Patents

Literature

30results about How to "Guaranteed combustion temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

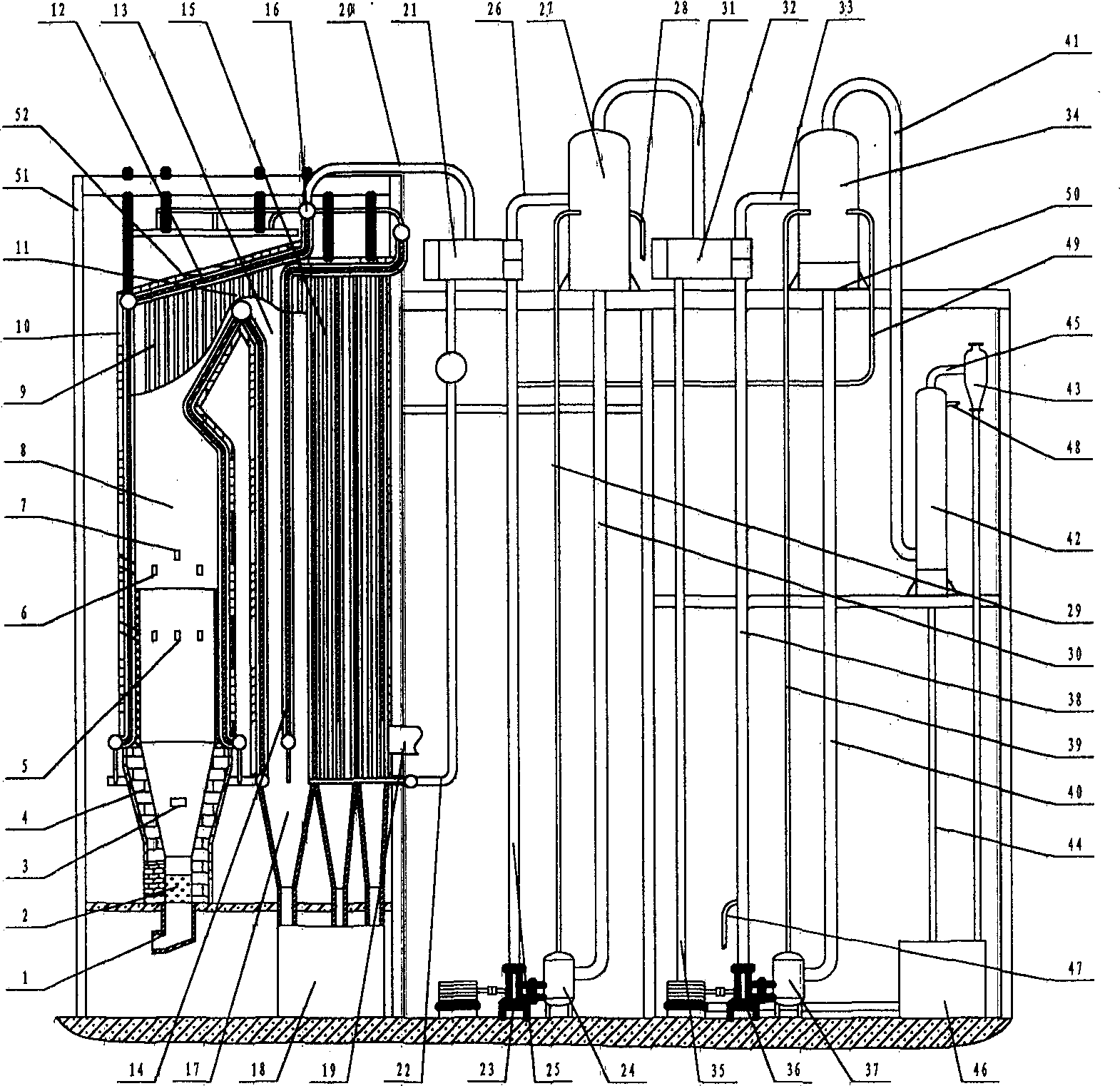

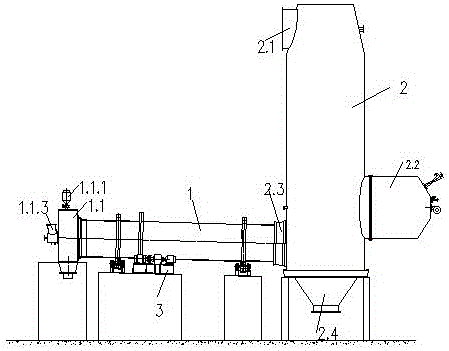

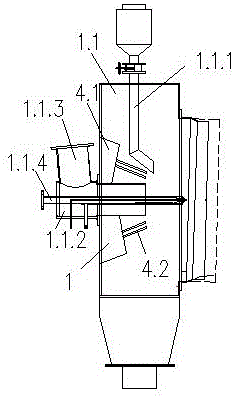

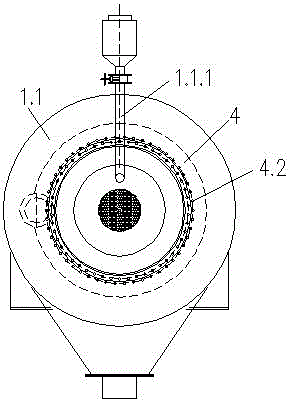

Burning process and burning boiler for processing high-density saliferous organic wastewater

ActiveCN103047659AGuaranteed combustion temperatureReduce flue gas velocityCombustion technology mitigationIncinerator apparatusChemical industryGas burner

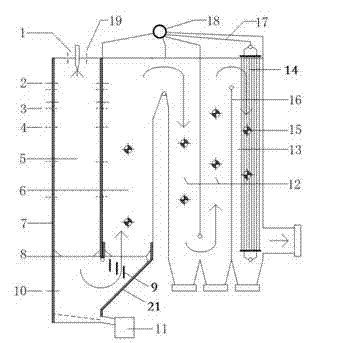

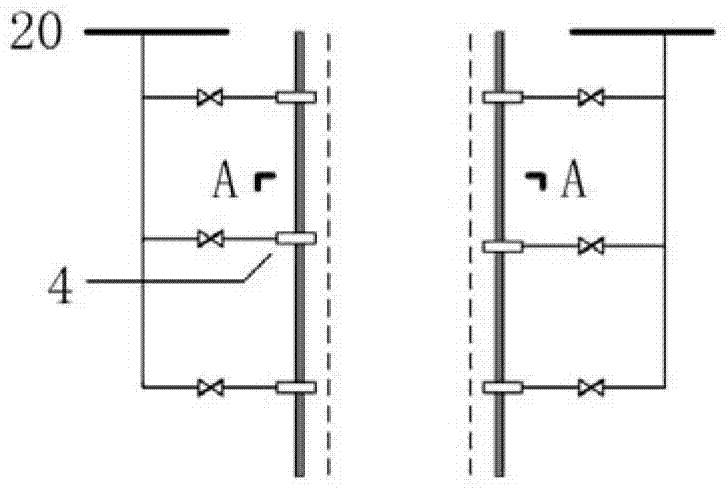

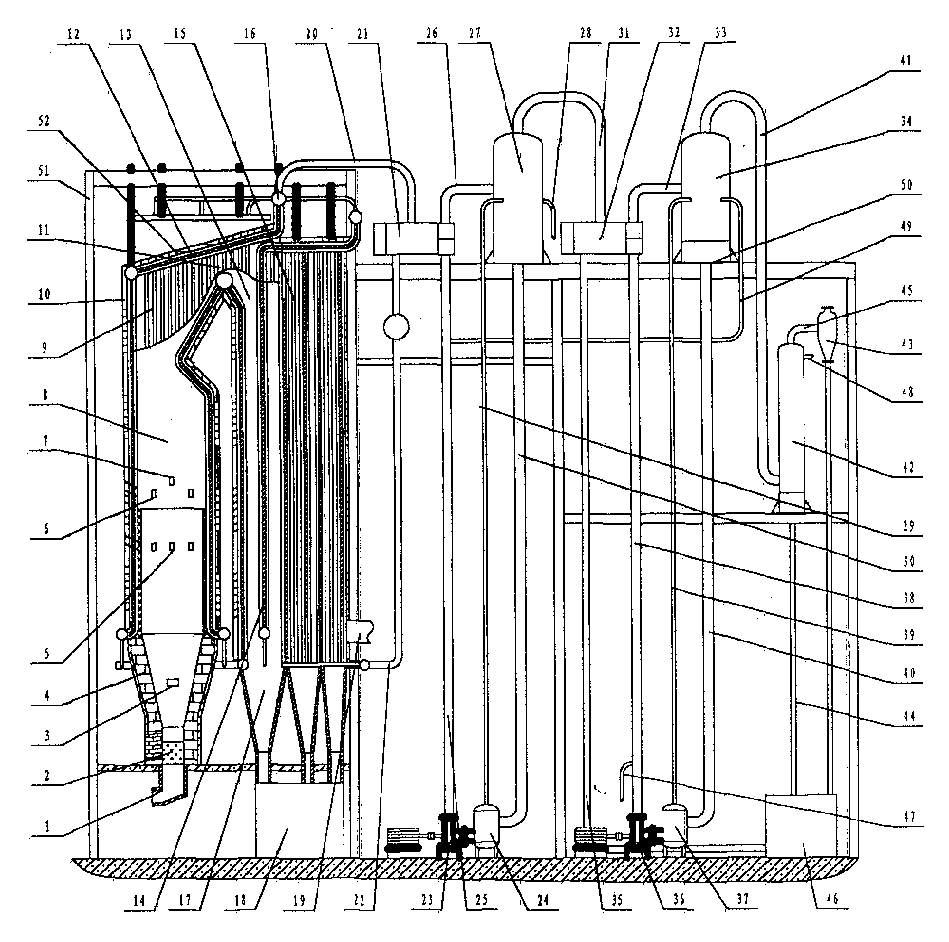

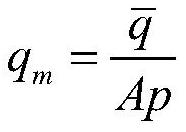

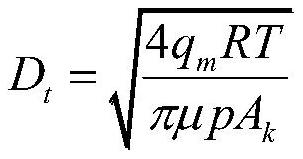

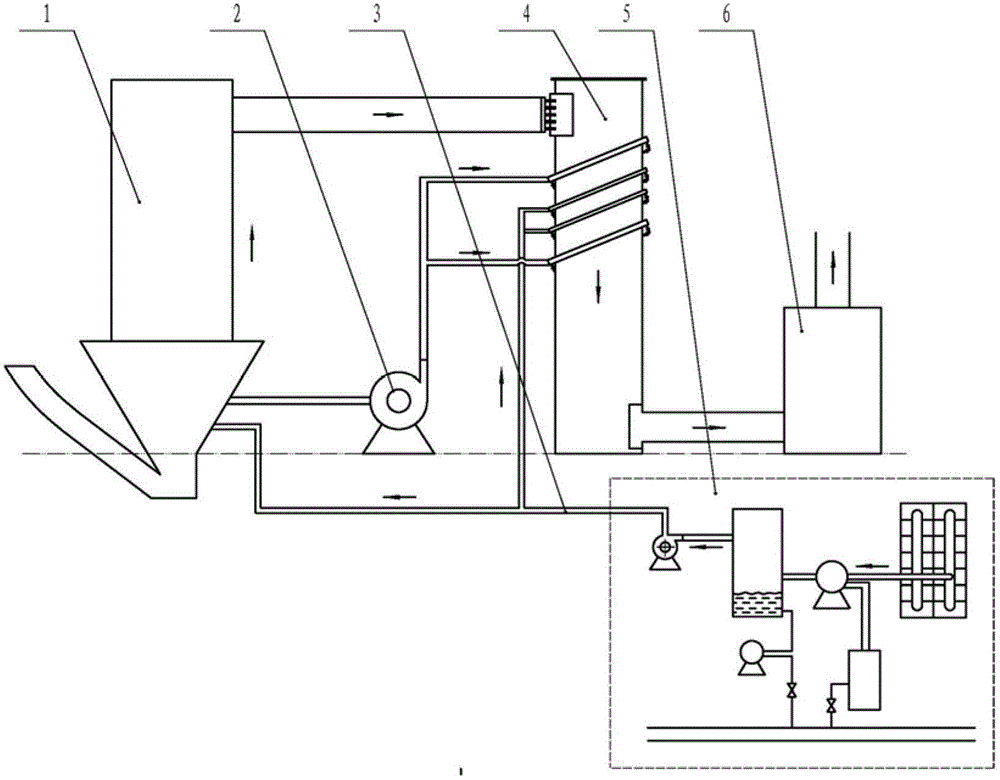

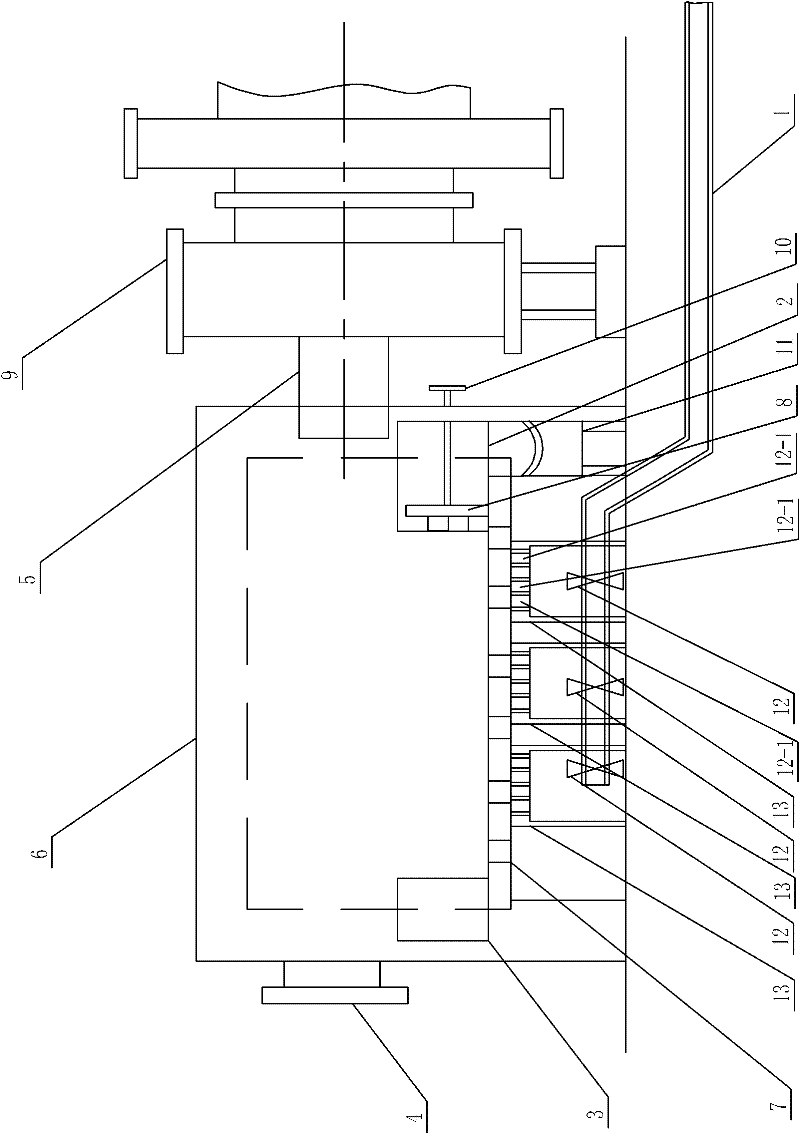

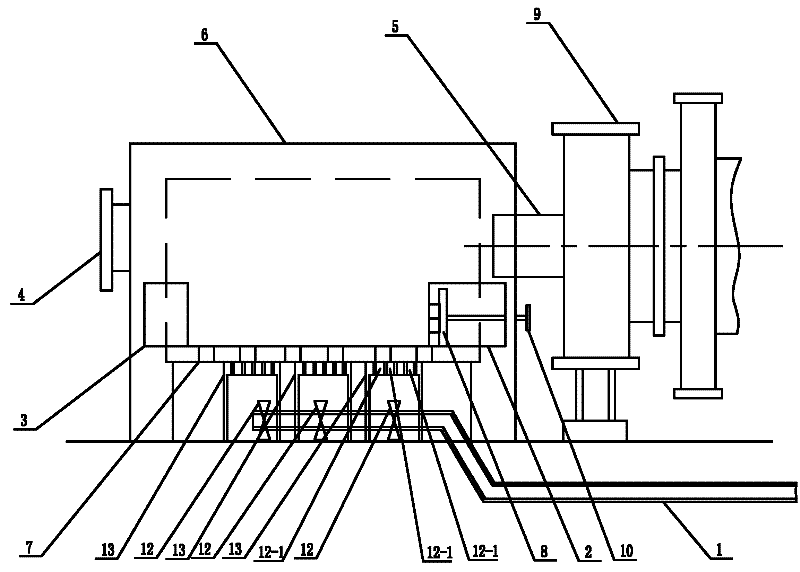

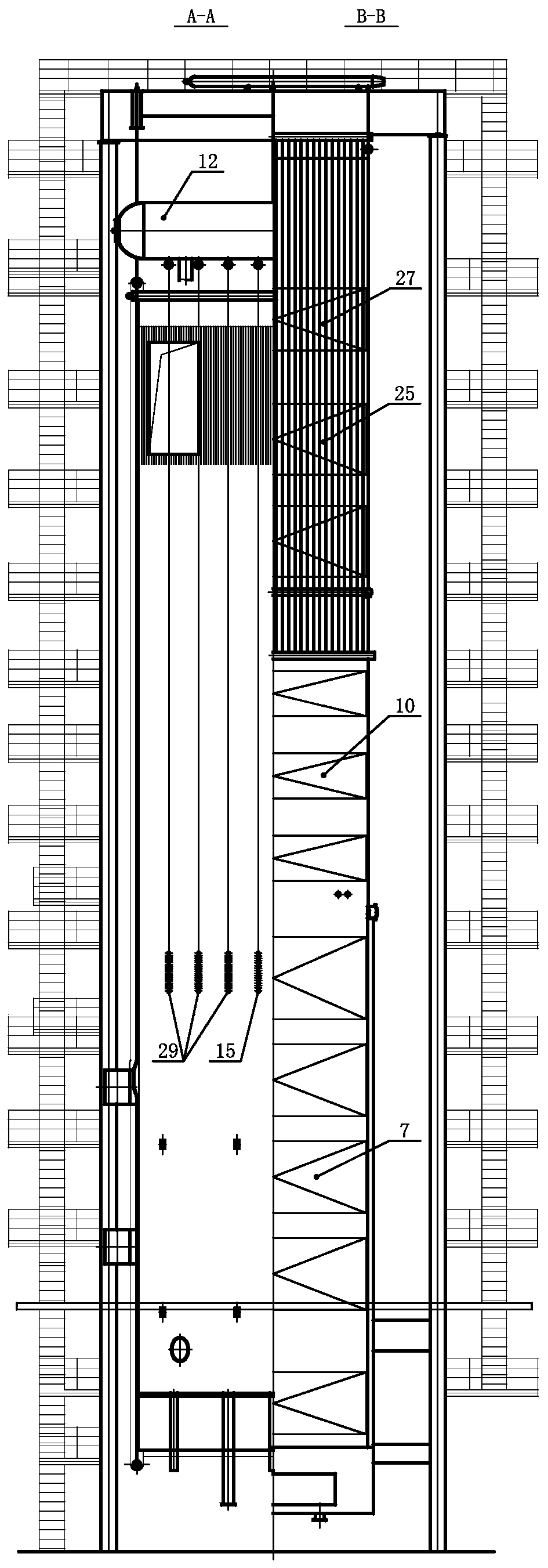

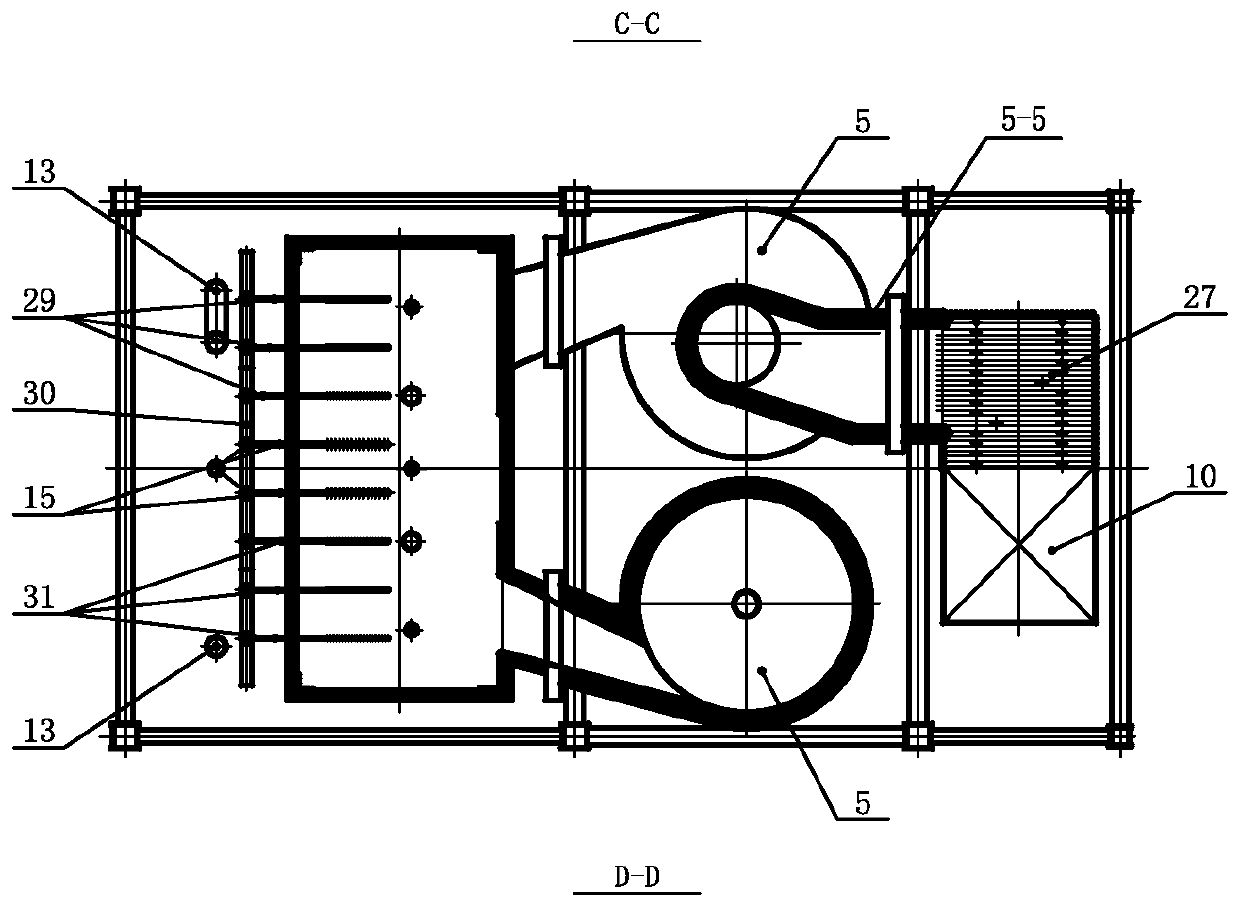

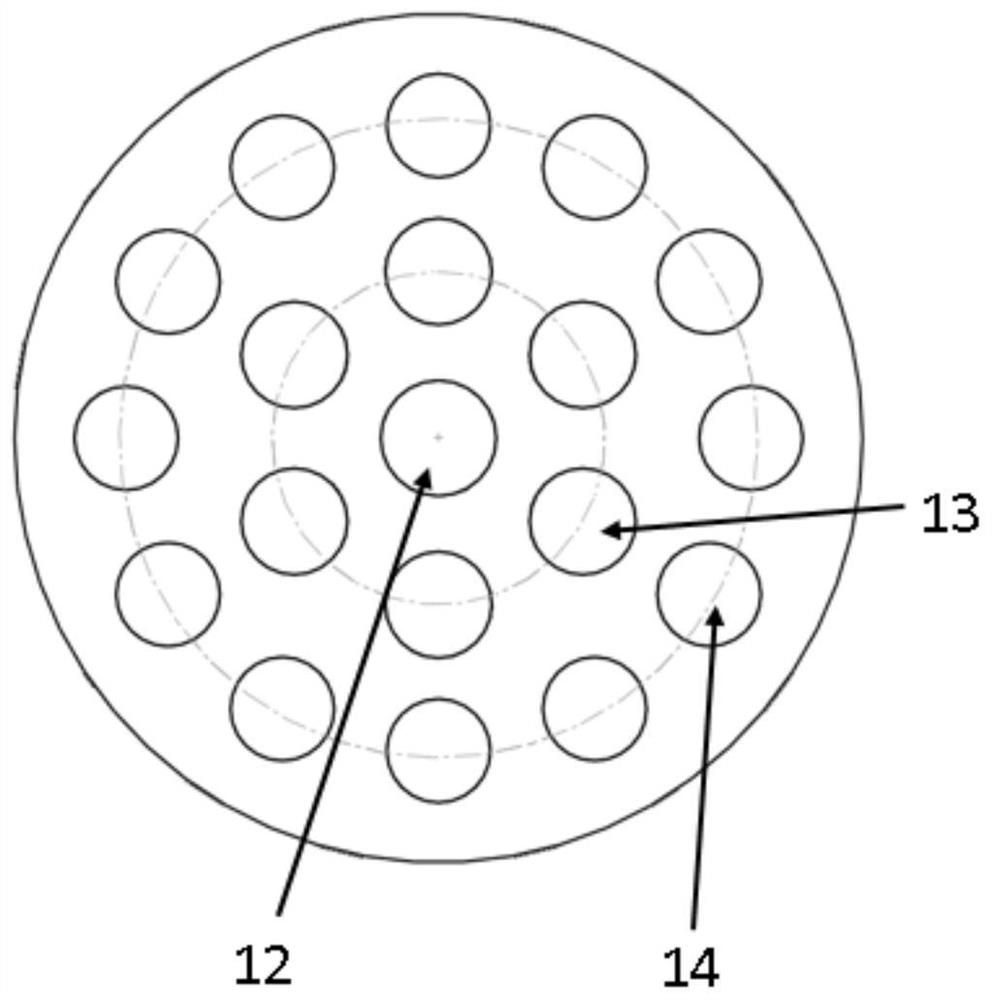

The invention discloses a burning process and a burning boiler for processing high-density saliferous organic wastewater. The burning boiler comprises a down heat insulation boiler cavity, a multilevel radiation cooling chamber, a convection heat exchange chamber, an ash blowing device, a steam outlet pipe and a steam pocket. The down heat insulation boiler cavity comprises a waste liquid atomizing spraying gun, a two-layer auxiliary gas burner, a secondary air nozzle, an air flow shielding device, a water cooling wall, a fireproof material, a compensation fuel gas burner, a liquid slag removing device and a root portion air nozzle. A radiation heat exchange chamber I comprises a water cooling wall, a fireproof material and a flow guide device. The convection heat exchange chamber comprises a water cooling wall and a convection screen. The burning process effectively controls and optimizes the problems of stable complete burning of heat value high-moisture waste liquid, heating surface slag bonding and ash accumulation, tail heating surface low temperature corrosion, NOX discharge and the like, has good processing effect on the high-density saliferous organic wastewater, achieves effective recycle of resources and is suitable for organic wastewater burning processing of chemical industries.

Owner:BEIJING NATION POWER GRORP +1

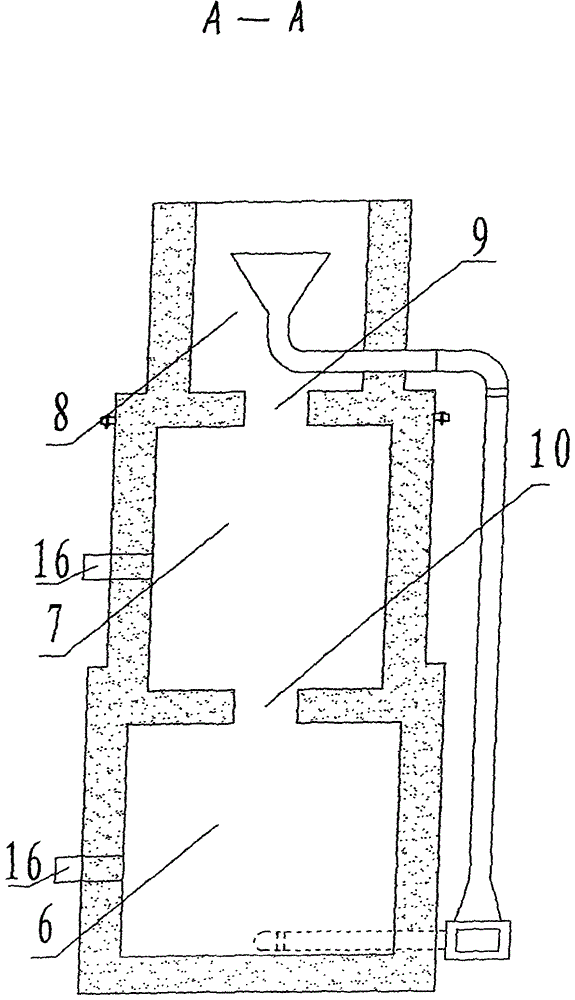

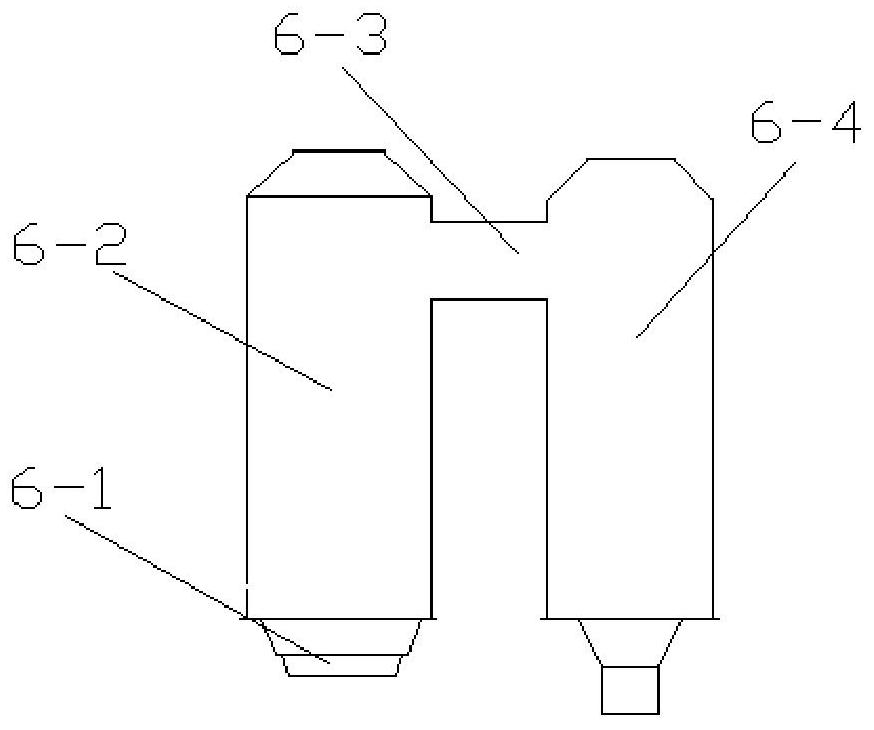

Medical waste incinerator applied with oxygen-enriched combustion technology

ActiveCN104006391AAvoid low temperatureBurn completelyIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberCombustible gas

The invention discloses a medical waste incinerator applied with the oxygen-enriched combustion technology, and belongs to the field of environmental-friendly and energy-saving devices. The medical waste incinerator comprises an incinerator body, a second combustion chamber, a combustion air fan, an oxygen-enriched air supply system and a smoke tail processing system. Combustible components of medical waste are decomposed into combustible gas (smoke) in the incinerator body, and combustible gas enters a second combustion chamber body and flows downwards; the combustion air fan delivers combustion air into the incinerator body and the second combustion chamber body; the oxygen-enriched air supply system is used for generating oxygen-enriched gas and leading the oxygen-enriched gas into the second combustion chamber body; the smoke is contacted with the common combustion air and the oxygen-enriched gas which enters into the second combustion chamber respectively, turbulence and perturbation are formed in a main combustion zone by the smoke, and therefore the fact that waste gas burns out is facilitated. According to the medical waste incinerator applied with the oxygen-enriched combustion technology, the burning temperature of the waste gas of the incinerator is guaranteed to the maximum extent through oxygen-enriched equipment and a secondary air system, the second combustion chamber is facilitated to form turbulent flow, the staying time of the smoke in the second combustion chamber is prolonged, and therefore dioxin is decomposed.

Owner:路宁 +1

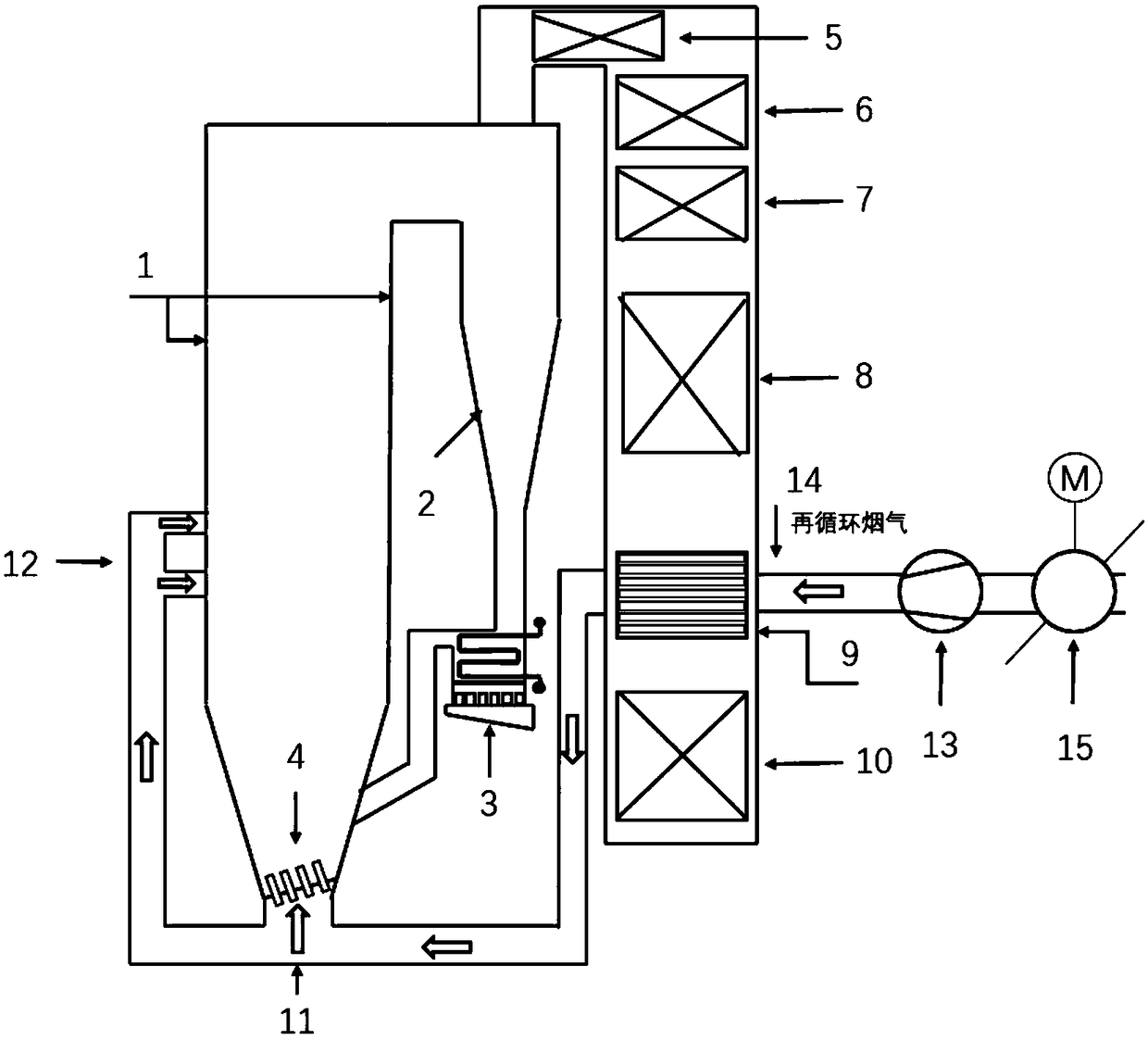

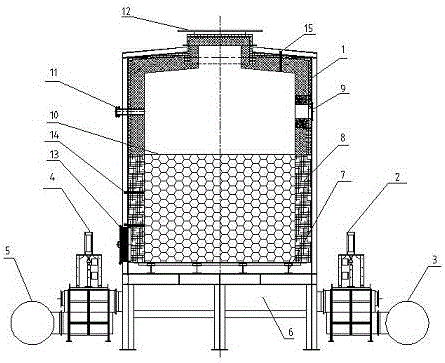

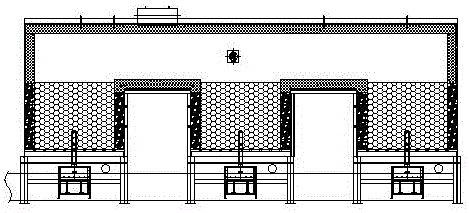

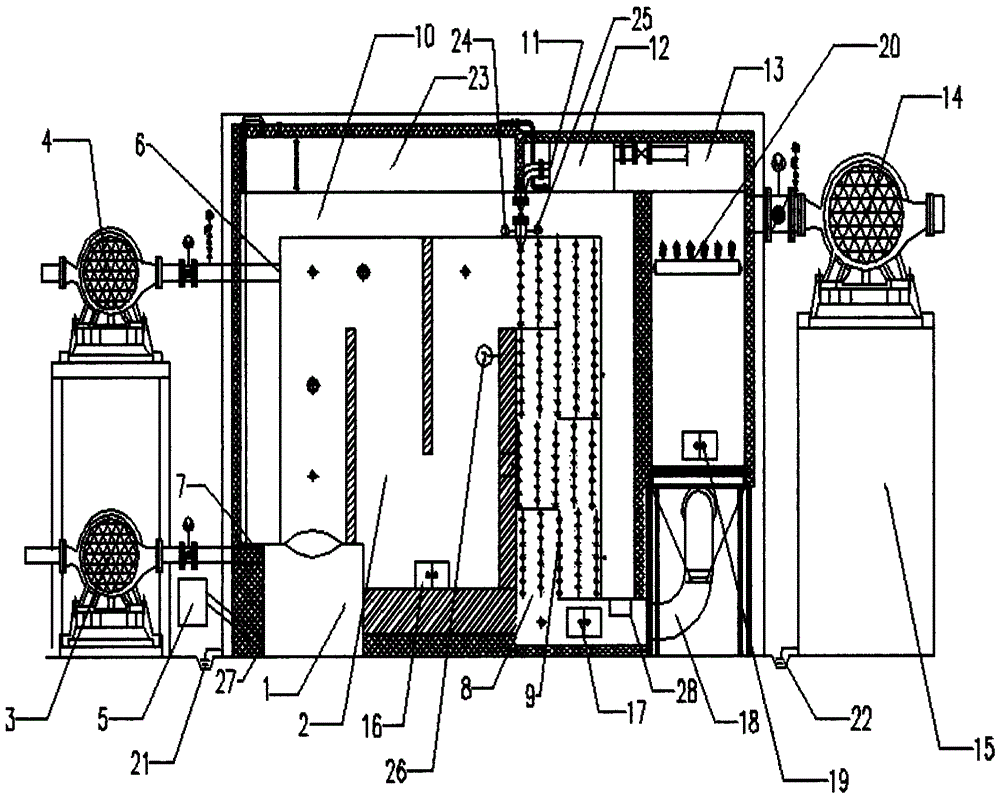

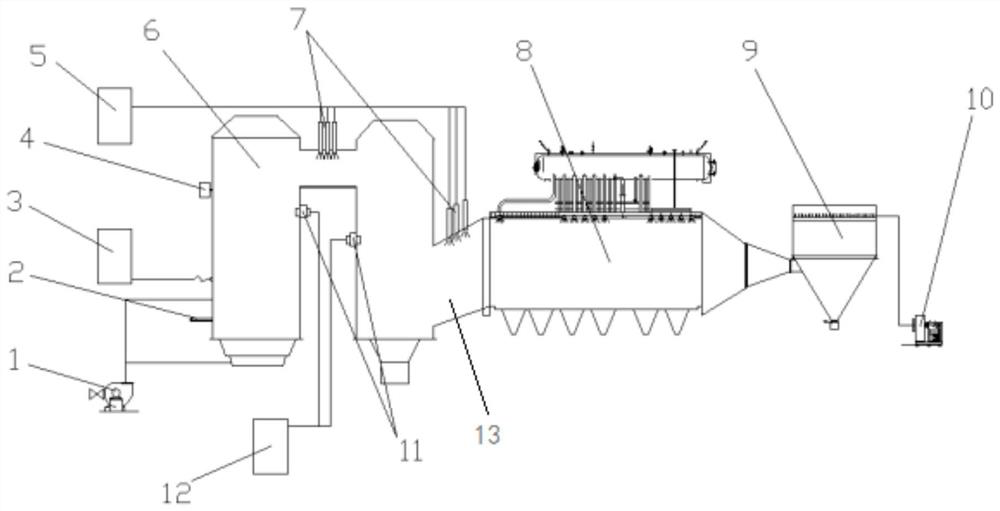

Circulating fluidized bed boiler applicable to garbage incineration

InactiveCN108758651AOvercoming the problem of insufficient combustion temperatureReduce heat absorptionFluidized bed combustionIncinerator apparatusAir volumeEvaporation

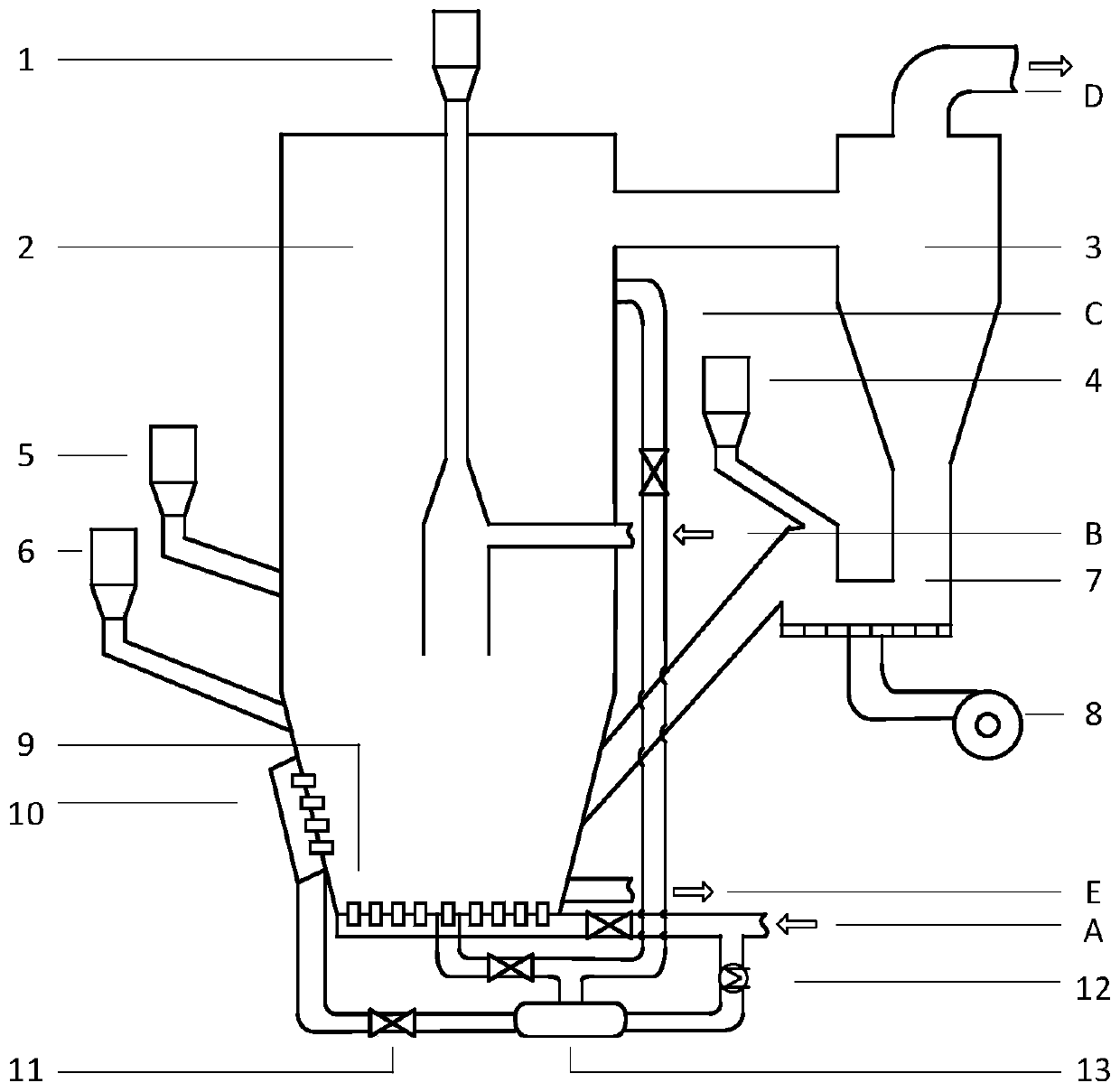

The invention discloses a circulating fluidized bed boiler applicable to garbage incineration. The circulating fluidized bed boiler applicable to garbage incineration comprises a hearth, an air distribution device, a separator, a material return valve, an external bed heat exchanger, a tail flue, a water-cooling pipe bundle, an evaporation pipe bundle, a low-temperature superheater, a coal economizer, a recirculating smoke heat exchanger, an air pre-heater and the like. According to the circulating fluidized bed boiler applicable to garbage incineration, an in-boiler water-cooling wall is completely poured-covered with a refractory material, so that a high combustion temperature of the circulating fluidized bed boiler is ensured. Meanwhile, recirculating smoke is heated by virtue of hot smoke in the tail flue, so that charge heat is increased, and the combustion stability of garbage incineration in the circulating fluidized bed boiler is further improved. The heated recirculating smokeis mixed with primary air and secondary air, so that a primary air amount used for fluidization is reduced while an air temperature is increased, the effect of enhanced graded combustion is further achieved, and the original generation of NOx is reduced. The problem of insufficient heating surface in the heat-insulation hearth is solved through arranging a high-temperature superheater in an external bed; and meanwhile, the problems of high-temperature corrosion of smoke, and coking in a biomass and garbage incineration process, are greatly solved.

Owner:HUANENG CLEAN ENERGY RES INST

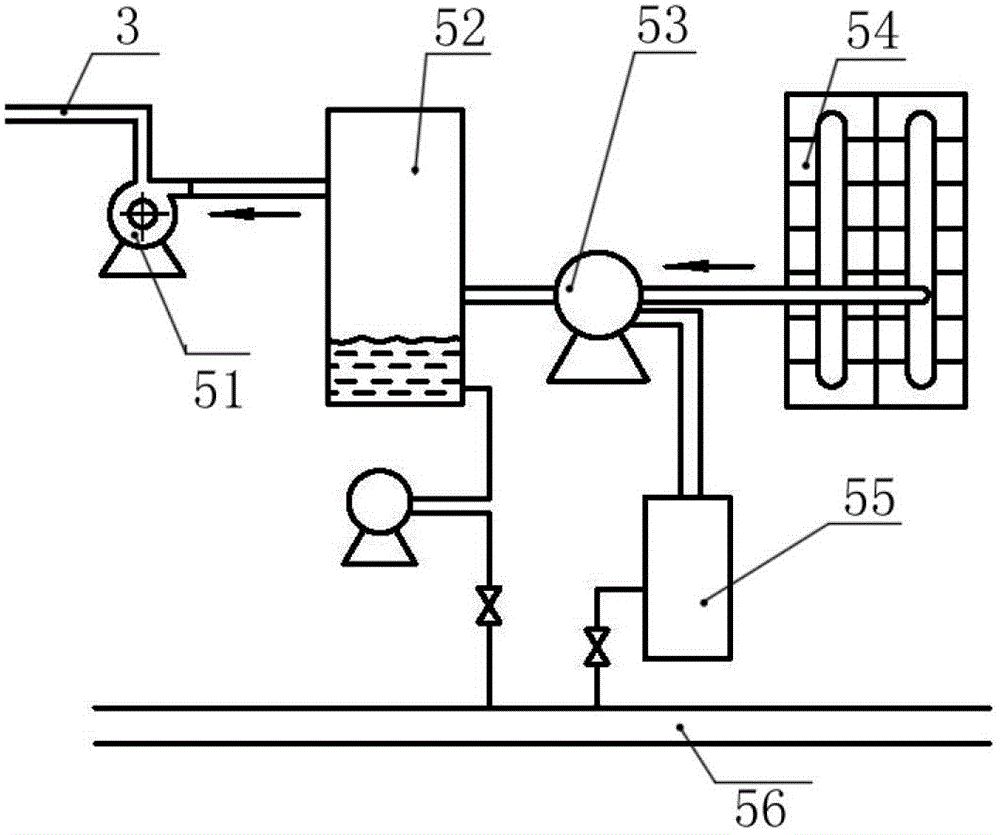

Hot-pipe type organic waste liquor treatment system

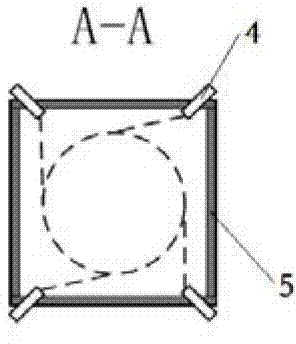

InactiveCN1367344AReduce processing costsGood controlIncinerator apparatusLiquid wasteCombustion chamber

The heat pipe organic waste liquor treatment equipment is characterized by that the combustion furnace and concentration device are integrated into one body, in which the cold water part of combustion chamber of combustion furnace, internal top wall and four side-walls of U-shaped fly ash settling chamber and heated face of water-cooling partition wall adopt heat-pipe water-cooling structure. Itsconcentration device is divided into two circulating loops respectively formed from heater, separator, circulating pump and balance box, the heat-pipe to end of heat-pipe water-cooling structure is communicated with heater, and the bottom end of heat pipe is communicated with return pipe of heater.

Owner:广西绿洲热能设备有限公司

Method for preparing high-grade secondary zinc oxide in rotary kiln through oxygen enriched combustion

The invention is a method for preparing high-grade zinc oxide by oxygen-enriched combustion in a rotary kiln. The steps are: preparation of zinc-containing materials: processing zinc-containing raw materials from various sources to make them meet the requirements of zinc-containing 6-20%, Moisture content of 10-20% is required, and the particle size is less than 1cm; Mixture ingredients: mix fuel with zinc-containing materials, the fuel accounts for 25-35% by mass in the mixture or the calorific value of the mixture is 1500-2000 Kcal / kg; put the mixture into the rotary kiln, and blow in oxygen-enriched air for combustion, so that zinc is enriched in the form of zinc oxide in the dust, and iron is enriched in the kiln slag; the dust is collected to obtain secondary zinc oxide products. The invention aims at the complex material rotary kiln volatilization process, first solves the combustion control problem, ensures the combustion temperature, and the kiln condition is stable, and then performs the fuel ratio according to the heat required for the reaction, thereby improving the kiln condition, increasing the combustion efficiency, and the rotary kiln treatment Quantity, secondary zinc oxide powder quality and recovery rate, while reducing energy consumption and saving costs.

Owner:GREENNOVO ENVIRONMENTAL TECH CO LTD

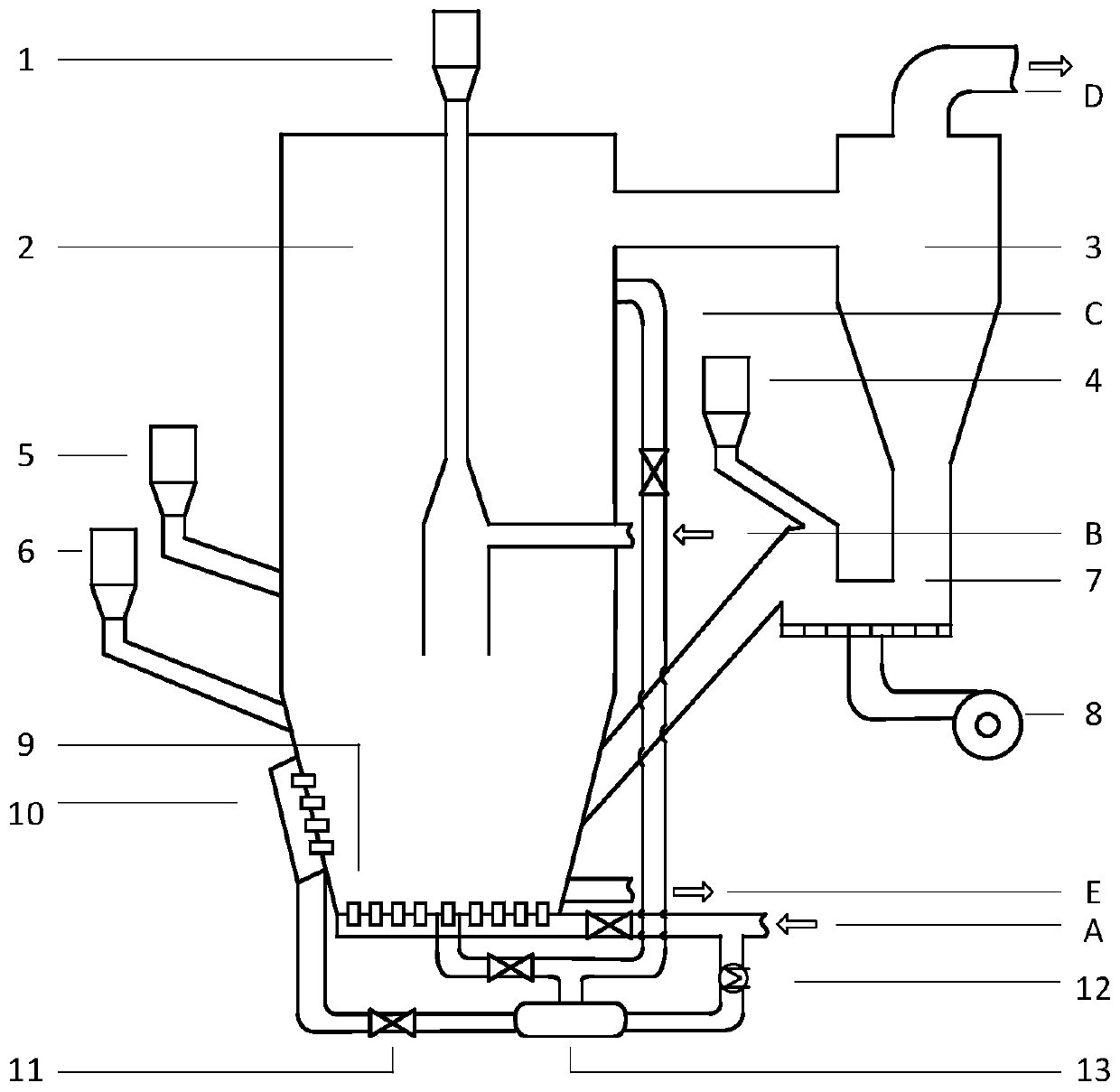

Combustion recycling system for gasified fly ash of fluidized bed

ActiveCN110260302AIncrease disturbanceExtended stayFluidized bed combustionIndirect carbon-dioxide mitigationCombustionFluidized bed

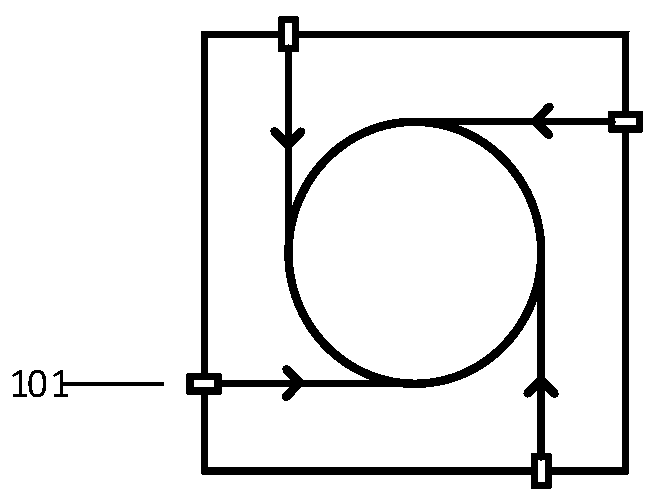

The invention discloses a combustion recycling system for gasified fly ash of a fluidized bed. The combustion recycling system for the gasified fly ash of the fluidized bed comprises a first fuel bin, a cyclone separator, a limestone bin and an air film separator, wherein the first fuel bin is arranged on the upper portion of a furnace hearth, and conveys fuel through a gradual enlargement pipeline to a boundary position of a furnace hearth dense phase zone and a furnace hearth lean phase zone, an inlet of the cyclone separator is connected with an outlet of the furnace hearth, an outlet of the cyclone separator is connected with an inlet of an ash bucket, an outlet of a gasified fly ash bin is connected with the ash bucket, an air blower is connected with the ash bucket, an outlet of the ash bucket is connected with the downside dense phase of the furnace hearth, the limestone bin is connected with the middle of the furnace hearth, a second fuel bin is connected with the downside dense phase zone of the furnace hearth, a downside wind distribution plate is arranged on an inclined plane on the bottom side of the furnace hearth, a bottom wind distribution plate is arranged at the bottom of the furnace hearth, the air film separator is arranged on the lower side of the exterior of the furnace hearth, an inlet of the air film separator is connected with an outlet of an air compressor, and an outlet of the air film separator is respectively connected with an over fire air pipeline, the bottom wind distribution plate and the downside wind distribution plate. The combustion recycling system for the gasified fly ash of the fluidized bed can achieve efficient consumption of the gasified fly ash in a circulating fluidized bed boiler, and reduces fuel consumption and NOx discharge amount of the circulating fluidized bed boiler on the premise of effectively using the gasified fly ash.

Owner:XI AN JIAOTONG UNIV

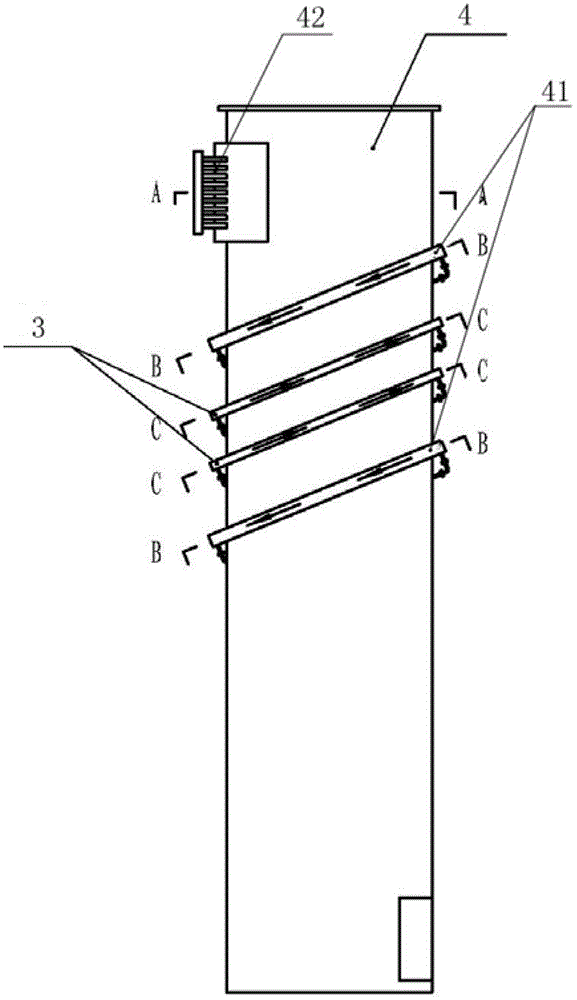

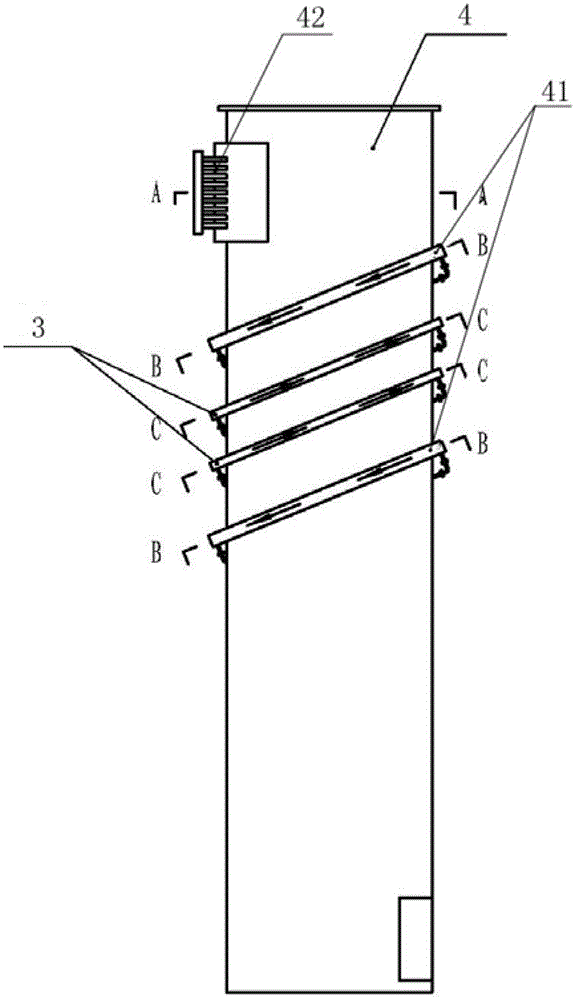

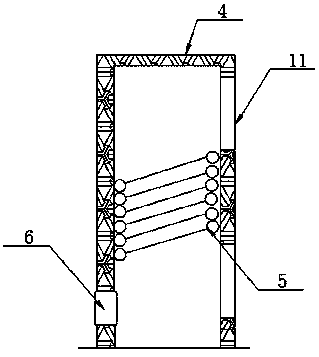

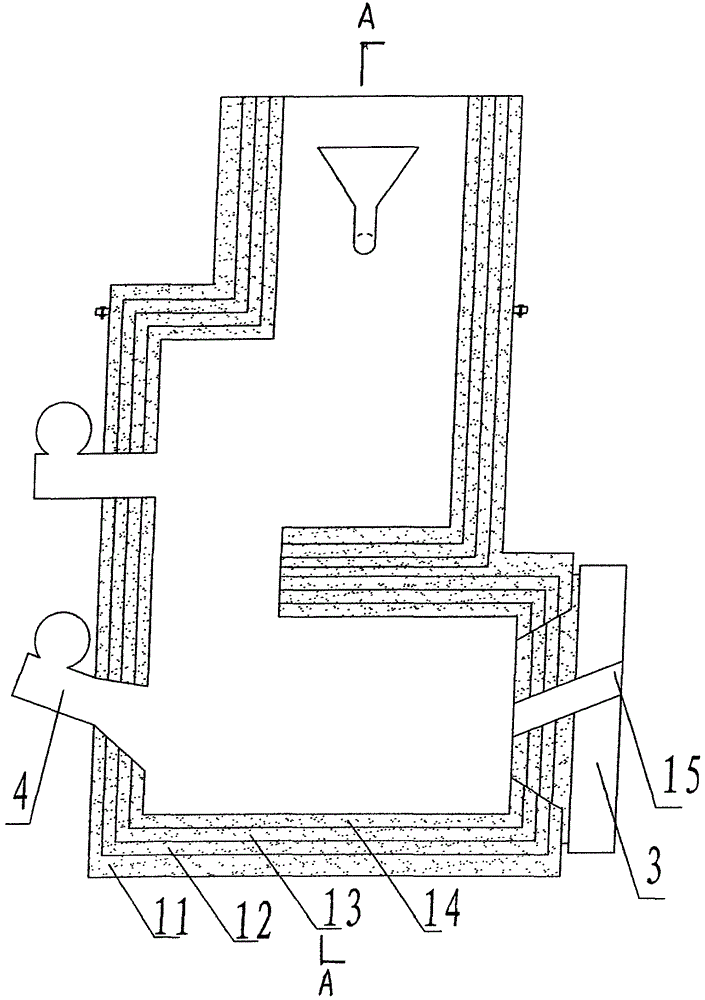

Biomass particle boiler with compact arrangement, small capacity and large output

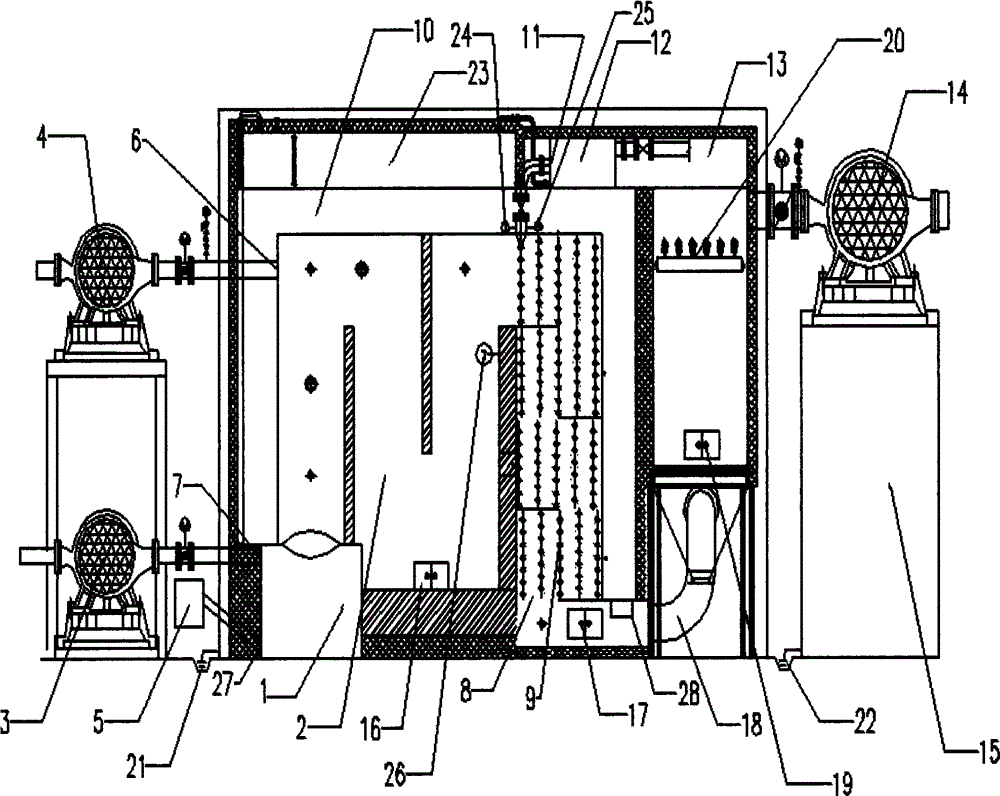

InactiveCN104832903AReduce insulation thicknessComplete heat exchangeLiquid degasificationBoiler controlIntelligent control systemCombustion chamber

The invention relates to a biomass particle boiler with compact arrangement, small capacity and large output. The biomass particle boiler comprises an intelligent control system, a combustion chamber, a combustor, a smoke outlet, a primary fan, a secondary fan, an induced air fan, a deaerator, a heat exchange chamber, a bag type dust remover, a steam and water separator, a steam separating cylinder and a boiler water purifier, wherein the heat exchange chamber adopts a convection pipe bundle to exchange heat; the heat exchange chamber is separated into four areas from top to bottom, and spraying and blowing devices are arranged at the four areas. The biomass particle boiler has the advantages that by adopting the multi-surface surrounding type deaerator, under the condition of guaranteeing the combustion temperature in the boiler, the heat insulation thickness is reduced, and supplied water can be preheated; the combustion chamber is separated from the heat exchange chamber; the combustion chamber is arranged in a folding way, and a secondary air increasing type is adopted, so the complete combustion is guaranteed; the heat exchange chamber is separated into the multiple areas, so the heat exchange is complete on the basis of guaranteeing a clean pipeline, and the temperature of tail exhaust smoke is low; by adopting the bag type dust removal, the smoke flowing to the atmosphere is very clean; by adopting the compact type arrangement, the size of the whole boiler is minimum.

Owner:吴恩珍 +1

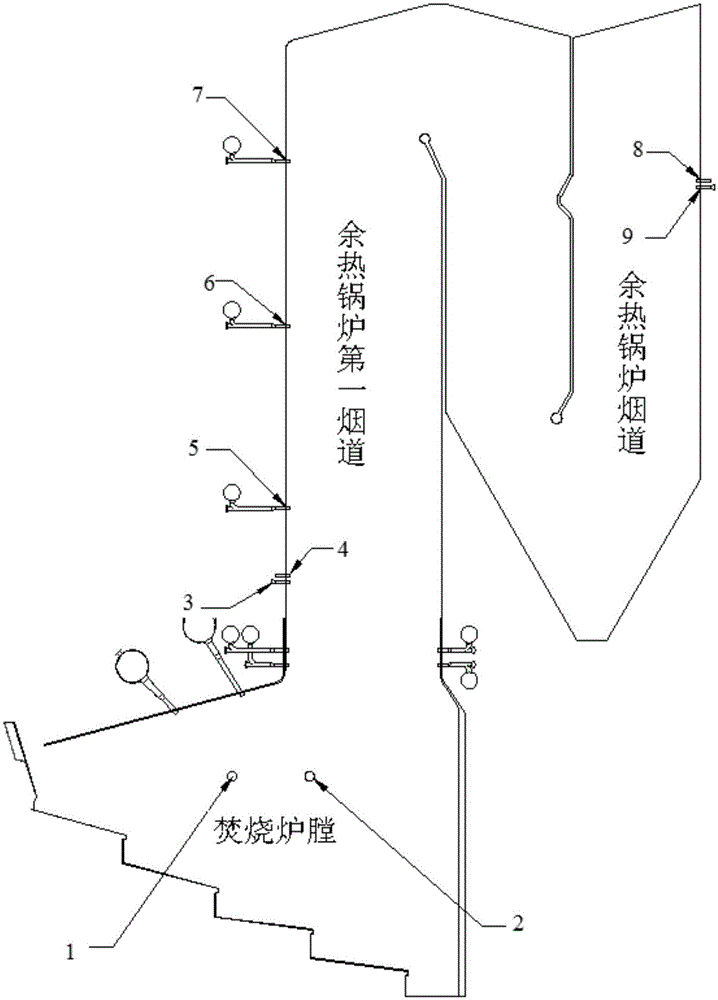

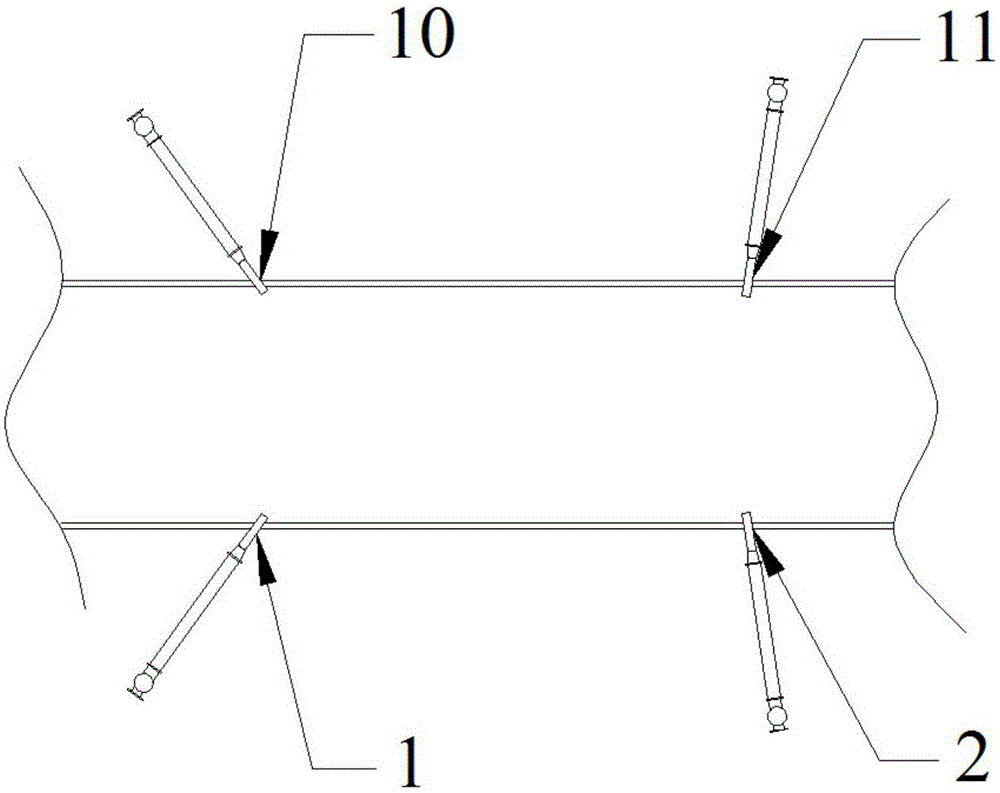

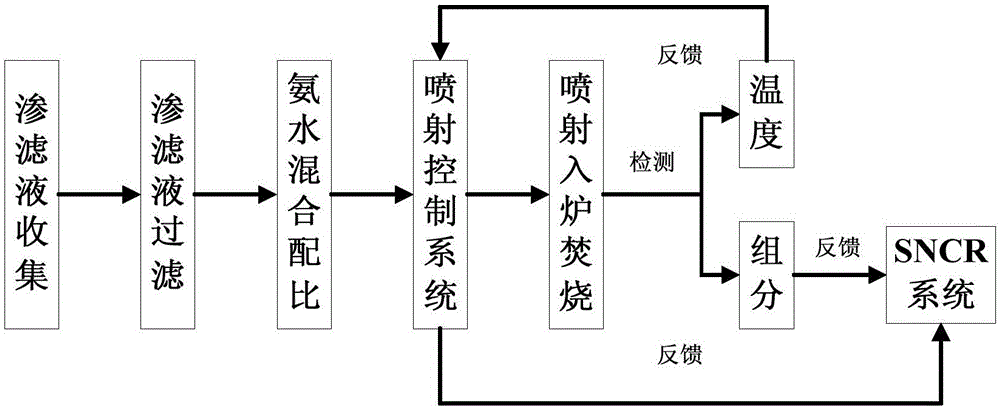

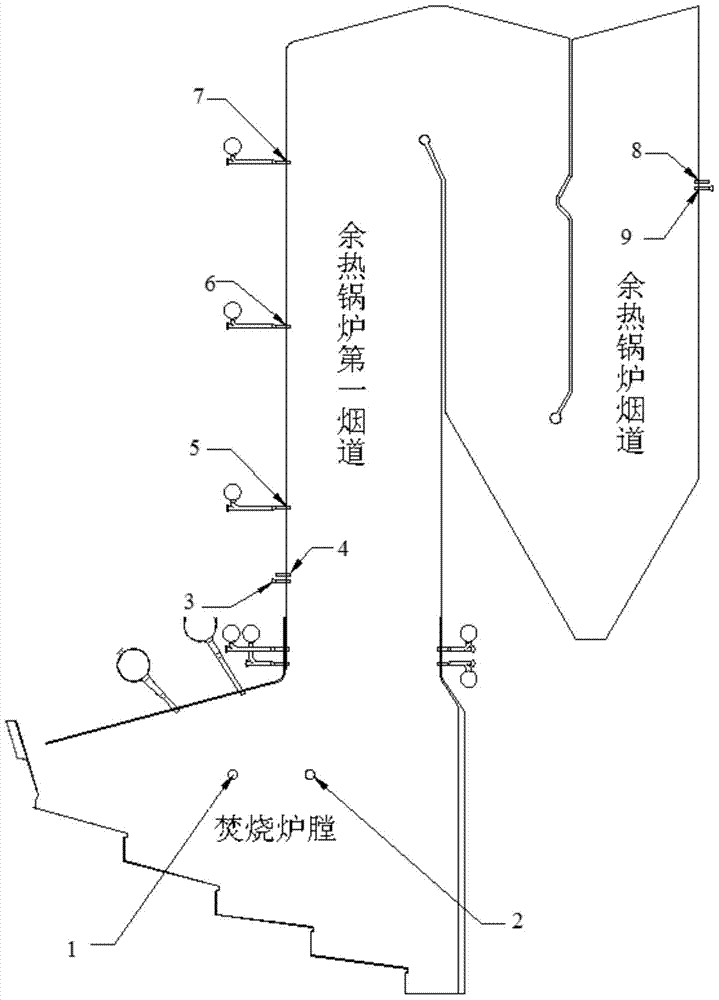

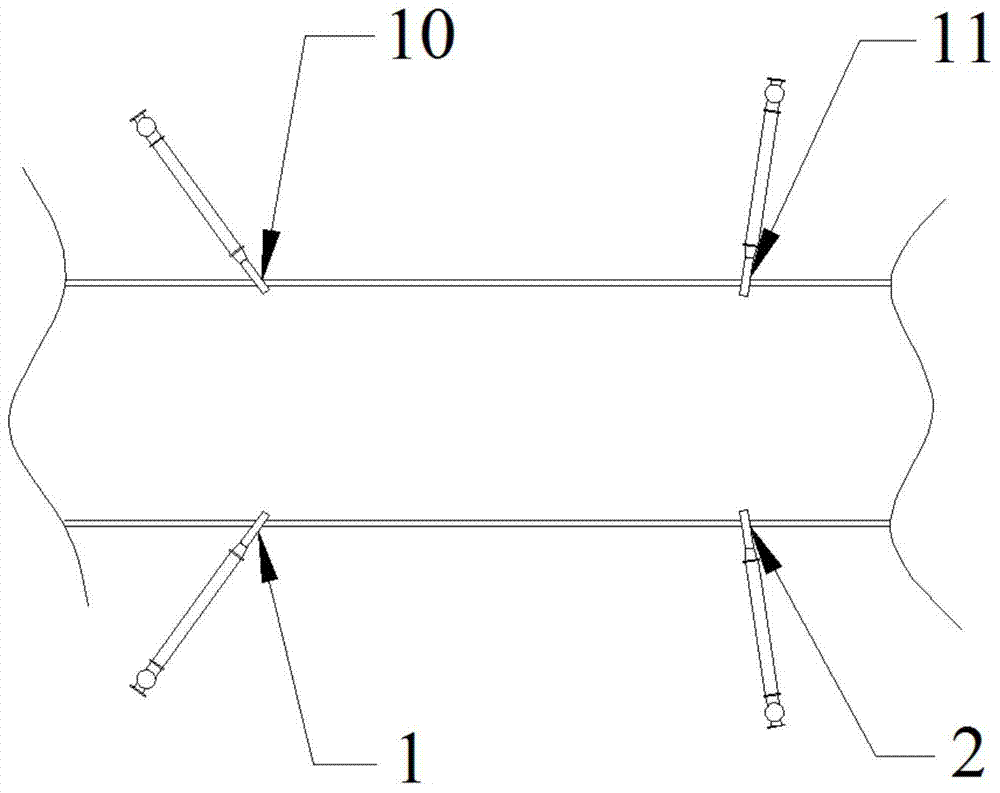

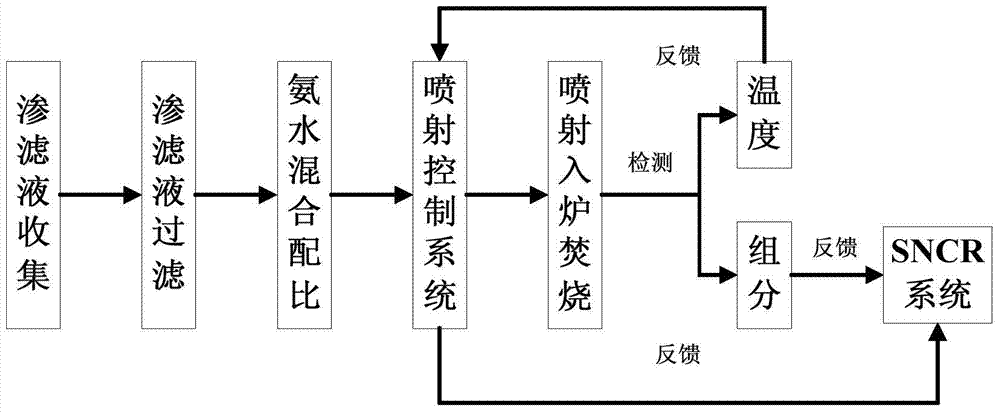

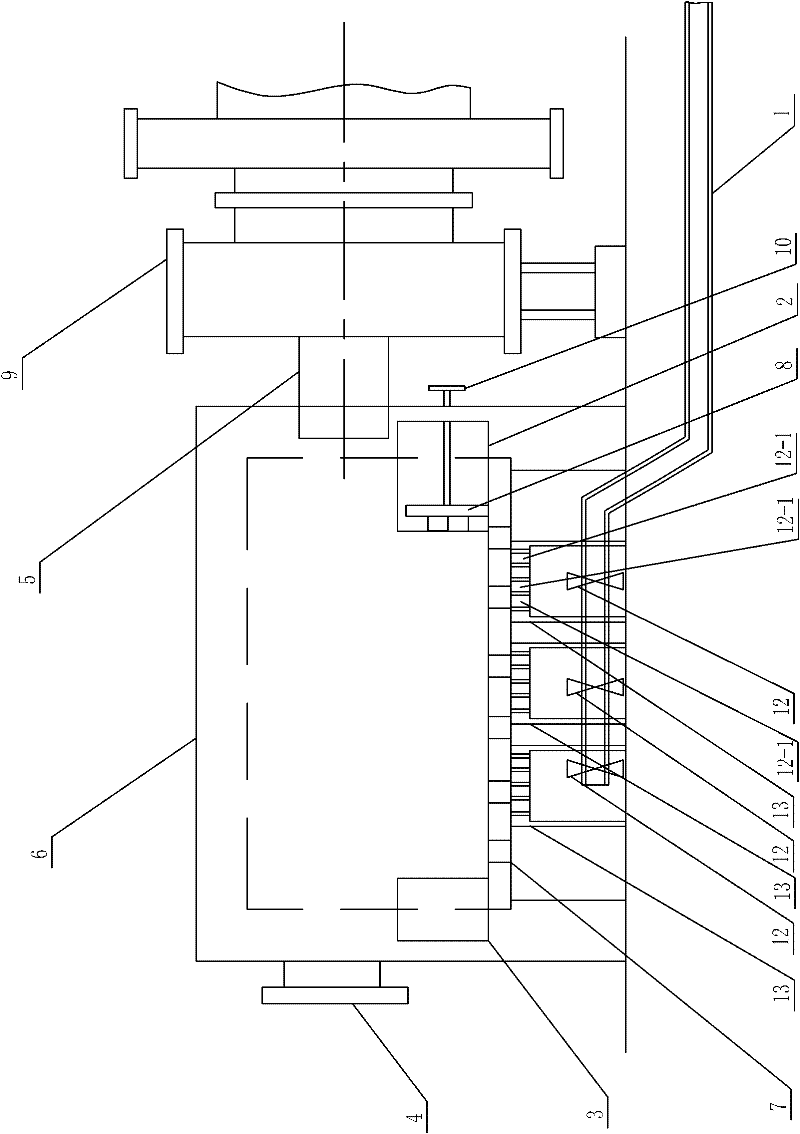

Leachate back-spraying denitration device and method for garbage incinerator

ActiveCN105157044ALow pricePracticalMultistage water/sewage treatmentIncinerator apparatusAmmonium hydroxideInfrared thermometry

The invention discloses a leachate back-spraying denitration device and method for a garbage incinerator. The device comprises a garbage leachate spray gun array, a thermocouple of a first flue, an infrared thermometer, an SNCR spray gun array and a sensor at a flue outlet. The method comprises the steps that leachate is firstly precipitated and filtered and is mixed with ammonium hydroxide, and according to the temperature value, flow control, automatic closing, clean water washing, adjustment on the mixed concentration of SNCR jet flow and ammonium hydroxide are carried out till the NOX value at the flue outlet meets the requirement. The leachate back-spraying operation can be sufficiently utilized, overall denitration is carried out through combination of mixed ammonium hydroxide and SNCR, water and compressed air sprayed into a denitration system are reduced, the temperature of a hearth of a boiler is guaranteed, and the usage amount of clean water, compressed air and electric power is greatly reduced. The device is low in price and high in practicability. The adopted method is simple, convenient and feasible and meets the requirement for environment protection. The method can be widely applied to various garbage incineration power plants and is wider in application prospect.

Owner:GZEPI HUACHENG ENVIRONMENTAL PROTECTION ENERGY CO LTD

Device guarantee regenerative thermal oxidizer (GRTO) capable of treating inflammable and explosive industrial organic waste gas more safely

The invention discloses a device guarantee regenerative thermal oxidizer (GRTO) capable of treating inflammable and explosive industrial organic waste gas more safely. The GRTO comprises an inlet gas flue, inlet gas switching valves, a furnace body, outlet switching valves, a purging air duct, an outlet flue and a burning system. Heat storage beds are filled with regular honeycomb ceramic heat accumulators, and the regular honeycomb ceramic heat accumulators are mainly made of dense cordierite and have the advantages of excellent acid, base and organic medium corrosion resistance, good heat storage effect, high heat recovery efficiency, small wind resistance, small coefficient of expansion caused by heat and contraction caused by cold, good anti-cracking ability, long service life and the like. All parts making contact with waste gas are coated with a high-temperature-resistant and corrosion-resistant coating, so that corrosion of the parts making contact with steel plates of the furnace body is avoided, and the relatively long service life of the furnace body can be guaranteed. The device GRTO can effectively decompose the organic waste gas into carbon dioxide and water vapor, the heat recovery rate is up to 95%, and the GRTO is safe, reliable, high in purification efficiency and suitable for organic waste gas treatment in multiple fields.

Owner:上海安居乐环保科技股份有限公司

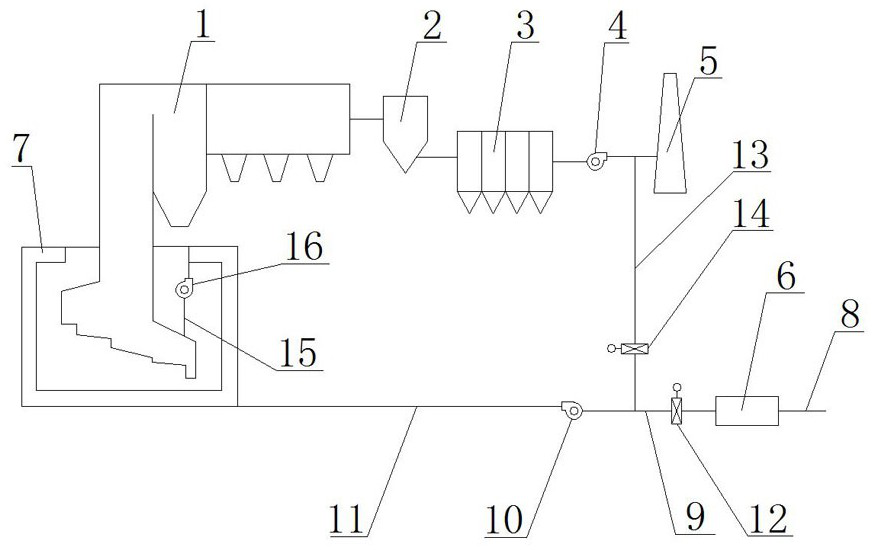

Flue gas recirculation system of household garbage incineration power plant

PendingCN113280351AIncreased inert gas contentSuppress generationEmission preventionIndirect carbon-dioxide mitigationAir preheaterInert gas

The invention discloses a flue gas recirculation system of a household garbage incineration power plant. The flue gas recirculation system comprises an incinerator, a reaction tower, a dust remover, an induced draft fan, a chimney and an air preheater, a flue gas outlet of the incinerator is connected with an inlet of the reaction tower, an outlet of the reaction tower is connected with one end of the dust remover, and the other end of the dust remover is connected with one end of the induced draft fan. The other end of the induced draft fan is connected with the chimney, air is introduced into one end of the air preheater, and the other end of the air preheater and the other end of the induced draft fan are connected with a secondary air chamber of the incinerator. According to the flue gas recirculation system of the household garbage incineration power plant, recycled flue gas replaces part of secondary air, so that the content of inert gas in a combustion area is increased, the flue gas absorbs heat, the concentration of oxygen is reduced, the flue gas and combustion-supporting air spread and combust in a high-temperature and low-oxygen atmosphere, the flame volume is multiplied, a local high-temperature area is reduced, temperature distribution is more uniform, generation of thermal NOx is inhibited, the coking problem of a hearth can be solved, and the heat efficiency and the generating capacity are improved.

Owner:CHINA TIANYING +1

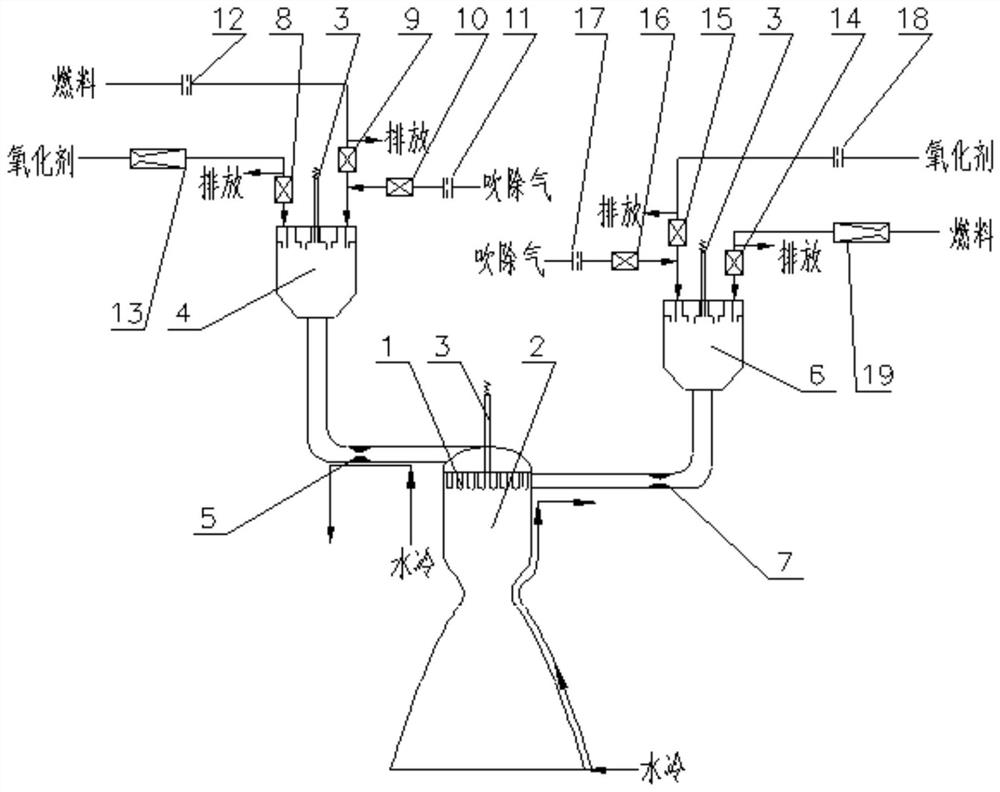

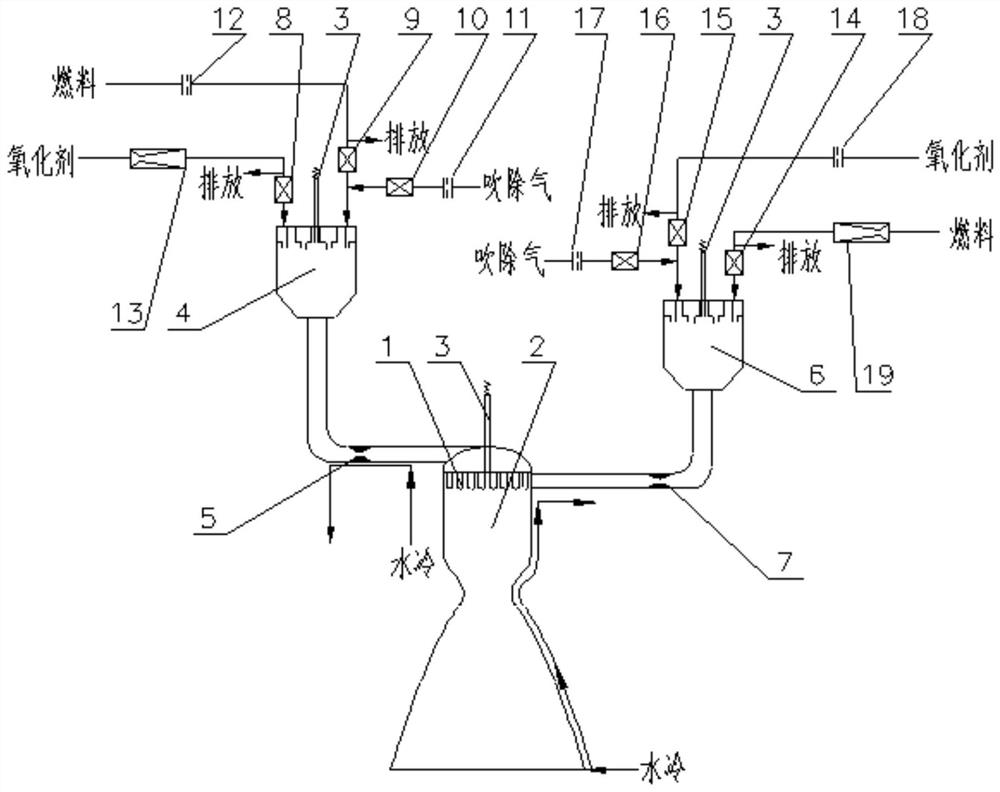

Gas-gas thrust chamber injector real supply condition thermal test device

ActiveCN112628026AFill in the gaps in hot test technologyRealize hot test simulationRocket engine plantsThrust chamberEngineering

The invention relates to the field of liquid rocket engines, particularly relates to a gas-gas thrust chamber injector real supply condition thermal test device, and aims to solve the problem that existing thrust chambers and injectors thereof are subjected to a thermal test aiming at liquid propellant blending combustion or gas-liquid blending combustion thrust chamber injectors, and both a test method and a test device cannot be used in a thermal test of a thrust chamber injector for gas-gas blending combustion. Both a test method and a test device cannot be used in a hot test of a thrust chamber injector for gas-gas blending combustion. The device comprises a thrust chamber test piece unit, an oxygen-enriched gas generator unit and a fuel-enriched gas generator unit, wherein the thrust chamber test piece unit comprises a thrust chamber test piece, the thrust chamber test piece is used for installing a tested injector, the oxygen-enriched gas generator unit comprises an oxygen-enriched gas generator, the fuel-enriched gas generator unit comprises a fuel-enriched gas generator, outlets of the oxygen-enriched gas generator and the fuel-enriched gas generator are connected with the thrust chamber test piece separately, and the oxygen-enriched gas generator and the fuel-enriched gas generator are used for supplying oxygen-enriched gas and fuel-enriched gas to the thrust chamber test piece.

Owner:XIAN AEROSPACE PROPULSION INST

A medical waste incinerator using oxygen-enriched combustion technology

ActiveCN104006391BAvoid low temperatureBurn completelyIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberEngineering

The invention discloses a medical waste incinerator applied with the oxygen-enriched combustion technology, and belongs to the field of environmental-friendly and energy-saving devices. The medical waste incinerator comprises an incinerator body, a second combustion chamber, a combustion air fan, an oxygen-enriched air supply system and a smoke tail processing system. Combustible components of medical waste are decomposed into combustible gas (smoke) in the incinerator body, and combustible gas enters a second combustion chamber body and flows downwards; the combustion air fan delivers combustion air into the incinerator body and the second combustion chamber body; the oxygen-enriched air supply system is used for generating oxygen-enriched gas and leading the oxygen-enriched gas into the second combustion chamber body; the smoke is contacted with the common combustion air and the oxygen-enriched gas which enters into the second combustion chamber respectively, turbulence and perturbation are formed in a main combustion zone by the smoke, and therefore the fact that waste gas burns out is facilitated. According to the medical waste incinerator applied with the oxygen-enriched combustion technology, the burning temperature of the waste gas of the incinerator is guaranteed to the maximum extent through oxygen-enriched equipment and a secondary air system, the second combustion chamber is facilitated to form turbulent flow, the staying time of the smoke in the second combustion chamber is prolonged, and therefore dioxin is decomposed.

Owner:路宁 +1

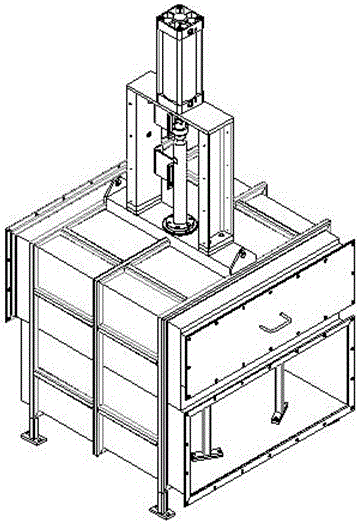

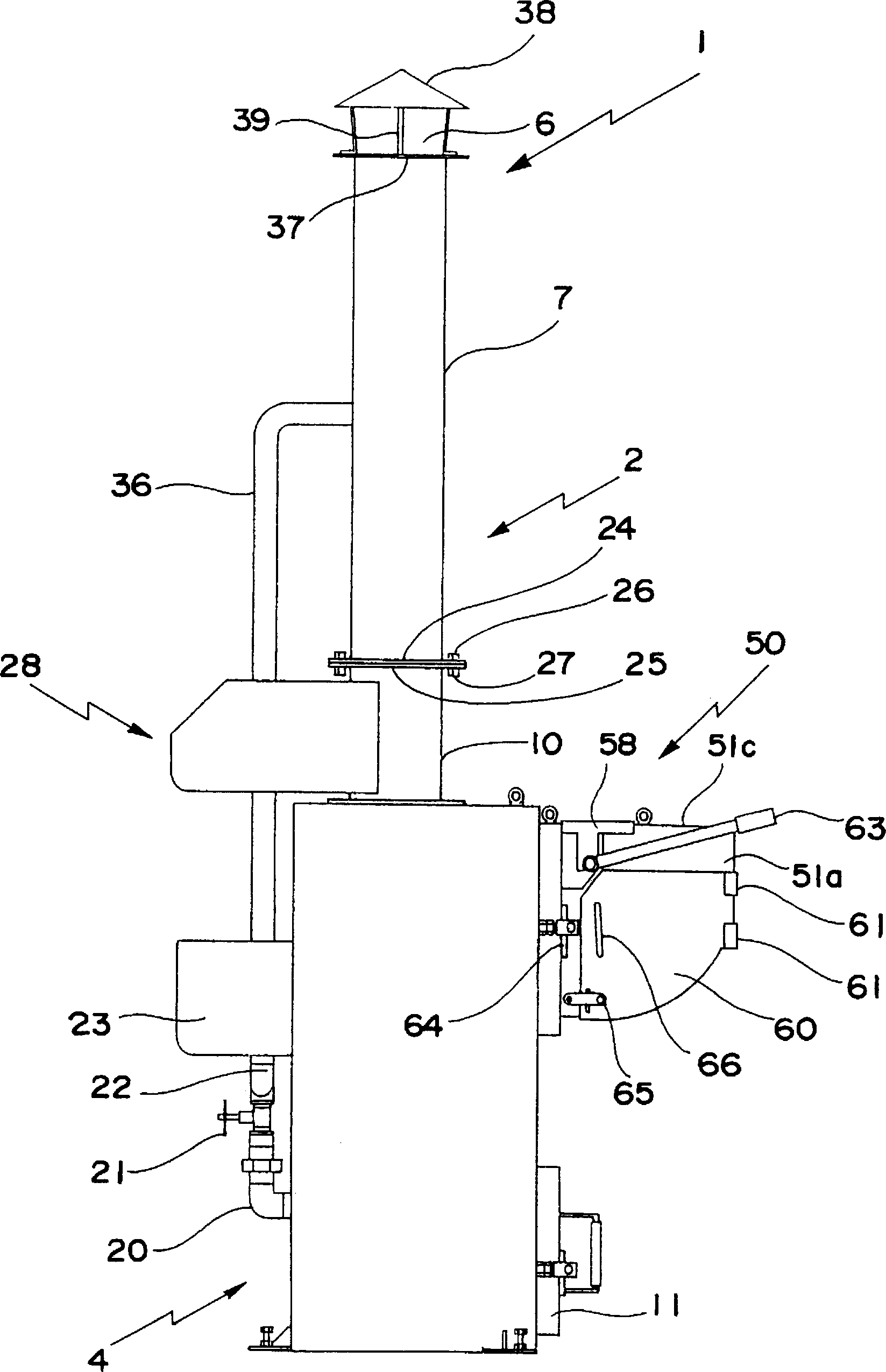

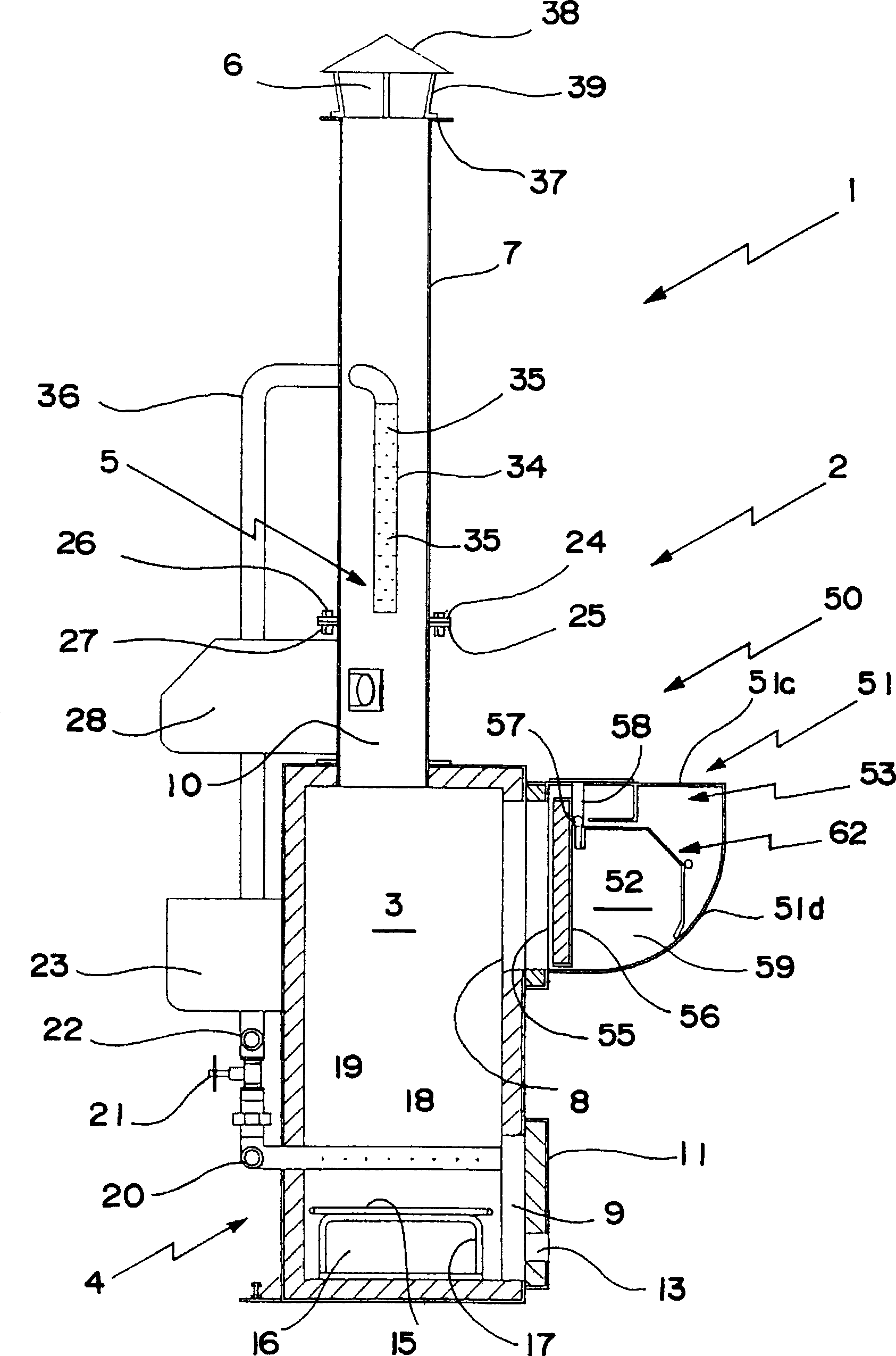

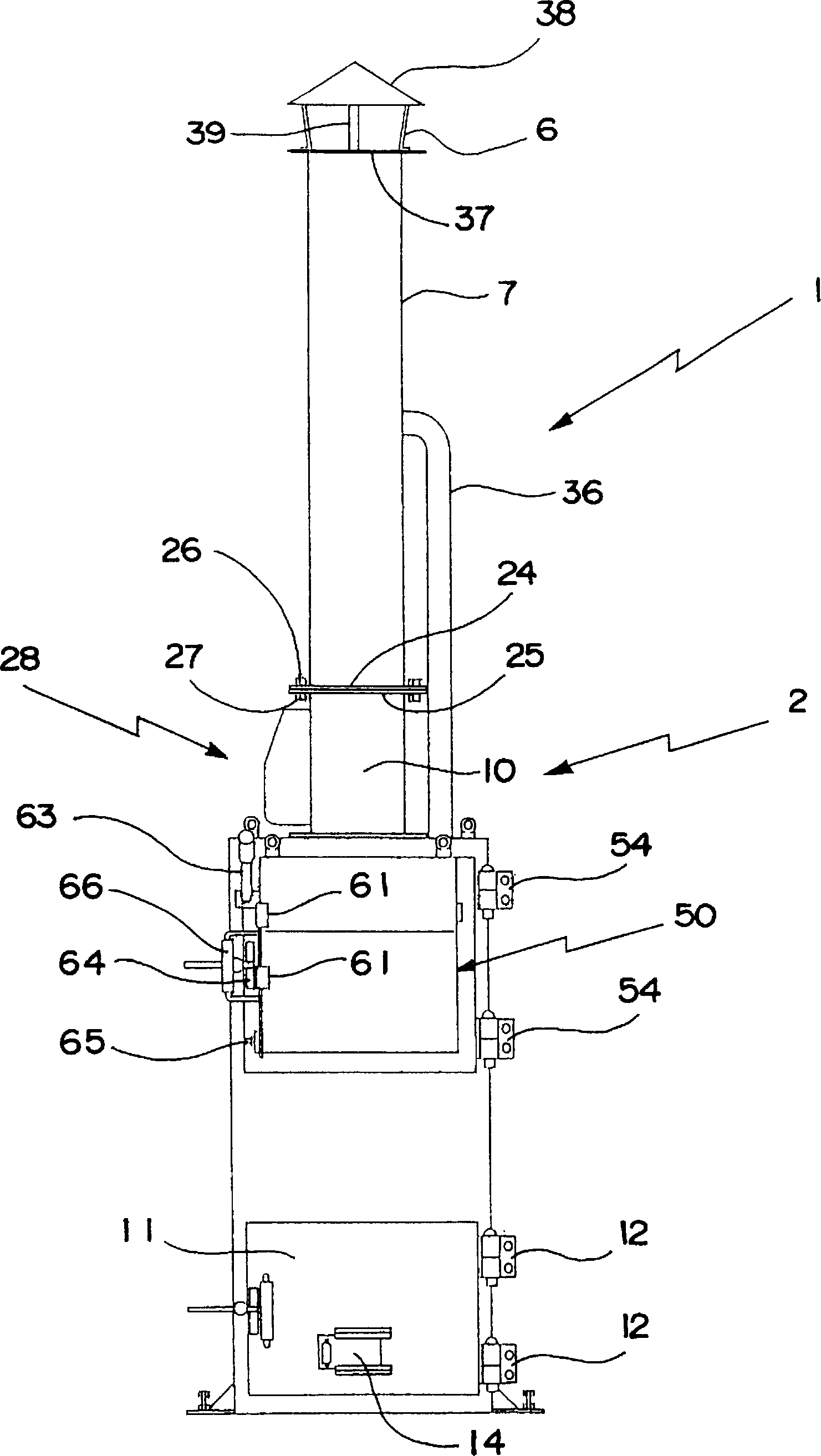

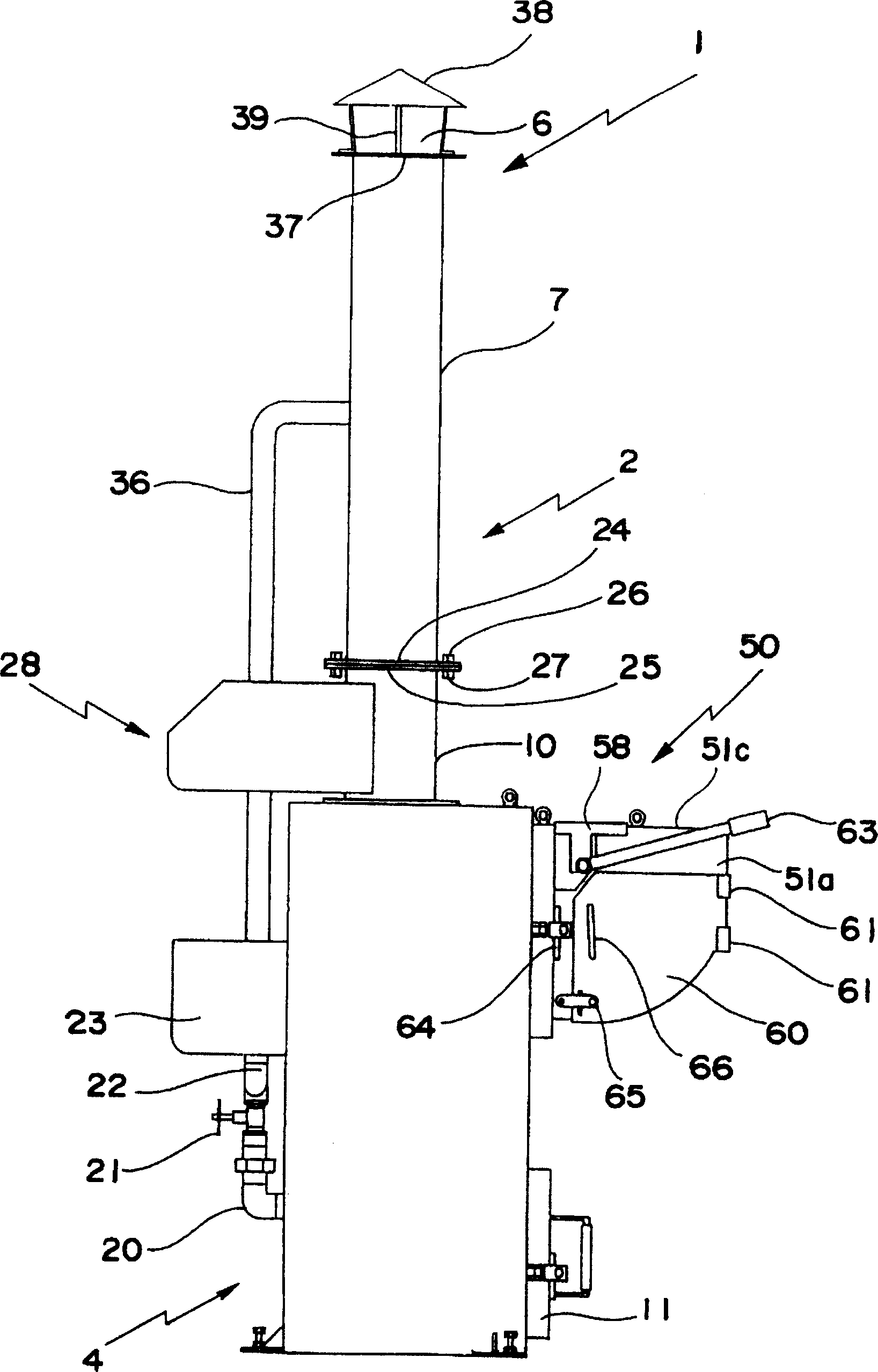

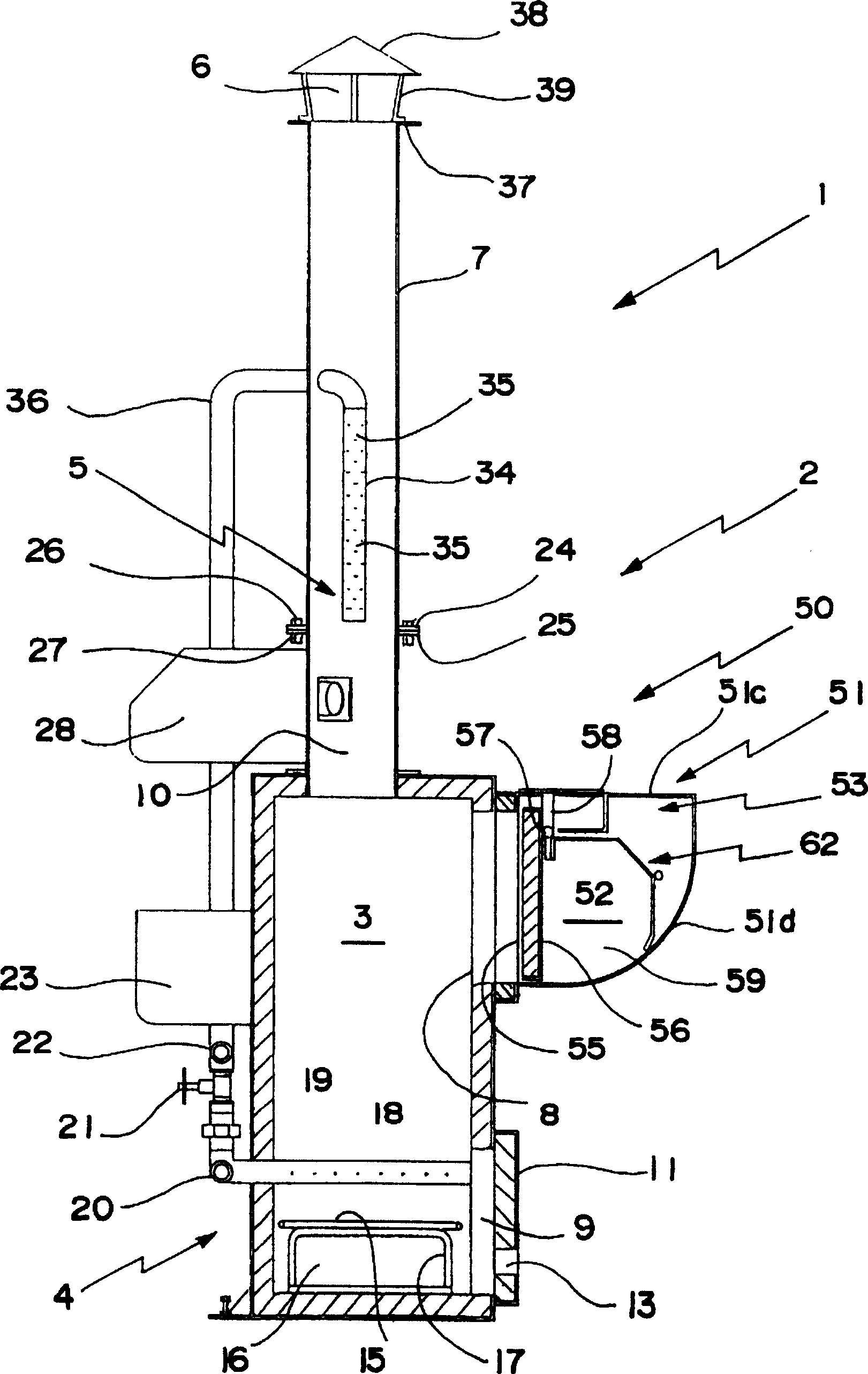

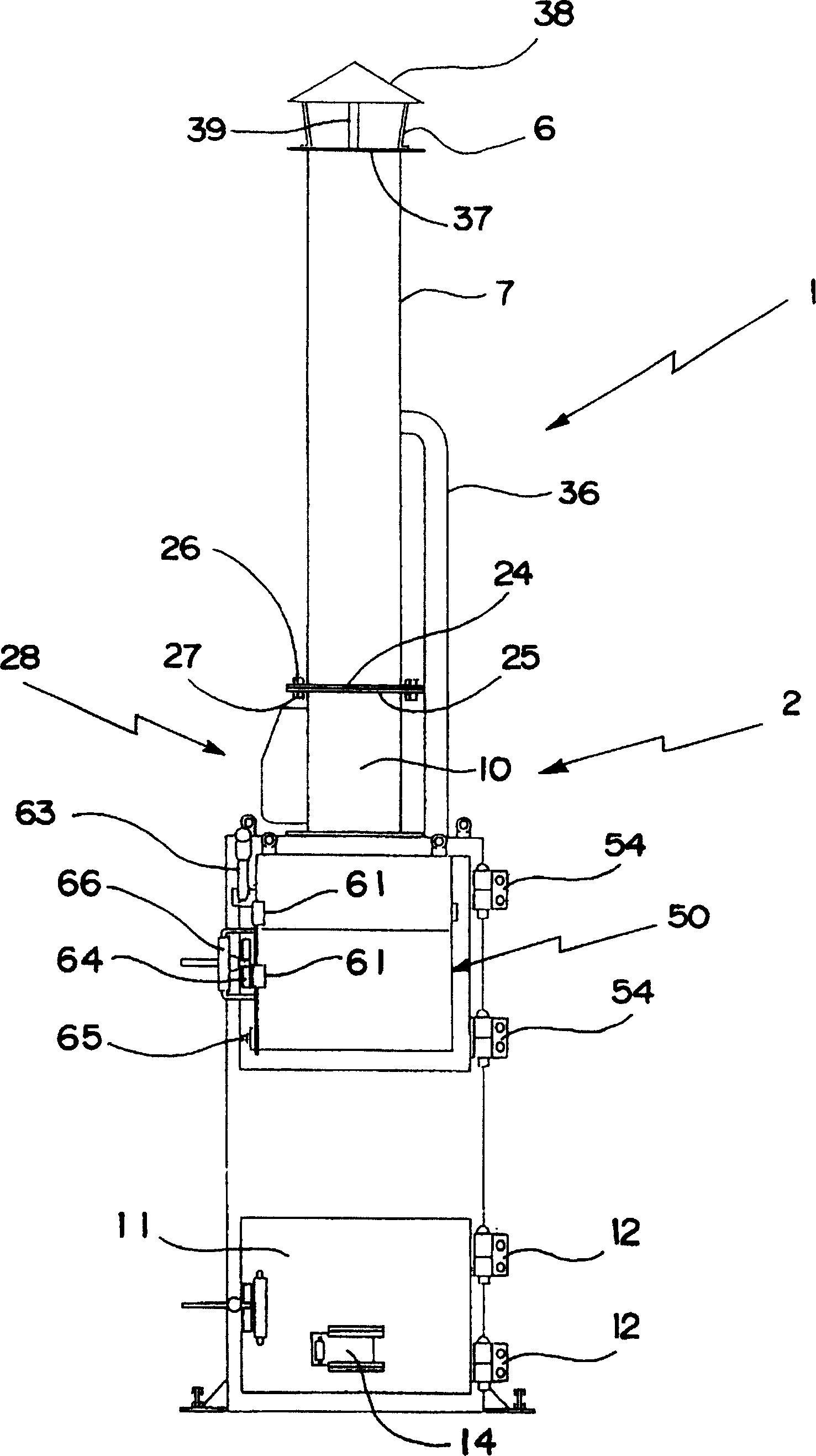

Small incinerator

InactiveCN1451905ASuppresses excretion to a very small levelPrevent inflowIncinerator apparatusCombustion chamberJoystick

The present invention is a small incinerator with an external air cut-off input device. The structure of the external air cut-off input device includes: a waste storage box with a waste storage room for temporarily storing waste, and a primary combustion chamber connected to the furnace body. An openable and closable opening and closing part airtight door and a waste input mechanism for inputting the waste temporarily stored in the waste storage room into the primary combustion chamber of the furnace body are provided between them. The structure of the waste input mechanism has: a waste moving plate that moves the waste stored in the waste storage chamber toward the primary combustion chamber of the furnace body; The airtight door is connected with the backward movement of the waste moving plate after throwing the waste into the primary combustion chamber of the furnace body to close the opening part and the movement operation lever of the airtight door.

Owner:和光机械工业株式会社

A device and method for back-spraying denitrification of leachate from a garbage incinerator

ActiveCN105157044BEmission reductionReduce dosageMultistage water/sewage treatmentIncinerator apparatusElectric powerStreamflow

The invention discloses a garbage incinerator leachate return spray denitrification device and method, comprising a garbage leachate spray gun array, a thermocouple of a first flue, an infrared thermometer, an SNCR spray gun array, and a sensor at the outlet of the flue. The method is to precipitate and filter the leachate and mix it with ammonia water. According to the temperature value, perform flow control and automatic shutdown and clean water cleaning, and adjust the SNCR injection flow rate and the mixed concentration of ammonia water until the NOX value at the flue outlet reaches the requirement. . It can make full use of the leachate back-spray operation, mix ammonia water and combine with SNCR for overall denitrification, reduce the water and compressed air injected into the denitrification system, ensure the temperature of the boiler furnace, and greatly reduce the clean water, compressed air and electricity dosage. The device is low in price and strong in practicability, the method adopted is simple and easy to implement, and meets the requirements of environmental protection, and can be widely used in various waste incineration power plants, and has broad application prospects.

Owner:GZEPI HUACHENG ENVIRONMENTAL PROTECTION ENERGY CO LTD

Energy-saving and environmentally-friendly combustion furnace for drier

ActiveCN102128544BGood preheating effectMeet the burning requirementsHeating arrangementSlagFlue gas

The invention discloses an energy-saving and environmentally-friendly combustion furnace for a drier, which relates to a combustion furnace and is used for solving the problems of high dust content of exhausted flue gas, the need of investment of dust removing equipment and sulfur removing equipment and the increase in power consumption and maintenance amount in the combustion process of conventional scattered coal. An oxygen supply pipeline of the combustion furnace is arranged at the bottom of a furnace body; a plurality of oxygen supply valves are arranged on the oxygen supply pipeline; a fire grate is clamped on the inner wall of the furnace body; a molded coal hole is formed on the furnace body; a slag outlet is formed on the furnace body; the molded coal hole and the slag outlet are horizontally arranged in sequence from right to left; the lower edges of the molded coal hole and the slag outlet and the upper end face of the fire grate are on the same horizontal plane; a transmission push plate is arranged in the furnace body; a piston type pull rod passes through the outer wall of the furnace body and is fixedly connected with the transmission push plate; and an observation port is formed at the left end of the furnace body. The combustion furnace is suitable for an indirect heat transfer rotary drum drier.

Owner:萝北瑞喆烯碳新材料有限公司

Small horizontal shell-type coal water slurry boiler

InactiveCN107763602AEasy dischargeEasy to disassemble and operateWater heatersSteam boilersCoal waterFlue

A small horizontal shell-type coal-water slurry boiler relates to the technical field of boilers; a fire tube is arranged in the boiler body, a steel frame is arranged at the bottom of the boiler body, a vertical flue is connected to one side of the boiler body, and a vertical flue is installed in the vertical flue There is a convection heating surface, the lower part of the vertical flue is provided with a dust removal door, the bottom of the vertical flue is provided with an ash bucket, the vertical flue is connected with the combustion chamber, and a burner is arranged on one side of the combustion chamber; The upper part of the vertical flue is provided with an ash door, one side of the ash door is provided with an ash platform, and one side of the ash platform is provided with a control room; the boiler body is connected with the dust collector, and the dust collector is connected with the dust collector. The induced draft fan is connected, and the induced draft fan is connected with the chimney through the tail flue. The small horizontal shell-type coal-water slurry boiler of the present invention can solve the problems of traditional small-scale horizontal shell-type coal-water slurry boilers and ash accumulation, ash discharge, and coking, and the smoke pipe at the rear tube plate of the boiler is not easy to be blocked by ash. The equipment has a long service life.

Owner:JIANGSU TIANMAI CHEM CO LTD

Efficient disturbance rotary incinerator

InactiveCN105864793AReliable technologyIncrease the level of automationIncinerator apparatusAir volumeCombustion chamber

An efficient disturbance rotary incinerator comprises an incinerator body. The incinerator body comprises a vertically-arranged vertical second combustion chamber and a transversely-arranged first combustion chamber. The vertical second combustion chamber comprises a vertical barrel. The first combustion chamber comprises a barrel and a first fire storage chamber arranged at the front end of the barrel, wherein the tail end of the barrel is connected with a smoke inlet. The first fire storage chamber comprises a cylindrical bin. A waste solid inlet pipeline is arranged on the side wall of the top end of the bin. An air volume adjusting pipeline is arranged in the center of the left side of the bin. One end of the air volume adjusting pipeline stretches into the bin. The part, exposed out of the bin, of the pipeline is provided with an airflow adjusting port vertically upward. The exposure end of the air volume adjusting pipeline is sealed. A waste slag and slurry inlet pipeline is arranged in the center of the exposure end of the air volume adjusting pipeline and internally provided with a first combustion-supporting gas pipeline. The tail end of the waste slag and slurry inlet pipeline is sleeved with a second combustion-supporting gas pipeline. A fire disc porous oxygen supplementing device is arranged on the periphery of the air volume adjusting pipeline and comprises an annular shell, and oxygen supplementing spray pipes evenly distributed around the circle center of the shell.

Owner:JIANGSU JINNIU ENVIRONMENTAL ENG EQUIP

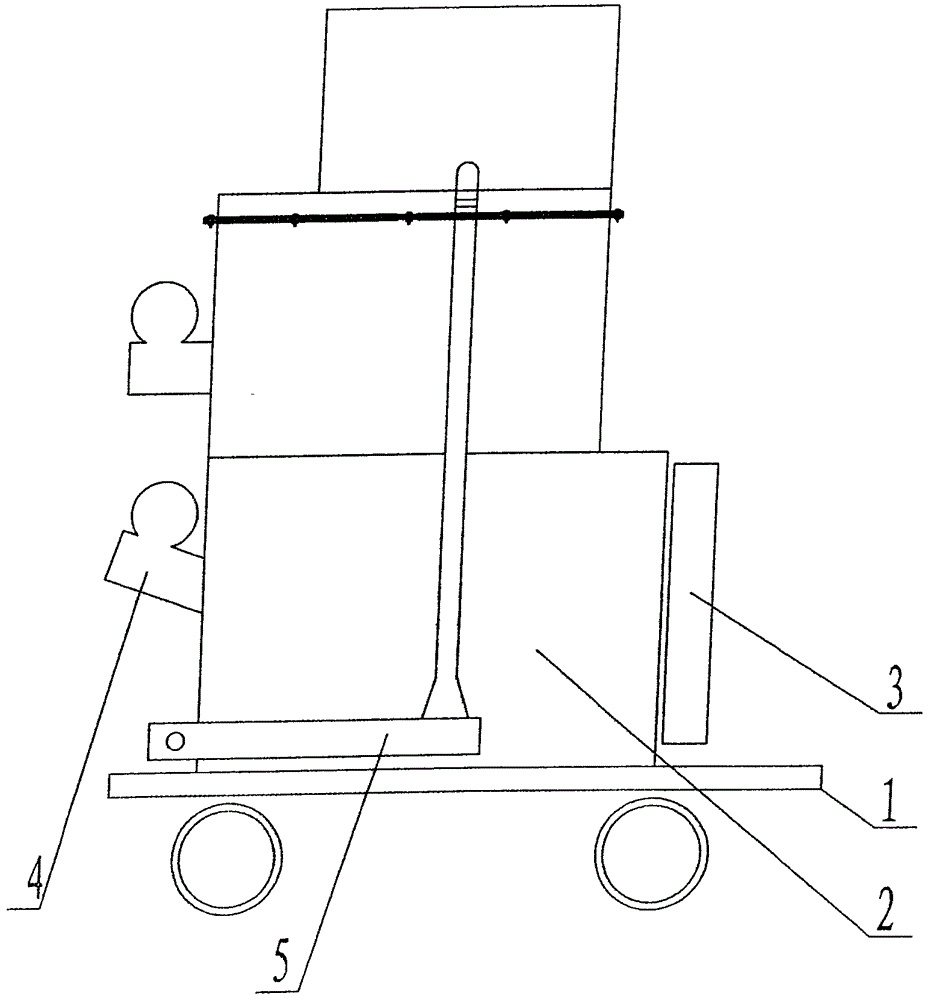

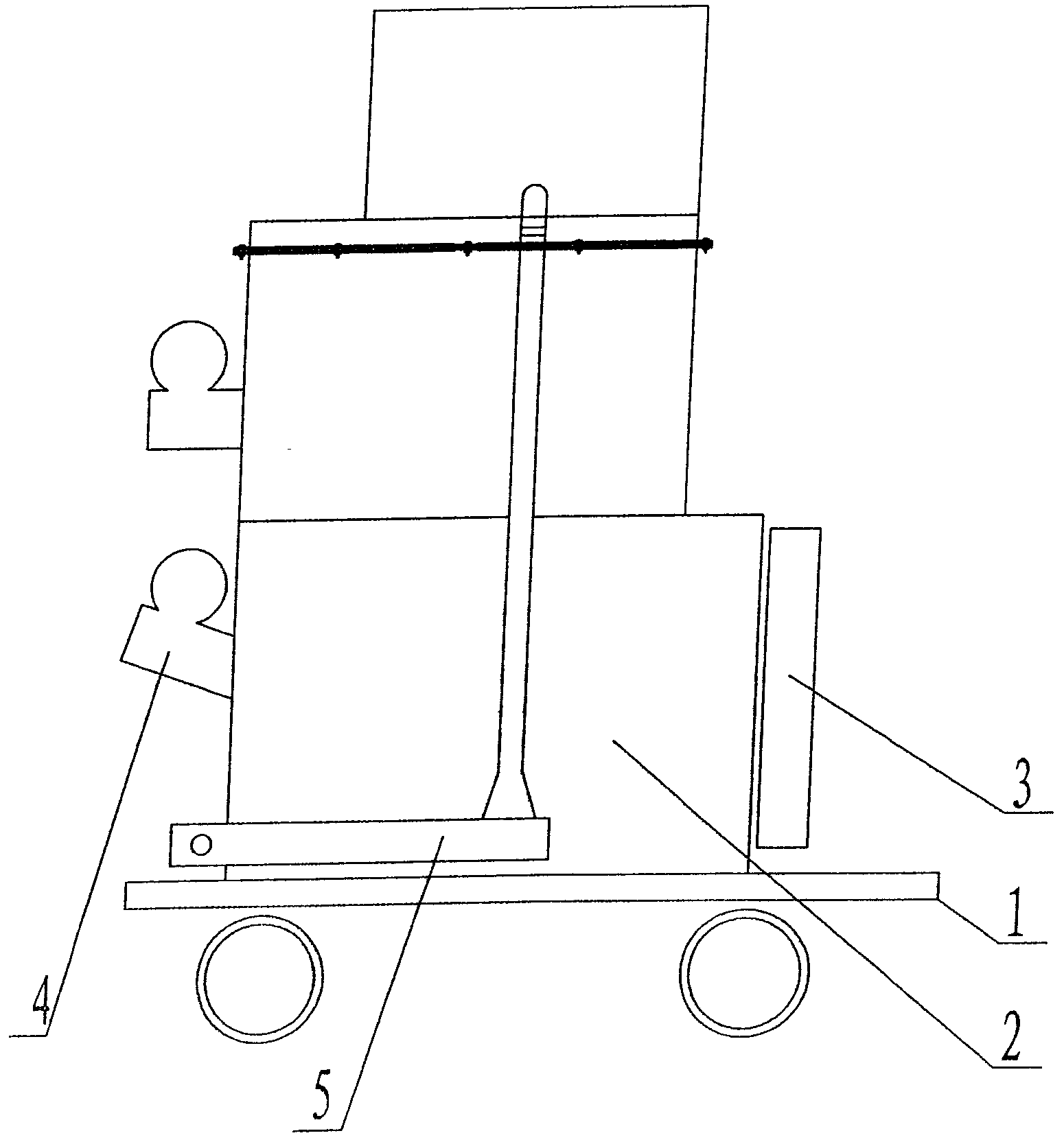

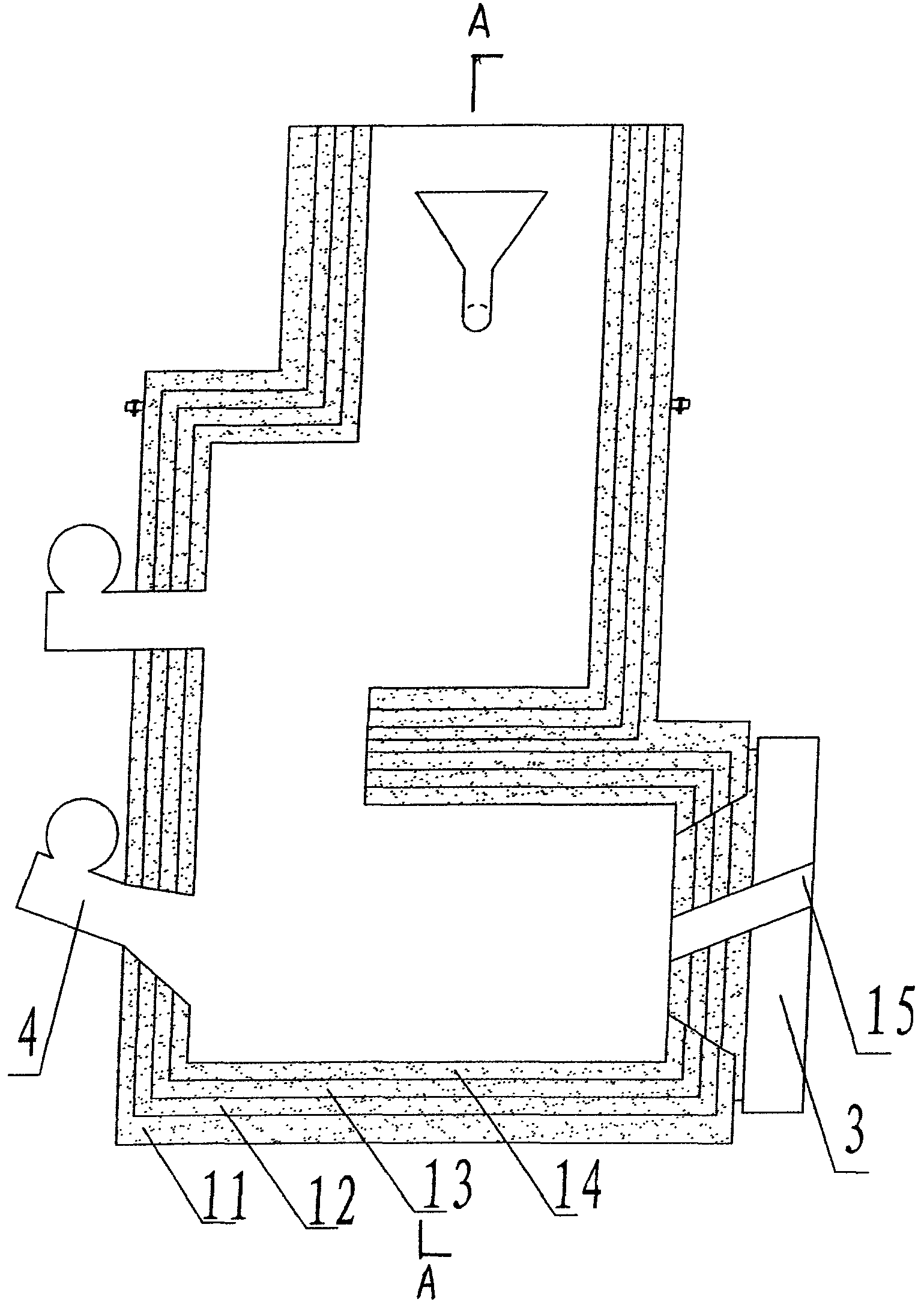

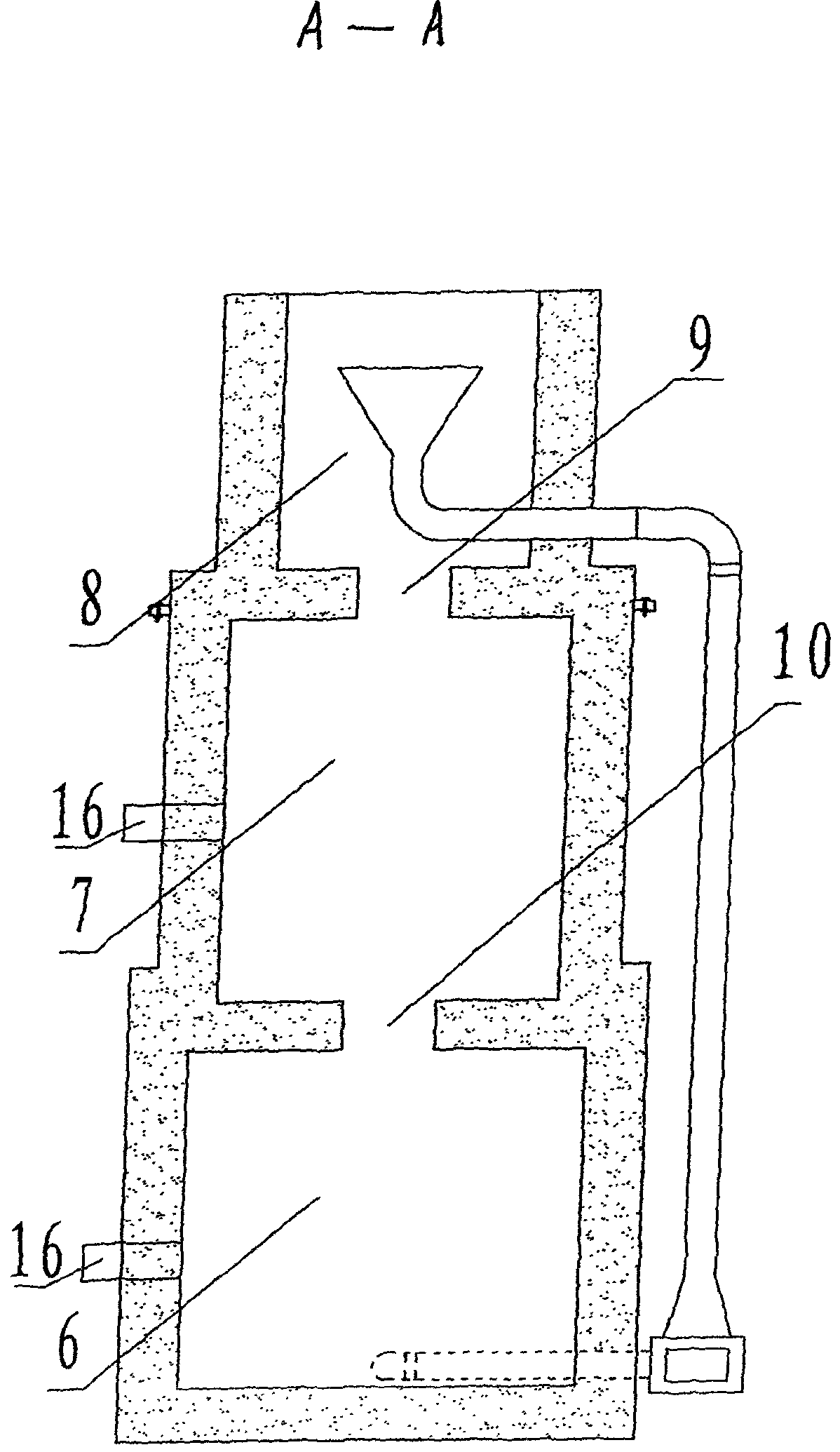

Mobile Animal Incinerator

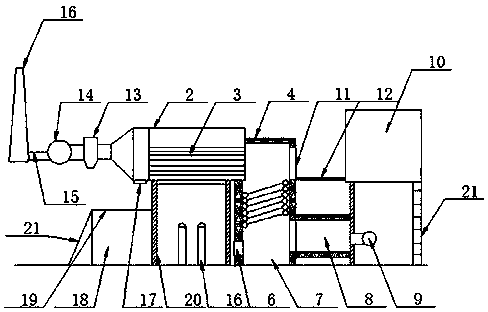

ActiveCN103528065BImprove incineration efficiencyQuality improvementCremation furnacesCombustion chamberCombustor

The invention discloses a movable animal incinerator which comprises a movable chassis, an incinerator body, an incinerator door, a first combustion chamber, a second combustion chamber and an air induction chamber. The movable animal incinerator is characterized in that an incinerator air distributing device is arranged outside the incinerator body, combustors are arranged on the first combustion chamber and the second combustion chamber respectively, the first combustion chamber and the second combustion chamber form an incinerator secondary combustion device through a combustion channel, the second combustion chamber is communicated with the air induction chamber through a flame discharging hole, and the air induction chamber and an air distributing pipe in the incinerator air distributing device form an incinerator chimney-free exhaust system. The movable animal incinerator is novel in design, reasonable in structure, good in treatment effect, free of environment pollution, and free of chimney.

Owner:浙江时迈环境科技有限公司

A compact, small-capacity, and high-output biomass pellet boiler

InactiveCN104832903BGuaranteed combustion temperatureGuaranteed cleanlinessLiquid degasificationBoiler controlCombustion chamberAtmospheric air

Owner:吴恩珍 +1

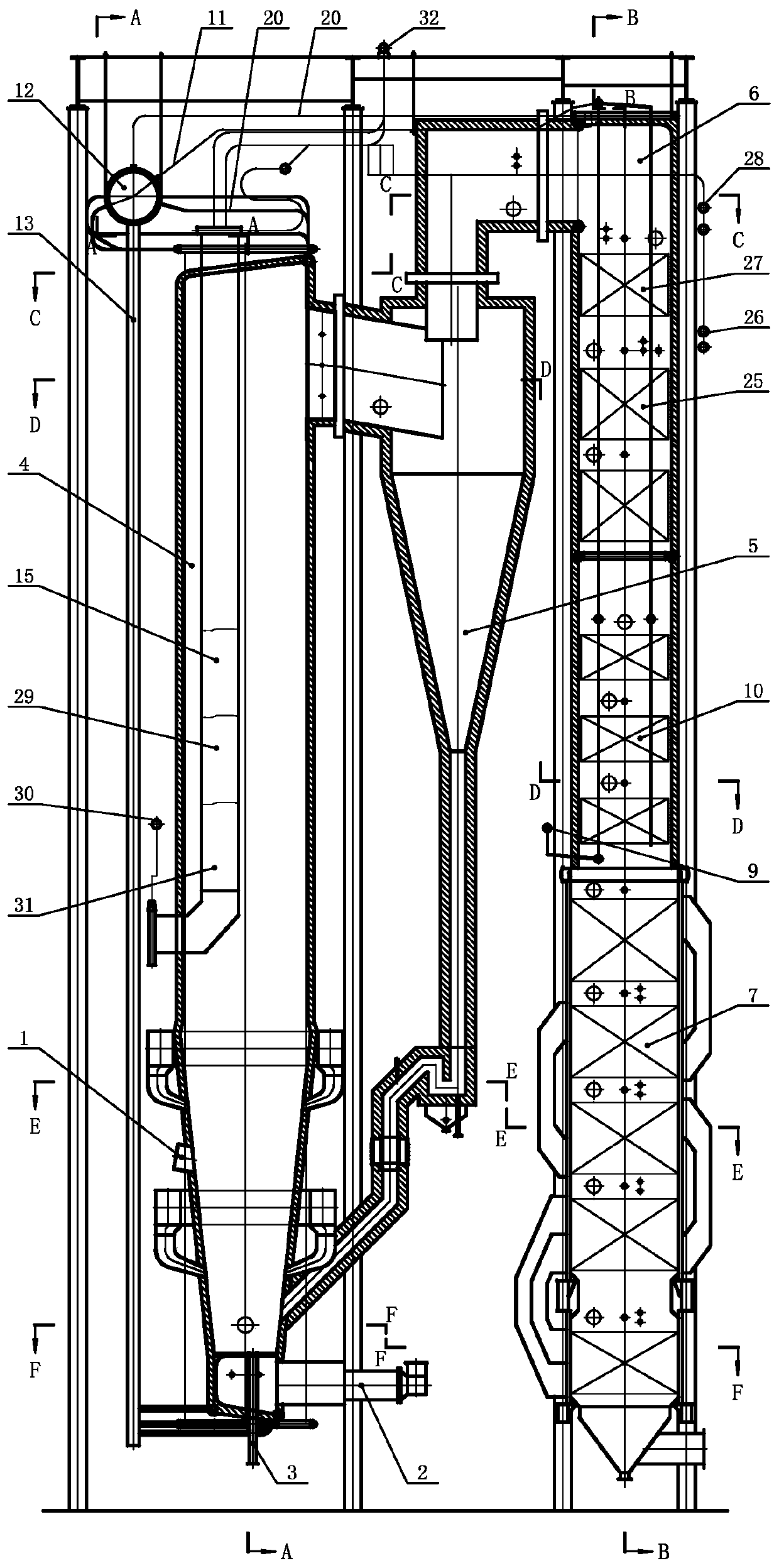

Pure-burning biomass environment-friendly circulating fluidized bed high-temperature and high-pressure steam boiler

The invention discloses a pure-burning biomass environment-friendly circulating fluidized bed high-temperature and high-pressure steam boiler, and relates to a circulating fluidized bed boiler. The boiler solves the problems of low in combustion efficiency, high in pollution emission, narrow in fuel range, difficulty in pure combustion, unsmooth feeding, poor sealing and poor reliability of an existing biomass circulating fluidized bed boiler. A feeding interface is positioned at a negative pressure point at the lower part of a hearth; the upper part of the hearth is sequentially provided witha water cooling screen, a middle temperature screen superheater and a high temperature screen superheater from the width direction; a first inlet flue communicates one end of a second inlet flue; thefirst inlet flue and the second inlet flue are all inclined downwards; an inclination angle of the first inlet flue is smaller than that of the second inlet flue; the other end of the second inlet flue communicates with the side wall of the upper end of a separator; the lower end of a steering chamber communicates with the upper end of the separator; a central cylinder is connected with the lowerend of the steering chamber; and the central cylinder is positioned in the separator. The boiler is used for cogeneration and power generation of a pure-burning biomass circulating fluidized bed boiler.

Owner:哈尔滨红光锅炉总厂有限责任公司

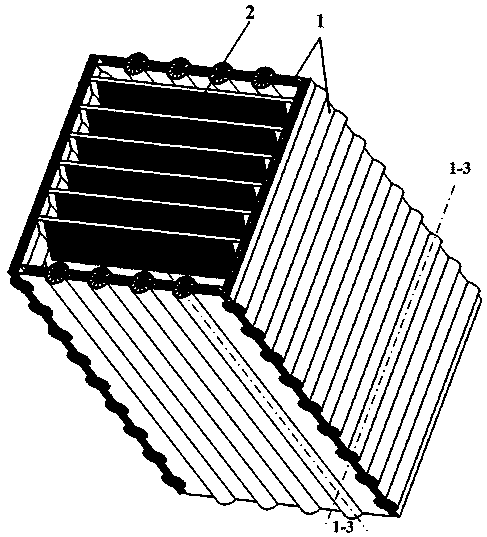

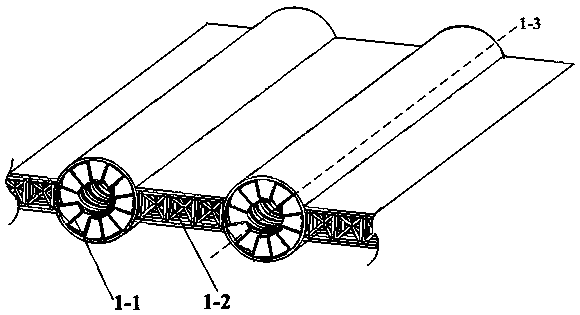

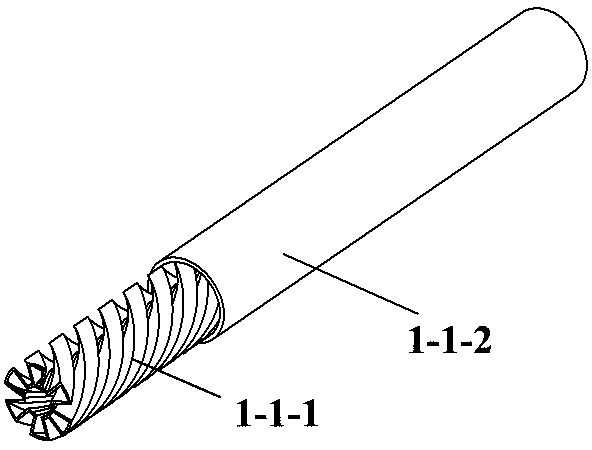

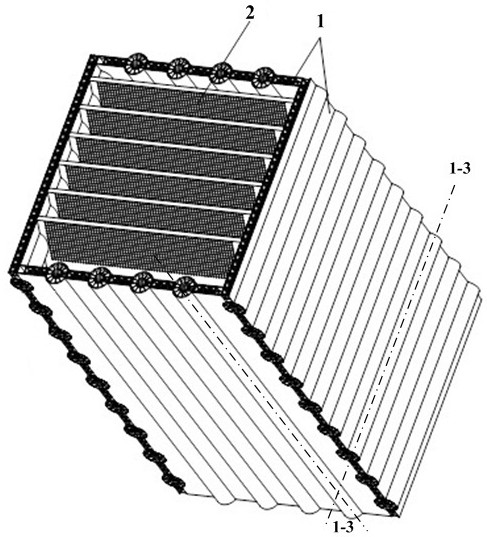

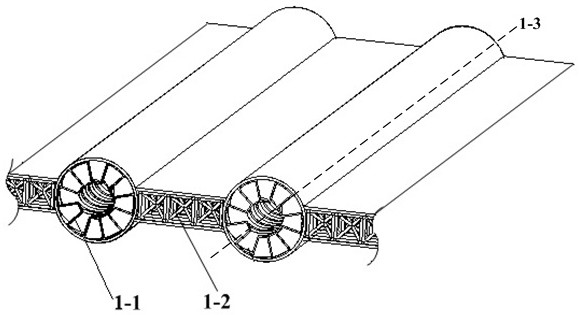

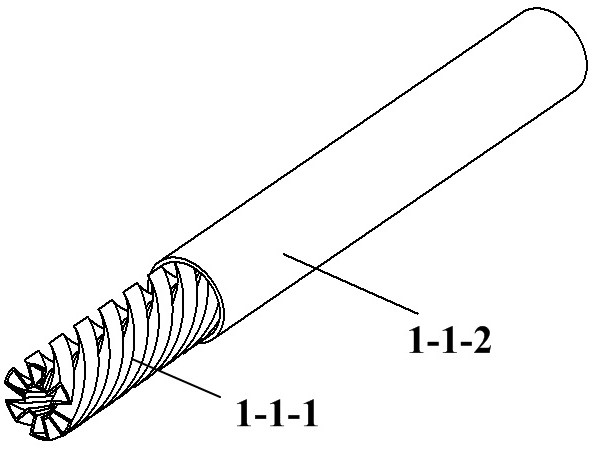

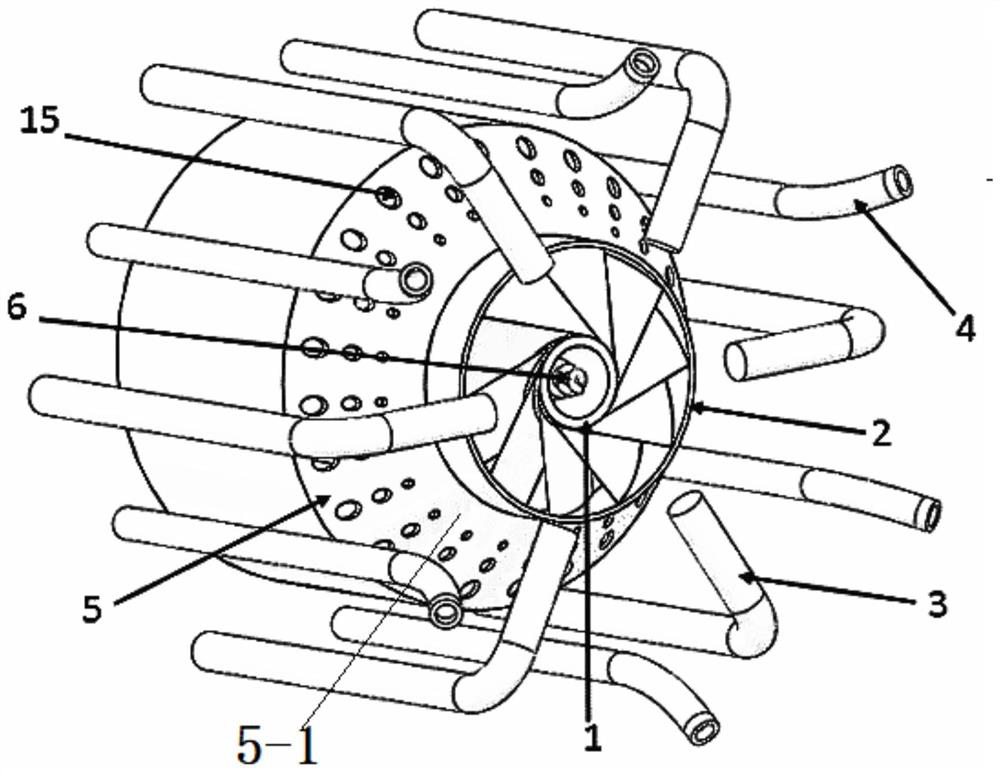

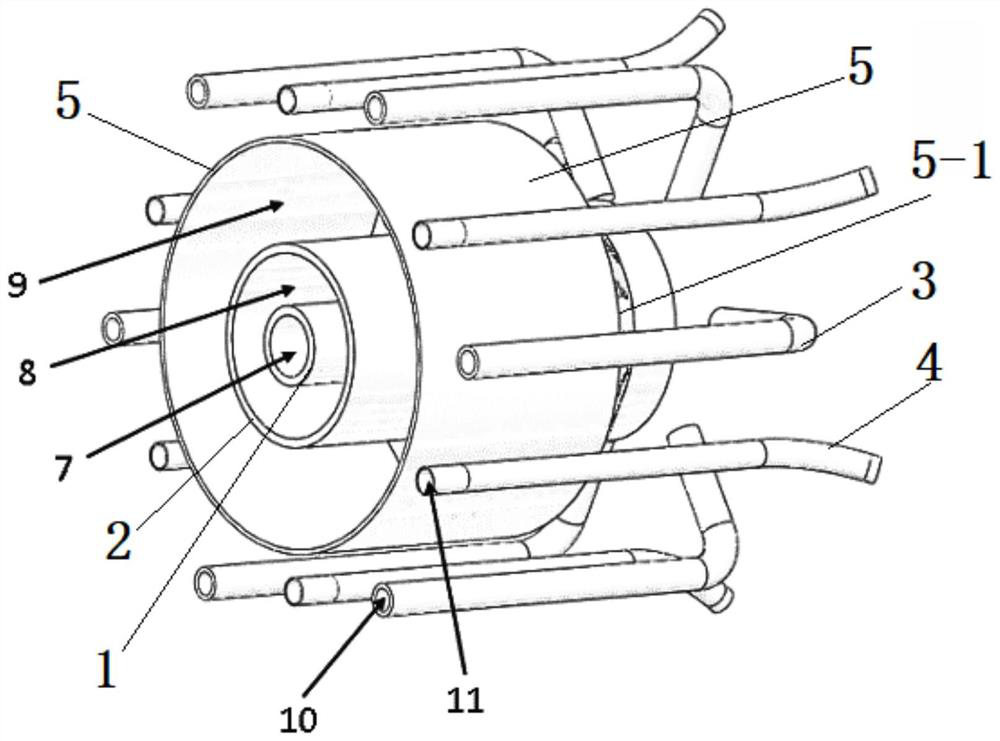

Hazardous waste waste heat preheating energy saver

ActiveCN111457393ASelf-cleaningGuaranteed combustion temperatureSievingScreeningThermodynamicsFlue gas

The invention belongs to a preheating device for treating solid particle waste (VOC components are wrapped in particles) generated in the chemical process before incineration, and relates to a novel hazardous waste waste heat preheating energy saver. The novel hazardous waste waste heat preheating energy saver comprises multi-wave inner spiral finned tubes, lattice topology composite layer coupling heating walls and porous multi-directional inclined screening plates. A waste heat energy saver shell is formed by the multi-wave inner spiral finned tubes and the lattice topology composite layer coupling heating walls together, and the porous multi-directional inclined screening plates are densely distributed in a device defined by the shell, wherein the cross section of the device is rectangular. By means of the novel hazardous waste waste heat preheating energy saver, flue gas waste heat is adopted as a hot source, the structure is clear, efficient utilization of flue gas waste heat is promoted, energy is saved, and the structure weight is reduced; and by means of the porous multi-directional inclined screening plates in the device, the soaking performance can be improved effectively, the partial overheating or overburning phenomenon is eliminated, the contact face is effectively expanded, the residence time of hazardous waste in the device is greatly prolonged, the moisture content in hazardous waste is obviously reduced, the incineration initial temperature is improved, the later burning temperature in a furnace is stabilized, and dangerousness of secondary pollution is greatly reduced.

Owner:CHANGZHOU UNIV

Small incinerator

InactiveCN1229591CSuppresses excretion to a very small levelPrevent inflowIncinerator apparatusCombustion chamberWaste management

The present invention is a small scale incinerator with the charge device cut-off from the outside air is so formed that the outside air cutoff / charge device comprises a waste storage box having a waste storage chamber temporarily storing the waste, an opening part closed door openably / closable provided in a space toward the primary combustion chamber of the furnace body, and a waste throw mechanism throwing the waste temporarily stored in the waste storage chamber to the primary combustion chamber in the furnace body. The waste throw mechanism is characterized in comprising a waste moving plate moving the waste stored in the waste storage chamber to the primary combustion chamber side of the furnace body, and a moving operation lever opening the opening part closed door by interlocked with the advancing movement of the waste moving plate and closing the opening part closed door by interlocked with the retreating movement, after the waste moving plate throws the waste in the primary combustion chamber of the furnace.

Owner:和光机械工业株式会社

Movable animal incinerator

ActiveCN103528065AImprove incineration efficiency and incineration qualityReduce height and volumeCremation furnacesTreatment effectCombustion chamber

The invention discloses a movable animal incinerator which comprises a movable chassis, an incinerator body, an incinerator door, a first combustion chamber, a second combustion chamber and an air induction chamber. The movable animal incinerator is characterized in that an incinerator air distributing device is arranged outside the incinerator body, combustors are arranged on the first combustion chamber and the second combustion chamber respectively, the first combustion chamber and the second combustion chamber form an incinerator secondary combustion device through a combustion channel, the second combustion chamber is communicated with the air induction chamber through a flame discharging hole, and the air induction chamber and an air distributing pipe in the incinerator air distributing device form an incinerator chimney-free exhaust system. The movable animal incinerator is novel in design, reasonable in structure, good in treatment effect, free of environment pollution, and free of chimney.

Owner:杭州时迈生物安全技术股份有限公司

Thermal test device for real supply conditions of gas-pneumatic thrust chamber injectors

ActiveCN112628026BFill in the gaps in hot test technologyRealize hot test simulationRocket engine plantsThrust chamberEngineering

The invention relates to the field of liquid rocket engines, in particular to a thermal test device for real supply conditions of an injector of a gas-pneumatic thrust chamber, so as to solve the problem that the existing thermal tests of the thrust chamber and its injector are aimed at the mixed combustion of liquid propellants Or the thrust chamber injector of gas-liquid mixed combustion, the test method and test device cannot be used in the hot test of the thrust chamber injector of gas-gas mixed combustion. The device includes a thrust chamber test piece unit, an oxygen-rich gas generator unit and a fuel-rich gas generator unit. The thrust chamber test piece unit includes the thrust chamber test piece, the thrust chamber test piece is used to install the injector under test, the oxygen-enriched gas generator unit includes the oxygen-enriched gas generator, the fuel-rich gas generator unit includes the rich-burn gas generator, The outlets of the oxygen-enriched gas generator and the fuel-rich gas generator are respectively connected to the thrust chamber test piece, and are used to supply oxygen-enriched gas and fuel-rich gas to the thrust chamber test piece.

Owner:XIAN AEROSPACE PROPULSION INST

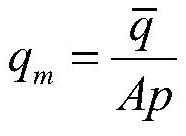

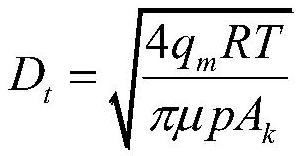

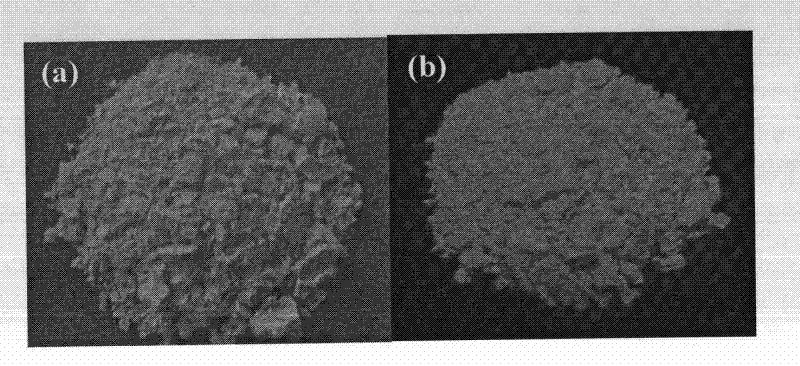

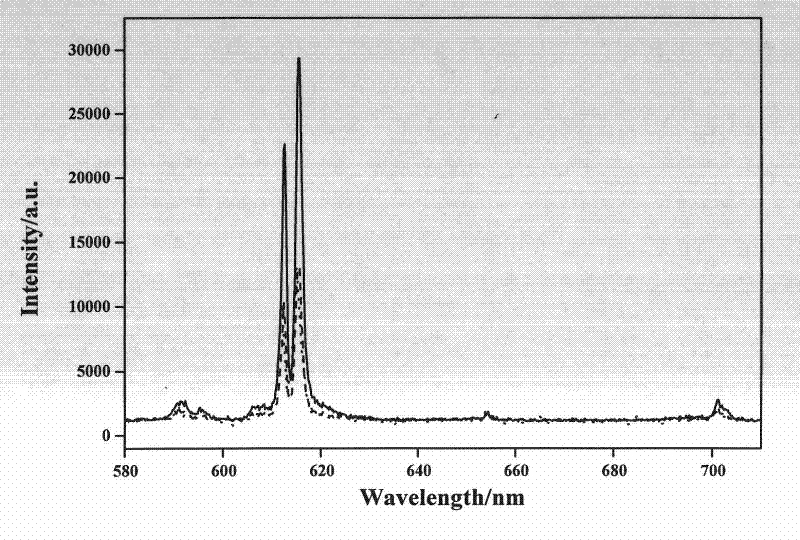

Preparation method of CaMoO4: Eu3+, Li+ red phosphor

The invention discloses a CaMoO4: Eu3+, Li+ red phosphor and a preparation method thereof, which belong to the field of luminescence materials. The CaMoO4: Eu3+, Li+ red phosphor is prepared by using Ca (NO3) 2.4H2O, (NH4) 6Mo7O24.4H2O, Eu (NO3) 3.6H2O and Li2CO3 as raw materials and using urea and thiourea as fuel through the steps of adjusting the pH value of solution with ammonia liquor; and then putting a precursor into a burning reaction furnace preheated to 600 to 800 DEG C to directly carry out combustion synthesis reaction so as to obtain the CaMoO4: Eu3+, Li+ red phosphor. Compared with the prior art, in the invention, urea and thiourea are used as fuel together, which ensures the combustion temperature and extends the combustion time, so that the luminous property of the obtained product is greatly improved, and the obtained product is fragile; and the method is simple to operate, does not require high temperature treatment, and is easy to realize industrialization.

Owner:GUANGXI NORMAL UNIV

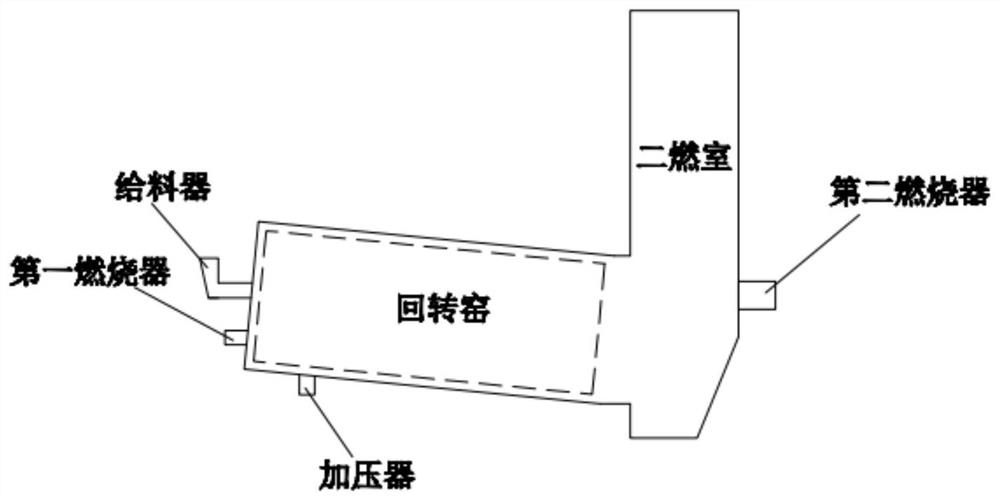

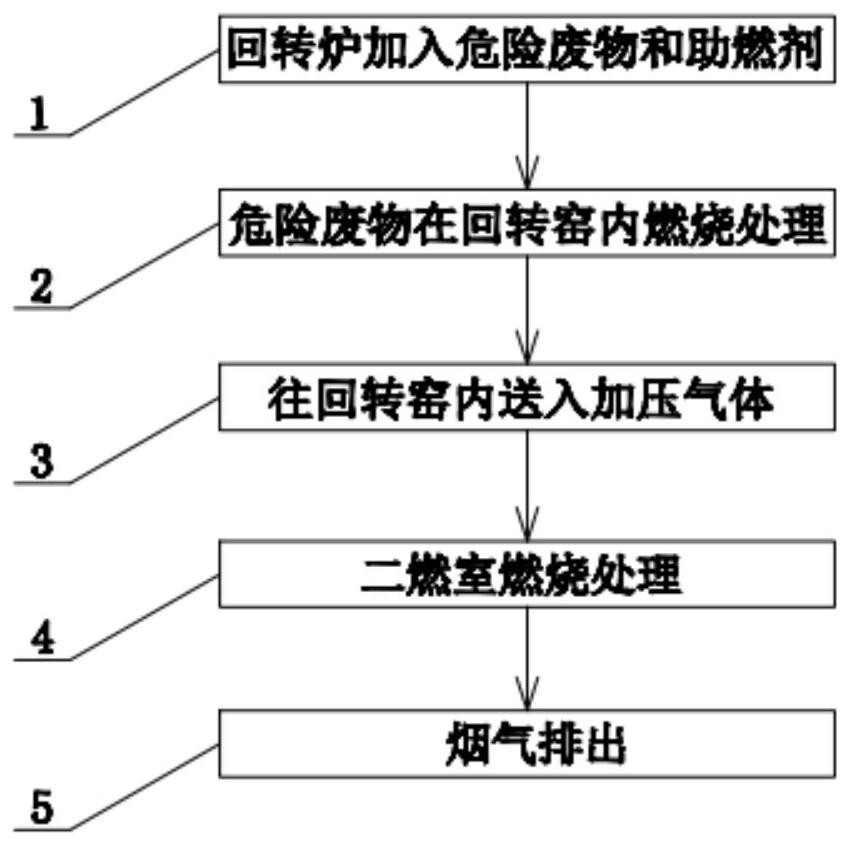

Hazardous waste rotary kiln incineration treatment process

InactiveCN113932225ACurb Odor and Nitrogen Oxide FormationWell mixedDirect carbon-dioxide mitigationIndirect carbon-dioxide mitigationProcess engineeringCombustion chamber

The invention discloses a hazardous waste rotary kiln incineration treatment process, and relates to a hazardous waste treatment process. Hazardous waste and a combustion improver are mixed and fed into a rotary kiln through a feeder, the hazardous waste is combusted in the rotary kiln, the hazardous waste is fully combusted along with rotation of the rotary kiln in the combustion process, and meanwhile the hazardous waste gradually slides downwards under the action of the gravity of the hazardous waste; and in the combustion process, pressurized gas is sprayed into the rotary kiln through a pressurizer located at the bottom of the rotary kiln, the pressurized gas contains gas with a certain oxygen concentration so as to meet the combustion requirement in the rotary kiln, then comburent enters a secondary combustion chamber and is further combusted in the secondary combustion chamber, it is guaranteed that the retention time of flue gas in the secondary combustion chamber is not less than 2 seconds, and finally, the flue gas is discharged. The process has the advantages that the removal rate of organic matters is high, the generation of odor and oxynitride can be effectively inhibited, the generated flue gas is free of peculiar smell and stink, and the generation of dioxin is effectively inhibited.

Owner:SHANGHAI CANZHOU ENVIRONMENTAL ENG

A combustion system for fluidized bed gasification fly ash

ActiveCN110260302BIncrease disturbanceExtended stayFluidized bed combustionIndirect carbon-dioxide mitigationCombustion systemCombustion

The invention discloses a combustion recycling system for gasified fly ash of a fluidized bed. The combustion recycling system for the gasified fly ash of the fluidized bed comprises a first fuel bin, a cyclone separator, a limestone bin and an air film separator, wherein the first fuel bin is arranged on the upper portion of a furnace hearth, and conveys fuel through a gradual enlargement pipeline to a boundary position of a furnace hearth dense phase zone and a furnace hearth lean phase zone, an inlet of the cyclone separator is connected with an outlet of the furnace hearth, an outlet of the cyclone separator is connected with an inlet of an ash bucket, an outlet of a gasified fly ash bin is connected with the ash bucket, an air blower is connected with the ash bucket, an outlet of the ash bucket is connected with the downside dense phase of the furnace hearth, the limestone bin is connected with the middle of the furnace hearth, a second fuel bin is connected with the downside dense phase zone of the furnace hearth, a downside wind distribution plate is arranged on an inclined plane on the bottom side of the furnace hearth, a bottom wind distribution plate is arranged at the bottom of the furnace hearth, the air film separator is arranged on the lower side of the exterior of the furnace hearth, an inlet of the air film separator is connected with an outlet of an air compressor, and an outlet of the air film separator is respectively connected with an over fire air pipeline, the bottom wind distribution plate and the downside wind distribution plate. The combustion recycling system for the gasified fly ash of the fluidized bed can achieve efficient consumption of the gasified fly ash in a circulating fluidized bed boiler, and reduces fuel consumption and NOx discharge amount of the circulating fluidized bed boiler on the premise of effectively using the gasified fly ash.

Owner:XI AN JIAOTONG UNIV

Hazardous waste multiphase cooperative treatment device and hazardous waste treatment method thereof

InactiveCN112393256AThe generation of solutionAchieve reductionEmission preventionAir/fuel supply for combustionParticulatesCombustion chamber

The invention discloses a hazardous waste multiphase cooperative treatment device and a hazardous waste treatment method thereof, and relates to a hazardous waste treatment device and a hazardous waste treatment method thereof. The problem that a large amount of acid gas and incompletely combusted organic components and furnace slag are generated by incineration of hazardous wastes in an existingincineration method is solved. The hazardous waste multiphase cooperative treatment device comprises an air blower, a feeding machine, a waste liquid tank, a high-pressure oxygen meter, an ammonia water tank, a multiphase reactor, an ammonia water spray gun, a rapid cooler, a dust remover, an induced draft fan, a waste gas spray head, a waste gas tank and a second flue. The process method comprises the steps that solid waste is placed on an air distribution plate of a combustion chamber, the air blower introduces air into the combustion chamber, and the waste liquid tank introduces waste liquid into the combustion chamber for combustion decomposition and waste gas burnout; primary removal is carried out on nitrogen oxide in the flue gas; and the rapid cooler is used for performing secondary denitration and absorbing the heat of the flue gas, then the dust remover is used for filtering particles in the flue gas, and the induced draft fan is used for leading out the flue gas to enter anacid making procedure.

Owner:中晟工程技术(天津)有限公司

A hazardous waste waste heat preheating economizer

ActiveCN111457393BImprove utilizationSelf-cleaningSievingScreeningSolid particleComponents of crude oil

Owner:CHANGZHOU UNIV

Nozzle, nozzle wall and compressed air energy storage afterburning chamber

PendingCN114857580AGuaranteed combustion stabilityStable combustionHeat storage plantsGaseous fuel burnerStructural engineeringRotational flow

The invention discloses a nozzle, a nozzle wall and a compressed air energy storage afterburning chamber. The nozzle comprises a plurality of back-spraying spray guns, a plurality of main fuel spray guns, a center fuel barrel, a rotational flow air barrel and a direct flow air barrel, a spiral atomizing nozzle is arranged at the outlet end of the central fuel barrel; rotational flow blades are arranged at the outlet end of the rotational flow air duct in an annular gap between the central fuel barrel and the rotational flow air duct; the outlet end of the direct-flow air duct is provided with a gradually-shrunk section, the small end of the gradually-shrunk section is connected with the outer wall of the outlet end of the rotational-flow air duct, a plurality of circles of round holes are formed in the gradually-shrunk section, and the diameter of the outer-side round holes is larger than that of the inner-side round holes; the plurality of back-spraying spray guns and the plurality of main fuel spray guns are alternately and uniformly arranged on the periphery of the direct-flow air duct; an outlet of the back-spraying spray gun is located on the downstream of the direct-flow air duct gradually-shrinking section and faces the gradually-shrinking section. An outlet of the main fuel spray gun inclines from inside to outside in the radial direction of the direct-flow air duct. The nozzle is simple in structure and small in investment, and the characteristics of combustion chamber temperature, combustion efficiency and pollutant control are well considered.

Owner:XIAN THERMAL POWER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com