A hazardous waste waste heat preheating economizer

An energy-saving and waste technology, which is applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of insufficient utilization of waste heat energy, reduction of moisture content of hazardous waste, and negative effects of the incineration process. Extends residence time, expands contact surface, reduces weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

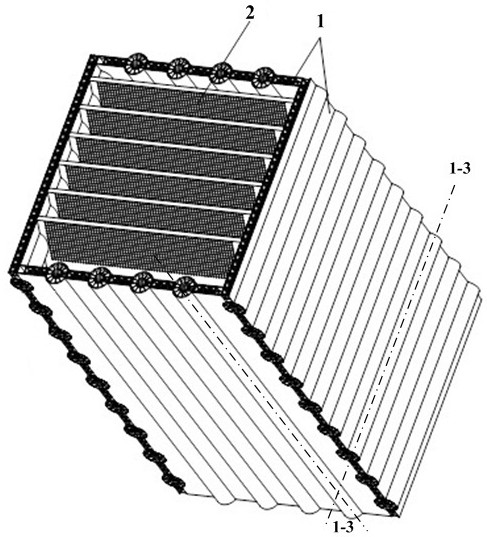

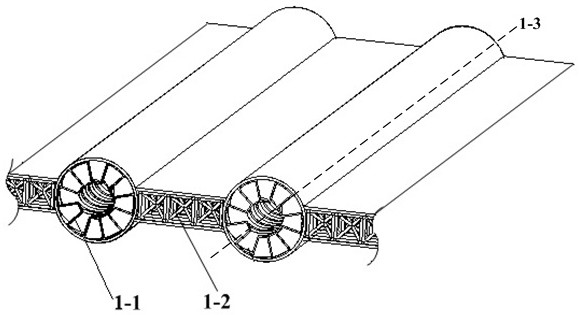

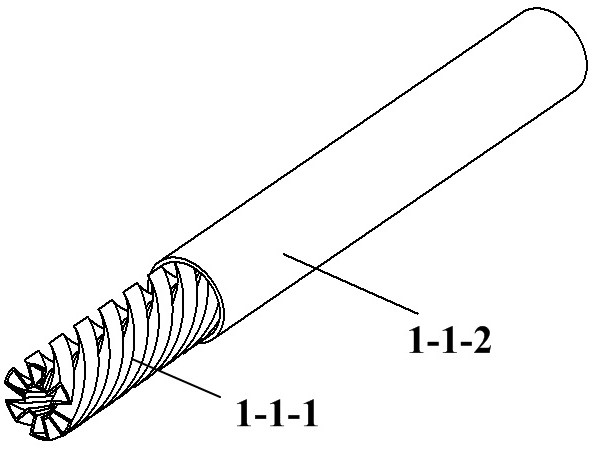

[0022] The present invention provides an embodiment of a hazardous waste waste heat preheating economizer. For details, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , a waste heat preheating economizer for hazardous waste in this embodiment is composed of a shell and a porous multi-directional inclined sieve plate; the cross section of the shell is rectangular, and the porous multi-directional inclined sieve plate is arranged inside; There is an included angle α on the horizontal ground, and the range of the included angle α is 35°~90°; the hazardous waste enters from the top of the housing, fully exchanges heat in the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com