A Gradient Pre-cooling Method Applicable to Red Globe Grapes

A gradient pre-cooling and red earth technology, which is applied in applications, preservation of fruits/vegetables through freezing/refrigeration, food science, etc., can solve problems such as small fluctuations in ear temperature, uneven differential pressure pre-cooling, and inconspicuous drying shrinkage , to achieve the effects of small temperature fluctuations, uniform differential pressure effects, and no obvious drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Differential pressure precooling method for red globe grapes

[0037] The present invention provides a kind of gradient precooling method applicable to red globe grapes, specifically comprising the following steps:

[0038] (1) Select Red Globe grapes with complete ears, complete fruits, and no pests and diseases, and pack them in material turnover baskets after harvesting by grade, and carry out pre-cooling treatment within 2 hours to 4 hours after picking;

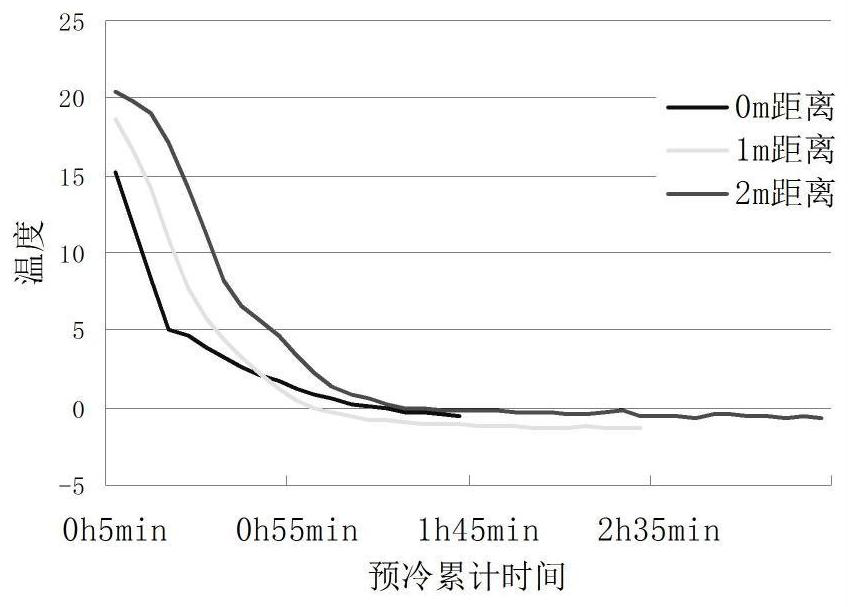

[0039] (2) Load the material turnover basket into the differential pressure pre-cooling device. After harvesting, the high-temperature ear materials pass through the differential pressure pre-cooling device. Under the condition of s-2.0m / s, the air temperature of the environment in the pre-cooling device box is reduced to 2°C-5°C, and the rapid cooling of the box environment is completed;

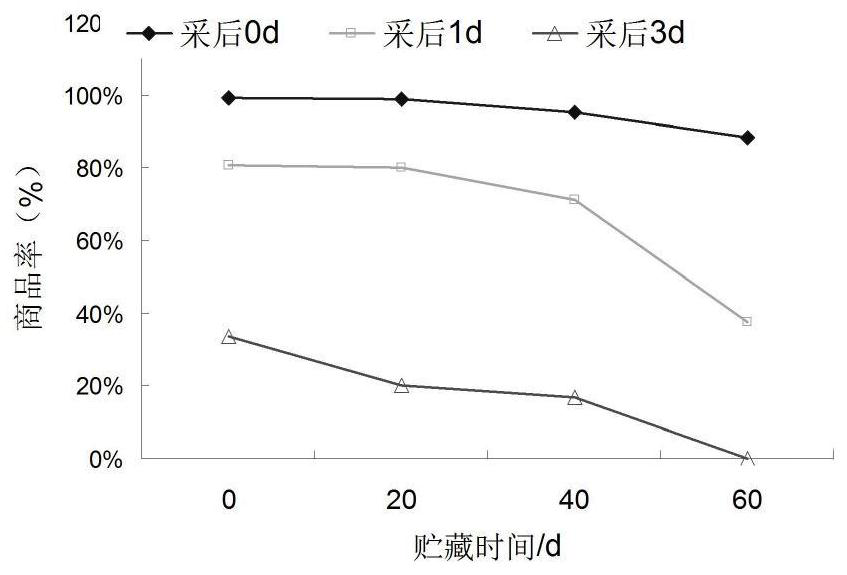

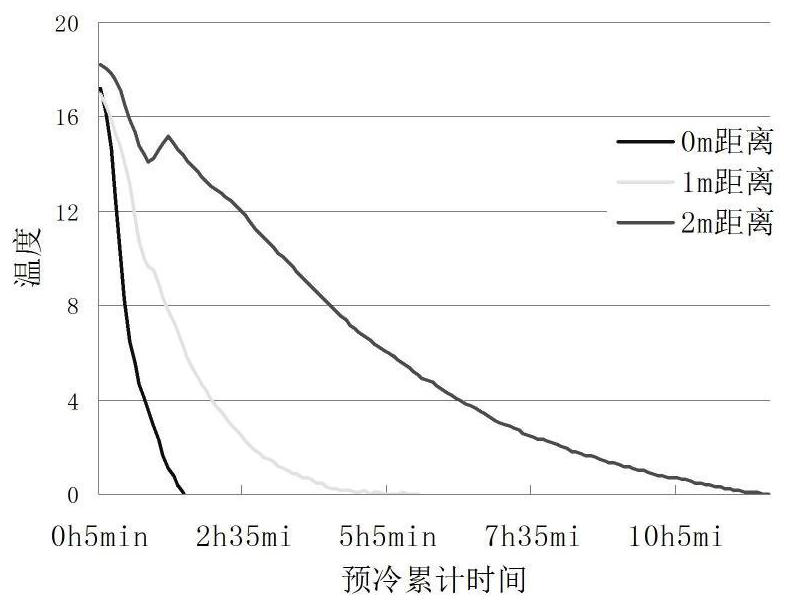

[0040] (3) Carry out rapid precooling of ear materials in the differential pressure precooling device, and com...

Embodiment 2

[0042] Embodiment 2: the precooling device adopted by the differential pressure precooling method of Red Globe grapes

[0043] as attached Figure 4-6 As shown, the pre-cooling device provided by the present invention includes a heat exchange chamber (1) and a pre-cooling chamber (2), and the heat exchange chamber (1) is arranged next to the pre-cooling chamber (2), and the heat exchange chamber (1) And pre-cooling chamber (2) is provided with cooling fan (7) above the partition, heat exchange chamber (1) and pre-cooling chamber (2) above the partition is provided with negative pressure fan; pre-cooling chamber (2) middle part is provided with sealing The layer (5) divides the pre-cooling chamber (2) into upper and lower spaces. The cooling fan (7) is located at the upper part of the sealing layer (5) close to the heat exchange chamber (1), and the negative pressure fan is located at the sealing layer (5) near the heat exchange chamber. The lower part of one end of the hot ch...

Embodiment 3

[0051] Embodiment 3: Differential pressure precooling method for red globe grapes

[0052] The invention provides a gradient precooling method suitable for Red Globe grapes. Red Globe grapes with complete ears, complete fruits, and no pests and diseases are selected, and after being graded and harvested, they are packed in material turnover baskets, and precooling is carried out within 2 hours after picking; the materials are turned over The baskets are loaded into the differential pressure pre-cooling device, and the high-temperature ear materials after harvest are passed through the differential pressure pre-cooling device. The air temperature in the internal environment is reduced to 2°C to complete the rapid cooling of the box environment; the rapid pre-cooling of the ear material is carried out in the differential pressure pre-cooling device to complete the rapid cooling of the material in the first stage, and the ambient air temperature is -2°C , differential pressure wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com