Patents

Literature

78results about How to "Reduce the difficulty of follow-up processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

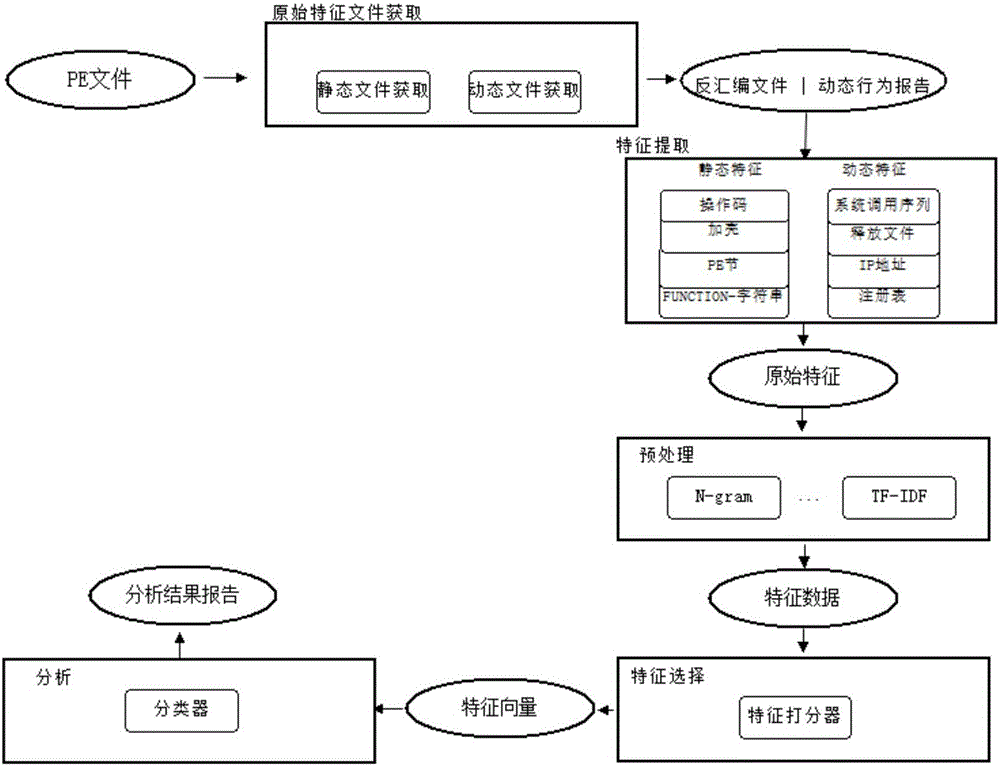

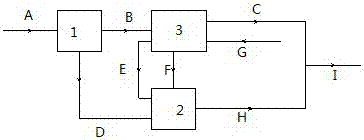

Malicious code analysis method and system based on semi-supervised learning

InactiveCN107180191ASolve classification problemsReduce the difficulty of follow-up processingPlatform integrity maintainanceDynamic featureDimensionality reduction

The present invention discloses a malicious code analysis method based on semi-supervised learning. The method is characterized in that analysis is carried out based on the multi-dimensional features, and static features and dynamic features of a malicious code are extracted; and the difficulty of the subsequent processing through dimensionality reduction is reduced, and by using the semi-supervised learning method, the problem of the classification of a small number of marked malicious code samples is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

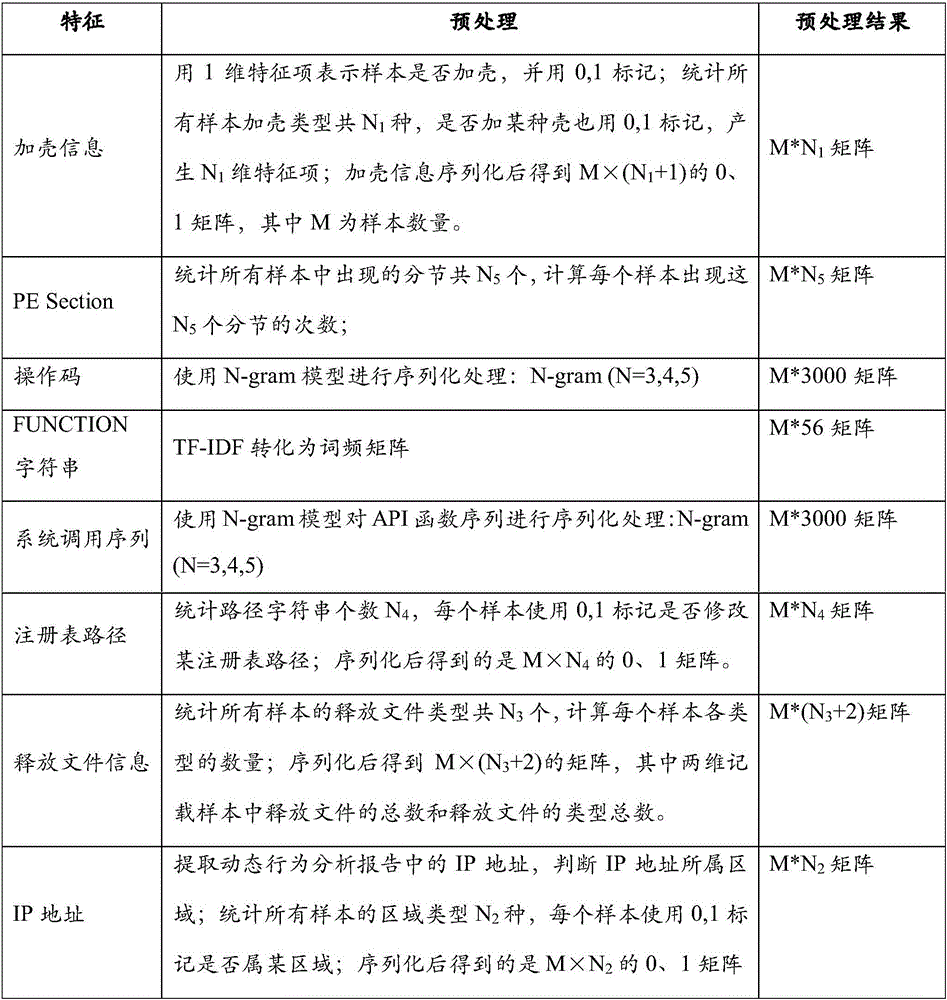

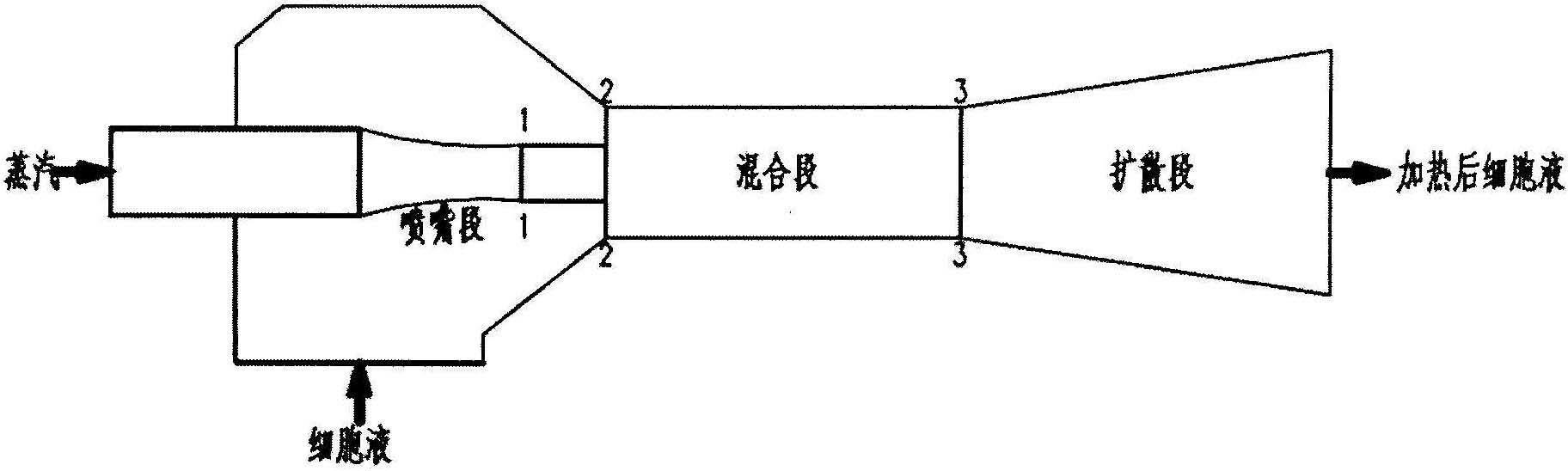

Process for extracting sweet potato protein by thermal deposition method

ActiveCN102558327ACompletely brokenEasy to separatePeptide preparation methodsPlant peptidesFiberSolubility

The invention relates to a process for extracting sweet potato protein by a thermal deposition method. The process is characterized by comprising the following steps of: treating cell sap to extract the sweet potato protein from the cell sap while producing sweet potato starch, separating and purifying by using a disc separator according to the difference of specific gravity of the protein and other substances such as starch and the like, removing fine fibers according to the solubility of the protein and the size of particles, and further purifying; purifying, concentrating, and degeneratingthe sweet potato protein to generate floccules according to the characteristic that the protein is degenerated at high temperature by a physical heating method; and concentrating, squeezing for dehydrating, drying, sieving, and performing aftertreatment to obtain a sweet potato protein commodity. The invention has the advantages that: (1) the sweet potato protein is degenerated by a steam jet cell sap heater, a moving part is not provided, and continuous production is ensured; (2) chemicals such as a flocculating agent and the like are not added, so that pollution is avoided, and subsequent treatment difficulty is reduced; and (3) the process is technically mature, and the industrial production capacity can be achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

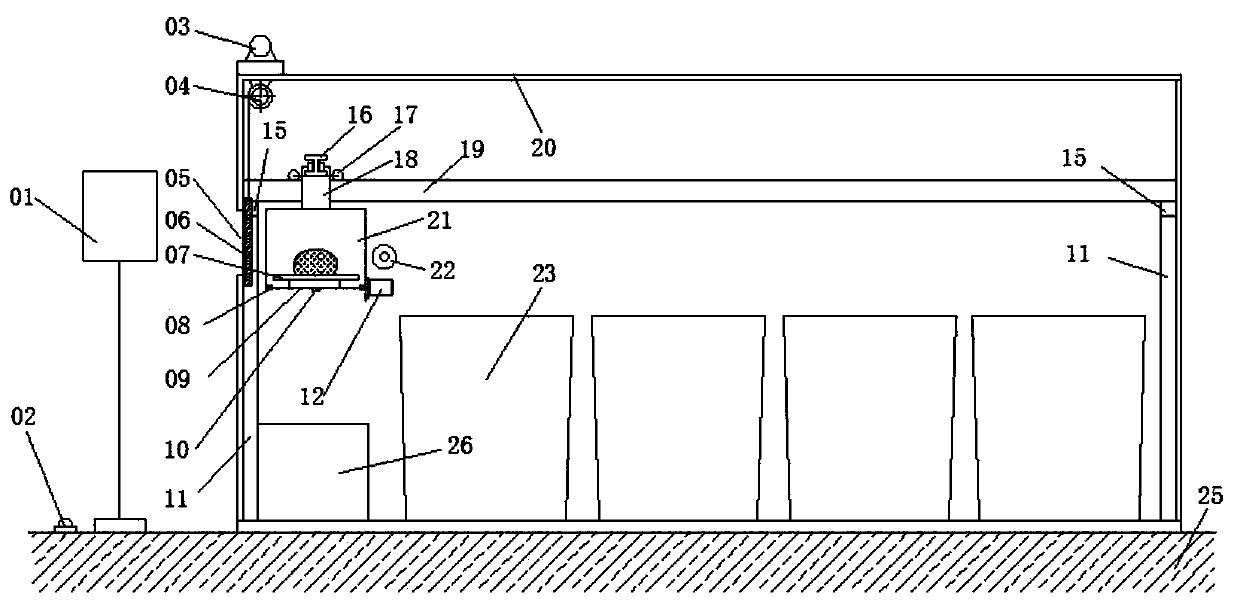

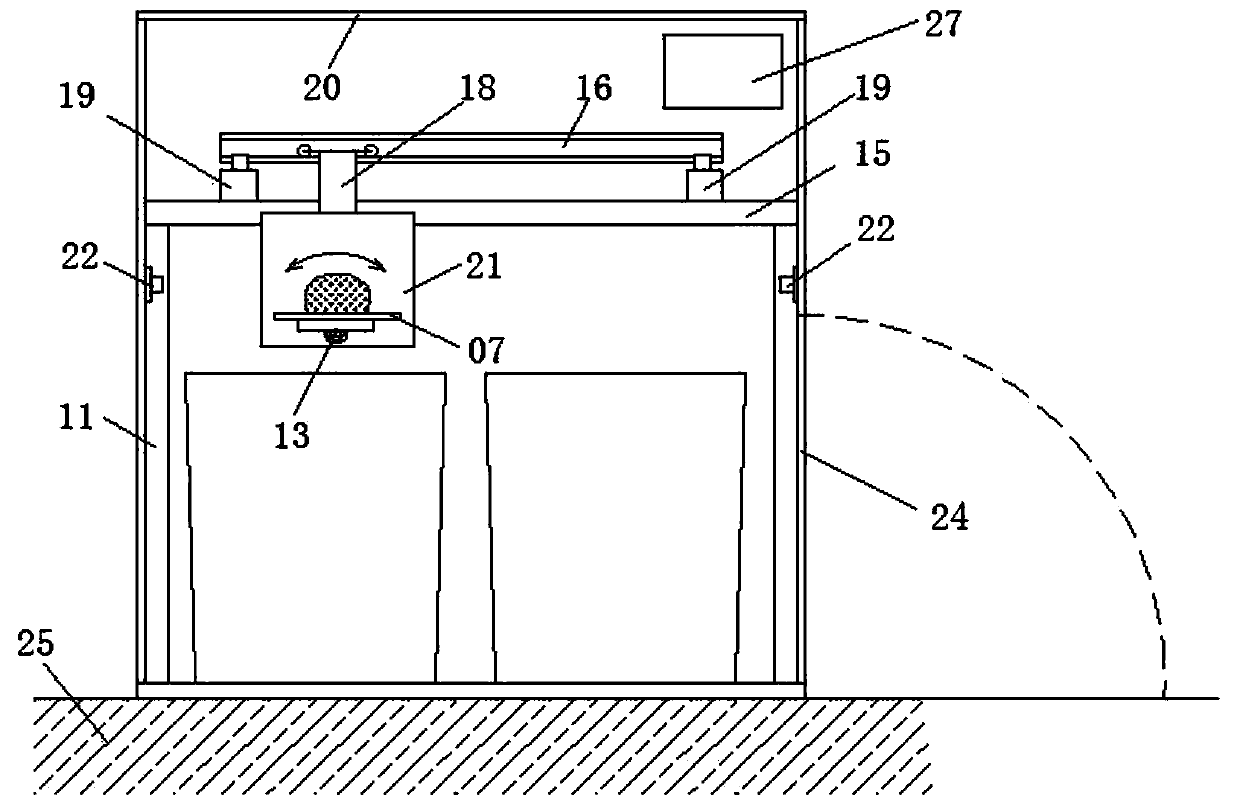

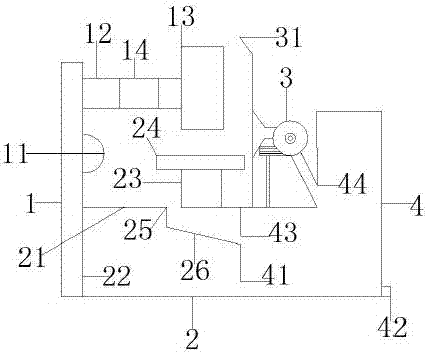

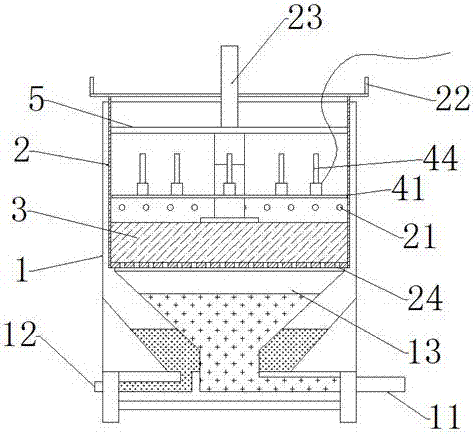

Intelligent monitoring, classifying and collecting device for household garbage

InactiveCN110525825AAvoid cross contaminationGood for weight lossRefuse receptaclesIntelligent lightingElectricity

The invention discloses an intelligent monitoring, classifying and collecting device for the household garbage. The device comprises a can body installed on the ground and a plurality of garbage cansarranged in the can body, a face recognition device is arranged at the outer side of the box body, and is electrically connected with a pedal switch, and a garbage throwing opening is formed on the side wall at one side of the box body. A gate is arranged on the garbage throwing opening and is controlled by the garbage throwing opening formed at the top in the box body, and an action mechanism, aweighing device, an intelligent control cabinet and an X-ray scanner are arranged in the box body. The device is ingenious in design and is easy to use.

Owner:HEFEI UNIV OF TECH

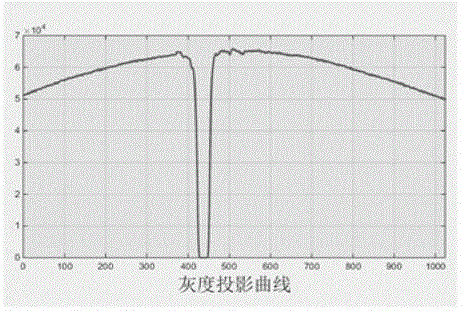

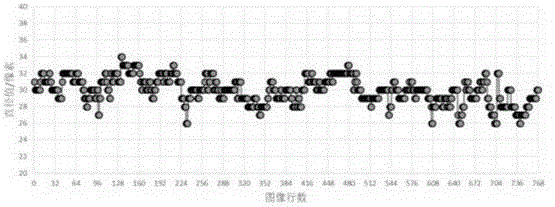

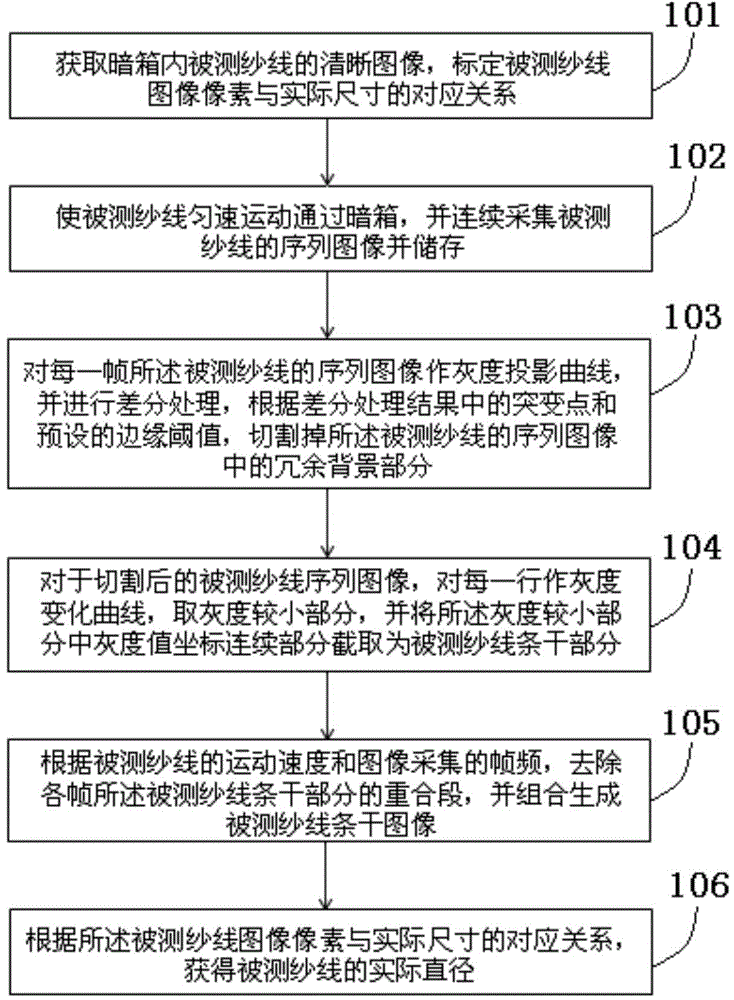

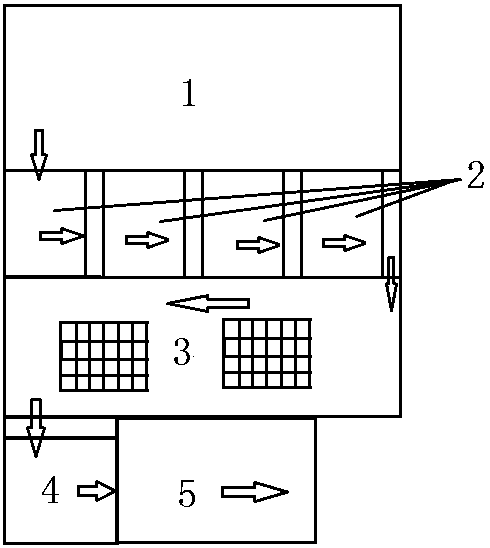

Image processing-based yarn diameter detection method

ActiveCN104535004AReduce the difficulty of follow-up processingShorten speedImage analysisUsing optical meansYarnImaging processing

The invention discloses an image processing-based yarn diameter detection method which comprises the following steps: acquiring a clear image of detected yarns in a dark box, and calibrating a corresponding relationship between the pixels of the detected yarns and the actual size; moving the detected yarns to pass through the dark box at a constant speed, continuously acquiring a sequence image of the detected yarns and storing the image; drawing a gray change curve for each row according to each frame of the sequence image of the detected yarns, taking a small-gray part, and intercepting a gray value coordinate continuing part in the small-gray part as a yarn evenness part of the detected yarns; removing the coinciding part of the yarn evenness part of the detected yarns in each frame according to the moving speed of the detected yarns and the frame frequency of image acquisition, and generating a yarn evenness image of the detected yarns; and obtaining the diameter of the detected yarns according to the corresponding relationship between the image pixels of the detected yarns and the actual size. The method disclosed by the invention has extremely high precision and accuracy, and the detection data can be used for determining the non-uniformity comprising long fragments, short fragments and periodic change of the yarns on different lengths.

Owner:湖州菱创科技有限公司

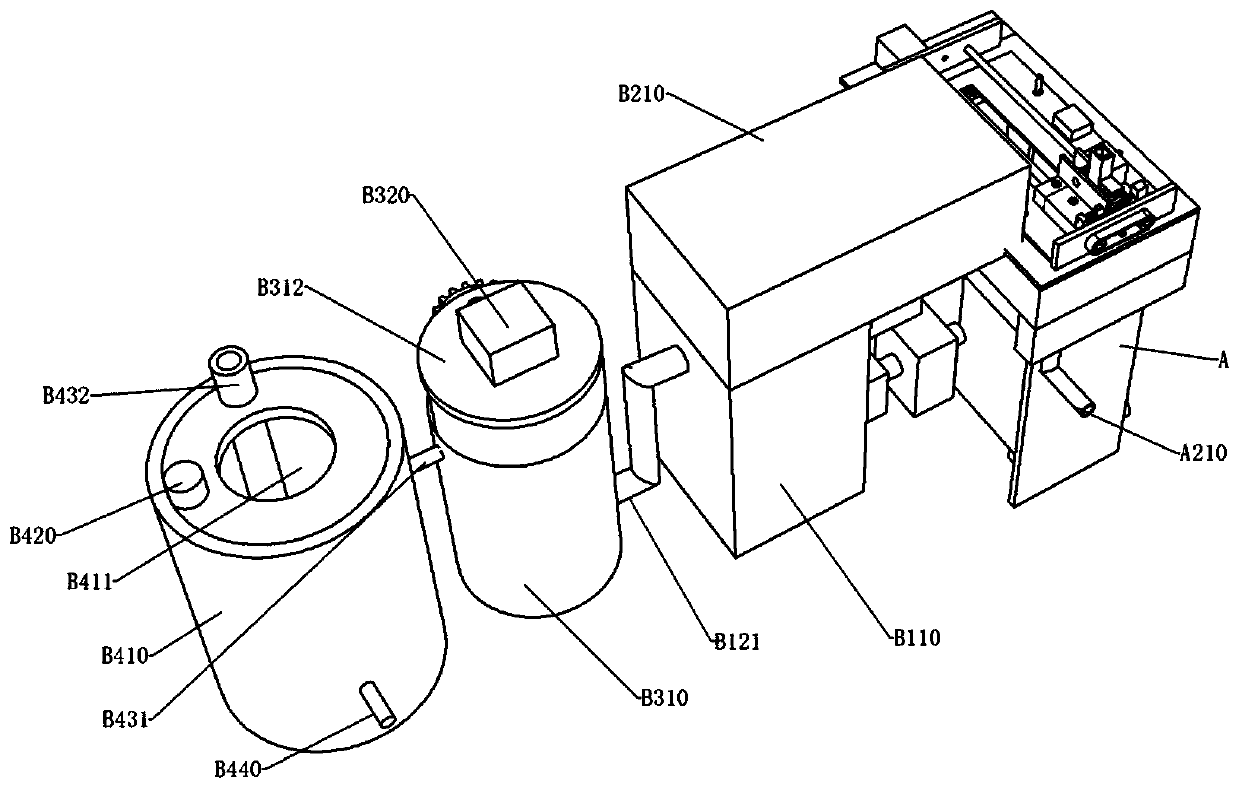

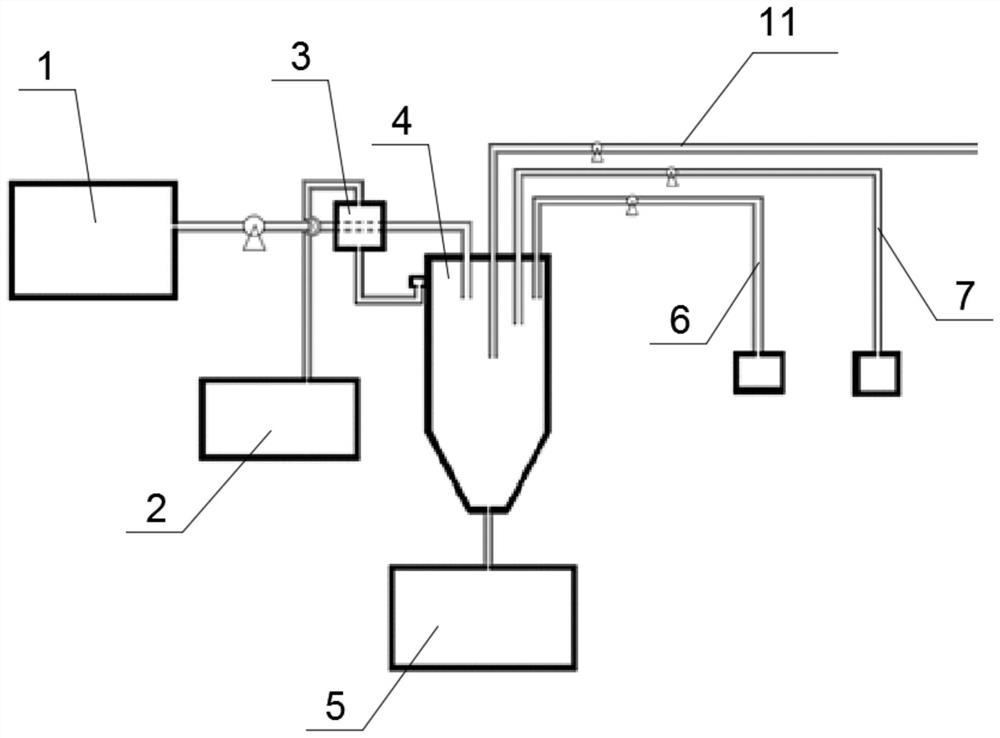

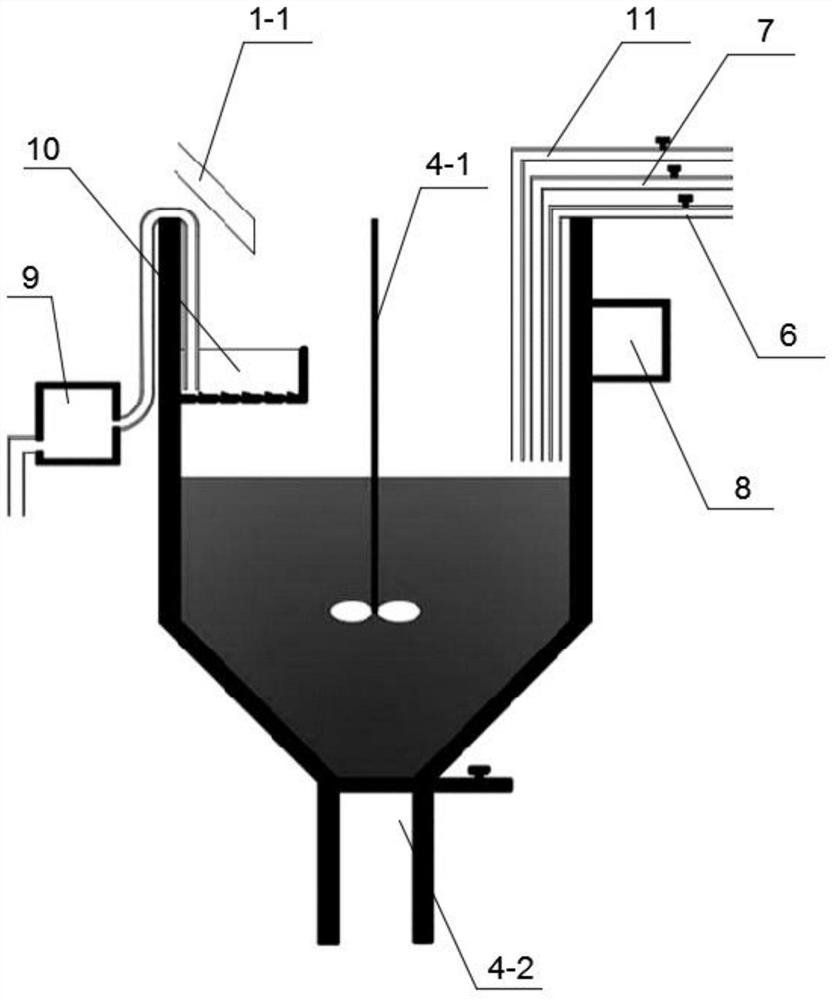

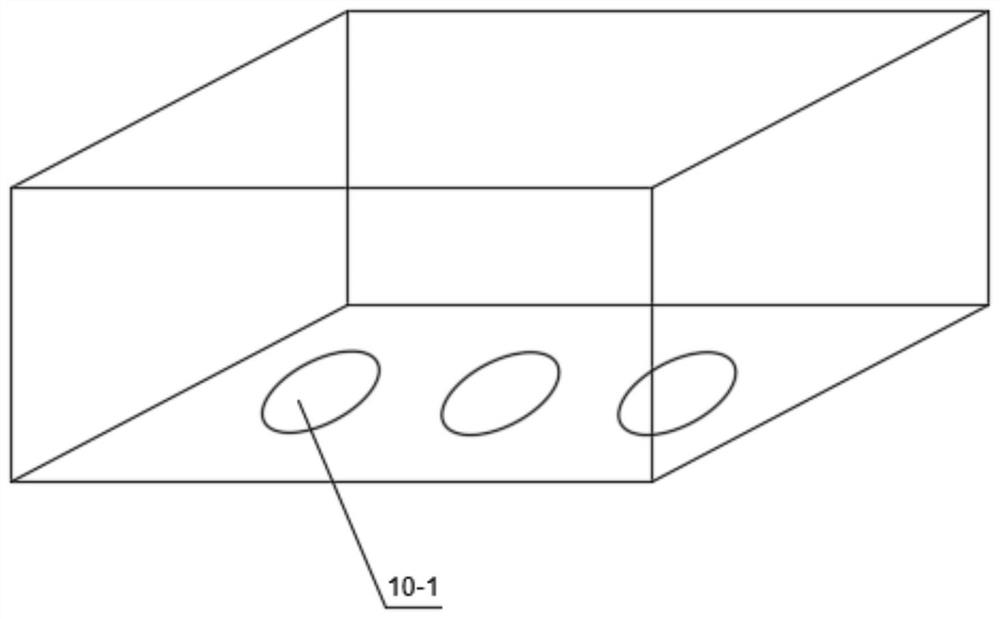

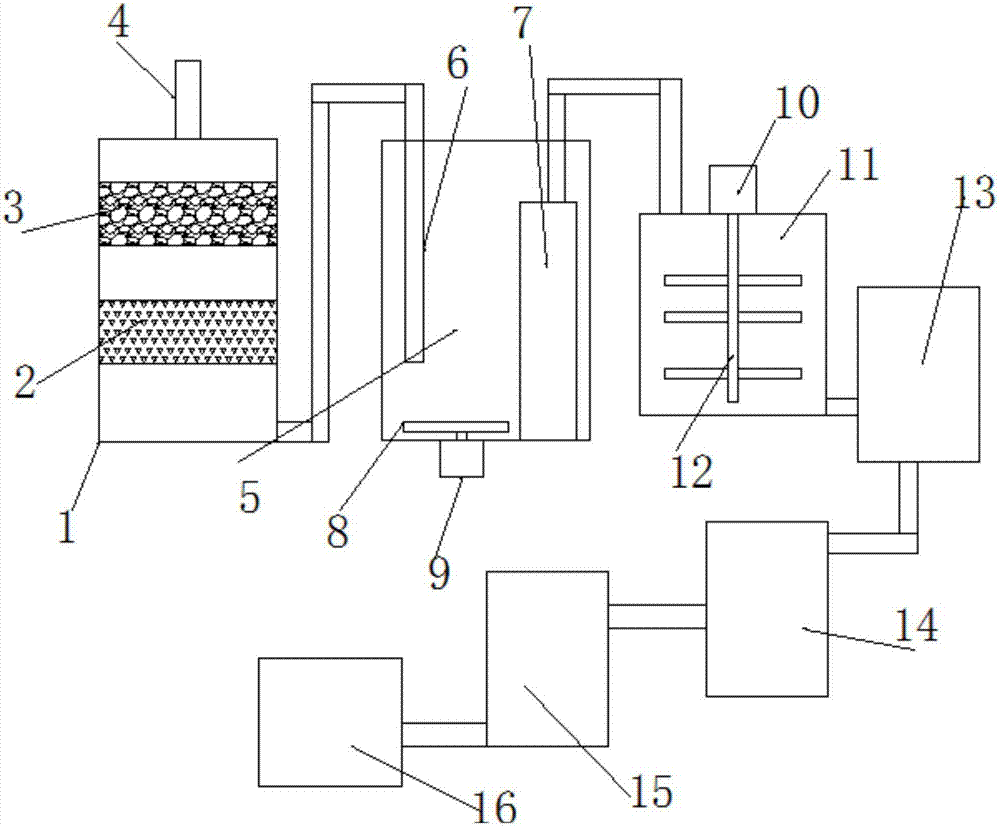

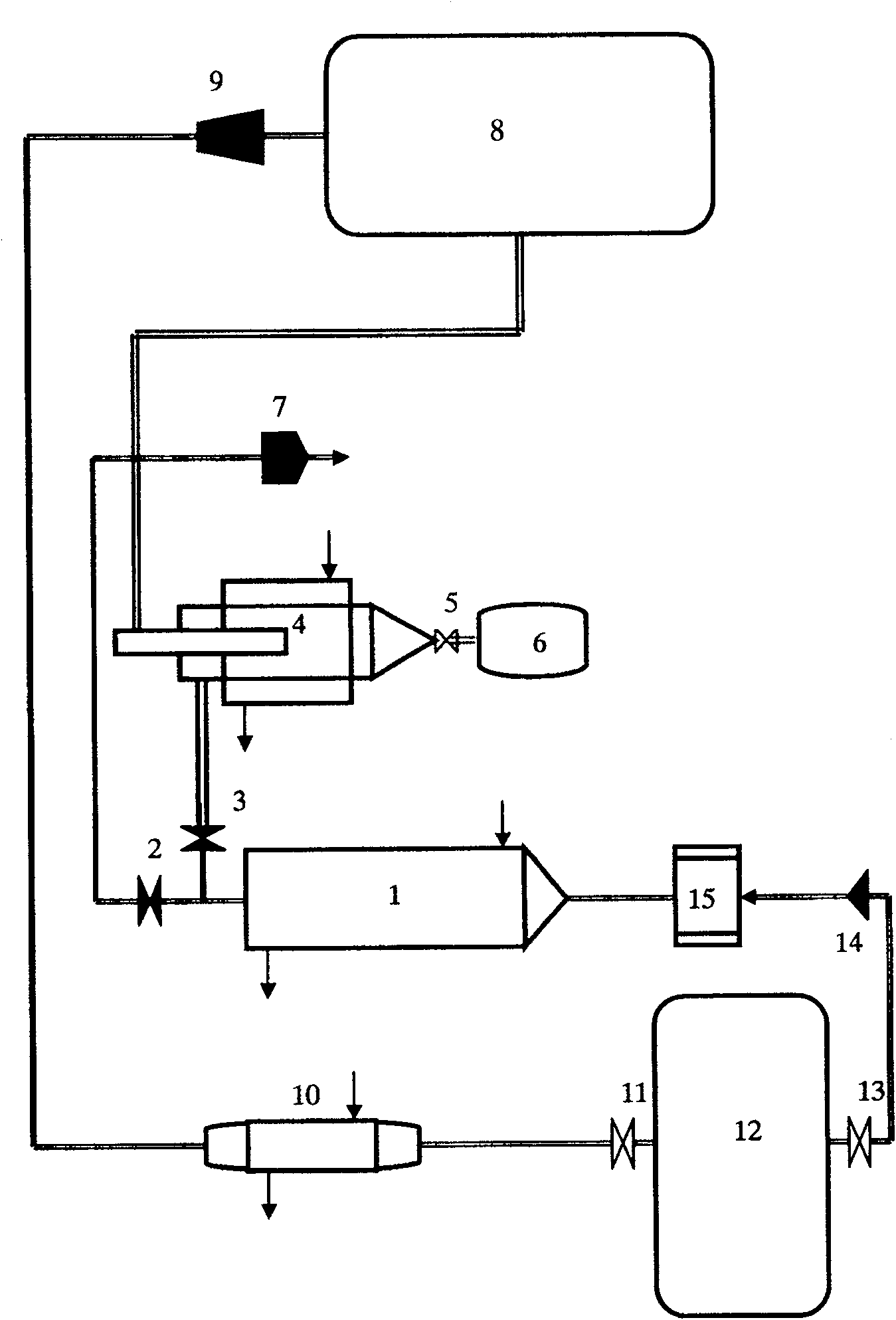

Ecological processing system used for aquatic product culture waste water and method thereof

InactiveCN107935296AReduce the difficulty of follow-up processingObvious diversificationTreatment using aerobic processesWaste water treatment from animal husbandryAquatic productBacterial strain

The invention discloses an ecological processing system used for aquatic product culture waste water and a method thereof. The system comprises a filtering-feeding fish culture pond, a primary filterpool, a biological floating island processing pool, a secondary filter pool, and a benthophyte treatment pool; wherein the primary filter pool and the secondary filter pool are filled with pelelith, plants are planted on an upper surface of the pelelith, and microbe bacterial strains are placed at a lower part. Through multilevel processing, each level of processing adopts omnibearing and multi-layered processing measurements, the aquatic product culture waste water can be efficiently processed and purified, and can be recycled, so that the ecological processing system achieves eco-environmentprotection.

Owner:HUBEI MAOYUAN WATER ECOLOGICAL RESOURCES DEV CO LTD

U-shaped soft vacuum dredged silt rapid drainage method

A U-shaped low vacuum dredging sludge rapid drainage method relates to a method which rapidly deals with the drainage of low concentration dredging sludge generated in the engineering construction of water conservancy, harbor approach, and substantially increases the concentration of the dredging sludge in the sludge stockyard. A U-shaped drainage system is formed by erecting a U-shaped sand bag in advance in a closing dam. The two ends of the U-shaped sand bag are respectively connected with an evacuating device and a venting device with a venting valve to form a space drainage system. In order to prevent clogging, when water is pumped, the venting valve is regulated to cause the drainage system to pump water in the low vacuum. During the pumping process, the venting valve is regulated according to the water content of the sludge in the closing dam; the vacuum pressure in the drainage system is gradually increased to guarantee the drainage efficiency of the system. The invention has simple technique and low cost, and is suitable for the large area of stockyard disposal project in the low concentration dredging sludge.

Owner:EAST ROUTE OF SOUTH TO NORTH WATER TRANSFER PROJECT JIANGSU WATER SOURCE

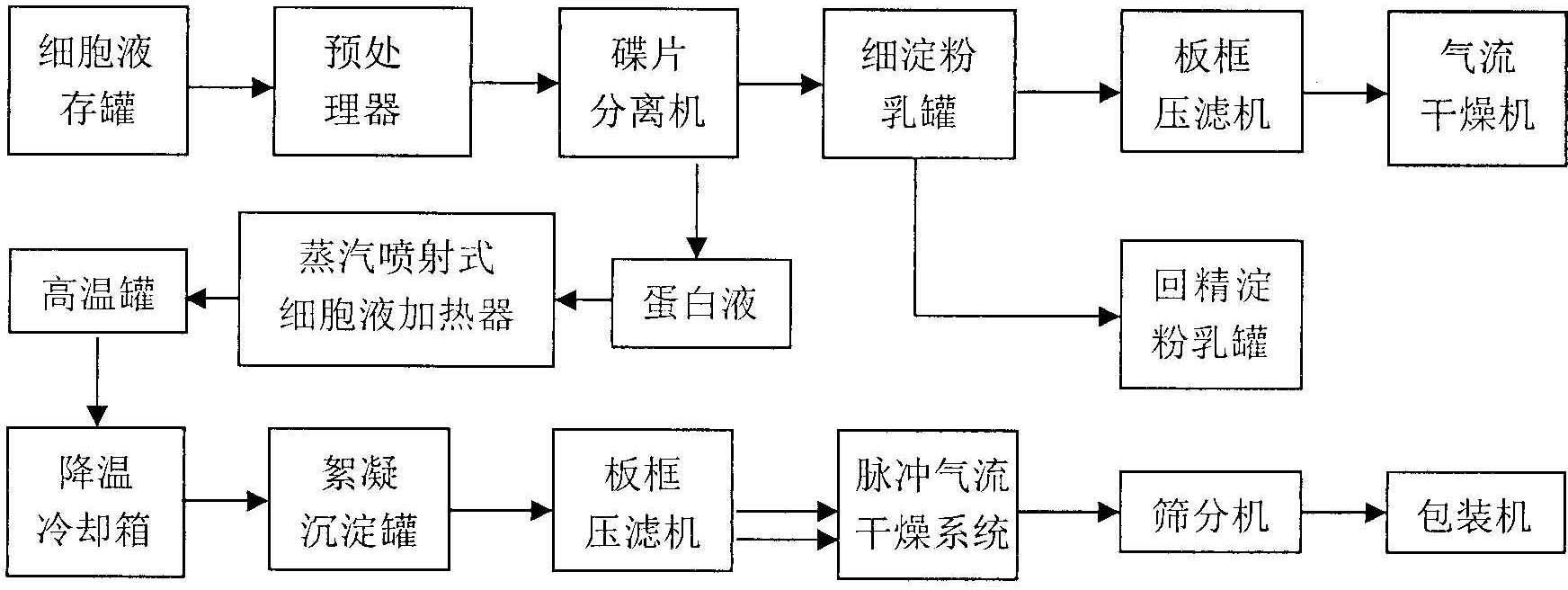

Highly-difficult waste water treatment method

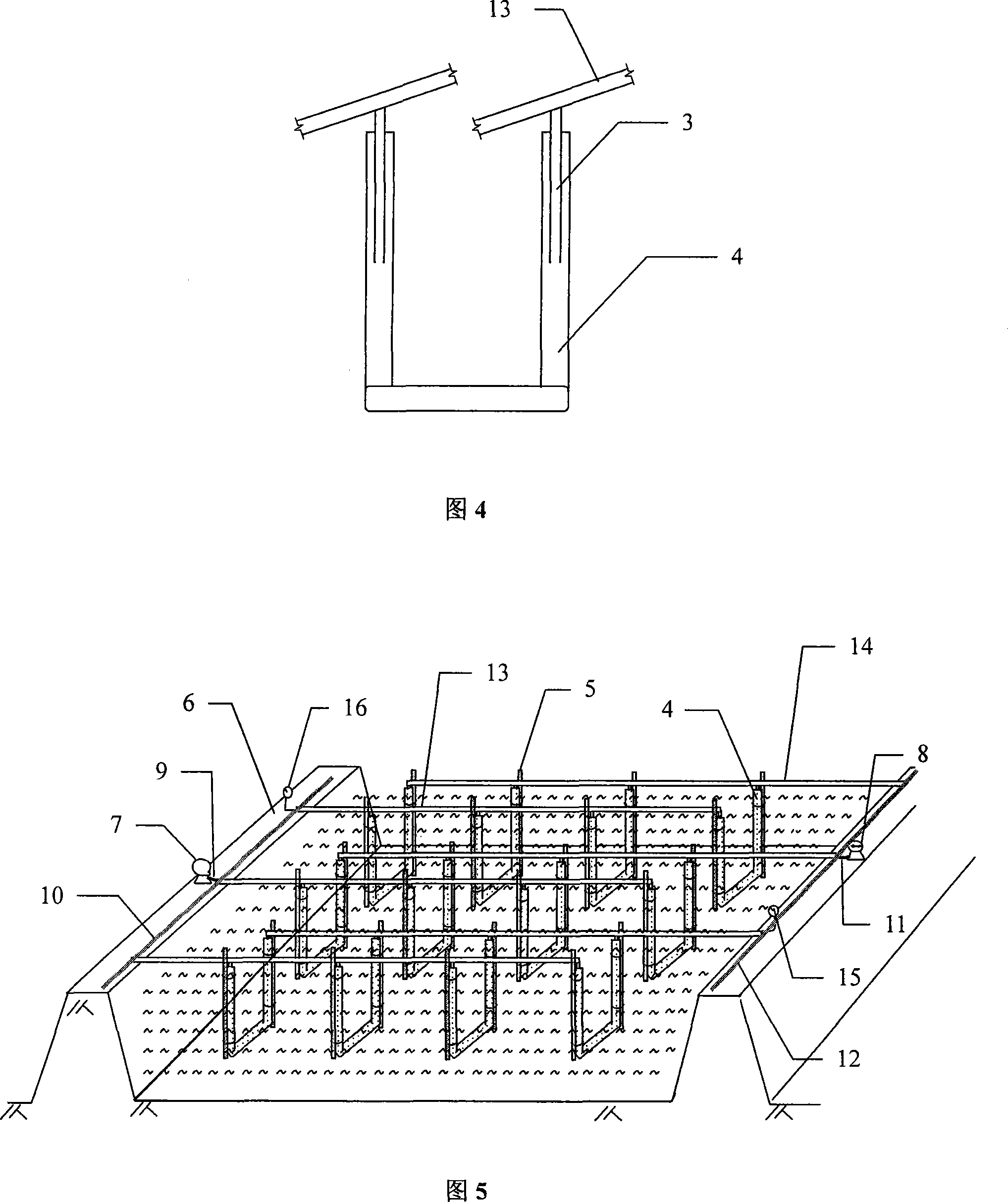

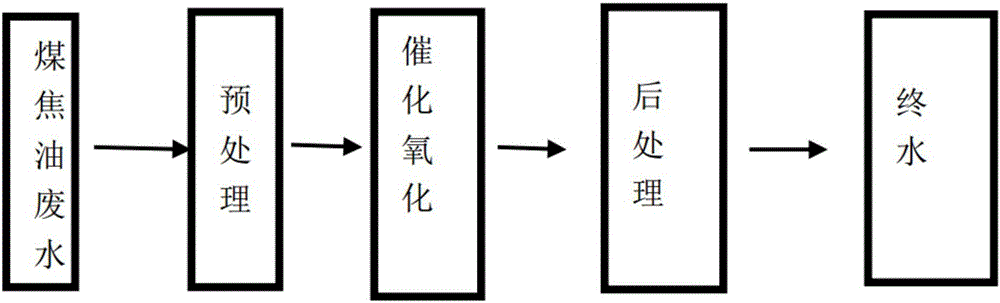

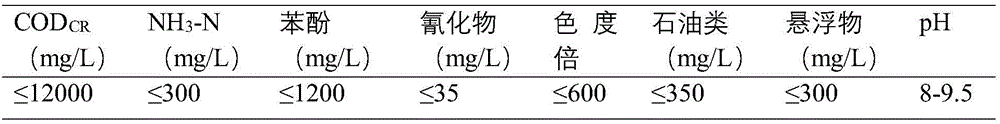

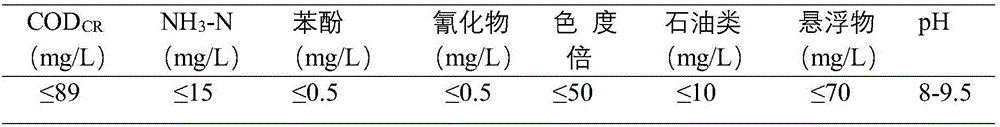

InactiveCN106745971ASolve the problem of difficult water discharge standardsReduce the difficulty of follow-up processingWater contaminantsMultistage water/sewage treatmentChemical oxygen demandCatalytic oxidation

The invention aims at providing a novel coal tar waste water treatment method. A purely-physicochemical method is adopted to overcome the defects of the prior art and handle results which are difficult in reaching the standard; the method mainly adopts a combined process comprising primary flocculation precipitation, catalytic oxidation and secondary precipitation, thus reducing the chemical oxygen demand (COD) in coal tar waste water as well as an ammonia nitrogen value, a cyanide value and a phenol value of the coal tar waste water, and enabling the effluent quality to reach the first-level sewage discharge standard in China. By adopting the purely-physicochemical method, the waste water treatment method is wider in application scope; by arranging a primary flocculation sedimentation tank, the suspended matters and chrominance of the organic waste water are greatly reduced; most organic and inorganic pollutants, phenol, aromatic hydrocarbons and cyanide in the water are removed by means of a catalytic oxidation two-stage tandem reaction; by adopting the catalytic oxidation reaction which combines a photocatalyst and micro-ozone, the production of a great deal of bubbles is avoided in a catalytic oxidation process; the adoption of ozone activated carbon filler is more conducive to the progress of the reaction and the removal of phenol; furthermore, less ozone is consumed, so that the waste water treatment method has less influence on the environment.

Owner:青岛万源环境科技有限公司

Method for increasing crystalizing efficiency of xylose in xylose mother solution

ActiveCN102603814ASimple stepsReduce processing costsSugar derivativesSugar derivatives preparationArabinoseTreatment costs

The invention belongs to the fields of biology and chemical industry, and particularly discloses a method for increasing the crystalizing efficiency of xylose in a xylose mother solution. The method comprises the following steps of: diluting the xylose mother solution; adding nutritional components; sterilizing; inoculating yeast for fermenting; removing glucose and galactose from the xylose mother solution; centrifugally separating yeast out of a zymotic fluid; filtering a clear zymotic fluid with a cross flow tube film; and removing a colloid contained in the zymotic fluid and fermentation metabolic products such as free proteins and the like produced in a fermenting process to obtain an ultra-filtered clear solution containing xylose and arabinose for use in subsequent production. The method has the advantages of simple steps, low treatment cost, high separating accuracy, good separating effect, great reduction in the subsequent treatment difficulty, great increase in product yield and suitability for wide popularization and application.

Owner:山东绿健生物技术有限公司

Method for removing environment hormone dimethyl phthalate in water body

InactiveCN101700923AReduce contentImprove safety and qualityWater contaminantsWater/sewage treatment by flocculation/precipitationWater sourceTherapeutic effect

The invention provides a method for removing environment hormone dimethyl phthalate in water body; the treated water is mainly used for water supplying in towns and cities and being stored in water plants; the method comprises the following steps: (1) flocculating agent-poly-dimethyl diallyl ammonium chloride is added in a reactor with source water, and the source water and the flocculating agent are completely stirred uniformly. (2) The source water treated in the step (1) is placed still for a while, and then the source water is discharged for subsequent treatment after carrying out flocculating settling. In the invention, the poly-dimethyl diallyl ammonium chloride is used as the flocculating agent to adsorb dimethyl phthalate in source water, and then the content of the dimethyl phthalate is effectively reduced through flocculating settling, so as to greatly improve the municipal engineering water supplying safety and hygienic quality. The method has the characteristics of convenient operation, low treating cost, easily-controlled conditions and stable treatment effect and can remove more than 60 percent of dimethyl phthalate organic matters in source water.

Owner:CHONGQING TAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for increasing crystalizing efficiency of xylose in xylose mother solution

ActiveCN102603814BSimple stepsReduce processing costsSugar derivativesSugar derivatives preparationChemical industryFree protein

The invention belongs to the fields of biology and chemical industry, and particularly discloses a method for increasing the crystalizing efficiency of xylose in a xylose mother solution. The method comprises the following steps of: diluting the xylose mother solution; adding nutritional components; sterilizing; inoculating yeast for fermenting; removing glucose and galactose from the xylose mother solution; centrifugally separating yeast out of a zymotic fluid; filtering a clear zymotic fluid with a cross flow tube film; and removing a colloid contained in the zymotic fluid and fermentation metabolic products such as free proteins and the like produced in a fermenting process to obtain an ultra-filtered clear solution containing xylose and arabinose for use in subsequent production. The method has the advantages of simple steps, low treatment cost, high separating accuracy, good separating effect, great reduction in the subsequent treatment difficulty, great increase in product yield and suitability for wide popularization and application.

Owner:山东绿健生物技术有限公司

Process for extracting oil

InactiveCN1962838AGood extractionComprehensive extraction rate is highFatty-oils/fats productionSolventDimethyl ether

The invention discloses a extracting method of grease, which is characterized by the following steps: 1) disintegrating materials to 10-40 order; 2) adopting liquid dimethyl ether as extraction solvent; conveying to materials with the rate of material and dissolvent at 1:2-1:24; extracting 30-120 min under the condition of pressure at 5-30 kilogram at 30-90 Deg C; 3) separating grease in the condition of pressure at 1-5 kilogramat 20-60 Deg C. The invention simplifies the manufacturing craft, which improving extracting rate effectively.

Owner:侯金荣 +1

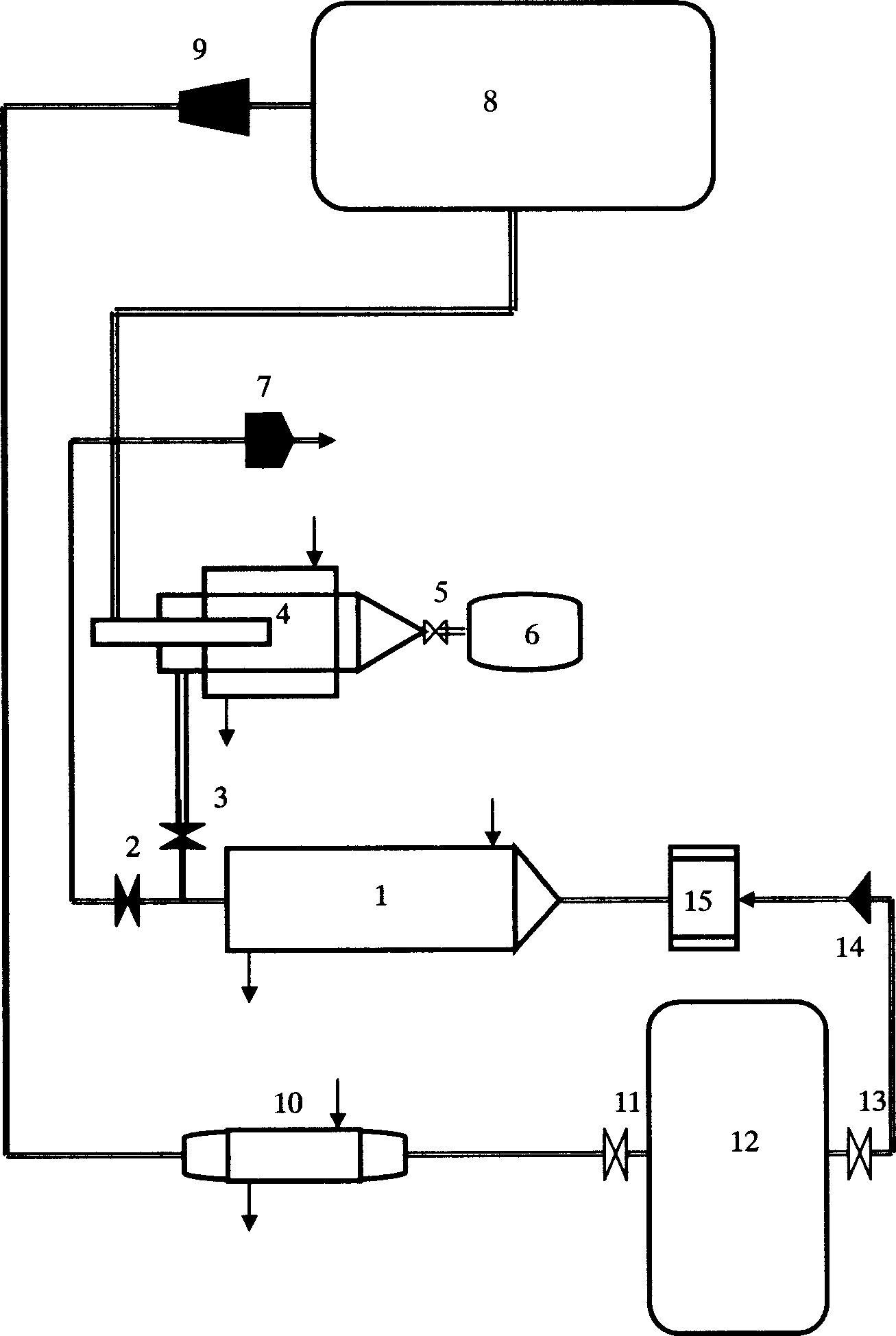

Method and device for removing nitrates from drinking water

InactiveCN102126789AAvoid excess electron donors and microbial overgrowthReduce processing difficultyWater contaminantsTreatment with anaerobic digestion processesChemistryActivated carbon

The invention relates to environmental protection, in particular to a method and a device for removing nitrates from drinking water. The method comprises the following steps that: organic micromolecules generated by the anaerobic digestion of strains in an anaerobic fermentation unit permeate through a separating diffusion layer and are diffused to enter a denitrification unit to serve as a reducing agent for strains subjected to habituated culture in the denitrification unit, namely an electron donor source, wherein for 30 to 50 mg / L of NO3<->-N nitrates at the temperature of between 20 and 25 DEG C, water is cut for 24 to 36 hours; and voltage difference between the denitrification unit and the anaerobic fermentation unit forms microbial current through activated carbon fibers, and the microbial current is transmitted to the denitrification unit from the anaerobic fermentation unit to promote bio-electrochemical denitrification, so that heterotrophic denitrification and bio-electrochemical denitrification are synchronously and synergetically to remove the nitrates from the drinking water. By the method and the device, an electron dornor is prevented from being excessive, and theproblem that the nitrates in the drinking water exceed the standard is solved economically and reliably. The method is suitable for removing the nitrates in the drinking water in large scale and is also suitable for the in-situ treatment of the nitrate pollution in a drinking water source.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

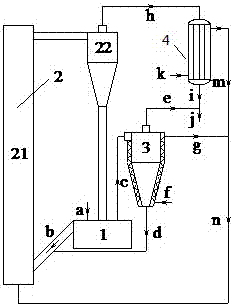

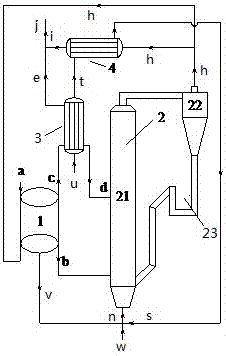

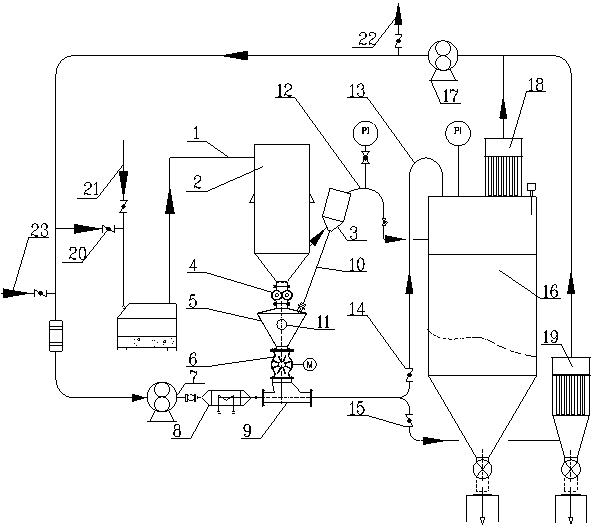

Double-bed gasification unit and method

PendingCN107083260AImprove gas qualityReduce the amount of pollutantsDirect heating destructive distillationGasification processes detailsTarPollutant

The invention relates to a double-bed gasification device, which includes: a pyrolysis furnace, a gasification furnace and a pyrolysis gas condensation separator, and re-adds the difficult-to-use low-quality tar produced by pyrolysis into the high-temperature gasification furnace to generate synthetic gas Or water gas, and reduce the tar component in the generated synthetic gas or water gas, improve the gas quality, reduce the amount of pollutants in the gas, and reduce the difficulty of subsequent gas treatment. At the same time, after the pyrolysis gas is cooled and liquefied, only the liquefied tar enters the gasifier again for re-gasification, and the pyrolysis coal gas of hydrocarbon-rich substances that cannot be gasified no longer participates in the gasification but directly interacts with the generated The mixed gas and water gas are mixed to form a mixture, thereby reducing the damage to the hydrocarbons in the pyrolysis gas, and these hydrocarbon-rich substances are transferred to the mixed gas, which greatly improves the calorific value and quality of the gas.

Owner:SHENWU TECH GRP CO LTD

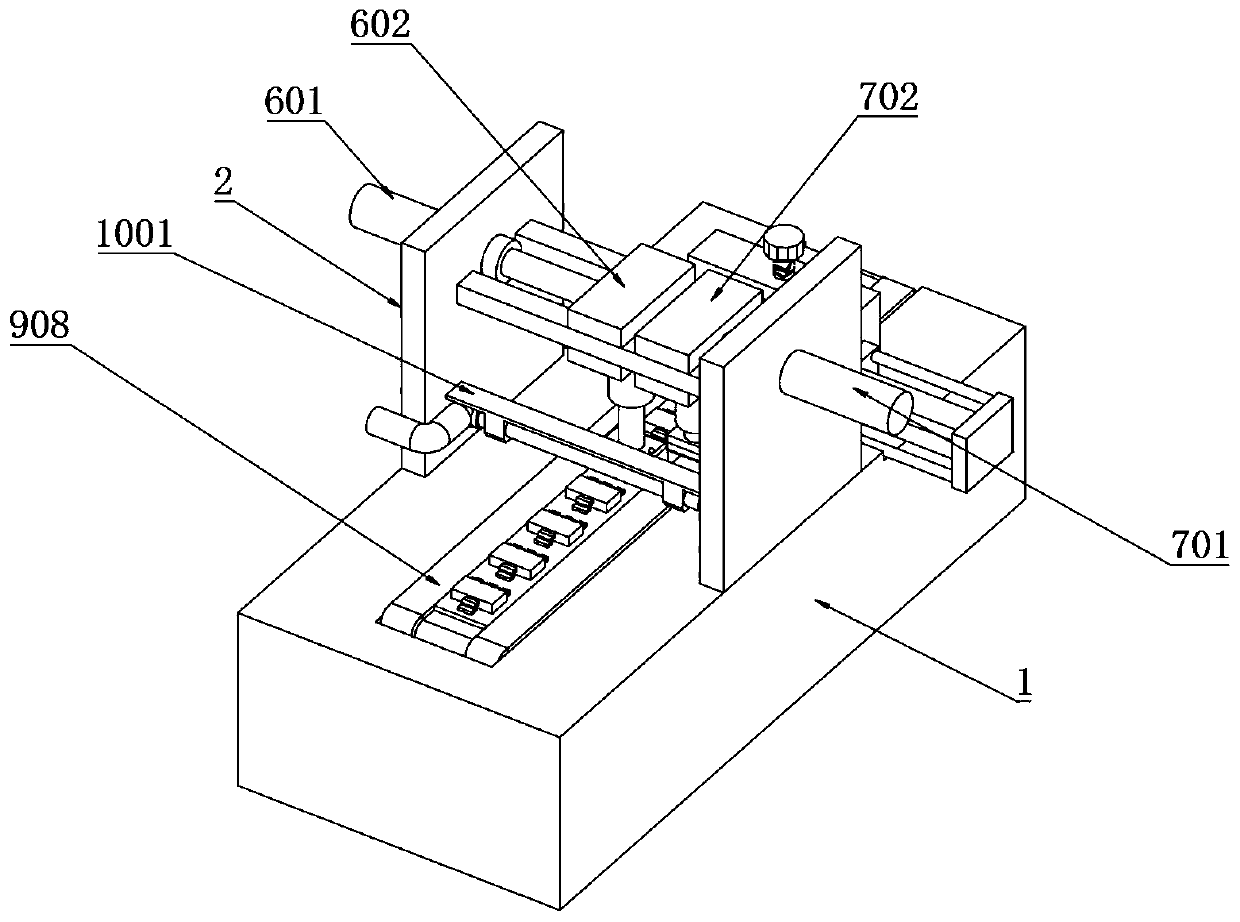

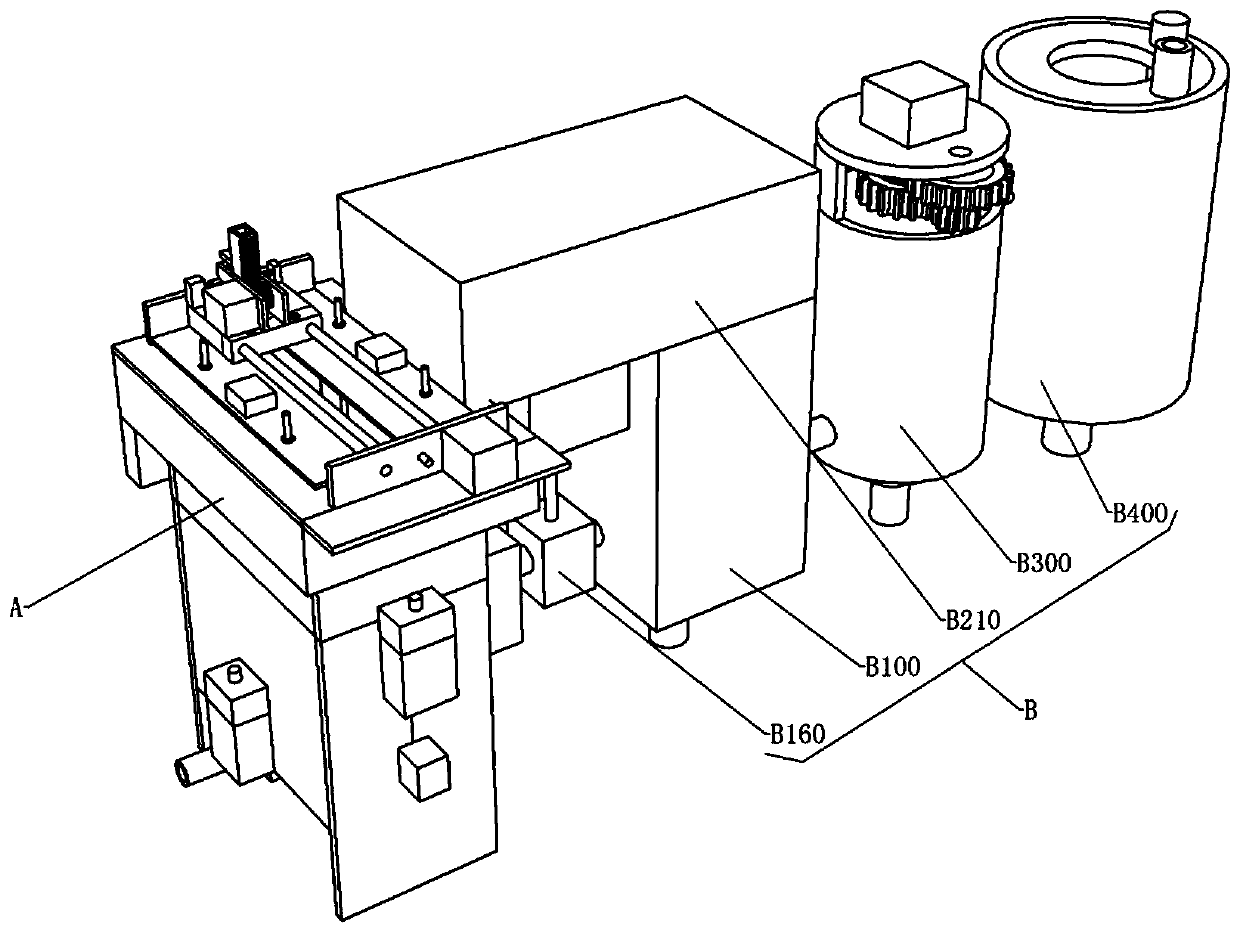

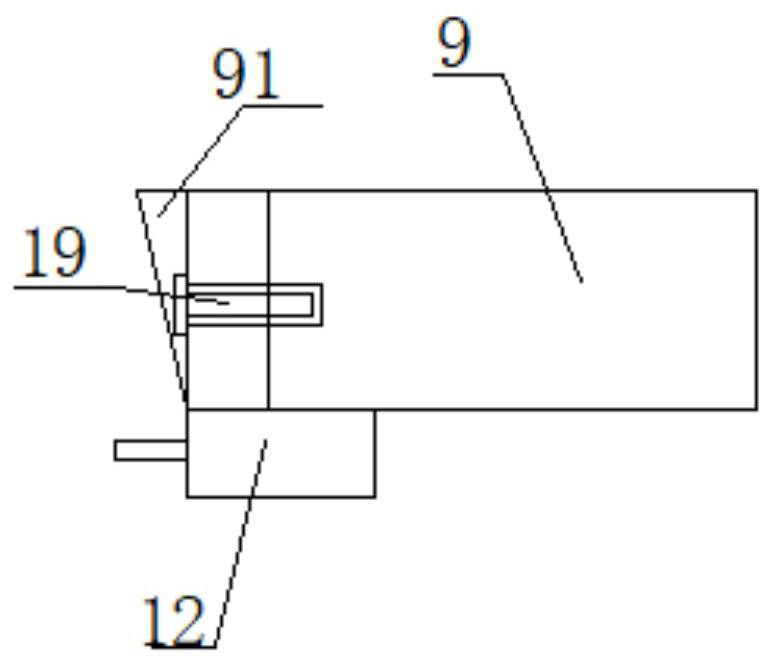

Portable chip removing device capable of screening

ActiveCN111554598AGood removal effectPrevent chip strips from being cut offSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingStructural engineeringMechanical engineering

The invention discloses a portable chip removing device capable of screening. The device comprises a fixed base, and an H-shaped supporting frame is welded to the edge of the top end of the fixed base. A feeding groove is formed in the middle of the top end of the fixed base; a conveying belt is mounted in the feeding groove; a limiting neck is formed in the middle of the bottom end of the inner wall of the H-shaped supporting frame; a first air cylinder is mounted on one side of the inner wall of the H-shaped supporting frame; an I-shaped screening mounting plate is mounted at the push rod end of the first air cylinder; a first hydraulic push rod is mounted in the middle of the bottom end of the I-shaped screening mounting plate; a screening plate is mounted at the push rod end of the first hydraulic push rod; and through a first air cylinder, an I-shaped screening mounting plate, a first hydraulic push rod, a screening plate, a screening groove and an indicating lamp, chips mounted on the surfaces of chip strips can be detected, and through detection and screening of the chips mounted on the surfaces of the chip strips, workers can find out damaged chips, so that the workers canconveniently remove the damaged chips.

Owner:深圳市耀芯微电子有限公司

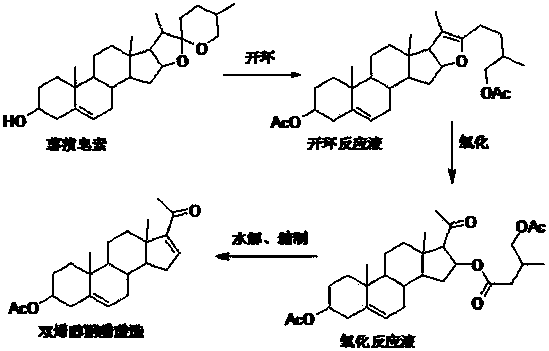

Method for producing 16-dehydropregnenolone acetate

InactiveCN104045676ALow equipment requirementsEliminate potential safety hazardsSteroidsDehydropregnenolone acetateOxidizing agent

The invention discloses a method for producing 16-dehydropregnenolone acetate. The method comprises the following steps: carrying out ring opening on diosgenine as a raw material, oxidizing, hydrolyzing, and refining to produce highly 16-dehydropregnenolone acetate. Compared with traditional 16-dehydropregnenolone acetate production methods, the method especially adopting highly active ozone as an oxidant in the oxidation reaction process has the advantages of novelty, mild reaction conditions, and easy control of the reaction product; the total yield of separated 16-dehydropregnenolone acetate reaches 79.5%, and is higher than an industrial average production level of 72-74%; and the oxidant in the reaction process can be recycled, so the method also has the advantages of realization of continuous production, production cost reduction, investment saving, labor intensity mitigation, high comprehensive utilization rate, and environmental protection, and provides a reference for the industrial production.

Owner:CHENGDU LAURELSCI TECH

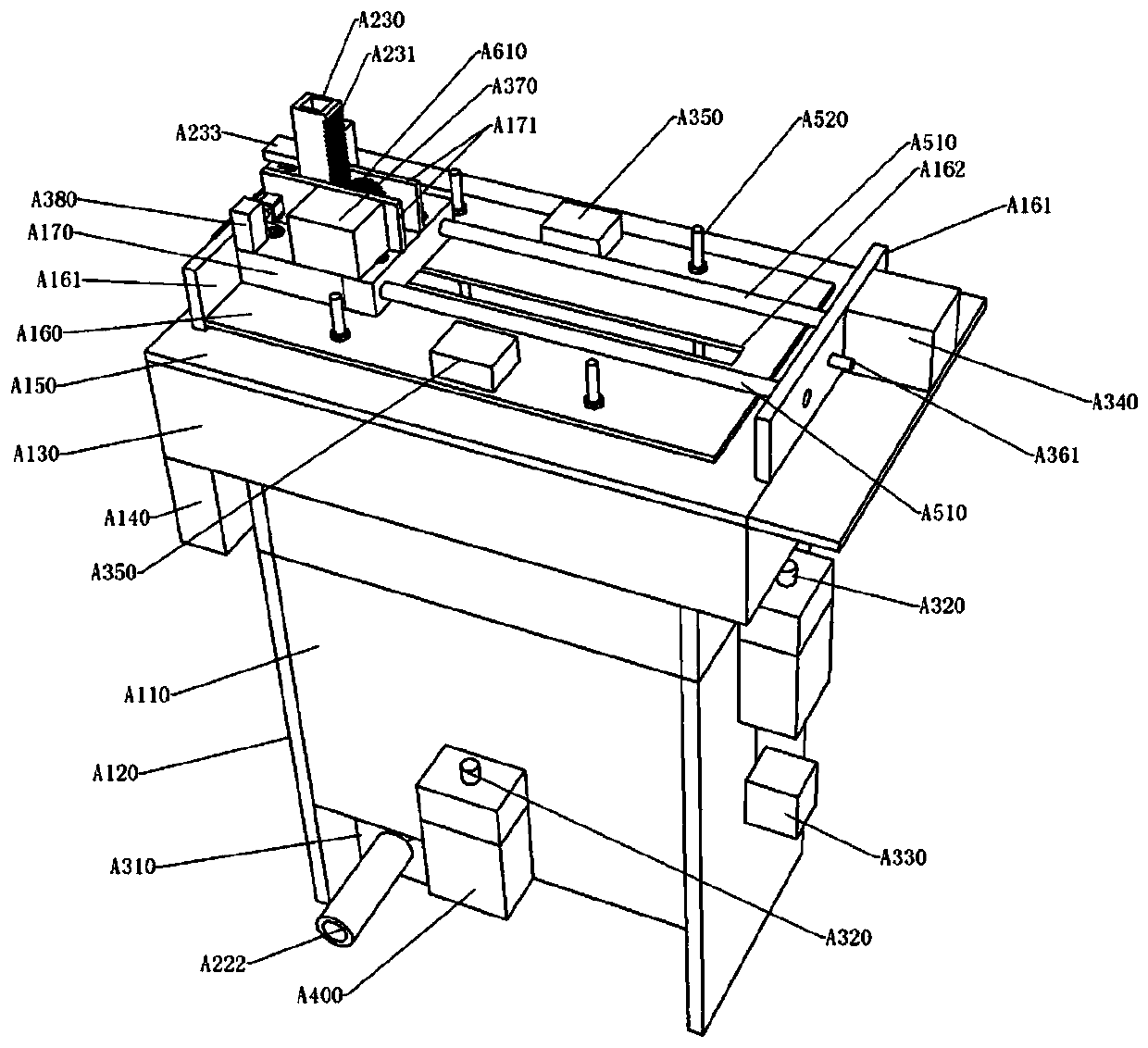

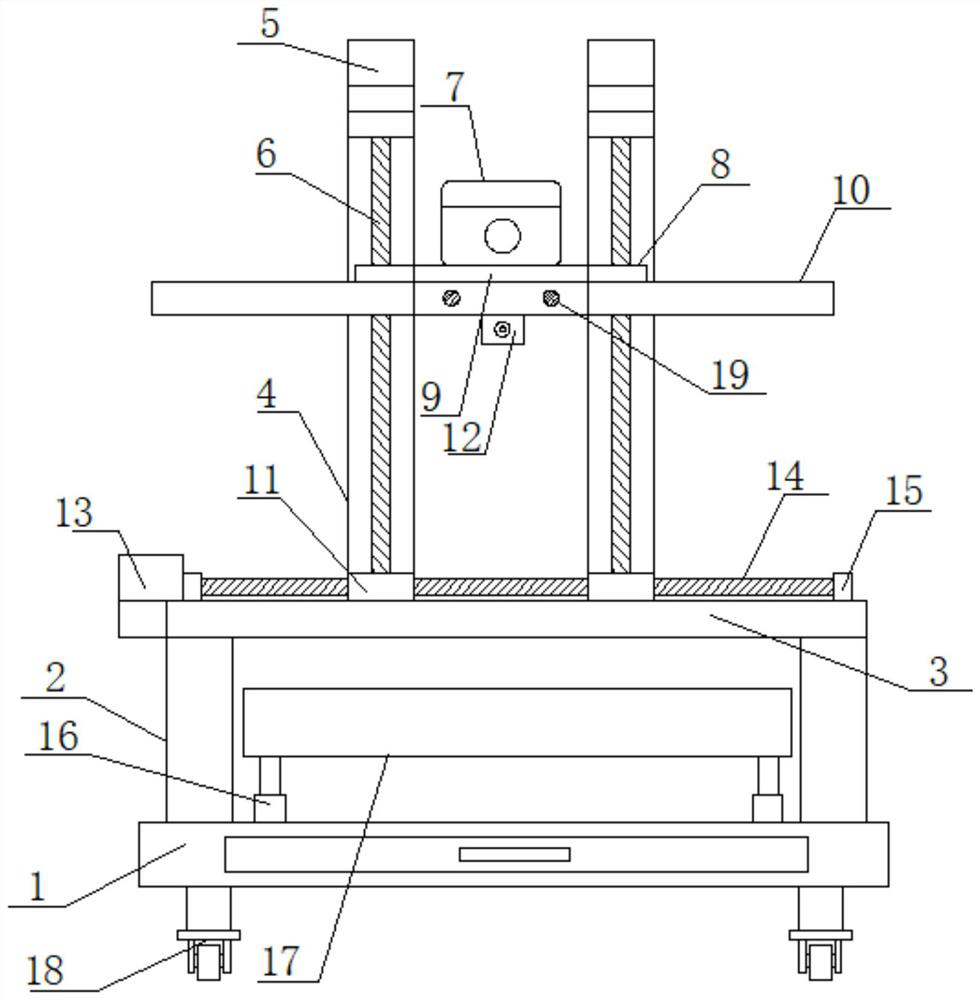

Polishing machine with dust suction device

InactiveCN107350948AImprove integrityImprove efficiencyPolishing machinesGrinding work supportsWorking environmentPulp and paper industry

The present invention relates to the technical field of polishing machines, and more specifically relates to a polishing machine with a dust suction device, which includes an operating table, the operating table includes a main operating table and an auxiliary operating table, and the main operating table includes a blower, a frame and a polishing disc , the operation sub-table includes the table, water tank, lifting device and support plate, adjust the lifting device to make the distance between the support plate and the polishing plate adapt to the size of the actual product, the dust suction fan sucks the dust into the dust box, the blower and The inlet increases the efficiency of dust entering the dust collection box, and the water tank reduces the flying degree of dust during subsequent processing; the invention is suitable for various product sizes, has more comprehensive dust collection, reduces the difficulty of subsequent processing, improves the working environment, and is suitable for popularization and use.

Owner:山东恒德智能装备科技有限公司

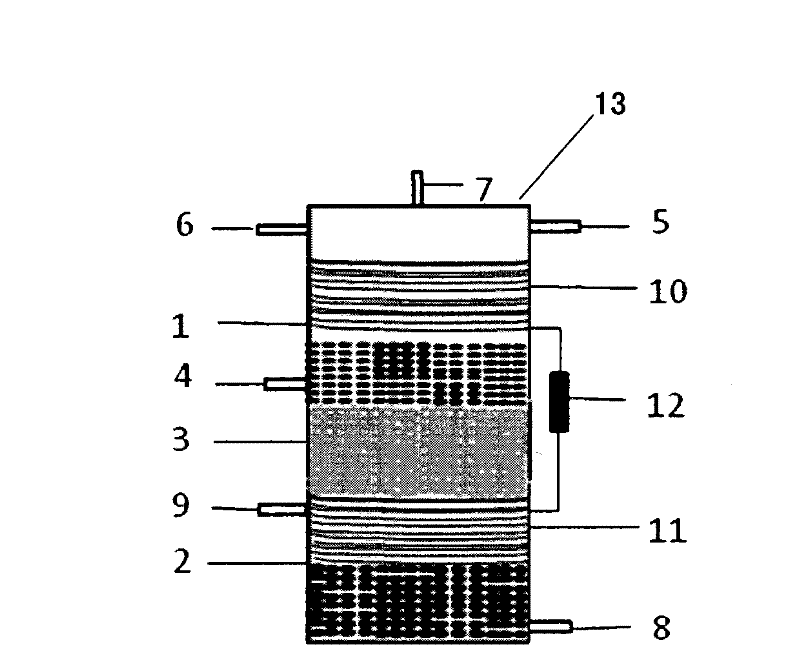

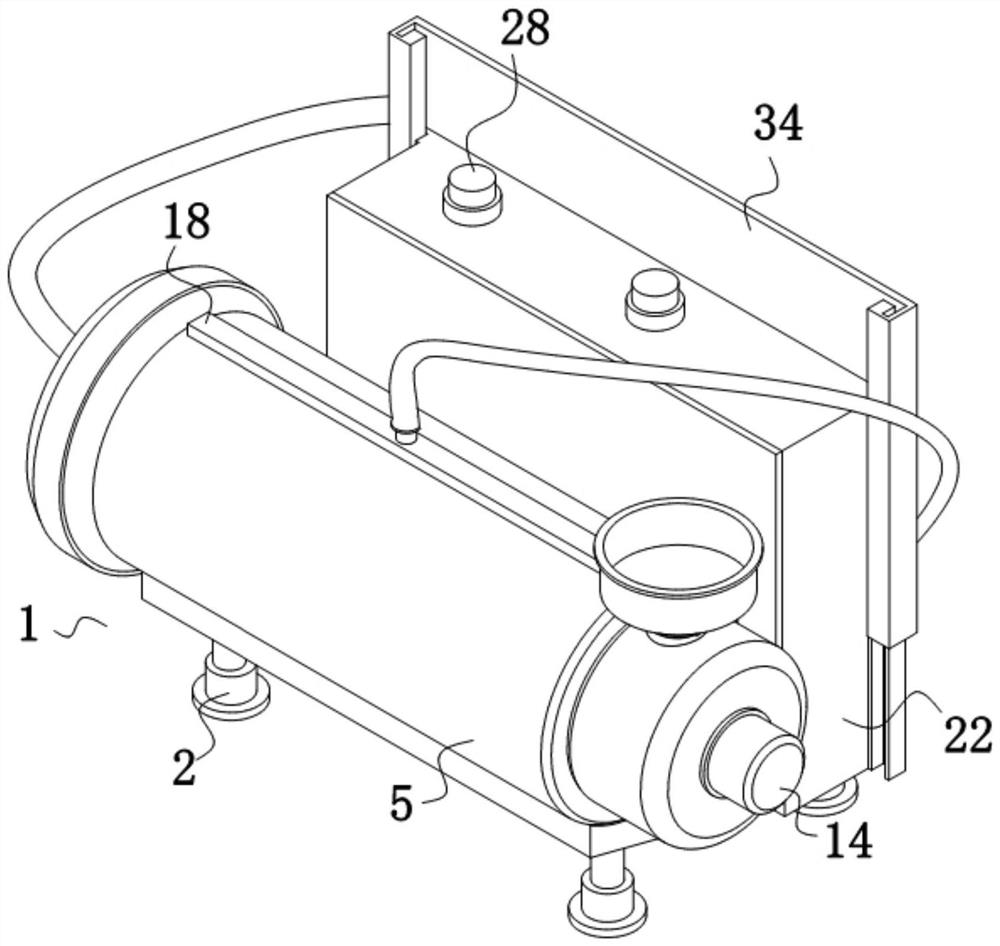

Filter and coal mine underground water purification system thereof

InactiveCN111111283ASimple structureReduce the difficulty of follow-up processingWaste water treatment from quariesWater/sewage treatmentSludgeWater filter

The invention relates to a filter and a coal mine underground water purification system thereof; the filter comprises two filter side plates, a filter shell and a filter screen, and the two filter side plates are respectively fixed at openings at two sides of the filter shell; an overflow shell is mounted at the top of the filter shell, an overflow weir is formed between the inner side of the overflow shell and the outer wall of the filter shell and communicates with the top of a water collecting tank in the water collecting shell, the bottom of the water collecting tank communicates with oneend of an overflow pipe, and the other end of the overflow pipe communicates with a purification water inlet pipe of a secondary purification module; a hollow filter cavity is formed in the filter shell, a V-shaped groove with the width gradually decreased from top to bottom is formed in the bottom of the filter cavity, a sludge auger is arranged in the V-shaped groove, a sludge auger shaft is fixedly sleeved with the sludge auger, and one end of the sludge auger shaft penetrates out of the filter shell and then is fixedly assembled with an output shaft of a sludge auger motor; countless through filter holes are formed in the filter screen, and a filter drain pipe is arranged above the filter screen and is used for conveying water filtered by the filter screen to a purification water inletpipe of a main purification module.

Owner:CHONGQING YIXI BRAND PLANNING CO LTD

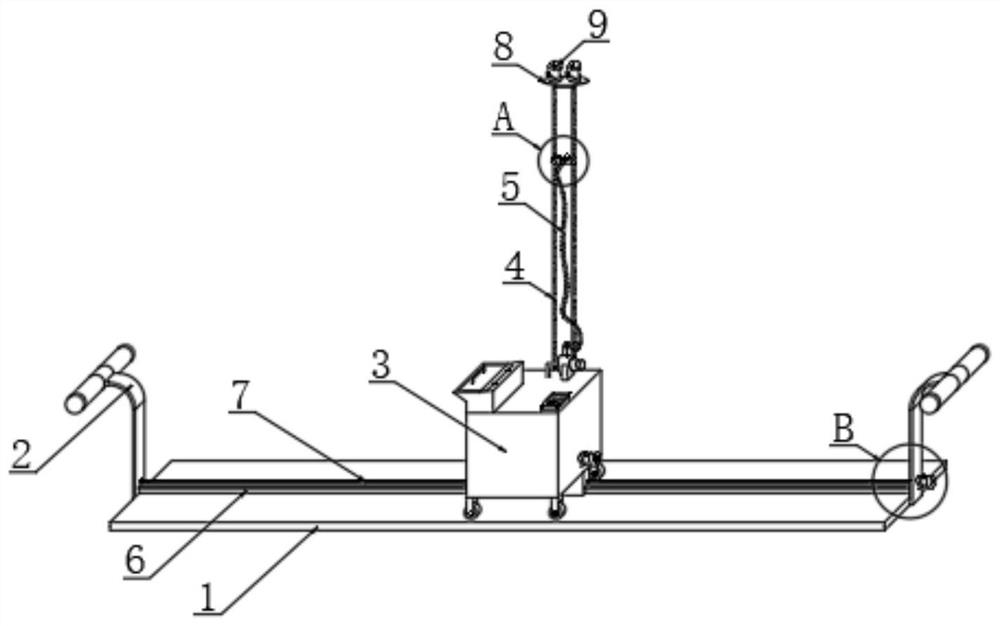

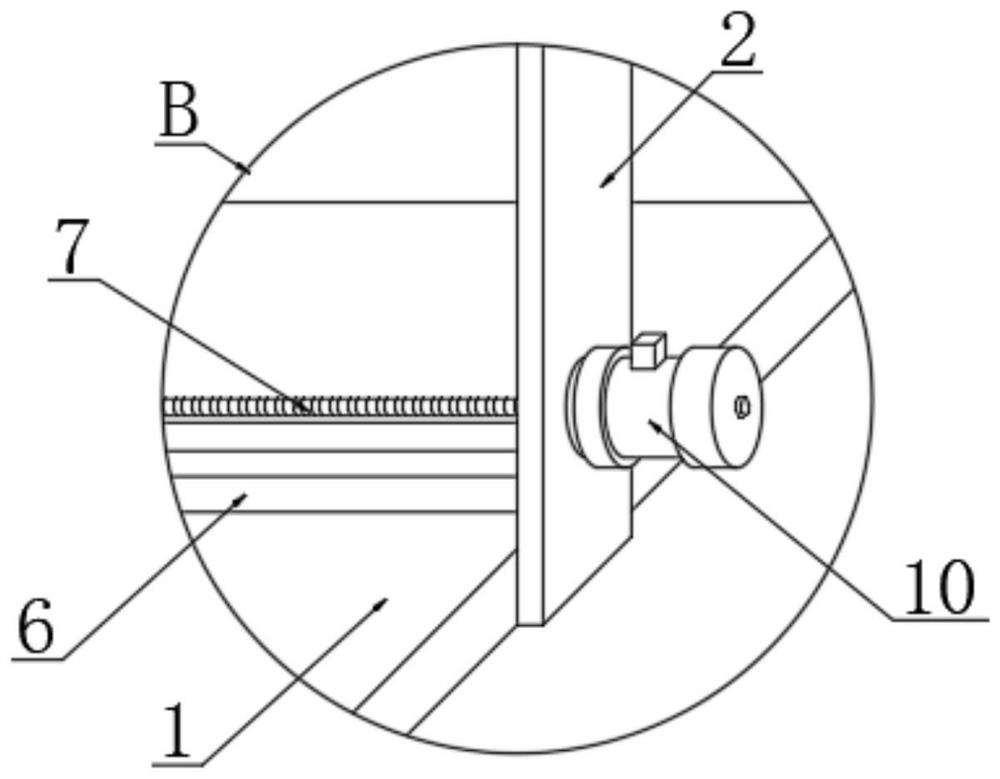

Automatic wall surface machining device for architectural decoration engineering

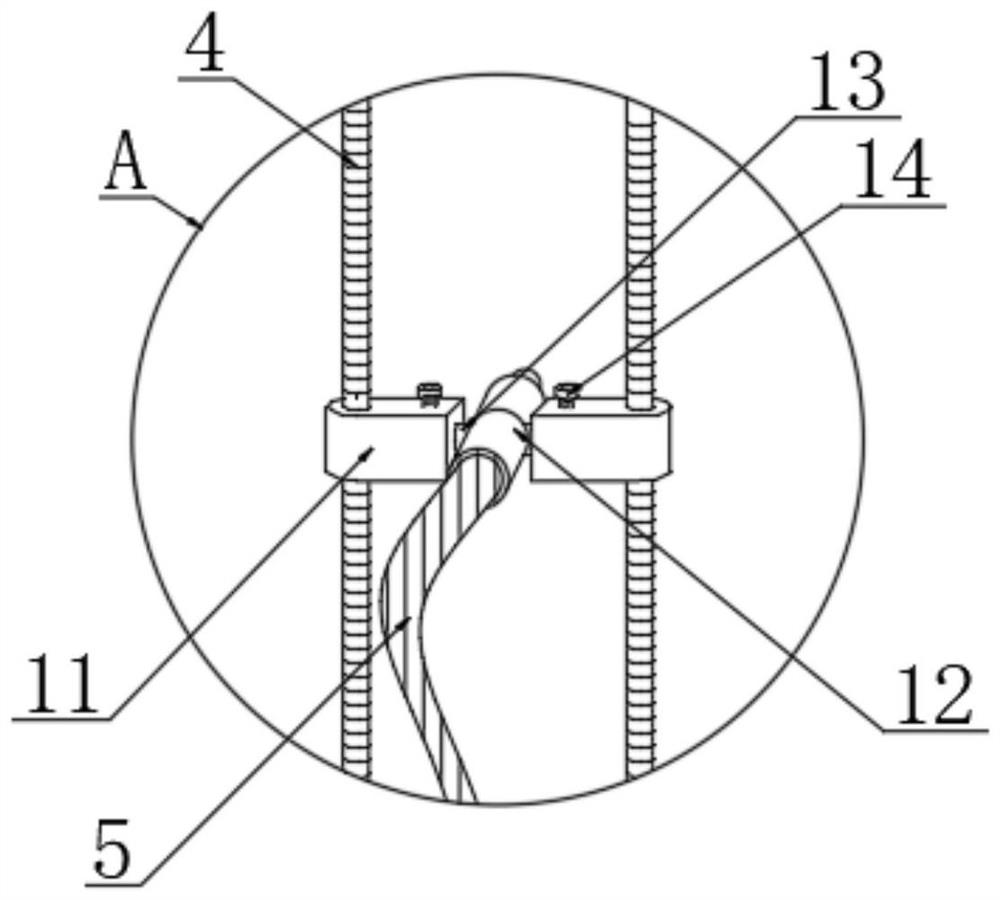

InactiveCN112252674AImprove processing qualityAvoid accumulationDischarging apparatusBuilding constructionsElectric machineryThreaded rod

The invention relates to the technical field of wall body machining, in particular to an automatic wall surface machining device for architectural decoration engineering. The device comprises a bottomplate, wherein a handle is welded to one end of the upper surface of the bottom plate, a sliding rail is welded to the upper surface of the bottom plate, a transverse moving threaded rod is rotatablymounted at the lower end of the inner side of the handle, a transverse moving motor is installed at the position, corresponding to the transverse moving threaded rod, of the outer surface of one sideof the handle, a spraying box is slidably installed on the outer surface of the sliding rail, a lifting threaded rod is rotatably installed behind the spraying box, a top plate is installed on the upper surface of the lifting threaded rod, a lifting motor is installed on the upper surface of the top plate, a lifting sliding seat is installed on the outer surface of the lifting threaded rod, a rotating rod is rotatably installed on the inner side of the lifting sliding seat, and a spray head is fixed to the outer surface of the rotating rod. The device is operated automatically, concrete can be prevented from being splashed to an operator, an intelligent control program is set, and spraying is uniform.

Owner:魏爱敏

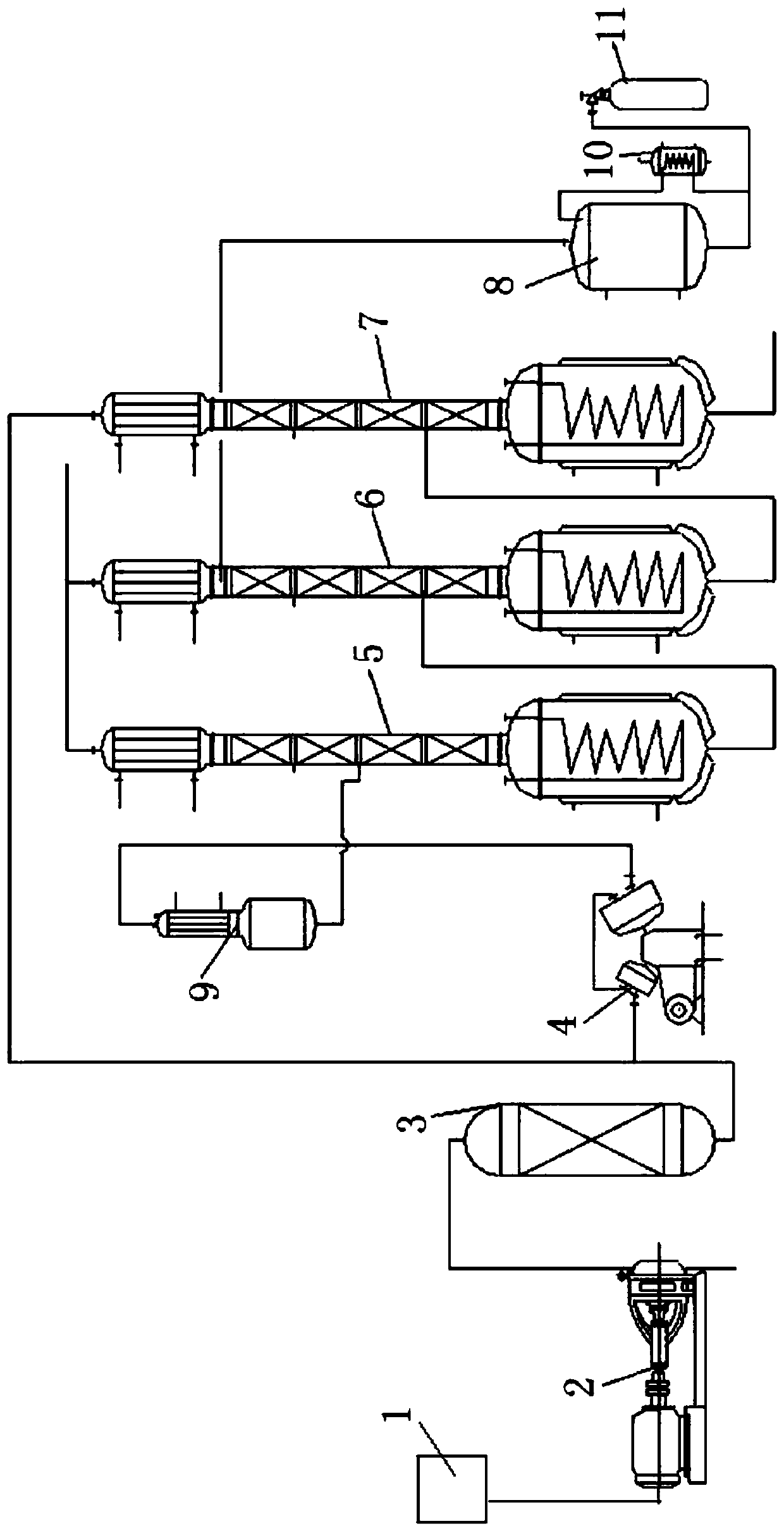

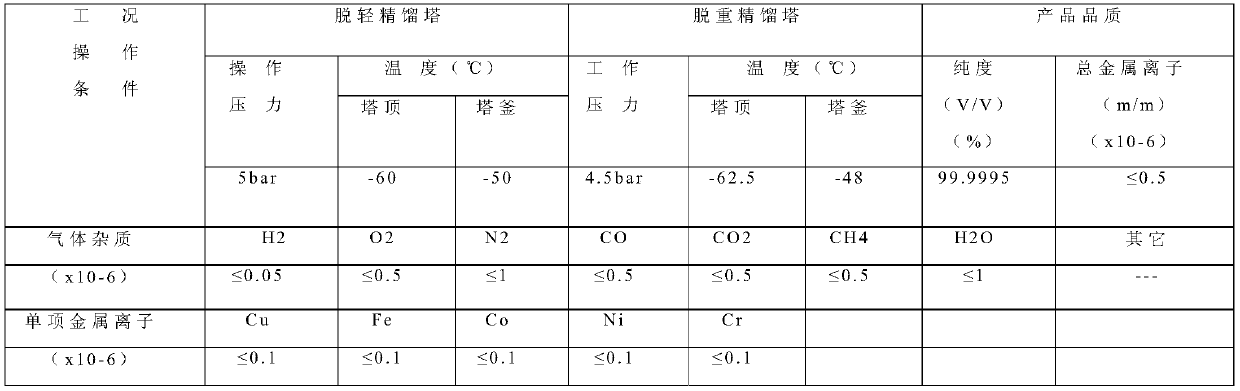

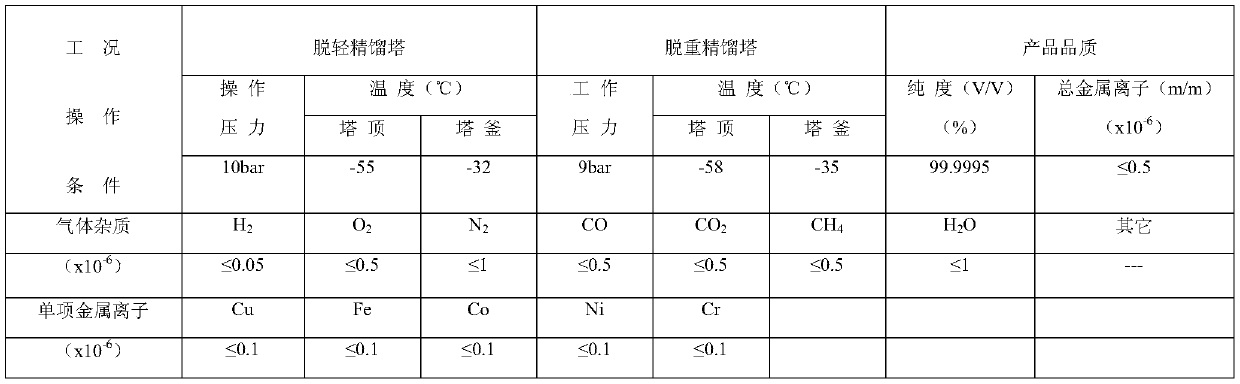

Preparation method of electronic-grade high-purity hydrogen chloride

PendingCN110255501AReduce pressure on environmental protectionImprove securitySolidificationLiquefactionHydrogen chloridePollution

The invention discloses a preparation method of electronic-grade high-purity hydrogen chloride. The preparation method includes subjecting toluene and chlorine to a chlorination reaction to produce chlorotoluene and a by-product, namely a hydrogen chloride gas, dewatering, liquefying and rectifying the by-product as a raw material to remove light components, and further performing rectification to remove heavy components to obtain the electronic-grade high-purity hydrogen chloride. The preparation method has the advantages that an original process for converting hydrogen chloride produced after toluene chlorination into hydrochloric acid is changed into a method for producing the electronic-grade high-purity hydrogen chloride, and the industrial hydrochloric acid is basically surplus waste liquid in actual chemical production and needs to be treated; by the preparation method, waste is turned into treasures, and new pollution is avoided.

Owner:SUZHOU JINHONG GAS CO LTD

Integrated efficient thermal washing-advanced oxidation combined oily sludge treatment system and oily sludge treatment method

PendingCN113003922AEfficient elutionReduce the difficulty of degradationSludge treatment by de-watering/drying/thickeningSludgePersulfate

The invention discloses an integrated high-efficiency thermal washing-advanced oxidation combined oily sludge treatment system and an oily sludge treatment method, and belongs to the technical field of oily sludge treatment. The method comprises a water washing process and an oxidation process, most crude oil can be efficiently and rapidly eluted in the water washing process, and the degradation difficulty is greatly reduced for subsequent oxidation treatment; in the oxidation process, persulfate is adopted as an oxidizing agent, green and environment-friendly treatment is achieved under the conditions of low temperature and water addition, harm to the environment is small, and an efficient solution is provided for oily sludge remediation.

Owner:SHANDONG UNIV OF SCI & TECH

System device and process for industrially producing aluminum chloride

ActiveCN108862347AImprove the environmentMeet environmental protection requirementsAluminium chloridesProcess systemsBulk crystal

The invention relates to a system device and a process for industrially producing aluminum chloride. An aluminum chloride steam discharged from a chlorination furnace enters a main catcher through a subliming pipe and is condensed into powder or crystals in a three-section way, bulk crystal materials are smashed through a crusher so as to enter a surge bin and a star type feeder, the materials arepneumatically conveyed in an accelerating chamber through a roots blower and are cooled in a cooler so as to enter a stock bin, a tail gas is filtered through a dust remover on the top part of the stock bin and is conveyed to an inlet of the roots blower through an air induced fan so as to be recycled, and part of tail gas enters a chlorine recycle pipe or enters a common chlorine treatment pipeline; meanwhile, an assistant catcher is also arranged for feeding a small amount of aluminum chloride powder and residual chlorine into the stock bin; the formation of a negative pressure system of the dust remover, the stock bin, the assistant catcher, the main catcher and the surge bin is realized through the air induced fan. The whole process system is green and environmental-friendly, the crystallization yield of aluminum chloride products is high, the product pneumatic conveying and the tail gas inducing are matched, the recyclability of the tail gas is good.

Owner:HUNAN HENGGUANG TECH

Emulsion continuous demulsification separation method based on magnetic particle dynamic bed

PendingCN113457221AEnhanced friction and shearImprove effluent qualityNon-miscible liquid separationPhysicsEmulsion

The invention relates to the technical field of waste emulsion treatment, and in particular, relates to an emulsion continuous demulsification separation method based on a magnetic particle dynamic bed. An emulsion continuous demulsification and separation device based on the magnetic particle dynamic bed is included; an alternating magnetic field is generated through a magnetic particle control system, so that magnetic particles are bound in a specific area in an emulsion flow path and do reciprocating motion, and the magnetic particle dynamic bed is formed; the emulsion passes through the dynamic bed in the direction perpendicular to the reciprocating motion of the particles, the magnetic particles collide with oil drops in the emulsion, the oil drops are captured, an oil-water interface film is damaged, oil drop coalescence is promoted, the coarse-grained demulsification and oil-water separation processes are completed, and the effects of continuously discharging water and discharging floating oil are achieved. The light transmittance of the emulsion can be improved to 95% or above from 5% or below, and the device has the characteristics of good effluent quality and stable operation, and solves the problems that continuous demulsification is difficult to realize, the magnetic field action is single, particles need specific modification, the demulsification efficiency is low and the like in magnetic particle demulsification research.

Owner:江苏绿赛格再生资源利用有限公司 +1

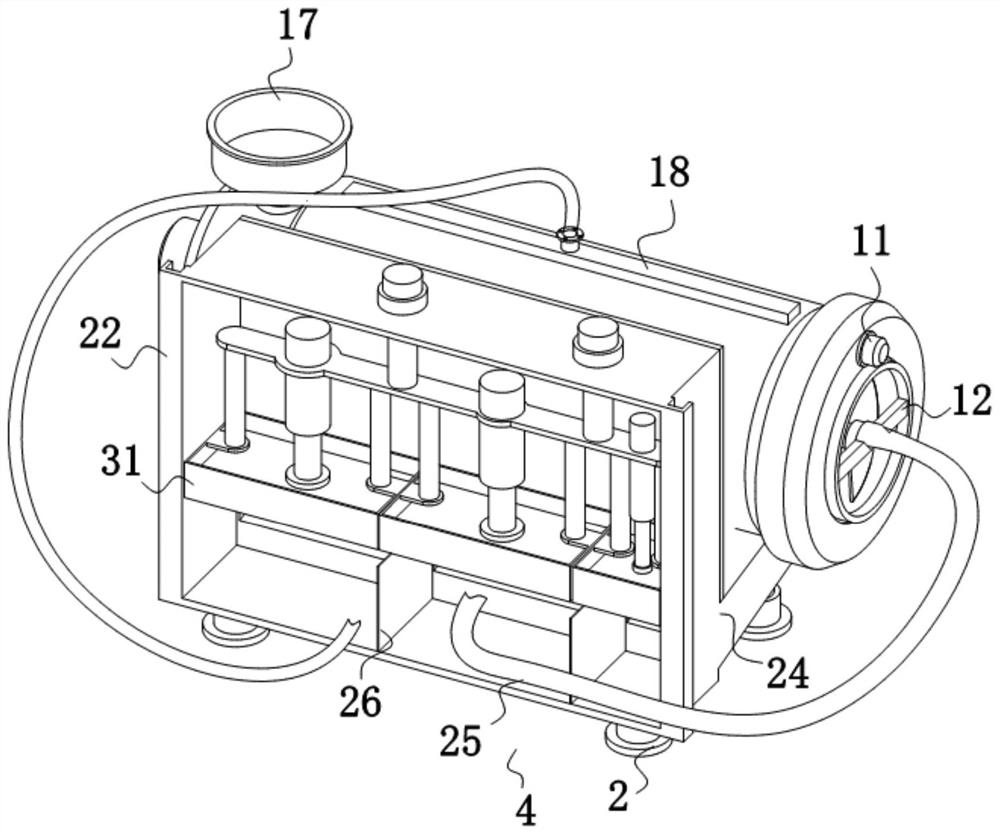

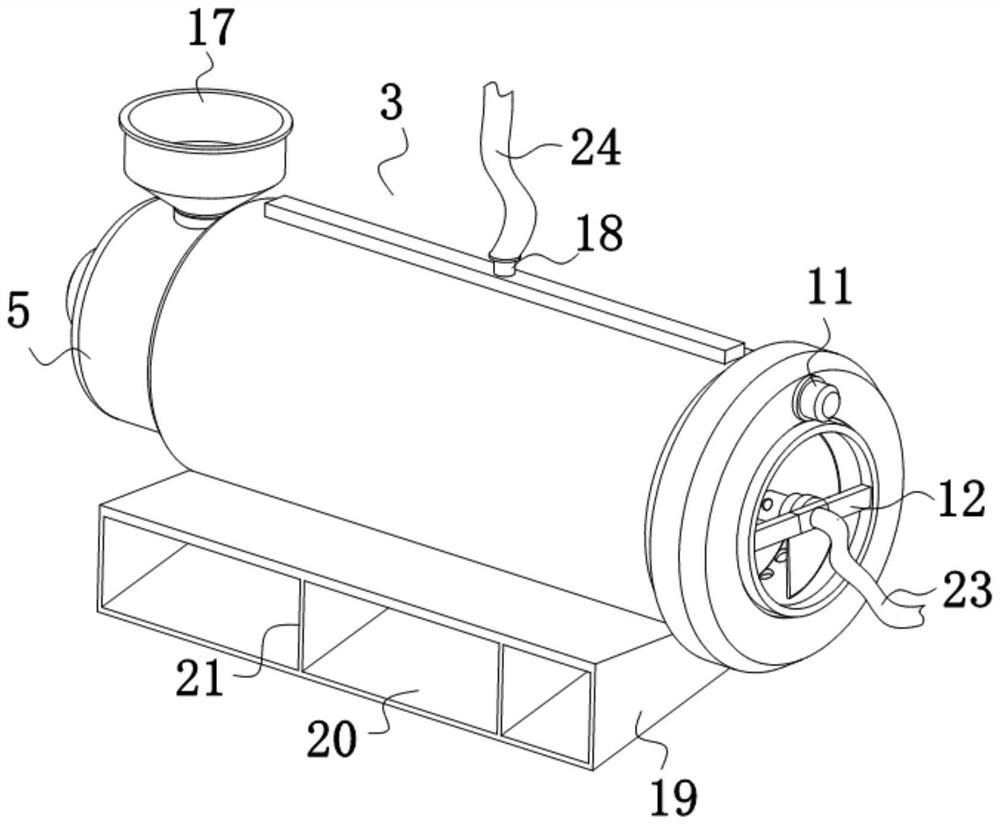

Primary treatment tank for machining waste water

InactiveCN106925028AEasy post-processingImprove processing efficiencyFiltration circuitsForeign matterWastewater

Disclosed is a primary treatment tank for machining waste water. The tank comprises a tank body, the bottom of the tank body is provided with a water outlet pipe and an oil outlet pipe, the interior of the tank body is divided into an intermediate water collecting area and an external oil collecting area through a water collecting hopper, the water outlet pipe extends into the tank body and is connected with the bottom of the water collecting hopper, the oil outlet pipe is directly communicated with the bottom of the tank body, the interior of the tank body is located above the water collecting hopper and provided with a split type filter barrel, the middle of the filter barrel is provided with a guide column, and the interior of the filter barrel is sequentially provided with an oil blocking layer, a metal collecting layer and a suspended matter filtering layer through the guide column. According to the primary treatment tank for the machining waste water, the defects of the prior art are overcome, firstly, the interior of the tank body is divided into the intermediate water collecting area and the external oil collecting area through the water collecting hopper, then the split type filter barrel is arranged above the water collecting hopper, the interior of the split type filter barrel is sequentially provided with the suspended matter filtering layer, the metal collecting layer and the oil blocking layer from top to bottom, suspended matter, metal foreign matter, floating oil and water are separated in sequence, so that post-treatment is carried out conveniently, the post-treatment efficiency is effectively improved, and the subsequent treatment difficulty is reduced at the same time.

Owner:HEFEISHI HANKUN MACHINERY

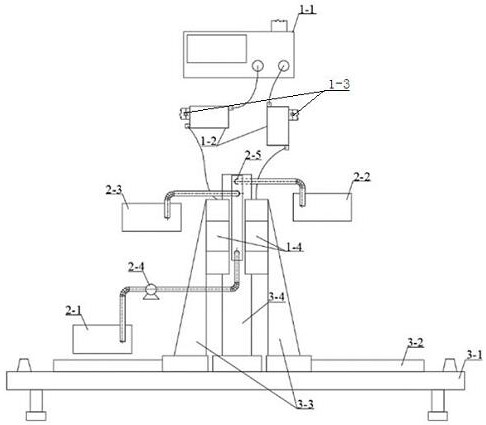

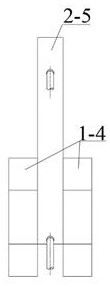

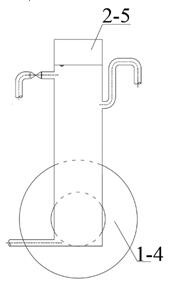

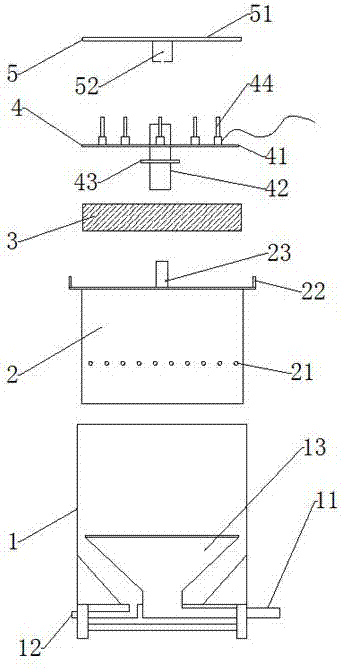

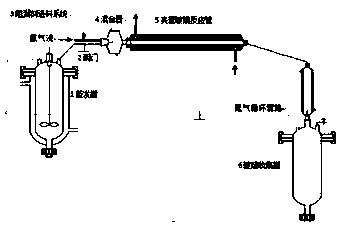

Polymerization inhibitor adding device for inhibiting pipeline polymerization reaction

ActiveCN110372486AIncrease profitReduce dosageCarbonyl compound separation/purificationEvaporationProduct gas

The invention discloses a polymerization inhibitor adding device for inhibiting pipeline polymerization reaction. Based on a production process of methacrolein, a set of polymerization inhibitor adding device composed of four parts of an evaporation feeding system, a polymerization inhibitor feeding system, a heat preservation jacket glass reaction pipe and a condensation collection device is designed. In particular, an adding method of a polymerization inhibitor is mentioned. According to the method, the polymerization inhibitor is added in the way of atomization to form aerosol which is fully mixed with polymerization gas, the same polymerization inhibition effect with less dosage as a traditional polymerization inhibitor can be achieved, and the problem of production capacity reductionor even shutdown caused by pipeline blockage is solved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Coal chemical industry high-concentration wastewater treatment device

InactiveCN107244786AImprove biodegradabilityReduce pollutionTreatment involving filtrationMultistage water/sewage treatmentHigh concentrationActivated carbon filtration

The invention discloses a treatment device for high-concentration wastewater in the coal chemical industry, which comprises a purification box. A feed pipe is arranged in the middle of the upper end of the purification box. A stone filter layer and an activated carbon filter screen are arranged in the feed pipe sequentially from top to bottom. The purification box at the bottom of the filter layer is provided with a net pocket, and the water outlet on the lower right side of the purification box is connected to the liquid inlet pipe of the flocculation reaction device through a conduit, and a water pump is worn on the liquid inlet pipe. The invention has a simple and reasonable structure, guarantees the biochemical treatment effect, thereby reducing membrane fouling, low membrane cleaning frequency and long service life, and the MBR effluent is stable without suspended matter, which can ensure the deep treatment effect, and is also suitable for hydrolytic acidification. At the same time, the mixing of materials can be accelerated through the stirring frame, which greatly improves the hydrolysis efficiency and has strong practicability.

Owner:ZHENGZHOU JIACHEN CHEM TECH CO LTD

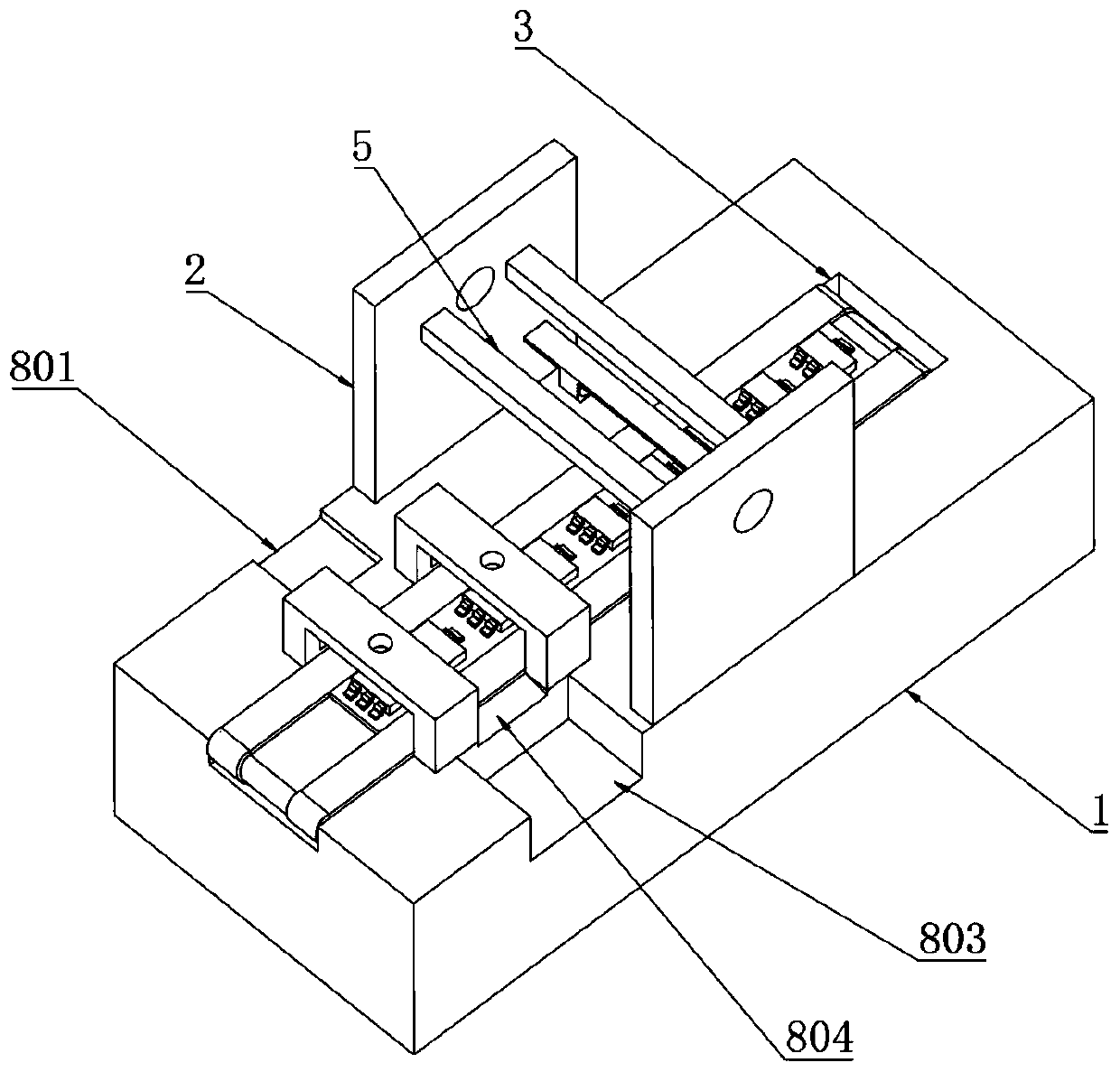

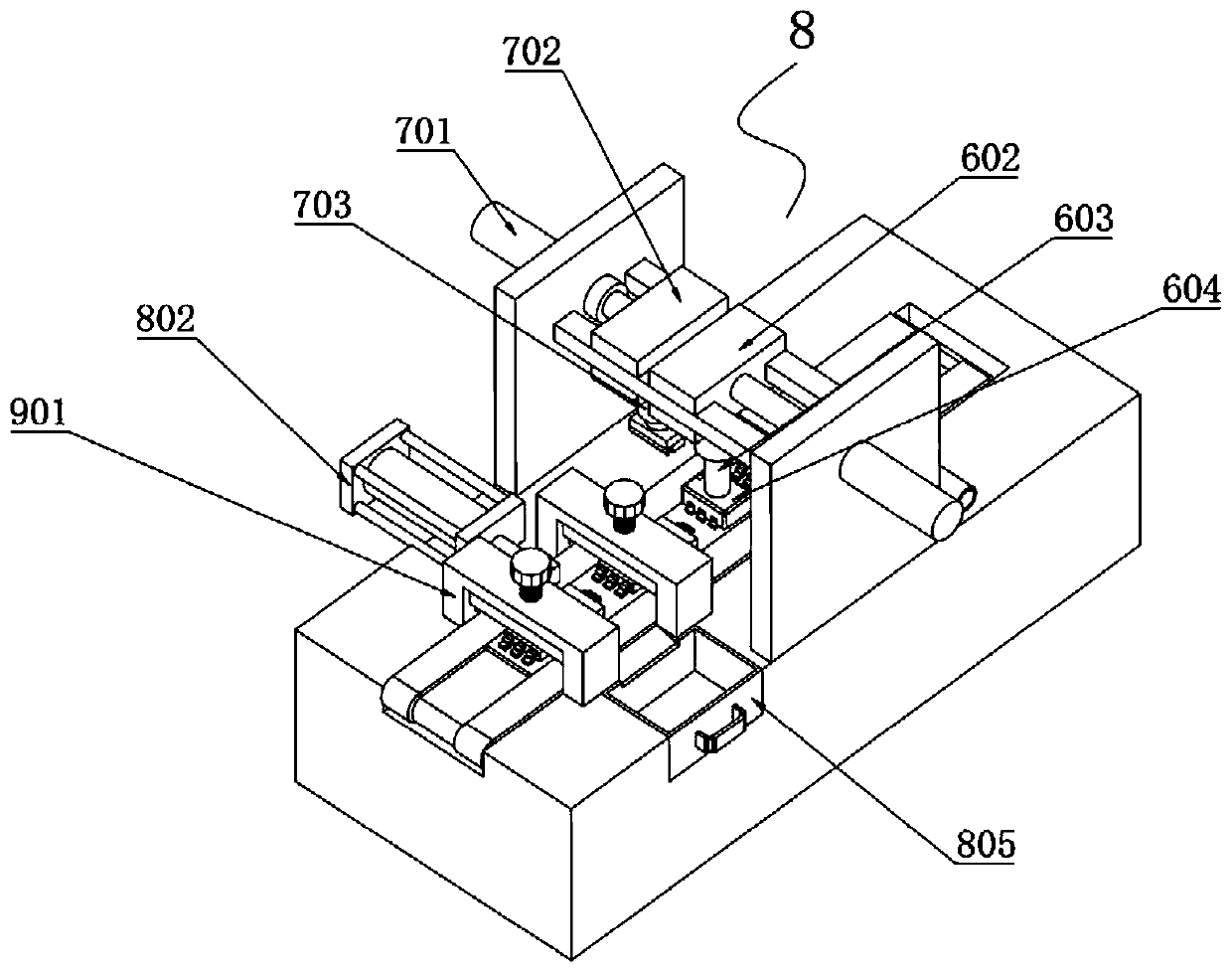

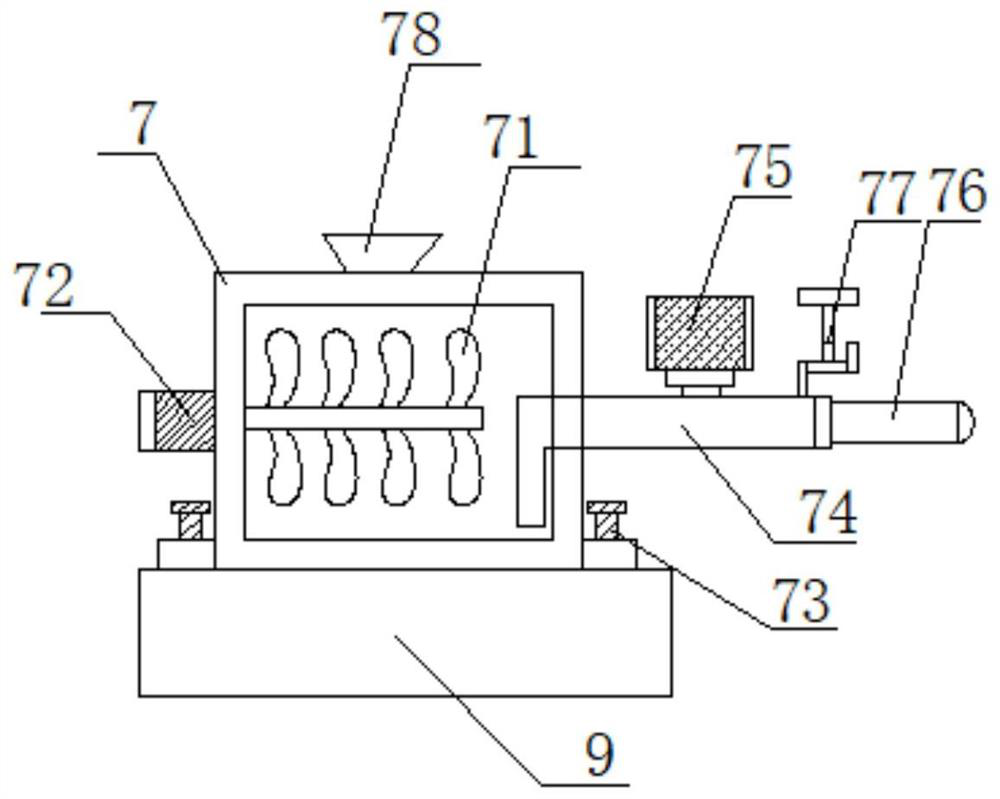

Scrap recovery treatment device for aluminum alloy machining

InactiveCN112848470AEnhanced screening efficiencyFacilitate targeted and differentiated treatmentSievingScreeningEngineeringMechanical engineering

The invention belongs to the technical field of aluminum alloy machining, and discloses a scrap recovery treatment device for aluminum alloy machining. The scrap recovery treatment device comprises a device body, wherein the device body comprises a screening mechanism and a compressing mechanism, the screening mechanism comprises a screening shell, a screening drum is rotationally connected to the interior of the screening shell through a bearing, a first screen hole area, a second screen hole area and a third screen hole area are sequentially arranged on the outer surface of the screen drum, screen holes are formed in the surfaces of the first screen hole area, the second screen hole area and the third screen hole area, the diameters of the screen holes are sequentially increased, and material blocking ring plates are arranged at the adjacent positions of the first screen hole area, the second screen hole area and the third screen hole area through first bearings. Through the design of the screening mechanism and the compression mechanism, the classified treatment and classified compression processes of scraps can be automatically completed, the working efficiency of the device is improved, the screening effect is guaranteed, resources are saved, the screening efficiency of the device is improved, and it is guaranteed that the device is in a benign and smooth working state all the time.

Owner:陈云

Process for extracting oil

InactiveCN100577783CGood selective extractionHigh extraction rateFatty-oils/fats productionSolventImpurity

The invention discloses a extracting method of grease, which is characterized by the following steps: 1) disintegrating materials to 10-40 order; 2) adopting liquid dimethyl ether as extraction solvent; conveying to materials with the rate of material and dissolvent at 1:2-1:24; extracting 30-120 min under the condition of pressure at 5-30 kilogram at 30-90 Deg C; 3) separating grease in the condition of pressure at 1-5 kilogramat 20-60 Deg C. The invention simplifies the manufacturing craft, which improving extracting rate effectively.

Owner:侯金荣 +1

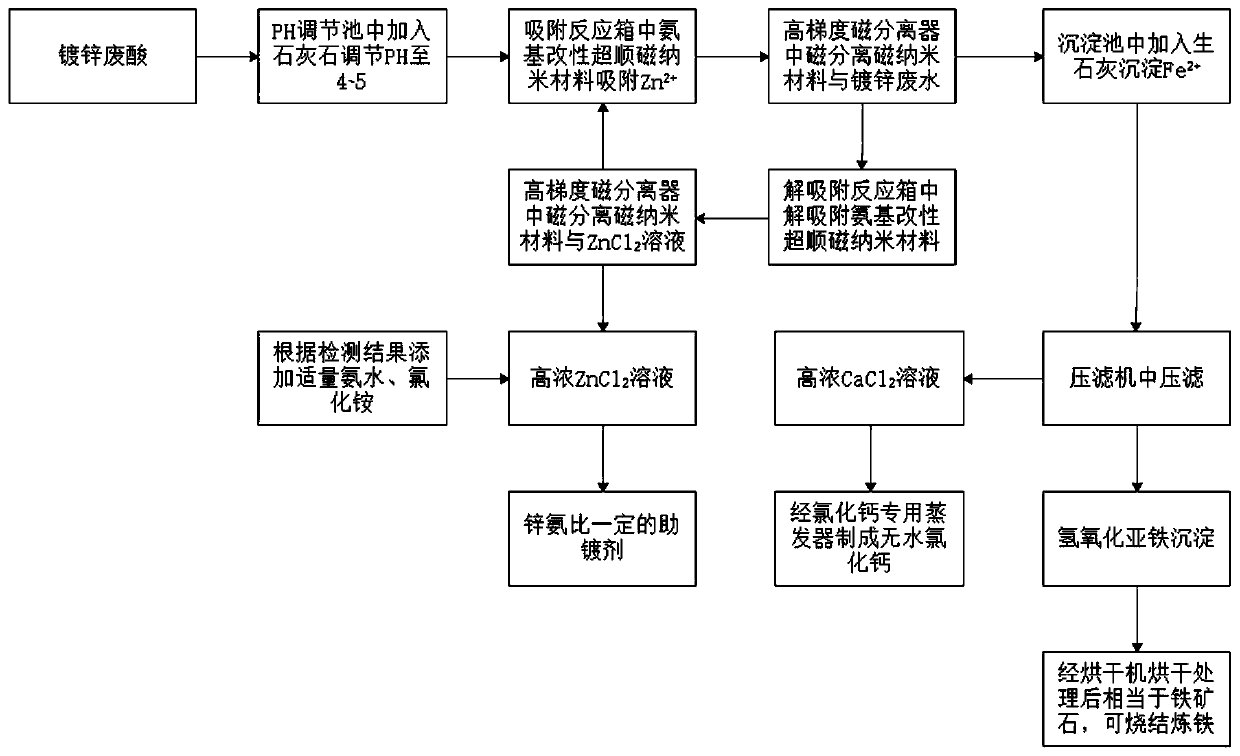

Resource recycling process of galvanizing waste acid

PendingCN110683707AAchieve recyclingOvercoming the separation problemZinc halidesCalcium/strontium/barium chloridesMagnetic separatorWastewater

The invention belongs to the technical field of waste acid treatment and resource recycling, and particularly relates to a resource recycling process of galvanizing waste acid The process comprises the following steps: introducing the galvanizing waste acid into a pH regulating tank, adding a proper amount of limestone into the pH regulating tank, and regulating a pH value to 4-6; introducing thegalvanizing wastewater with the adjusted pH value into an adsorption reaction box; adding hydrochloric acid into the desorption reaction box; after reacting for a period of time, introducing a solution into a high-gradient magnetic separator; and introducing a residual solution in a high-gradient magnetic separator in the step 2 into a sedimentation tank, and adding a proper amount of quick lime into the sedimentation tank to completely precipitate Fe<2+> in the solution. The invention aims to solve the long-standing problems of high investment cost, high operation cost, high energy consumption and the like in the field of treatment and resource recycling of galvanizing waste acid.

Owner:YUNNAN UNIV

Building decoration engineering wall surface processing device

PendingCN113001294AFully automatedImprove processing qualityGrinding carriagesGrinding drivesPolishingElectric machinery

The invention belongs to the technical field of building tools, and discloses a building decoration engineering wall surface processing device which comprises a device base, a movable processing table, a rack, a lifting motor, lifting threaded rods, a coating stirring barrel, a mounting table plate and lead screws. Machine columns are installed at the two ends of the device base, the movable processing table is installed through the machine columns in a supporting mode, lead screw bases are installed at the two ends of the movable processing table, the lead screws are installed on the lead screw bases, lead screw motors in driving connection with the lead screws are installed at one end of the movable processing table, and T-shaped lead screw sliding blocks are installed on the lead screws in a sliding mode. The rack is fixedly mounted at the tops of the T-shaped lead screw sliding blocks, the lifting threaded rods are mounted at the inner top and the inner bottom of the rack through threaded seats, and the lifting motor in driving connection with the lifting threaded rods is mounted at the top of the rack. According to the device, the lead screw motors and the screw rods are matched with the lifting motor and the lifting threaded rods, so that automatic scraping, scribing, spraying, drilling and polishing operations are realized; and the operation cost is reduced, and the building decoration quality is effectively improved.

Owner:HENAN POLYTECHNIC INST

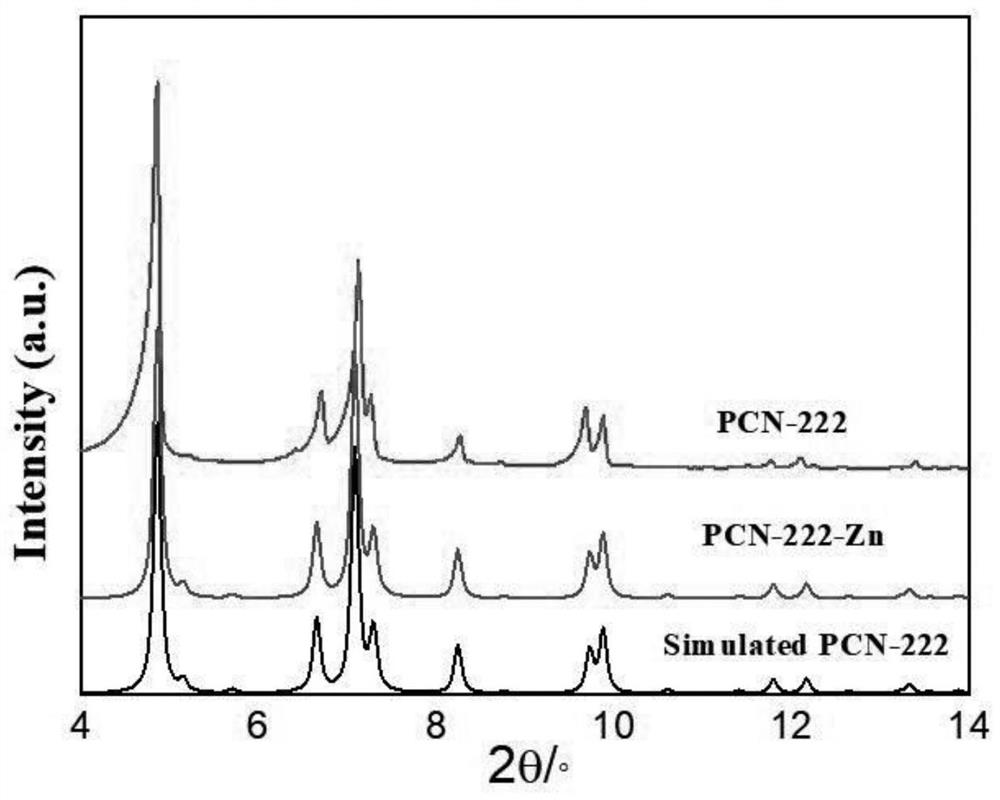

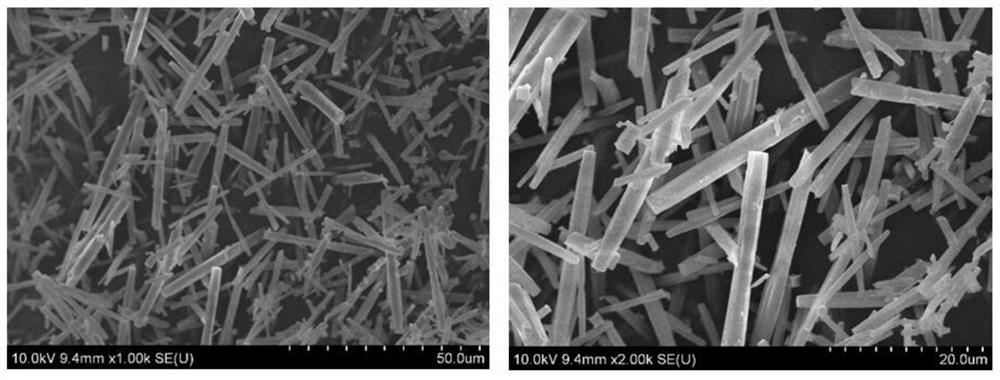

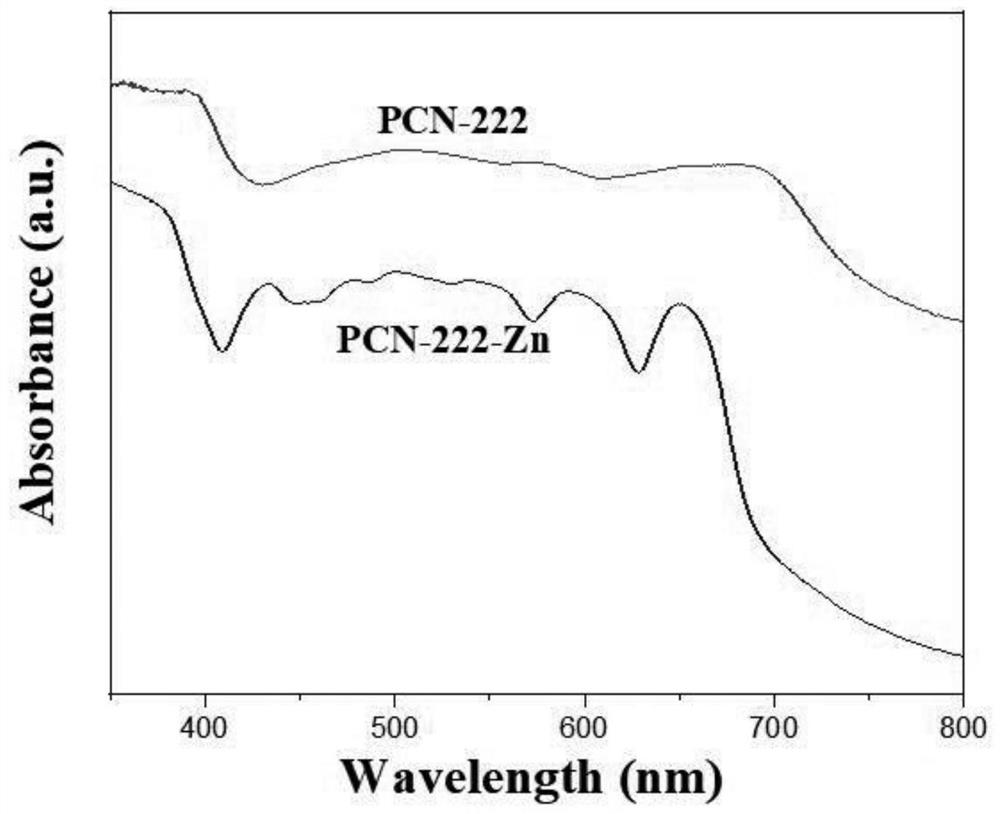

Preparation method and application of efficient photocatalytic material PCN-222-Zn for reducing CO2 into formic acid

PendingCN111905817AHigh formic acid selectivityInhibitory complexOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic effectPhoto catalysis

The invention relates to a preparation method of a high-efficiency photocatalytic material PCN-222-Zn for reducing CO2 into formic acid, which comprises the following steps: a, weighing a proper amount of ZnCl2 powder, adding the ZnCl2 powder into a mixed solution, dissolving the materials uniformly, and adding a proper amount of pure-phase PCN-222 crystal to obtain a mixed solution; b, transferring the mixed solution obtained in the step a into a hydrothermal reaction kettle, and reacting for 10-14 hours; c, carrying out acidification treatment on the mixed liquid by using an acidic compoundto remove metal ions except Zn 2+; and d, cooling the acidified mixed solution in the step c to room temperature, carrying out centrifuging, washing and drying treatment to obtain the PCN-222-Zn target product. The catalyst product can reduce CO2 into formic acid, has formic acid selectivity as high as 98% and is remarkable in catalytic effect.

Owner:HUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com