Preparation method of CaMoO4: Eu3+, Li+ red phosphor

A red phosphor, ca1-xmoo4 technology, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of prolonging burning time, low energy consumption, and improving luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

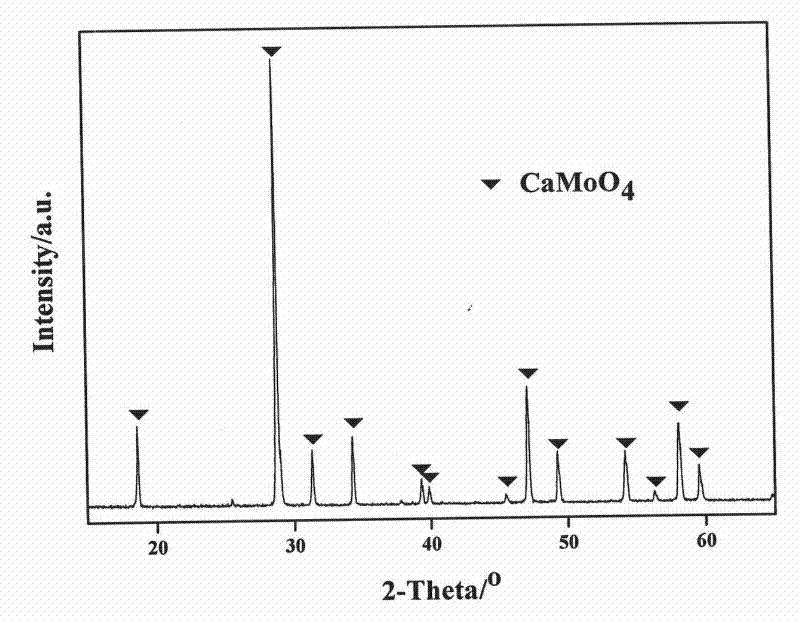

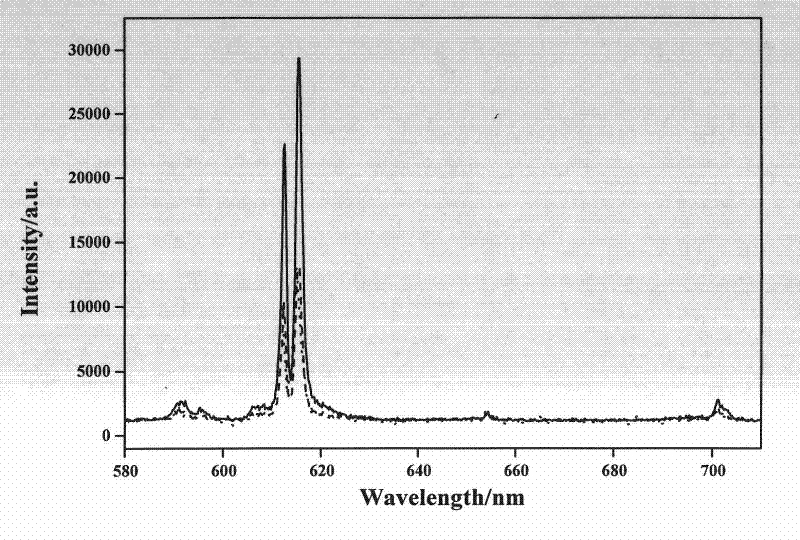

[0021] According to the chemical formula Ca 1-x MoO 4 :Eu 3+ x , Li + y (x=0.18, y=0.10) Weigh the corresponding medicines.

[0022] Take Ca(NO 3 ) 2 4H 2 O 0.5807g, Eu(NO 3 ) 3 ·6H 2 O 0.2409g is dissolved in water to form a solution, and Li 2 CO 3 0.0111g is dissolved in nitric acid to form nitric acid solution, and the two solutions are mixed to obtain solution A; get (NH 4 ) 6 Mo 7 o 24 4H 2O 0.5297g was dissolved in water to obtain solution B, and solution A was added while stirring in solution B, then urea 0.9008g and thiourea 0.2283g were added to obtain suspension C; adjust the pH value of suspension C to 4.0 with ammonia water , to obtain a suspension D; move the suspension D into a combustion reaction furnace, and carry out a combustion reaction at 800 ° C. The reaction ends within 4 minutes, and the reaction product is CaMoO according to the present invention. 4 :Eu 3+ , Li + red phosphor.

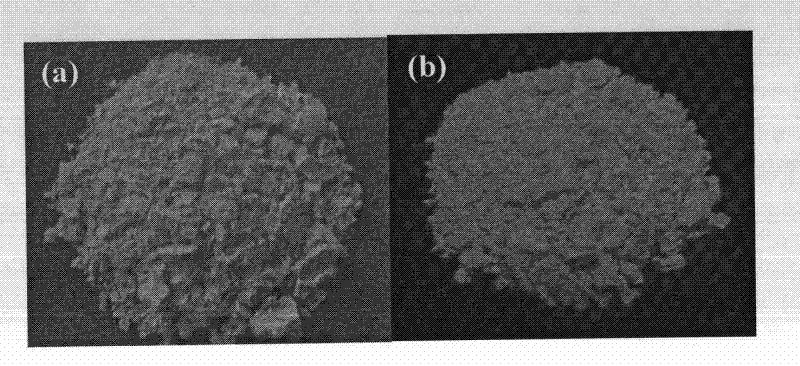

[0023] figure 1 The real photo of the sample prepared...

Embodiment 2

[0027] According to the chemical formula Ca 1-x MoO 4 :Eu 3+ x , Li + y (x=0.15, y=0.10) Weigh the corresponding medicines.

[0028] Take Ca(NO 3 ) 2 4H 2 O 0.6020g, Eu(NO 3 ) 3 ·6H 2 O 0.2007g, it is dissolved in water, take Li 2 CO 3 0.0111g is dissolved in nitric acid, and two solutions are mixed to obtain solution A; Take (NH 4 ) 6 Mo 7 o 24 4H 2 O 0.5297g was dissolved in water to obtain solution B, and solution A was added while stirring in solution B, then urea 0.7207g and thiourea 0.4567g were added to obtain suspension C; adjust the pH value of suspension C to 3.5 with ammonia water , to obtain a suspension D; move the suspension D into a combustion reaction furnace at 700°C to carry out a combustion reaction, and the reaction ends within 5 minutes to obtain the CaMoO of the present invention. 4 :Eu 3+ , Li + red phosphor.

Embodiment 3

[0030] According to the chemical formula Ca 1-x MoO 4 :Eu 3+ x , Li + y (x=0.20, y=0.15) Weigh the corresponding drugs.

[0031] Take Ca(NO 3 ) 2 4H 2 O 0.5666g, Eu(NO 3 ) 3 ·6H 2 O 0.2676g dissolved in water, take Li 2 CO 3 0.0166g is dissolved in nitric acid, and two solutions are mixed to obtain solution A; Take (NH 4 ) 6 Mo 7 o 24 4H 2 O0.5297g was dissolved in water to obtain solution B, and solution A was added while stirring in solution B, then urea 1.0810g and thiourea 0.1142g were added to obtain suspension C; the pH value of suspension C was adjusted to 4.0 with ammonia water , to obtain a suspension D; move the suspension D into a combustion reaction furnace at 600°C to carry out a combustion reaction, and the reaction ends within 3 minutes to obtain the CaMoO of the present invention. 4 :Eu 3+ , Li + red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com