Engine inlet air cooling method

An air cooling and engine technology, applied in the field of aerospace power, can solve the problems of long evaporation distance, complex heat exchanger structure, large air flow loss, etc., to reduce flow loss and manufacturing difficulty, improve air pre-cooling efficiency, The effect of increasing the droplet evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

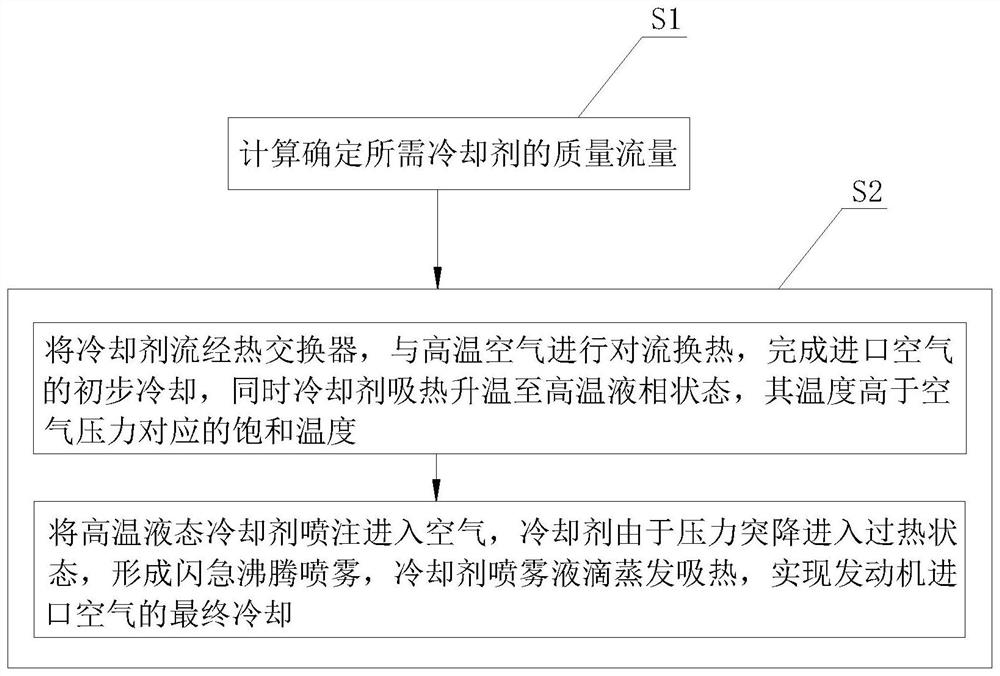

[0034] Embodiment: a kind of engine inlet air cooling method, as figure 1 As shown, it specifically includes the following steps:

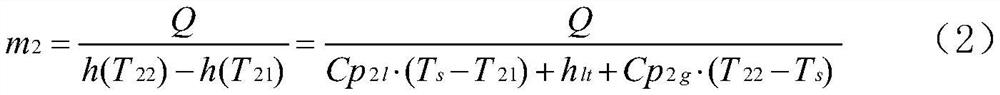

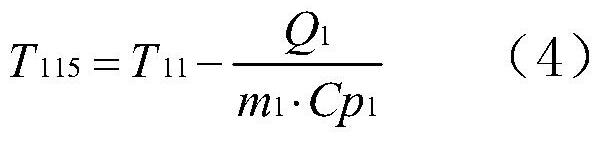

[0035] S1, according to the cooling requirement of engine inlet air, calculate and determine the flow rate of required coolant, coolant should have characteristics such as high specific heat, low boiling point, high latent heat, preferably water among coolant. The air mass flow rate at the engine inlet is m 1 , temperature T 11 , pressure P 11 , requiring cooling down to T 12 , the coolant initial temperature T 21 , pressure P 21 , flows through the heat exchanger to absorb heat and raise the temperature to T 215, and then the injection enters the air to evaporate and absorb heat. After the droplet is completely vaporized, the temperature continues to rise, and its final temperature T 22 with T 12 equal. Among them, the engine inlet air temperature T 11 Range is 400~900K, pressure P 11 0.1 ~ 0.3MPa, the air temperature T after cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com