Heat exchanger with ozone conversion and high-temperature precooling functions

A heat exchanger, high temperature technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc. High energy consumption, high pre-cooling efficiency and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

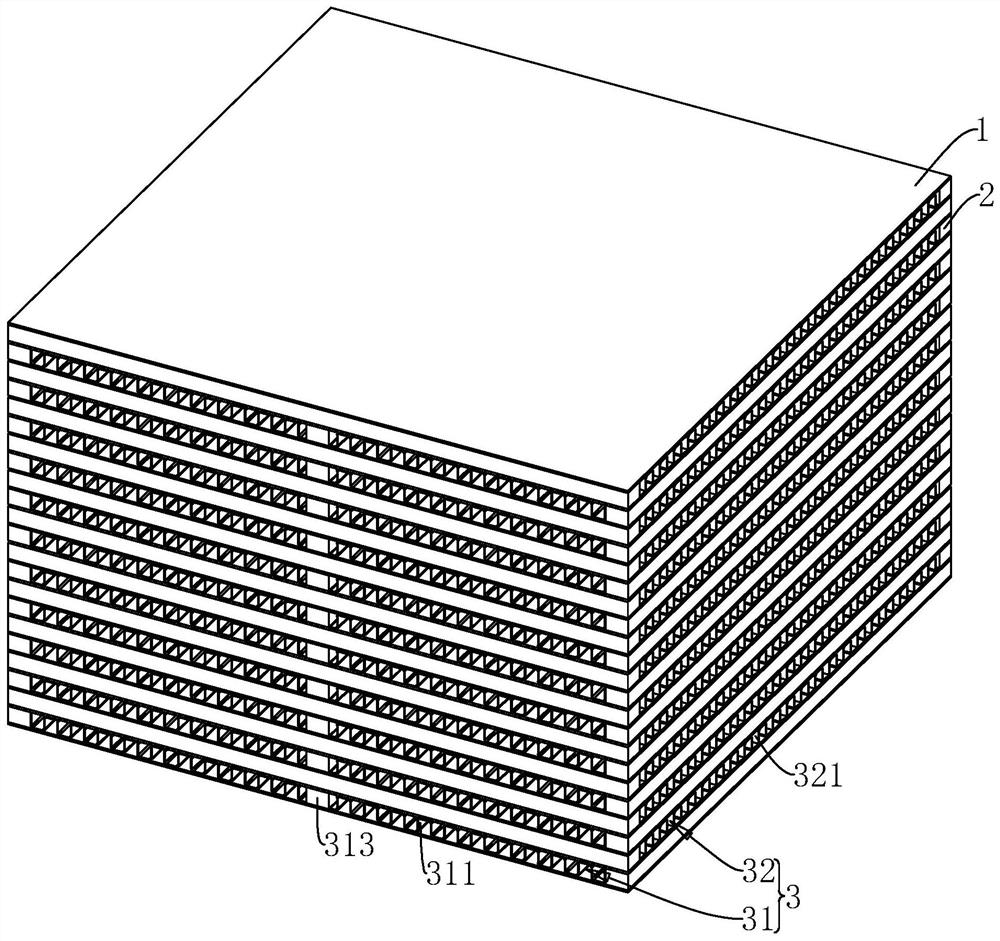

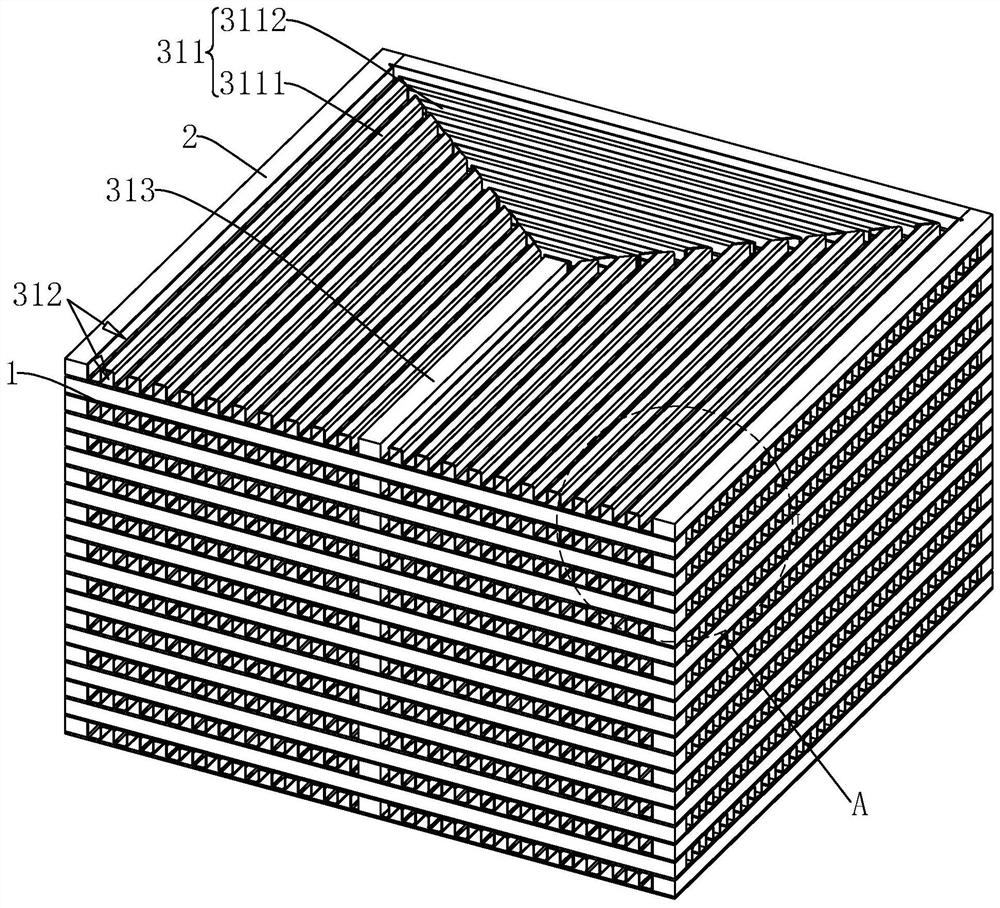

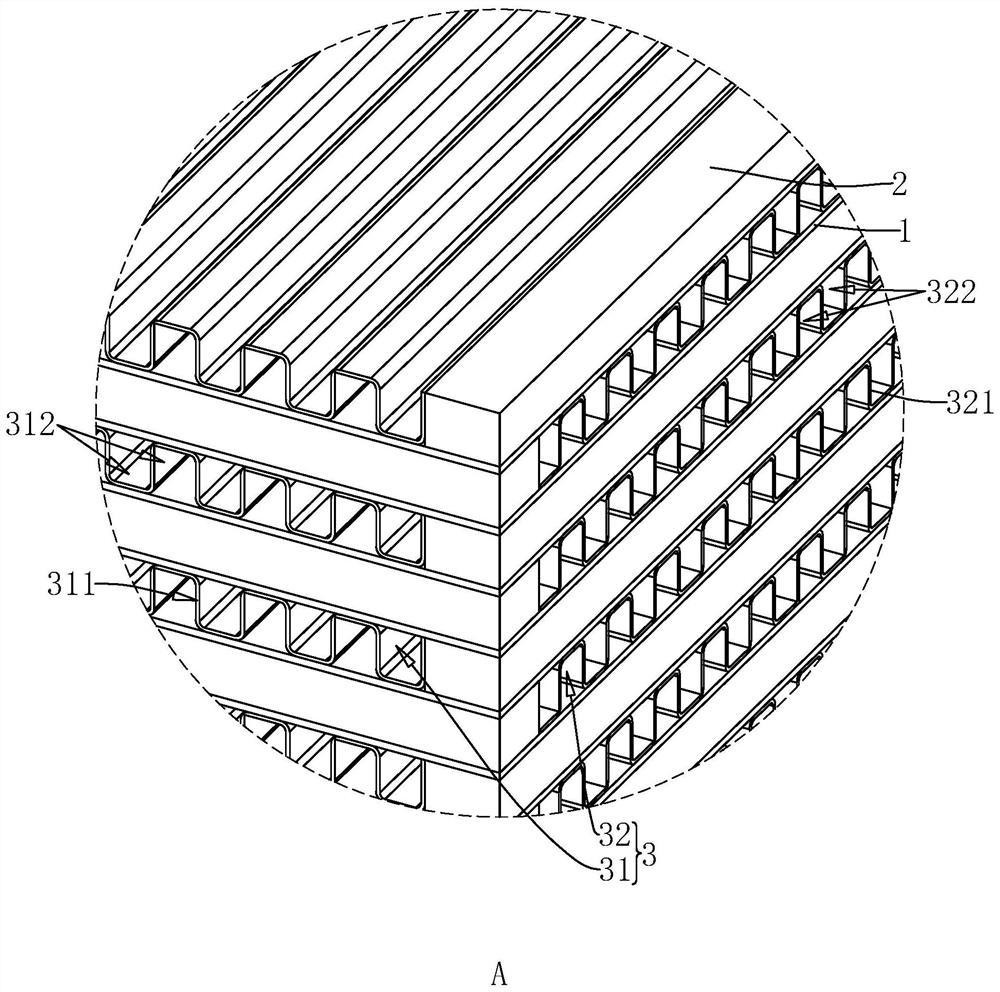

[0033] The following is attached Figure 1-4 The application is described in further detail.

[0034] The embodiment of the present application discloses a heat exchanger with functions of ozone conversion and high-temperature pre-cooling. refer to figure 1 , the heat exchanger includes a plurality of partitions 1 arranged at intervals and a seal 2 fixed between two adjacent partitions 1, and two adjacent partitions 1 and the seal 2 between two partitions 1 are in common Enclosing the installation chamber 3. Wherein, the installation cavity 3 includes a plurality of hot cavities 31 for the air introduced by the aircraft engine to enter and a plurality of cold cavities 32 for the fan pipeline air of the gas turbine engine to enter, and the hot cavities 31 and the cold cavities 32 alternately It is set so that the cold gas in the cold cavity 32 can exchange heat with the hot gas in the hot cavity 31, so as to realize the cooling and precooling of the high-temperature gas.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com