Application of Regenerative Electrode of Zinc-ion Battery in Electrochemical Reduction of Carbon Dioxide

A zinc-ion battery, carbon dioxide technology, applied in the direction of electrodes, electrolytic organic production, electrolytic components, etc., can solve the problems of low conversion rate, high energy consumption, limited high-efficiency utilization, etc., and achieve the effect of high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

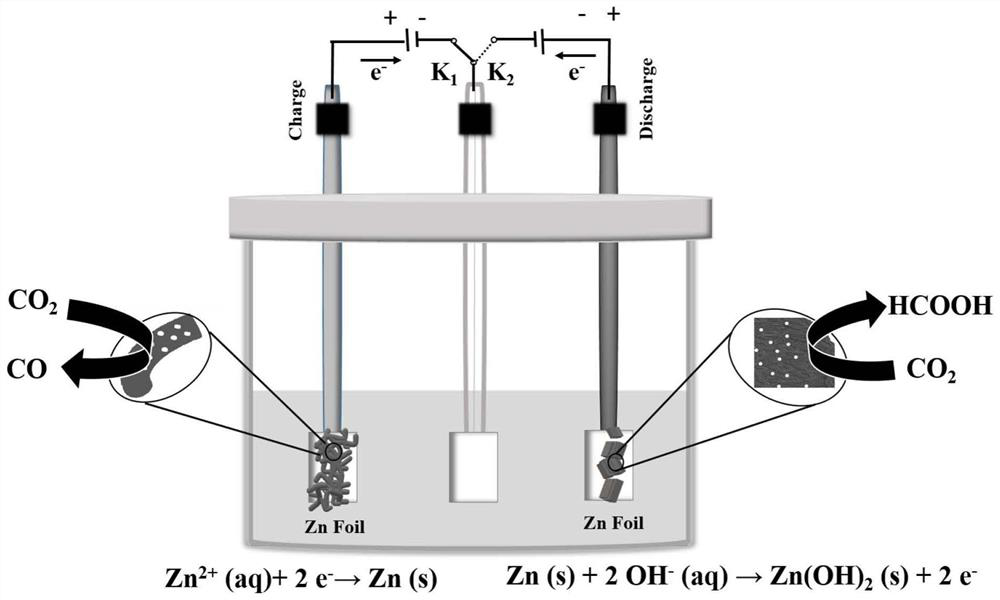

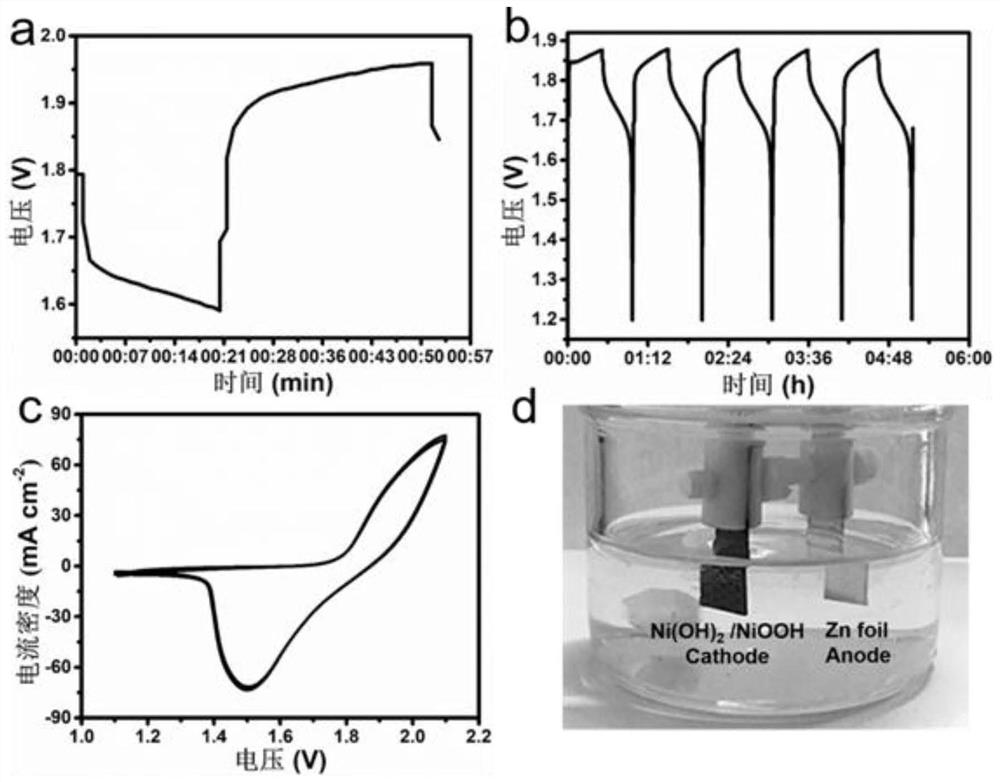

[0053] (1) Carry out corrosion and regeneration treatment on the zinc sheet negative electrode by charging and discharging the nickel-zinc battery, specifically: the nickel electrode is a commercial sintered nickel electrode (nickel oxyhydroxide / nickel hydroxide), and the purity of the zinc negative electrode is 99.9%- 99.99% zinc flakes, zinc oxide or zinc oxalate saturated 6M potassium hydroxide as electrolyte. Finally, for the assembly of the battery ( figure 2 ), using the blue electric battery test system to conduct charge and discharge tests on nickel-zinc batteries.

[0054] (2) By adjusting the charge and discharge conditions: charge and discharge current density (10, 20, 30mA cm -2 ), charge and discharge cycles (1, 2, 3, 4, 5), charge time (10, 20, 30, 40, 50 minutes), discharge cut-off voltage (1.0, 1.2, 1.4, 1.6V) and constant Voltage charge and discharge, etc., to corrode and regenerate the zinc sheet negative electrode. By controlling the above experimental p...

Embodiment 2

[0075] (1) Carry out corrosion and regeneration treatment on the zinc sheet negative electrode by charging and discharging the nickel-zinc battery, specifically: the nickel electrode is a commercial sintered nickel electrode (nickel oxyhydroxide / nickel hydroxide), and the purity of the zinc negative electrode is 99.9%- 99.99% zinc flakes, 6M potassium hydroxide saturated with zinc oxide as electrolyte. Finally, for the assembly of the battery ( figure 2 ), using the blue electric battery test system to conduct charge and discharge tests on nickel-zinc batteries.

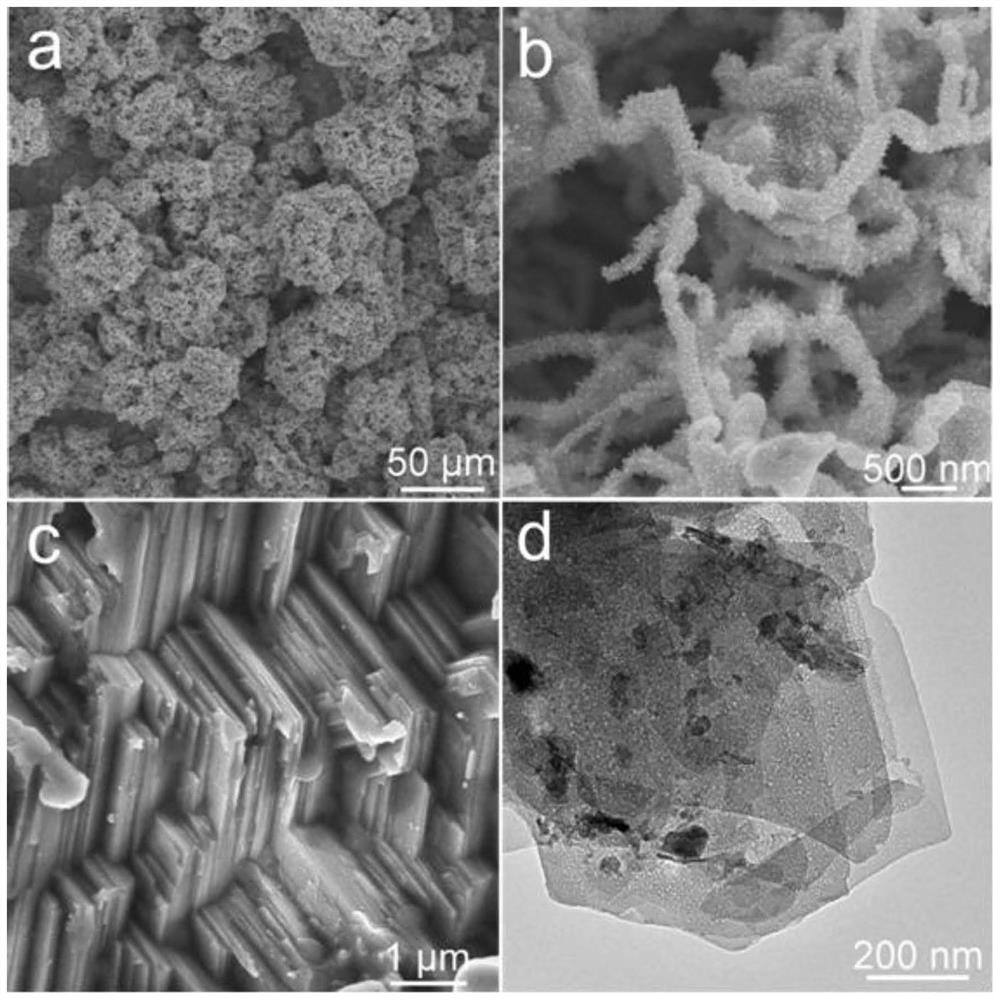

[0076] (2) The last step of the control is charging, the charge and discharge current density is 20mA cm -2 , the number of charge and discharge cycles is 1 cycle, the discharge time is 20 minutes, the charging time is 30 minutes, the temperature of the electric test room is 25 ° C, and the zinc sheet negative electrode is corroded and regenerated. Zinc@zinc oxide nanowires with a core-shell structure will be gene...

Embodiment 3

[0081] (1) Carry out corrosion and regeneration treatment to the zinc sheet negative electrode by charging and discharging the zinc-air battery, specifically: the air electrode is commercial activated carbon (sprayed on foamed nickel), and the zinc negative electrode has a purity of 99.9%-99.99% Zinc sheet, zinc oxide or zinc oxalate saturated 6M potassium hydroxide as electrolyte. Finally, for the assembly of the battery ( Figure 10 ), the battery shell is made of PMMA material, and the charge and discharge test of the zinc-air battery is carried out by using the blue electric battery test system. Figure 10 Schematic diagram of the zinc-air battery setup.

[0082] (2) By adjusting the charge and discharge conditions: charge and discharge current density (10, 20, 30mA cm -2 ), charge and discharge cycles (1, 2, 3, 4, 5), charge time (10, 20, 30, 40, 50 minutes), discharge cut-off voltage (1.0, 1.2, 1.4, 1.6V) and constant Voltage charge and discharge, etc., to corrode and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com