Highly-difficult waste water treatment method

A waste water treatment and waste water technology, applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing energy consumption and cost of sewage treatment, increasing the processing load of biochemical stations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

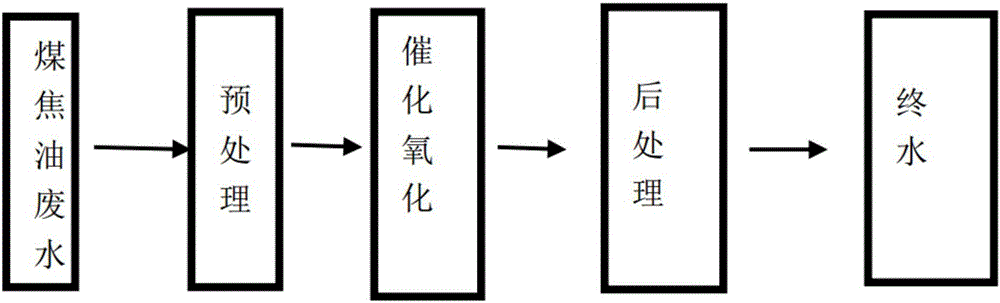

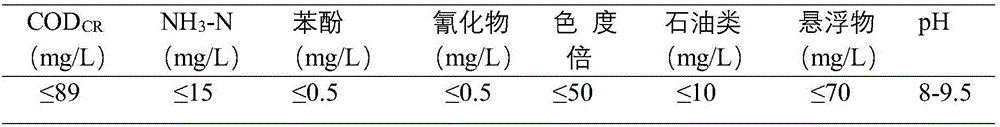

[0017] A method for treating difficult wastewater, comprising the steps of:

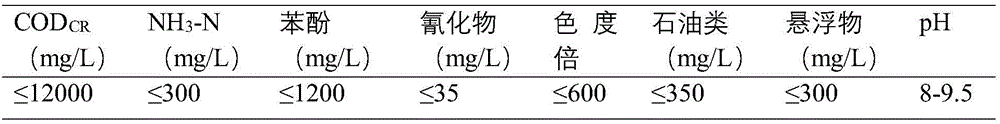

[0018] (1) Pretreatment: inject the coal tar processing wastewater into the primary flocculation sedimentation tank through the pipeline mixer, the influent water quality of the coal tar processing wastewater: COD 10000~15000mg / L, volatile phenol 700~1100mg / L, NH 3 -N 100~300mg / L, cyanide 20~50mg / L, chroma 400~600 times, petroleum 200~400mg / L, suspended matter SS 200~400mg / L, pH 8~9, in the primary flocculation sedimentation tank Add 10% organic flocculant in the medium, add 10ml / L to the wastewater and stir, control the hydraulic retention time in the pool for 1-2 hours, the primary flocculation sedimentation first removes the macromolecular organic matter, suspended matter and part of the chroma in the wastewater, The sludge is discharged into the sludge thickening tank, and the SS of the pretreated wastewater is less than 20mg / L, and the chroma is less than 200 times.

[0019] (2) Catalytic oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com