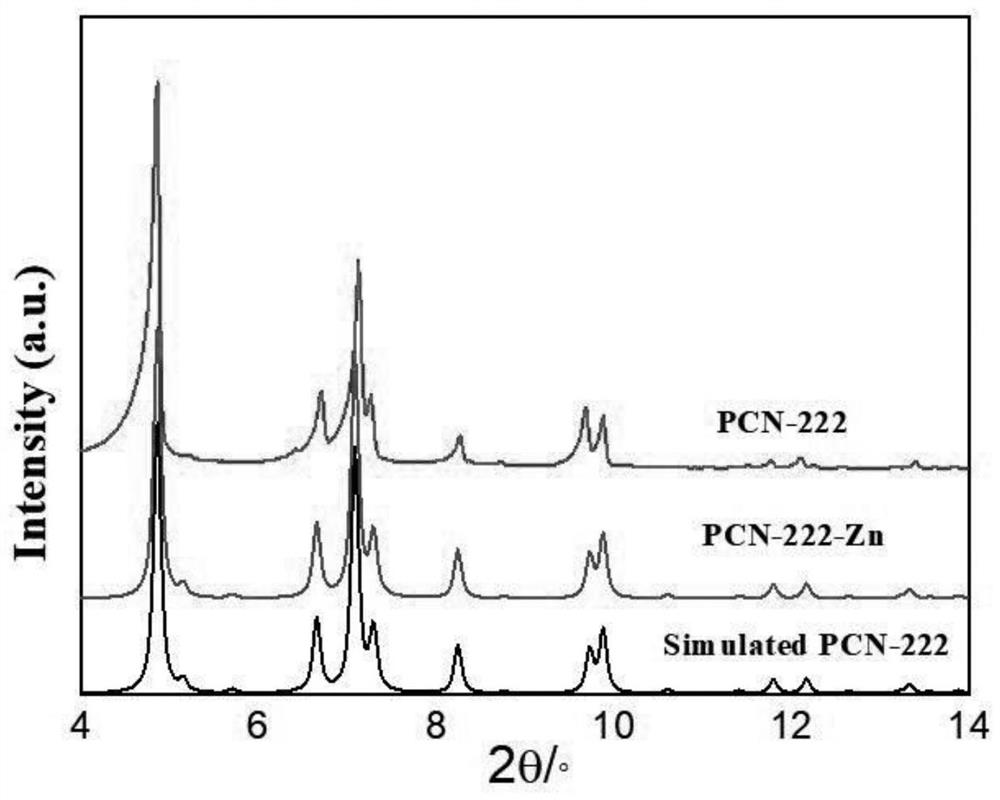

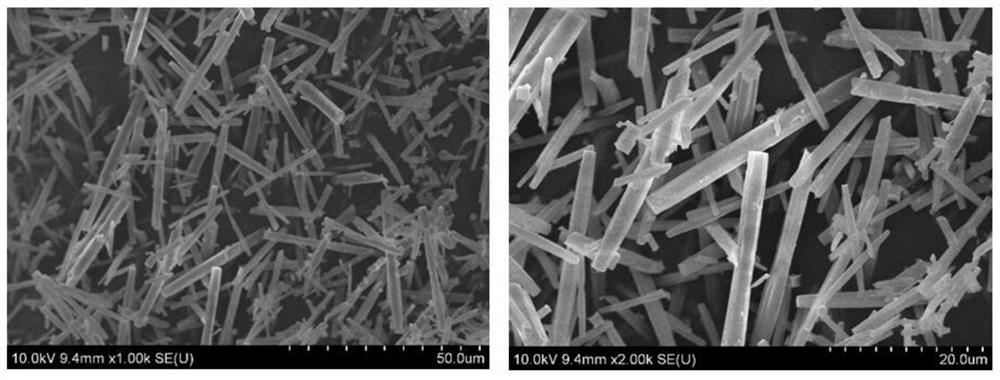

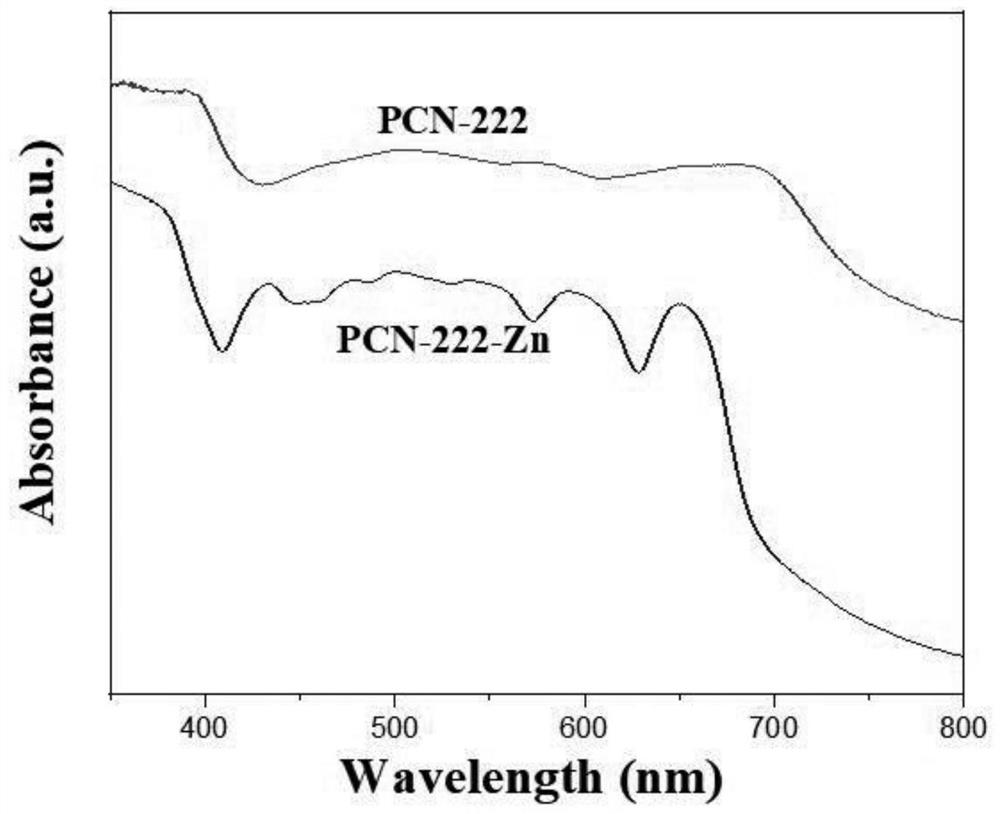

Preparation method and application of efficient photocatalytic material PCN-222-Zn for reducing CO2 into formic acid

A technology of PCN-222 and pcn-222-zn, which is applied in the field of preparation of high-efficiency photocatalytic material PCN-222-Zn, can solve the problems of increasing practical application costs, low catalytic efficiency, and difficult separation, and reduce the difficulty of subsequent processing , improve the photocatalytic efficiency, and facilitate the promotion and application of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a CO reduction 2 It is the preparation method of the efficient photocatalytic material PCN-222-Zn of formic acid, and described preparation method comprises the following steps:

[0031] a. Weigh an appropriate amount of ZnCl 2 The powder was added into the mixed solution, and after being ultrasonically dissolved at 50° C. for 10 minutes, an appropriate amount of pure-phase PCN-222 crystal was added, and stirred at room temperature for 50 minutes to obtain a mixed solution.

[0032] Wherein, the mixed solution in step a includes DMF and 2,6-lutidine, and the volume ratio of the 2,6-lutidine to DMF is 1:5. while ZnCl 2 The molar concentration of the powder in the mixed solution is 0.0167mmol / mL; the mass concentration of the pure phase PCN-222 crystal in the mixed solution is 4.17mg / mL.

[0033] b. Then transfer the mixed solution in step a to a hydrothermal reactor, and react at 150° C. for 12 hours.

[0034] c. Utilize HCl to acidify the mi...

Embodiment 2

[0043] This embodiment provides a CO reduction 2 It is the preparation method of the efficient photocatalytic material PCN-222-Zn of formic acid, and described preparation method comprises the following steps:

[0044] a. Weigh an appropriate amount of ZnCl 2 The powder was added into the mixed solution, and after being ultrasonically dissolved at 50° C. for 10 minutes, an appropriate amount of pure-phase PCN-222 crystal was added, and stirred at room temperature for 50 minutes to obtain a mixed solution.

[0045] Wherein, the mixed solution in step a includes DMF and 2,6-lutidine, and the volume ratio of the 2,6-lutidine to DMF is 1:5. while ZnCl 2 The molar concentration of the powder in the mixed solution is 0.0125mmol / mL; the mass concentration of the pure phase PCN-222 crystal in the mixed solution is 4.8mg / mL.

[0046] b. Then transfer the mixed solution in step a to a hydrothermal reactor, and react at 150° C. for 12 hours.

[0047] c. Utilize HCl to acidify the mix...

Embodiment 3

[0052] This embodiment provides a CO reduction 2 It is the preparation method of the efficient photocatalytic material PCN-222-Zn of formic acid, and described preparation method comprises the following steps:

[0053] a. Weigh an appropriate amount of ZnCl 2 The powder was added into the mixed solution, ultrasonically dissolved at 40° C. for 15 minutes, then an appropriate amount of pure phase PCN-222 crystals was added, and stirred at room temperature for 30 minutes to obtain a mixed solution.

[0054] Wherein, the mixed solution in step a includes DMF and 2,6-lutidine, and the volume ratio of the 2,6-lutidine to DMF is 0.8:4.5. while ZnCl 2 The molar concentration of the powder in the mixed solution is 0.007mmol / mL; the mass concentration of the pure phase PCN-222 crystal in the mixed solution is 3.6mg / mL.

[0055] b. Then transfer the mixed solution in step a to a hydrothermal reactor, and react at 140° C. for 14 hours.

[0056] c. Utilize HCl to acidify the mixed liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com