Preparation method of electronic-grade high-purity hydrogen chloride

A hydrogen chloride, electronic-grade technology, applied in the direction of chlorine/hydrogen chloride, chemical instruments and methods, chlorine/hydrogen chloride purification, etc., can solve the problems of great social harm, violent boiling of mixed acid, serious material consumption, etc., and achieve safety and environmental protection pressure Effects of lifting, purification and yield increase, reduction in equipment construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

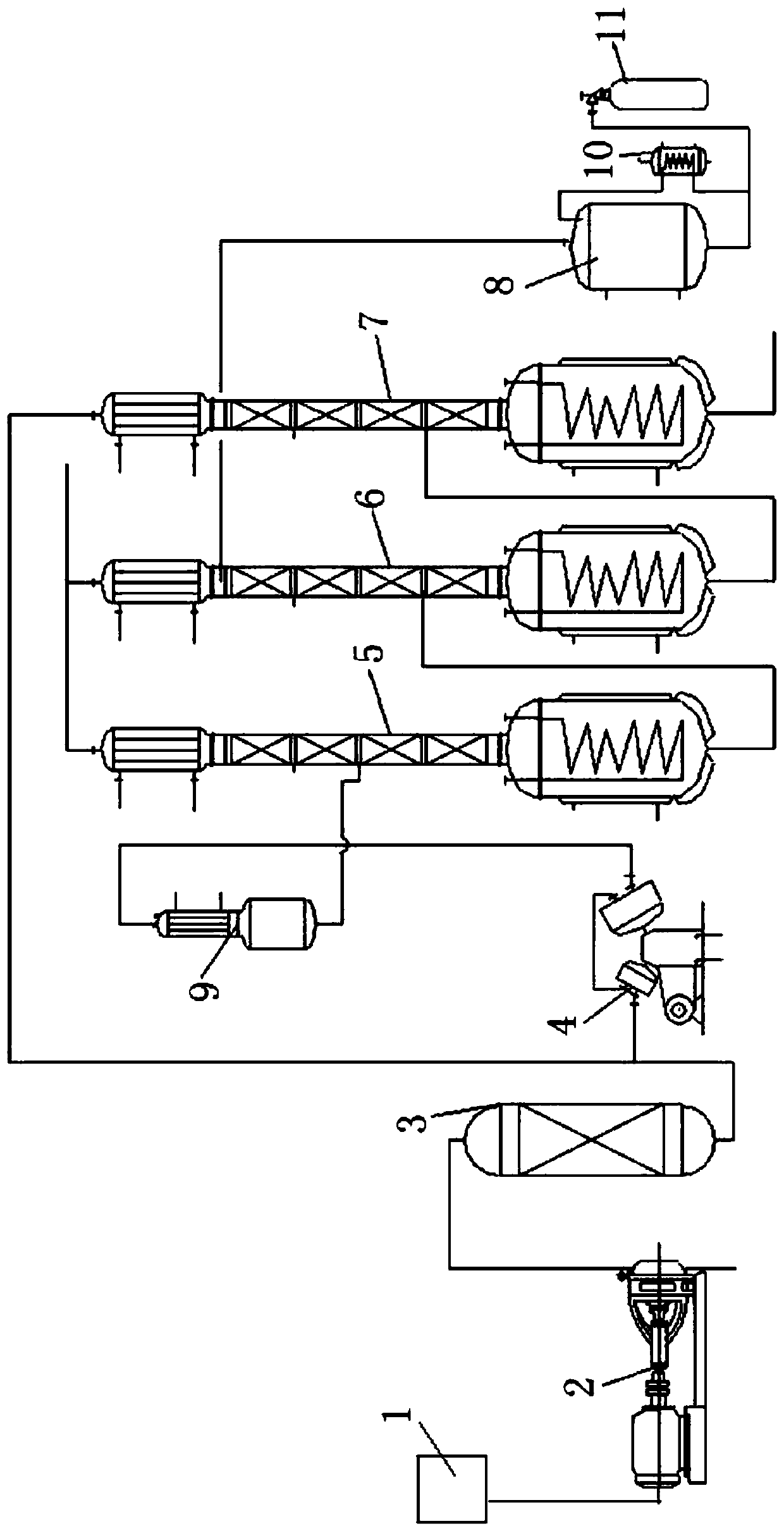

[0044] see figure 1 , as shown in the legend therein, a method for preparing electronic-grade high-purity hydrogen chloride comprises the following steps:

[0045] S1, collecting the by-product hydrogen chloride produced during the production of monochlorotoluene as raw material gas source 1, enters S2;

[0046] S2. Pass the raw material gas into the drier 3 through the first gas compression conveying equipment 2, the moisture in the raw gas is removed, and enter S3;

[0047] S3, feed the raw material gas after dehydration into the lightening rectification tower 5 through the second gas compression conveying equipment 4, obtain the tower bottom product A and the tower top product A with a lower boiling point than hydrogen chloride, and enter S4;

[0048] S4, the tower bottom product A is passed in the weight-removing rectification tower 6, obtain the tower top product B, reflux liquid and the tower bottom product B with boiling point higher than hydrogen chloride, enter S5; ...

example 1

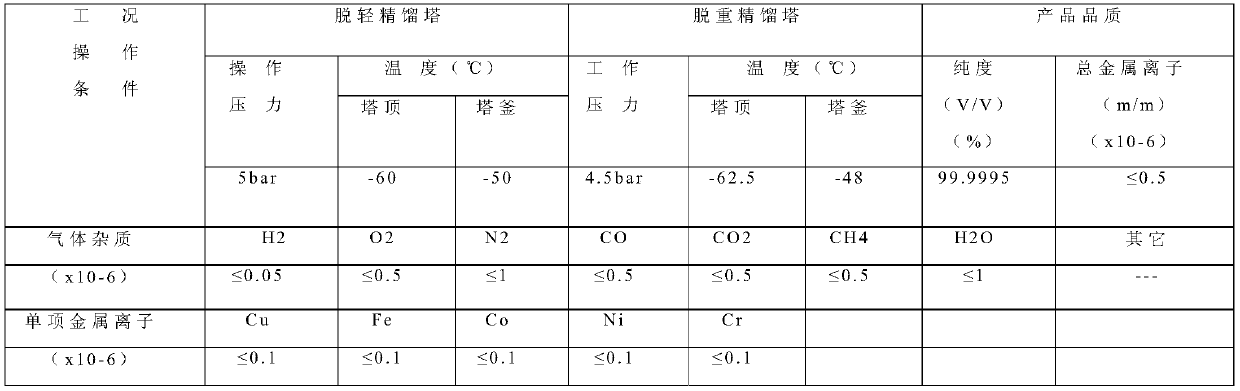

[0063] The pre-cooling liquefier uses liquid nitrogen as the refrigerant, and the light-removing rectification tower and the heavy-removal rectification tower adopt low-temperature and low-pressure rectification

[0064]

example 2

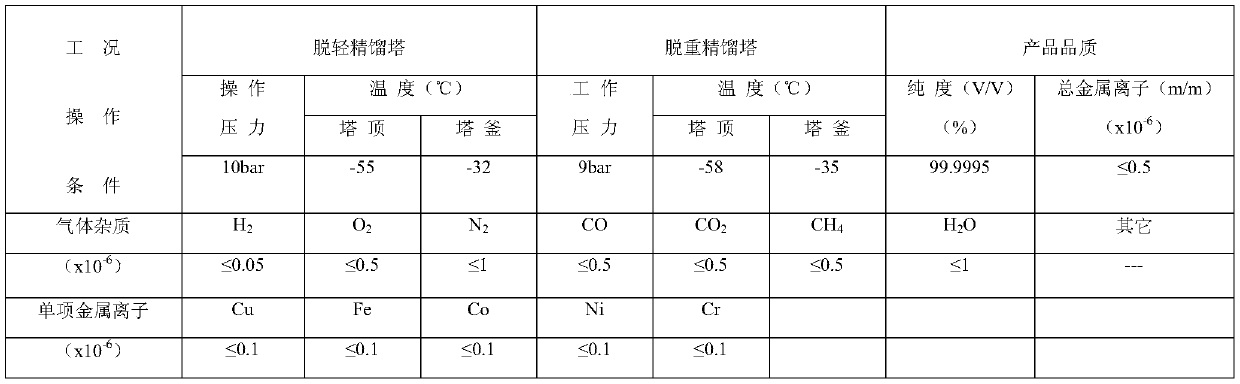

[0066] The pre-cooling liquefier uses dichloromethane and ethylene glycol as the refrigerant, and the light-removing rectification tower and the heavy-removal rectification tower adopt low-temperature and medium-pressure rectification

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com