Filter and coal mine underground water purification system thereof

A filter and filter shell technology, which is used in fixed filter element filters, filtration separation, mining wastewater treatment, etc., can solve the problems that the purified water cannot meet the requirements of underground mining, cannot meet the purification of underground wastewater, and the purification efficiency is low. Stirring efficiency and effect, improving mixing efficiency and effect, increasing purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

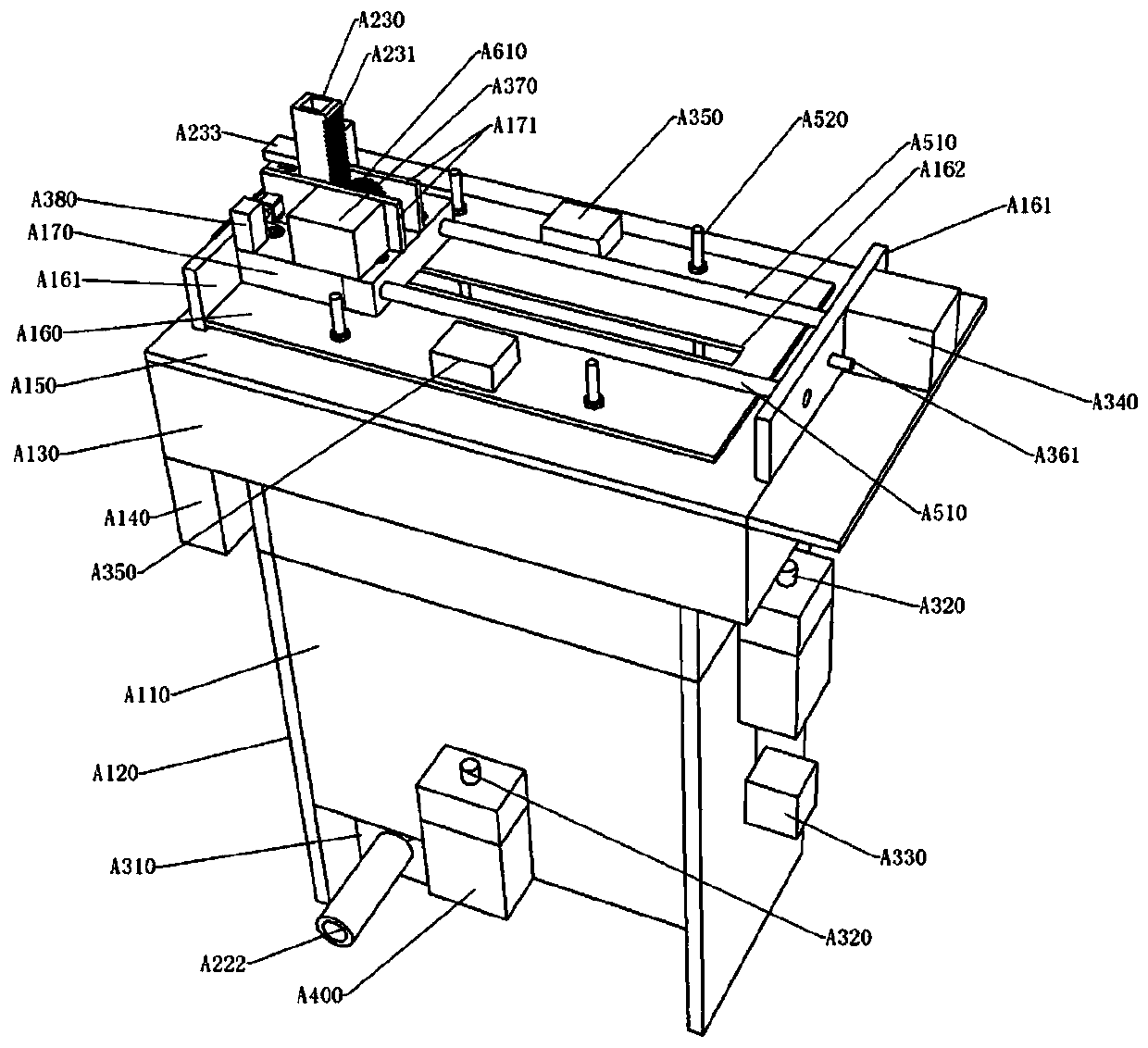

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

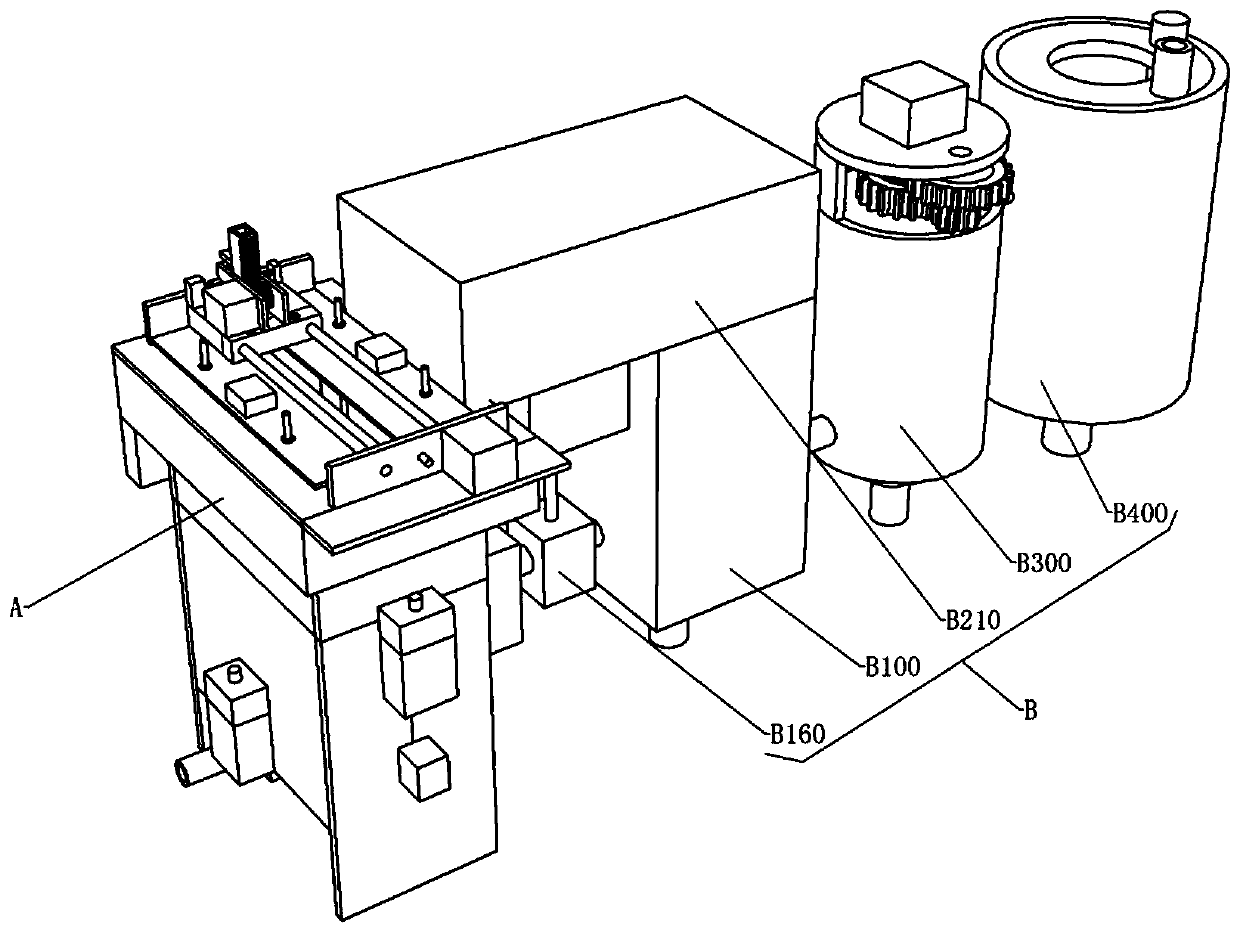

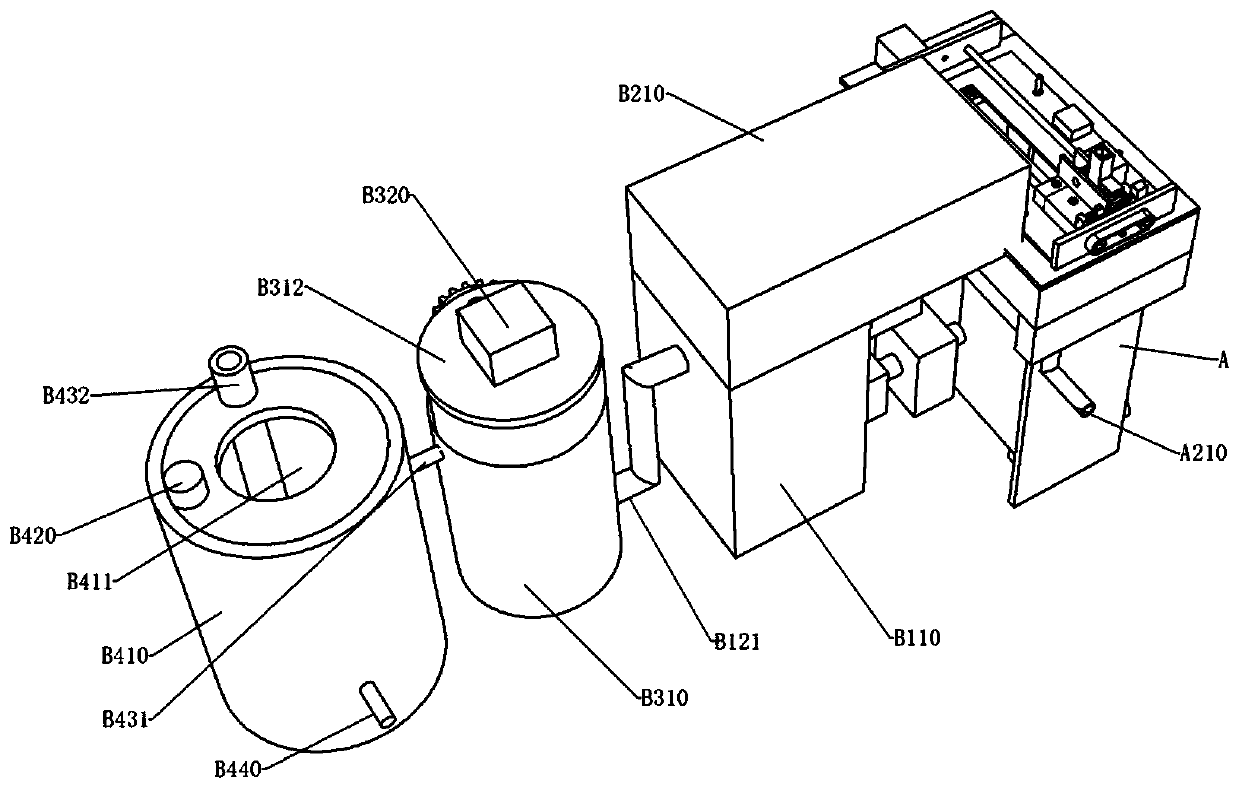

[0034] see Figure 1-Figure 25 , the coal mine underground water purification system of the present embodiment includes:

[0035] Filter A is used to remove floating solids, some light suspended solids, large solid impurities, etc. in the wastewater;

[0036] Purification module B is used to settle the suspended solids in the waste water through chemicals with magnetic seeds (such as flocculants, acid-base agents, etc.), and finally separate clean water with less impurities;

[0037] Magnetic separator C is used to separate the magnetic species in the sludge for reuse.

[0038] After the wastewater passes through the filter, most of the wastewater enters the main purification module for treatment, while the water containing a large amount of floating and suspended solids ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com