Building decoration engineering wall surface processing device

A technology of architectural decoration engineering and processing equipment, which is applied in the direction of construction, building structure, stone processing equipment, etc., can solve the problems of manual control of slotting direction not vertical, many working environments for operators, and low work efficiency, etc., to achieve benefits Ease of use, increased processing quality, and labor-saving effects in the spraying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

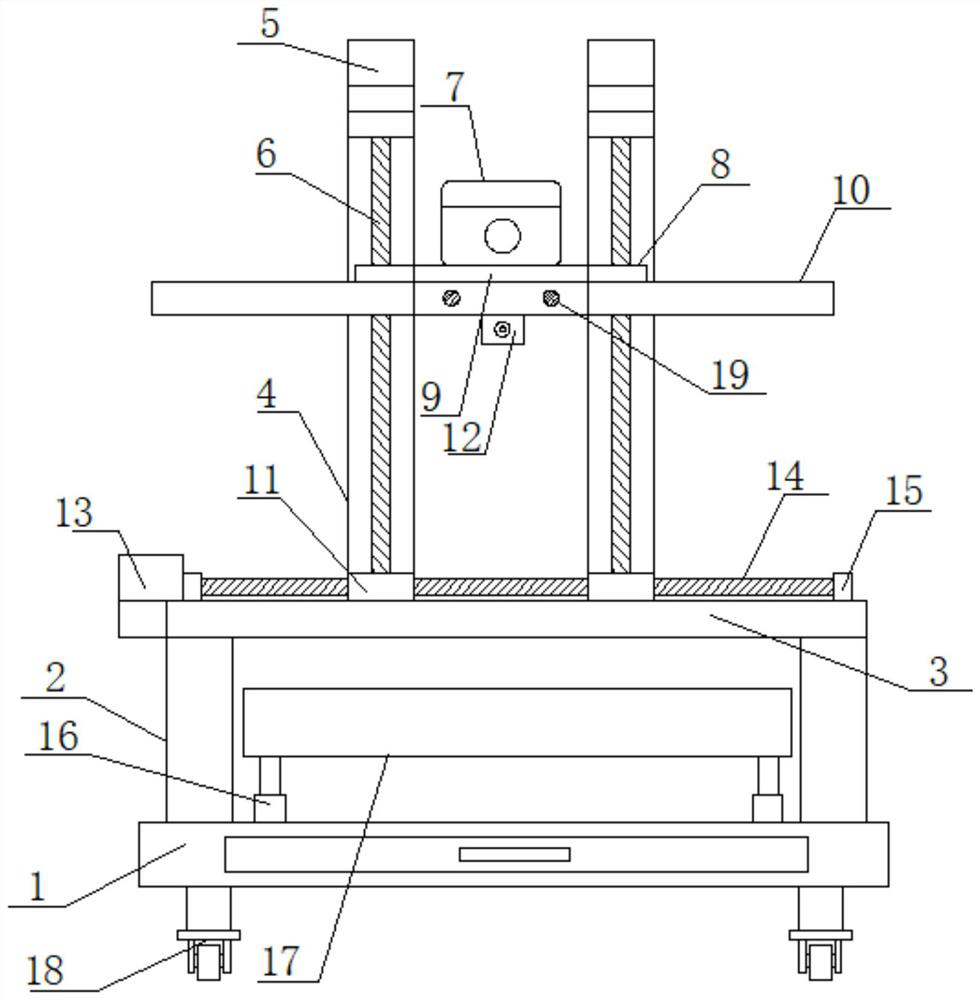

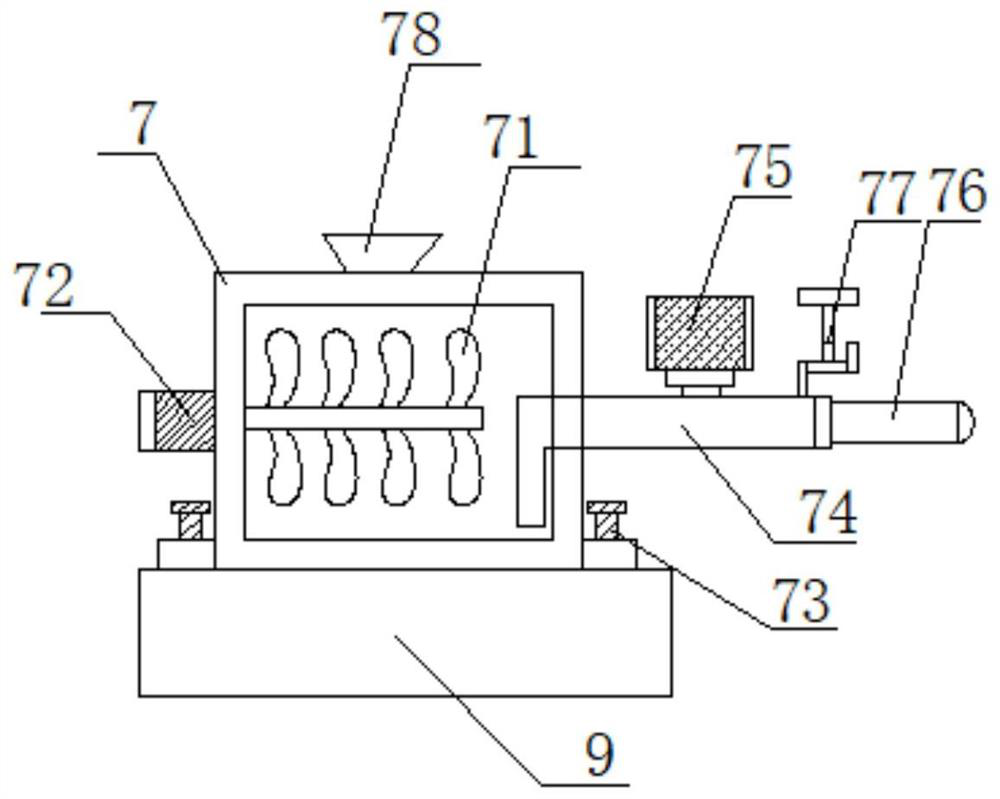

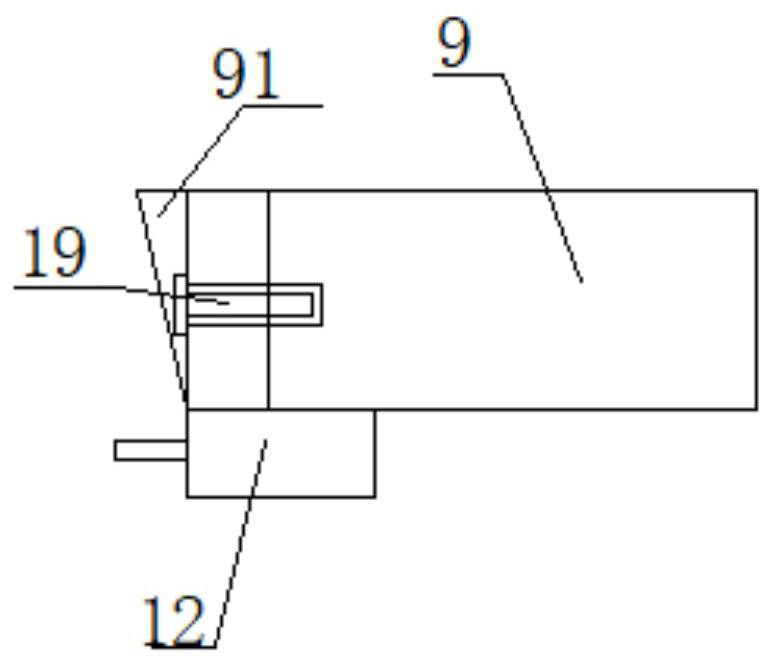

[0039] Such as Figure 1-4 As shown, the present invention proposes a wall surface processing device for architectural decoration engineering, including a device base 1, a machine column 2, a mobile processing table 3, a frame 4, a lifting motor 5, a lifting threaded rod 6, a paint mixing drum 7, and a mounting table Plate 9, scraper plate 10, T-shaped screw rod slider 11, scriber 12, screw motor 13, screw rod 14 and lifting platform 17; organic column 2 is installed on the two ends of device base 1, and is supported by machine column 2 Mobile processing table 3 is installed, and screw mandrel seat 15 is installed on the two ends of mobile processing table 3, and screw mandrel 14 is installed on the screw mandrel seat 15, and one end of mobile processing table 3 is installed with screw mandrel 14 driving connections. Screw motor 13, on the screw mandrel 14, T-shaped screw rod slider 11 is slidably installed, and the bottom of T-shaped screw screw slider 11 is slidably connecte...

Embodiment 2

[0054] Such as Figure 5-6 As shown, different from the wall surface processing device for building decoration engineering in Embodiment 1, the installation table 9 is installed with a drilling machine 20, and the drilling machine 20 is driven and connected with a drill bit 21.

[0055] When the present invention is in use, the staff removes the paint mixing drum 7 from the mounting platen 9, installs the drilling machine 20 on the mounting platen 9, installs the drill bit 21 on the drilling machine 20, and starts the screw mandrel The motor 13 drives the frame 4 to move horizontally on the screw rod 14 through the T-shaped screw rod slider 11, and moves to a suitable position. The lifting motor 5 is controlled by the controller to drive the installation table 9 through the lifting slide seat 8. The threaded rod 6 moves up and down, and the controller is electrically connected with the drilling machine 20 to control the drilling machine 20 to drive the drill bit 21. Different ...

Embodiment 3

[0057] Such as Figure 7-8 As shown, the wall surface processing device for building decoration engineering is different from that in Embodiment 1, and the feature is that a grinder 22 is installed on the installation platen 9 , and a grinding disc 23 is installed on the drive shaft of the grinder 22 .

[0058] When the present invention is in use, the staff will remove the drilling machine 20 from the mounting platen 9, install the grinding machine 22 on the mounting platen 9, install the grinding disc 23 on the grinding machine 22, and start the screw mandrel The motor 13 drives the frame 4 to move horizontally on the screw rod 14 through the T-shaped screw rod slider 11, and moves to a suitable position. The lifting motor 5 is controlled by the controller to drive the installation table 9 through the lifting slide seat 8. The threaded rod 6 moves up and down, and the controller is electrically connected with the grinder 22 to control the grinder 22 to drive the grinding dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com