Polymerization inhibitor adding device for inhibiting pipeline polymerization reaction

A polymerization reaction and adding device technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve problems such as pipeline polymerization blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

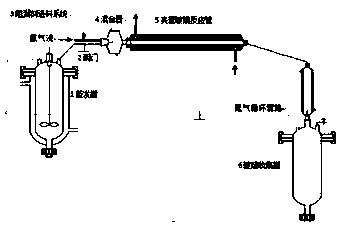

[0027] Embodiment 1: the polymerization experiment of independent evaporation polymerization product, as figure 1 As shown, the heating temperature of the evaporation tank is 90°C, the flow rate of the evaporation gas in the evaporation tank is kept at 10 L / min, and the flow rate is controlled by a valve. The evaporation gas source of the evaporating tank flows through the mixing tank and is connected to the polymerization glass tube through a Φ6 tetrafluoro tube, and the temperature of the glass tube oil bath is 160°C. Observe the polymerization phenomenon, and through the time-lapse video observation, the obvious polymerization time is 7h.

Embodiment 2

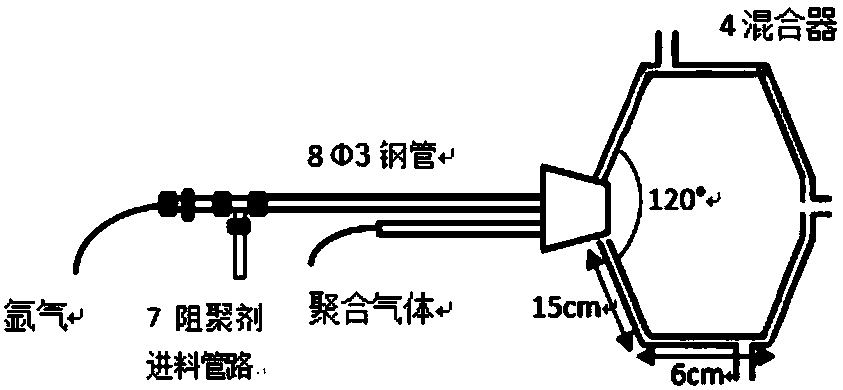

[0028] Embodiment 2: Polymerization experiment connected with the production pipeline, the pipeline gas source flow is controlled by a valve, the flow is 10L / min, the polymerization inhibitor is an aqueous solution of hydroquinone, the feed flow is 10ul / min, and the argon flow is 1L / min , the atomized gas of hydroquinone and the gas source of the production pipeline are mixed evenly in the mixing tank and then connected to the polymerization glass tube through the Φ6 PTFE tube. The temperature of the glass tube oil bath is 160 ° C. Through time-lapse video observation, within 3 days No apparent polymerization occurred.

Embodiment 3

[0029] Example 3: Polymerization experiment of independently evaporating polymerization products. The heating temperature of the evaporation tank was 90° C., and the flow rate of the evaporation gas in the evaporation tank was kept at 6 L / min, and the flow rate was controlled by a valve. The polymerization inhibitor is methyl hydroquinone ethanol solution, the feed flow rate is 2ul / min, and the argon gas flow rate is 1L / min. After being mixed evenly by the mixer, it is passed into the glass reaction tube. Polymerization in the tube, no obvious polymerization was found within 3 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com