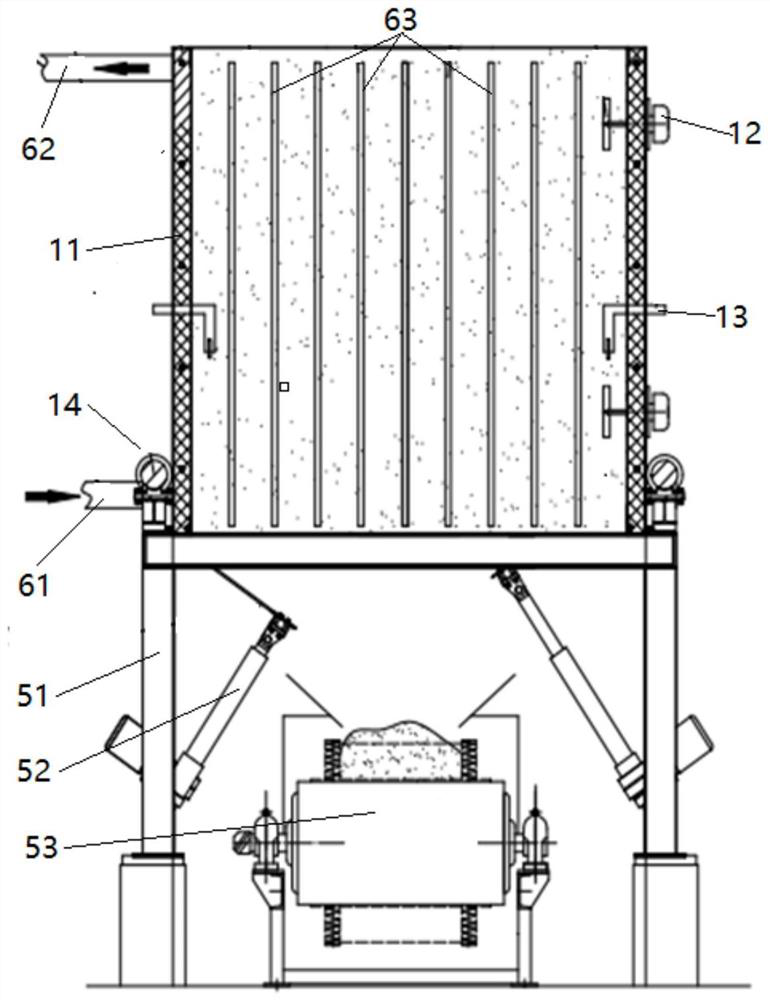

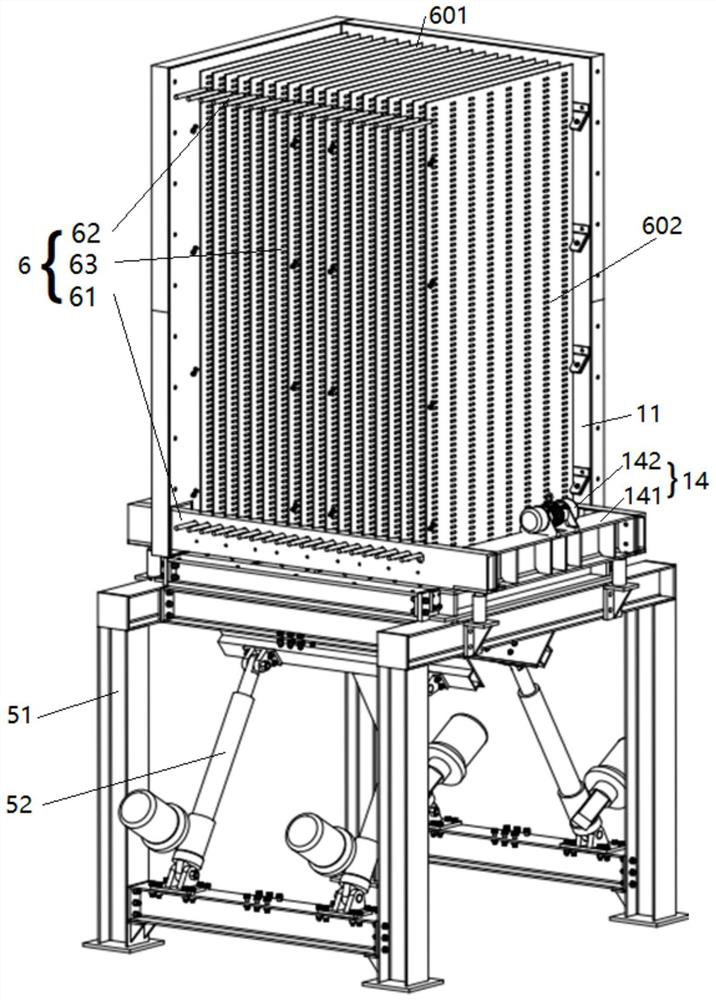

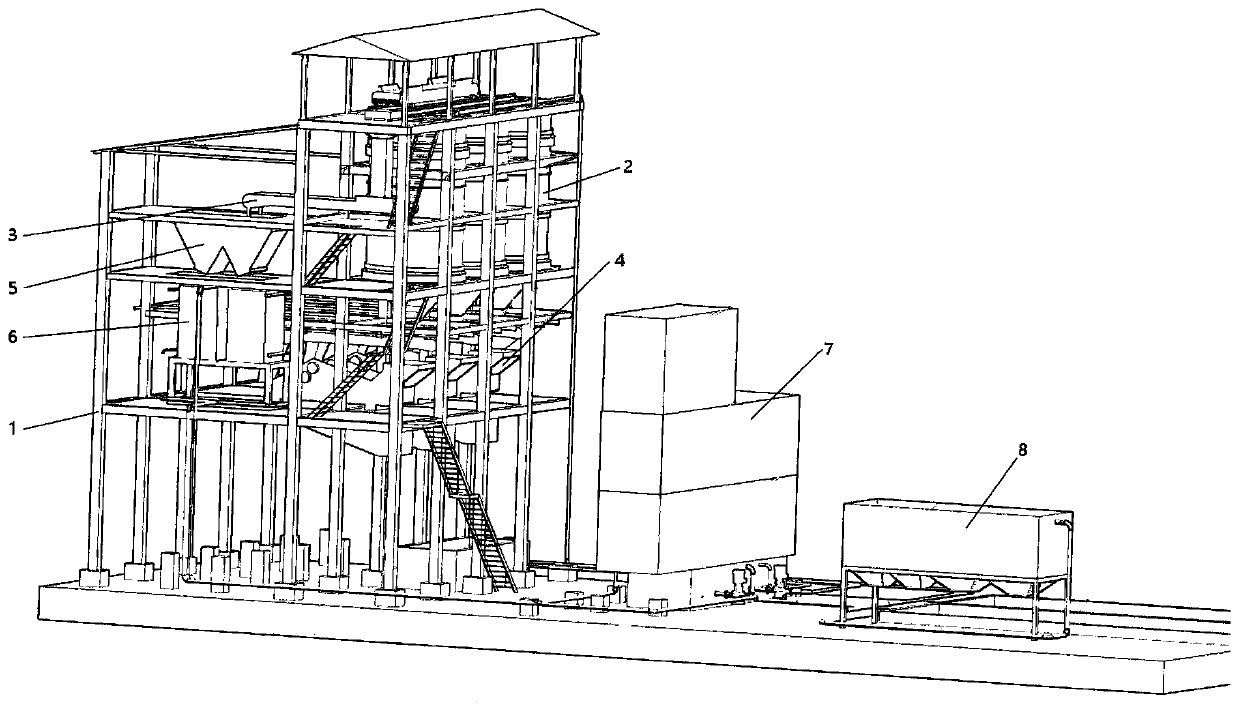

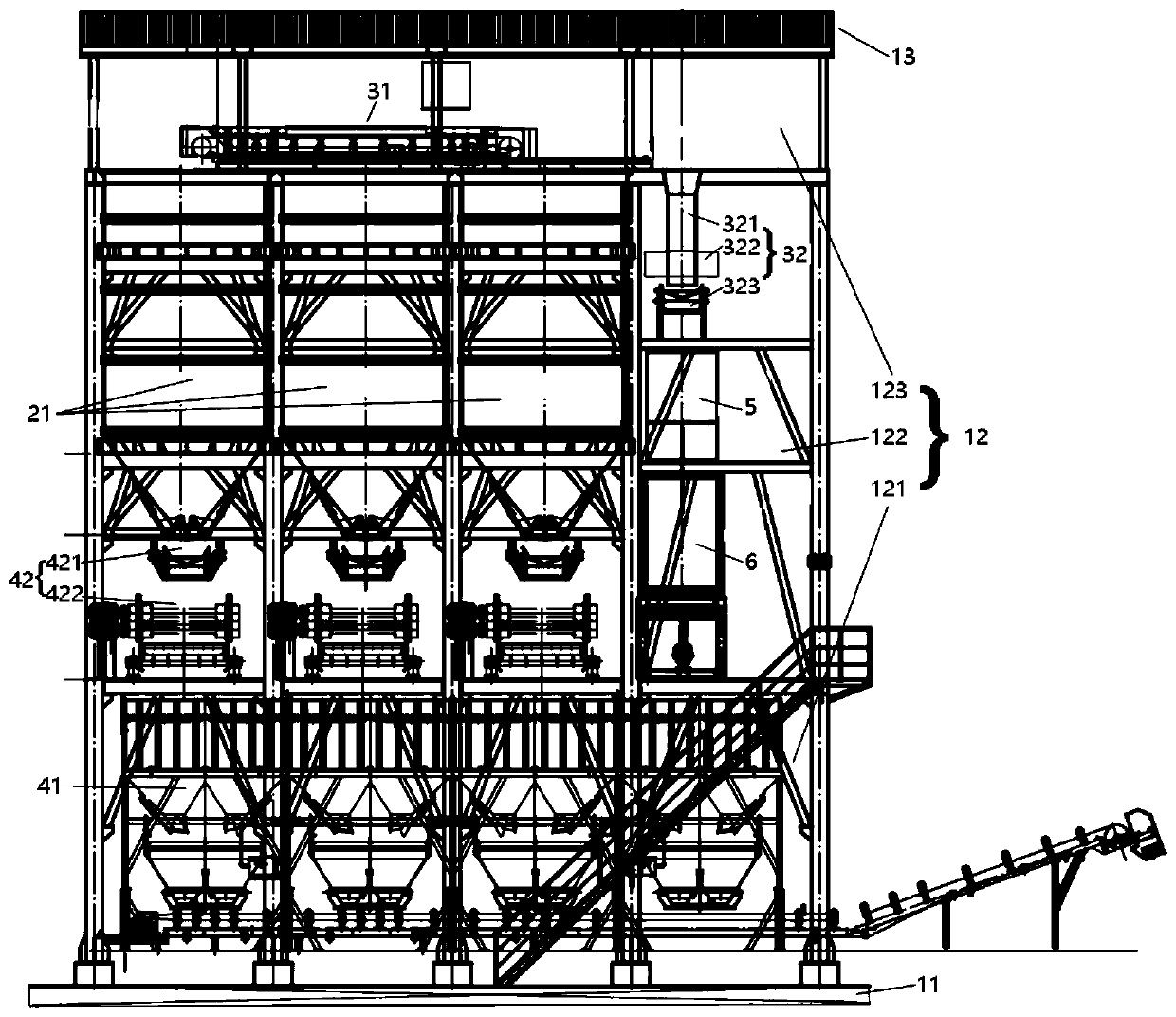

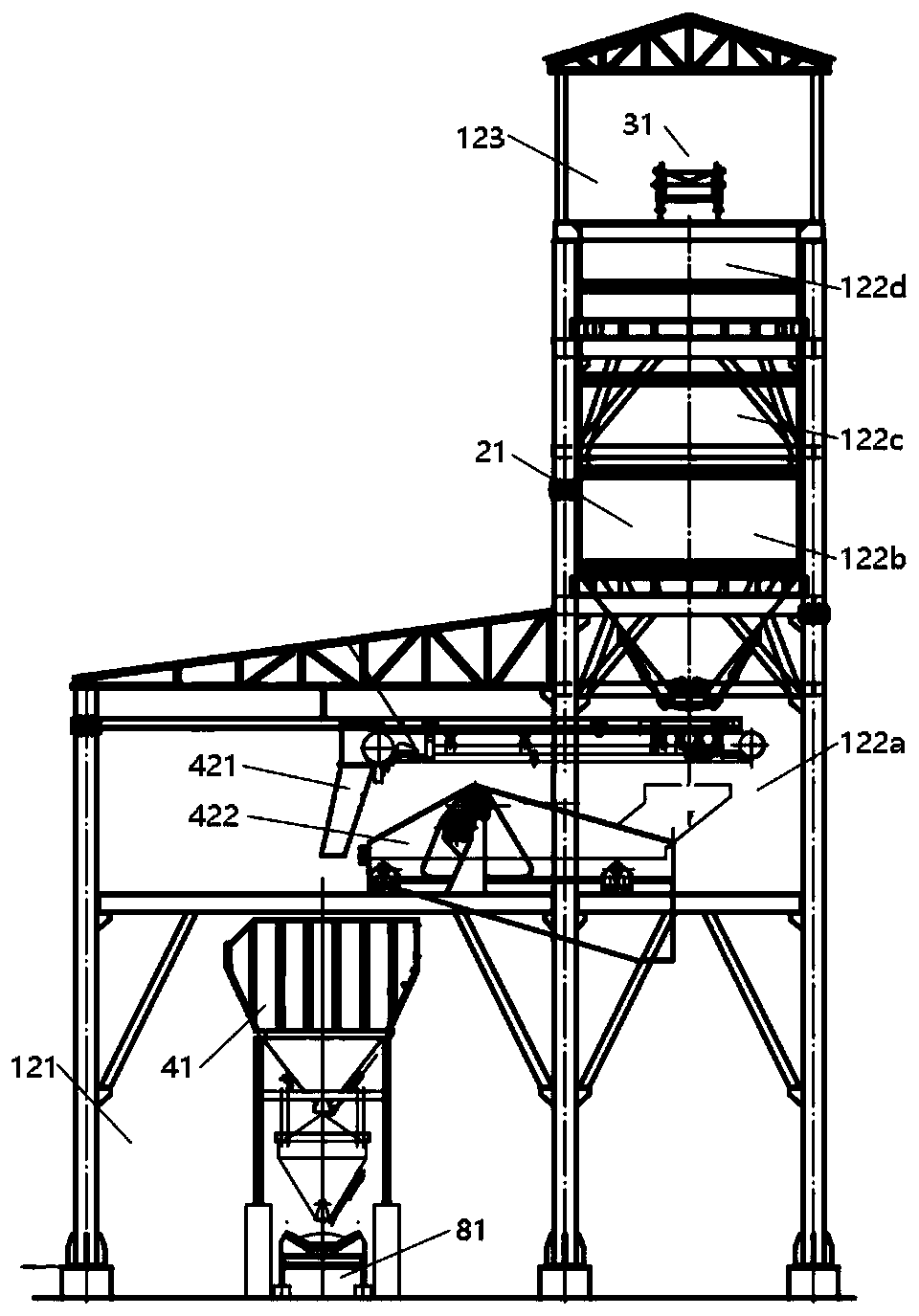

Sand aggregate temperature control system

PendingCN111906943AShort pre-cooling timeSmall footprintTemperatue controlMixing operation control apparatusTemperature controlThermodynamics

The invention provides a sand aggregate temperature control system. The sand aggregate temperature control system comprises a pre-cooling part, an aggregate conveying part, a refrigerating part and aliquid conveying part; a heat exchange structure is arranged in the pre-cooling part; the aggregate conveying part is used for conveying aggregate into the pre-cooling part; the refrigerating part isused for refrigerating or heating pre-cooling liquid; the refrigerating part is connected with the pre-cooling part through the liquid conveying part; the liquid conveying part conveys the pre-coolingliquid into the pre-cooling part, so that the pre-cooling liquid makes contact with the heat exchange structure and exchanges heat with the heat exchange structure; and the pre-cooling part discharges the pre-cooling liquid, and the aggregate conveying part conveys the aggregate to the pre-cooling part, so that the aggregate makes contact with the heat exchange structure and exchanges heat with the heat exchange structure. The problems of large occupied area and low production efficiency of existing water-cooled aggregate pre-cooling are solved. According to the sand aggregate temperature control system, through mutual cooperation of the pre-cooling part and the heat exchange structure, the site size required by aggregate pre-cooling is reduced, use of narrow sections such as river valleys is facilitated, and the use range is expanded; and a large amount of pre-cooling can be carried out at the same time, the pre-cooling time of single-batch aggregate is shortened, and the pre-coolingefficiency is improved.

Owner:DADU RIVER HYDROPOWER DEV

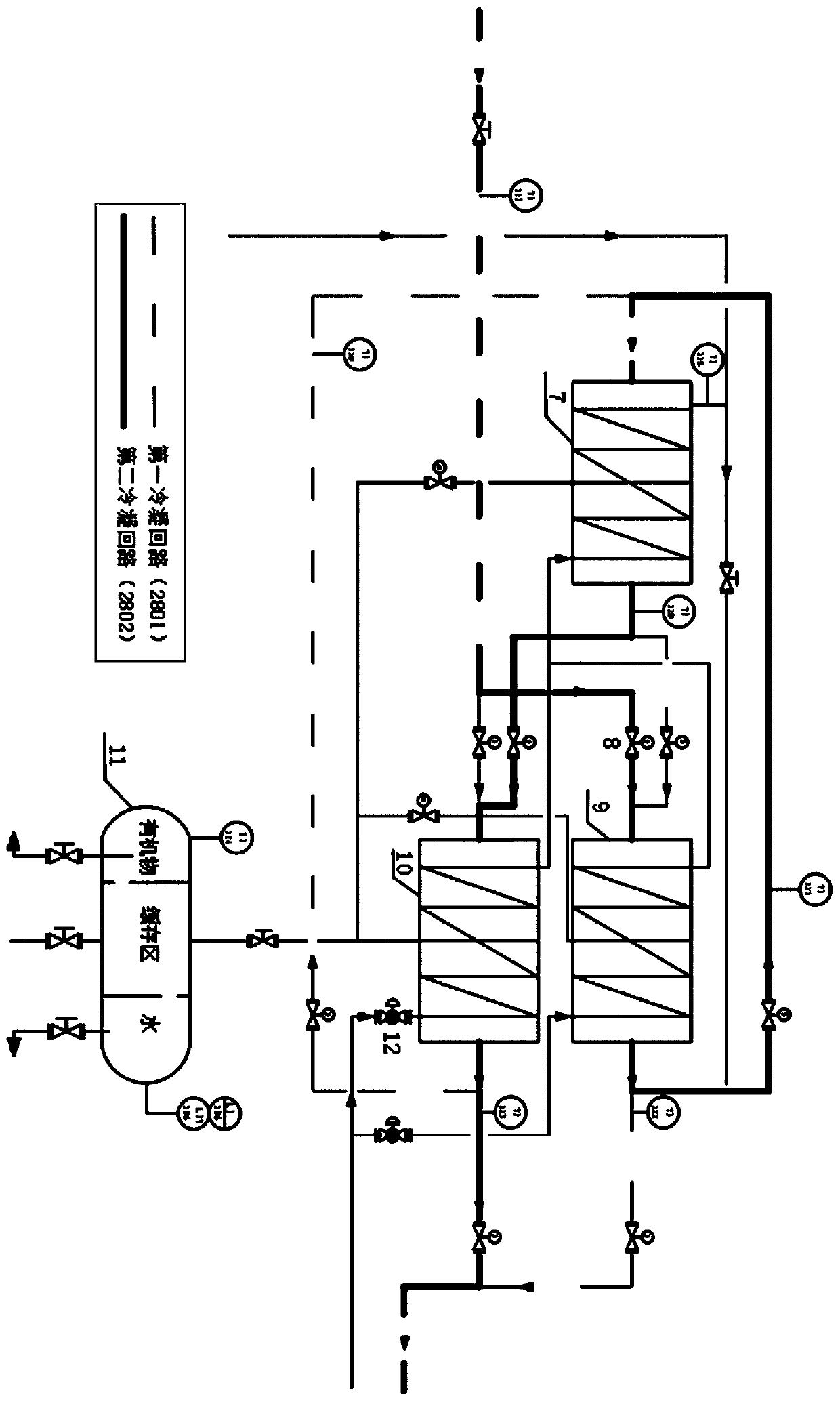

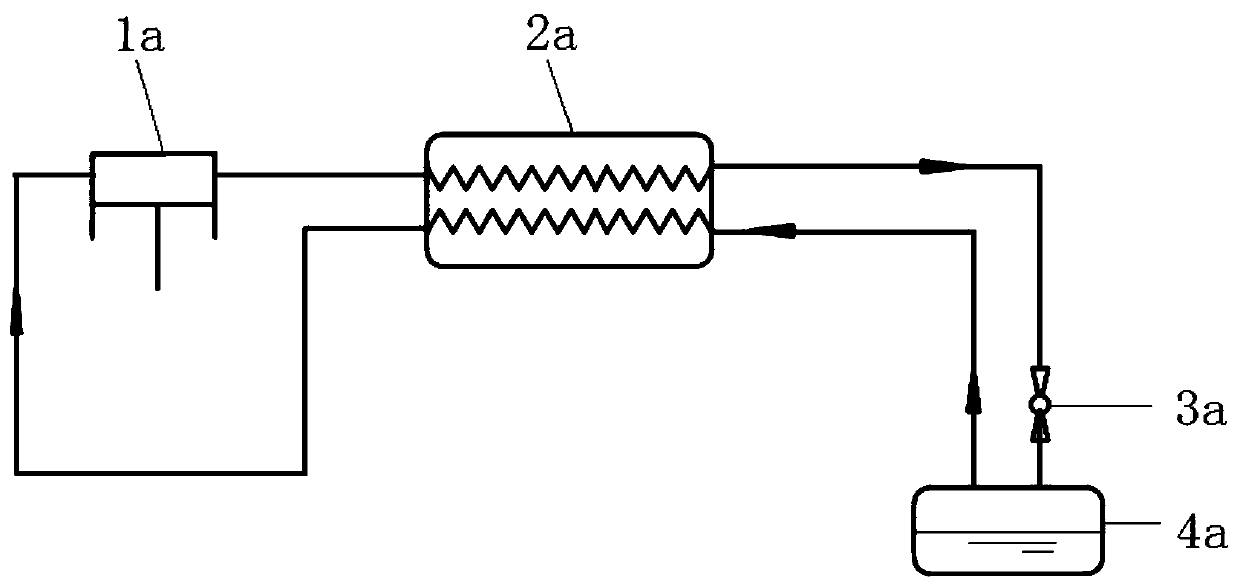

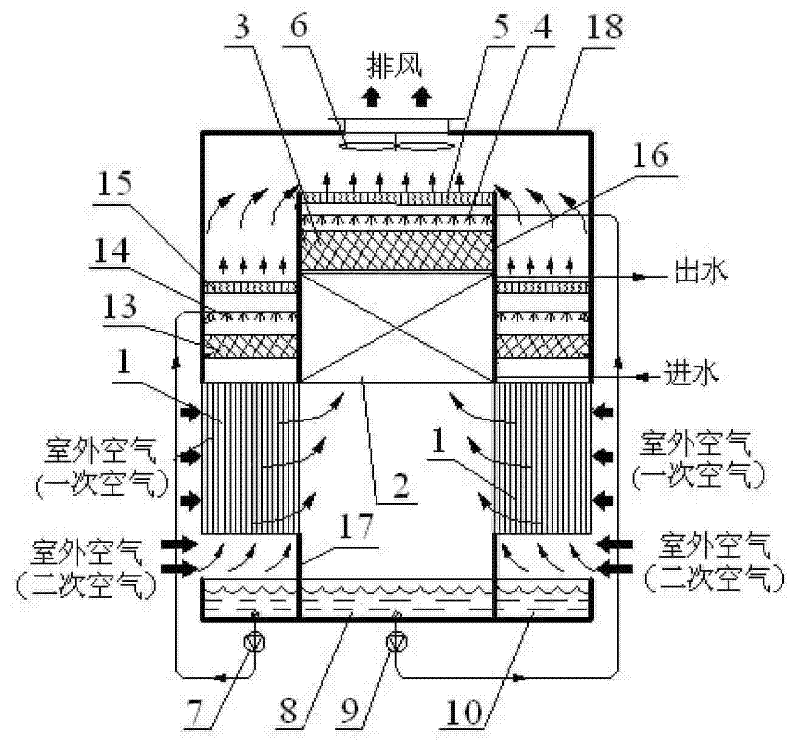

Closed evaporation cooling high-temperature cold water unit

InactiveCN101634476BImprove pre-cooling efficiencyAvoid cloggingTrickle coolersTubular elementsEvaporative coolerEvaporation

The invention discloses a closed evaporation cooling high-temperature cold water unit which comprises an evaporation cooling coil pipe, a filter I, a water distributing device I, a water blocking plate I and a fan, wherein the filter I, the water distributing device I, the water blocking plate I and the fan are sequentially arranged at the upper part; a group of pipe type indirect evaporative coolers are arranged outside both sides of the bottom of the evaporation cooling coil pipe; the upper part of each pipe type indirect evaporative cooler is sequentially provided with a filler II, a waterdistributing device II and a water blocking plate II; the lower part of each pipe type indirect evaporative cooler is provided with an opening type water tank II; the lower part of the evaporation cooling coil pipe is provided with an opening type water tank I, and the opening type water tank II and the opening type water tank I are separated by a barrier; the opening type water tank II is communicated with the water distributing device II by a pipeline; and the opening type water tank I is communicated with the water distributing device I by a pipeline. The unit can meet the requirement of the water temperature at a dry type or dry working condition sensible heat tail end, prevent a phenomenon of dew formation at the sensible heat tail end and conform to the requirement of the water temperature of an evaporation cooling semi-centralized type air-conditioning system in the northwest district.

Owner:XI'AN POLYTECHNIC UNIVERSITY

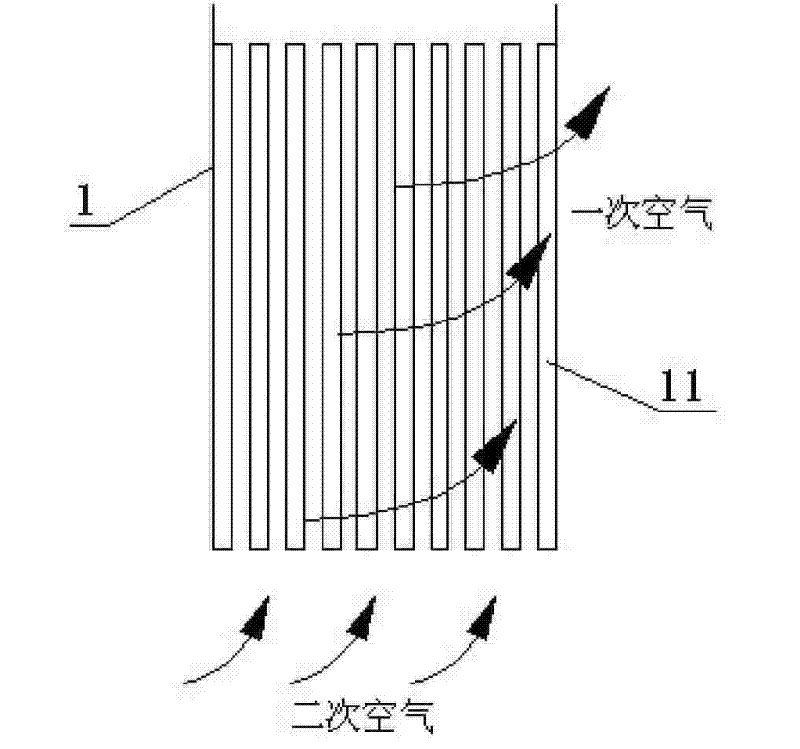

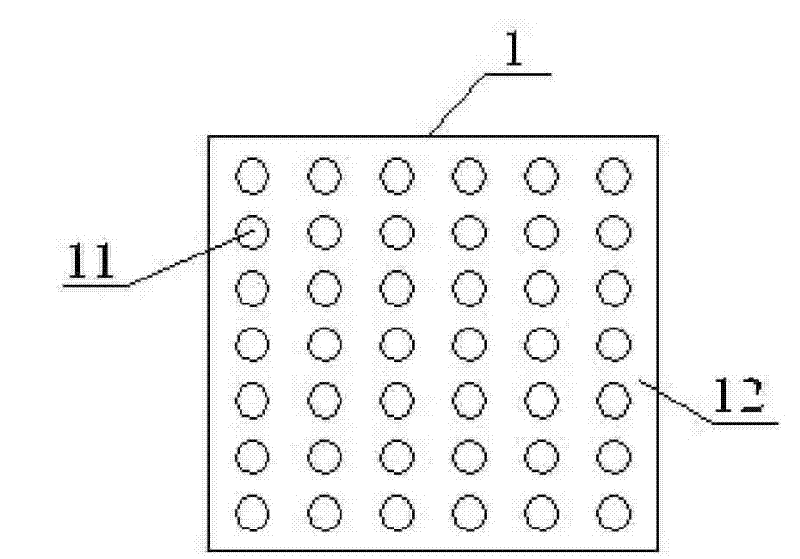

Novel cold air flow vortex type differential pressure pre-cooling device

PendingCN109197991AAvoid short circuitAvoid the shortcomings of large differences in pre-cooling effectsLighting and heating apparatusCooling fluid circulationCold airDifferential pressure

The present invention discloses a novel cold air flow vortex type differential pressure pre-cooling device. The novel cold air flow vortex type differential pressure pre-cooling device consists of a condensing unit, a pre-cooling room, a ventilation system and a control system; the pre-cooling room is composed of a device room and an agricultural product processing room; the pre-cooling room is successively provided with a fin tube evaporator containing a cold air machine, the ventilation system and the agricultural product processing room; the enclosure structure of the device room is polyurethane insulation boards; an outlet of the condensing unit is connected with an inlet of the fin tube evaporator containing the cold air machine via an arranged electronic expansion valve; and an outlet of the fin tube evaporator containing the cold air machine is connected with an inlet of the condensing unit. The novel cold air flow vortex type differential pressure pre-cooling device is based onan air jet technology and an airflow vortex effect, combines a unique air inlet eccentric structure design, enables cold air flow to conduct a reverse vortex motion, forms a central low pressure zone, improves pre-cooling pressure difference on both sides of products and further enhances the pre-cooling effect.

Owner:TIANJIN UNIV OF COMMERCE

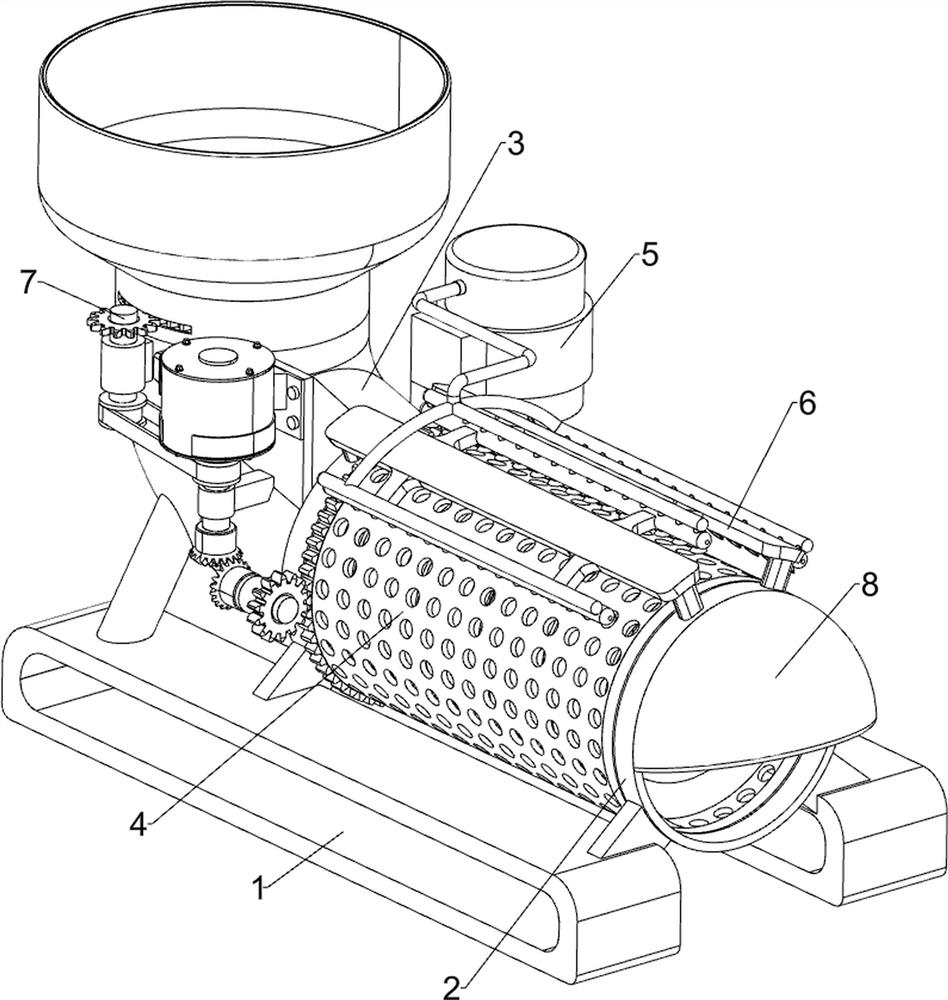

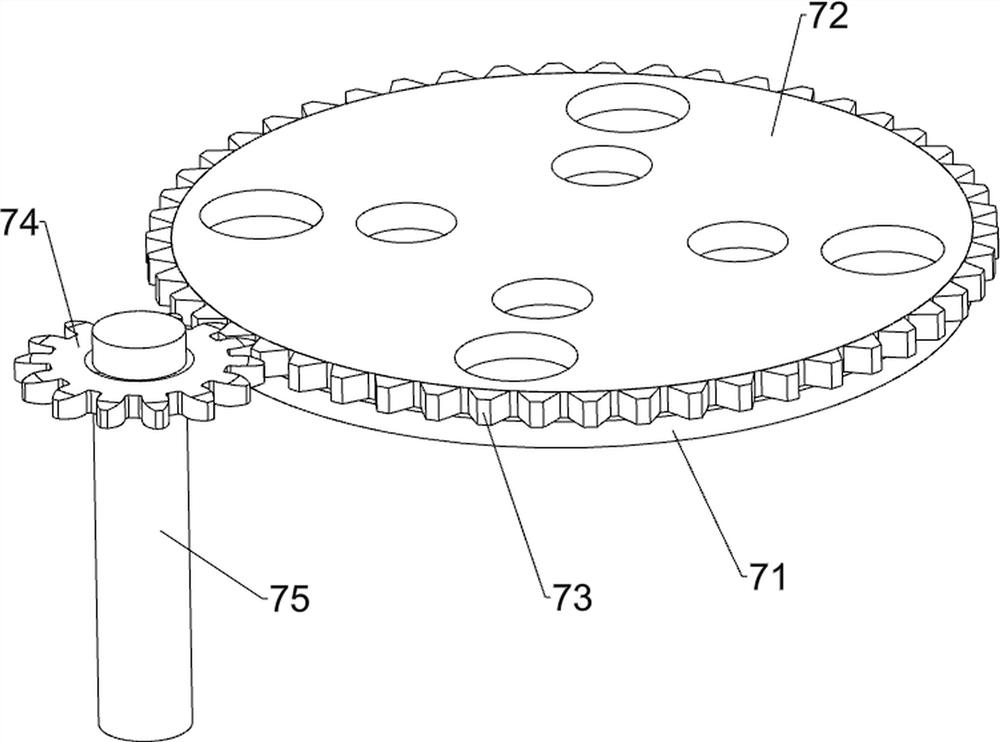

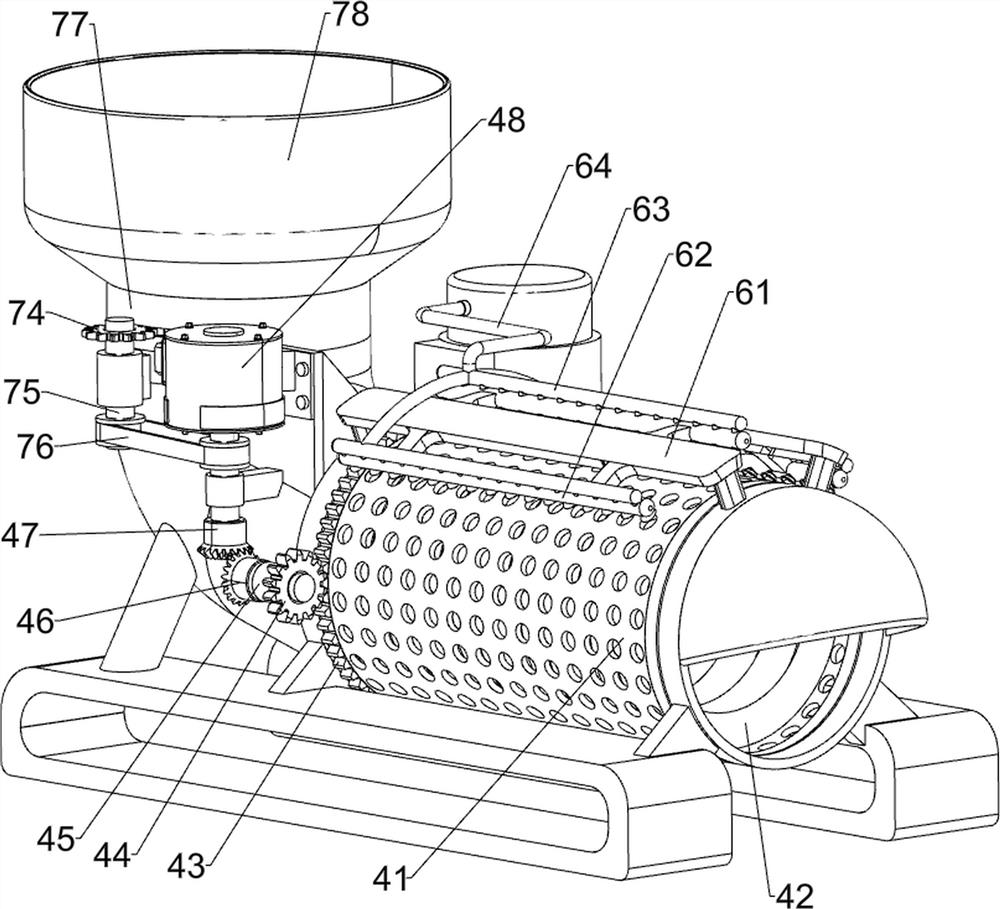

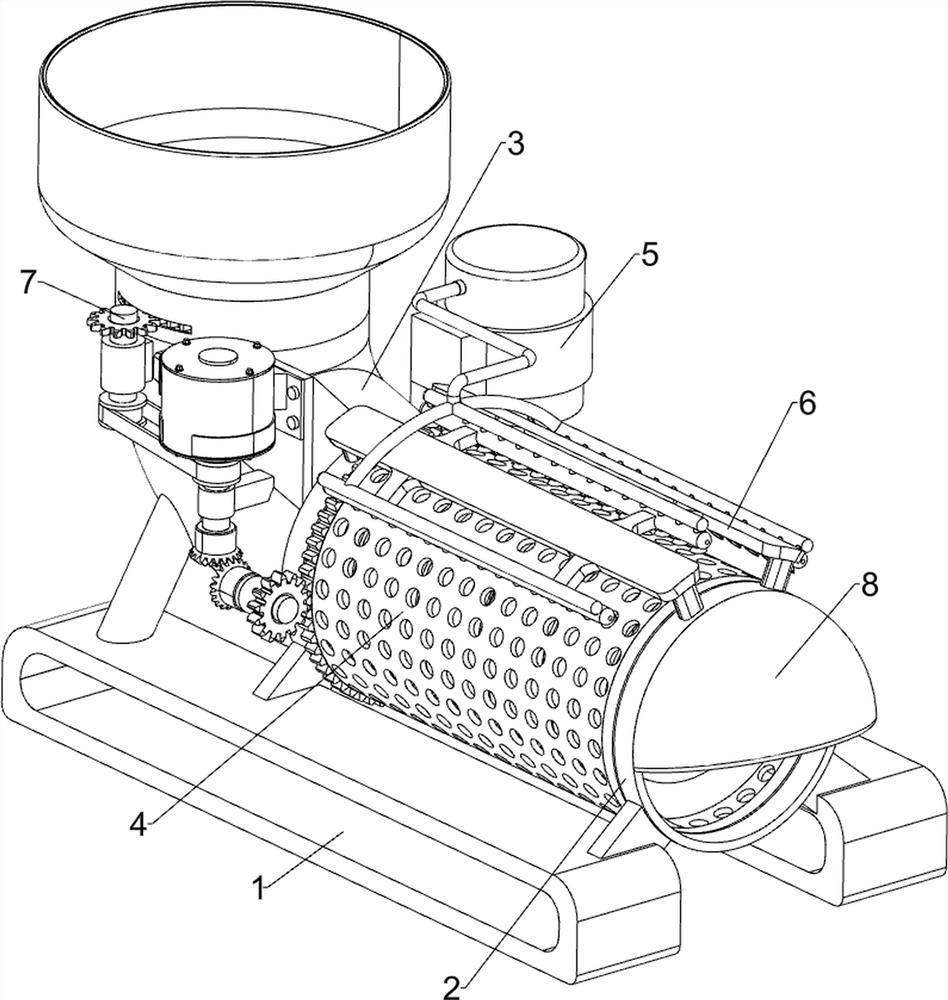

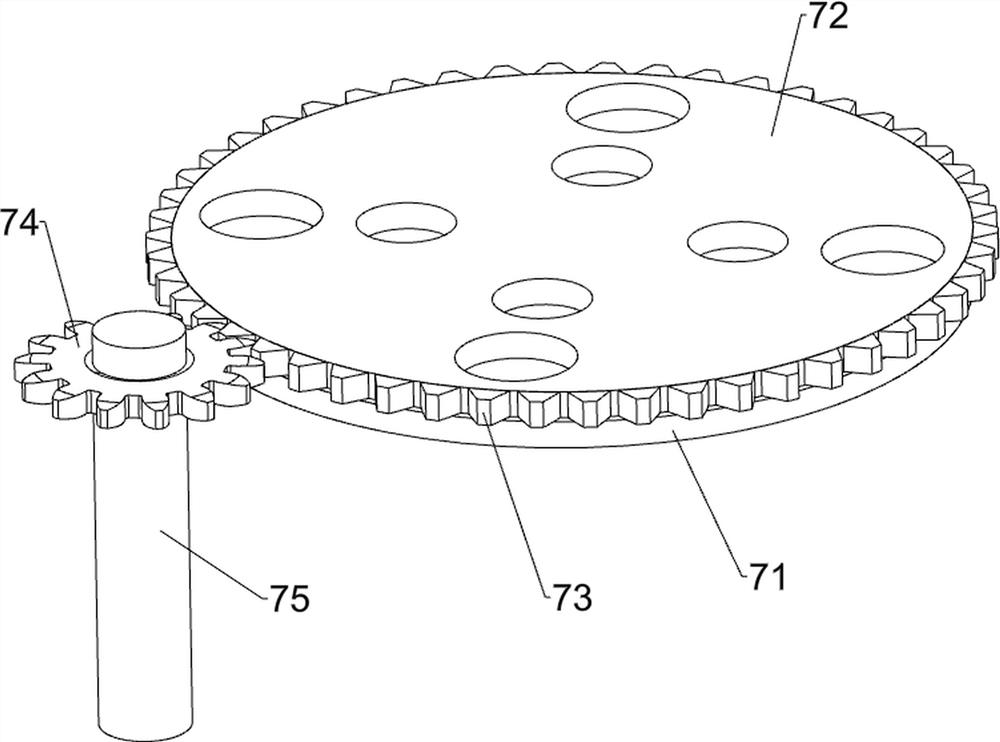

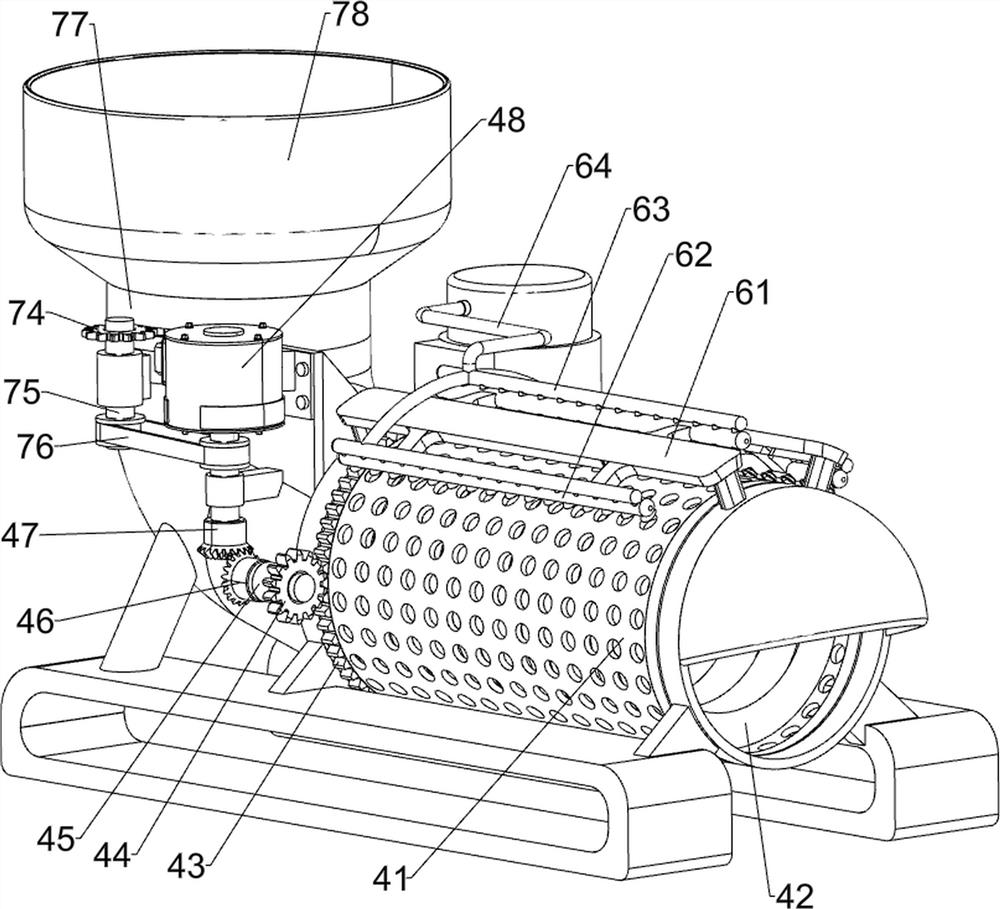

Pre-cooling device of concrete aggregate

ActiveCN112622050AIncrease the gapImprove pre-cooling efficiencySolid waste managementMixing operation control apparatusClassical mechanicsStructural engineering

The invention relates to a cooling device, in particular to a pre-cooling device of concrete aggregate. The pre-cooling device of the concrete aggregate enables aggregate to move, can increase gaps among the aggregate and improve the pre-cooling efficiency. The pre-cooling device of the concrete aggregate comprises a base, a feeding pipeline, a rotating mechanism and a pressurizing mechanism, wherein the two sides of the upper side of the base are both connected with mounting frames, the side, close to the mounting frame on one side, of the base is connected with the feeding pipeline, the rotating mechanism is mounted between the mounting frame and the feeding pipeline, the pressurizing mechanism is mounted on the base, and the pressurizing mechanism is in transmission connection with the rotating mechanism. The aggregate can be rotated and moved rightwards through the rotating mechanism, so that the purposes of moving the aggregate and increasing the gaps among the aggregate are achieved; cold water can be sprayed onto the aggregate through cooperation of the pressurizing mechanism and a water spraying structure, then the aggregate can be pre-cooled, and the pre-cooling efficiency can be improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

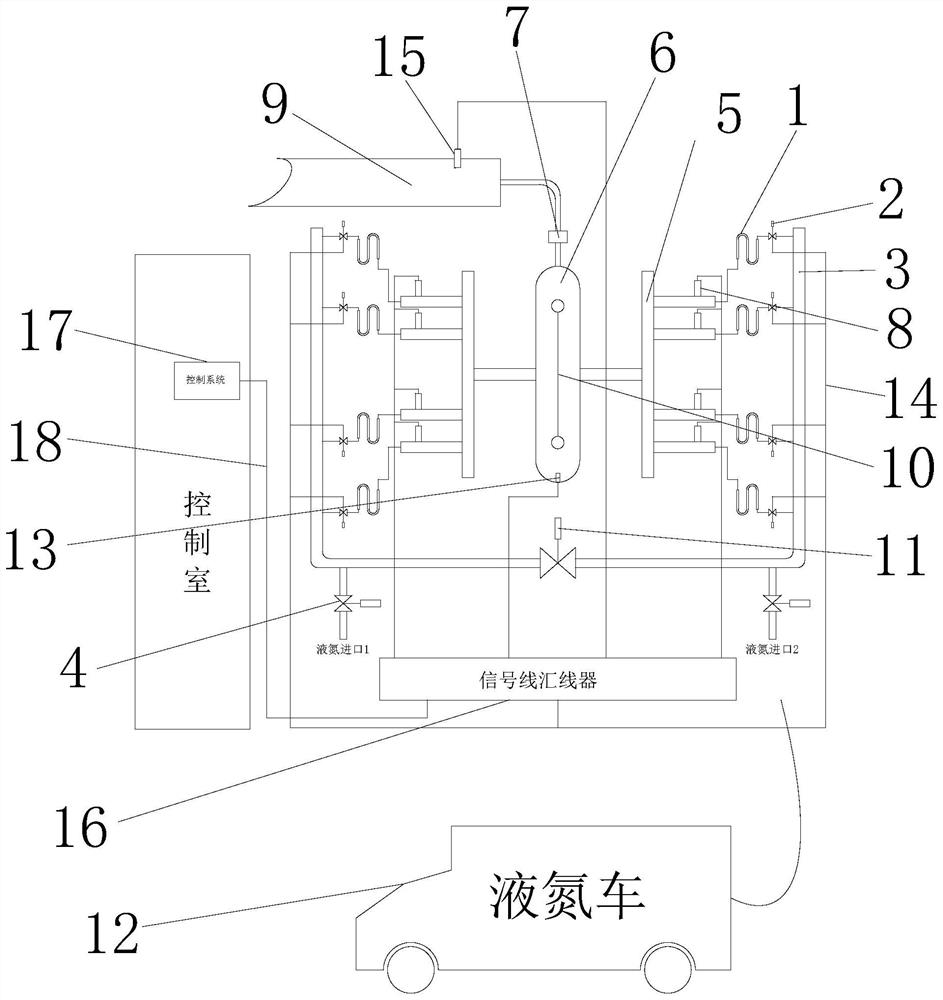

Pre-cooling vaporization prying type device

PendingCN114263849AImprove cooling effectAvoid damageContainer filling methodsNon-pressured vesselsControl systemEngineering

The invention discloses a precooling vaporization prying type device, and relates to the technical field of LNG pipeline precooling. The precooling vaporization prying type device comprises two vaporizer inlet gathering pipes, a signal line gathering device and a liquid nitrogen truck, the structures of the two vaporizer inlet gathering pipes are the same, and a block valve is arranged between the two vaporizer inlet gathering pipes. According to the precooling vaporization prying type device, low-temperature nitrogen gasified by the multiple vaporizers enters the vaporizer outlet gathering pipe and is gathered into the gas-liquid separation tank through the vaporizer outlet gathering pipe to be separated, liquid nitrogen sinks to the bottom of the tank to be treated, and the low-temperature nitrogen gas upwards enters the precooled device to be treated; a plurality of low-temperature gases with different temperatures are mixed to reach the desired pre-cooling temperature, then the pre-cooled device is pre-cooled, the process is controlled by a control system, the pre-cooled device is gradually cooled according to requirements, the damage of the pre-cooled device caused by sudden cooling of the pre-cooled device is avoided, the damage of the device is avoided, and the pre-cooling purpose is achieved.

Owner:HENAN CHENHUA ENG & EQUIP

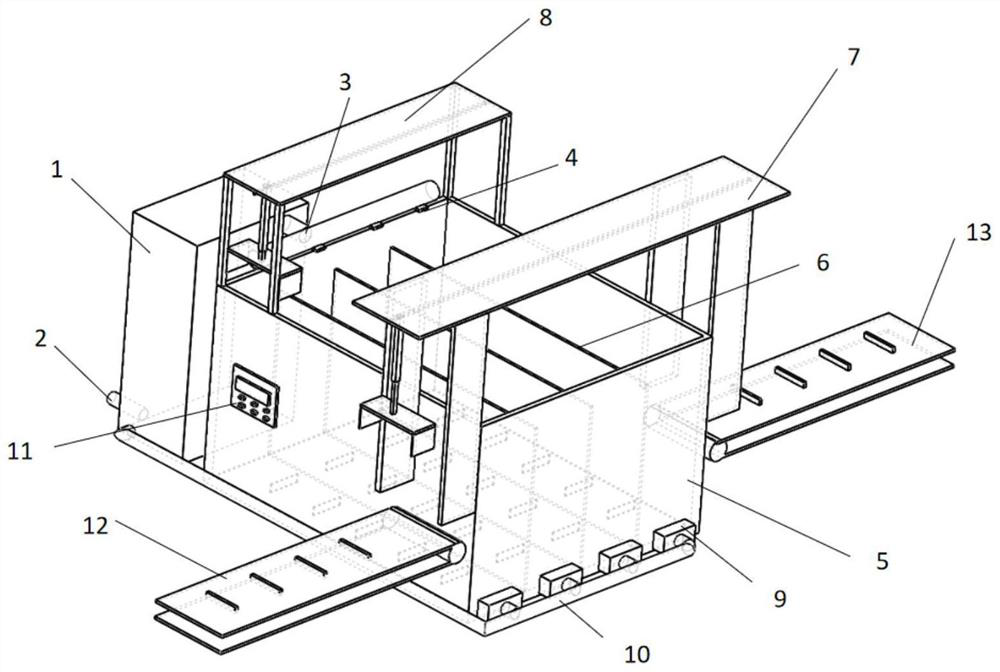

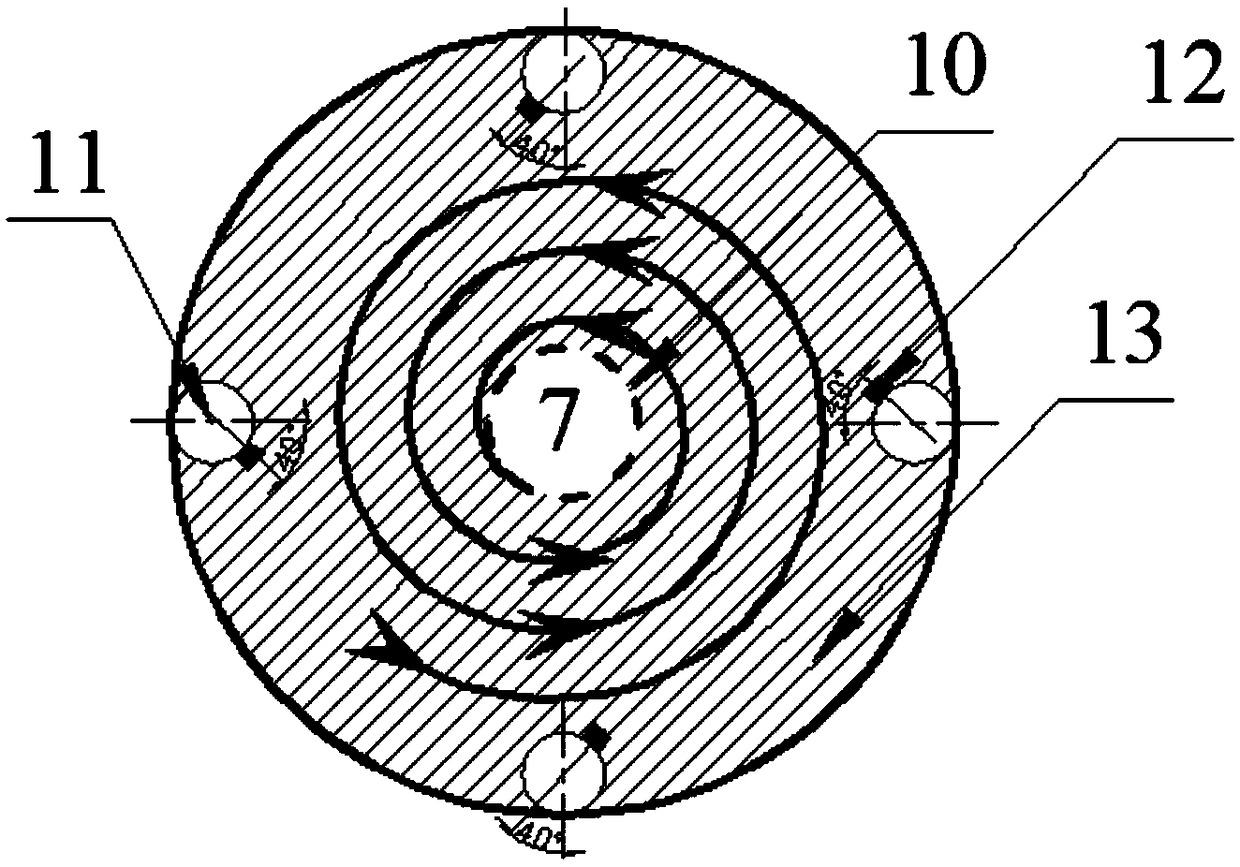

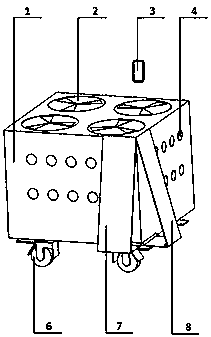

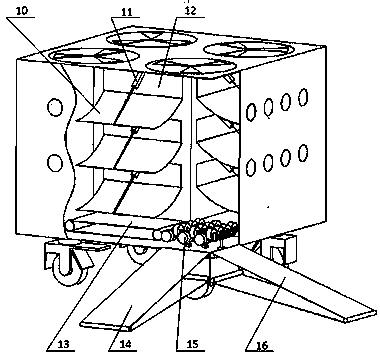

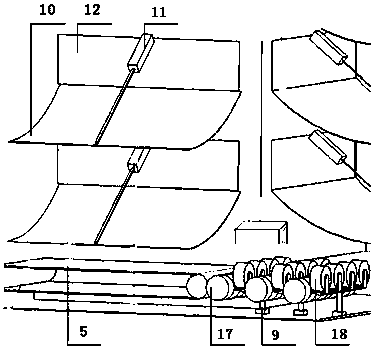

A mobile differential pressure precooling device

ActiveCN105910368BImprove work efficiencyExtended working hoursLighting and heating apparatusDomestic refrigeratorsDifferential pressureMovable type

The invention relates to a movable type differential pressure precooling device. The movable type differential pressure precooling device comprises a controller and a square box body, wherein self-locking mobile wheels are arranged at the bottom of the box body; a goods feed inlet and a goods discharge outlet are formed in the side walls of the box body; square refrigeration units are arranged in the center of the inside of the box body; a square transfer channel encircling the refrigeration units for a circle is arranged between the side walls of the refrigeration units and the side walls of the box body; transfer direction conversion units are arranged at the four corners of the transfer channel correspondingly; cold wind outlets distributed vertically are formed in the four side walls of each refrigeration unit correspondingly; and a cooling capacity adjust and control cover plate is arranged outside each cold wind outlet. The movable type differential pressure precooling device has the beneficial effects of improving precooling efficiency and precooling quality, facilitating the achievement of unattended and refined management, prolonging the preservation time of fresh fruits and vegetables, mushrooms and other agricultural products, improving product quality and quality safety, reducing labor cost, and having good economical benefits and promotion value.

Owner:QINGDAO AGRI UNIV

A Gradient Pre-cooling Method Applicable to Red Globe Grapes

ActiveCN108041155BSolve the problem of disease and rotImprove pre-cooling efficiencyFruits/vegetable preservation by freezing/coolingChilling injuryThermodynamics

The invention discloses a gradient pre-cooling method suitable for red globe grapes. The process is optimized by an orthogonal experiment method, and the pre-cooling efficiency is improved through a two-stage gradient differential pressure pre-cooling method. The air temperature in the rapid pre-cooling stage adopts -3°C , the differential pressure wind speed is 1.0 m / s, the center temperature of the grape fruit is pre-cooled to 3°C, the differential pressure effect is uniform, the interaction between the differential pressure pre-cooling air temperature and wind speed is obvious, and the cooling rate can be doubled by 1.23~1.75. During this period, the grapes did not suffer from chilling damage, the ear stems and fruit stems faded in color, and the drying shrinkage was not obvious. The temperature fluctuation range of the red globe grape ears treated with precooling was small, and the respiration intensity and humidity fluctuations were relatively stable. The problem of disease and rot easily caused by improper preservation has extensive practicality and development value in the field of fruit and vegetable preservation.

Owner:新疆农业科学院农产品贮藏加工研究所

Heat exchanger with ozone conversion and high-temperature precooling functions

InactiveCN113587701AReduce energy consumptionReduce volumeIndirect heat exchangersTubular elementsPtru catalystEngineering

The invention relates to the field of heat exchangers, in particular to a heat exchanger with ozone conversion and high-temperature precooling functions. The heat exchanger comprises a plurality of partition plates and sealing strips fixedly connected between every two adjacent partition plates; every two adjacent partition plates and the sealing strips located between every two partition plates jointly define a mounting containing cavity; each mounting containing cavity comprises a hot cavity body and a cold cavity body, gas introduced by an aircraft engine enters the hot cavity body, air of a fan pipeline of a gas turbine engine enters the cold cavity body, hot cavity fins for guiding the gas flowing direction are mounted in the hot cavity body, and the surfaces of the hot cavity fins are coated with ozone catalysts. The heat exchanger has the advantages that ozone conversion and high-temperature pre-cooling are achieved, meanwhile, the size and weight of the heat exchanger can be reduced, and the energy consumption of an aircraft is reduced.

Owner:BEIJING CRONDA NEW TECH CO LTD +1

A concrete aggregate pre-cooling device

ActiveCN112622050BIncrease the gapImprove pre-cooling efficiencySolid waste managementMixing operation control apparatusClassical mechanicsStructural engineering

The invention relates to a cooling device, in particular to a pre-cooling device for concrete aggregates. The present invention provides a concrete aggregate pre-cooling device capable of moving aggregates, increasing the gap between aggregates, and improving pre-cooling efficiency. A concrete aggregate pre-cooling device, comprising: a base, on which both sides are connected with mounting frames; a feed pipe, a side of the base close to one side of the mounting frame is connected with a feed pipe; a rotating mechanism, the mounting frame is connected to the feeder A rotating mechanism is installed between the material pipelines; a pressurizing mechanism is installed on the base, and the pressurizing mechanism is connected with the rotating mechanism by transmission. The present invention can make the aggregate rotate and move to the right through the rotating mechanism, so as to achieve the purpose of enabling the aggregate to move and to increase the gap between the aggregates. By spraying on the aggregate, the aggregate can be pre-cooled, and the pre-cooling efficiency can be improved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Aggregate precooling system

PendingCN111531715AAvoid pollutionReduced maintenance needsDispersed particle filtrationMixing operation control apparatusStructural engineeringMechanical engineering

The invention provides an aggregate precooling system. The aggregate precooling system comprises a cooling building, a precooling part, a conveying part, a plurality of discharging parts. The precooling part is fixed on the cooling building and comprises a plurality of aggregate precooling bins. The conveying part comprises a sliding part slidably arranged on the cooling building, and after the sliding part slides and communicates with one aggregate precooling bin, aggregate is conveyed into the aggregate precooling bin. The discharging parts correspond to the aggregate precooling bins one toone. The problem that an existing aggregate precooling effect is poor is solved. According to the aggregate precooling system, through mutual cooperation of the conveying part, the precooling part andthe discharging parts, automatic aggregate precooling is achieved, the labor cost is reduced, the aggregate precooling efficiency is improved, the construction period is shortened, and the productioncost is reduced. The aggregate precooling bins increase the contact time and the contact area of aggregate and precooling liquid, the precooling effect is improved, part of the aggregate is graduallyimmersed by the precooling liquid along with continuous adding of the pre-cooling liquid, and the precooling effect is effectively improved.

Owner:DADU RIVER HYDROPOWER DEV

Automatic precooling system and precooling method for LNG storage tank based on efficient communication

ActiveCN113339695BSolve blindnessImprove pre-cooling effectFluid handling accessoriesContainer discharging methodsMonitoring siteIntegrated operations

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com