Patents

Literature

1682 results about "Convection flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Convection is the flow of heat by the movement of a warmed gas. The buildings see a 30 percent saving in energy as air circulates by natural convection to the upper floors. Convection is the transfer of heat by motion of the heated material, such as air. Convection is the flow of heat by the movement of a warmed gas.

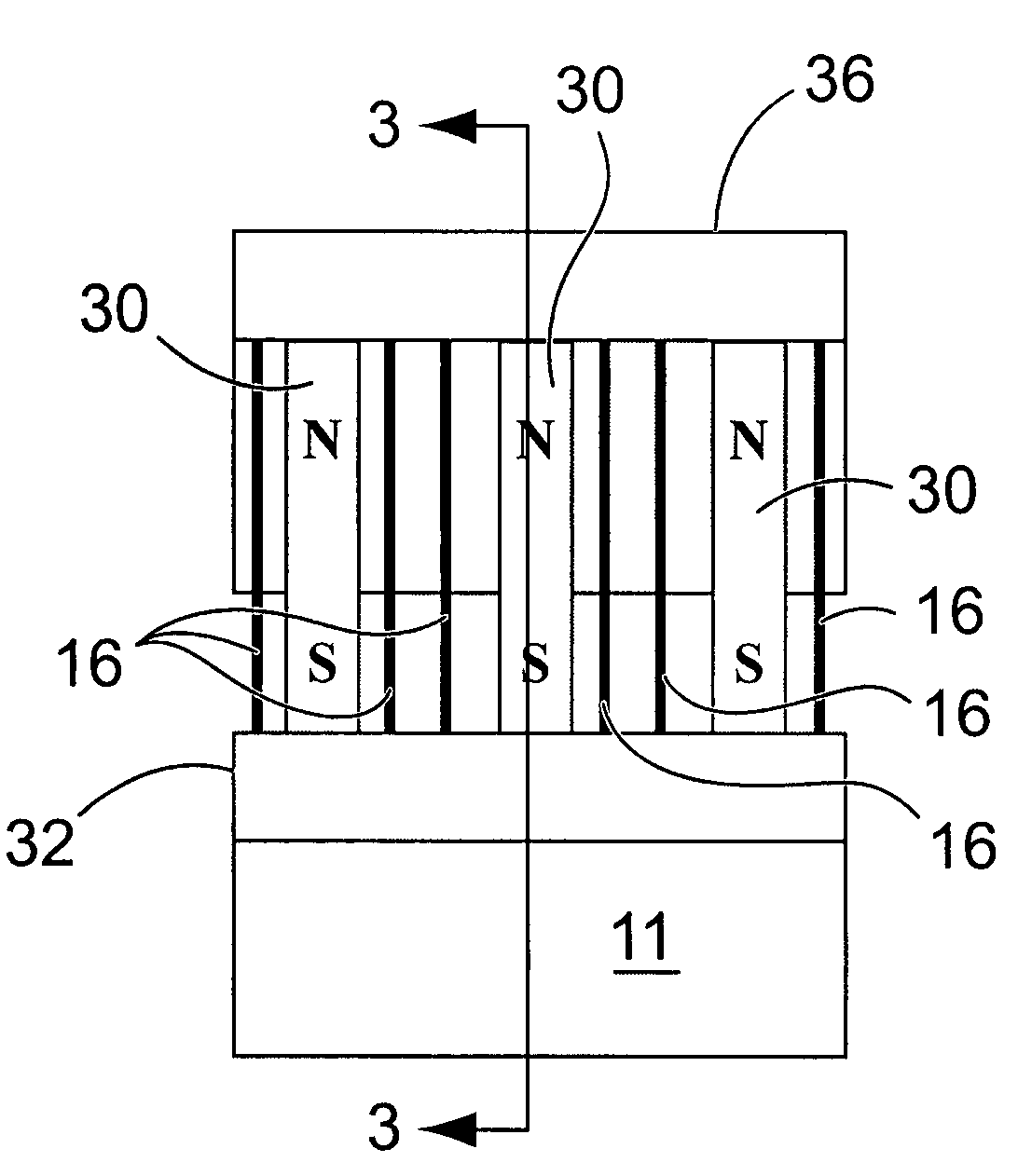

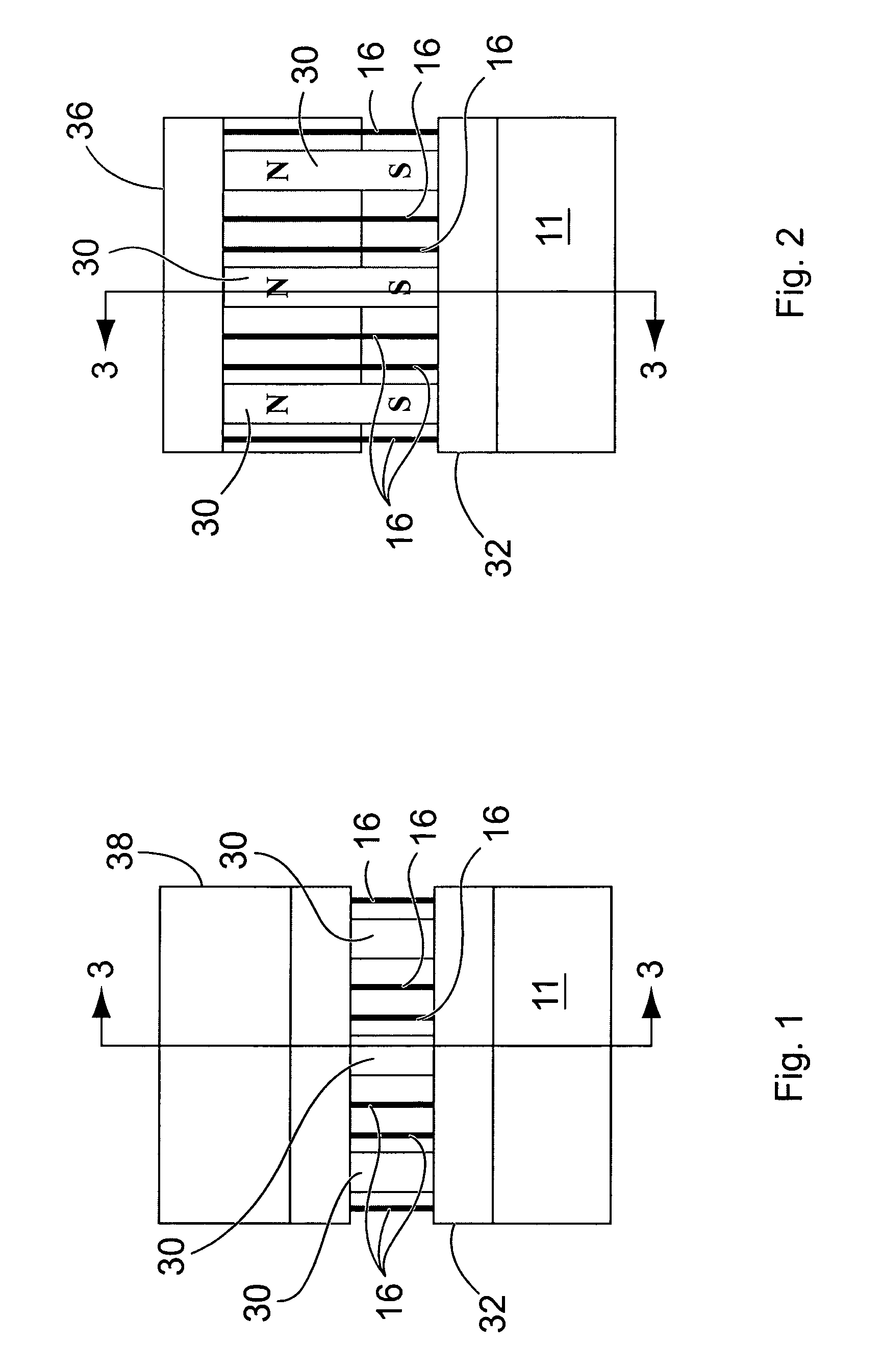

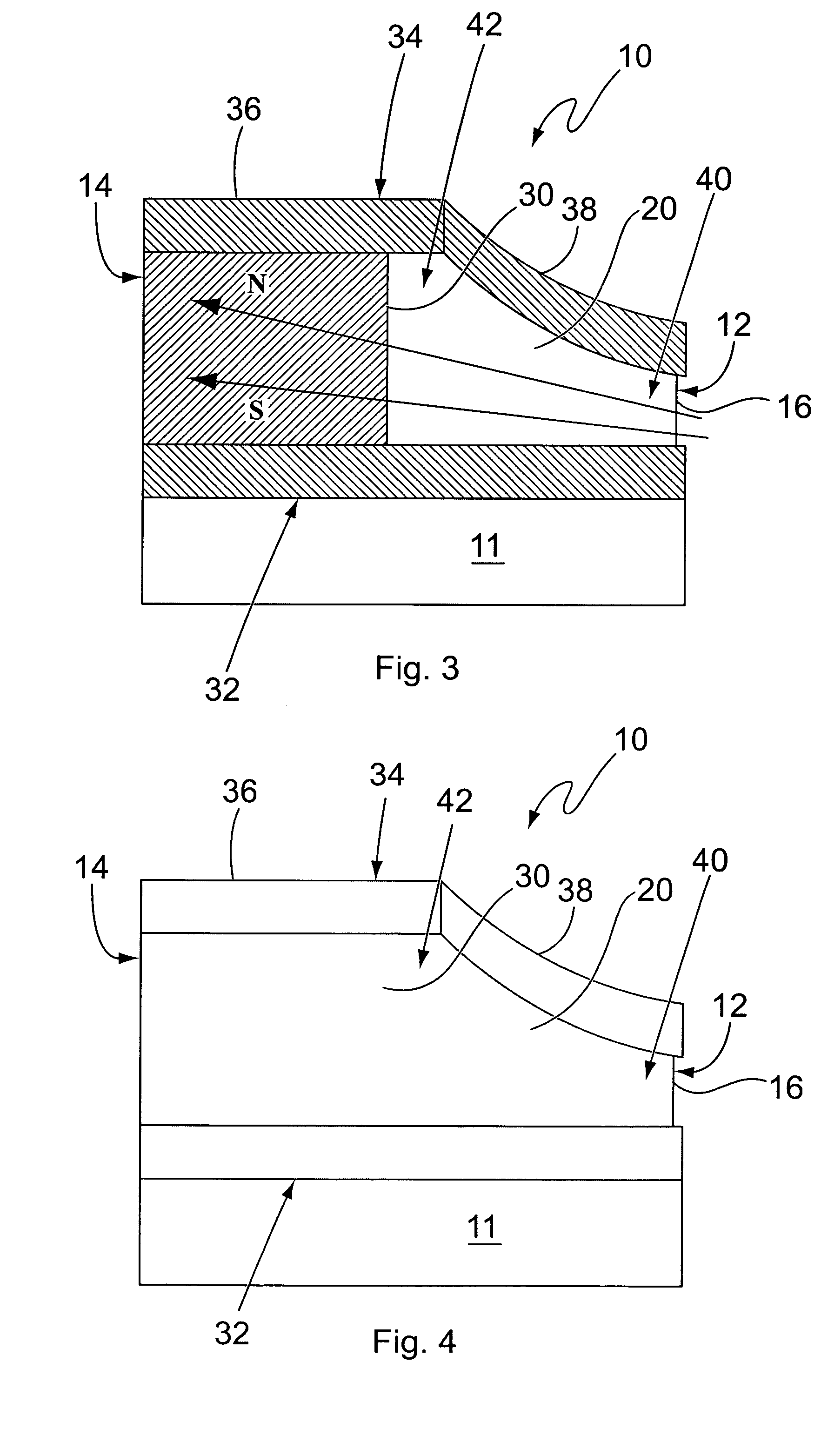

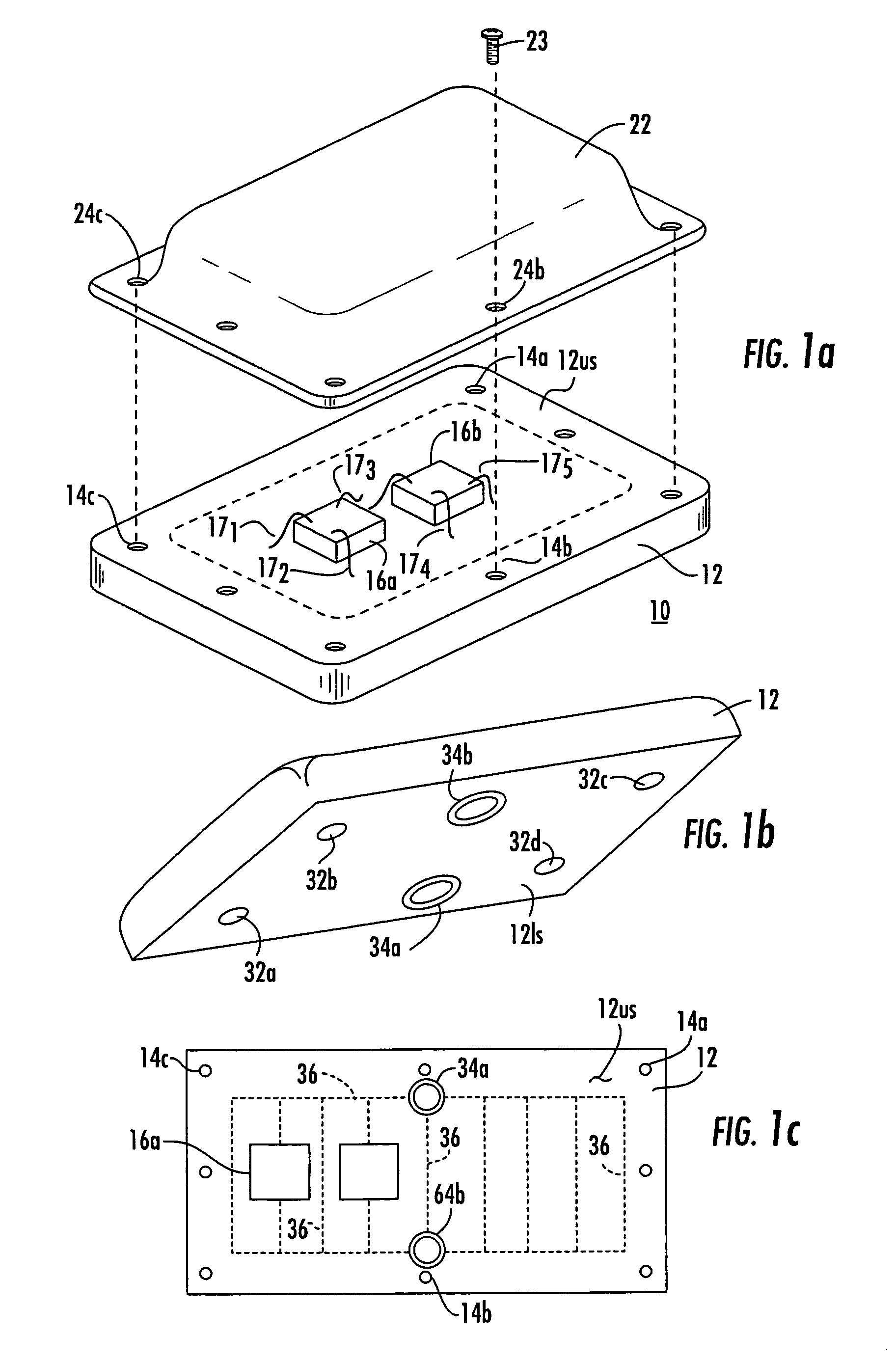

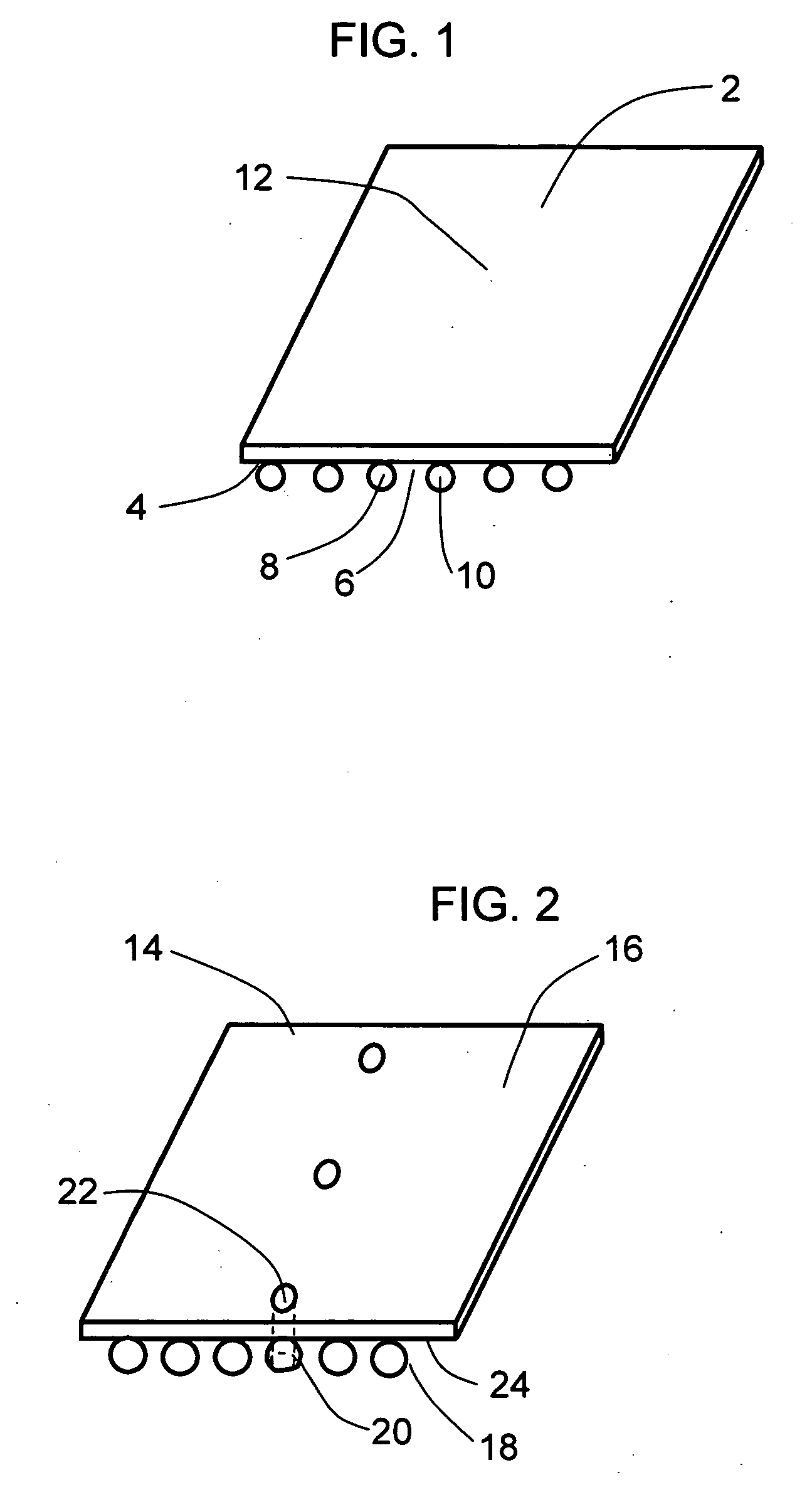

Magnetically enhanced convection heat sink

InactiveUS7031160B2Increased convection coolingHigh trafficElectromagnets without armaturesSemiconductor/solid-state device detailsMagnetic sourceConvection heat

A magnetically enhanced convection heat sink comprises a heat sink member for dissipating heat from a heat source. A magnetic source creates a magnetic field concentrated at a first location, the intensity of the magnetic field decreasing from the first location to a second location. The heat sink member is positioned within the magnetic field and in a gas flow path between the first and second locations. Gas, having paramagnetic properties, entering the heat sink at the first location is heated by the heat sink member, and as the gas becomes warmer is displaced by cooler gas causing the warmer gas to move toward the second location as it is further heated by the heat sink.

Owner:THE BOEING CO

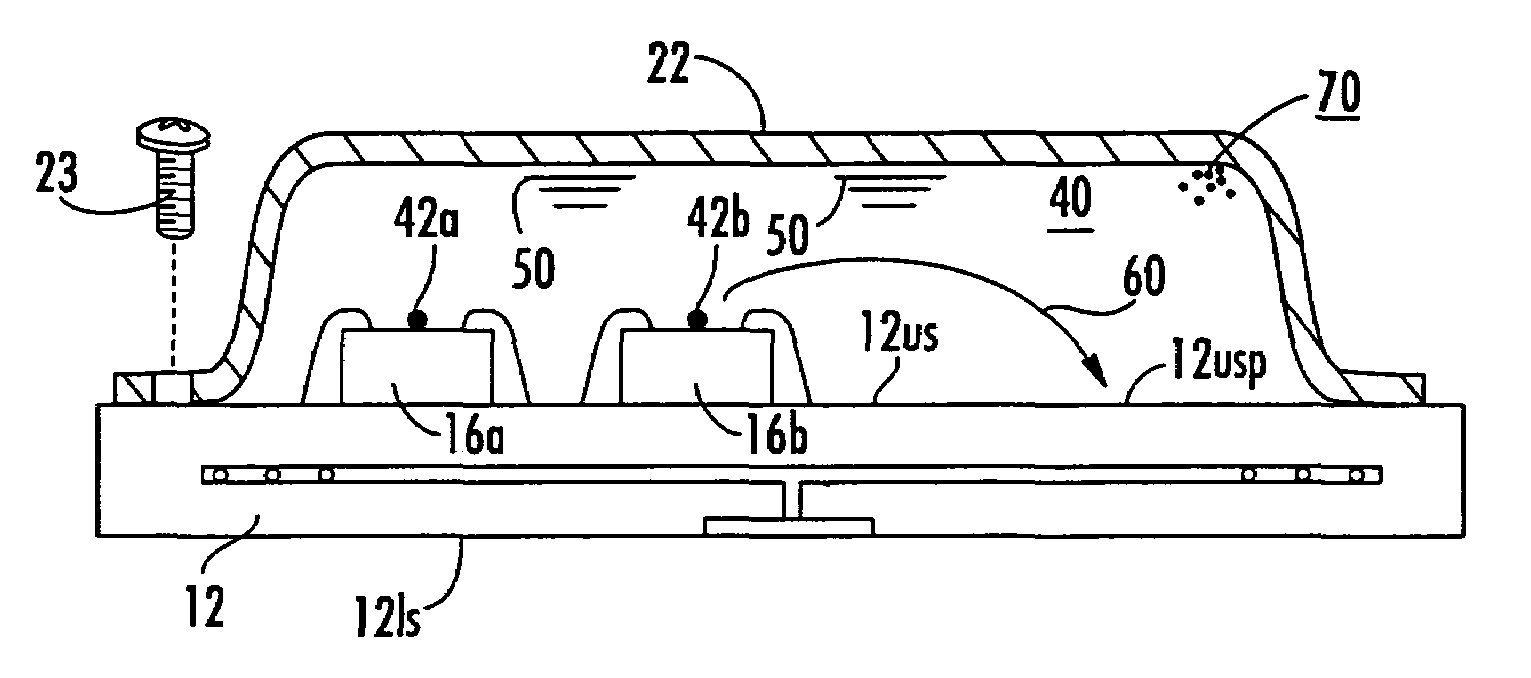

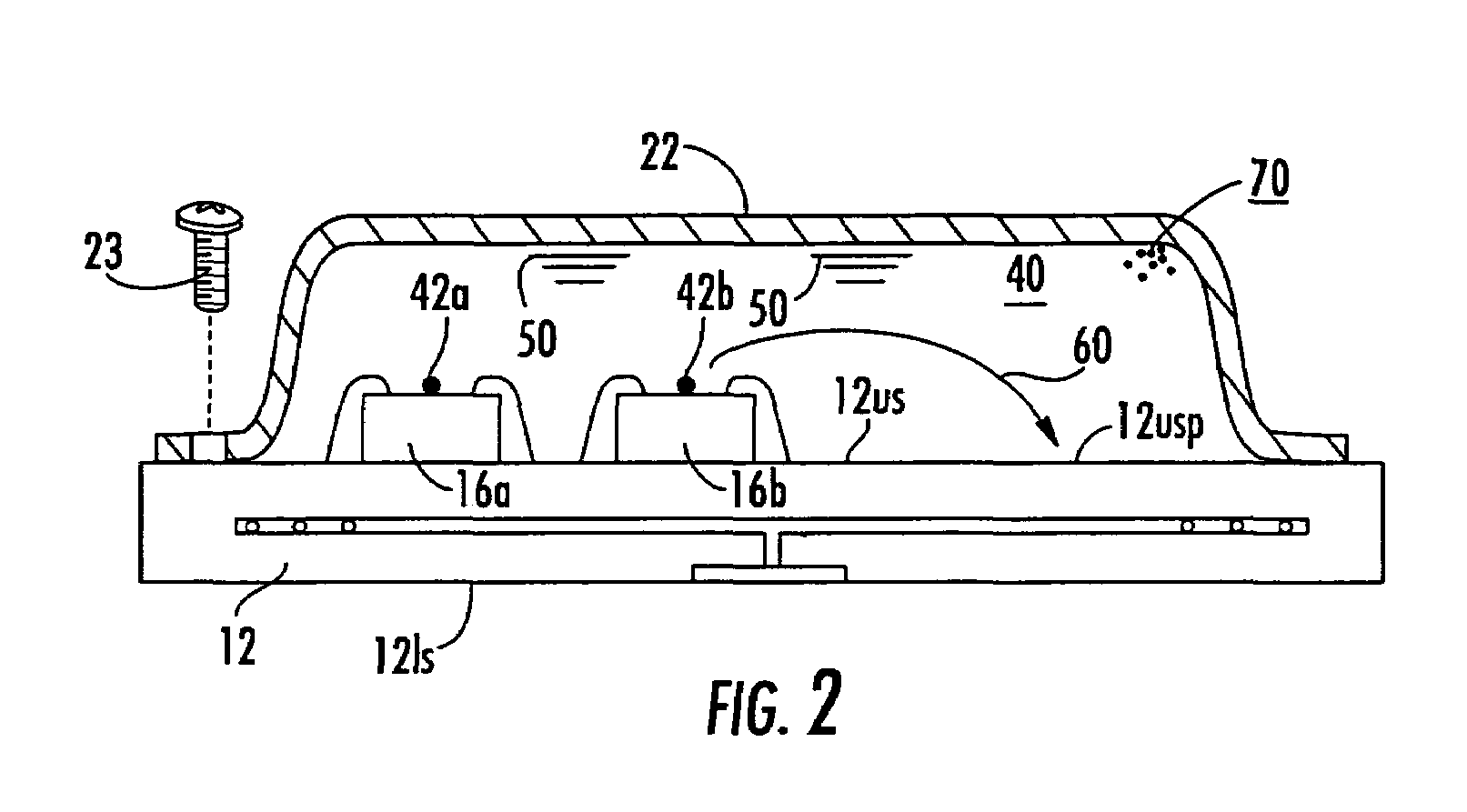

Parallel cooling of heat source mounted on a heat sink by means of liquid coolant

InactiveUS6992888B1Semiconductor/solid-state device detailsSolid-state devicesBoiling pointEngineering

A module includes a cold plate. Solid-state heat sources are thermally mounted on the cold plate in a chamber defined by the cold plate and a lid. Cooling of the heat sources is enhanced by a dielectric liquid within the chamber. The liquid has a boiling point slightly below the temperatures of “hot” spots, to form small bubbles during operation, which enhance convection flow. The liquid may be a mixture of fluorocarbons of different boiling points. The liquid may contain diamond particles.

Owner:LOCKHEED MARTIN CORP

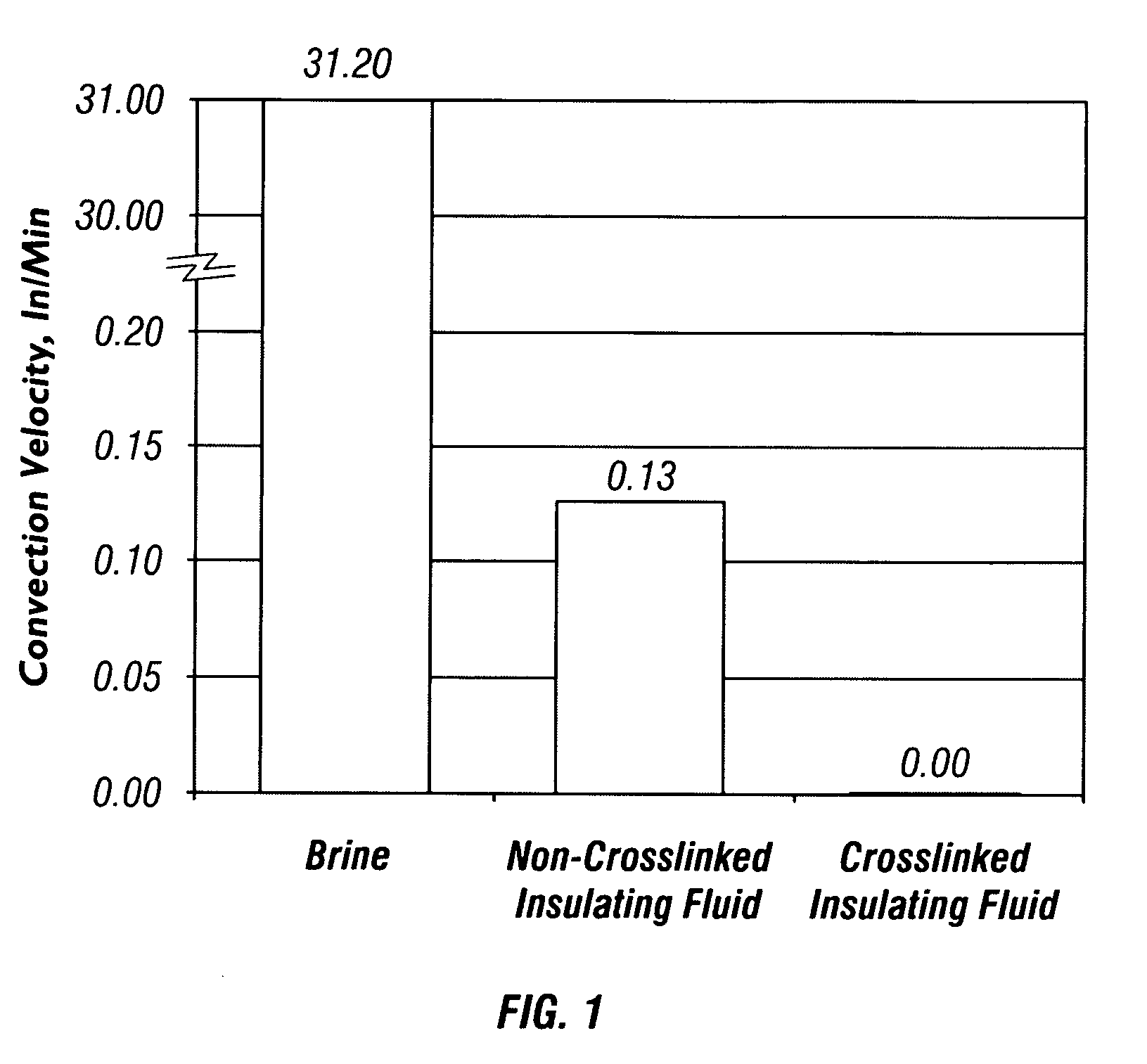

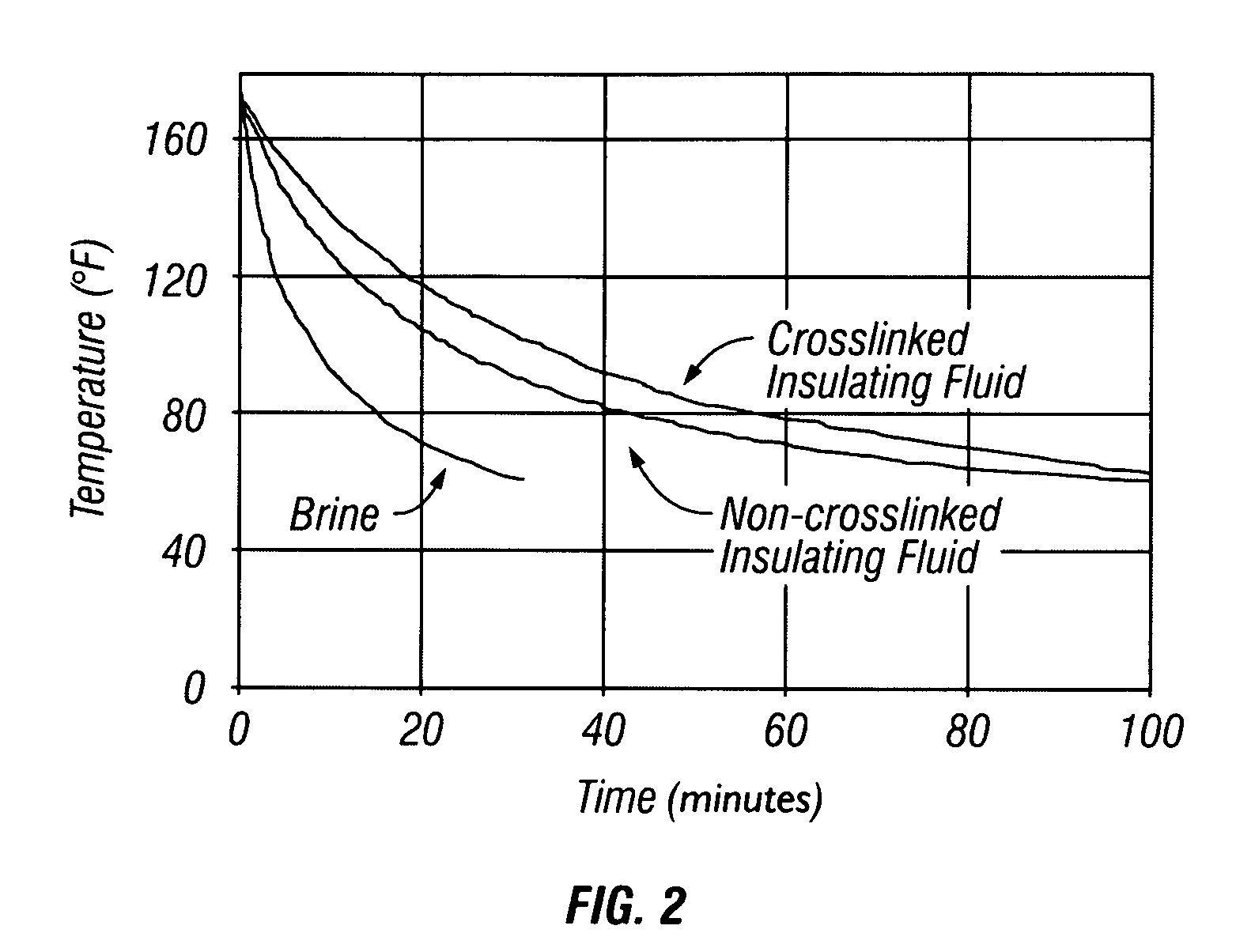

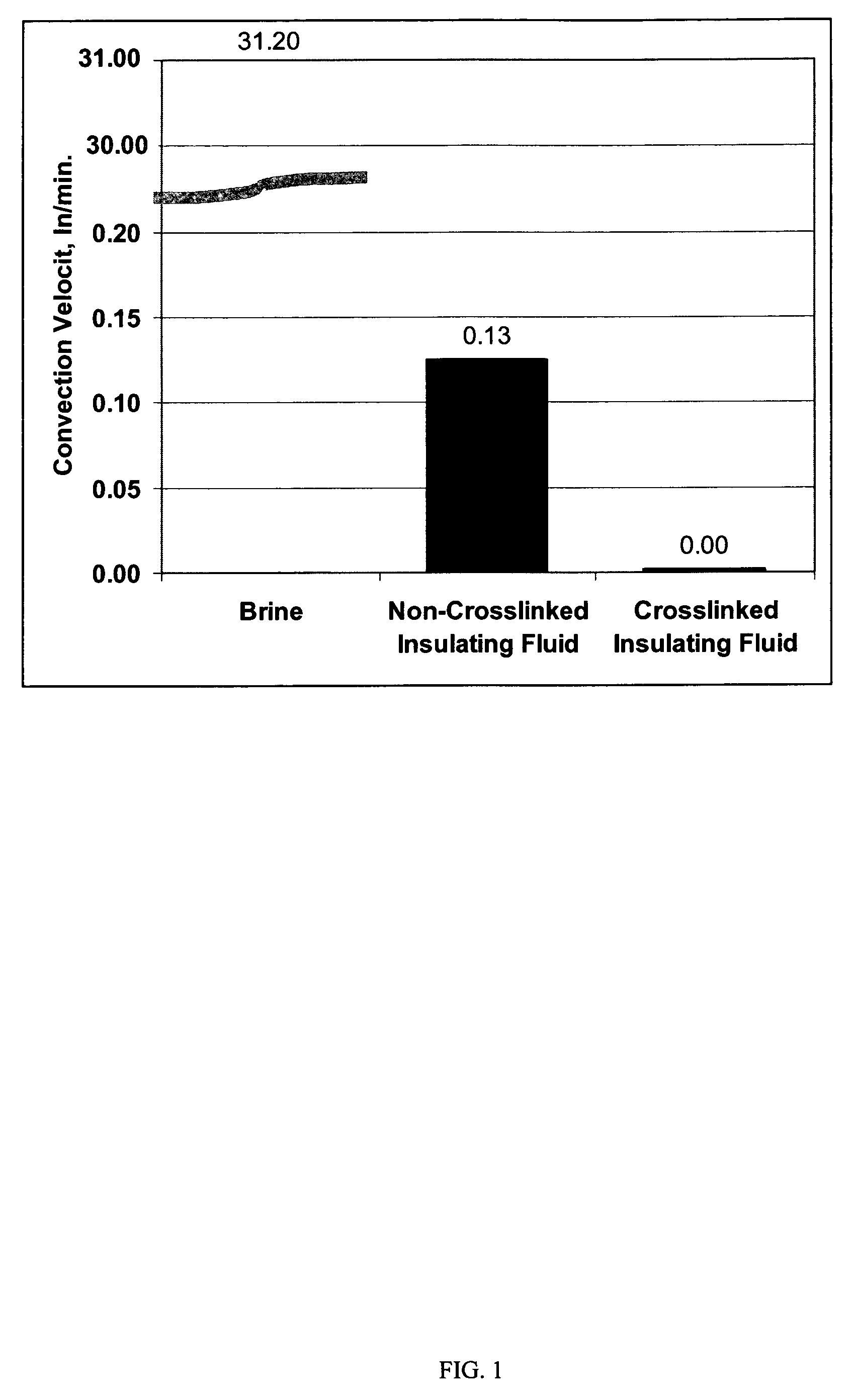

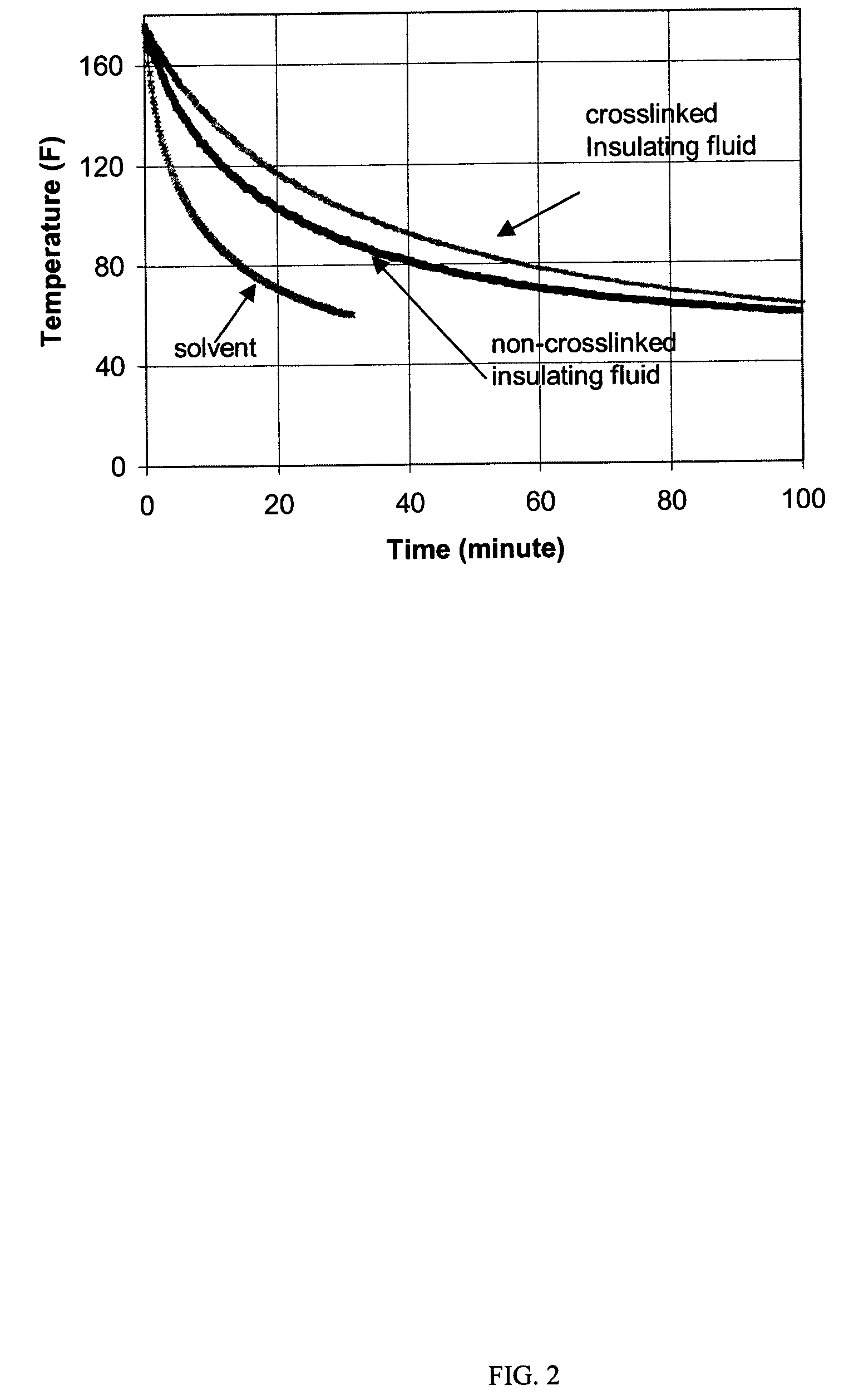

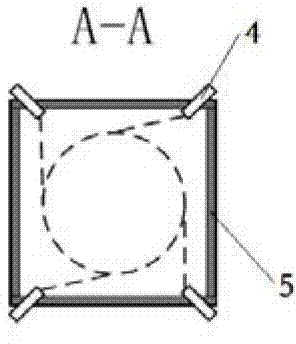

Methods of using crosslinkable compositions

InactiveUS7306039B2Improve the level ofFacilitate cross-linkingCosmetic preparationsDrilling rodsHeat lossesProduction tubing

A thermal insulating packer fluid contains water and / or brine, a crosslinkable viscosifying polymer, a crosslinking agent and an optional set retarder. The composition is capable of inhibiting unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli. The viscosity of the composition is such as to reduce the convection flow velocity within the annulus.

Owner:BAKER HUGHES INC

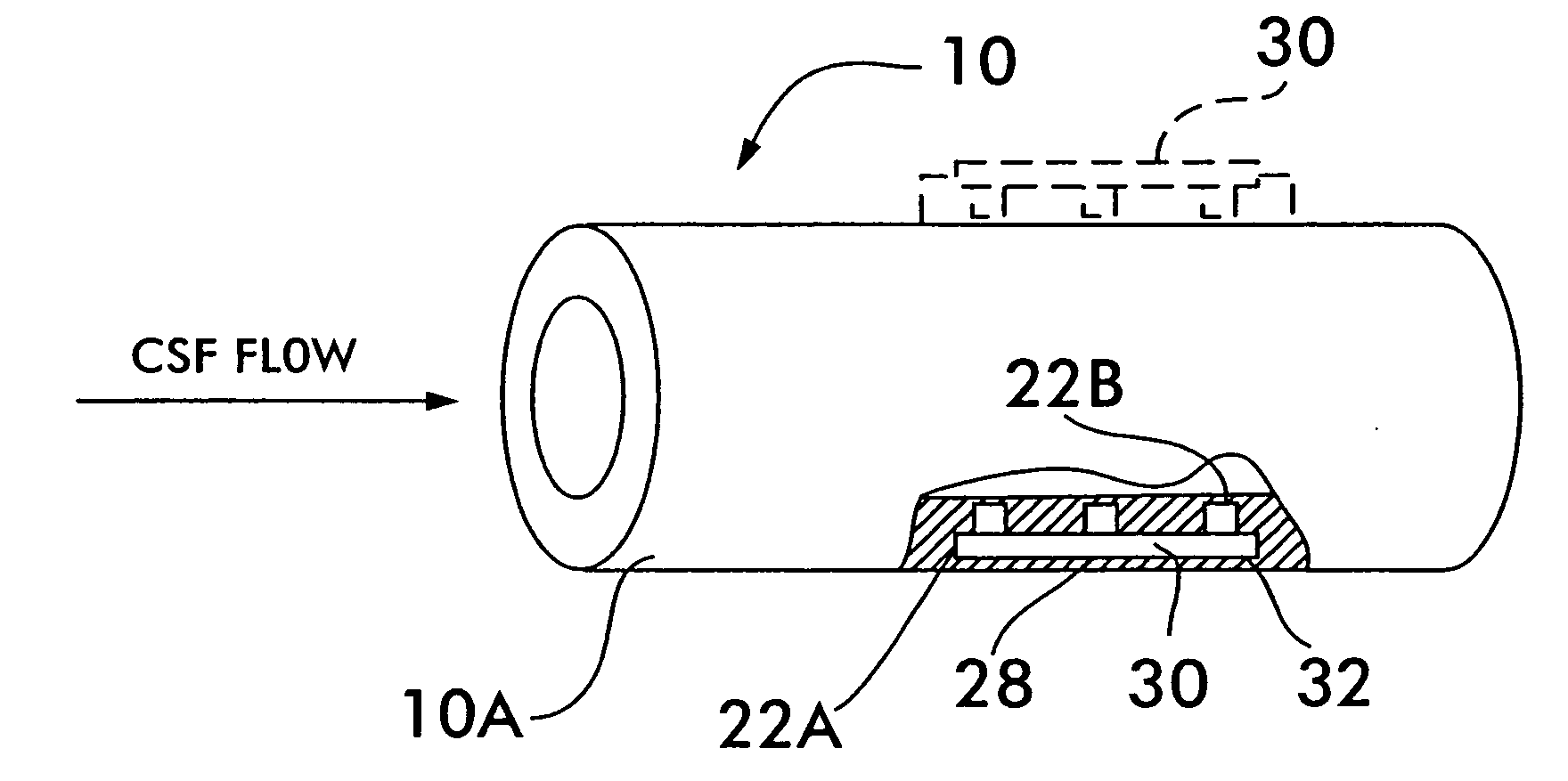

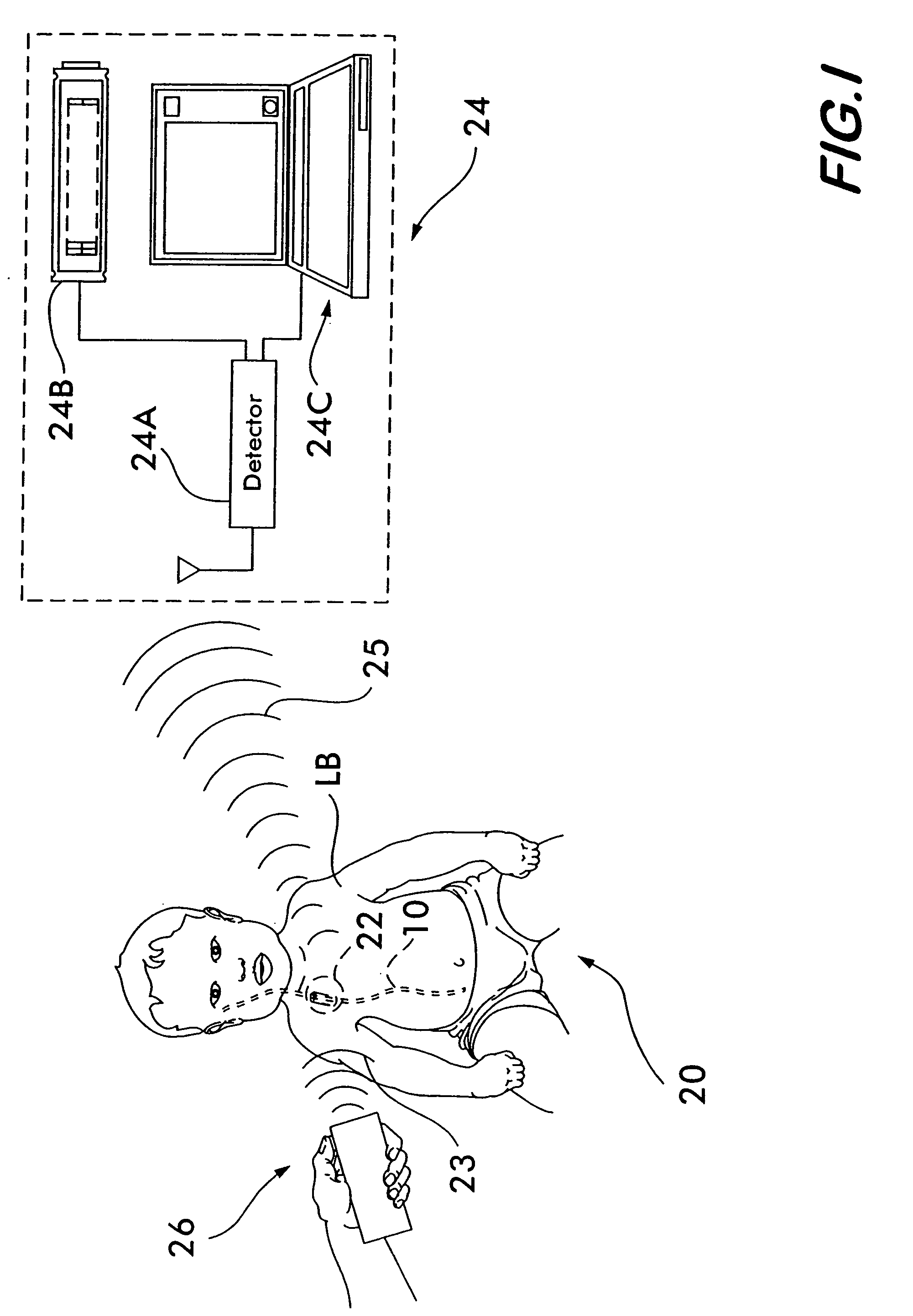

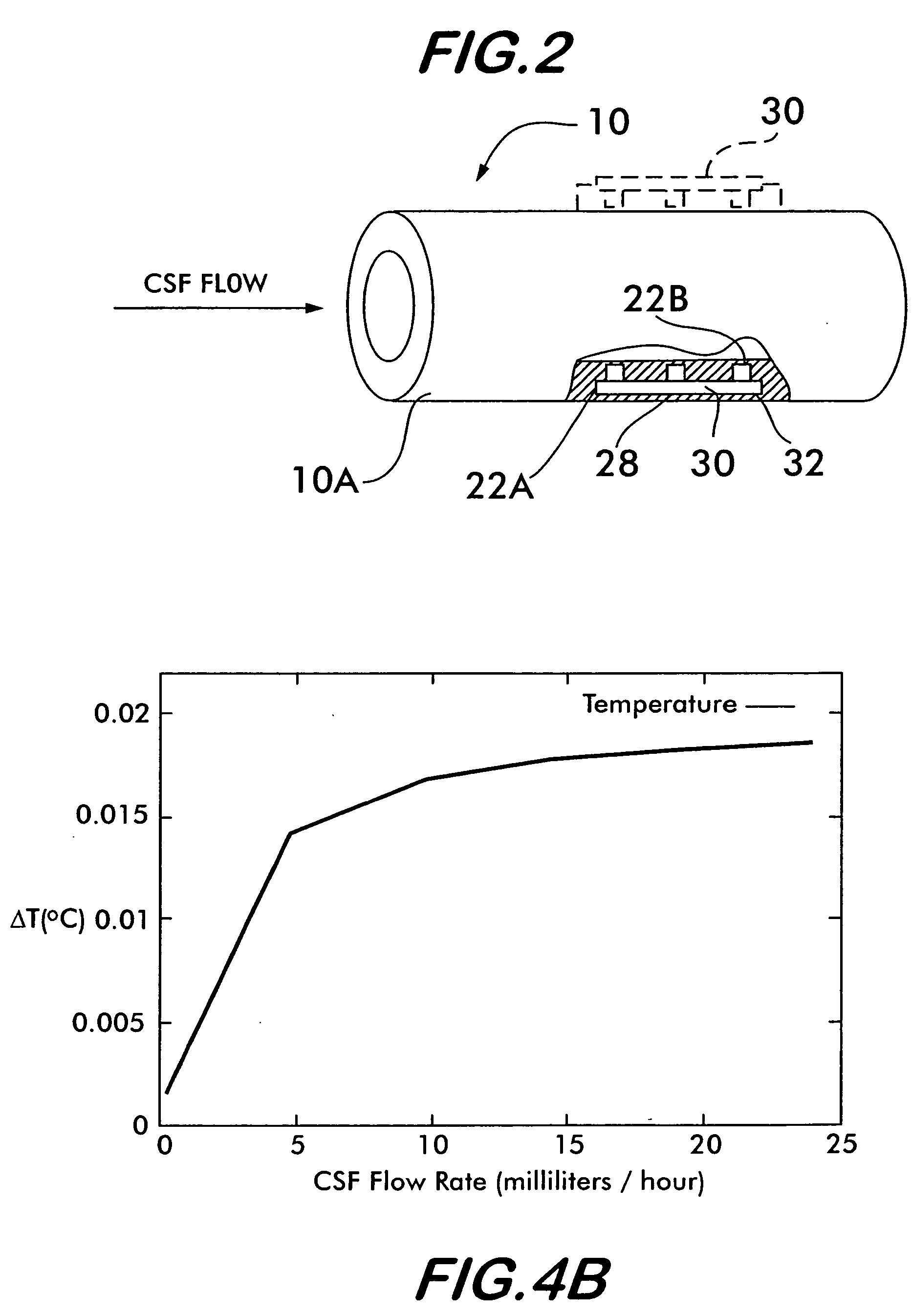

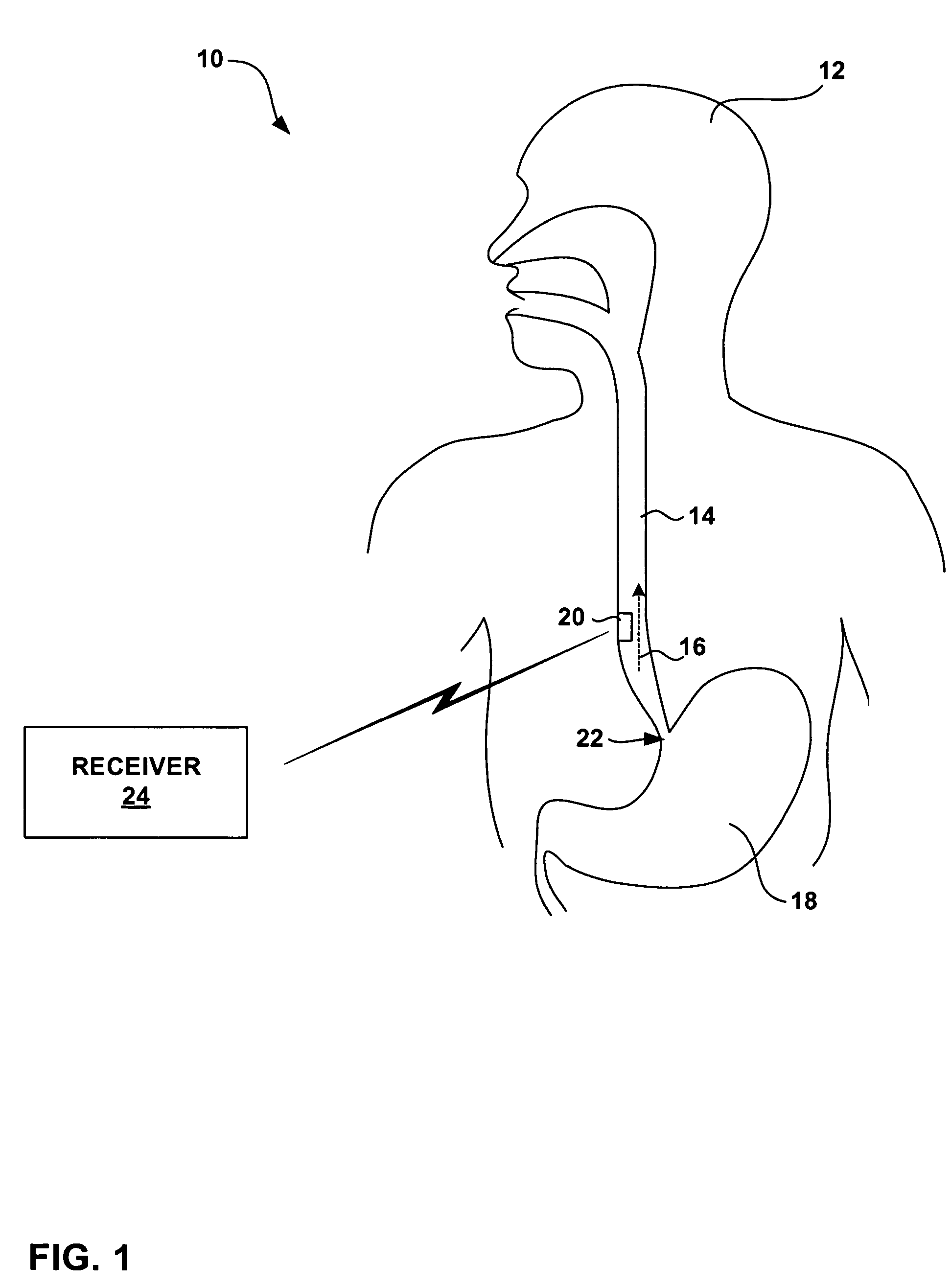

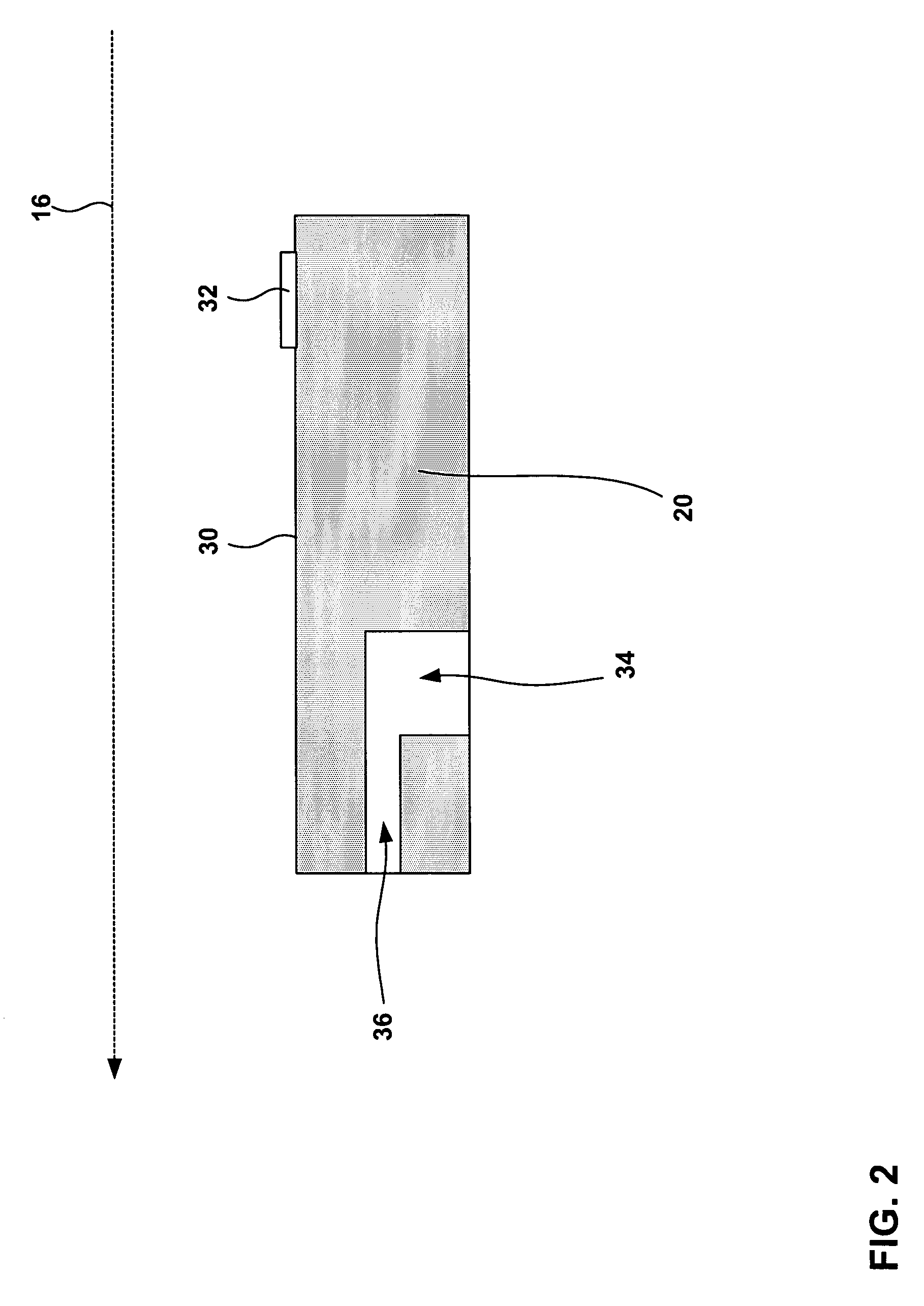

System and method for measuring flow in implanted cerebrospinal fluid shunts

InactiveUS20050204811A1Volume/mass flow by thermal effectsWound drainsFlow diverterCerebrospinal fluid shunt

A system and method for a thermal convection flow detection in a cerebrospinal fluid shunt that uses very little power for extended operation and for providing flow data to a remotely-located device.

Owner:NEFF INDIVIDUAL JANINE +1

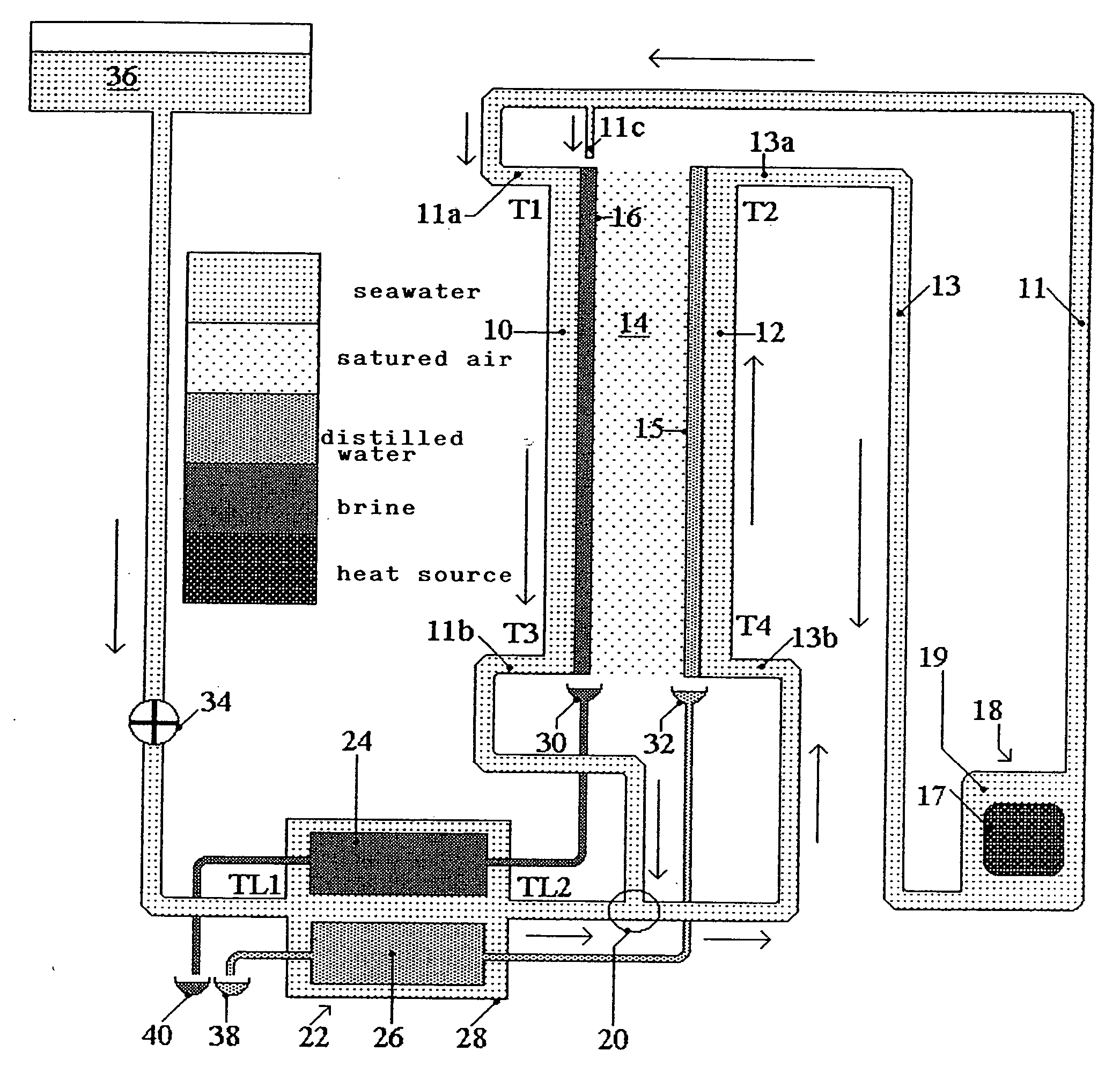

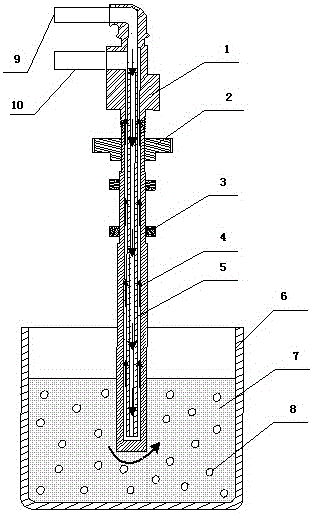

Distillation methods and devices in particular for producing potable water

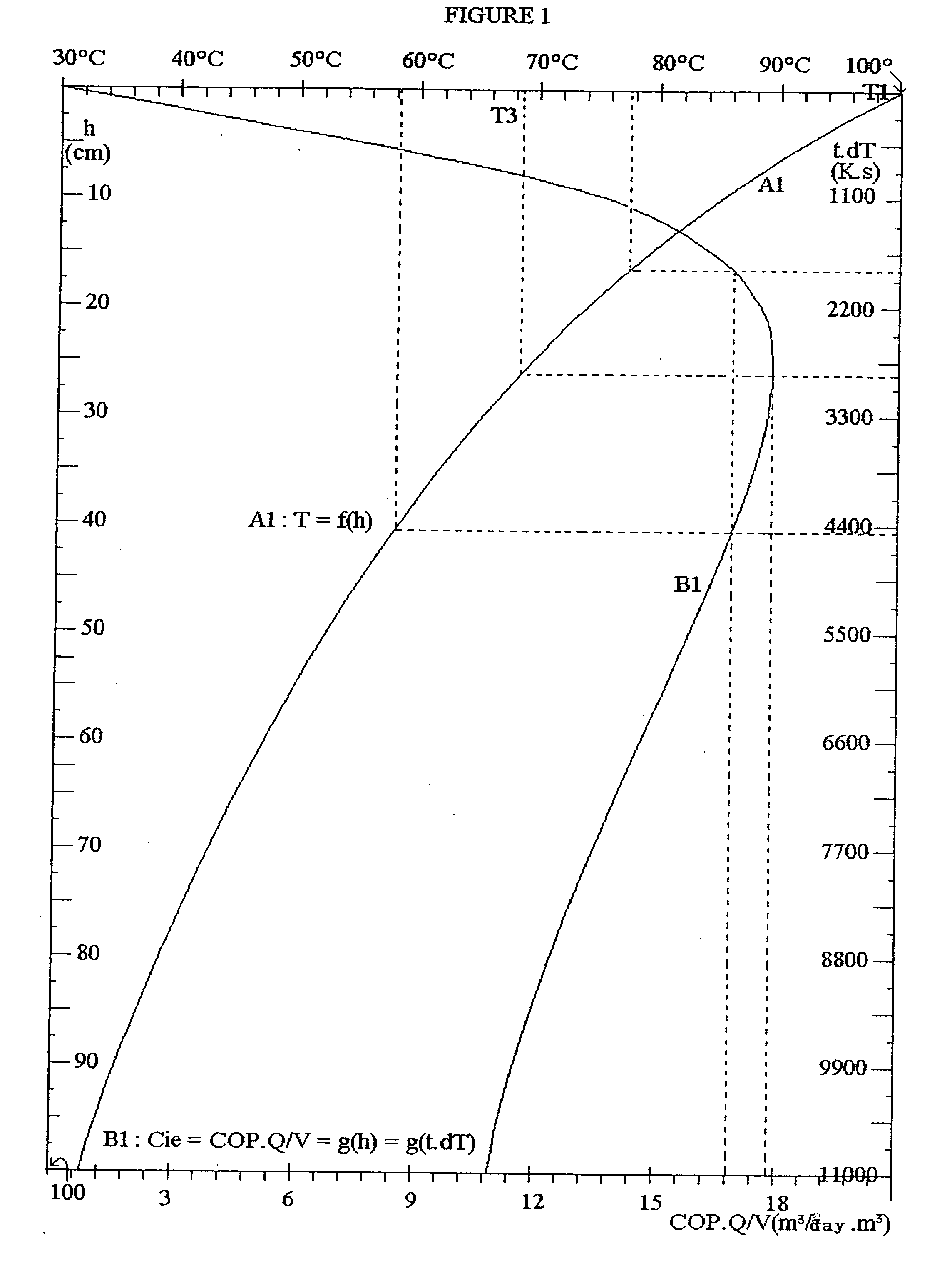

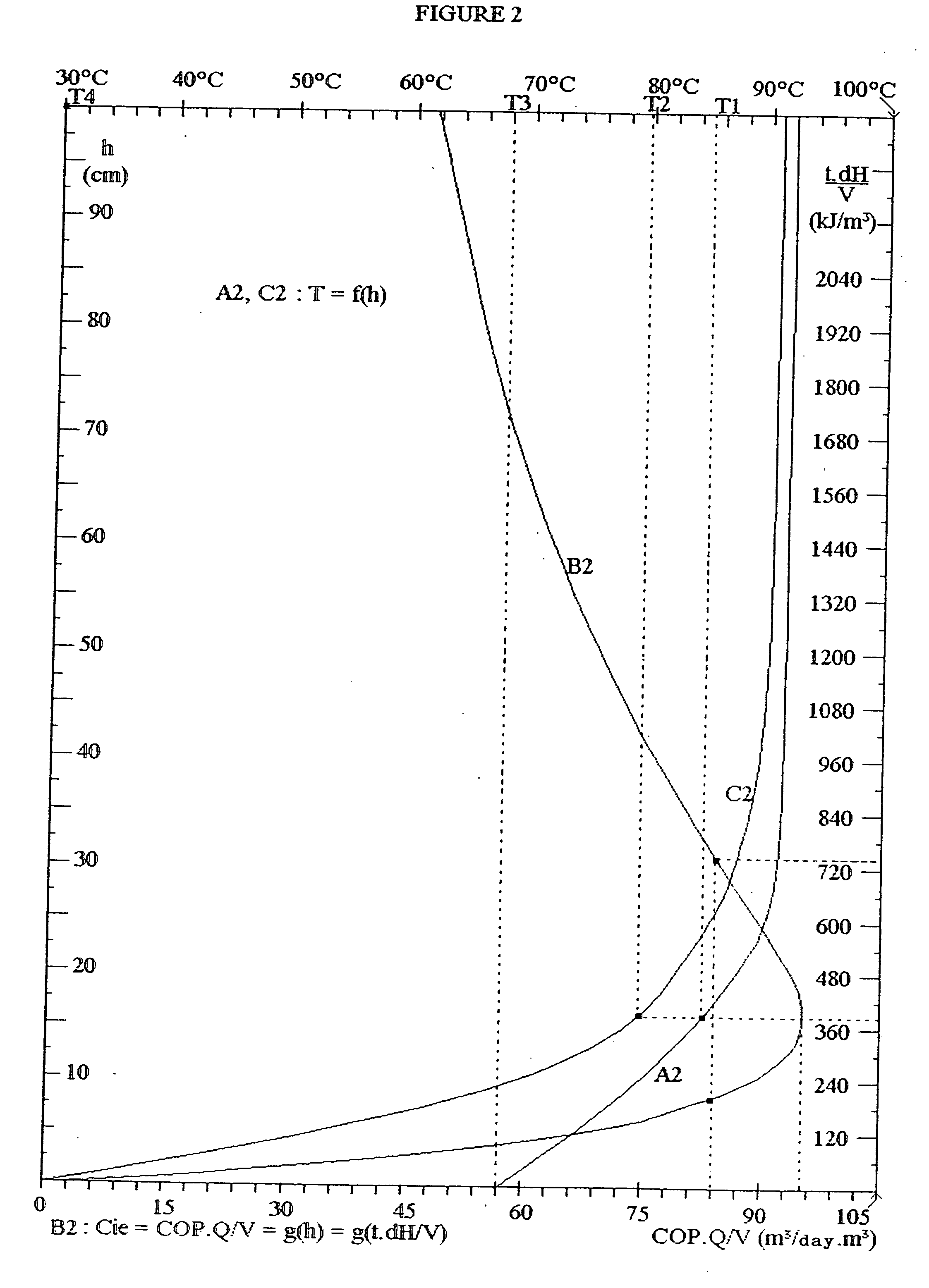

InactiveUS20060272933A1Improve efficiencyHigh densityGeneral water supply conservationAuxillariesEngineeringSeawater

The inventive device is embodied in the form of a chamber-oven for diffusing vapour and saturated hot air which circulate in a closed circuit by natural convection. Said device is embodied in the form of a domestic-use solar energy collecting device provided with a greenhouse whose surface is equal to 1 m2 and produces from 50 to 100 litres / day of distilled water. The device comprises a distillation unit arranged between two furnaces (59′, 79′) in a temperature-controlled container (48′). Said distillation unit comprises 100 flat thin hollow plates having a surface of 20 dm2 by face and an active volume of 200 dm3. The fine and tensioned walls (54) of said plates are provided with a hydrophilic coating (60′) and internal (56′) and inter-plate (58′) spaces. The lower chimney (59′) comprises a greenhouse (118′, 119′) whose bottom is embodied in the form of an impermeable black layer provided with a thin hydrophilic carpet on the rear part thereof. Saturated hot air at a temperature of 80° C. enters inside (56′) hollow plates from bellow and exits from the top at a temperature of 50° C. A high chimney (79′) is provided with a monoblock heat exchanger (84′) which is transversed by a non-potable water to be distilled which, afterwards is spread warm (40° C.) over the hydrophilic coating (60′). During passage through the heat exchanger (84) the air is cooled to 30° C. and moved down by gravity to the inter-plate spaces (58′) and exits therefrom at a temperature of 78° C. The distilled water condensed in the plates and by the heat exchanger is collected and removed. Brine is received in the bottom of the inter-plate space and distributed along the thin hydrophilic carpet of the bottom (122′) of the greenhouse. An air current passes along said hot carpet is heated and saturated and enters the plates. The brine liquor finally flows in an air-preheating tank (63′) which is emptied each morning. The greenhouse can be substituted by a heating tube transversed by a heating fluid or associated with another steam-jet tube. The more powerful chamber-ovens can produce at least 200 m3 / day of distilled water for collective consumption. Said invention can be used for salt removal from seawater, co-generating electricity and potable water and for producing food concentrates.

Owner:THE THIRD MILLENIUM WATER

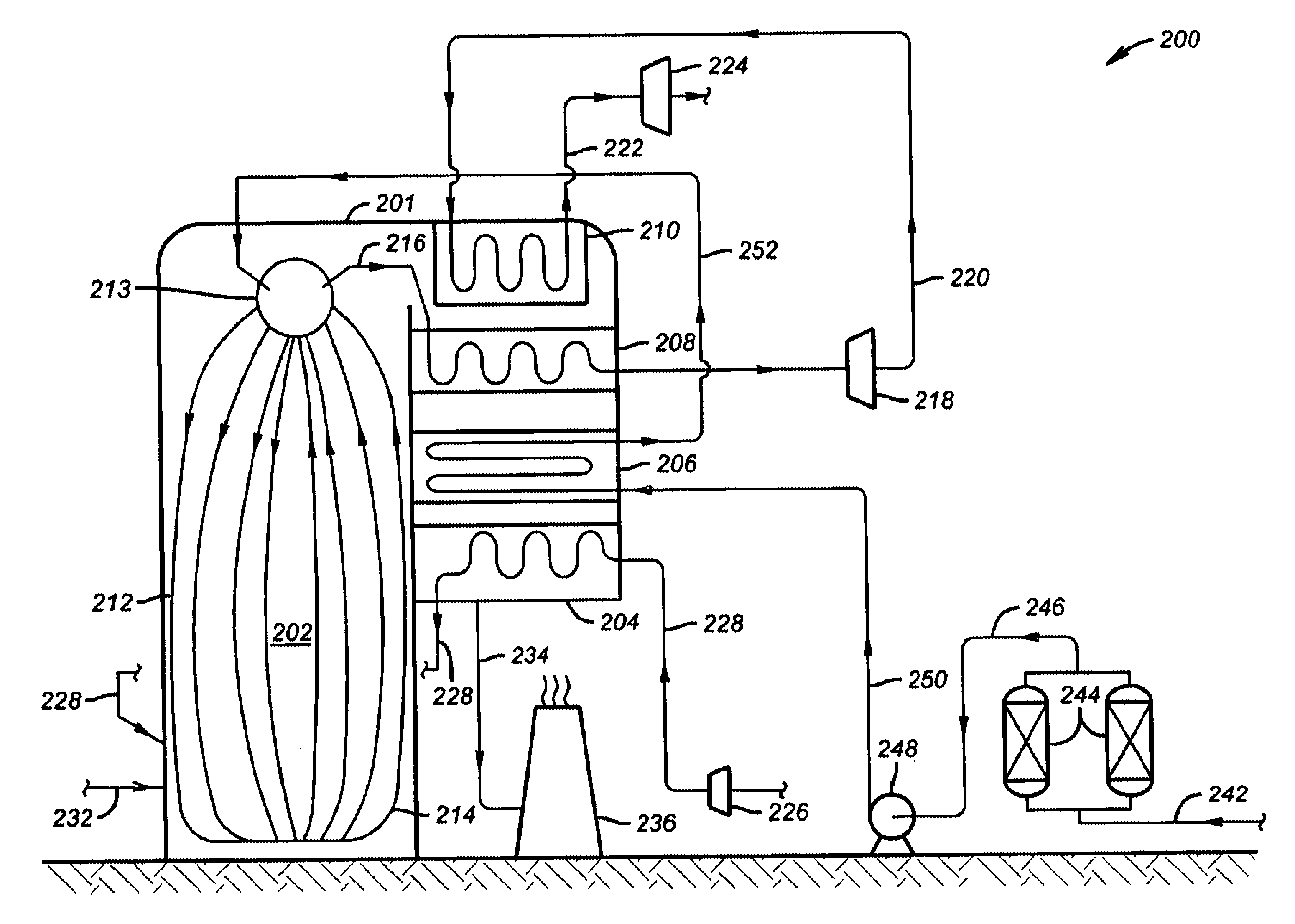

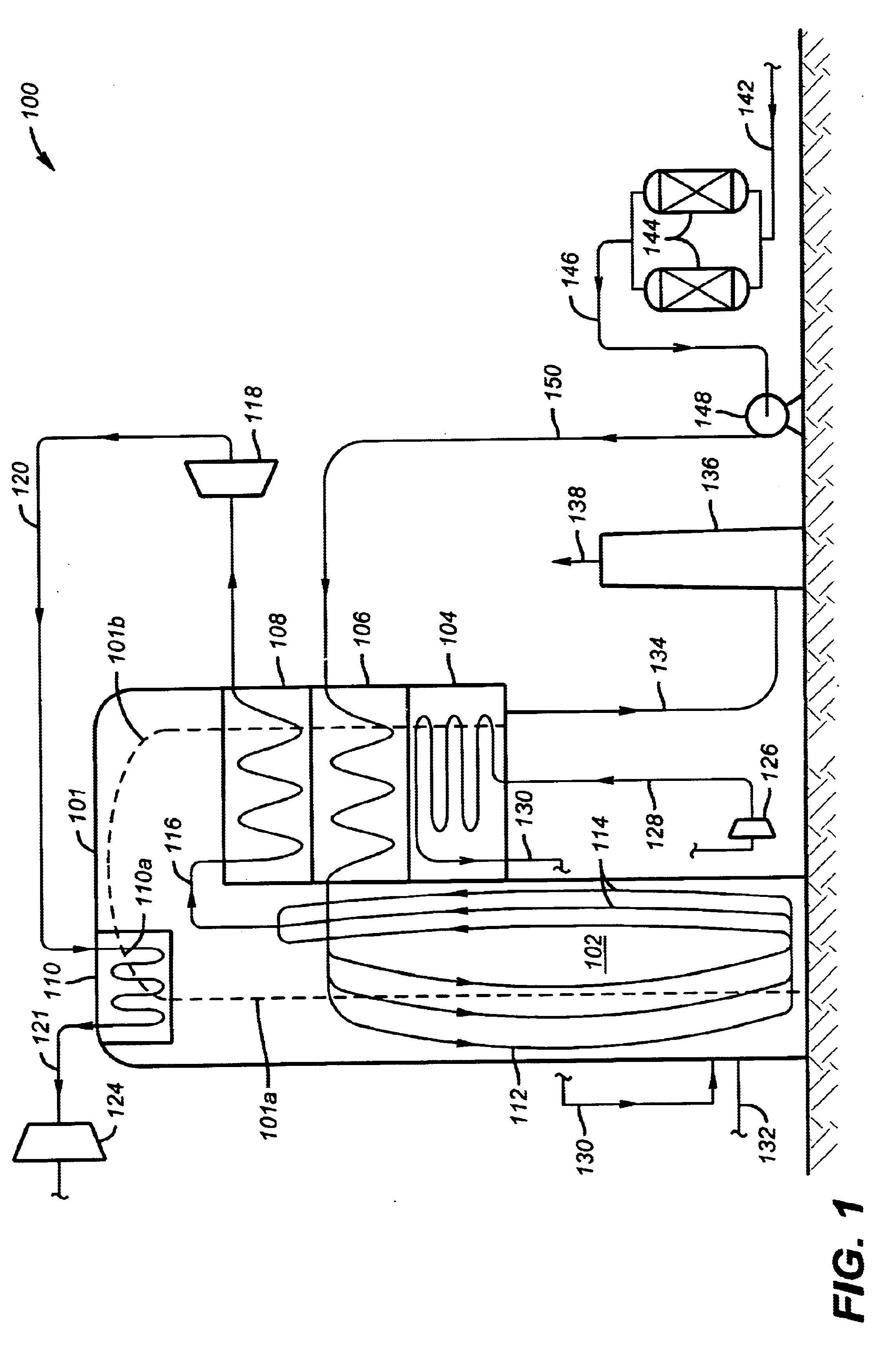

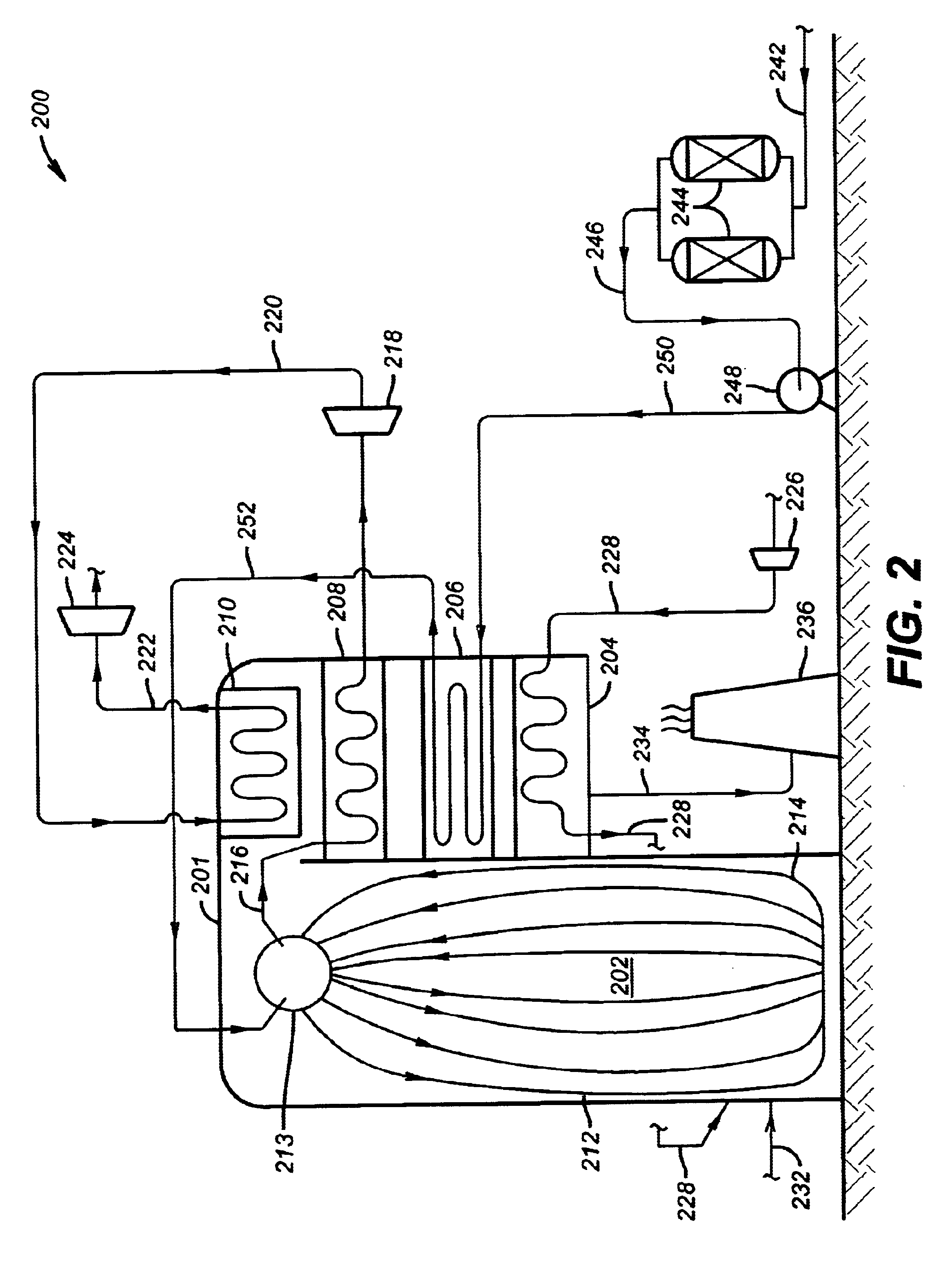

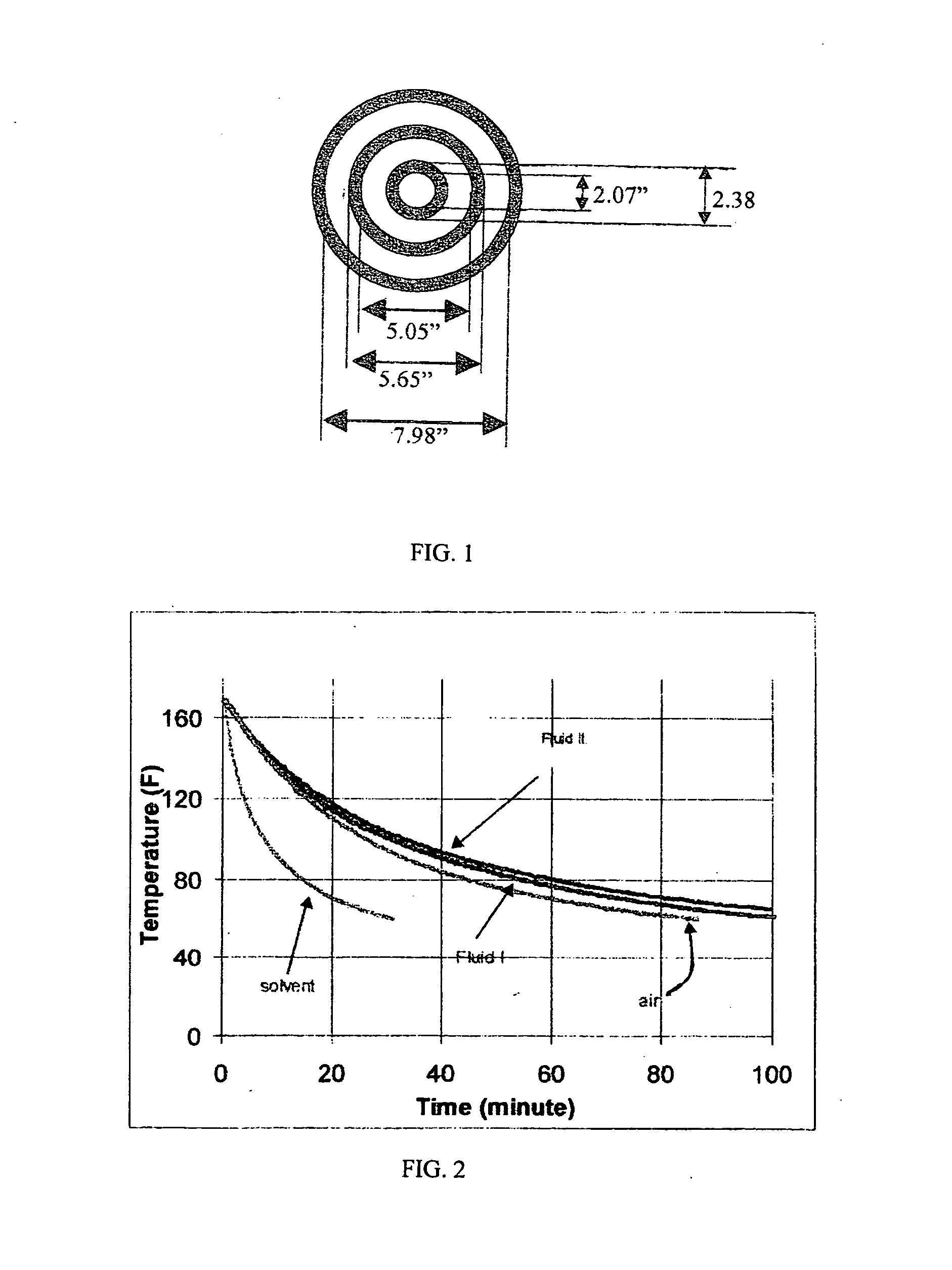

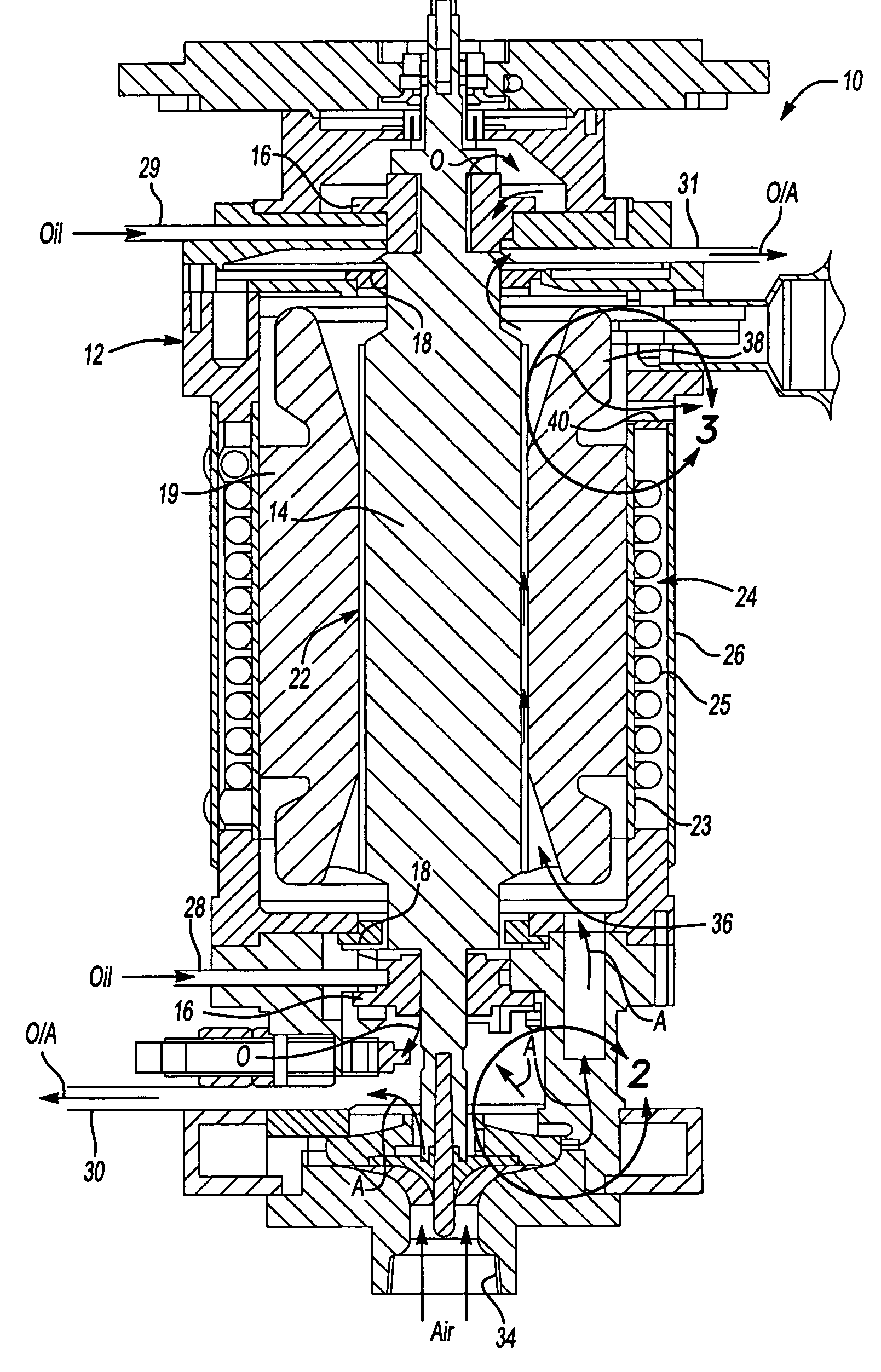

Steam generation apparatus and methods

Steam generation apparatus and methods are presented that are dedicated to oxygen-enriched air combustion of a fuel, wherein the oxygen concentration of the oxygen-enriched air may range from just above 21 percent to 100 percent. One apparatus comprises an oxygen-enriched air preheater through which oxygen-enriched air flows and exchanges heat indirectly with flue gas, creating a preheated oxygen-enriched air stream. The apparatus further comprises a boiler having a radiant section and a convection section, and other heat transfer units adapted to handle reduced flue gas flow rate and higher temperature flue gases than comparable air / fuel combustion boilers, thus allowing a smaller heat transfer surface area, a more compact design and a higher efficiency.

Owner:AIR LIQUIDE AMERICA INC +1

Crosslinkable thermal insulating compositions and methods of using the same

InactiveUS20050038199A1Low viscosityEasy to pumpCosmetic preparationsDrilling rodsHeat lossesProduction tubing

A thermal insulating packer fluid contains water and / or brine, a crosslinkable viscosifying polymer, a crosslinking agent and an optional set retarder. The composition is capable of inhibiting unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli. The viscosity of the composition is such as to reduce the convection flow velocity within the annulus.

Owner:BAKER HUGHES INC

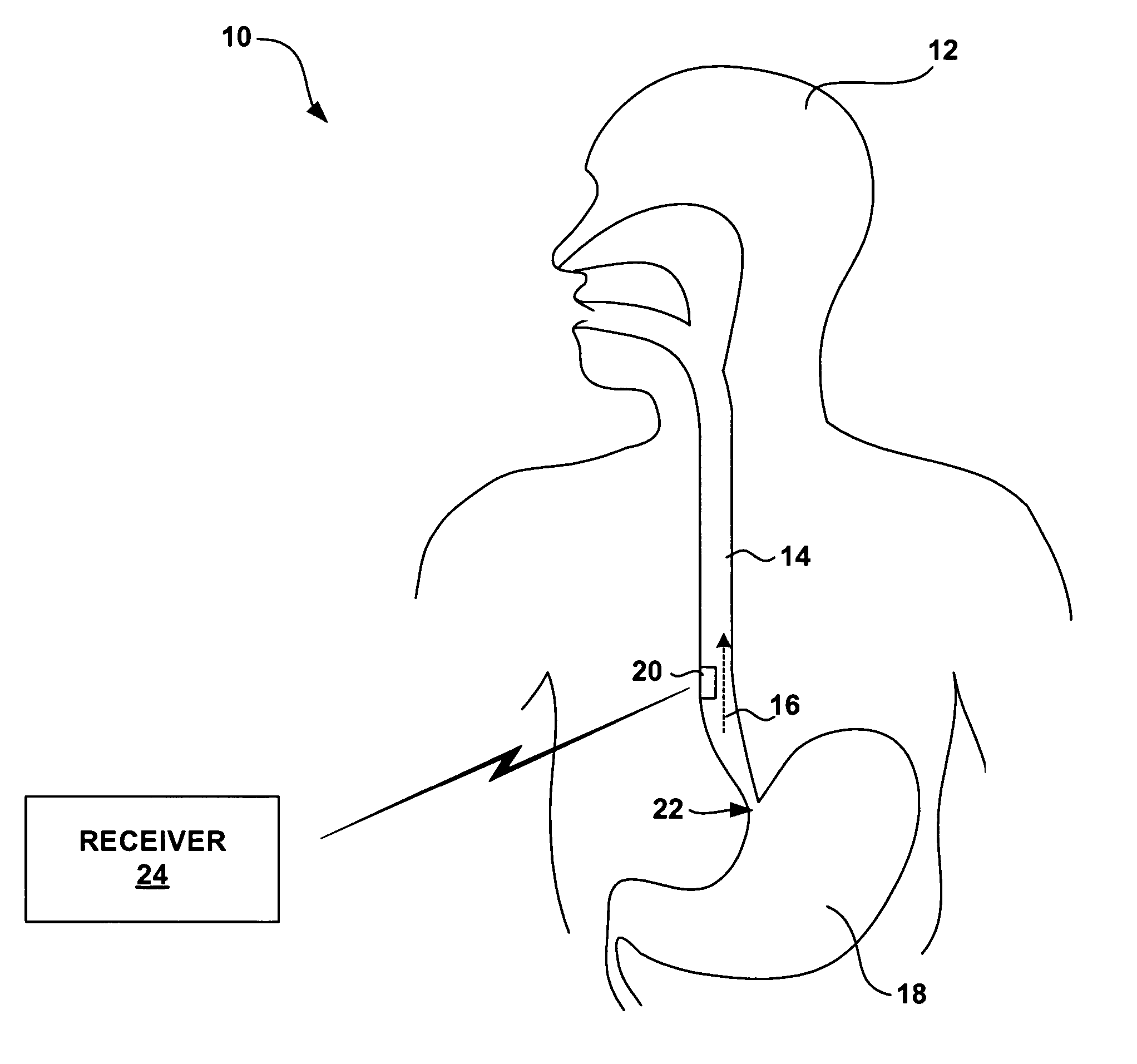

Monitoring fluid flow in the gastrointestinal tract

InactiveUS20050182342A1Reliable diagnosisEarly diagnosisSurgeryPerson identificationOptical flowEsophageal reflux disease

A sensor capable of sensing the flow of fluids is placed in the gastrointestinal tract. The sensor may be, for example, an ultrasonic flow sensor, an optical flow sensor, or a thermal convection flow sensor. A system for monitoring fluid flow in the gastrointestinal tract may include monitor configured for placement in the gastrointestinal tract that includes such a sensor. The monitor measures the flow of fluid in the gastrointestinal tract based on the output of the senor. The monitor may take the form of a capsule with a means or mechanism for attachment to a mucosal lining of the gastrointestinal tract. In exemplary embodiments, the sensor is placed in the esophagus, senses the flow of fluid from the stomach into the esophagus, and is used to diagnose gastroesophageal reflux disease (GERD).

Owner:MEDTRONIC INC

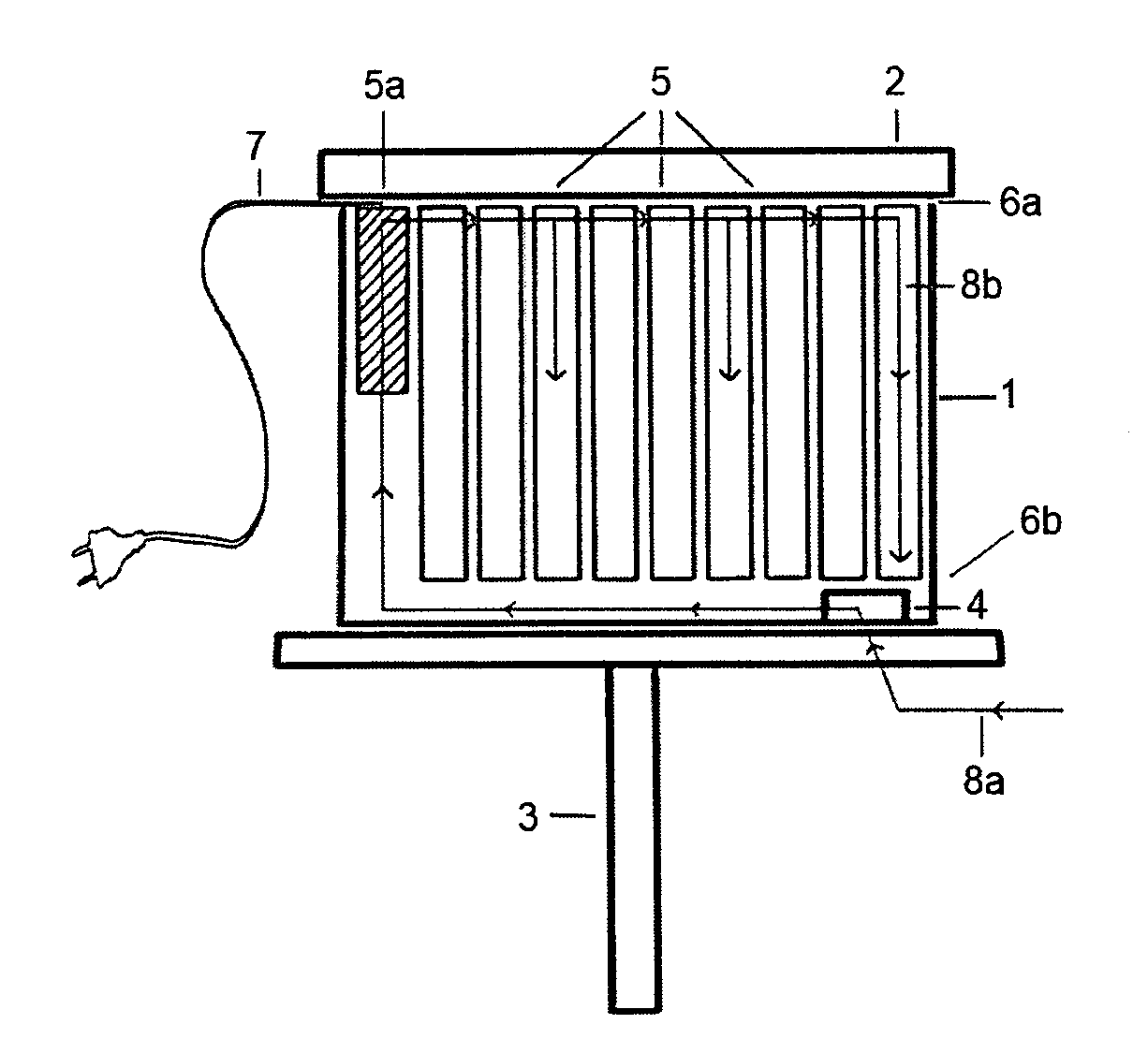

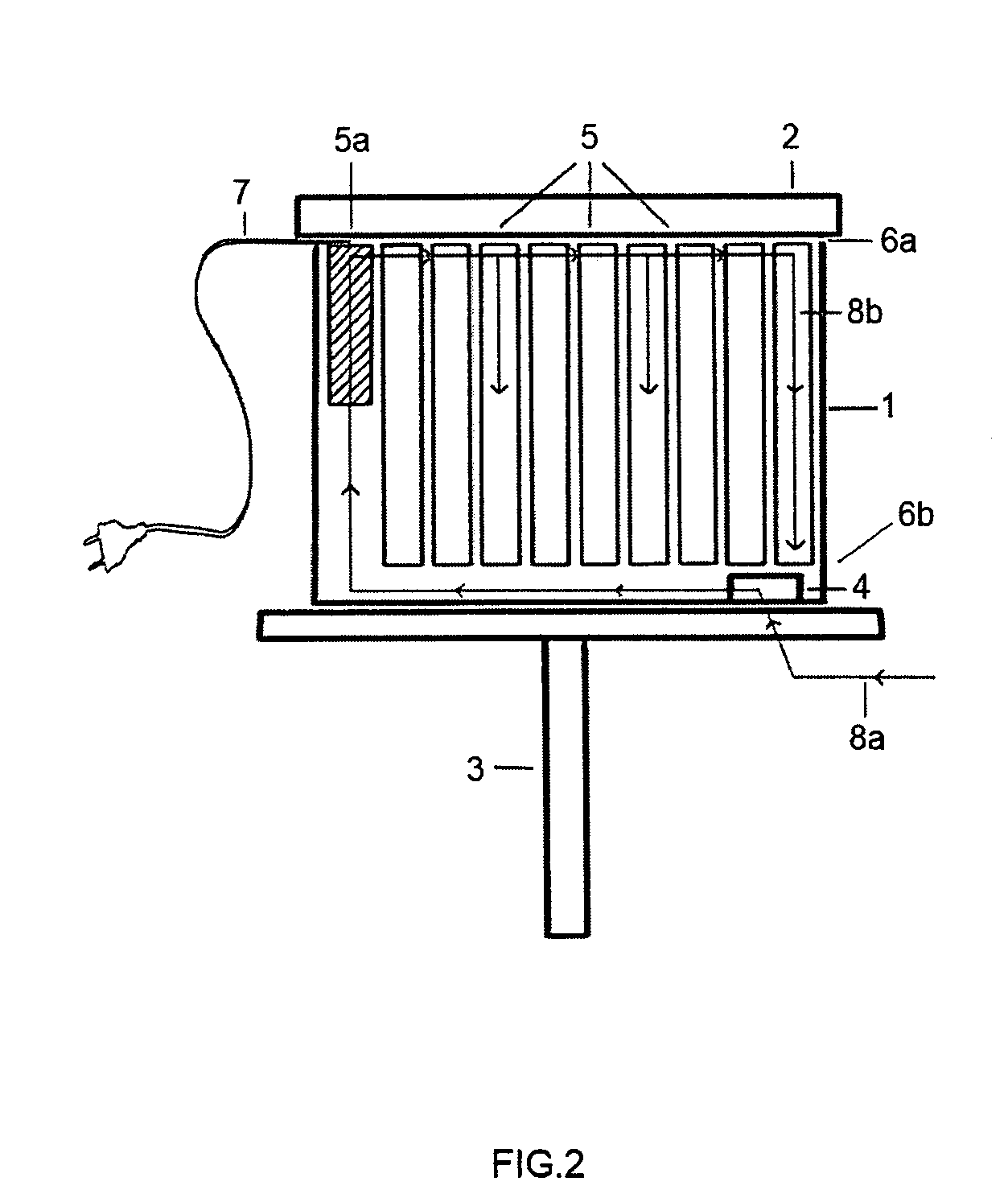

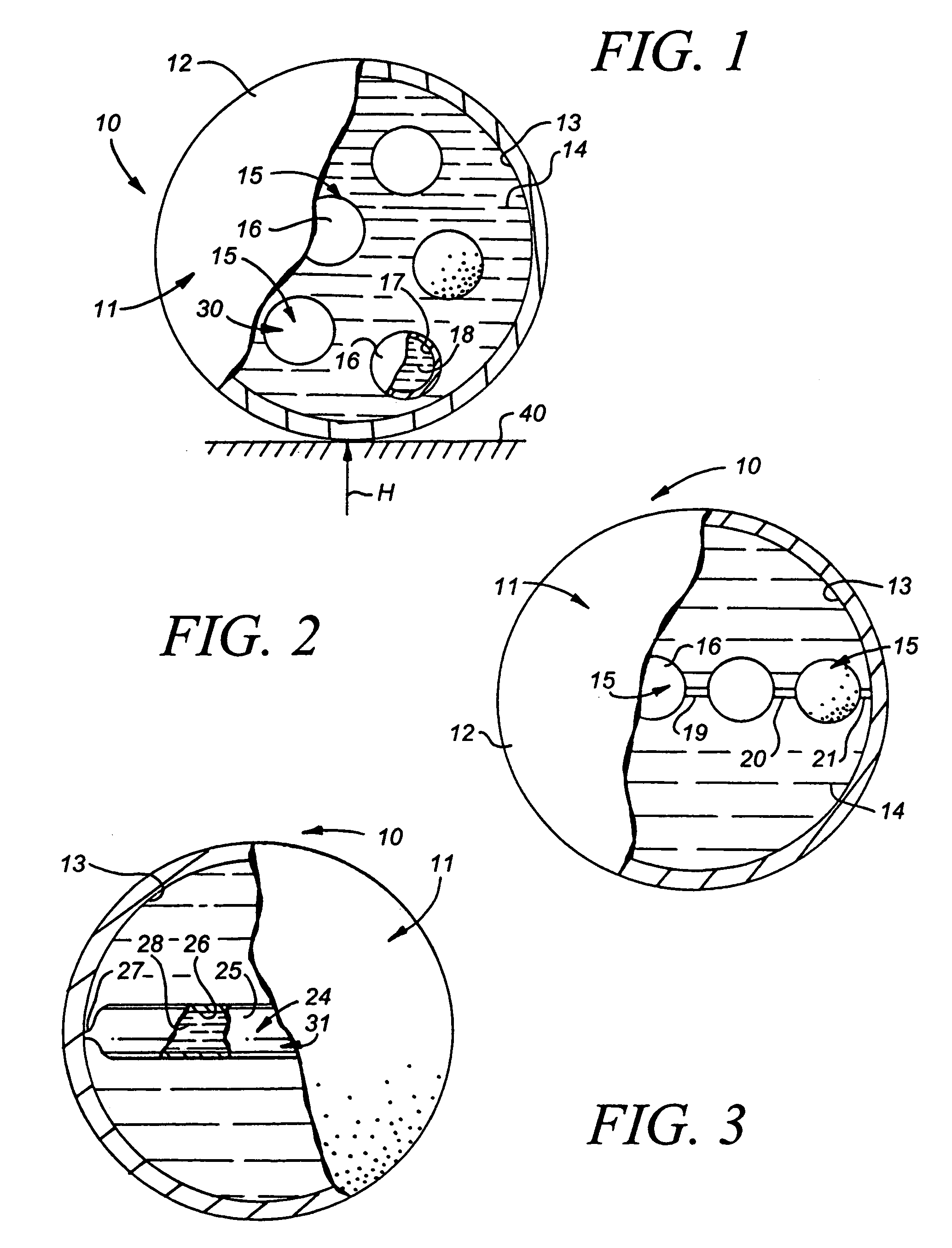

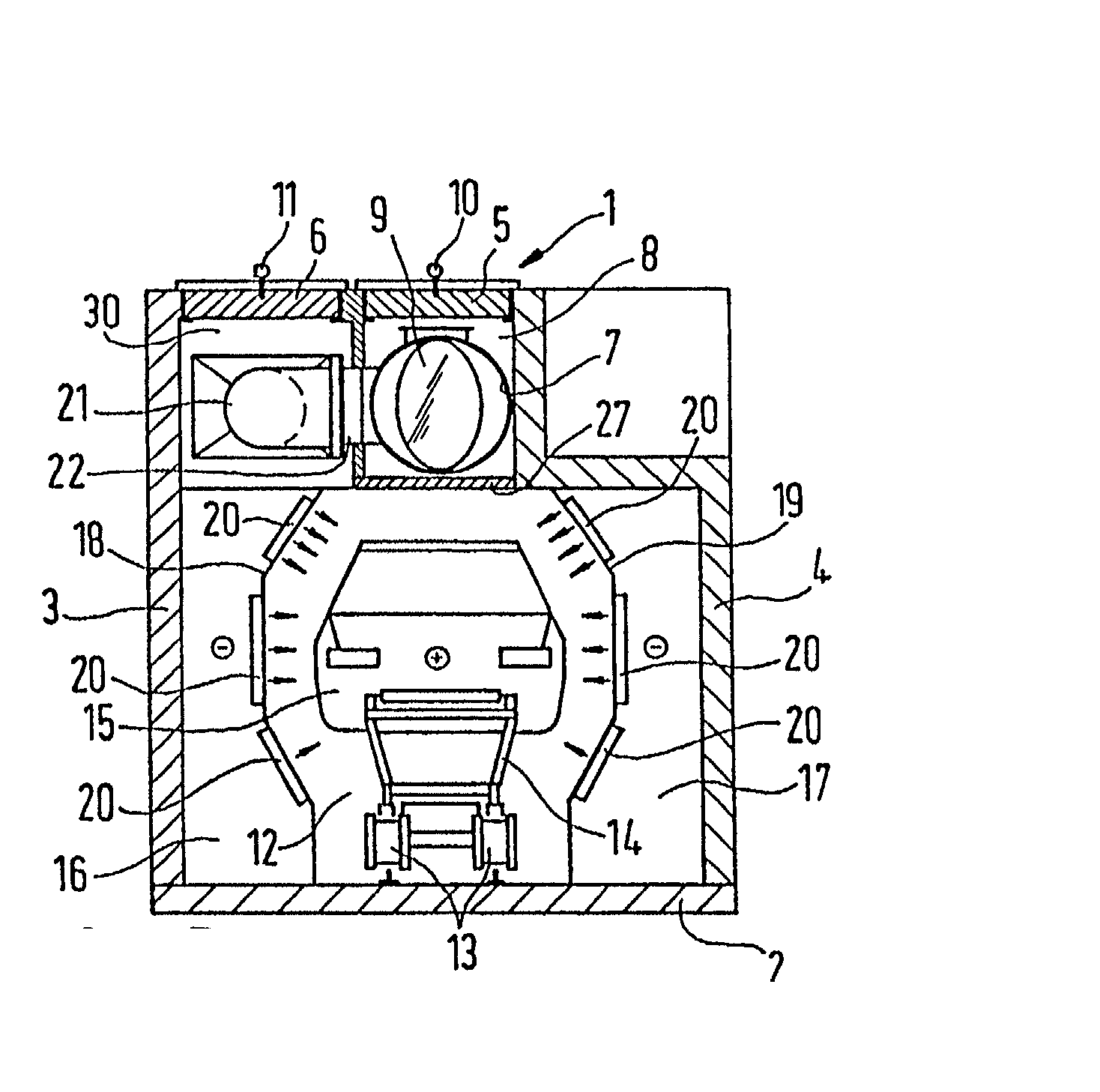

Device for hygienizing, warming, and dehumidifying a beehive

InactiveUS20080064298A1Increase productionReduce the amount of solutionBeehivesPower flowEngineering

A device 30 and associated process are described for hygienizing and warming beehives aiming at the improvement of the production of organic bee produce, said device comprising providing a bee box 1 containing frames 5 for honey production and bee housing, one frame 5a being left for inserting a ceramic block 11 provided with at least one row containing from 8 to 32 channels 11a and where the lower and upper ends of these channels 11a are opened towards the interior of the beehive, channels 11a being thermally insulated from the remaining of frame 5a with the aid of wings 15a, 15b and traversed by conducting filaments 14a, 14b connected to an energy source 20 through wire 7, whereby whenever electrical current traverses said filaments 14a, 14b the temperature inside said channels attains from 300-350° C. with the consequent heating of circulating air in the beehive by convection, the warmed air from the upper ends of said channels creating a negative pressure in the lower ends of same, whereby the outer colder air is sucked towards the interior of said channels, alternatively by using a fan or air pump, with the consequent extermination of the microorganisms present in the air as they cross warmed channels 11a.

Owner:JUNQUEIRA DE SOUZA MARCIO +2

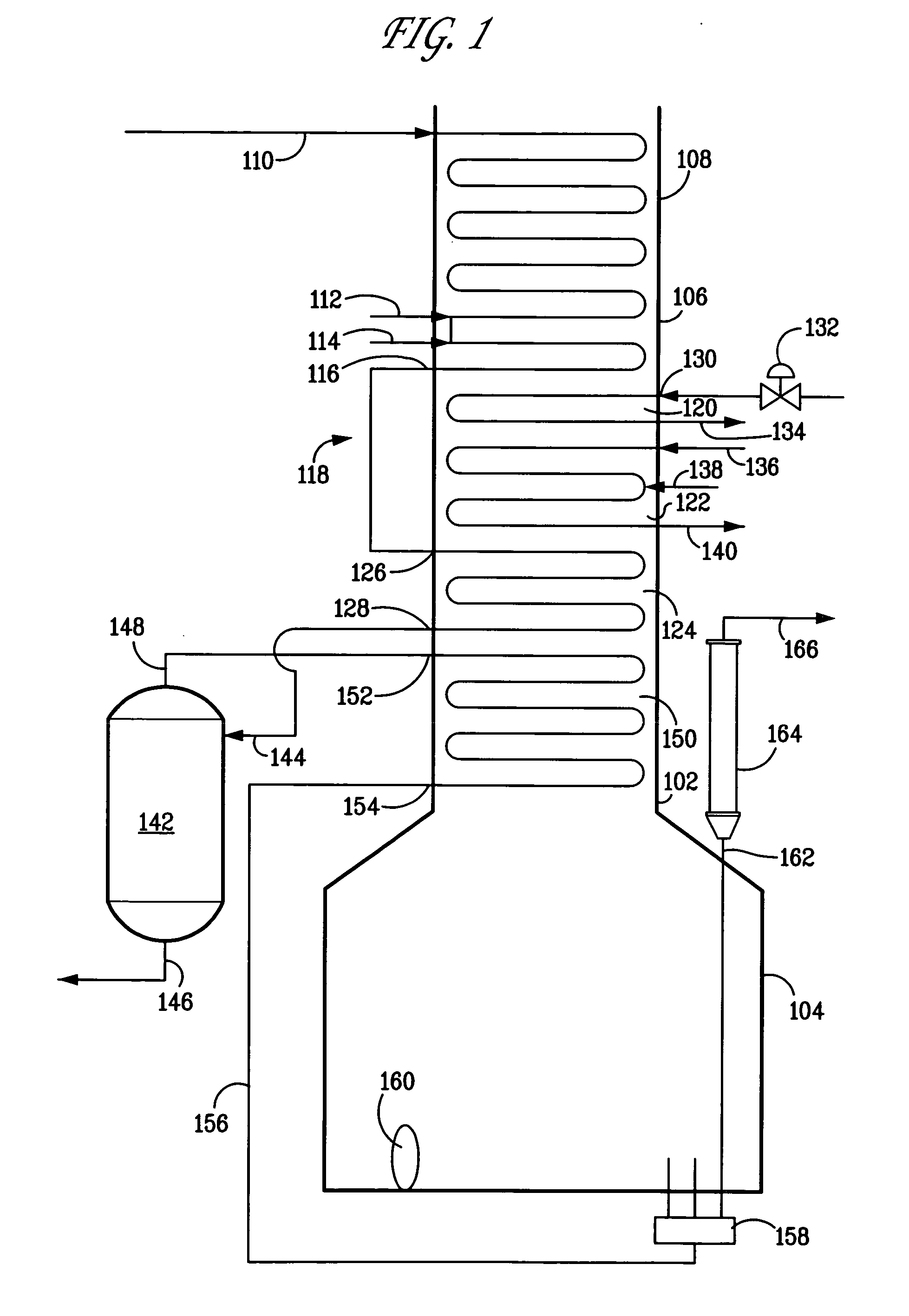

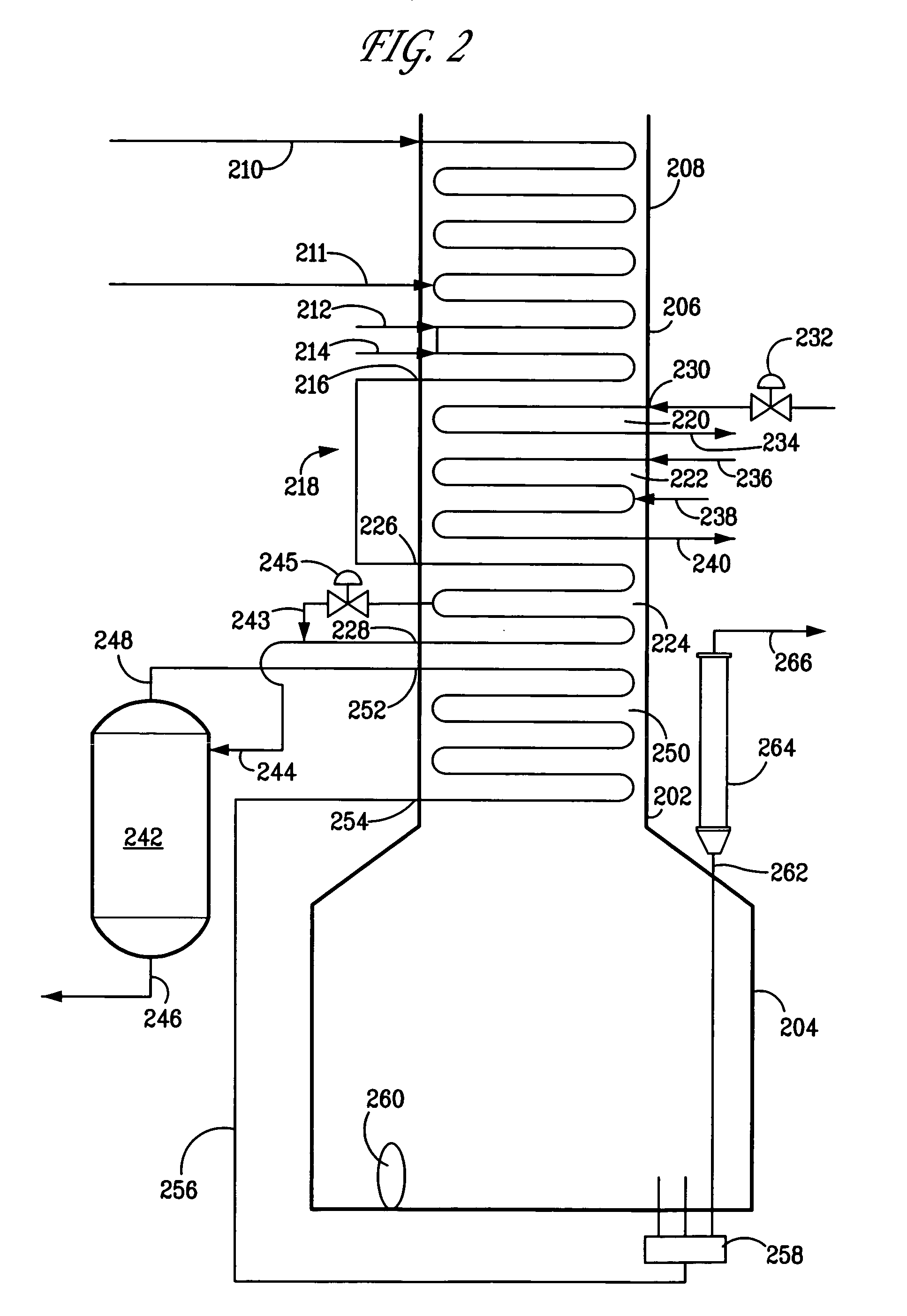

Apparatus and process for controlling temperature of heated feed directed to a flash drum whose overhead provides feed for cracking

InactiveUS20050261536A1Great heat contentThermal non-catalytic crackingHydrocarbon oil cracking processVapor liquidTemperature control

An apparatus and process are provided for cracking hydrocarbonaceous feed, wherein the temperature of heated effluent directed to a vapor / liquid separator, e.g., flash drum, whose overhead is subsequently cracked, can be controlled within a range sufficient so the heated effluent is partially liquid, say, from about 260 to about 540° C. (500 to 1000° F.). This permits processing of a variety of feeds containing resid with greatly differing volatilities, e.g., atmospheric resid and crude at higher temperature and dirty liquid condensates, at lower temperatures. The temperature can be lowered as needed by: i) providing one or more additional downstream feed inlets to a convection section, ii) increasing the ratio of water / steam mixture added to the hydrocarbonaceous feed, iii) using a high pressure boiler feed water economizer to remove heat, iv) heating high pressure steam to remove heat, v) bypassing an intermediate portion of the convection section used, e.g., preheat rows of tube banks, and / or vi) reducing excess oxygen content of the flue gas providing convection heat.

Owner:EXXONMOBIL CHEM PAT INC

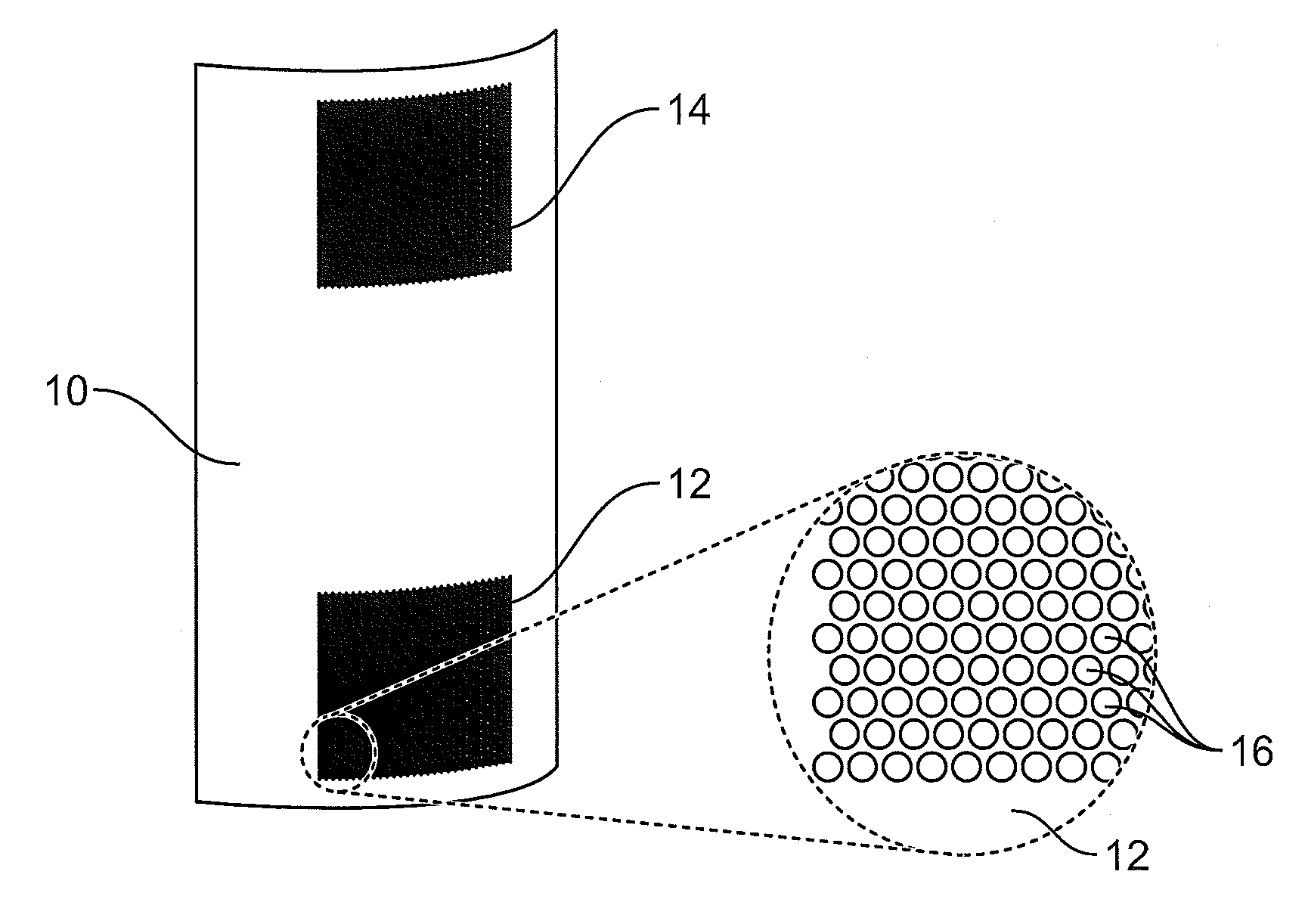

Burning process and burning boiler for processing high-density saliferous organic wastewater

ActiveCN103047659AGuaranteed combustion temperatureReduce flue gas velocityCombustion technology mitigationIncinerator apparatusChemical industryGas burner

The invention discloses a burning process and a burning boiler for processing high-density saliferous organic wastewater. The burning boiler comprises a down heat insulation boiler cavity, a multilevel radiation cooling chamber, a convection heat exchange chamber, an ash blowing device, a steam outlet pipe and a steam pocket. The down heat insulation boiler cavity comprises a waste liquid atomizing spraying gun, a two-layer auxiliary gas burner, a secondary air nozzle, an air flow shielding device, a water cooling wall, a fireproof material, a compensation fuel gas burner, a liquid slag removing device and a root portion air nozzle. A radiation heat exchange chamber I comprises a water cooling wall, a fireproof material and a flow guide device. The convection heat exchange chamber comprises a water cooling wall and a convection screen. The burning process effectively controls and optimizes the problems of stable complete burning of heat value high-moisture waste liquid, heating surface slag bonding and ash accumulation, tail heating surface low temperature corrosion, NOX discharge and the like, has good processing effect on the high-density saliferous organic wastewater, achieves effective recycle of resources and is suitable for organic wastewater burning processing of chemical industries.

Owner:BEIJING NATION POWER GRORP +1

Thermal insulation compositions containing organic solvent and gelling agent and methods of using the same

InactiveUS20070259791A1Reduce convection flow velocityLow viscosityInsulationFluid removalOrganic solventThermal insulation

A thermal insulating packer fluid contains an organic solvent of low thermal conductivity and a gelling agent which is hydratable in the solvent. The composition is capable of inhibiting unwanted heat loss from production tubing or uncontrolled heat transfer to outer annuli. The viscosity of the composition is sufficient to reduce the convection flow velocity within the annulus.

Owner:BAKER HUGHES INC

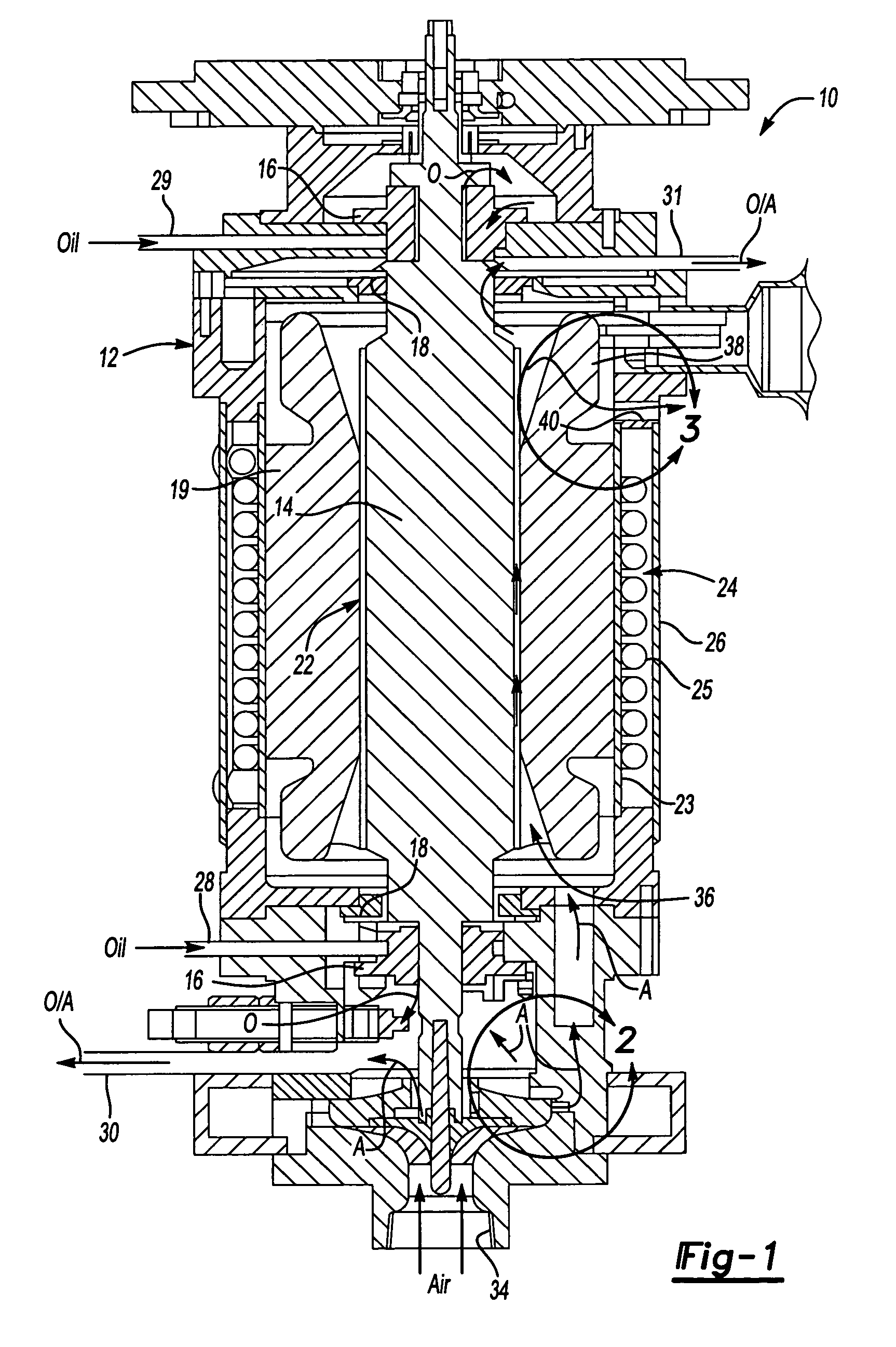

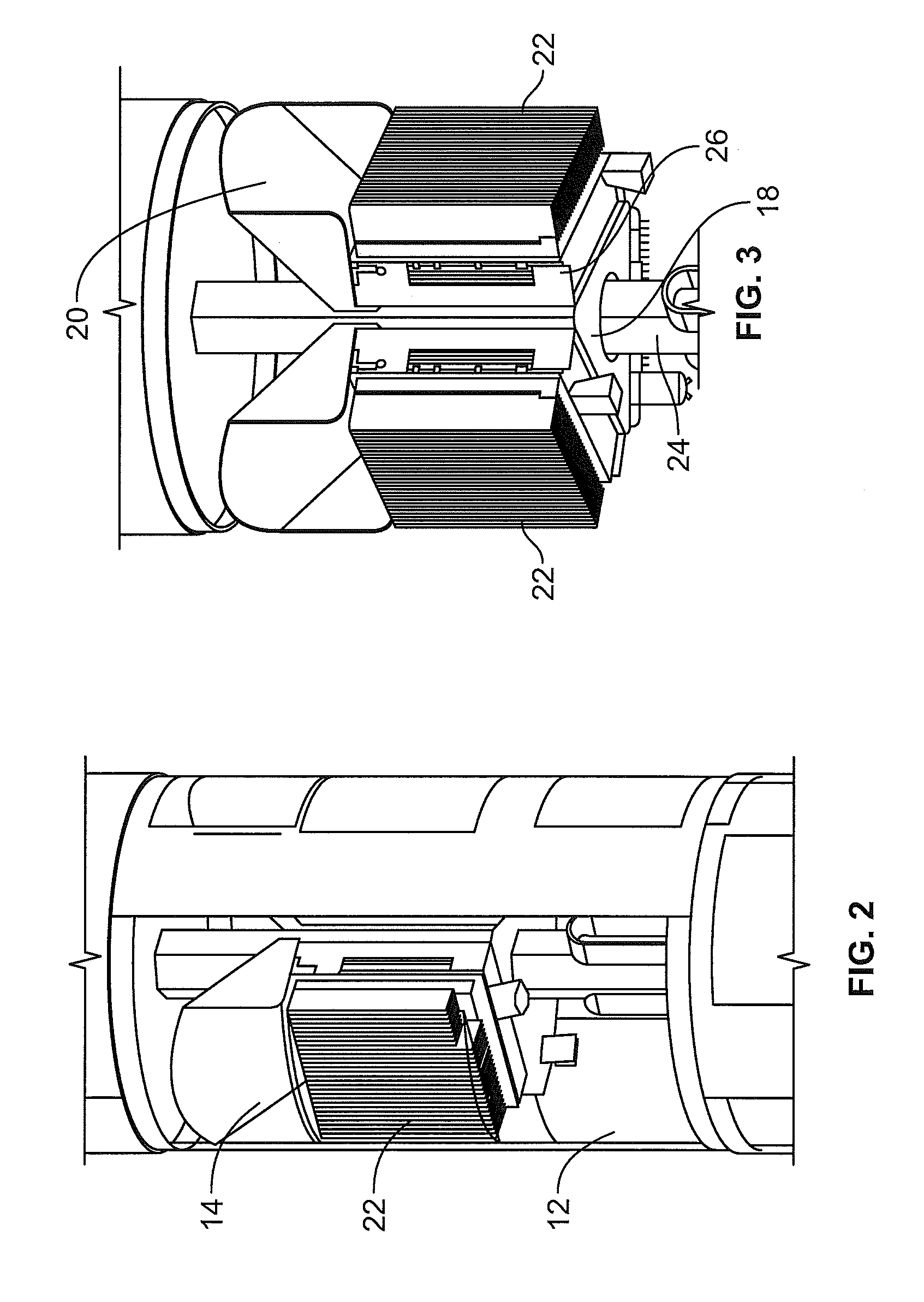

Rotary machine cooling system

ActiveUS7160086B2Reduce air volumeMinimized in sizePositive displacement pump componentsPiston pumpsImpellerFriction reduction

A rotary machine cooling system is provided that includes a housing having an inlet and outlet. A rotor supported in the housing for rotation about an axis with the rotor including an outer surface. A stator is disposed within the housing about the rotor having an inner surface adjacent to the outer surface of the rotor. A gap is formed between the inner and outer surfaces sufficient to reduce friction and permit convection cooling. The gap is in fluid communication with the inlet and outlet, and a pumping device pumps a cooling gas from the inlet into the gap and through said outlet. The pumping device includes an impeller affixed to an end portion of the rotor to create an axial airflow into the gap. Preferably, the present invention air cooling system is used in conjunction with a liquid cooling system arranged exteriorly to the stator. The liquid cooling system reduces the amount of air needed to flow between the gap to remove the desired amount of heat from the machine.

Owner:SUNDYNE LLC

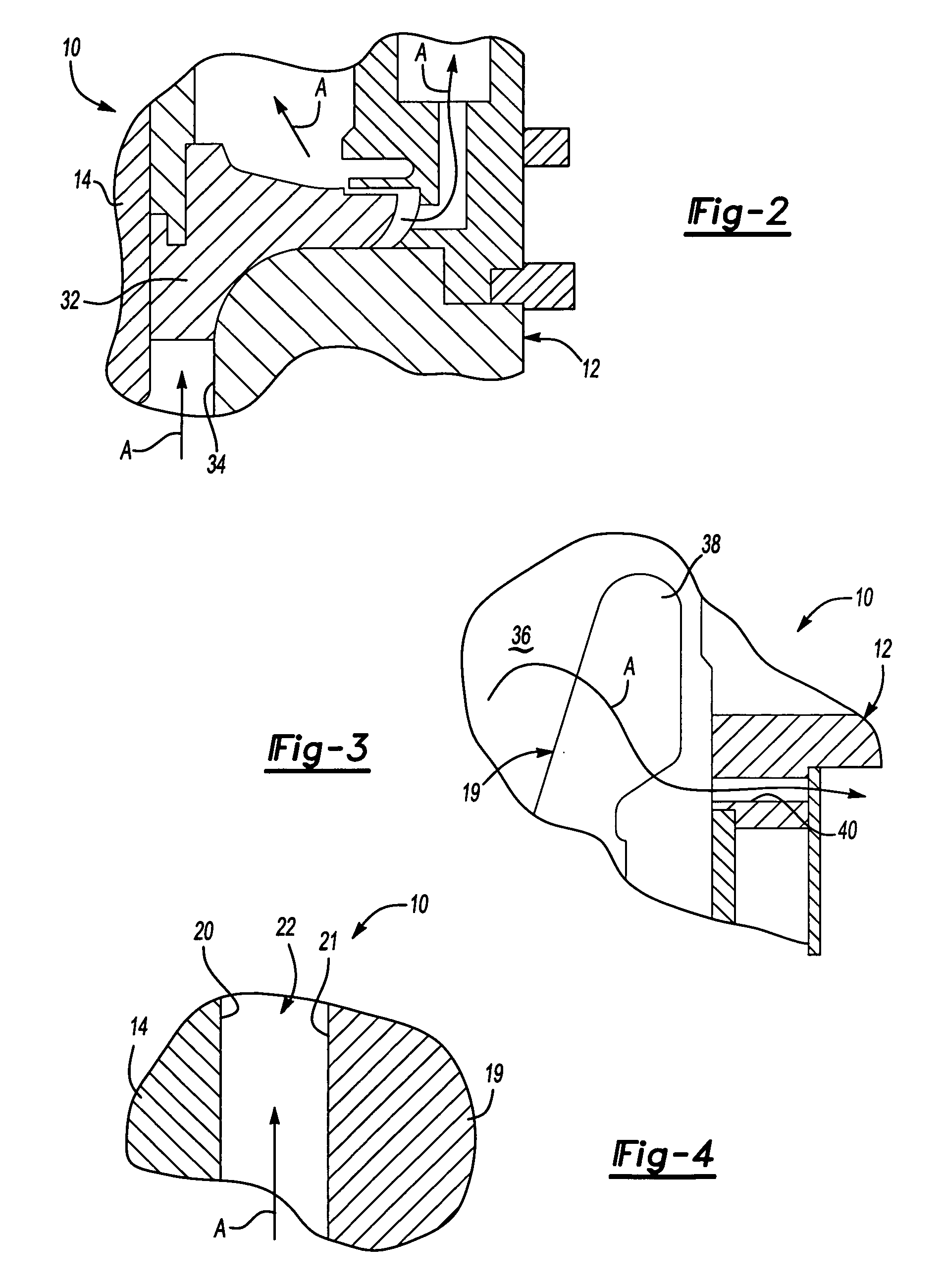

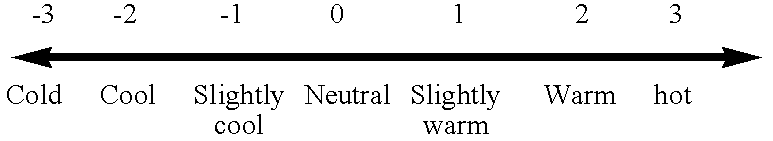

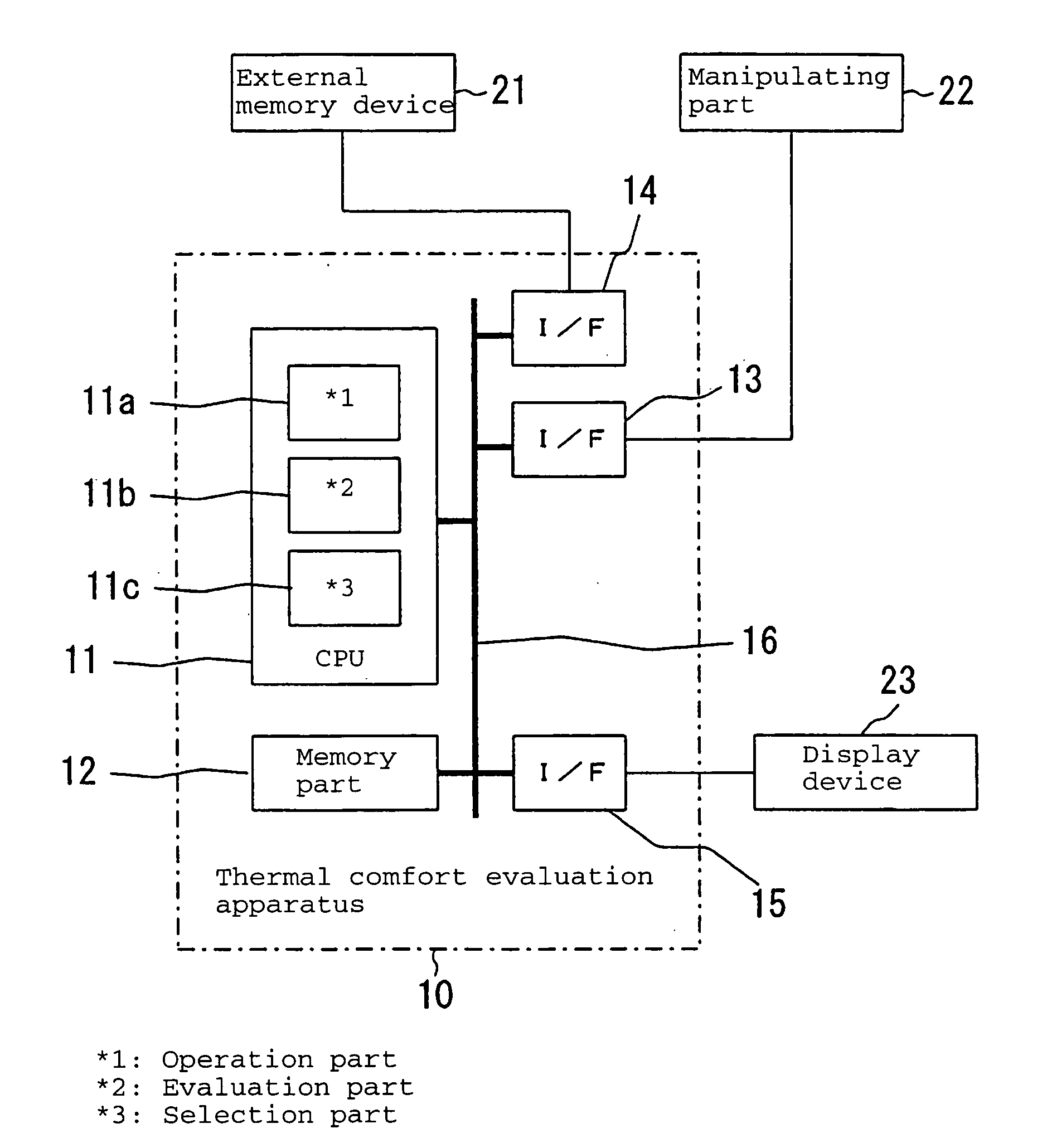

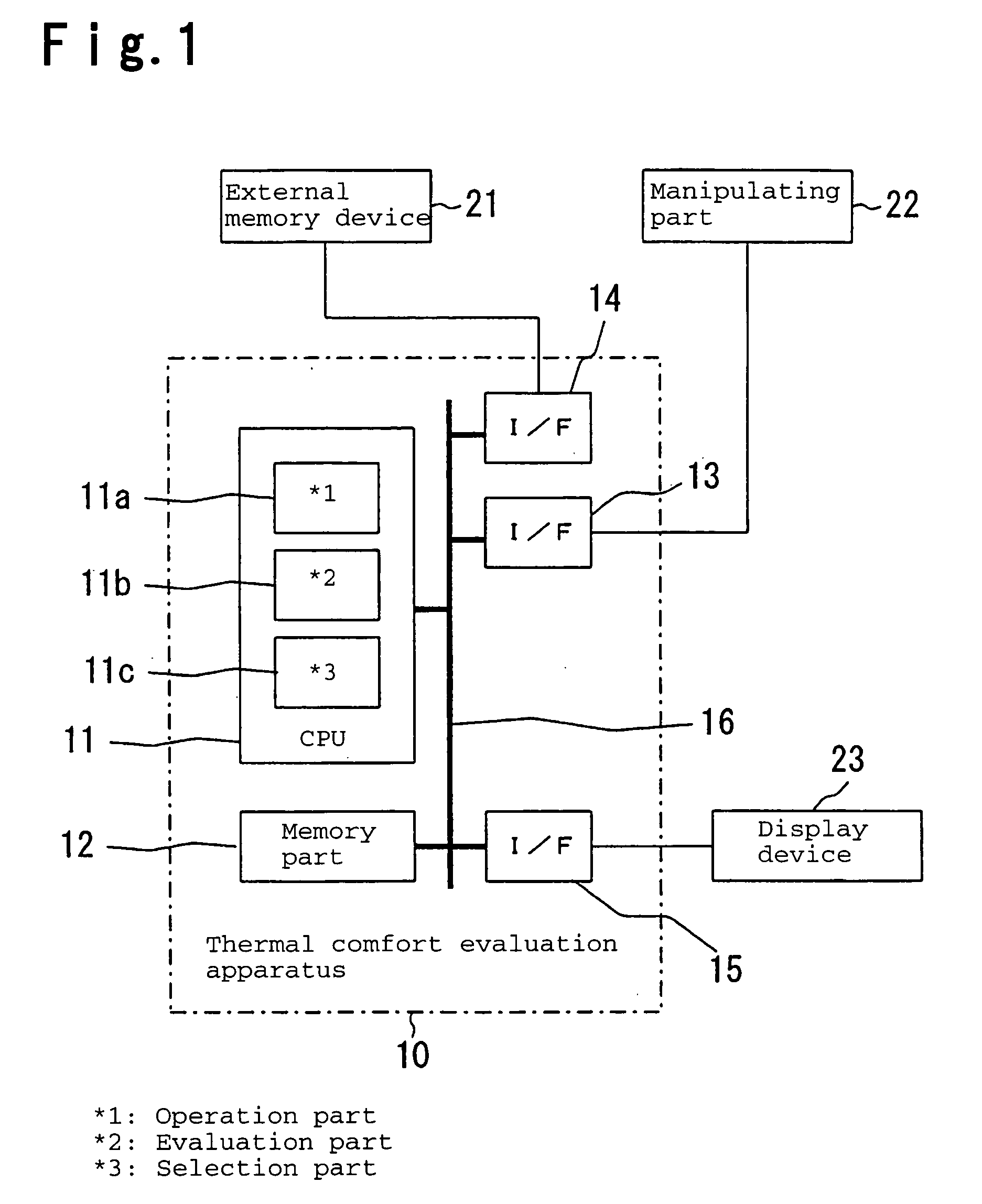

Method for evaluating thermal comfort of a structure and an assisting method, program or system for designing a structure in consideration of thermal comfort

InactiveUS20040133406A1Computation using non-denominational number representationAerodynamics improvementMeasurement deviceLaboratory device

A step of preparing data of (1) material properties of a first part and so on and data of (2) an amount of solar radiation passing through the translucent member to reach a measuring device having a shape imitating a human body part, an amount of solar radiation to the structure, an amount of convection heat transfer in the structure, an amount of radiation heat transfer in the structure, humidity in the structure and / or a thermo-regulating function of the measuring device, and calculating at least one of the amount of heat loss from the surface of the measuring device, the temperature of the measuring device and / or the wettedness at the surface of the measuring device based on at least one in each of data (1) and (2), and a step (b) of calculating a thermal comfort index of the measuring device by using a result of the above calculation, are presented, whereby the thermal comfort of a structure is evaluated without using a laboratory equipment.

Owner:ASAHI GLASS CO LTD

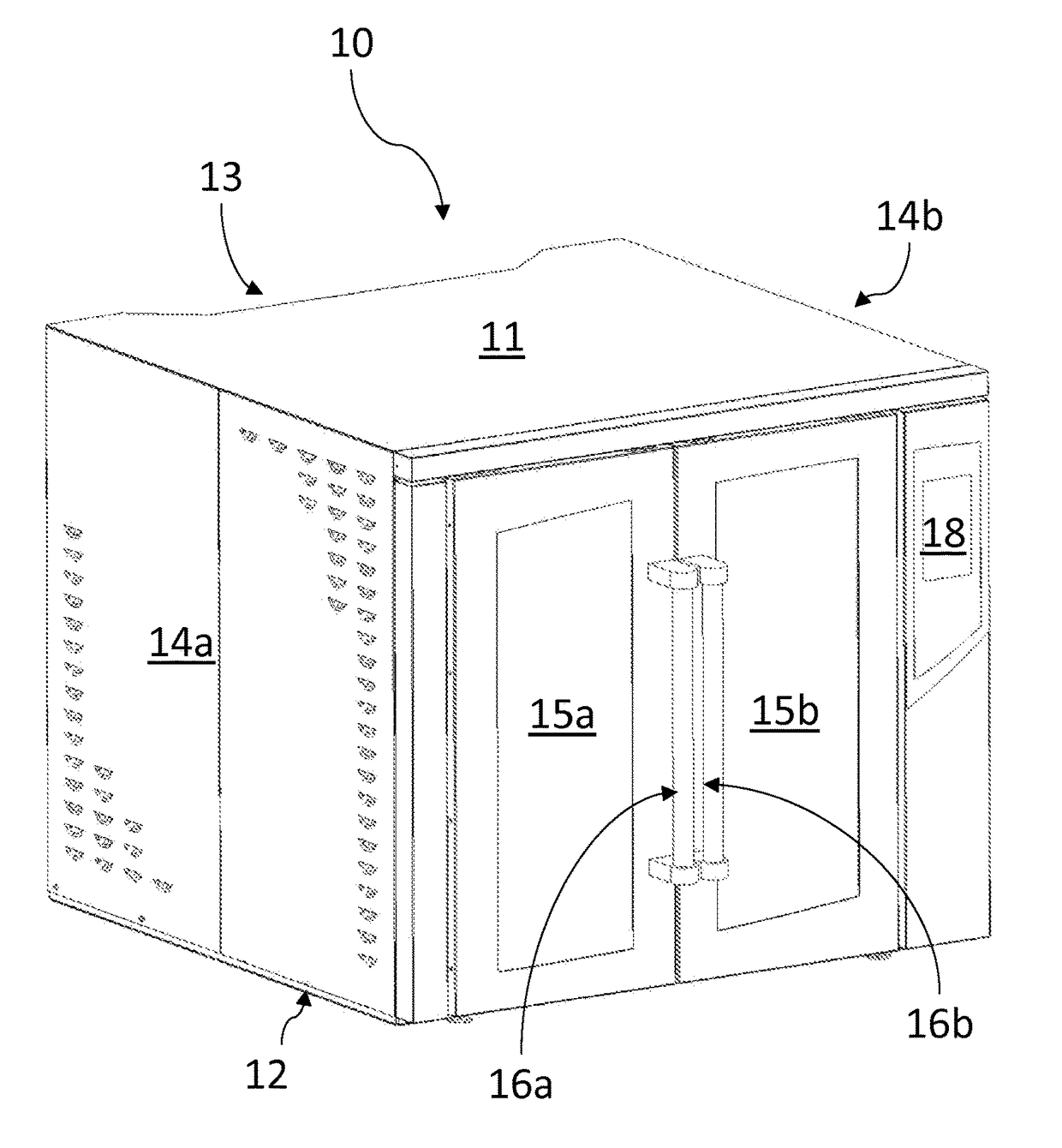

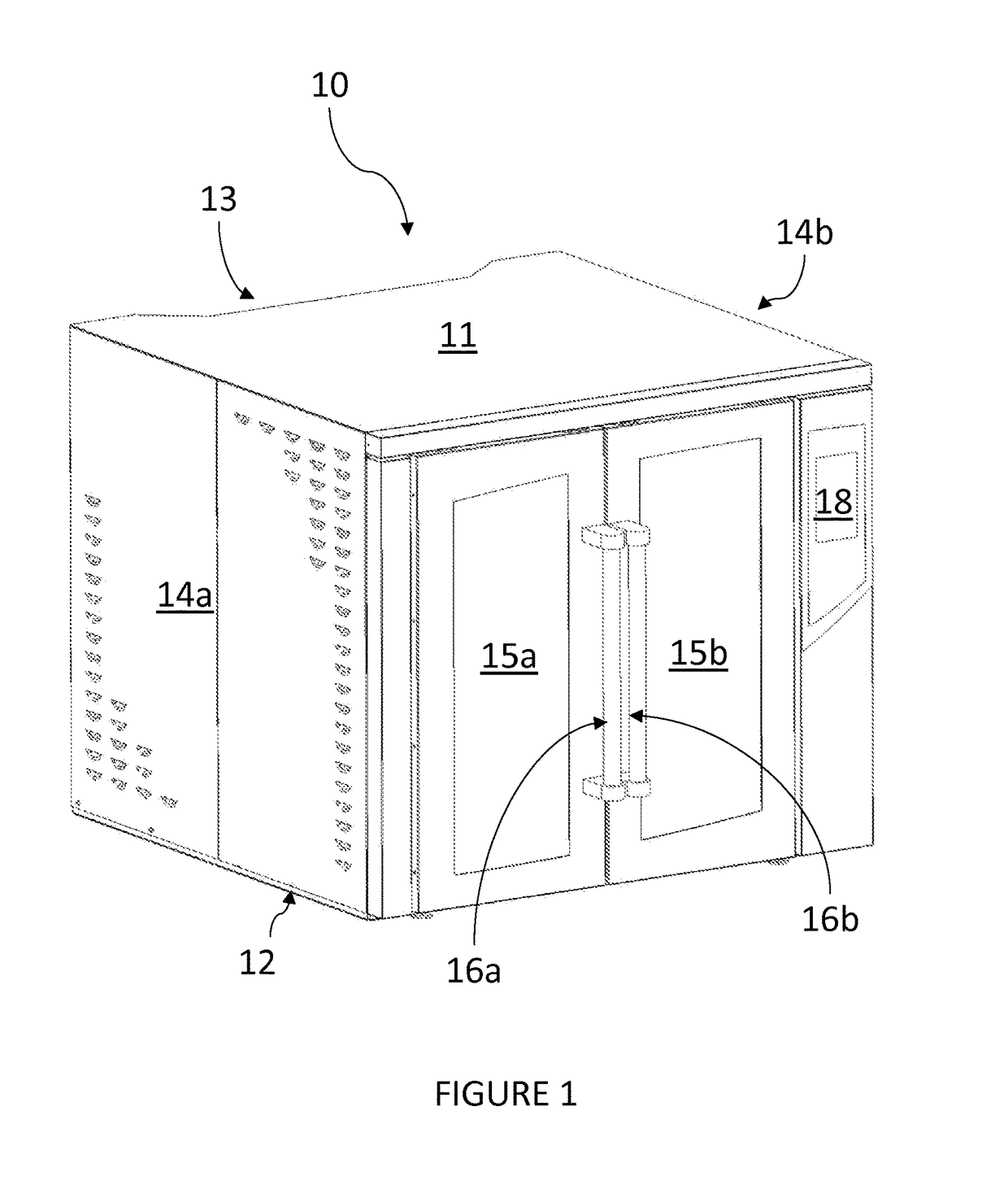

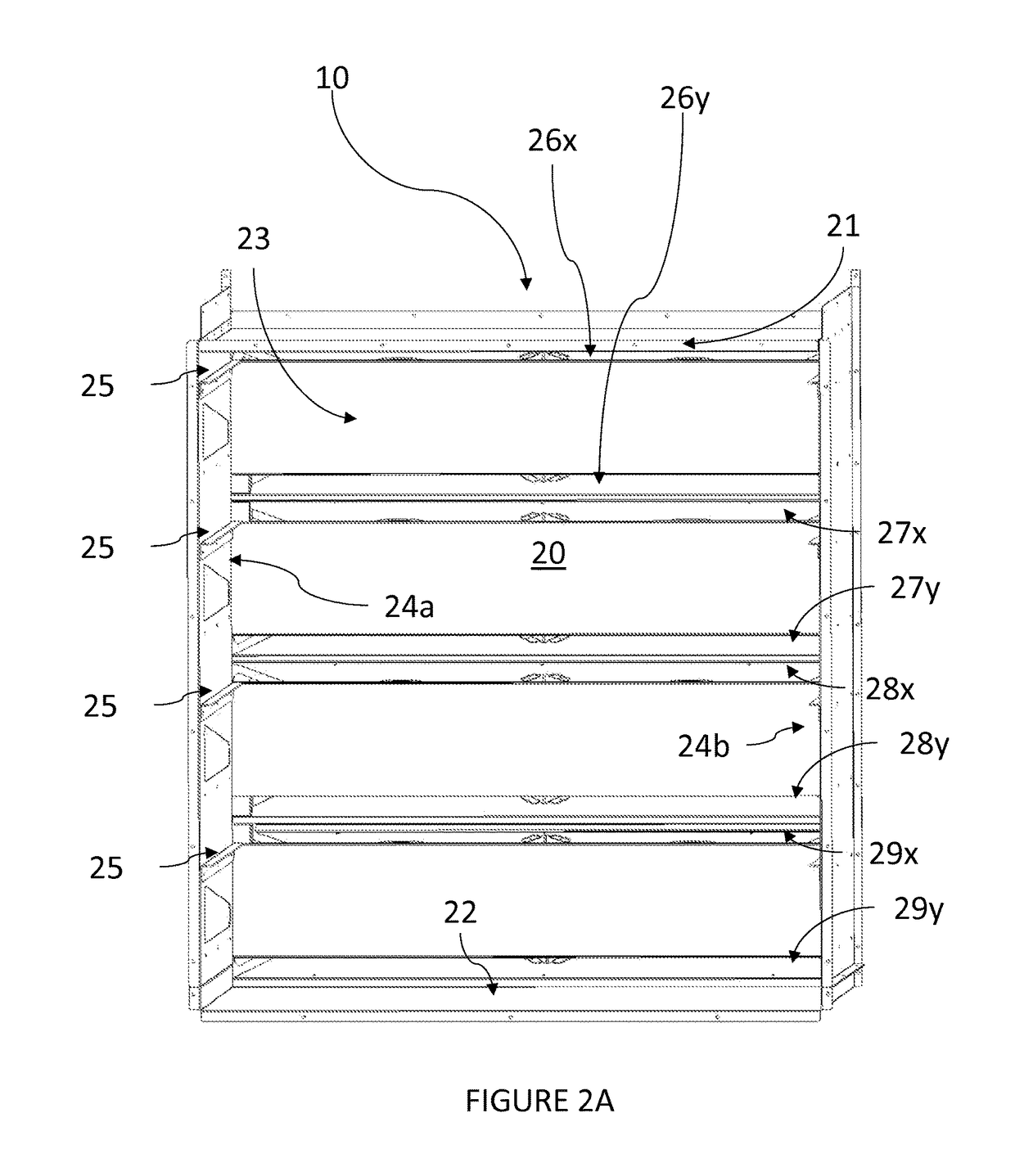

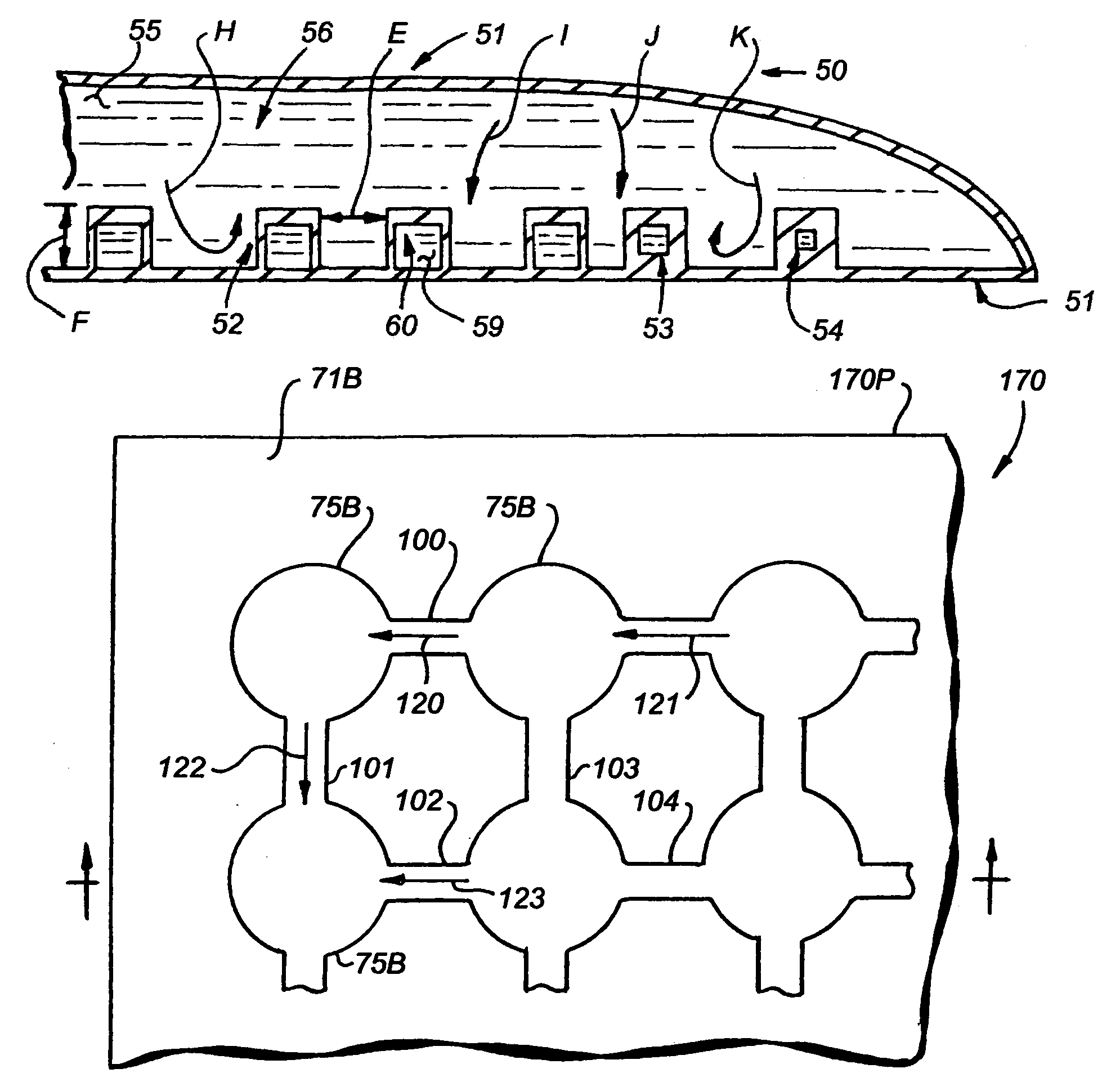

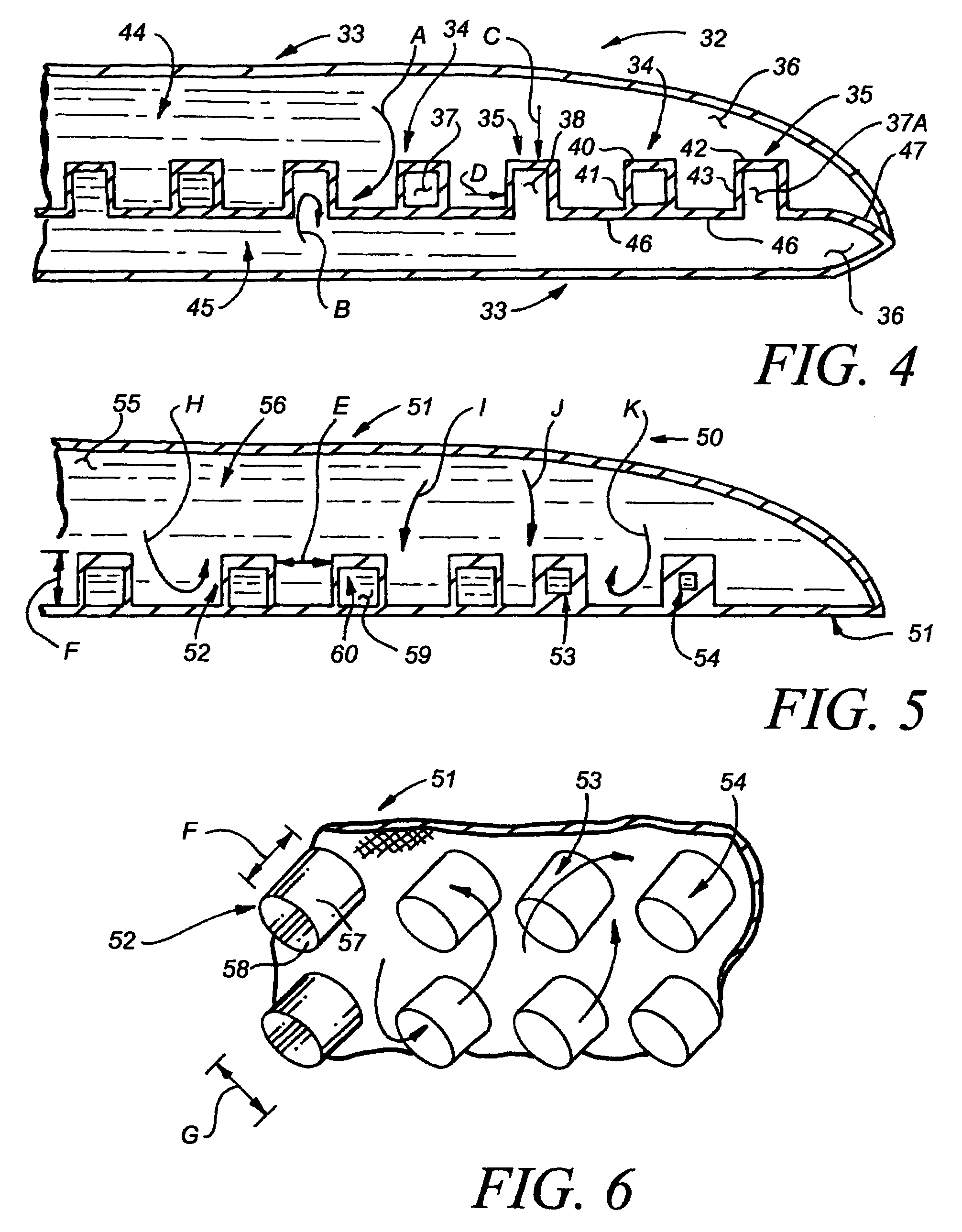

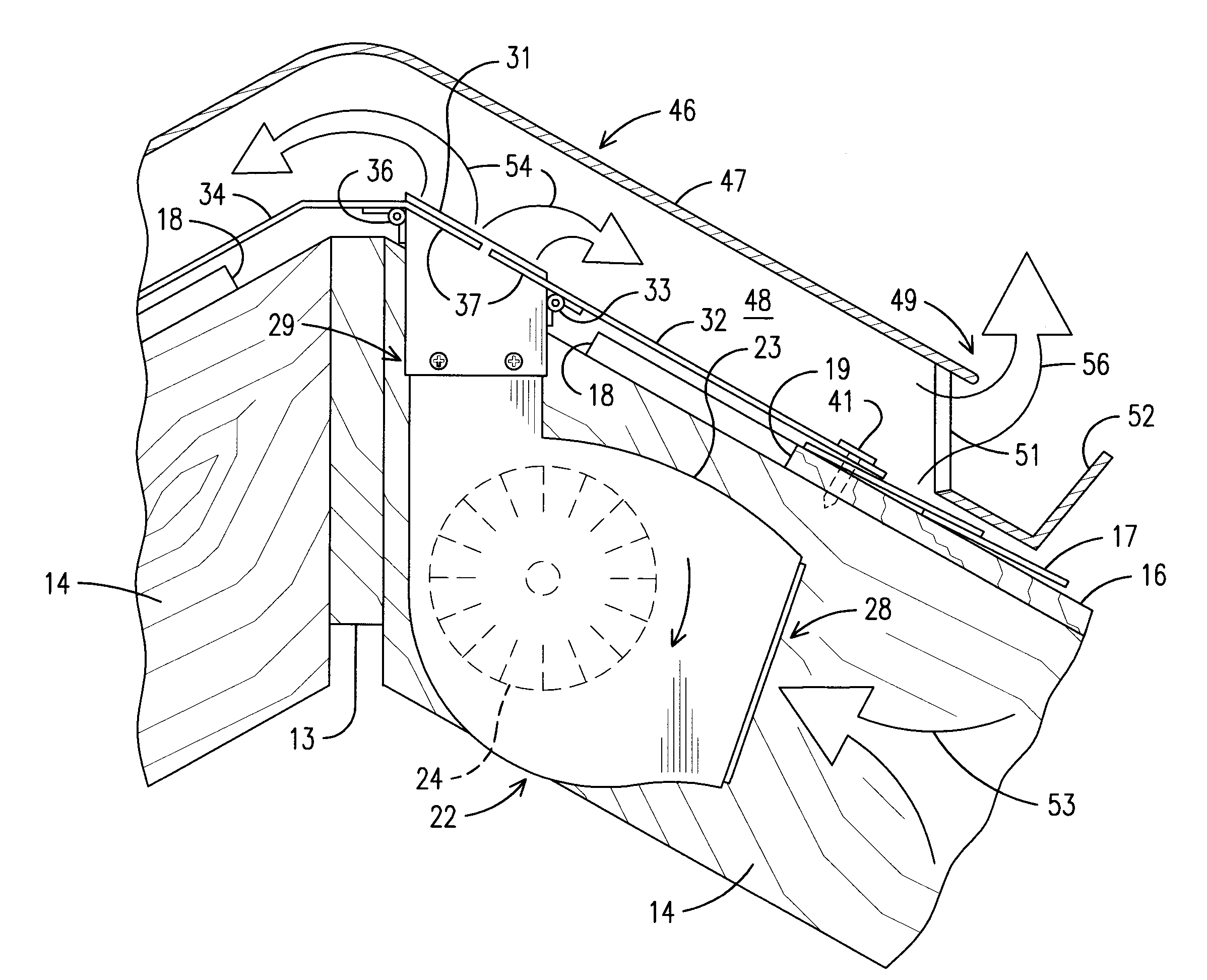

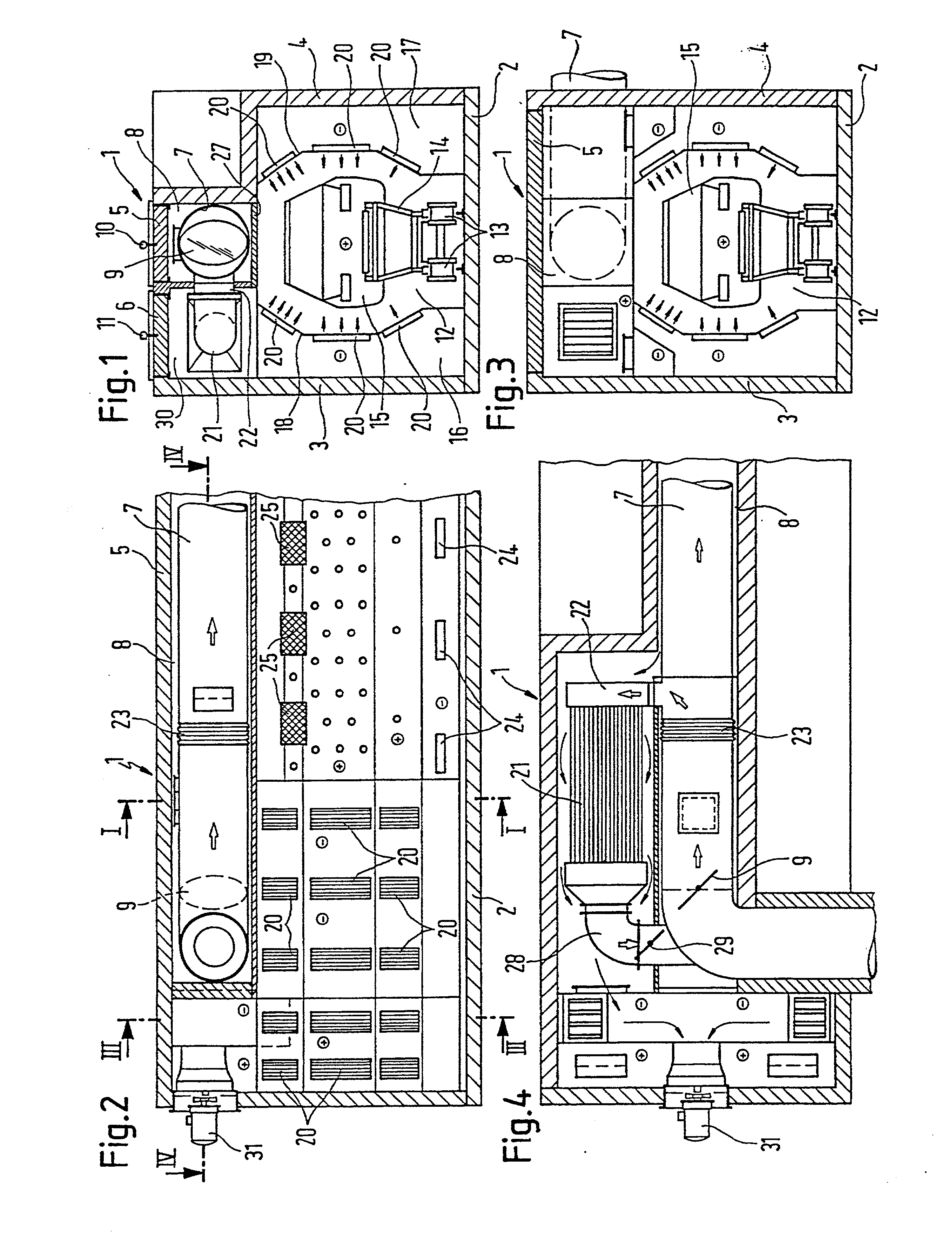

Multi-zone oven with variable cavity sizes

ActiveUS9677774B2Extended cooking timeDomestic stoves or rangesOven air-treatment devicesCavity sizeAir blower

A convection oven is disclosed. The convection oven comprises a housing having an oven cavity and an oven door for access to the oven cavity, at least one air blower for generating heated air, one or more air channels for directing the heated air from the air blower toward the oven cavity, and one or more removable air plenums, wherein each removable air plenum is connected to one of the one or more air channels, comprises an air intake edge for receiving the heated air from the air channel, defines the top or the bottom of a cooking chamber within the oven cavity, and comprises a plurality of air vents for directing the heated air into the cooking chamber. The convection oven may further comprise a control panel for separately and independently controlling each of the cooking chambers defined by the removable air plenums.

Owner:ALTO SHAAM

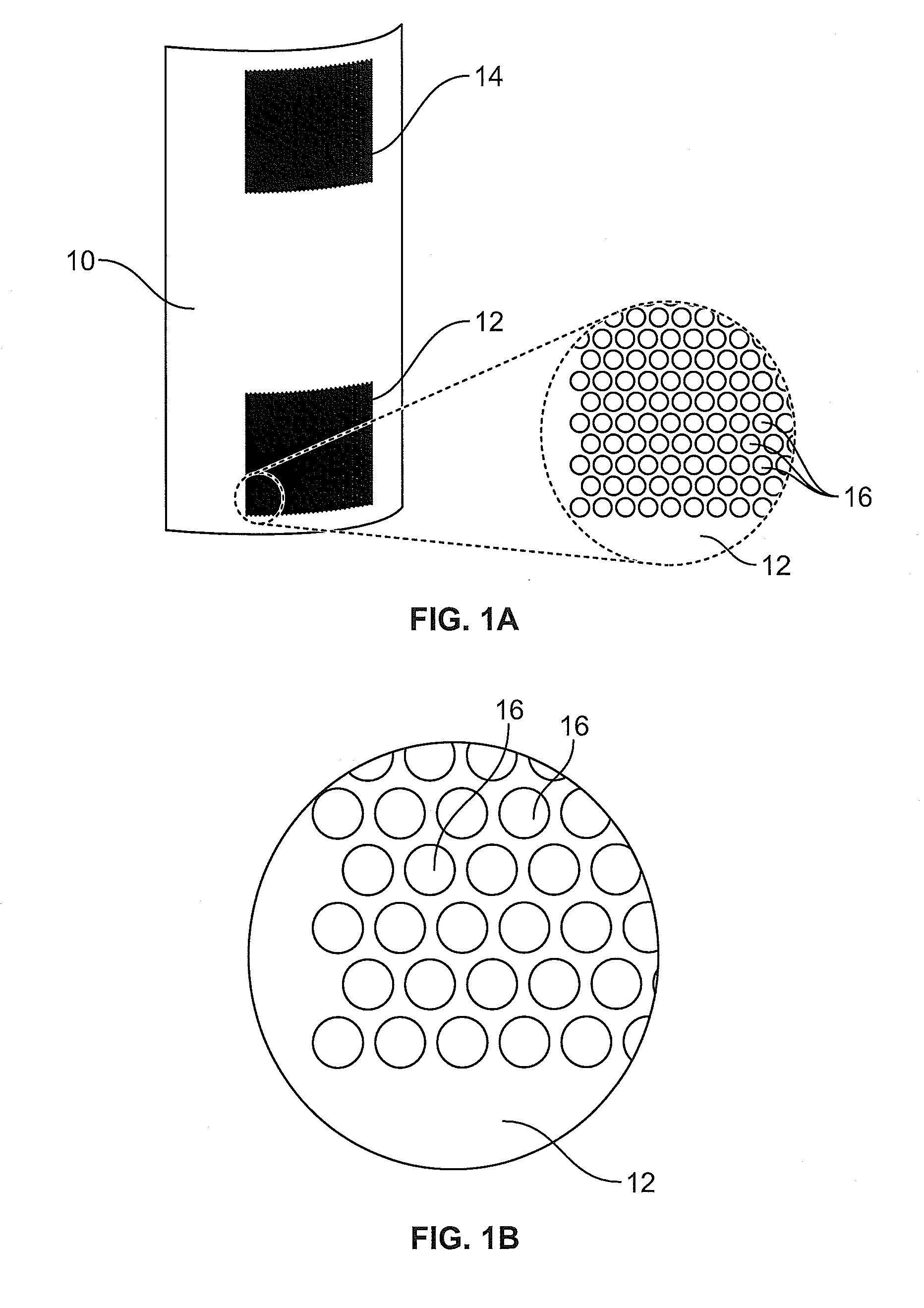

Air purification and decontamination system

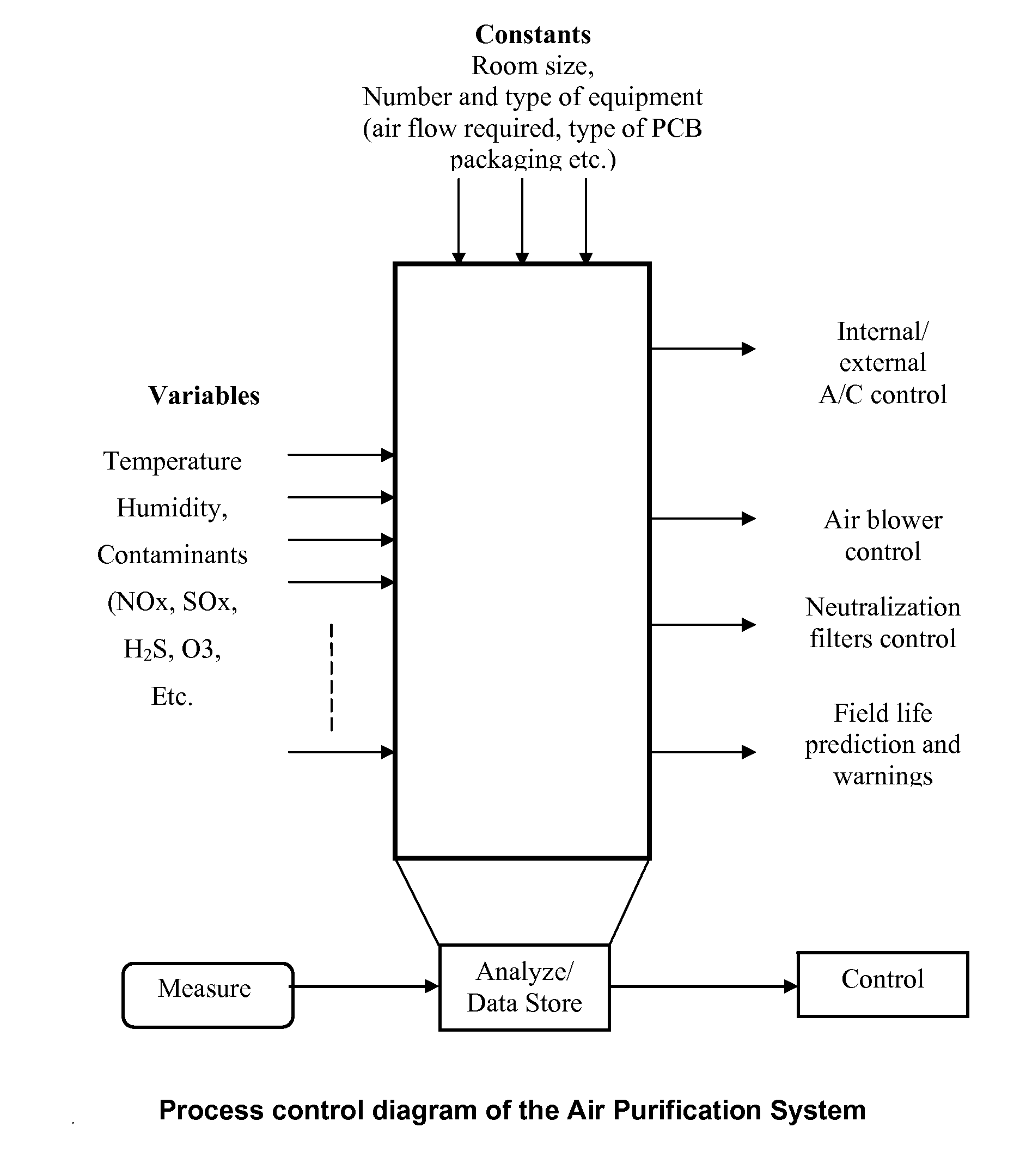

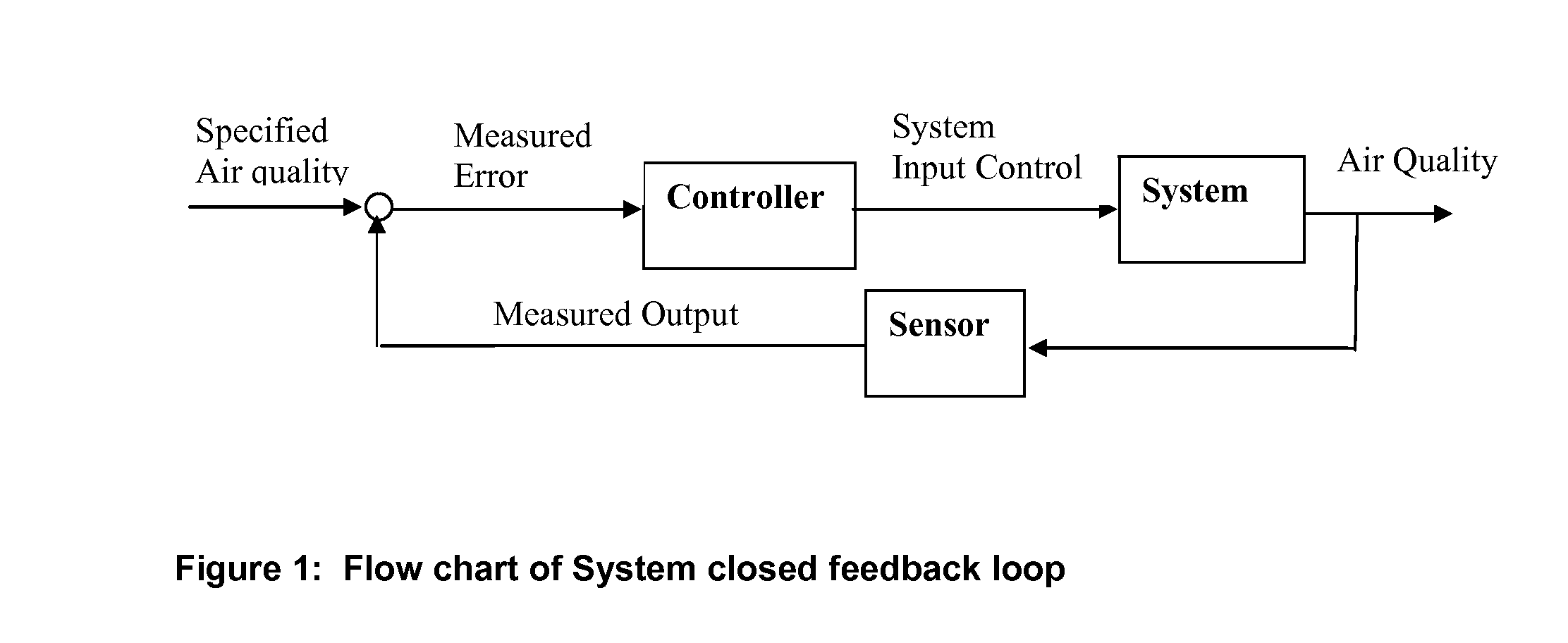

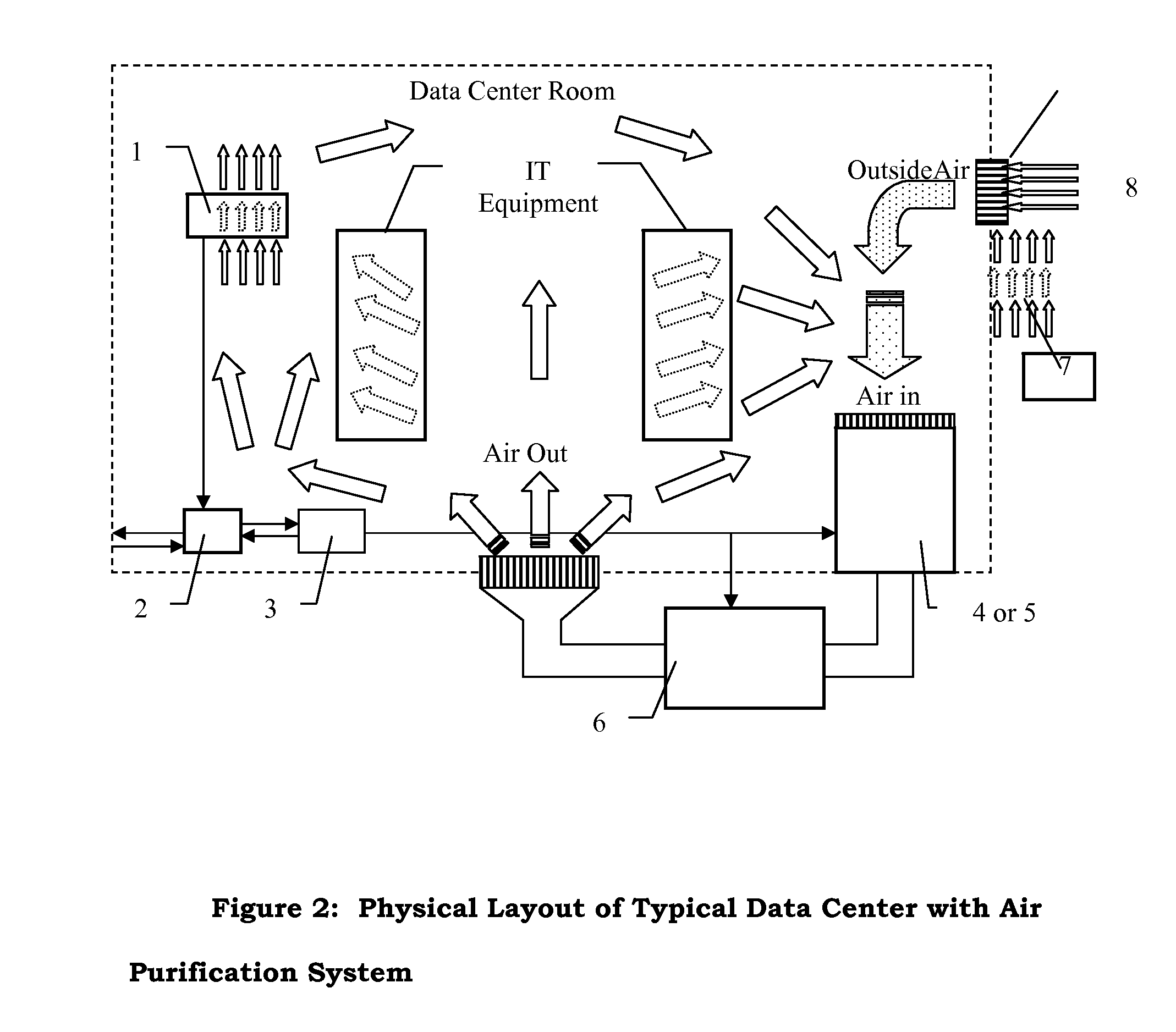

InactiveUS20120111190A1Minimize corrosivenessEffective regulationCombination devicesGas treatmentEnvironment of AlbaniaCorrosion

A closed loop air handling system for monitoring and cleaning air from corrosive contaminants. Commonly occurring corrosive elements found in air can react in combination together and with other environmental conditions to increase the propensity for corrosion to occur. The higher corrosive level of air can react with metals causing degradation, wear and often lead to premature failure. This is especially prevalent in environments using forced air convection for cooling, such as data centers. The electronic circuitry is especially vulnerable to such corrosion and requires an environmentally controlled atmosphere with mild corrosiveness for long term reliability. The invention involves circulating the air in a closed loop and monitors and adjusts parameters of active filtration and purification to minimize corrosive agents. The system maintains a milder corrosive environment and better accommodates the use of “free cooling” from outside air for improved energy efficiency and lower carbon emissions. Air quality data is also collected and used to estimate equipment life time expectancy and substantiate warranty claims over exceeding manufacturers recommended environmental operating conditions.

Owner:DARIAVACH NADER G

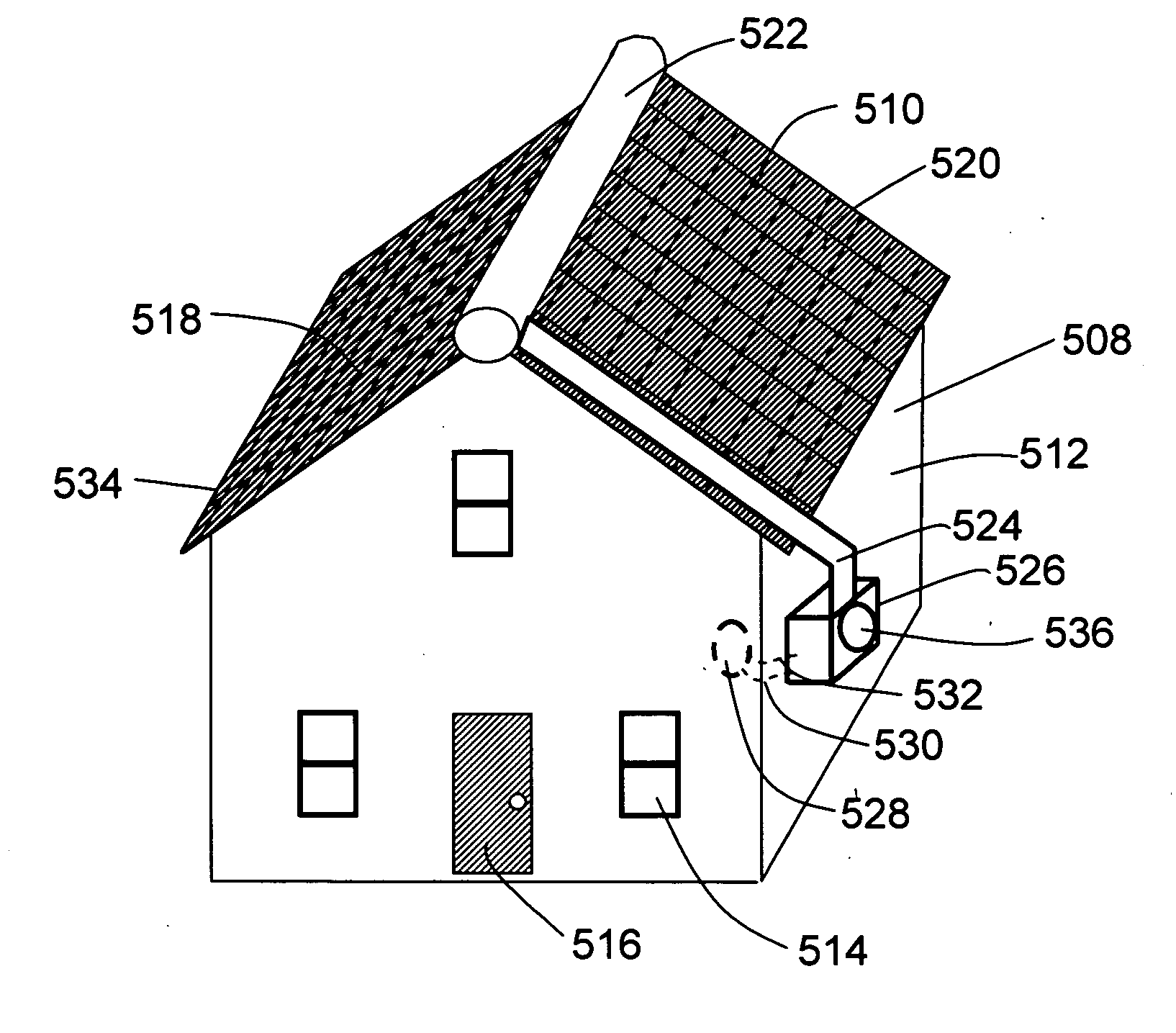

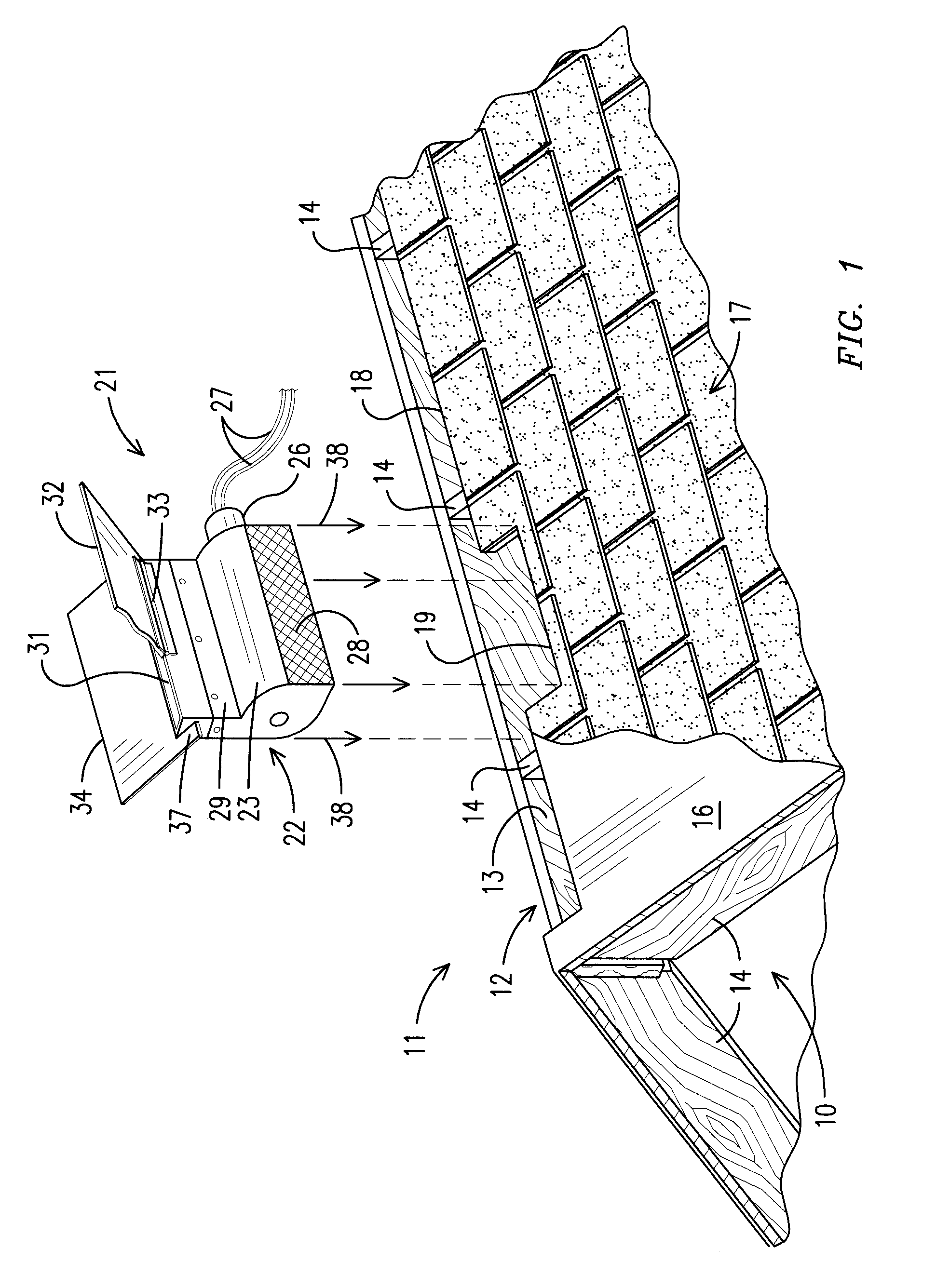

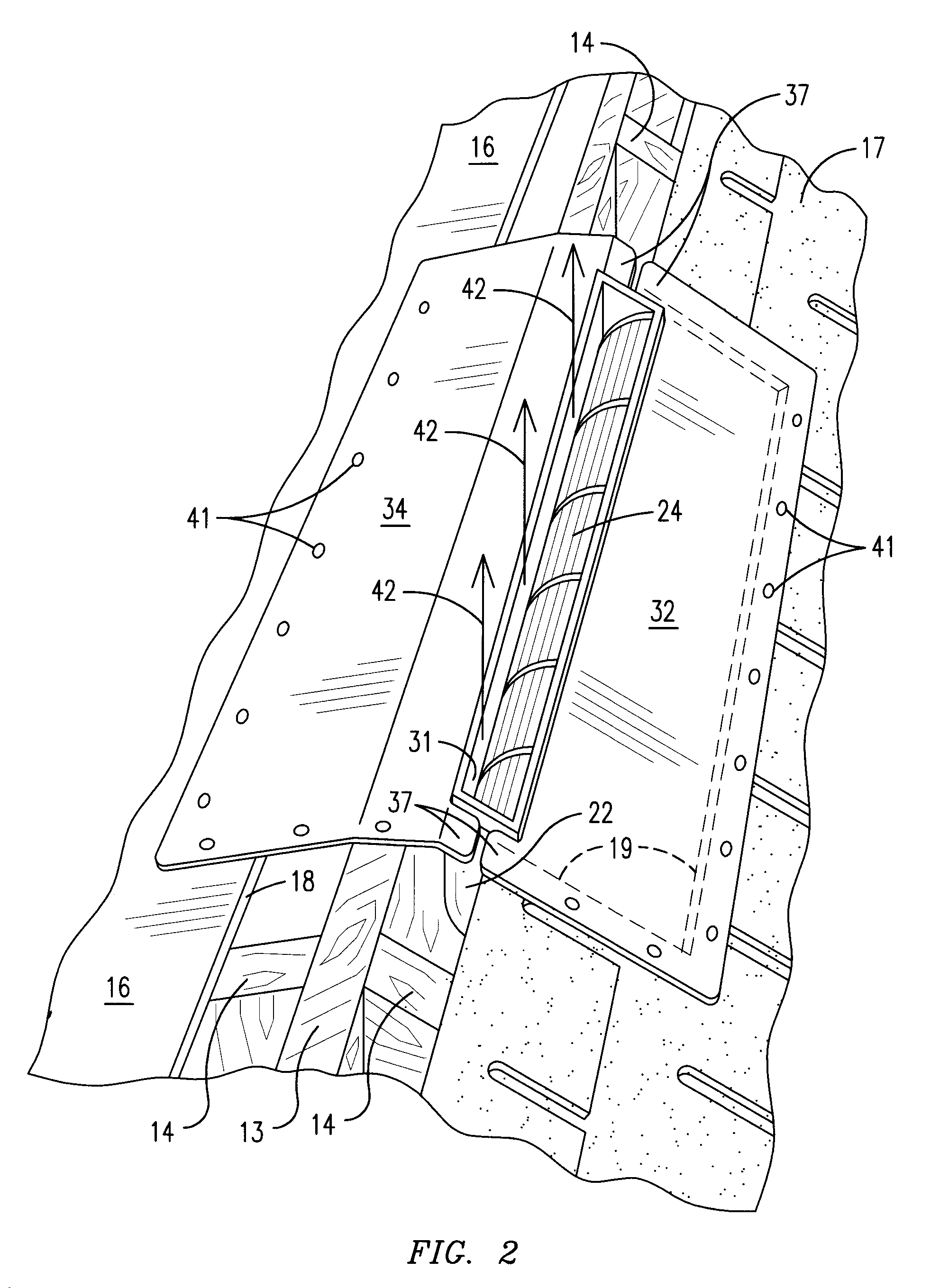

Ventilated roofing tiles

InactiveUS20070130850A1Improve insulation effectSolar heating energyBuilding roofsRoof tileForced air convection

Ventilated roofing tiles along with other multilayered energy saving and / or producing constructions are disclosed. Also disclosed are insulating bonding constructions having enhanced energy saving attributes. The ventilated roofing tiles employ heat transfer means that may include natural and / or forced air convection.

Owner:SIERRA MADRE MARKETING GROUP

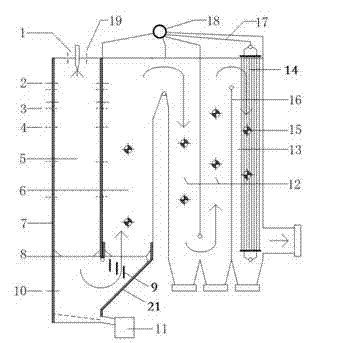

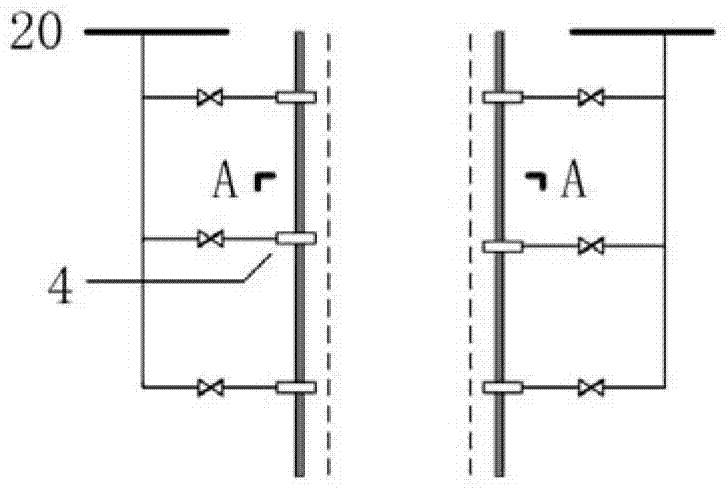

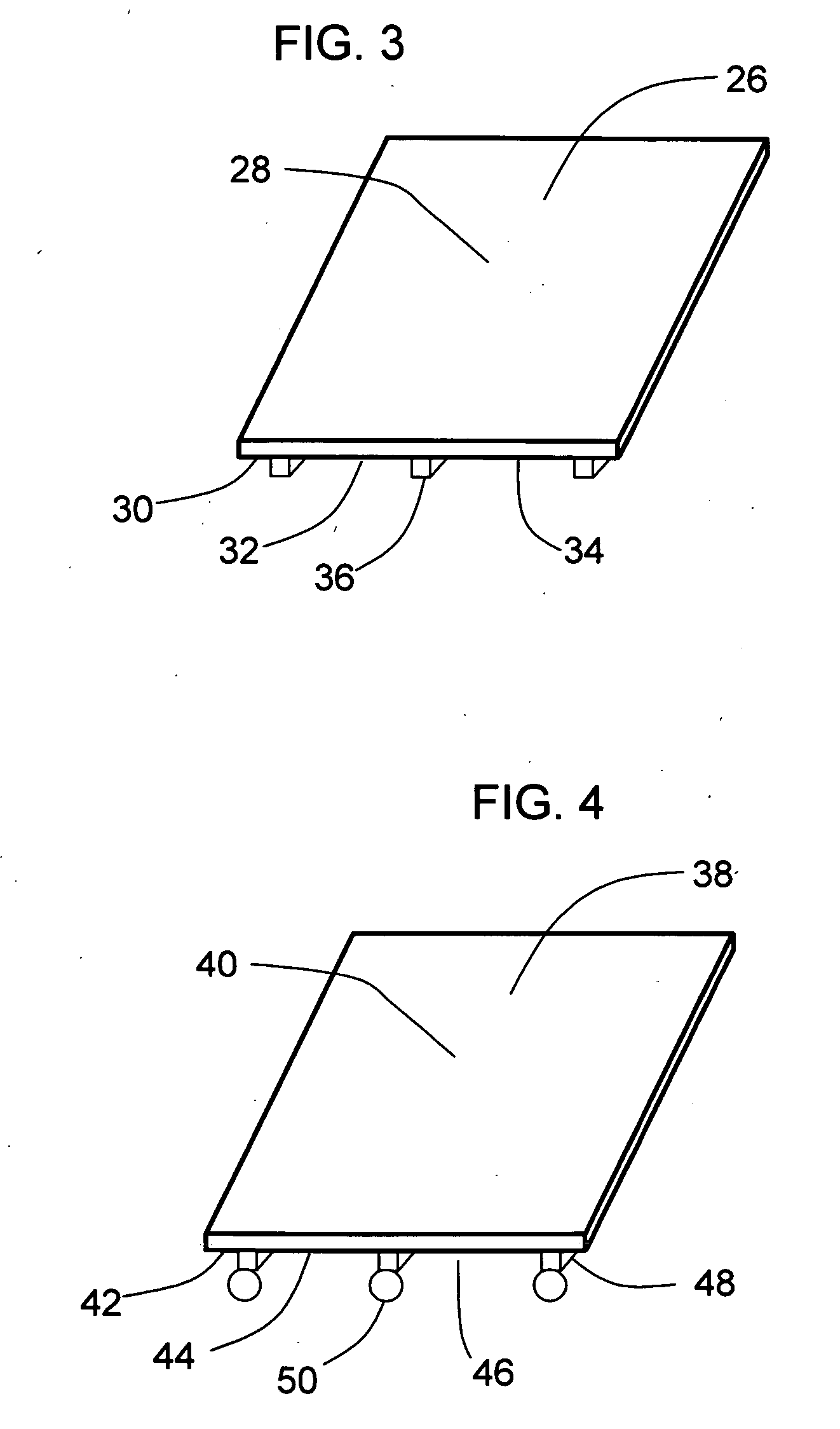

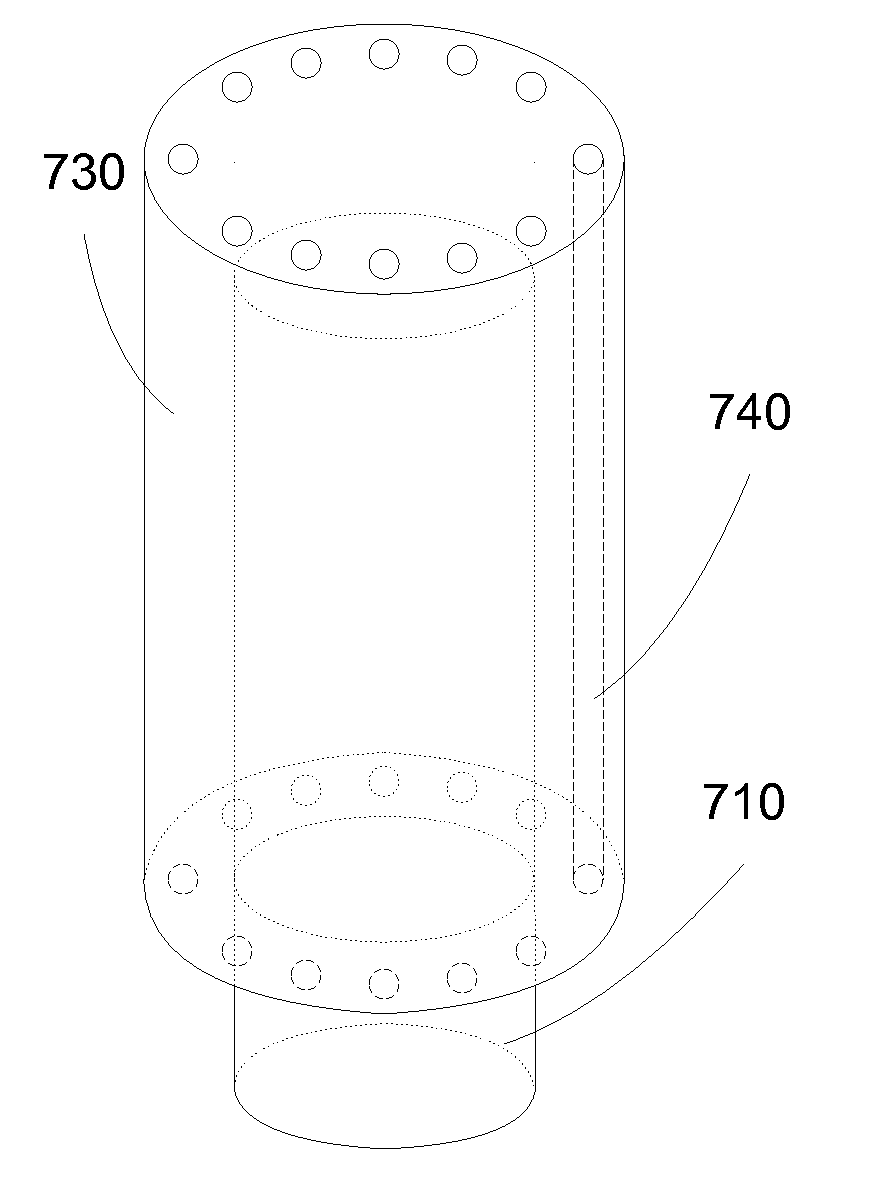

Method and device for preparing semi-solid state slurry through intensive cooling stirring

The invention discloses a method for preparing semi-solid state slurry through intensive cooling stirring. The method comprises the following steps: placing overheated alloy melt in a crucible or a casting ladle, descending a rotary stirring shaft internally introduced with a circular cooling medium in the alloy melt through a lifting device, driving the convection heat exchange of the alloy melt through stirring, continuously cooling the rotary stirring shaft through the circular cooling medium, stirring for a fixed period of time or cooling the melt to a set temperature, raising the rotary stirring shaft to prepare the semi-solid state slurry and form an ingot casting; closing the casting ladle containing the semi-solid state slurry to formation equipment and pouring the semi-solid state slurry into a cavity or material chamber of the formation equipment to take the shape; and taking out a formed part and moving the crucible or the casting ladle back to an original position and filling the overheated alloy melt to perform the next semi-solid state slurry preparation. The invention further provides a device for realizing the above method. Through the adoption of the method and device provided by the invention, large volume of semi-solid state slurry can be prepared once, and the semi-solid state slurry can be continuously produced in batch, and then the rheolytic formed part can be prepared through the combination of pressure casting, rolling, die-forging and other conventional formation equipment.

Owner:SHANGHAI INST OF TECH

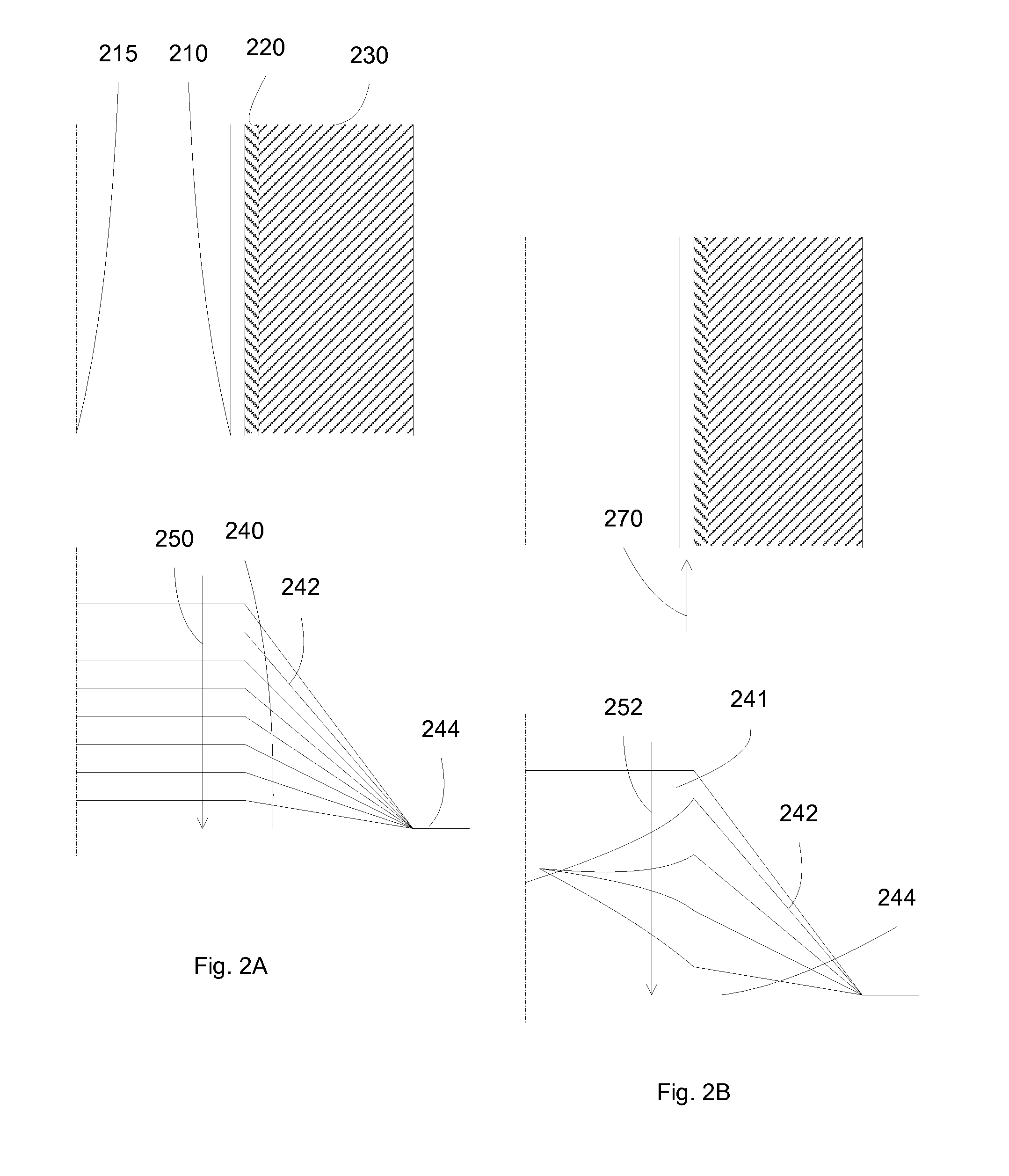

Thermally active convection apparatus

Owner:MODULAR THERMAL TECH LLC

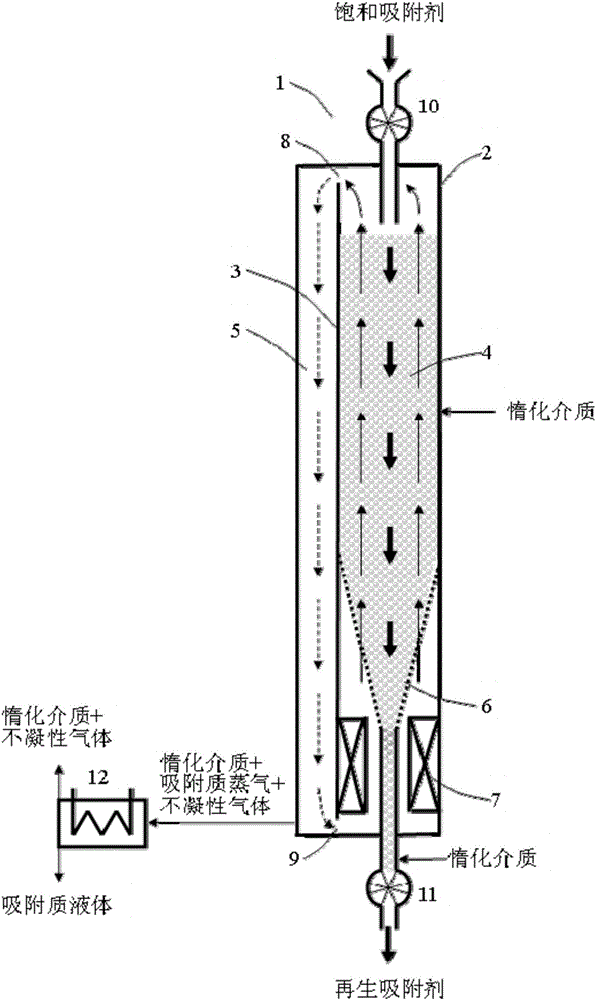

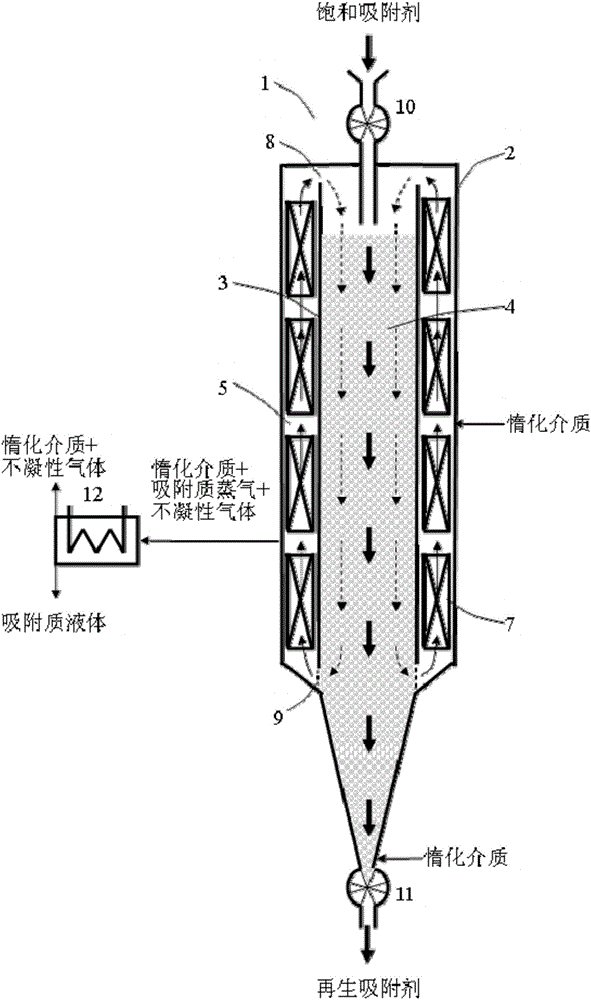

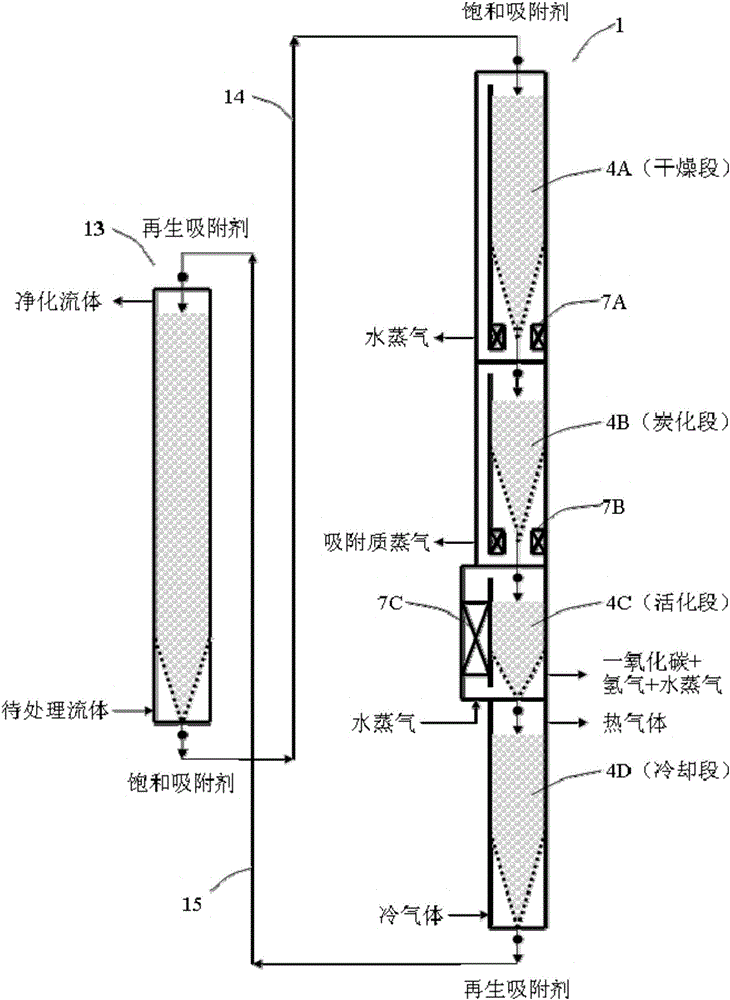

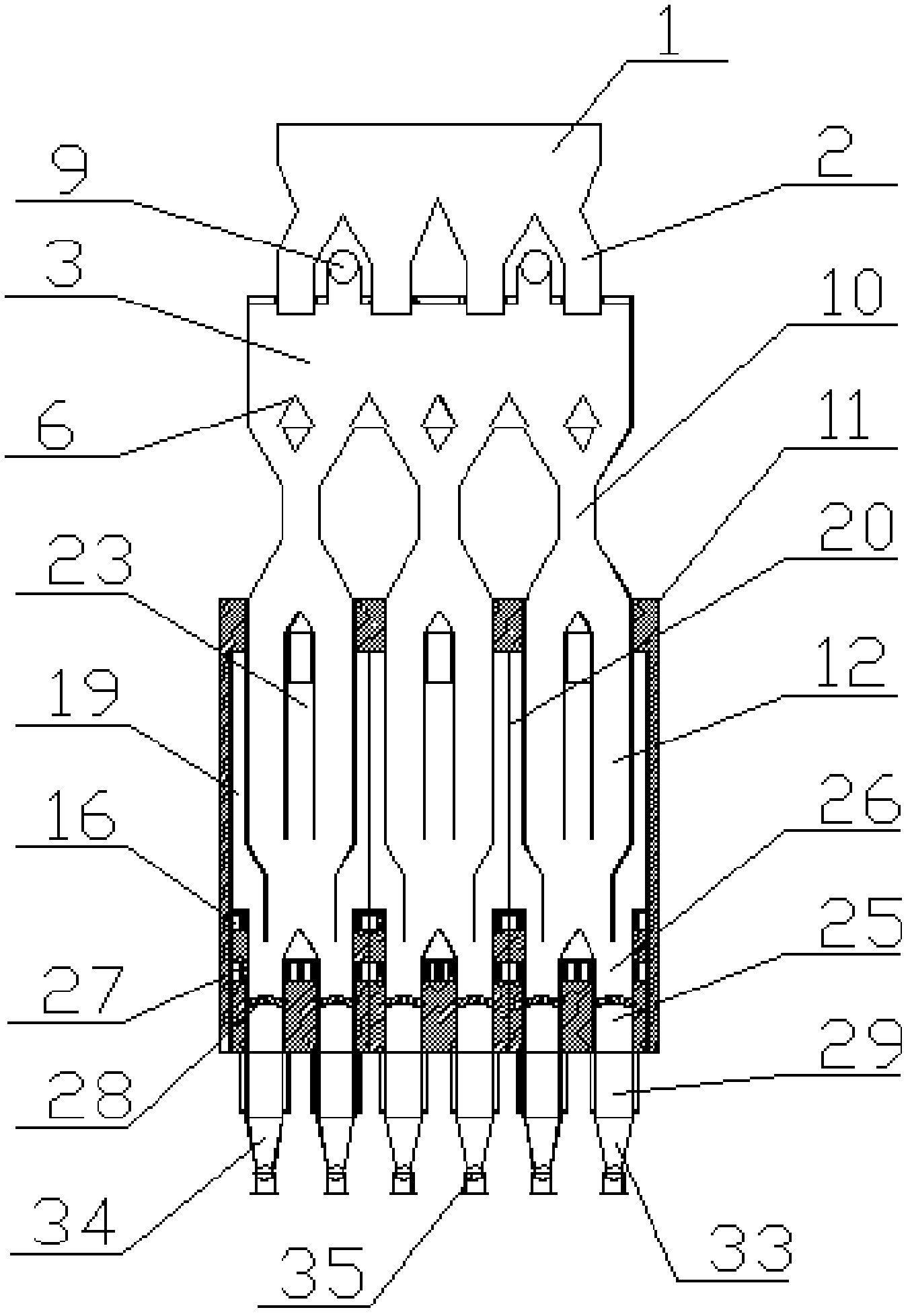

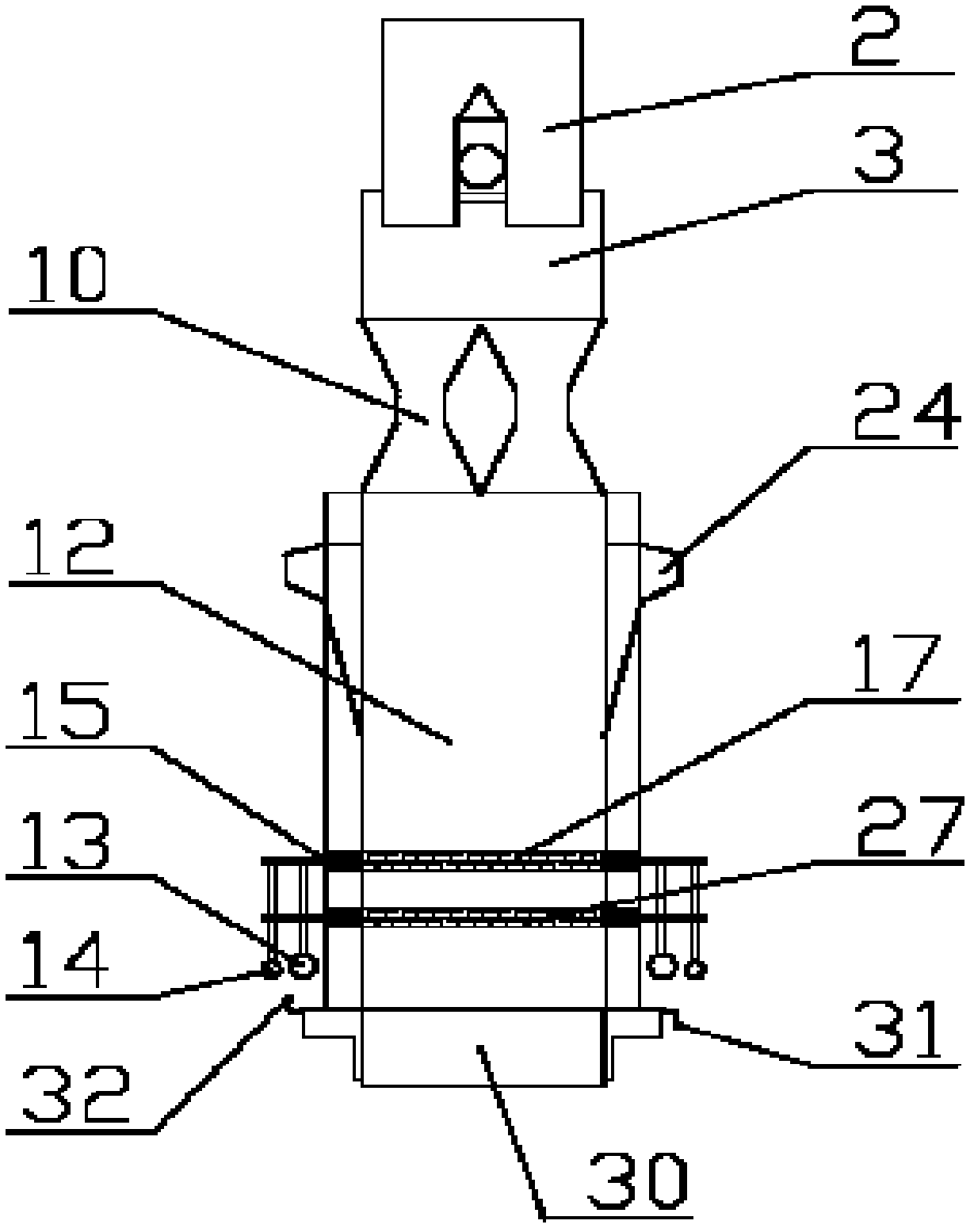

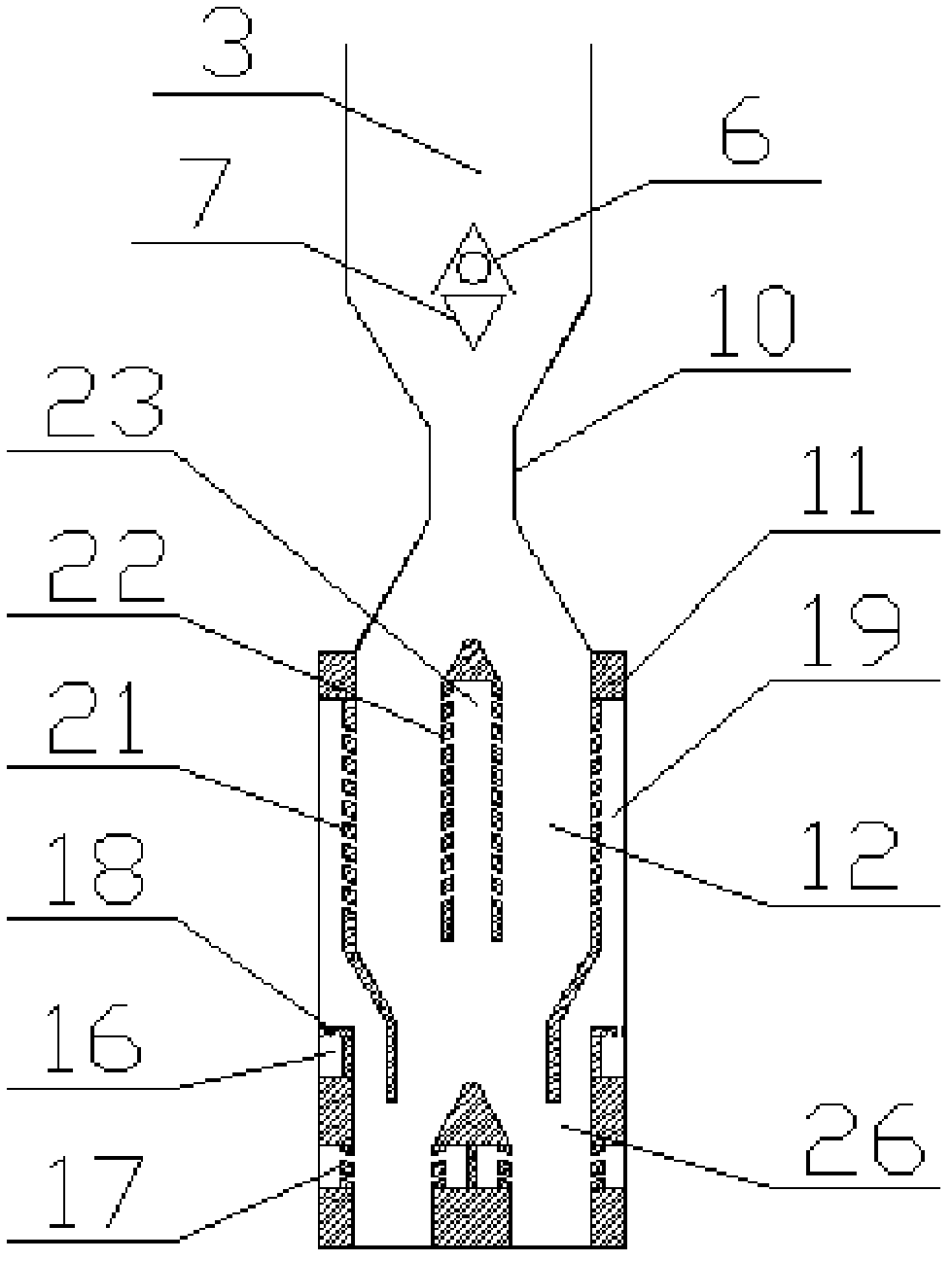

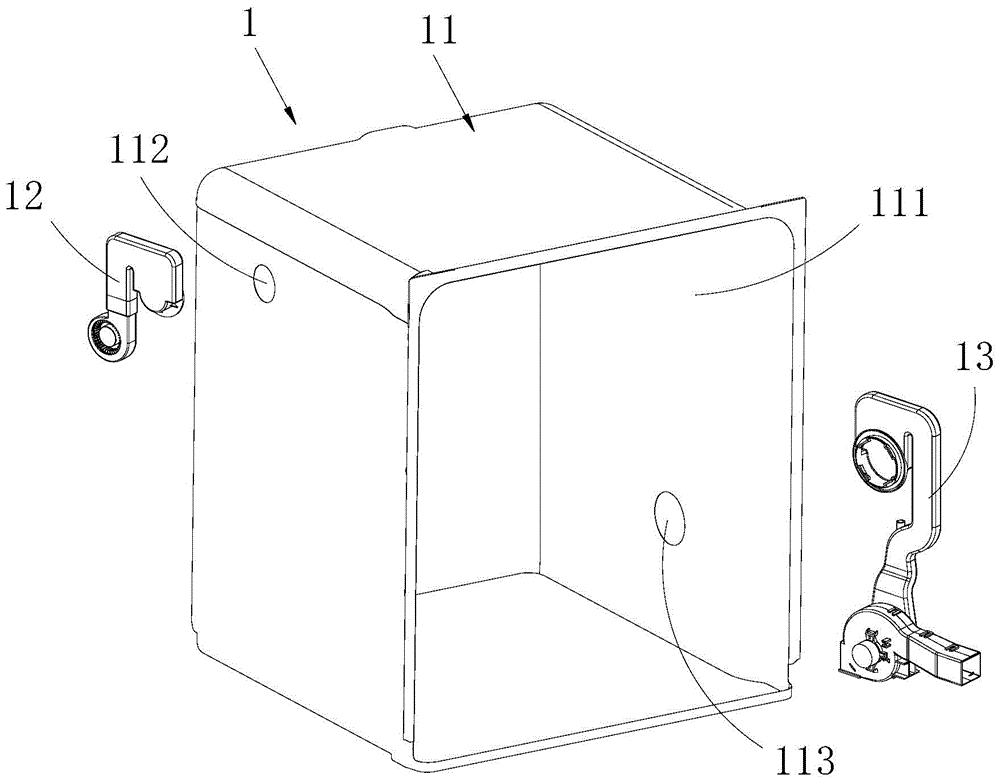

A solid adsorbent regenerating device and an adsorption device applying the regenerating device

InactiveCN106563428AReduce consumptionReduce heat lossGas treatmentSpecific water treatment objectivesSorbentNatural convection

A solid adsorbent regenerating device and an adsorption device applying the regenerating device are disclosed. The regenerating device includes a regenerating heater and an absorbent bed. The regenerating device is configured in a manner that heating by the regenerating heater allows gas in the regenerating device to circularly flow between the regenerating heater and the adsorbent bed, and heat provided by the regenerating heater is transferred through the circular airflow to the adsorbent bed so that an adsorbent is heated and regenerated. According to one embodiment, the inside of a furnace body of the regenerating device is divided into two parts, top ends of the two parts are communicated with each other, bottoms of the two parts are communicated with each other, and the regenerating heater is in one of the two parts. The adsorption device applying the regenerating device is also disclosed. Circular heating in a natural convection manner is utilized to regenerate the solid adsorbent. The regenerating device and the adsorption device have advantages of low consumption of inert gas, no or extremely low waste emission, a high heat efficiency, simple equipment, a low cost, and the like.

Owner:GUANGDONG UNIV OF TECH

Gas heat carrier low-temperature pyrolyzing furnace and gas heat carrier low-temperature pyrolyzing method

InactiveCN102676187AImprove heat utilization efficiencyReduce contact timeCoke quenchingDirect heating destructive distillationHeat carrierBrick

The invention discloses a gas heat carrier low-temperature pyrolyzing furnace and a gas heat carrier low-temperature pyrolyzing method. High-moisture materials are subjected to drying preprocessing in the pyrolyzing furnace by means of a gas heat carrier convection drying method, and hot gas is uniformly distributed in a drying section under the action of a gas distribution umbrella. Dried materials enter a dry distillation area where gas heat carriers transversely penetrate through materials, and exchange heat with the gas heat carriers prior to heating to enable low-temperature pyrolytic reaction. Gas in the furnace is formed by mixing lower coke quenching coal gas with hot flue gas in a combustion area, enters a flame path, then flows across a material layer from a flame path lattice wall to a gas collection lattice wall to enter a gas collection chamber, and is finally led out of the furnace through a gas collection passage formed by double-faced gas collection lattice walls and gas collection chamber gas distribution bricks. Pyrolyzed product hot semi-cokes enter a combined dry quenching device to be cooled and pass through a coal gas quenching area and a water-cooling heat exchange area sequentially. A guide chute on the lower portion of the furnace is connected with a discharger and a conveyor, and semi-cokes are uniformly led out and conveyed to a semi-coke storage yard under the action of the discharger and the conveyor.

Owner:北京德天御投资管理有限责任公司

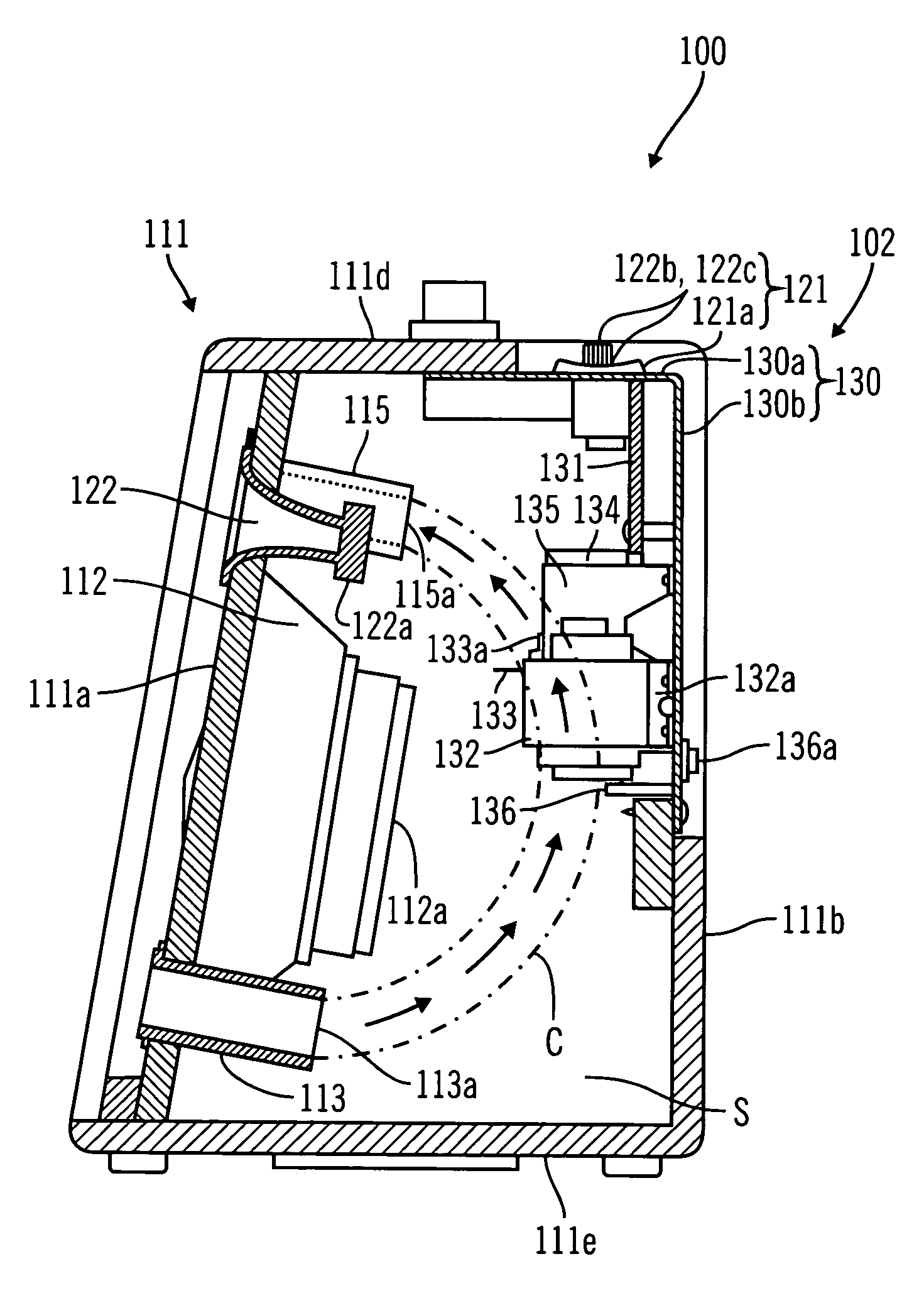

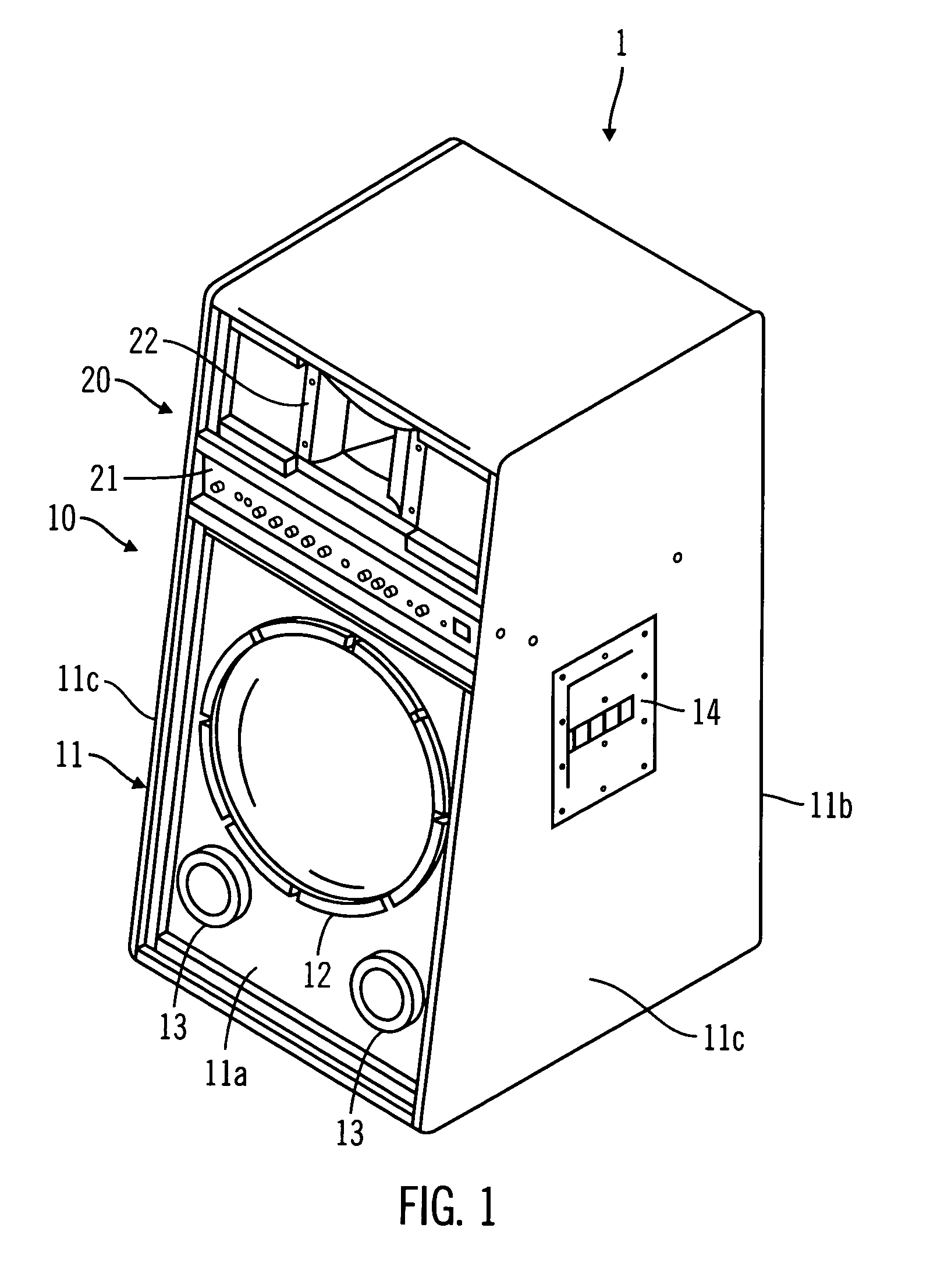

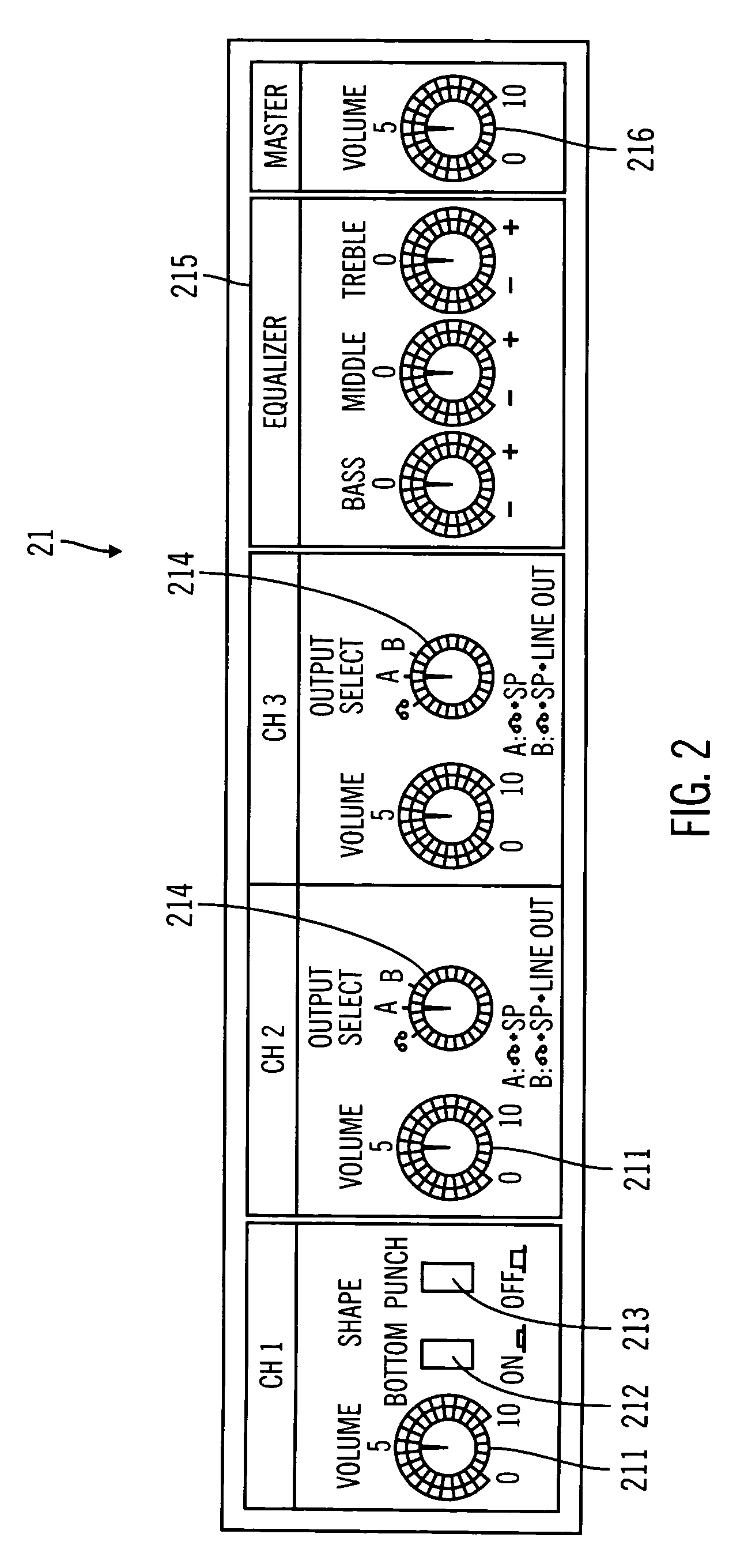

Speaker installation and method

InactiveUS6956956B2Efficiently dissipatedFrequency/directions obtaining arrangementsTransducer casings/cabinets/supportsAudio power amplifierEngineering

A speaker system in which it is possible for power amplifier heat radiation and satisfactory audio characteristics to coexist. The power amplifier, and other components which are sources of heat, are arranged in an air flow convection path that is formed in a curved path from a lower bass reflex port toward an upper bass reflex port of a speaker box. The heat is exhausted (radiated) to the outside from the interior air space of the speaker box by the air flow and air from outside is introduced into the interior air space with good efficiency. In addition, the power amplifier includes a heat sink. The heat sink includes gaps that are formed between each of a plurality of fins which are opened in a vertical or diagonal direction such that the air flow convection path passes through the gaps.

Owner:ROLAND CORP

Ridge Vent with Powered Forced Air Ventilation

ActiveUS20110124280A1Improve ventilationBuilding roofsLighting and heating apparatusImpellerForced-air

A ridge vent with powered forced air ventilation includes a ridge vent that is configured to be installed along the ridge of a roof covering an elongated ridge slot on either side of a ridge beam of the roof. Hot air from the attic below escapes by convection through the ridge slot and is expelled to ambient atmosphere through the ridge vent. A blower is mounted in a blower opening formed at a predetermined location along the ridge vent on one side of the ridge beam. The blower includes a blower housing forming an inlet within the attic and an outlet oriented to force air upwardly through the vent slot to be expelled through the ridge vent. A pair of baffles are hingedly secured to the housing adjacent its outlet and can be hinged up for dropping the blower through the blower opening during installation, and then hinged down and attached to a roof deck covering the blower opening and a portion of the ridge slot on the other side of the ridge beam. The baffles secure the blower and help to isolate its outlet from the attic space below. An impeller is disposed in the housing and is driven by an electric motor, which may be driven by electricity from a solar panel, electricity from a household electrical service, or both depending upon availability of sunlight and other conditions.

Owner:BMIC LLC

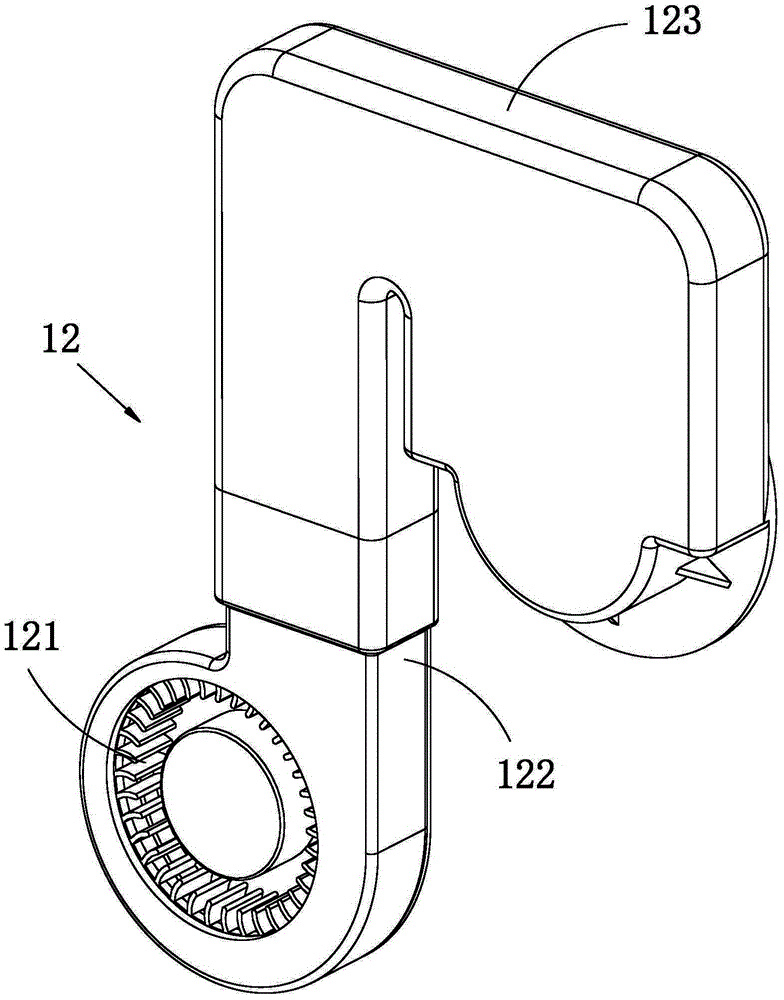

Drying machine and dish washing machine

ActiveCN104586336ASmooth convectionReduce noiseTableware washing/rinsing machine detailsEngineeringExhaust pipe

The invention relates to the technical field of dish washing machines, and provides a drying machine and a dish washing machine. The drying machine comprises an inner container, the side wall of the inner container is connected with an air inlet mechanism and an exhaust mechanism, the air inlet mechanism comprises an air inlet pipe, the side wall of the inner container is provided with an air inlet hole and an exhaust hole, the air inlet hole and the exhaust hole are distributed at different heights, and the air inlet pipe is connected with the air inlet hole; the exhaust mechanism comprises an exhaust motor and an exhaust pipe, and the two ends of the exhaust pipe are connected with the exhaust motor and the exhaust hole respectively. After tableware in the dish washing machine is rinsed, outside air enters the inner container through the air inlet hole, the exhaust motor pumps the air in the inner container through the exhaust hole, and the air is exhausted outside through the exhaust pipe; the air inlet hole and the exhaust hole are distributed at different heights, so that air convection is formed in the inner container, the drying effect is greatly improved, energy consumption is lowered, air convection is smooth, noise is low, the structure is simple, and potential safety hazards are avoided.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

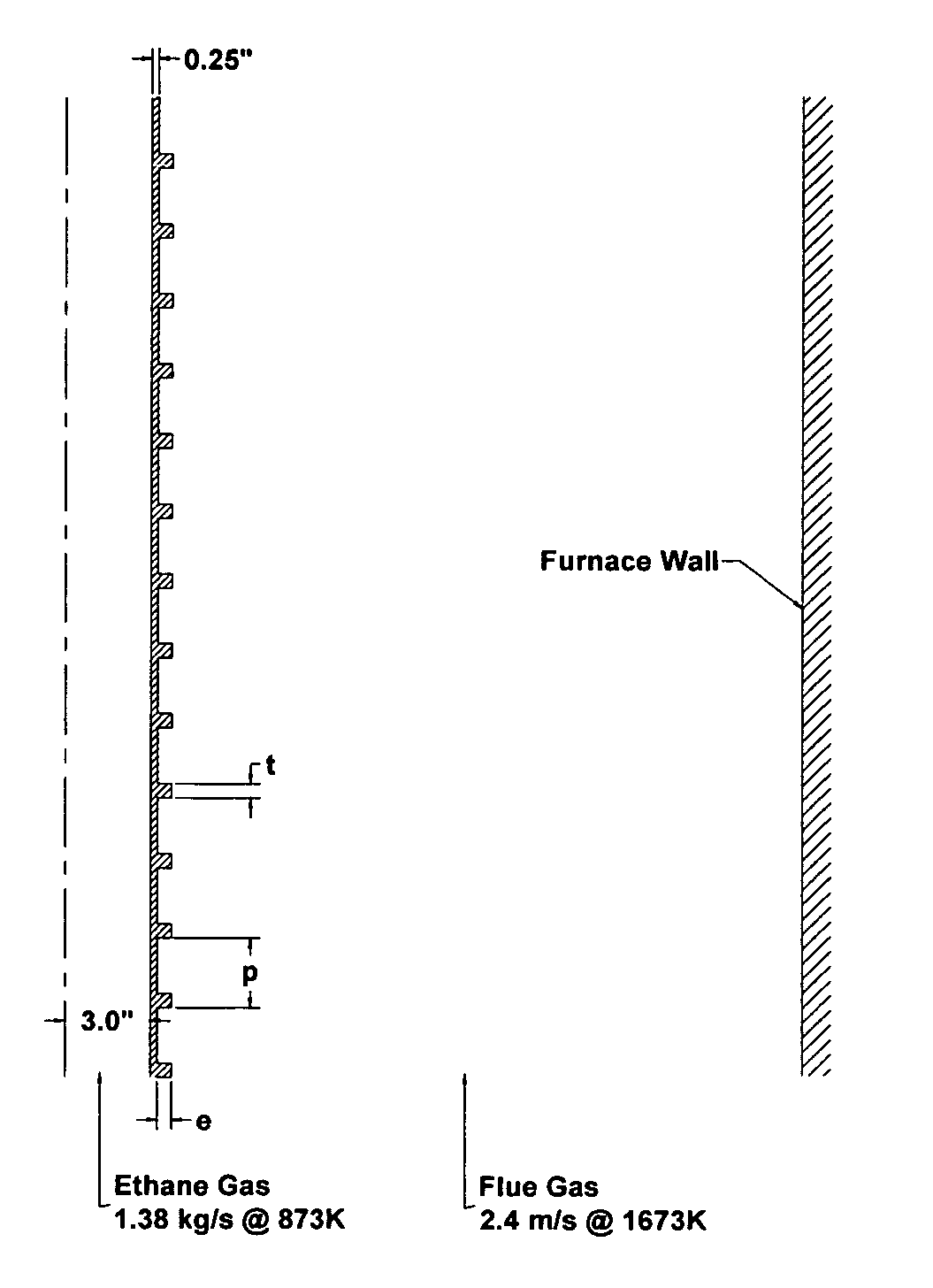

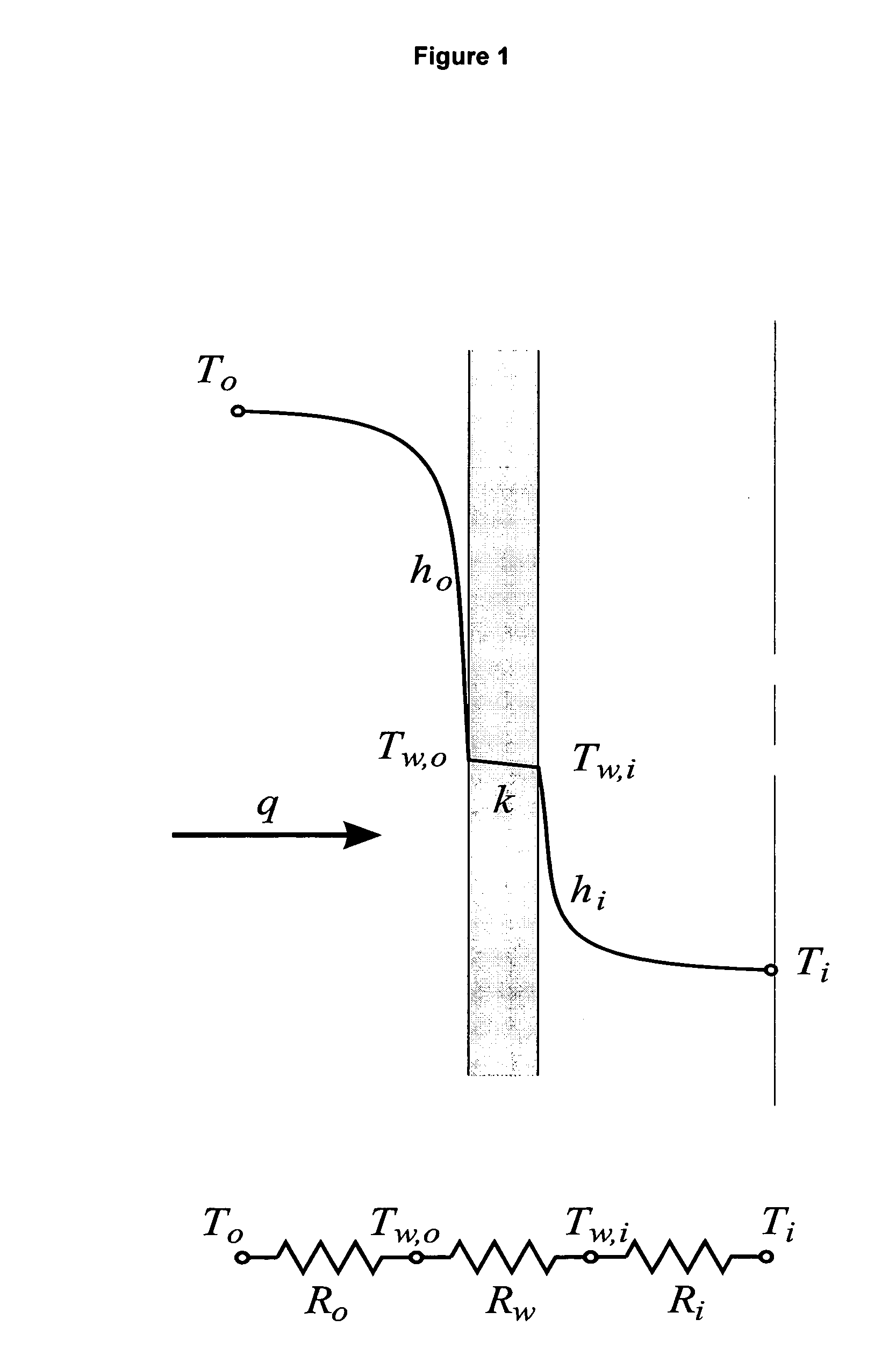

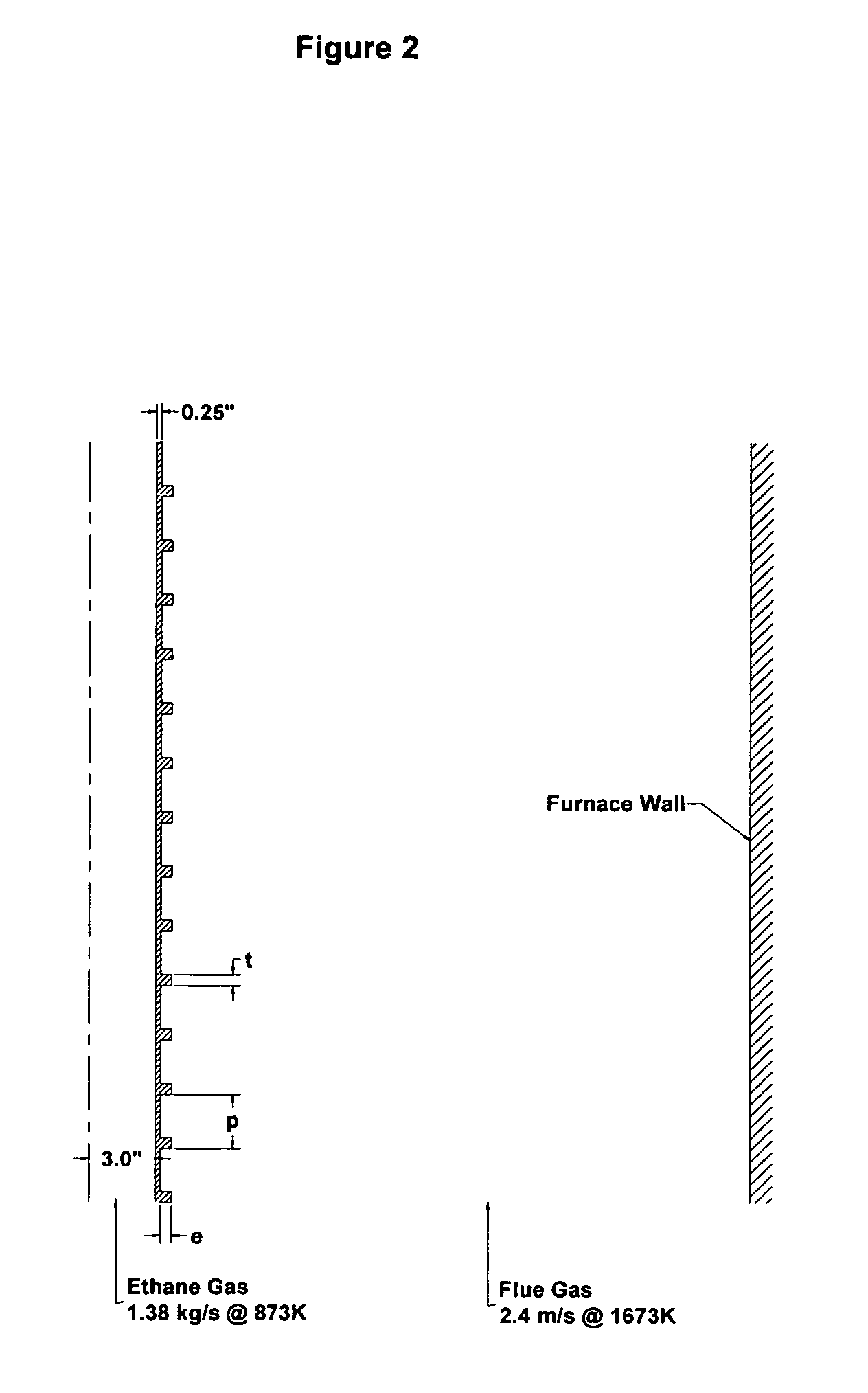

External ribbed furnace tubes

ActiveUS7128139B2Thermal non-catalytic crackingMetal-working apparatusVertical tubeRadiative heating

In a radiant heating box there is a convection current which flows over the surface of tubes in the box. Adding ribs to the external surface of vertical tubes provides an enhancement to the heat transfer by convection and increases the heat transfer to the tubes.

Owner:NOVA CHEM (INT) SA

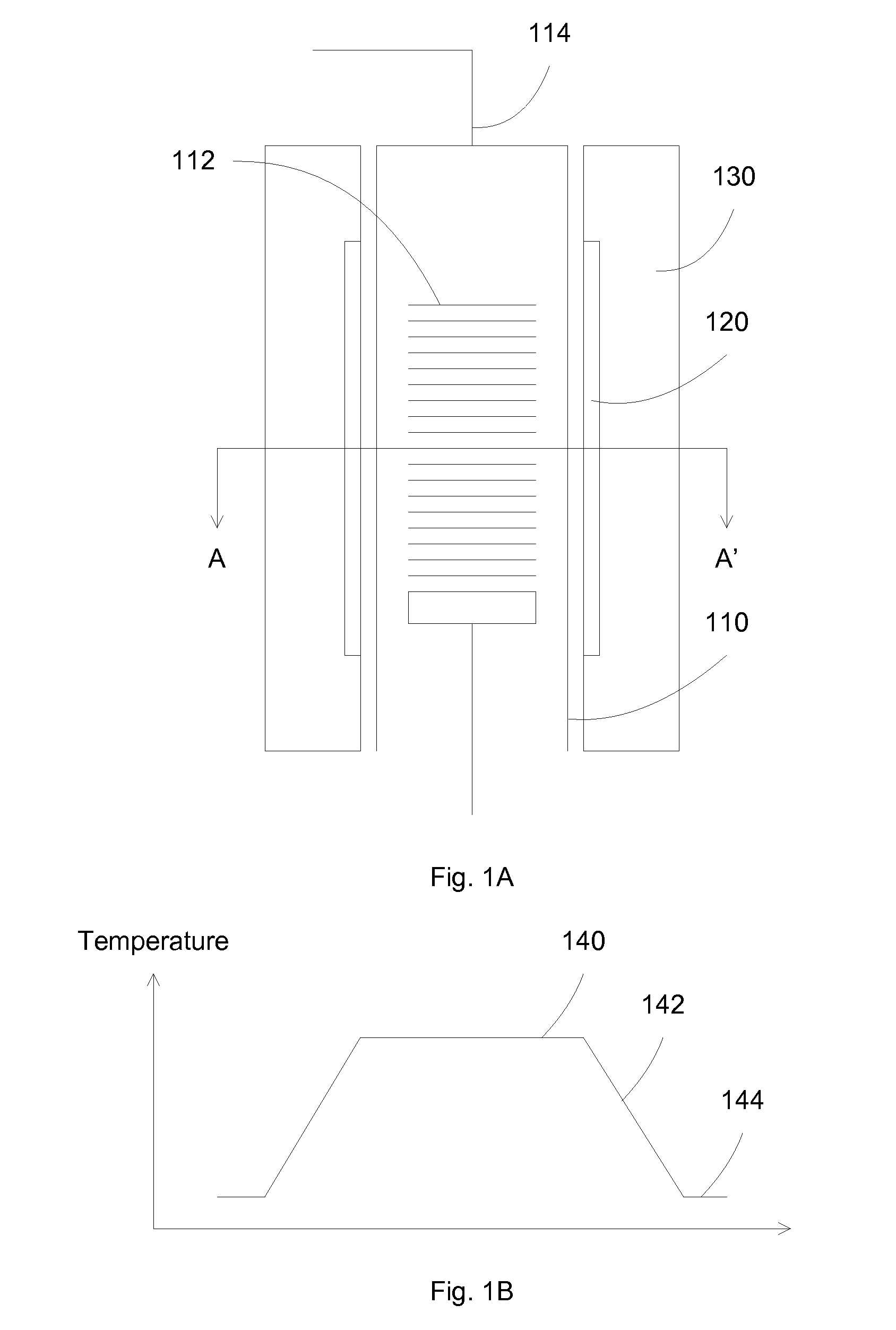

Heater elements with enhanced cooling

ActiveUS20130062333A1Improve cooling effectSpeed up coolingMuffle furnacesSemiconductor/solid-state device detailsForced convectionEngineering

A heater assembly with enhanced cooling pursuant to various embodiments described herein makes use of fluidic flow in the insulation or in the space used for insulation. By creating a natural convection or forced convection flow, the heater cools down faster, it can operate at lower temperatures and / or higher temperature precision, and it can improve temperature controllability by generating higher heat loss rates.

Owner:EMAMI ARSALAN

Paint dryer and paint dryer system

InactiveUS20020148137A1Reduce excess spaceConfiguration highLiquid surface applicatorsDrying solid materials with heatAir cycleThermodynamics

The inventive paint dryer, comprises a cabin (12) for housing objects (15) that are to be painted and dried. At least one fresh air supply (8) is provided in order to introduce fresh air into an air circulation system pertaining to the dryer (1) resulting in the circulation of said air. At least one pure gas supply line (7) is provided, wherein thermally cleaned and heated waste air is introduced as a pure gas, thereby maintaining the waste gas circulated in the circulation system at the desired temperature in such a way that objects (15) arranged in the cabin (12) can be dried by radiation and / or convection. The pure gas supply line (7) is surrounded by the fresh air supply line (8) at least along a longitudinal pipe segment and at least in said longitudinal pipe section the pure gas supply pipe (7) is constructed in such a way as to allow for the transmission of heat to fresh air flowing into the fresh air supply (8). The invention also relates to a paint dryer unit comprising several paint dryer modules which are positioned one after the other and configured as paint dryers according to the invention.

Owner:ABB FLAEKT AB

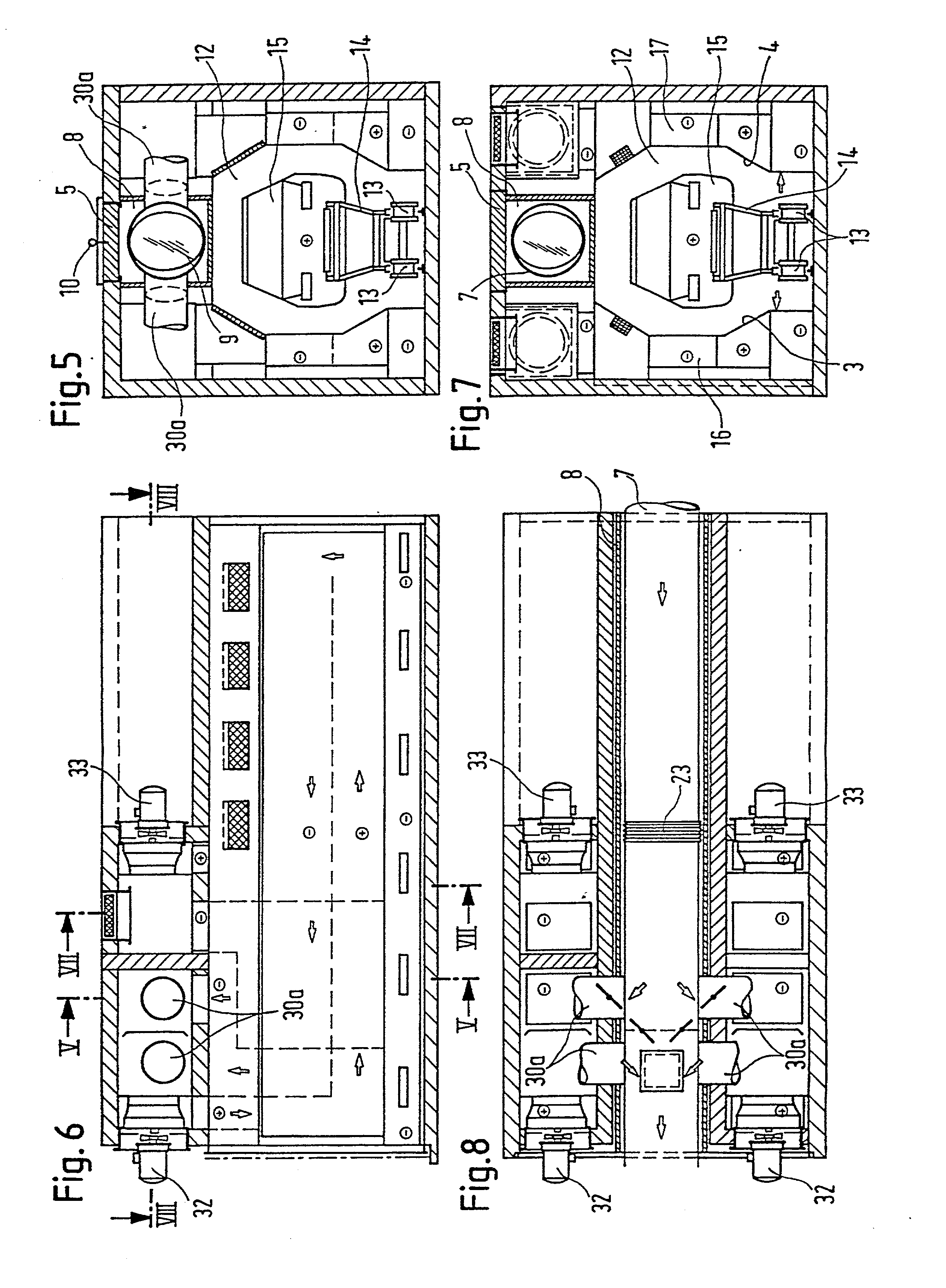

System for online monitoring of gathered dust on convection heating surface of boiler

InactiveCN103604132AReal-time calculation of ash deposit thicknessTake advantage ofMeasurement devicesSolid removalPower stationControl signal

The invention discloses a system for online monitoring of gathered dust on a convection heating surface of a boiler. The system comprises a data acquisition device, a dust blowing monitoring control device and a dust blowing device. The system is used for directly monitoring and calculating the thickness of the gathered dust on the convection heating surface in real time and comparing the thickness of the gathered dust with a critical thickness of the gathered dust, and if the thickness of the gathered dust is more than or equal to the critical thickness of the gathered dust, the system outputs a dust blowing control signal to realize intelligent monitoring and control of the gathered dust on the convection heating surface. The system for online monitoring of the gathered dust can calculate the thickness of the gathered dust in real time no matter how the running state of the boiler changes; the data acquisition device is simple in structure, and the current data acquisition device of a power station boiler can be fully used; dust blowing can be performed on the convection heating surface of the boiler accurately in real time; the thickness data of the gathered data, which is calculated in real time, can be uploaded to a DCS (distributed control system) of a power station to provide technical data for optimization of the running of the boiler.

Owner:TAIYUAN UNIV OF TECH +1

Rrh concealment module/methods in natural convection

ActiveUS20150017937A1De-icing/drying-out arrangementsElectrical apparatus contructional detailsCold airNatural convection

Disclosed is an apparatus with a concealment module, the concealment module including an inlet panel and an outlet panel, the outlet panel located higher than the inlet panel. Also included is a remote radio head disposed with the concealment module, mounted on a support, and located between the inlet panel and the outlet panel. A first baffle is located under the remote radio head to prevent cool air from the inlet panel from being diverted to a space between the remote radio head and the support. A second baffle is located to direct cooling air over a back of the remote radio head. A third baffle is located on top of the remote radio head to direct heated cooling air to the outlet panel. A fourth baffle is located to direct cooling air over the front of the remote radio head.

Owner:COMMSCOPE TECH LLC

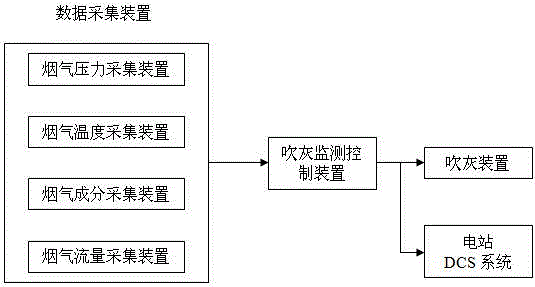

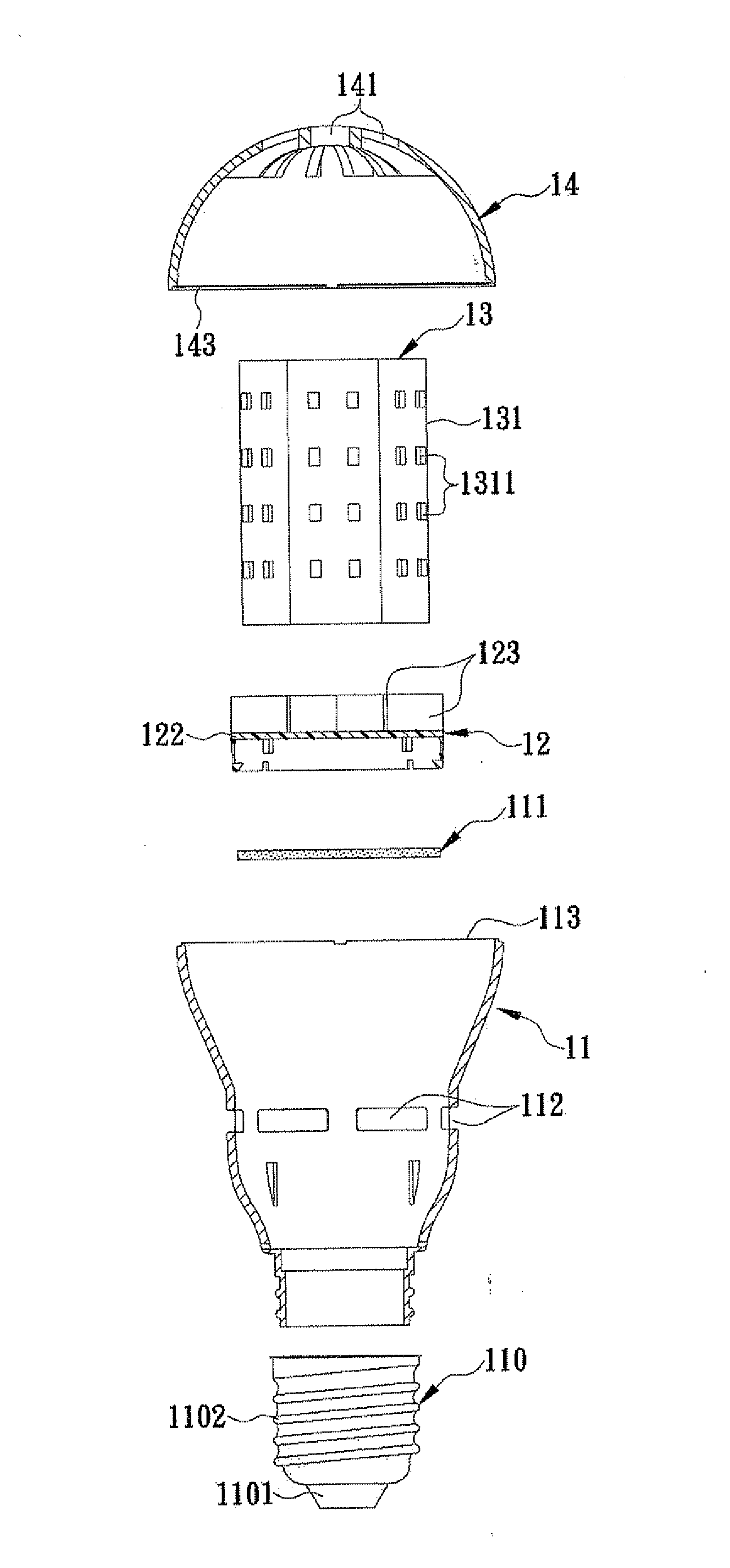

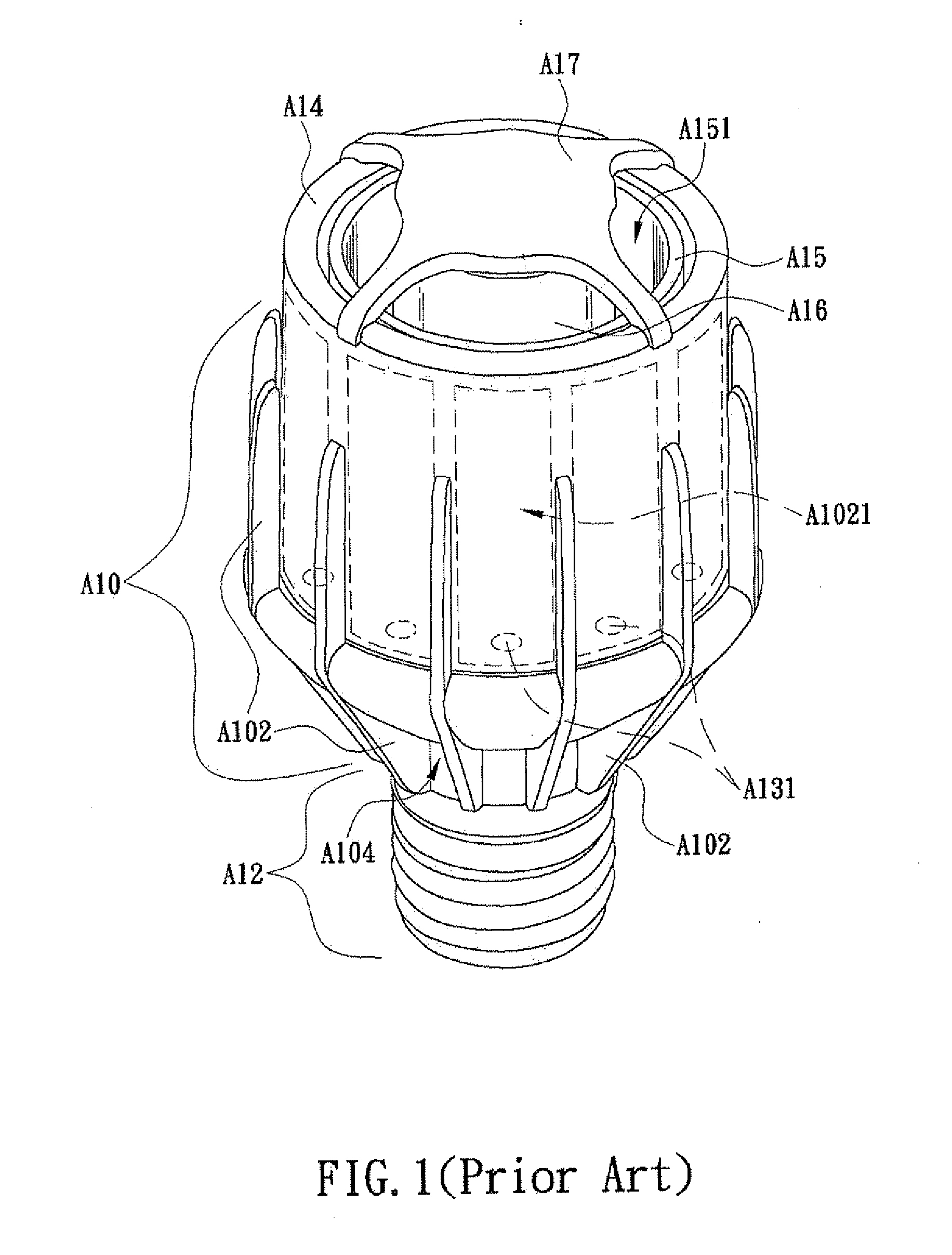

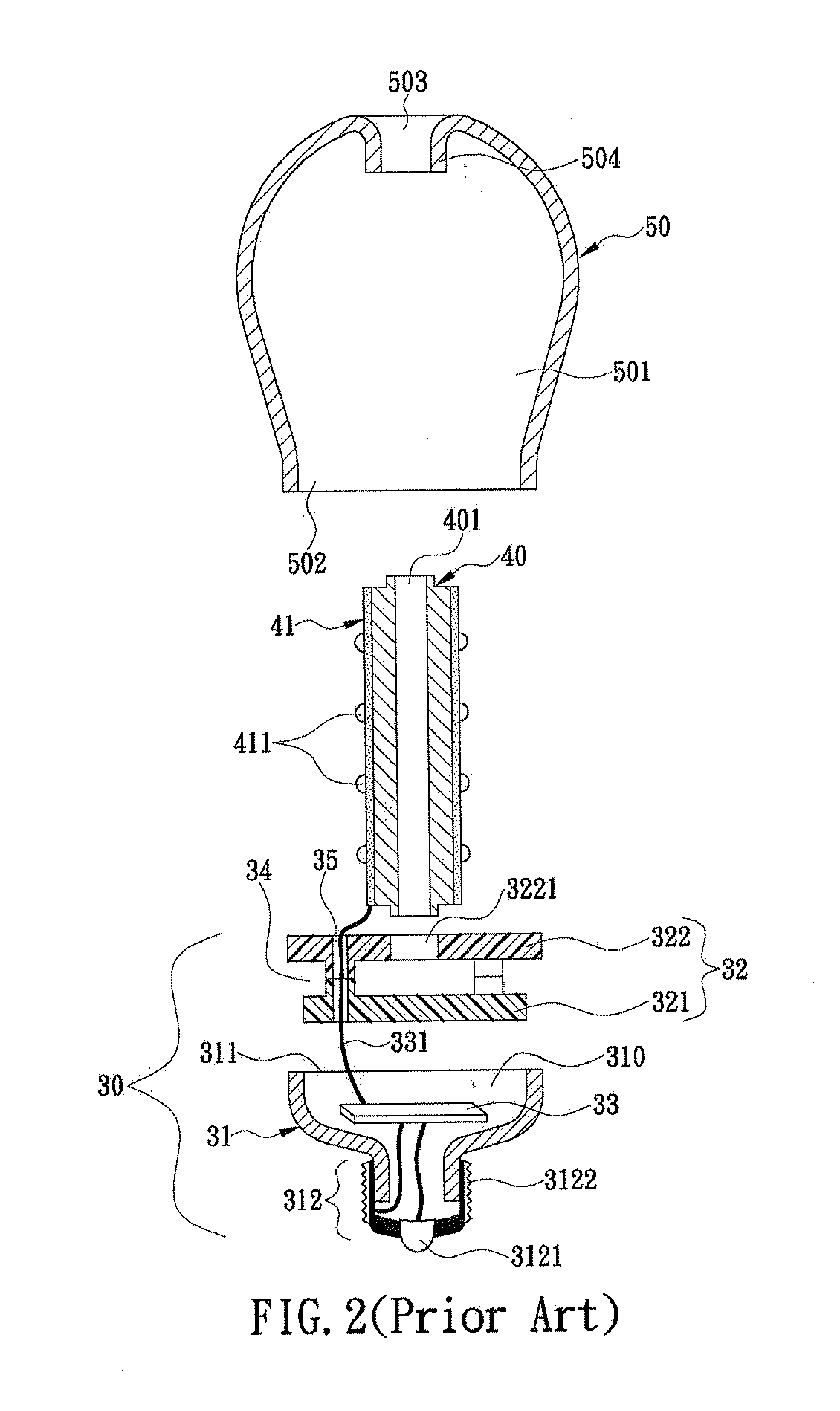

Light emitting diode bulb with central axis bidirectional convection heat dissipation structure

InactiveUS20150176830A1Thermal conductivityImprovement factorNon-electric lightingPoint-like light sourceCouplingEngineering

An LED bulb includes a lower cover having ventilation holes formed at outer periphery thereof, and a first coupling opening formed at top side thereof; a separating unit provided within the lower cover at a position between lower edges of the ventilation holes and bottom side of the lower cover, and having a convection pathway formed at top side thereof; a heat sink having bottom end positioned on top side of the separating unit; and an upper cover having top side formed with convection hole corresponding to top end of the heat sink, and a second coupling opening formed at bottom side thereof. When the second and first coupling openings are coupled with each other, the upper and lower covers are assembled together to form a central axis bidirectional convection heat dissipation pathway sequentially through the ventilation hole, the convection pathway, the heat sink and the ventilation hole accordingly.

Owner:SKYNET ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com