Integrated efficient thermal washing-advanced oxidation combined oily sludge treatment system and oily sludge treatment method

A technology of advanced oxidation and combined treatment, applied in sludge treatment, dehydration/drying/thickened sludge treatment, chemical instruments and methods, etc., can solve problems such as inability to achieve treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

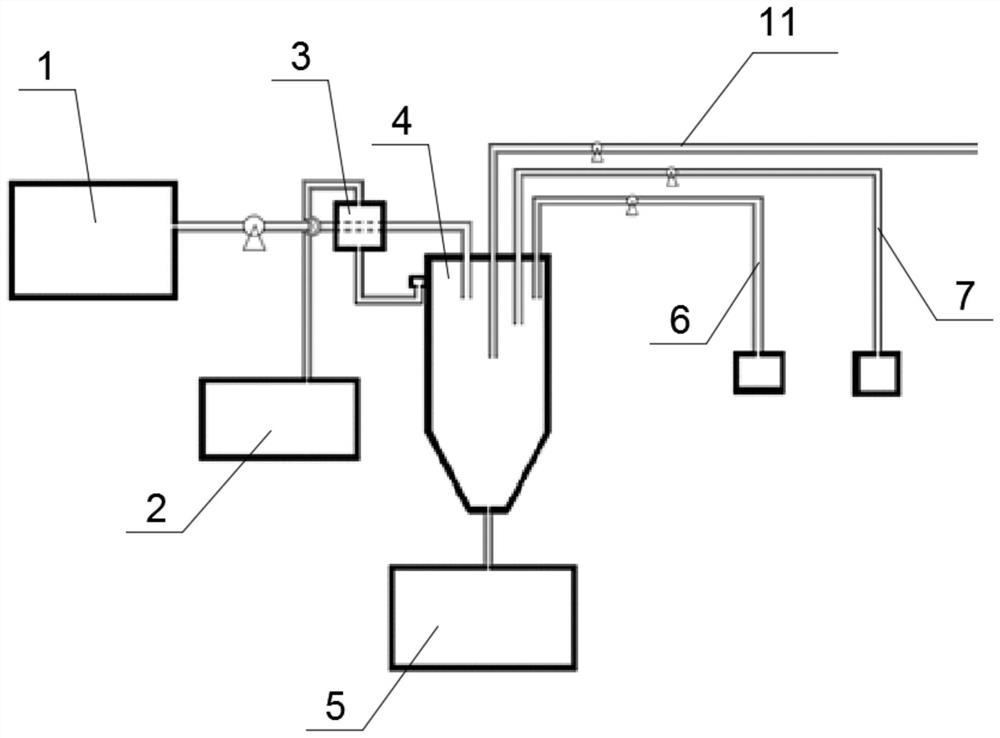

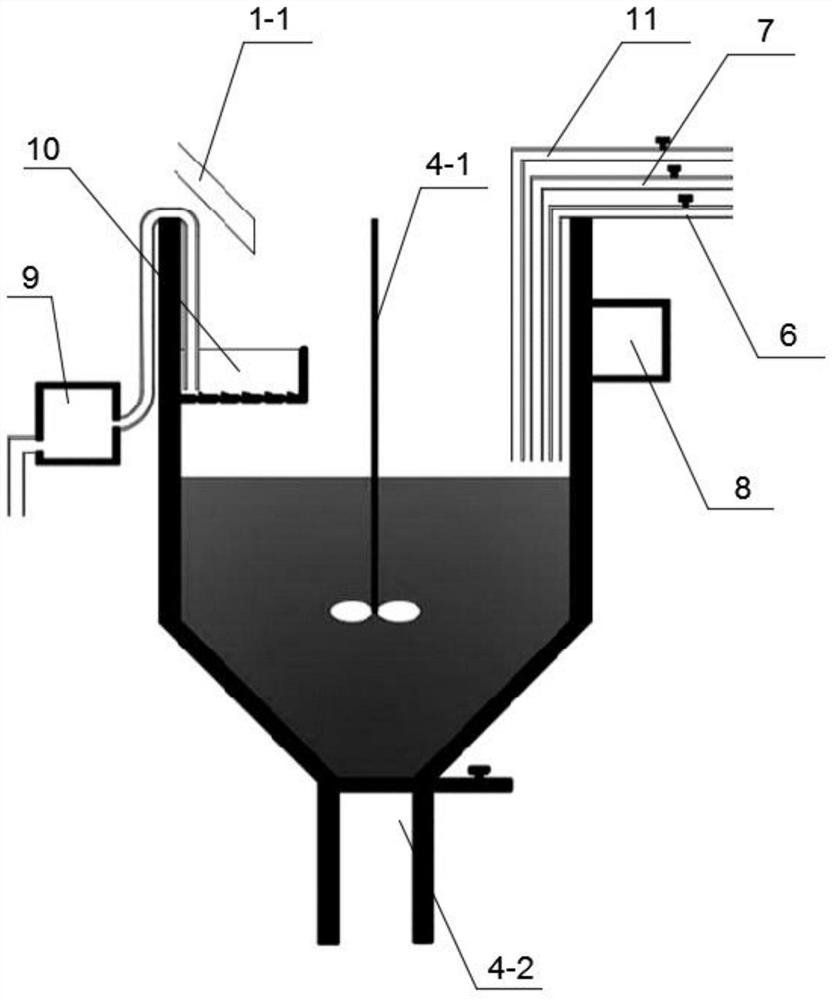

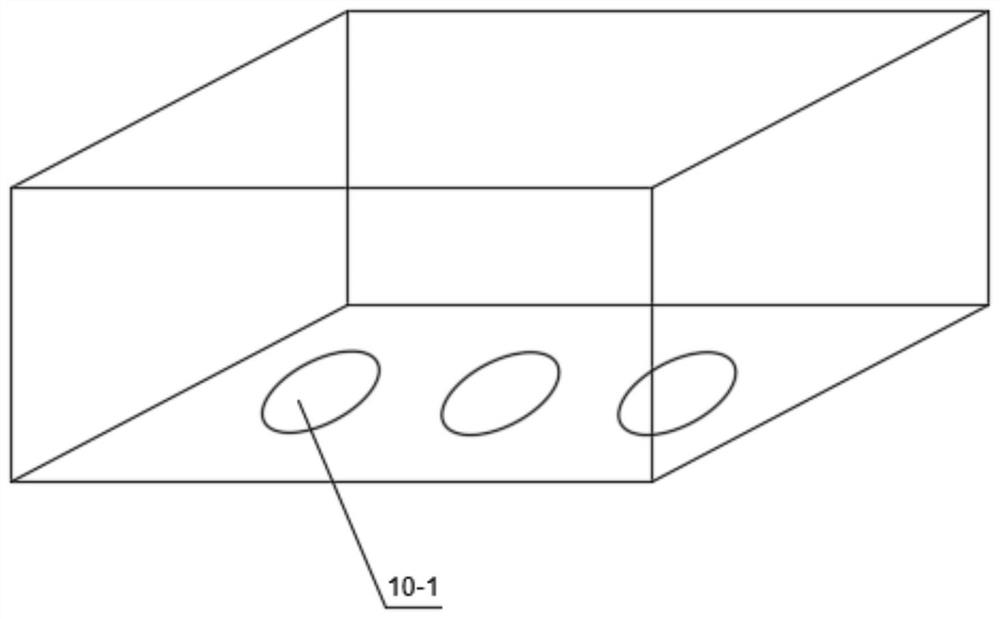

[0071] In order to achieve high-efficiency treatment of oily sludge, the present invention provides an integrated high-efficiency thermal washing-advanced oxidation combined treatment system for oily sludge, the system includes: a central treatment pool 4, an agitator 4-1 for stirring materials And a temperature control device 8 for controlling the temperature in the central treatment pool 4, the inlet end of the central treatment pool 4 is respectively connected to the oily sludge feed channel 1-1, the water washing channel 6, the oxidizing agent feed channel 7 and the water washing agent Feed channel 11; the lower end of the central treatment tank 4 is connected with a sludge discharge channel 4-2.

[0072] As a preferred scheme, in order to improve the treatment effect of the oily sludge entering the central treatment tank 4, the oily sludge entering the central treatment tank 4 through the oily sludge feed channel 1-1 is pre-treated before entering the central treatment tan...

Embodiment 2

[0077] A method of using the high-efficiency hot washing-advanced oxidation combined treatment of oily sludge using the system of Example 1,

[0078] (1) Fill the oily sludge into the central treatment tank 4 through the oily sludge feed channel 1-1, and do not need to preheat for the first filling, and then use the wastewater to preheat after the wastewater is generated in the central treatment tank 4;

[0079] (2) Washing stage

[0080] According to the mass volume ratio 1g of oily sludge and washing agent: 10ml adds synergistic water washing agent to central treatment tank 4 through water washing agent feed channel 11 (synergistic water washing agent is made up of water washing agent and strengthening agent, and wherein water washing agent is TritonX- 100:SDBS=7:3 (mass ratio), concentration is 20g / L, and strengthening agent is the sodium carbonate that mass fraction is 1.5wt%), start temperature control device 8 control temperature at 55 ℃, keep stirring for 2 hours, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com