System device and process for industrially producing aluminum chloride

A technology of aluminum trichloride and system device, applied in aluminum chloride, aluminum halide and other directions, to achieve the effect of improving product quality, improving packaging environment, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

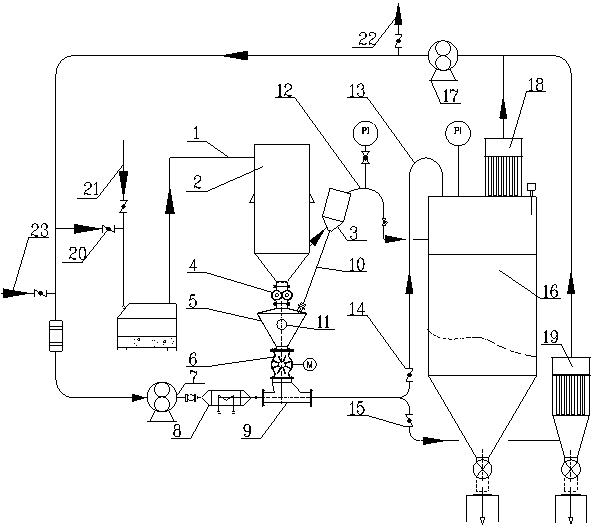

[0034] 1. A system device for industrial production of aluminum trichloride, which consists of a chlorination furnace sublimation tube, a main catcher, a secondary catcher, a crusher, a buffer bin, a star feeder, a Roots blower, a cooler, Acceleration chamber, negative suction pipe A, buffer warehouse sight glass, negative suction pipe B, pneumatic conveying main pipe, qualified product pipeline, unqualified product pipeline, silo, induced draft fan, dust collector A, dust collector B, chlorine gas recycling pipe, Composed of commodity chlorine pipeline, conventional chlorine gas treatment pipeline and nitrogen protection pipeline;

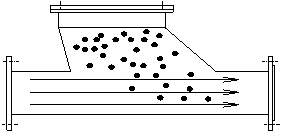

[0035] The main trap is flat and divided into three sections connected by flanges, with a large heat dissipation area. Different tapping frequencies are used for the flat surfaces on both sides of the upper, middle and lower sections of the main trap to make it adhere to the inner wall of the main trap. The aluminum trichloride powder or crystal f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com