Patents

Literature

582results about How to "Rapid precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

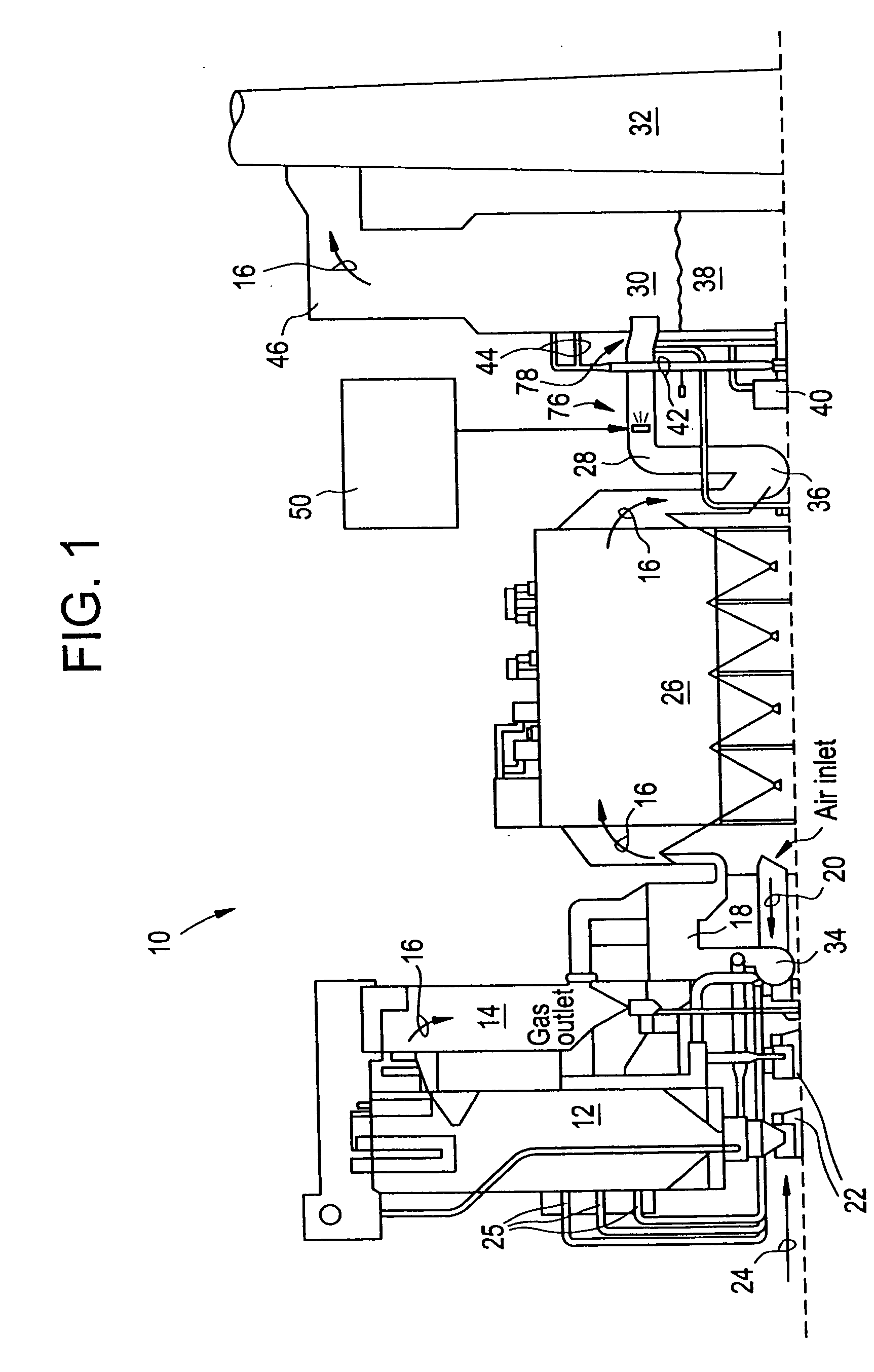

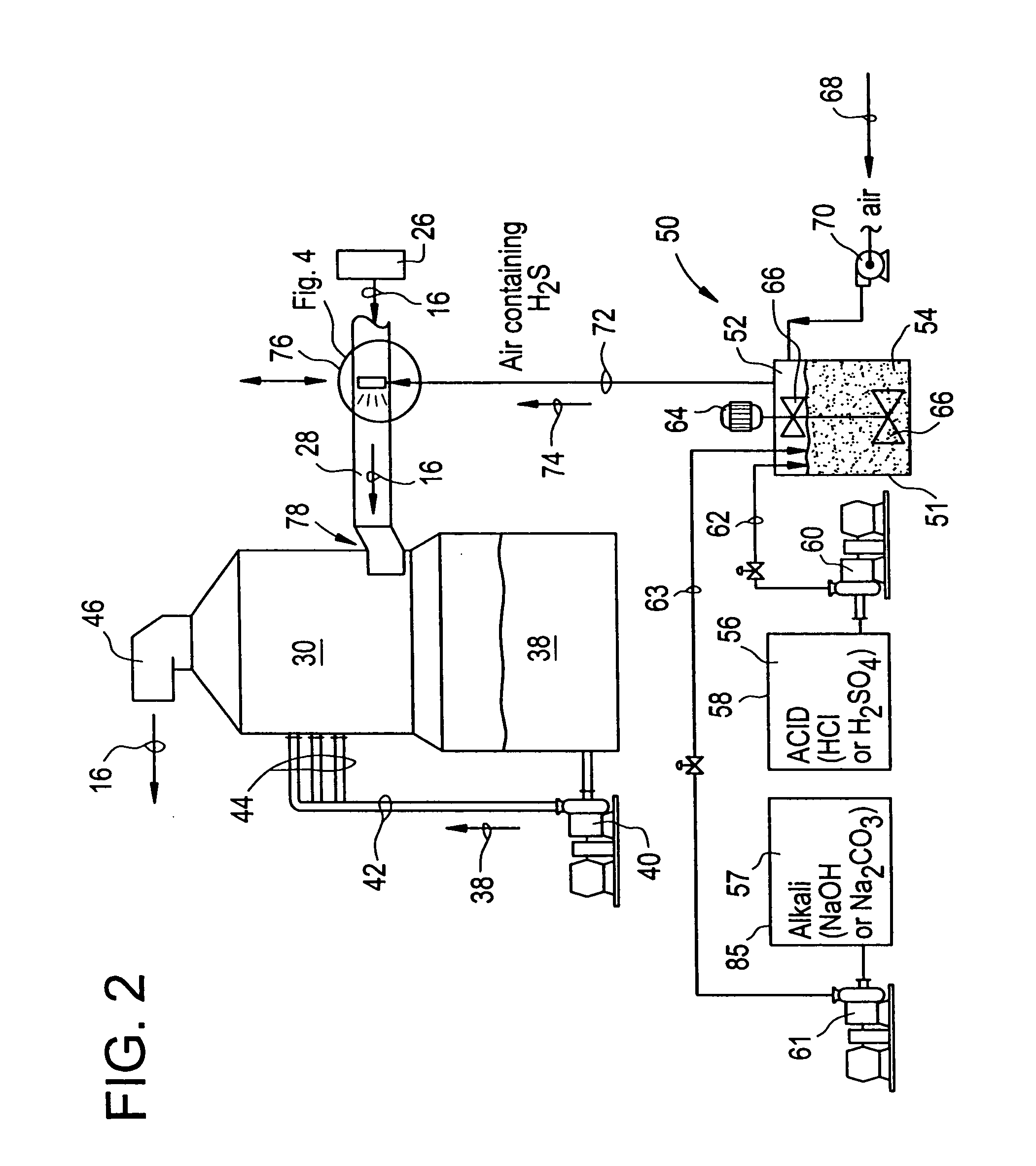

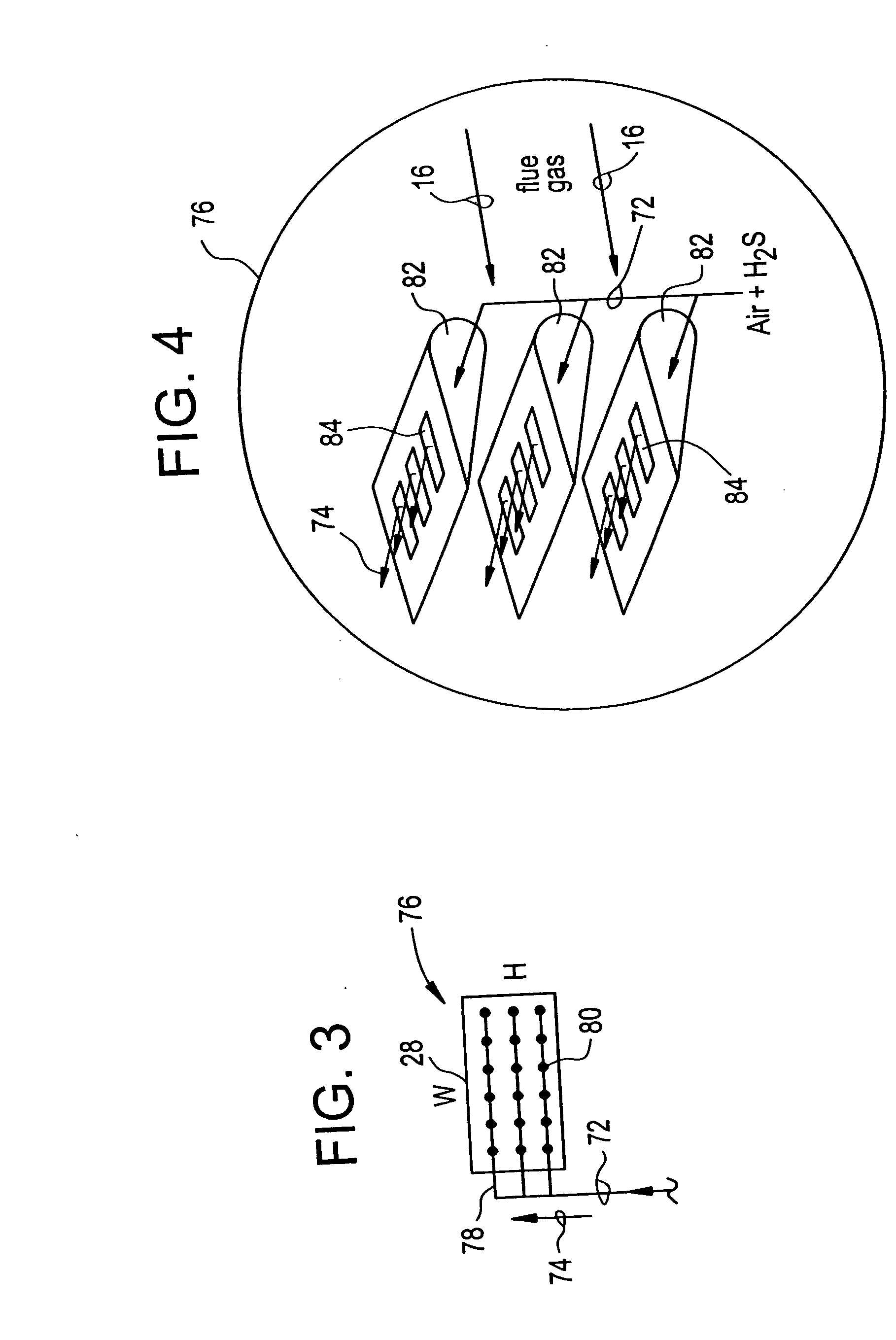

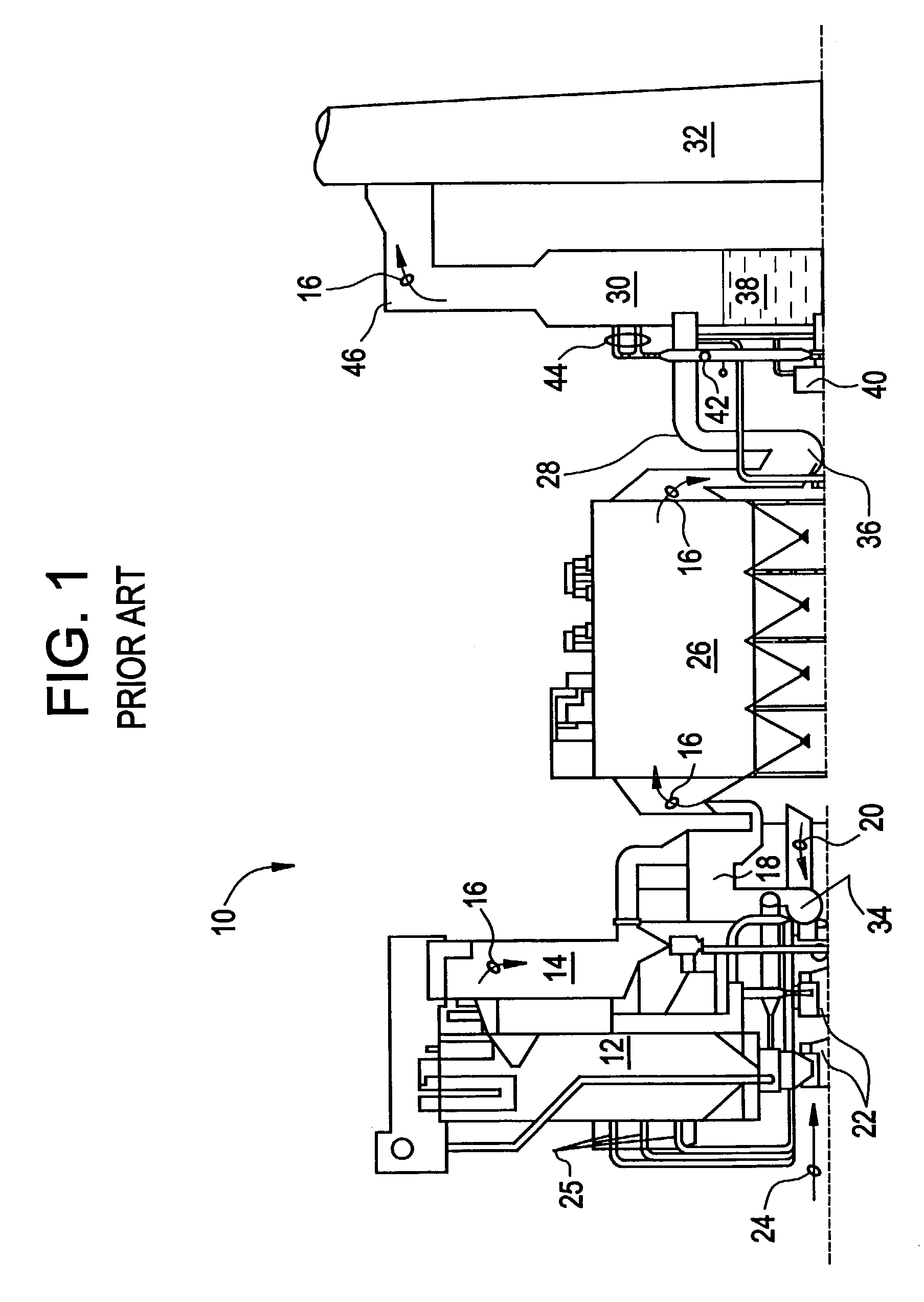

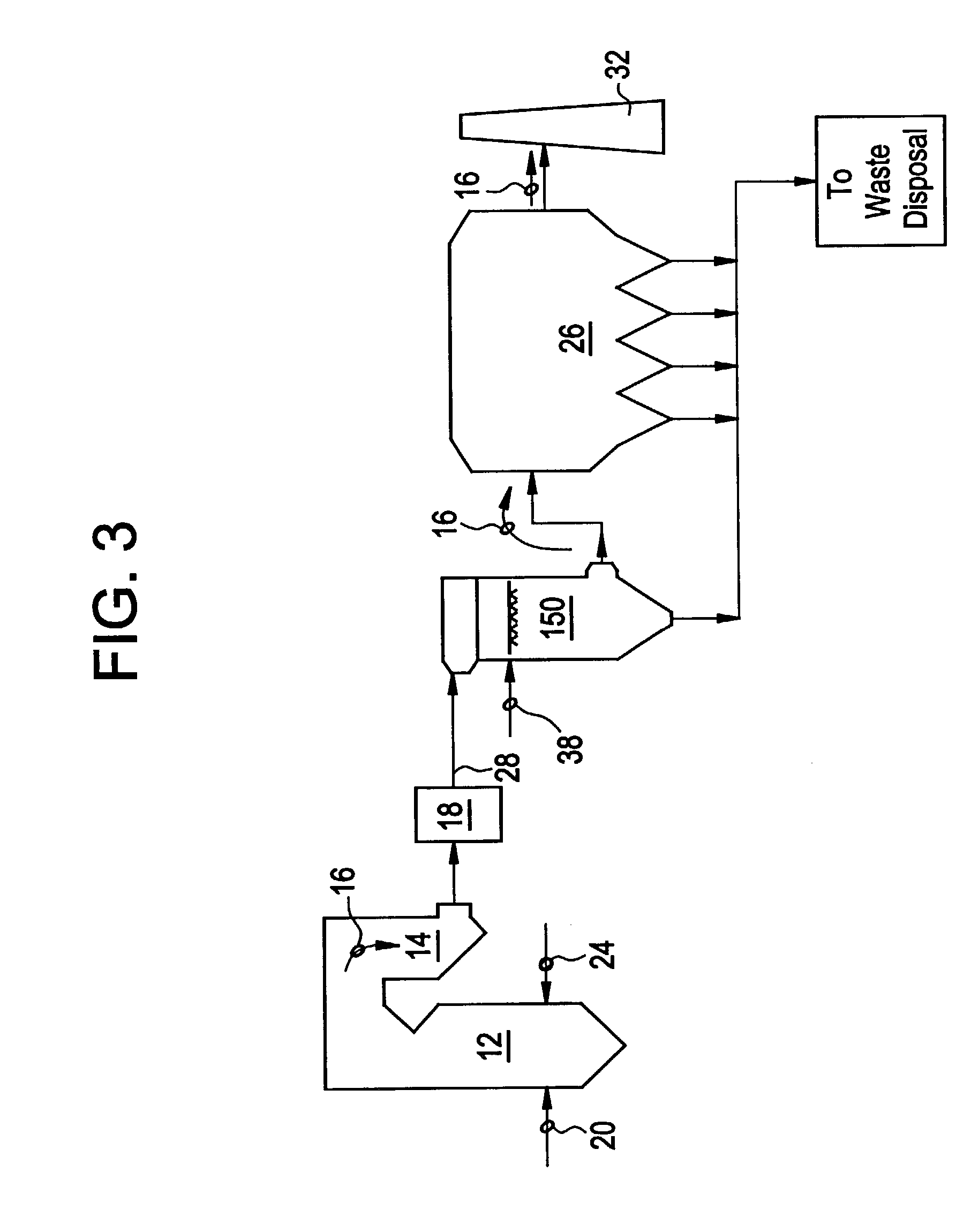

Method for control of mercury

InactiveUS20050169824A1Inherent safety advantageEfficient removalUsing liquid separation agentEmission preventionCoalWet scrubber

A method and apparatus for reducing mercury in industrial gases such as the flue gas produced by the combustion of fossil fuels such as coal adds hydrogen sulfide to the flue gas in or just before a scrubber of the industrial process which contains the wet scrubber. The method and apparatus of the present invention is applicable to installations employing either wet or dry scrubber flue gas desulfurization systems. The present invention uses kraft green liquor as a source for hydrogen sulfide and / or the injection of mineral acids into the green liquor to release vaporous hydrogen sulfide in order to form mercury sulfide solids.

Owner:DOWNS WILLIAM +1

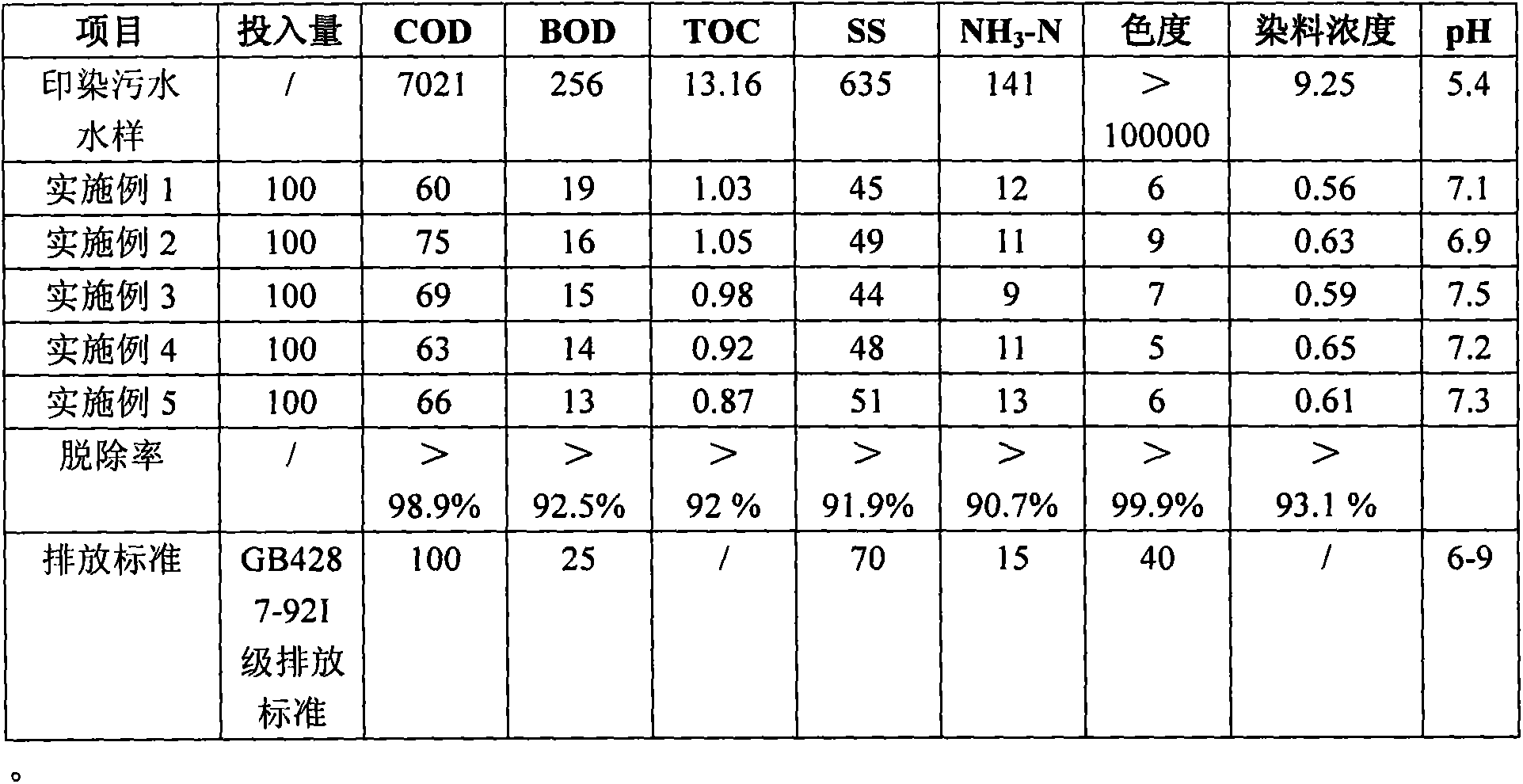

Dyeing wastewater treatment agent and preparation method thereof

InactiveCN103708593ASustainable processingHigh chromaWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionDyeing wastewaterPollution

The invention relates to the technical field of wastewater treatment, and particularly relates to a dyeing wastewater treatment agent and a preparation method thereof. The dyeing wastewater treatment agent comprises the following raw materials in parts by weight: 2-10 parts of ferrous sulfate, 20-30 parts of magnesium sulfate, 0.5-2 parts of polyacrylamide, 10-20 parts of iron nitrate, 1-5 parts of nickel nitrate, 40-60 parts of polyaluminum chloride, 10-20 parts of modified kieselguhr, 8-22 parts of meerschaum powder, 10-20 parts of crosslinked rectorite, 5-10 parts of chitosan-graphene composite material and 1-3 parts of graphene nano layer / MnO2 compound. The dyeing wastewater treatment agent provided by the invention has the advantages of convenient production method, low investment, quick effect taking and no secondary pollution.

Owner:HANDAN COLLEGE

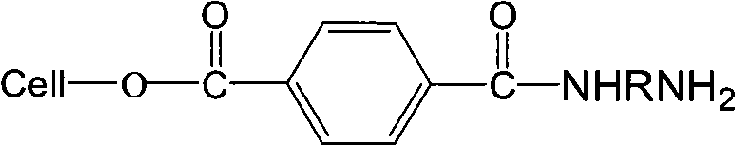

Technique for purifying and producing industrial phosphoric acid by wet-process phosphoric acid

The invention relates to the technique for purifying and producing industrial phosphoric acid by wet-process phosphoric acid, which comprises the following steps of: (1) desulfurization and defluorination sedimentation-filtration process; (2) the extraction of wet-process phosphoric acid after desulfurization and defluorination process; (3) the washing of organic phase after extraction; (4) the back extraction of the organic phase after washing; (5) the refining of aqueous phase after the back extraction; (6) concentrating till containing 85wt% H3PO4 and recycling organic solvent. The technique has the beneficial effects that (1) the wet-process phosphoric acid produced by adopting the existing sulfuric acid process does need to be preconcentrated; (2) compound extracting agent of the technique has good suitability for the extraction of the wet-process phosphoric acid; (3) the compound extracting agent has better separating effect on iron ions and other heavy metal ions; (4) emulsion generated by the organic phase in the washing process can be eliminated by a warming / stewing mode; (5) the technique adopts amidine fiber adsorption column to refine wet-process phosphoric acid and can effectively absorb trace metal ions, and the clearance of the metal ions can reach 99 wt%.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Biodegradable Resin Composition

The present invention relates to a method of producing a biodegradable resin composition, which includes step (1) of mixing a biodegradable resin, a plasticizer and a crystal nucleating agent with one another at the melting point (Tm) of the biodegradable resin or more, wherein the crystal nucleating agent is an aliphatic compound having, in its molecule, two or more of at least one group selected from an ester group a hydroxyl group and an amide group, and step (2) of thermally treating the resulting biodegradable resin composition at a temperature of from the glass transition temperature (Tg) to less than Tm of the composition, as well as a biodegradable resin composition, which contains a biodegradable resin, a plasticizer, and the above crystal nucleating agent, and which satisfies the following conditions: the haze thereof with a thickness of 0.5 mm after thermal treatment at 60° C. for 36 or 60 hours is 20% or less; the storage elastic modulus (E′) at a temperature of 25° C. and a frequency of 50 Hz is 1×108 to 2×109 Pa; and the storage elastic modulus (E′) at a temperature of 60° C. and a frequency of 50 Hz is 1×107 to 1×109 Pa.

Owner:KAO CORP

Fresh mangosteen powder and its prepn process

InactiveCN1810159AImprove adsorption capacityRapid precipitationFood preservationFood preparationFreeze-dryingSiraitia grosvenorii

The present invention discloses fresh mangosteen powder and its preparation process. The fresh mangosteen powder is prepared with mature fresh mangosteen fruit, and through freeze drying and crushing. The present invention has simple technological process, high yield and low cost, and the fresh mangosteen powder effective components of the fresh mangosteen fruit maintained, is delicious, and may be used as health food directly and as the material for producing mangosteen food, health article, medicine and cosmetics.

Owner:蒋向军

Oil-containing wastewater treatment agent and preparation method thereof

ActiveCN103864177AReduce CODReduce BODFatty/oily/floating substances removal devicesLiquid separationTherapeutic effectPollution

The invention belongs to the technical field of sewage treatment agents, and in particular relates to an oil-containing wastewater treatment agent and a preparation method thereof. The oil-containing wastewater treatment agent disclosed by the invention comprises the following raw materials in parts by weight: 35-45 parts of polyacrylamide, 15-25 parts of polymeric aluminium, 12-18 parts of expanded graphite, 15-20 parts of zeolite mineral, 20-30 parts of hydrolyzed tannin, 3-5 parts of organic acid, 5-10 parts of TiO2, and 3-5 parts of chitosan-graphene composite material. The oil-containing wastewater treatment agent disclosed by the invention has the advantages of being good in treatment effect, low in production cost, high in purity, free from toxicity, influence to operators and secondary pollution after treatment; the preparation method is simple and easy for popularization.

Owner:广州小众环保科技有限公司

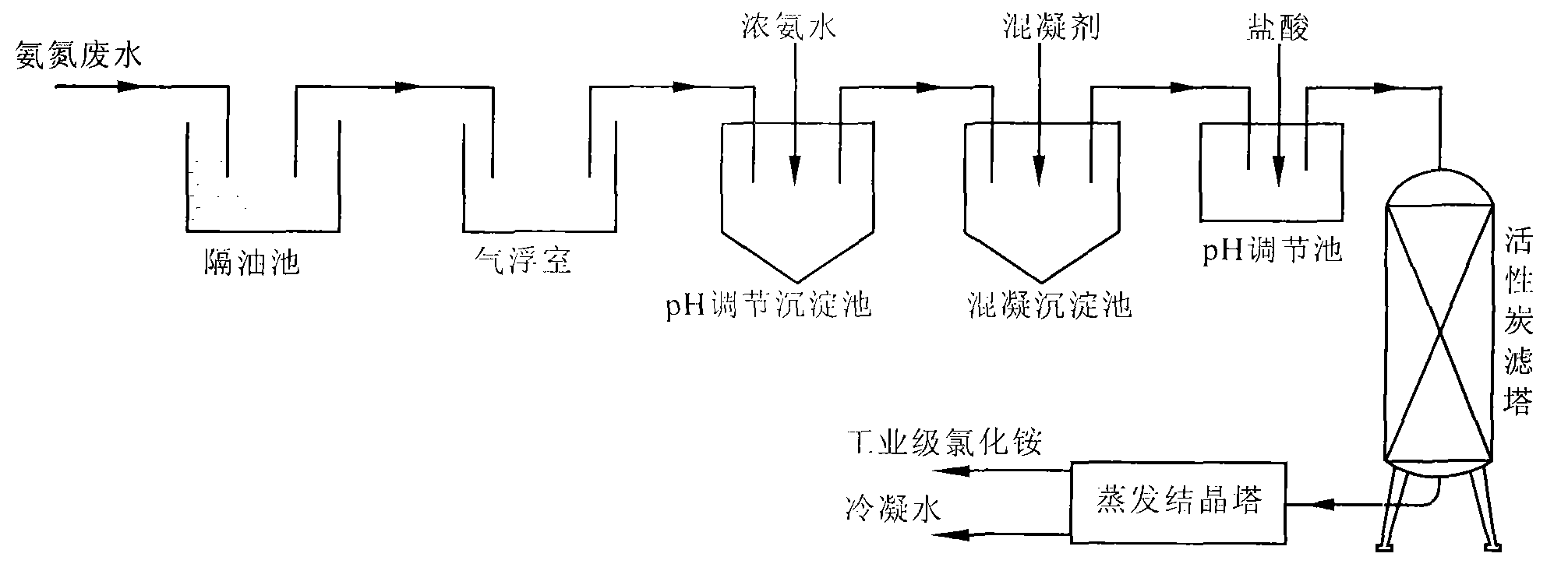

Compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and treatment method

InactiveCN101555053ASimple processing methodLow costFatty/oily/floating substances removal devicesMultistage water/sewage treatmentRare earthPolyacrylamide

The invention provides a compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and a treatment method, belonging to the technical field of chemical environment protection and resource recovery. The compound coagulant is a mixed liquor of ammonium oxalate, ammonium sulphate, heavy metal precipitator DTCR and polyacrylamide (PAM). The treatment method for treating wastewater by using the compound coagulant comprises the following steps: firstly, oil substances in the wastewater are removed through a separation tank and an air floating chamber; secondly, the wastewater enters a pH adjusting precipitation tank to adjust the pH value to be 7.5-8.5; thirdly, the wastewater enters a coagulative precipitation tank, the compound coagulant is added, the wastewater after being coagulated and precipitated enters the pH adjusting precipitation tank to adjust the pH value to be 2.5-4, the wastewater after being adjusted the pH value enters an active carbon filter tower to be absorbed and filtered and then is evaporated and concentrated under the condition of negative pressure. The compound coagulant has simple treatment method, low cost and good effect. The treatment method has short process and simple and easy treatment, not only solves the problem of the pollution of the highly concentrated ammonian wastewater, but also achieves the purpose of recovering valuable materials.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

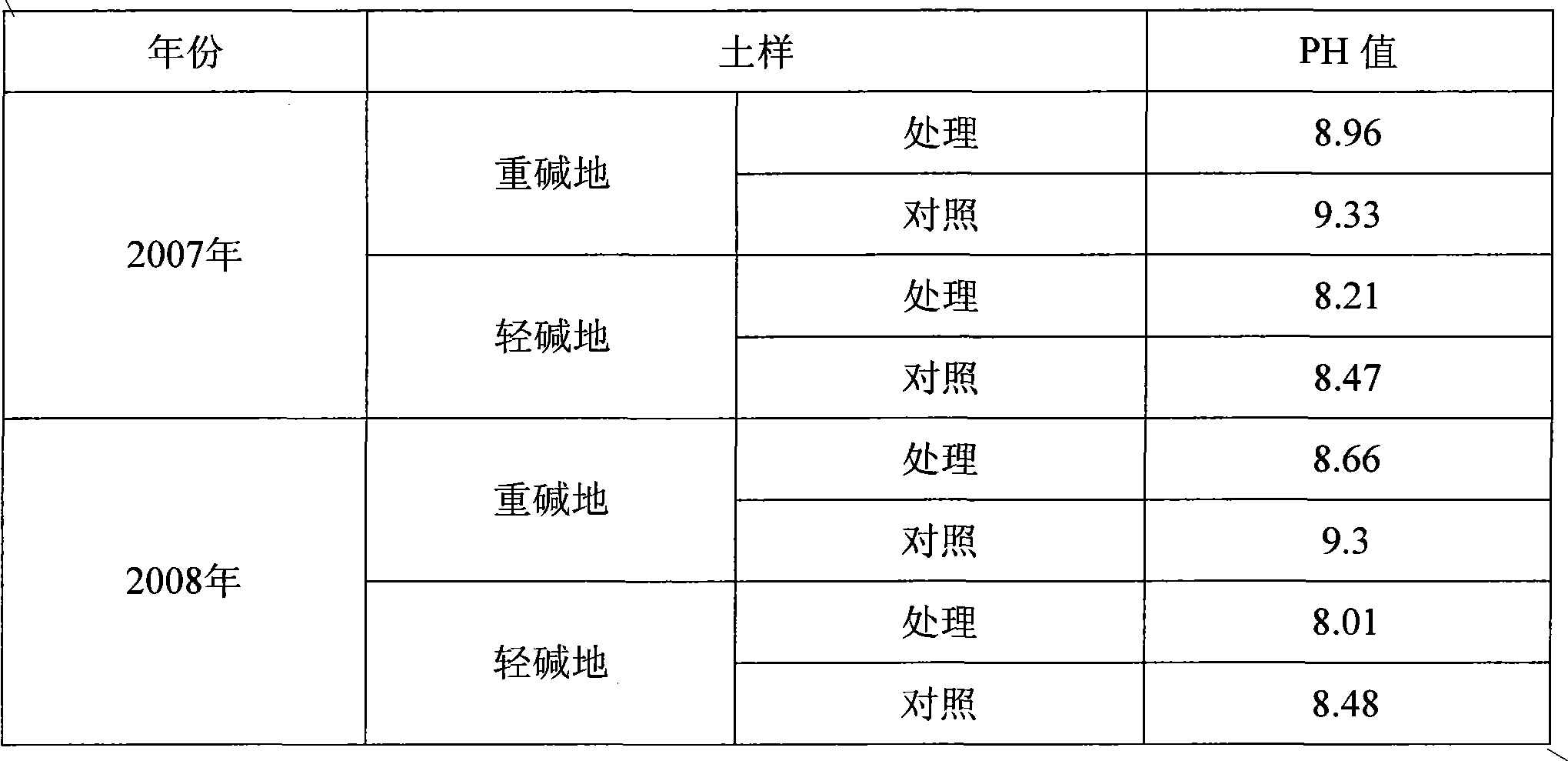

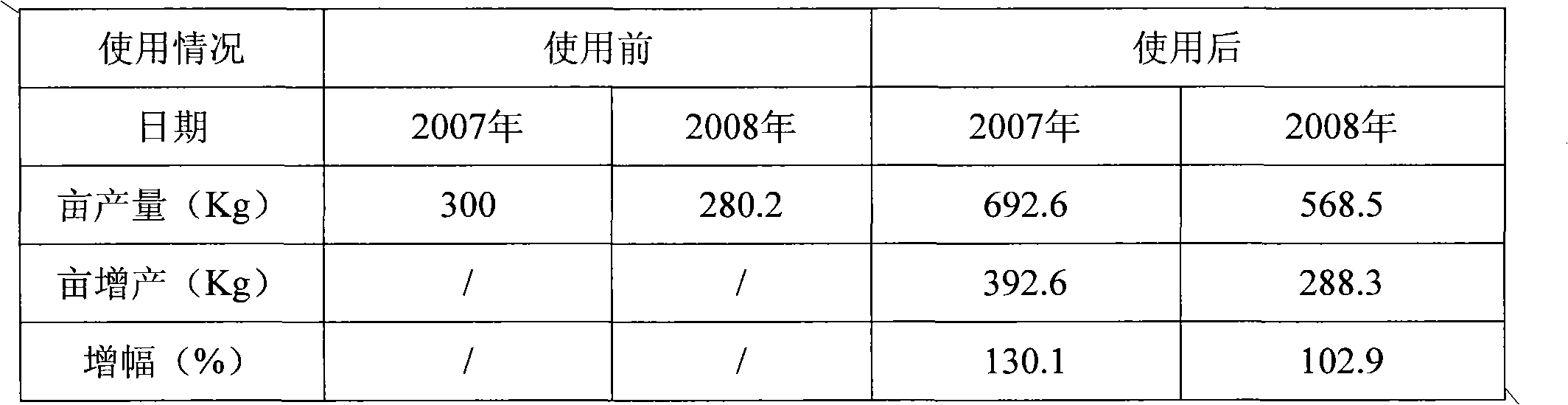

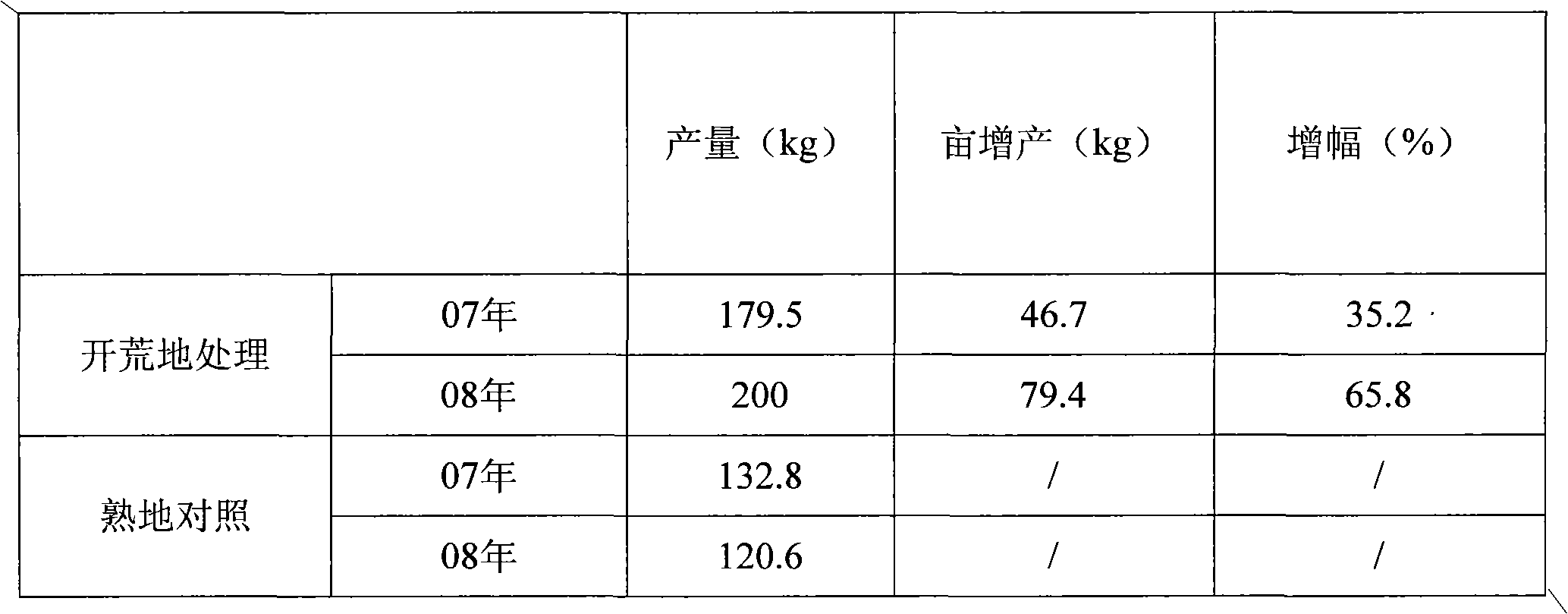

Industrial sludge treatment method and method for preparing various fertilizers by using treated industrial sludge

ActiveCN102010108ARapid precipitationDehydration fastSludge processingMultistage water/sewage treatmentAlkali soilWater insoluble

The invention discloses an industrial sludge treatment method and a method for preparing various fertilizers by using the treated industrial sludge. The industrial sludge treatment method comprises the following steps of: after industrial sludge is diluted, adding a heavy metal ion capturing and precipitating agent DTCR and reacting the agent with heavy metal ions in waste solution so as to generate water-insoluble chelated salt; adding a polyacrylamide flocculating agent to ensure that the chelated salt forms flocculent precipitates; and removing the flocculent precipitates to obtain sludge water, and adding potato water into the sludge water to ferment the sludge. The method for preparing various fertilizers by using the treated industrial sludge comprises the following steps of: preparing a powdery biological bacterial fertilizer by taking the sludge water obtained from the treated sludge as a raw material; and preparing a granular organic fertilizer and a fertilizer for changing saline and alkaline lands into fertile farmlands by taking the powdery biological bacterial fertilizer as a raw material. The industrial sludge treatment method has low cost and does not cause secondary pollution to the environment. The biological bacterial fertilizer and the granular organic fertilizer which are produced by the invention are used in lands of various areas, the yield is improved by 15 to 20 percent; and the fertilizer for improving the saline and alkaline lands has extremely obvious saline and alkaline transformation effect.

Owner:LIAOCHENG JINTAIYANG BIOCHEM

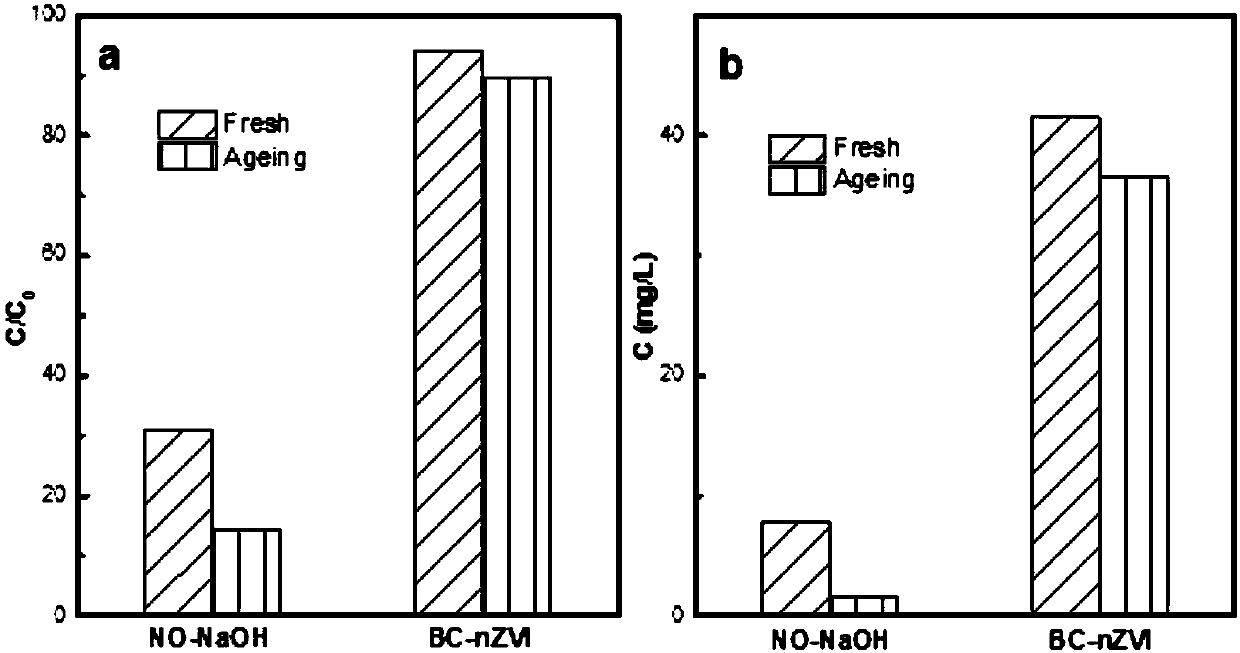

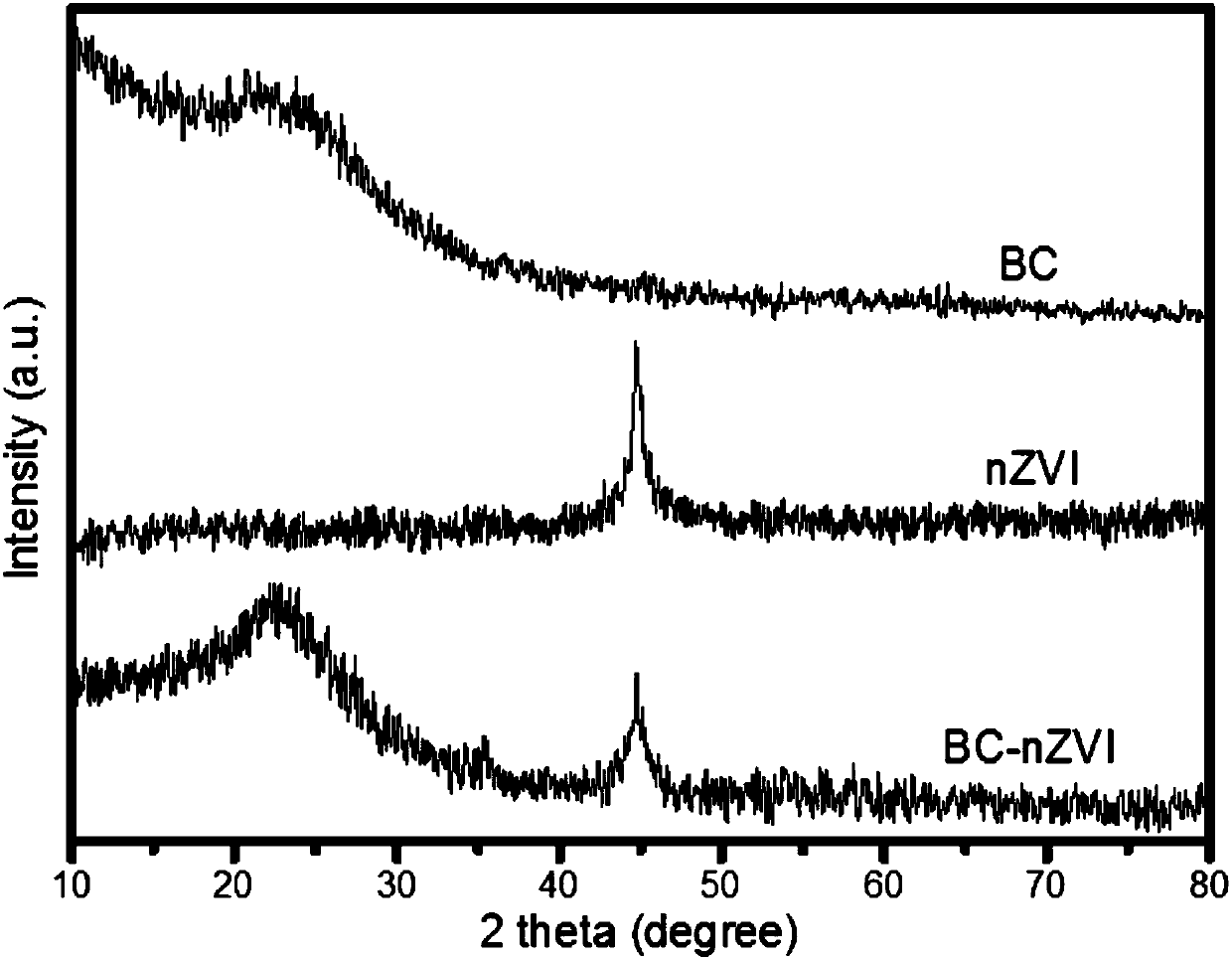

Method for preparing supported biochar catalysis material

InactiveCN107930629ARapid precipitationEvenly dispersedWater contaminantsCatalyst activation/preparationFreeze-dryingPolyethylene glycol

The invention discloses a method for preparing a supported biochar catalysis material. The method comprises the following steps: breaking and sieving dried biomass, charring the biomass at 500-800 DEGC to prepare biochar, impregnating the biochar in a polyethylene glycol 4000-containing FeSO4 solution in a nitrogen environment under a strong stirring condition according to a mass ratio of iron tothe biochar being not less than 1:1, dropwise adding a NaOH-containing sodium borohydride solution, and filtering, washing and freeze-drying the obtained reaction product after the reaction is finished in order to the biochar-supported nanometer zero-valence iron catalysis material. The supported biochar catalysis material BC-nZVI prepared in the invention has excellent removal and reduction effects on nitrobenzene wastewater, and allows the removal rate to reach 95% and the reduction rate to reach 80% within 6 h; the combination between the Fe and the biochar in the composite material is strong and highly stable, so long-term storage and no secondary pollution of the catalysis material are achieved.

Owner:NANJING UNIV OF SCI & TECH

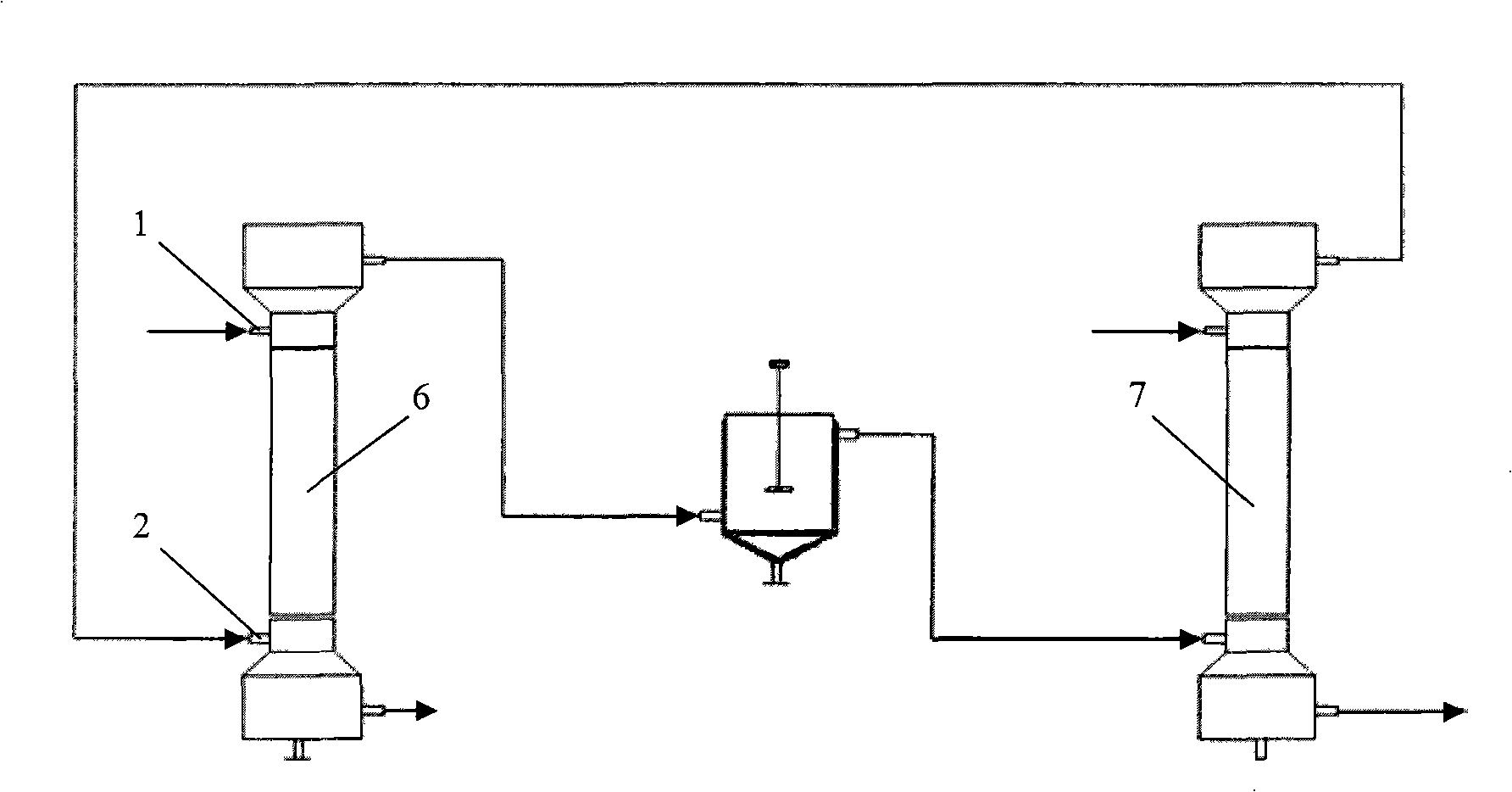

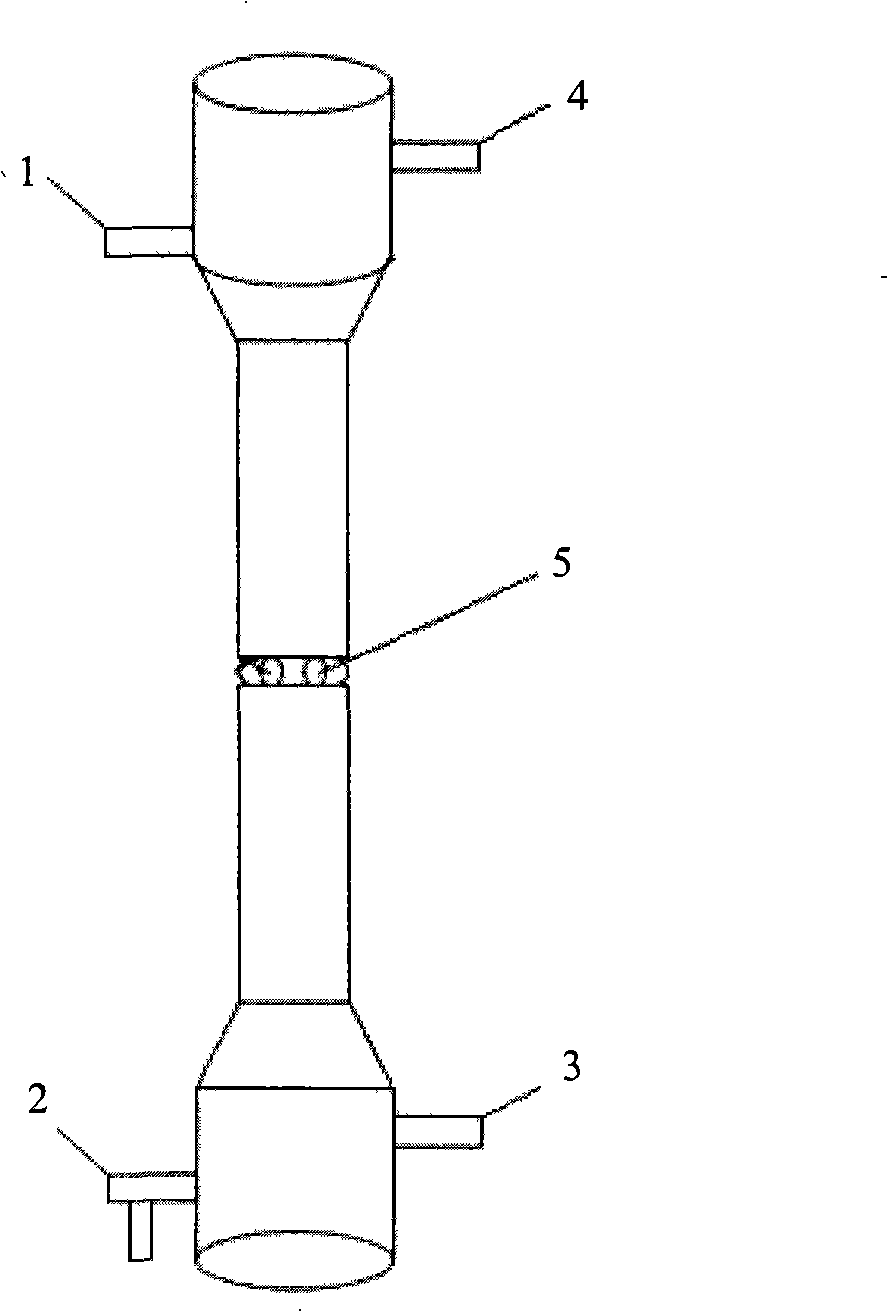

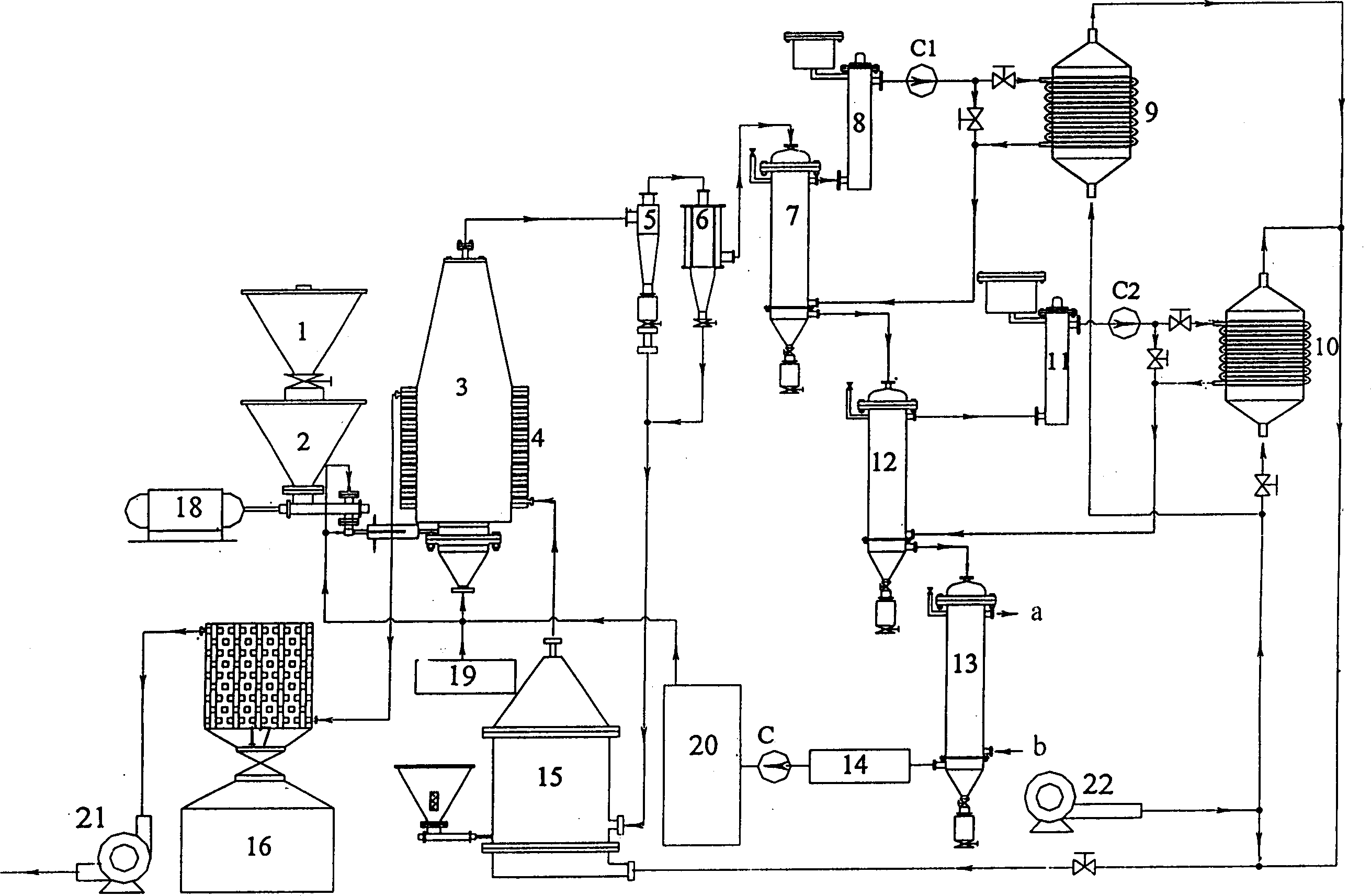

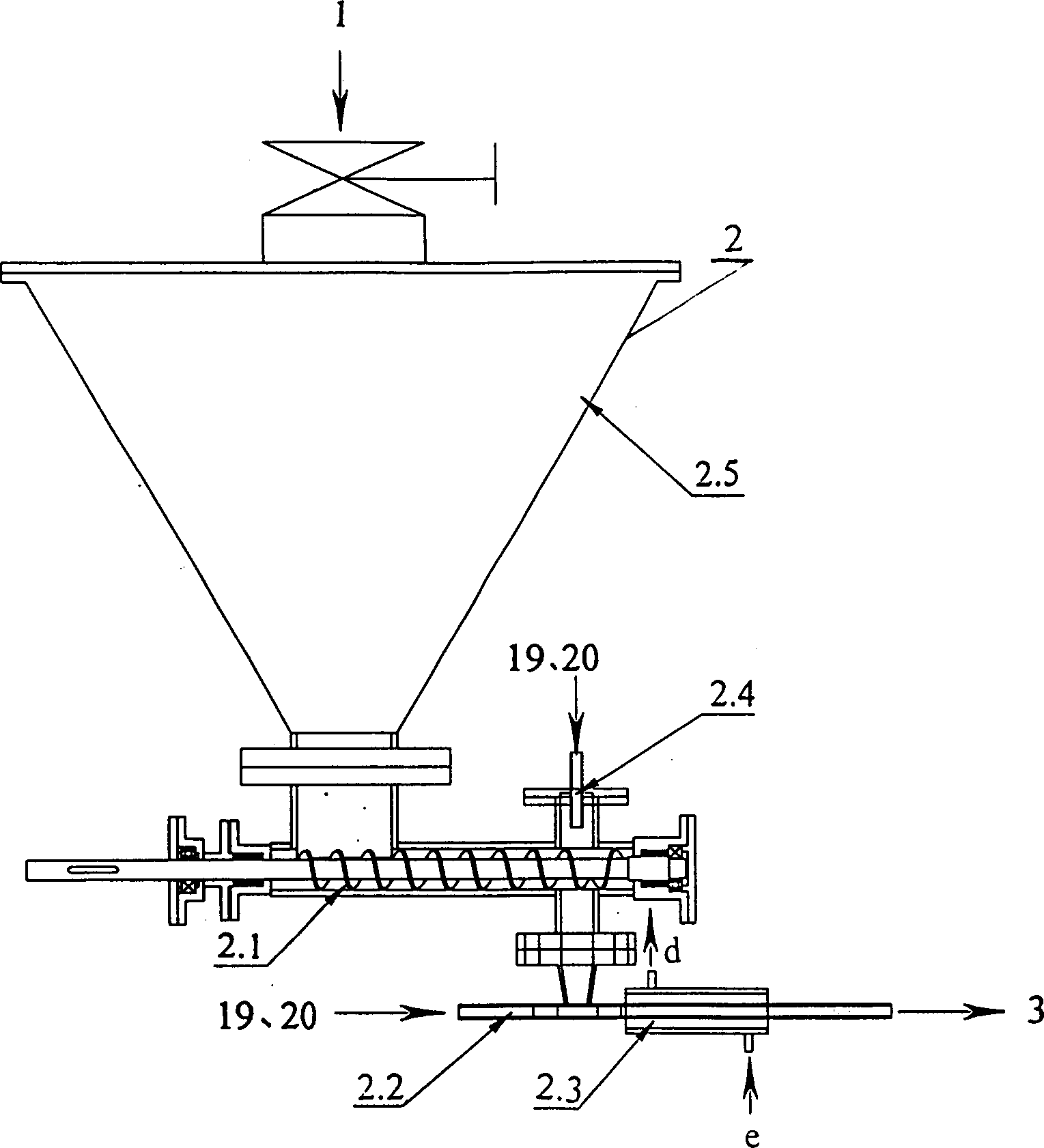

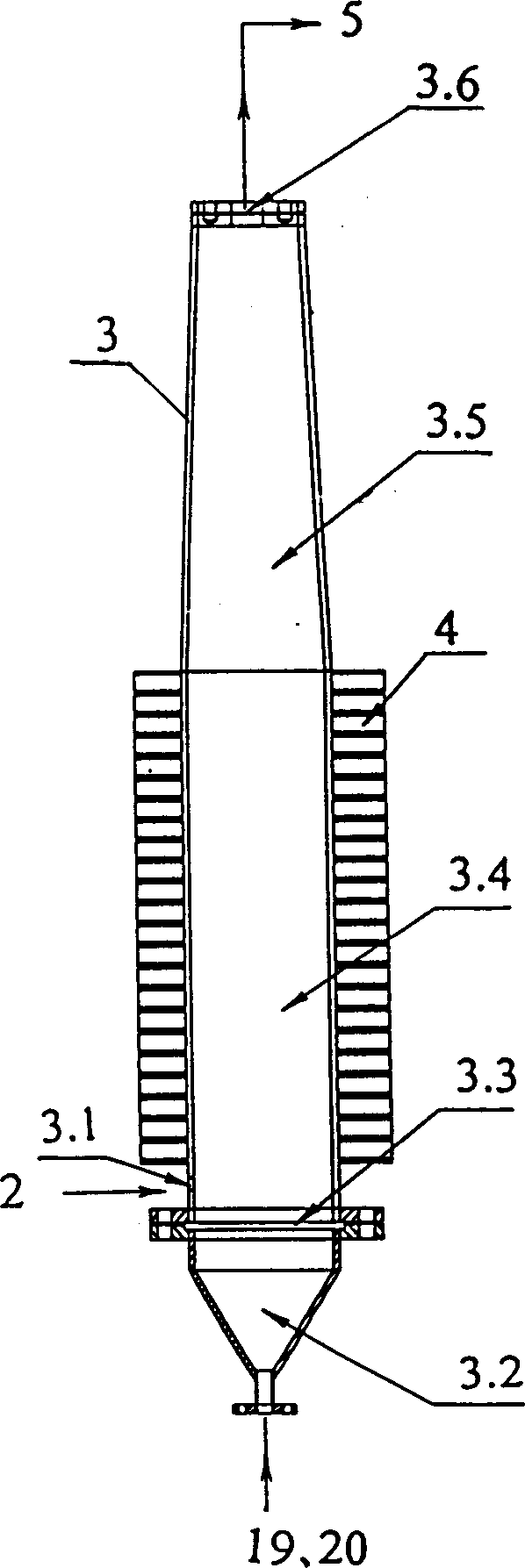

Biomass integrated thermocracking equipment for preparing liquid fuel

InactiveCN1390915ALow costGuaranteed smooth feedingLiquid hydrocarbon mixture productionBiomassProcess engineering

A integrated biomass thermocracking equipment for preparing liquid fuel is composed of cyclone separator, carbon filter, multi-stage condensing system consisting of two air coolers, two heat-transfer oil heaters and three condensers, self-heating system consisting of two air coolers, carbon burner and heat exchanger of reactor, combined feeder, and cross-section variable fluidized-bed reactor. Its advantages are flash temp-rasing of biomass, fast eduction out of volatile components and recovering solid carbon.

Owner:ZHEJIANG UNIV

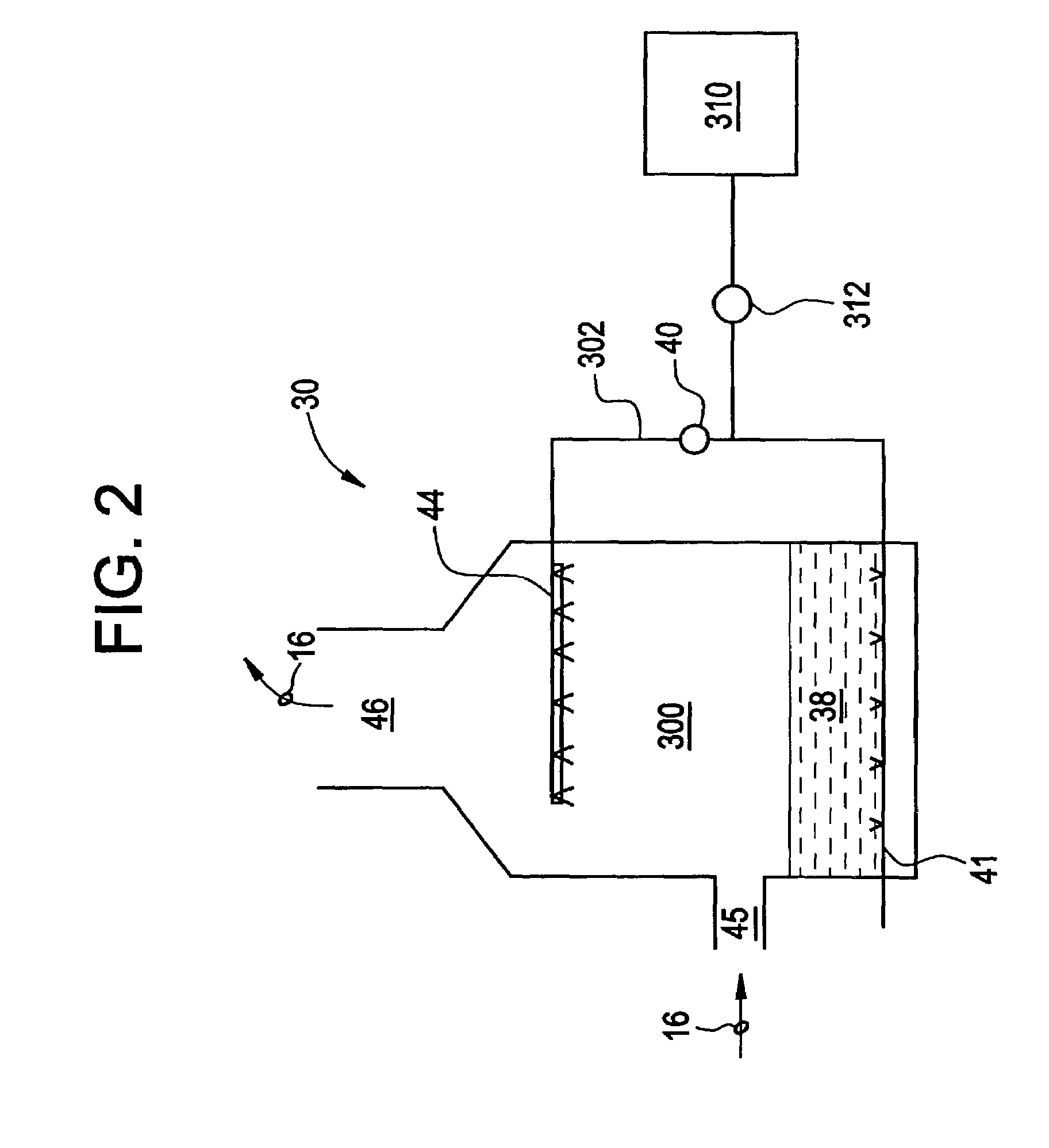

Use of sulfide-containing liquors for removing mercury from flue gases

InactiveUS7037474B2Inherent safety advantageEfficient removalGas treatmentExhaust apparatusPotassium sulfideIndustrial gas

A method and apparatus for reducing and removing mercury in industrial gases, such as a flue gas, produced by the combustion of fossil fuels, such as coal, adds sulfide ions to the flue gas as it passes through a scrubber. Ideally, the source of these sulfide ions may include at least one of: sulfidic waste water, kraft caustic liquor, kraft carbonate liquor, potassium sulfide, sodium sulfide, and thioacetamide. The sulfide ion source is introduced into the scrubbing liquor as an aqueous sulfide species. The scrubber may be either a wet or dry scrubber for flue gas desulfurization systems.

Owner:THE BABCOCK & WILCOX CO

Two component compositions containing tetrabasic zinc-amino acid halide complexes and cysteine

Owner:COLGATE PALMOLIVE CO

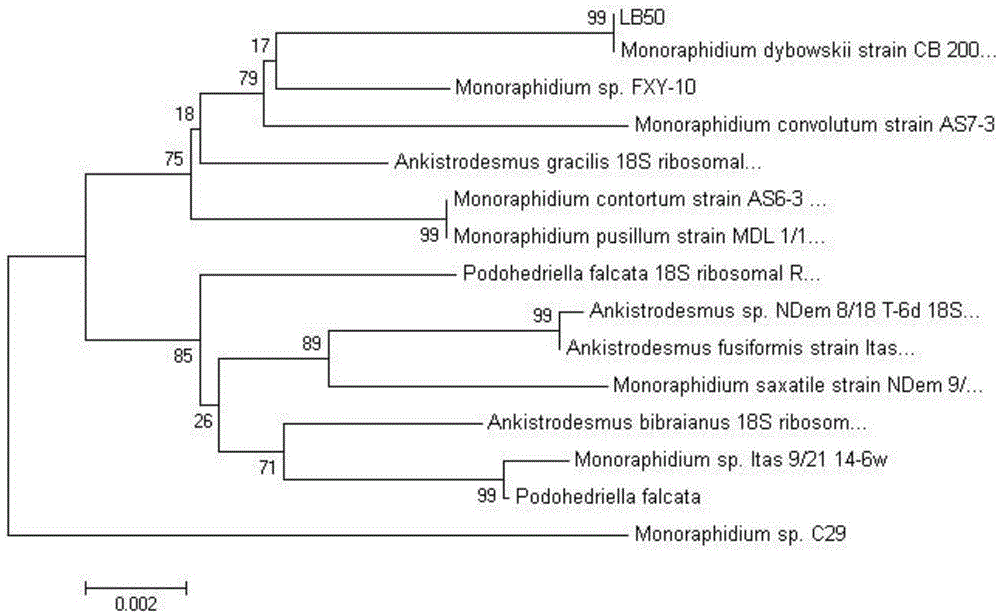

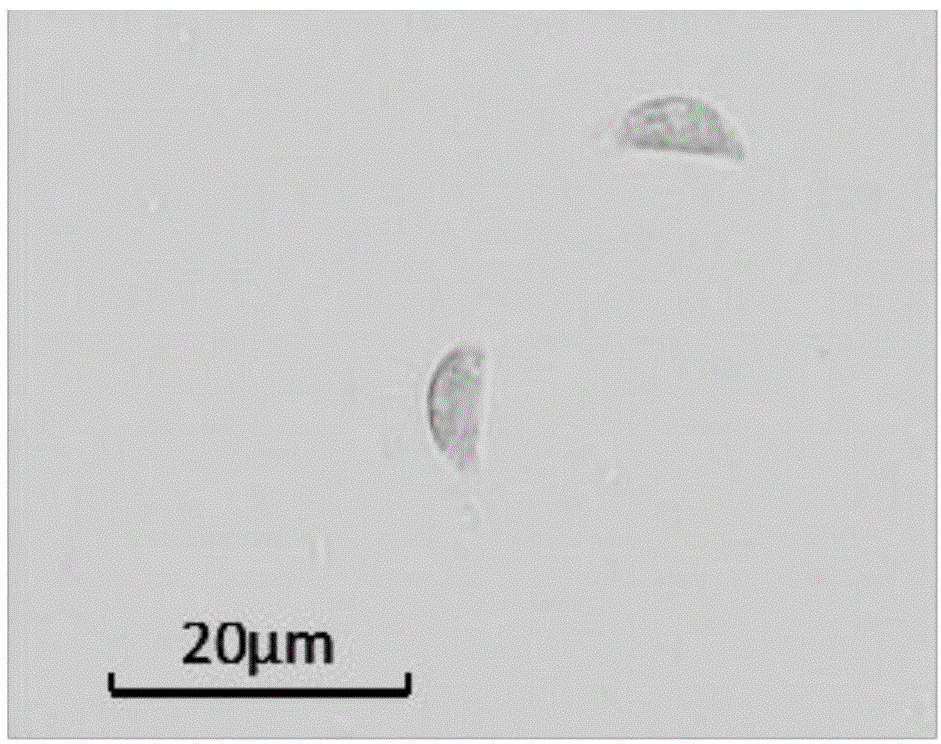

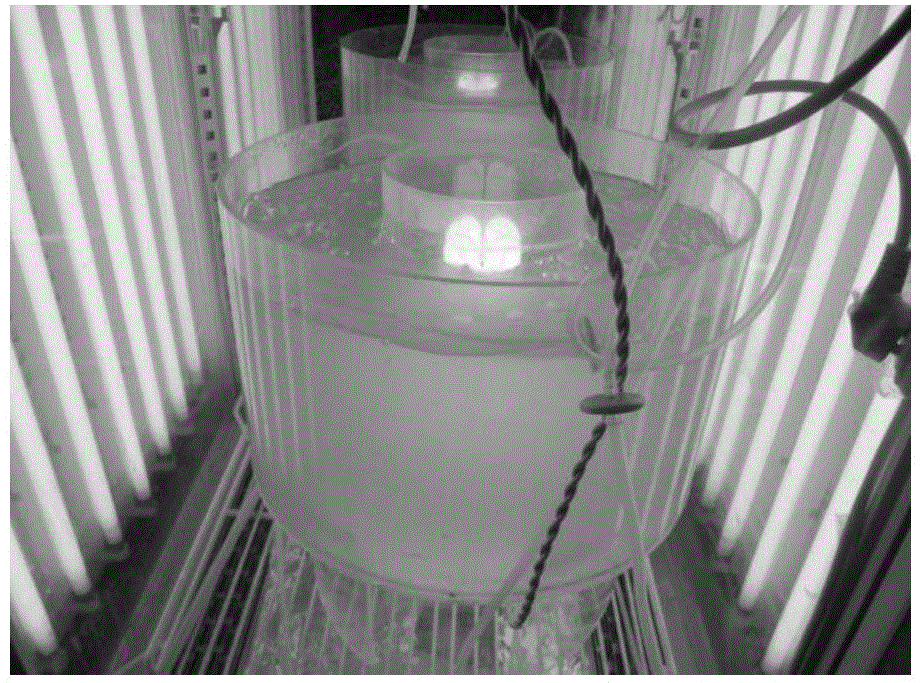

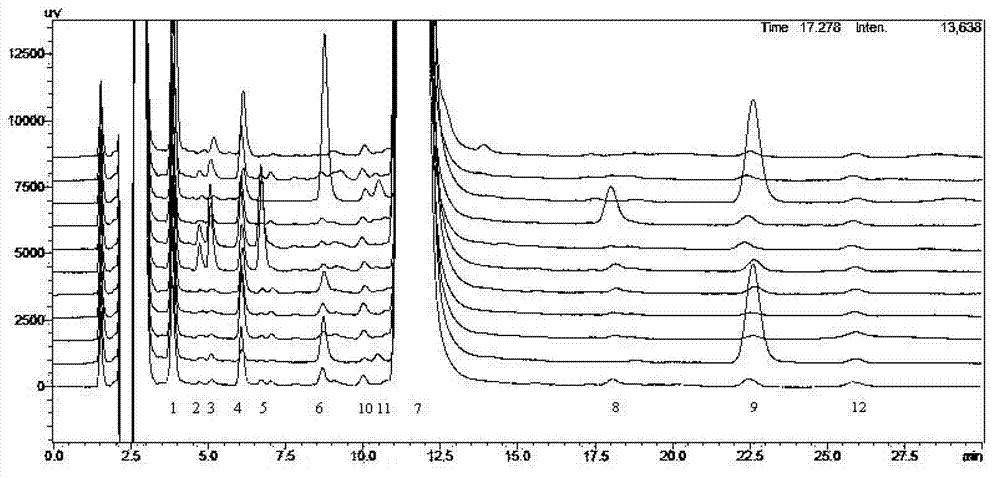

Acquisition and application of grease-producing monoraphidium LB50

The invention discloses acquisition and application of grease-producing monoraphidium LB50, and relates to screening and culture utilization technologies of the grease-producing monoraphidium. An algae species obtained by separating from field environment is subjected to 18S rDNA sequence analysis and morphological identification and is determined as a member of monoraphidium, and the sequence is shown as SEQ NO.1. The grease-producing monoraphidium LB50 is capable of bearing high-concentration sodium bicarbonate, is easy for open-type culture and is rich in grease; and when the growth and collection speed is kept at 22.2 g / m<2>*d, the grease content reaches 30.4% by dry weight of a cell, and aliphatic acid contained in grease contains octadecatrienoic acid and octadecatetraenoic acid which account 15% or more of aliphatic acid.

Owner:INST OF AQUATIC LIFE ACAD SINICA +1

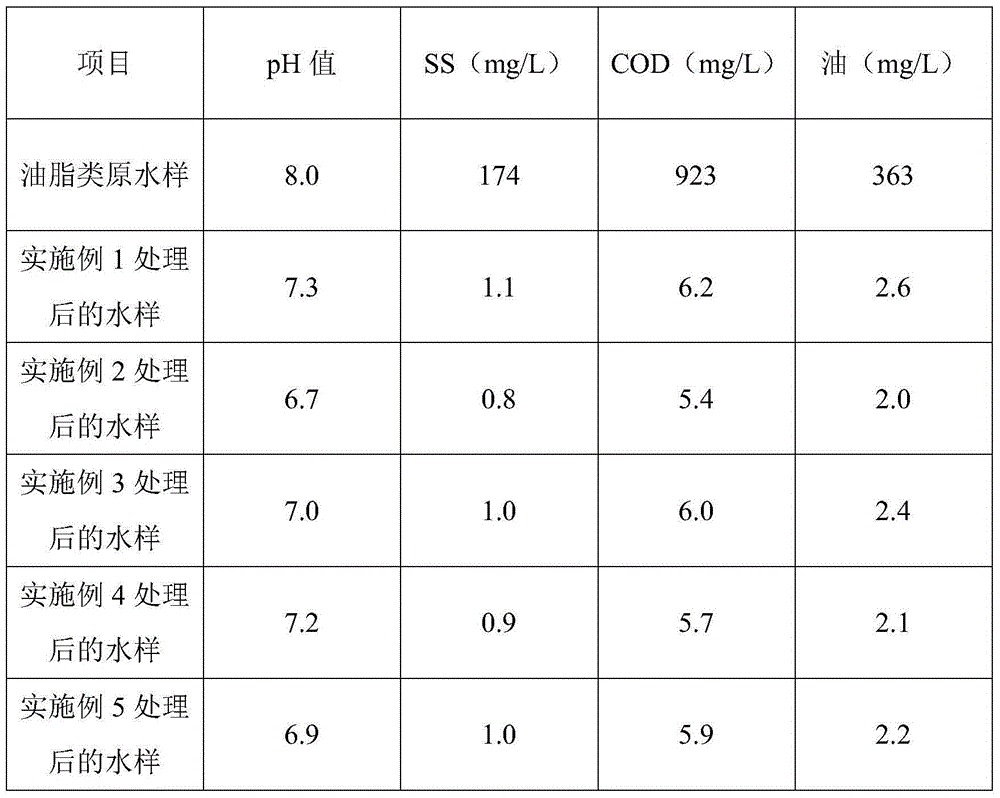

Grease sewage treatment agent

ActiveCN105174489AReduce moisture contentRapid precipitationScale removal and water softeningBiological water/sewage treatmentChemical oxygen demandPollution

The invention discloses a grease sewage treatment agent and belongs to the technical field of sewage treatment agent preparation. The grease sewage treatment agent comprises the following raw materials in parts by weight: 40 to 80 parts of enzyme preparation, 40 to 80 parts of demulsifier, 30 to 60 parts of flocculant, 30 to 60 parts of coagulant aids, 30 to 60 parts of foaming agent, 20 to 50 parts of flotation agent, 20 to 50 parts of bactericide, 10 to 20 parts of corrosion inhibition antisludging agent and 10 to 20 parts of deoxidant. The grease sewage treatment agent disclosed by the invention has the beneficial effects that existence forms of water-in-oil and oil-in-water in water can be broken to rapidly remove a large amount of SS (suspended solid), grease and COD (chemical oxygen demand); the grease sewage treatment agent is high in efficiency and has no corrosivity; secondary pollution cannot be caused to sewage in later stage, and the treatment cost is reduced.

Owner:江苏中丽新材料有限公司

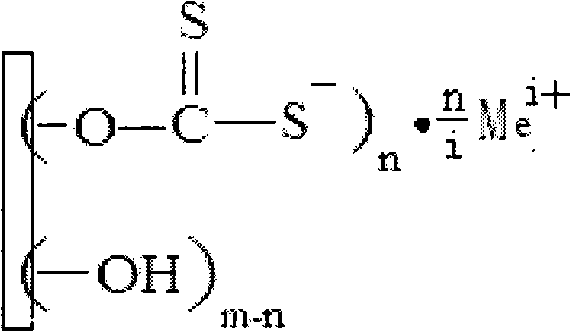

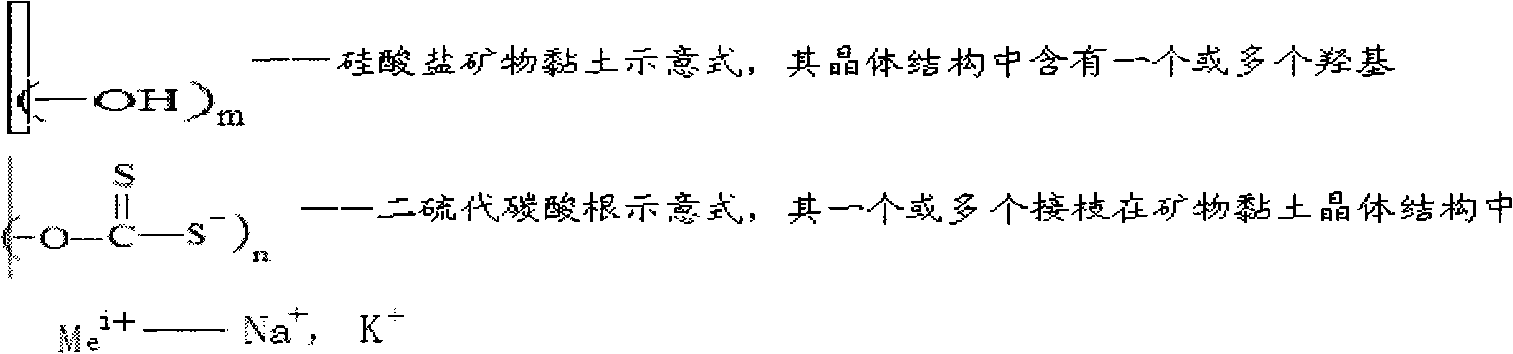

Clay-based xanthogenate, and preparation method and application thereof

InactiveCN102463104ARich reservesSimple processing technologyOther chemical processesWater/sewage treatment by flocculation/precipitationSoil remediationGraft reaction

The invention belongs to chemical materials and mainly relates to clay-based xanthogenate, and a preparation method and application thereof. The invention provides a clay-based xanthogenate compound. The other purpose of the invention is to provide the preparation method and the application of the clay-based xanthogenate. The clay-based xanthogenate compound and the preparation method thereof are characterized in that the compound is formed by alkalifying various mineral clays and then carrying out modifying or grafting reaction by adding carbon disulfide; and the method is simple, strong in operability, low in cost and easy for large-scale production, popularization and application. More particularly, the clay-based xanthogenate compound provided by the invention can be used as novel high-efficient heavy metal ion coagulant and can be applied in the fields, such as waste water treatment, soil remediation, wet-process metallurgy, environmental protection, ecological construction and the like, thus, the clay-based xanthogenate compound has the characteristics of simple and easy operation, rapidness, convenience, high metallic ion removing rate, easy solid-liquid separation and the like. The clay-based xanthogenate compound is an environment-friendly functional material and also has a wide application prospect in other fields.

Owner:王永斌

Processing technique of noctilucent glazing floors

ActiveCN103061487AImprove adhesionControl curing speedLaminationLamination apparatusWeather resistanceFloor slab

The invention belongs to the field of floor processing, in particular to a processing technique of noctilucent glazing floors. The processing technique is good in decoration and comprises the following steps of (1) processing a floor slab; (2) coating noctilucent primer on the floor slab processed in the step (1) to obtain a first floor slab; (3) coating elastic primer, wear-resisting primer and hardening primer on the first floor slab processed in the step (2) to obtain a second floor slab; and (4) coating glazing paint on the second floor slab processed in the step (3) to obtain the noctilucent glazing floors. The glazing paint is coated outside the noctilucent primer of the processed floors to enable the floors to give out full and soft light at night, simultaneously friction losses or oxidation of the noctilucent primer can be well avoided, weather resistance of the noctilucent primer is strengthened, and lighting service life of the noctilucent primer is prolonged. The glazing paint is applied to the surface of the floors, glossiness, abrasive resistance and fire resistance of the floors are strengthened, flame retardant efficiency of the floors is good, strength is high, and deformation caused by external temperature and humidity is not easy to cause.

Owner:如东文园投资开发有限公司

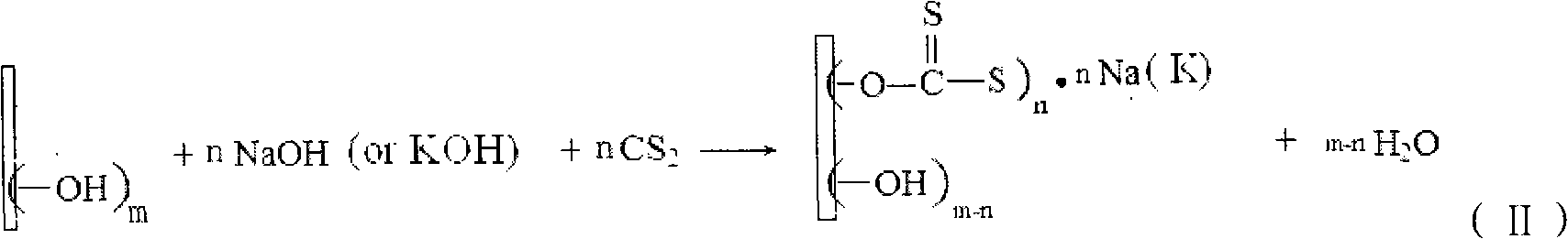

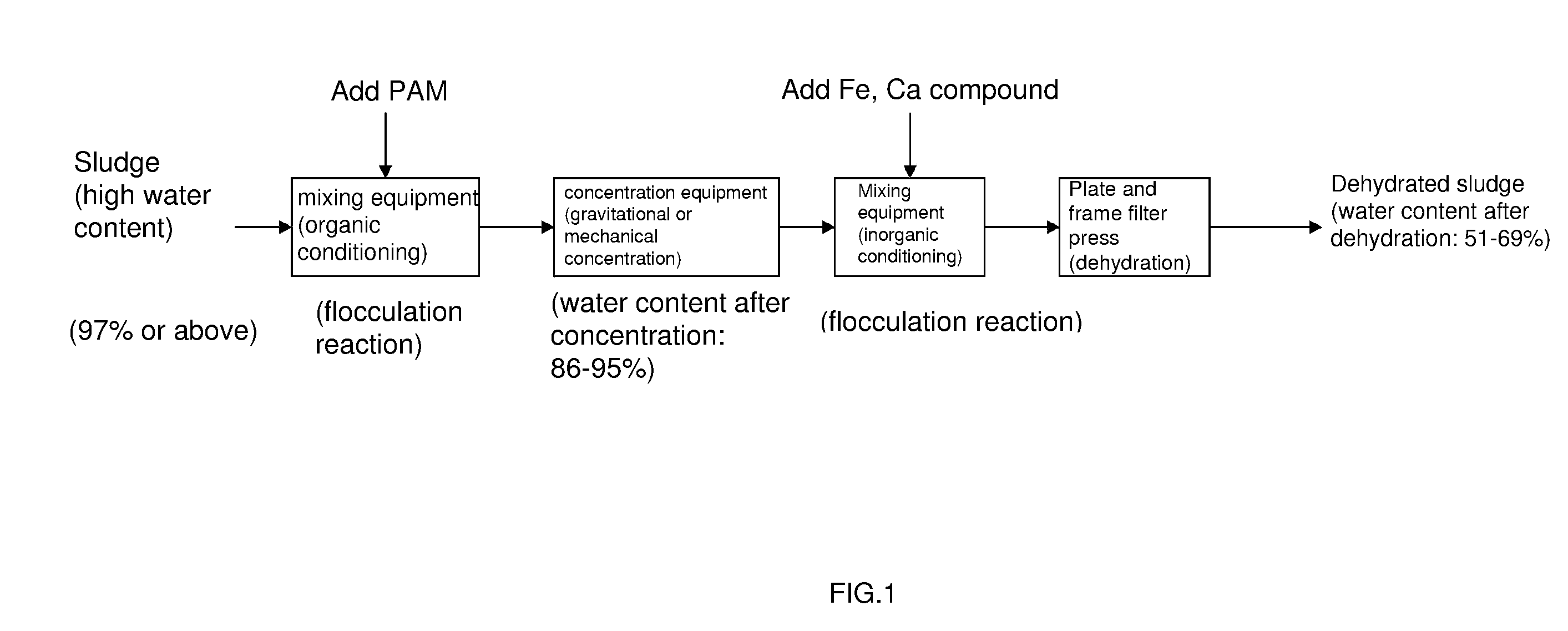

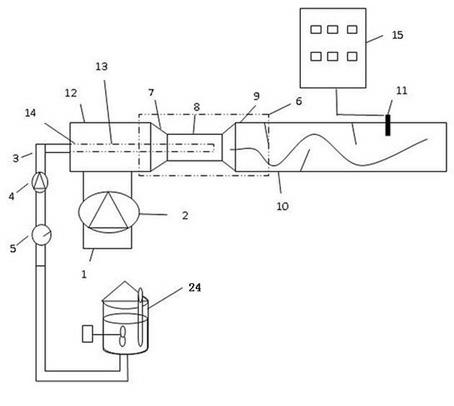

Sludge concentration and dehydration method

InactiveUS20100282683A1Reduce moistureConsumes least amount of energySludge treatment by de-watering/drying/thickeningSolid sorbent liquid separationSludgePolyacrylamide

A sludge concentration and dehydration method is provided, which comprises the following steps: (1) add an organic agent (polyacrylamide) to the sludge for initial conditioning, then concentrate the sludge; (2) add an inorganic agent (a compound containing Fe and Ca) to the sludge for further conditioning, then transport the sludge to a dehydrator for dehydration; (3) dispose the dehydrated sludge correspondingly when it satisfies the requirements for final disposal.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

Southern ionic type rare earth mine ammonia-free mining process

InactiveCN107217139ARapid precipitationAvoid influenceProcess efficiency improvementOxideHigh concentration

The invention provides a southern ionic type rare earth mine ammonia-free mining process. On the basis of the in-situ ore leaching technology, magnesium sulfate plus sodium sulfate is served as an ore leaching agent, sand sodium bicarbonate is served as a precipitating agent to produce rare earth carbonate, or an extraction manner is adopted to produce qualified high-concentration rare earth material liquid to be served as a product. The process comprises the steps that the ore leaching agent performs percolation and leaching on rare earth, a rare earth mother solution is collected, magnesium oxide enriches rare earth, sulfuric acid dissolves rear earth enriched products, impurities of the rare earth enriched products are removed in the same slot, and the sodium bicarbonate precipitates or extracts the rare earth. By means of the process, influences of ammonia nitrogen on the environment are avoided radically, the rare earth enriched products are precipitated rapidly through characteristics of magnesium oxide, the precipitate is small in size, and time of the whole process is greatly shortened.

Owner:赣州稀土开采技术服务有限公司

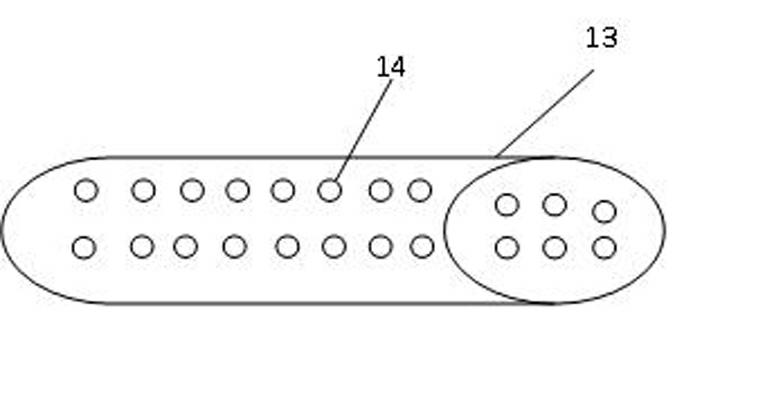

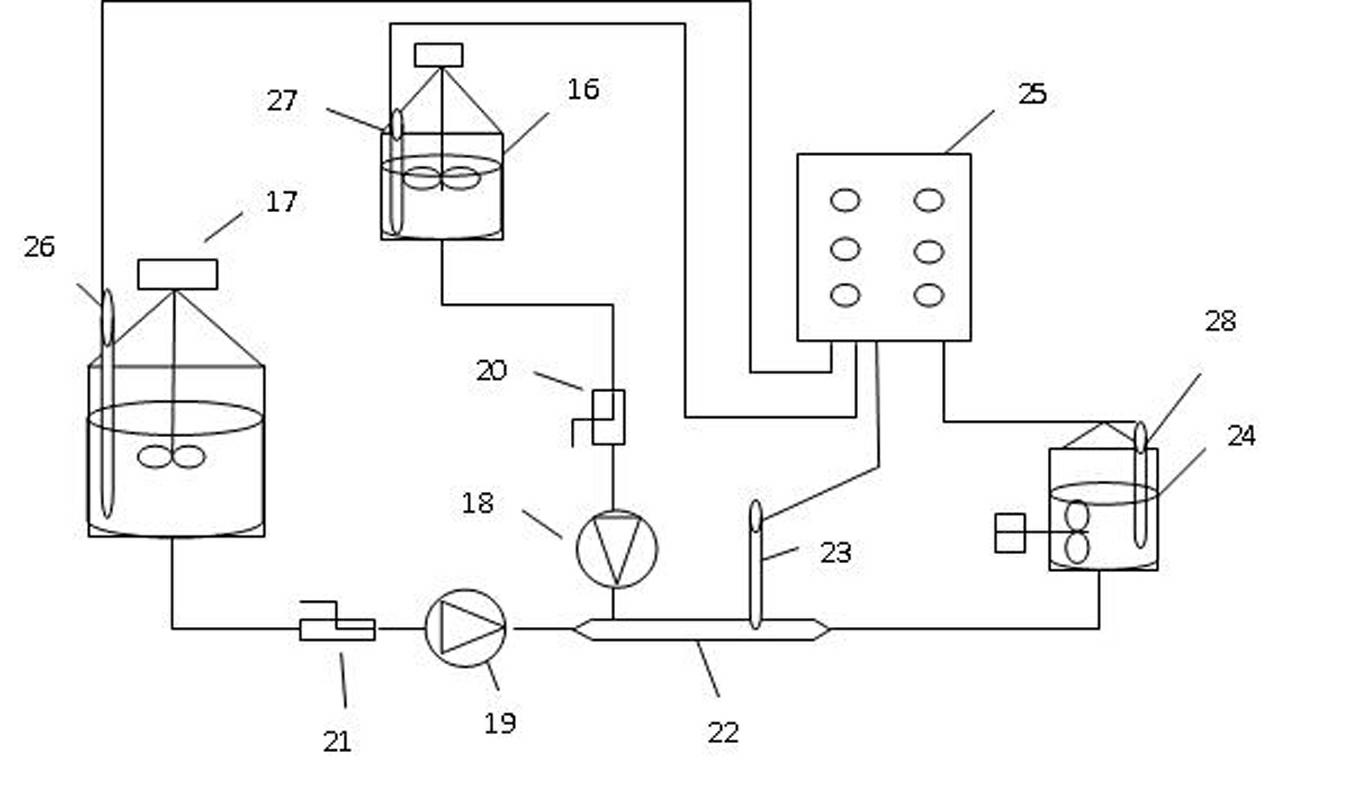

Automatic acid mixing apparatus and method thereof, and automatic pipeline iodic acid apparatus and method thereof

ActiveCN102351945AUniform precipitationRapid precipitationPeptide preparation methodsOther dairy technologyHigh concentrationAutomatic control

An objective of the invention is to provide an automatic acid mixing apparatus and a method thereof, and an automatic pipeline iodic acid apparatus and a method thereof. Therefore, problems of nonuniform mixing and over high local acidity are solved, wherein the problems exist in a current on-line souring system. The automatic pipeline iodic acid apparatus comprises a material pipeline, a material variable frequency pump, an acid pipeline, a diluted acid variable frequency pump, a Venturi tube and a mixer; an entrance section of the Venturi tube is connected with a premixer; an acid jetting pipeline is arranged in the premixer; and a tail portion of the mixer is connected with an iodic acid pH monitor, which is connected with an automatic control module. according to the invention, the automatic pipeline iodic acid apparatus is utilized to enable automatic iodic acid to be realized; a diluted acid that is configured by the automatic iodic acid apparatus enters the automatic acid mixing apparatus to carry out automatic acid mixing. Besides, materials can be mixed fully, rapidly and high efficiently; occurrences of unstable acid concentration and a local peracid phenomenon during the iodic acid processing can be effectively avoided; and denaturation of active materials with acid nonresistant performance on the condition of acid with high concentration can be reduced.

Owner:甘肃华羚乳品股份有限公司

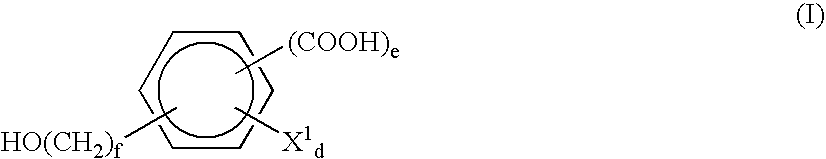

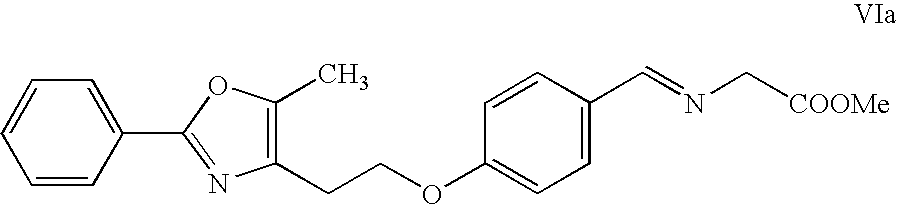

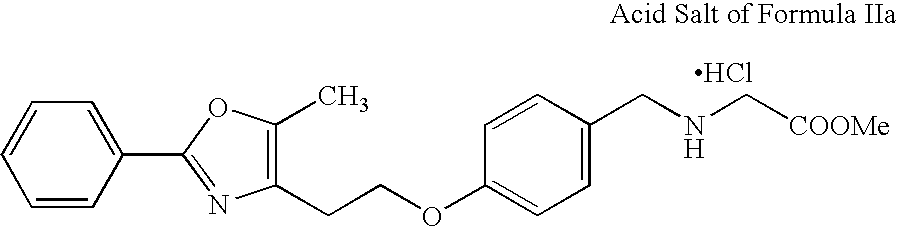

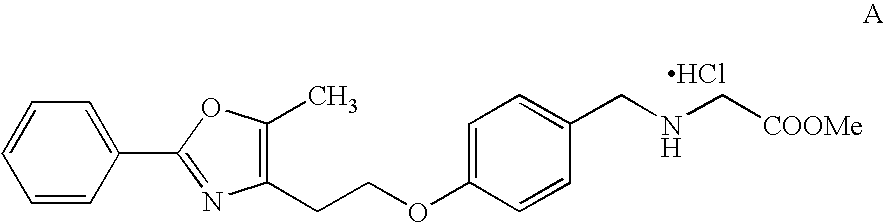

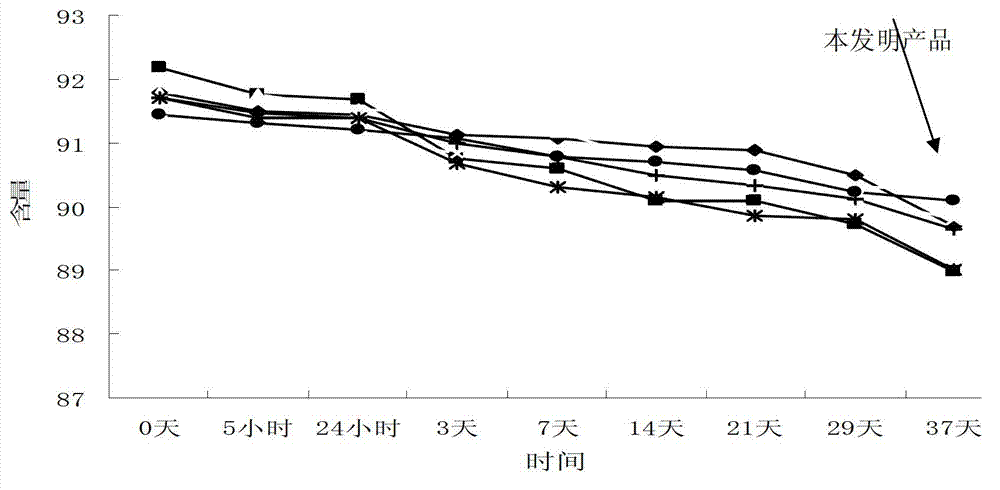

Process employing controlled crystallization in forming crystals of a pharmaceutical

InactiveUS20050256314A1Improve filtration efficiencyImprove washing efficiencyOrganic chemistryCrystallization separationState of artCrystallization kinetics

A process is provided which employs reactive controlled crystallization to produce drug substance having desirable crystal properties which process involves providing reactants A and B in liquid or solution form and adding reactant B to reactant A using a cubic or incremental addition technique to control extent of reaction and thus crystallization kinetics, including supersaturation and nucleation, to produce crystals of drug substance which are generally larger, better quality and with few fines and narrow particle size distribution than normally obtainable employing prior art crystallization techniques. In addition, crystals of drug substance produced by the above process is also provided.

Owner:BRISTOL MYERS SQUIBB CO

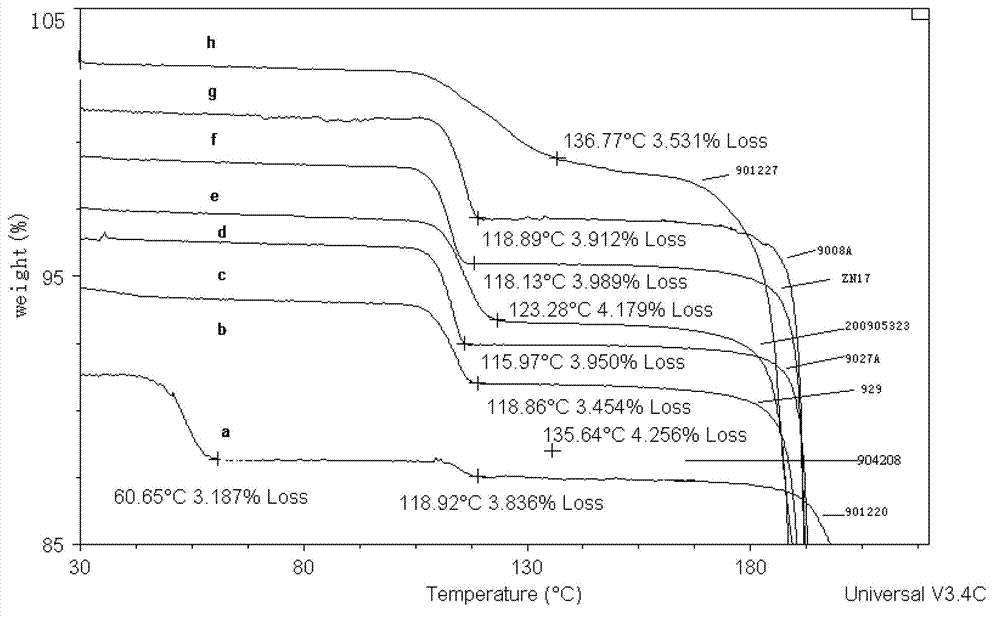

Crystallization method of ceftezole sodium

InactiveCN102775426AReduce contentIncrease humidityOrganic chemistryActivated carbonCeftezole Sodium

The invention relates to a crystallization method of ceftezole sodium. The crystallization method comprises the steps of: dissolving ceftezole acid in a solvent, carrying out nitrogen washing protection, adding a salifying agent to adjust pH until the solid is completely dissolved, adding activated carbon, carrying out titanium rod filtering, carrying out ultrafiltration, adding the solvent in filter liquor under the ultrasonic wave condition, carrying out gradient cooling to separate out crystals, filtering, washing, carrying out suction filtration, and carrying out vacuum drying to obtain the ceftezole sodium. The crystallization method adopts an ultrasound crystallographic orientation method to be combined with a gradient cooling solvent crystallization method to obtain the ceftezole sodium which obviously improves hygroscopicity, is high in purity, even in particles and good in batch repeatability and is a stable type I crystal form, and thus stability and safety of products are obviously improved.

Owner:天津新丰制药有限公司

Two component compositions containing zinc amino acid halide complexes and cysteine

ActiveUS9675823B2Rapid precipitationCosmetic preparationsToilet preparationsGlycinePersonal Care Product

Owner:COLGATE PALMOLIVE CO

Efficient composite heavy metal chelating agent

ActiveCN103663663AWide range of applicationsStrong adsorption and flocculation abilityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionHeavy metal chelationTreatment effect

The invention relates to an efficient composite heavy metal chelating agent and a preparation method thereof. The efficient composite heavy metal chelating agent comprises the components in percentage by mass as follows: 35%-40% of nanometer aluminum oxide, 15%-20% of ethylene diamine tetraacetic acid and 40%-60% of sodium carboxymethyl starch. The efficient composite heavy metal chelating agent is non-toxic and has no harm to aquatic lives, pH value is not required to be adjusted when heavy metal wastewater is treated, and the treatment effect is superior to that of a traditional heavy metal treatment method.

Owner:NANJING XINHAO POLYMER MATERIAL

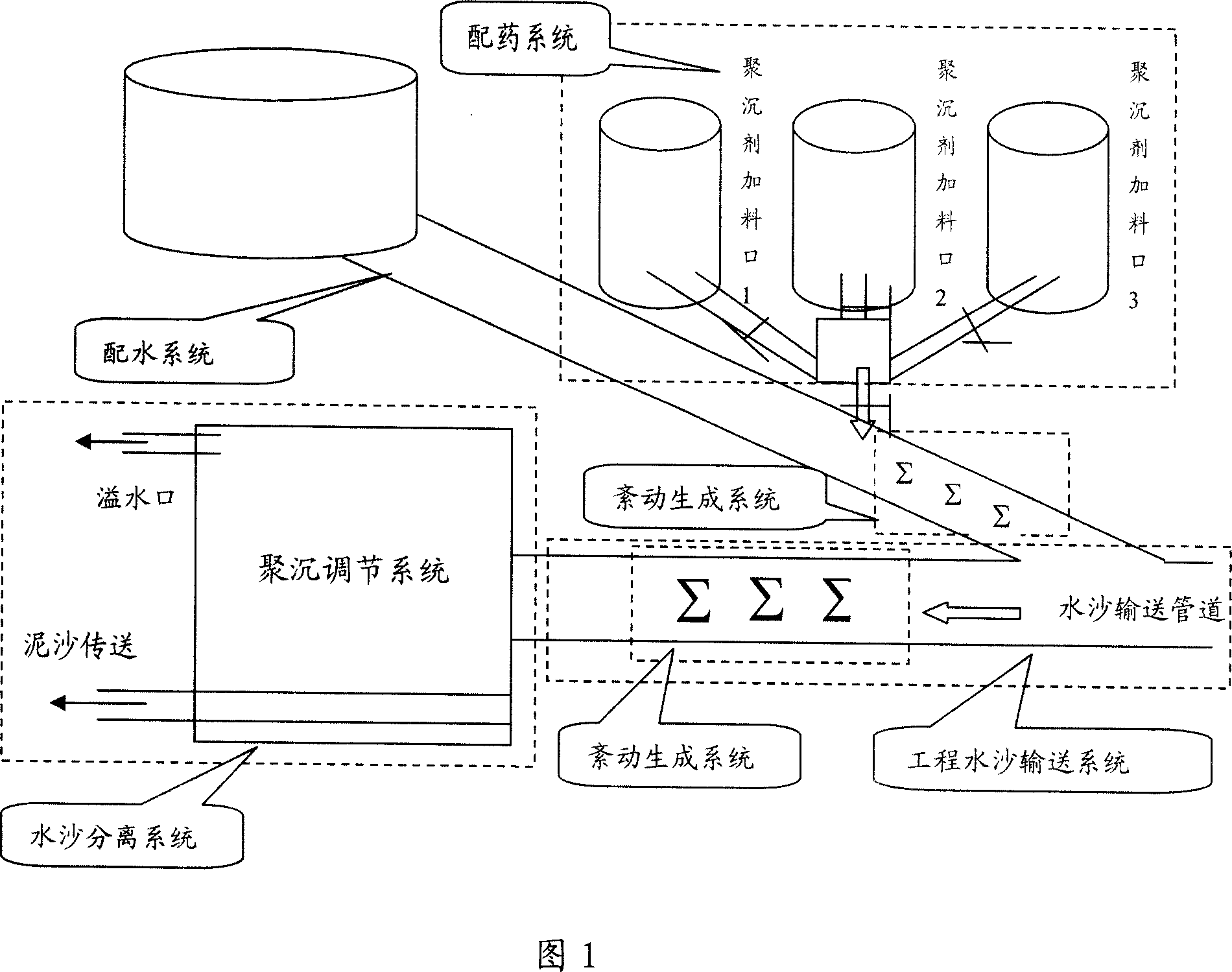

Mud coagulation agent and mud coagulation separation method

ActiveCN101016181AHigh densitySettling fastSedimentation separationWater/sewage treatment by flocculation/precipitationPolyacrylamideFerric

The invention discloses a making method of mud coagulation agent, which comprises the following steps: allocating each component with 0.025-0.100% ferric polysilicate, 0.025-0.100% polyacrylamide and 0.025-0.100%Na2CO3; making solutions; adding each solution into mud sequently; stirring to form turbulence; blending to separate from mud turbulence under flow turbulence condition for 0.5 min.

Owner:ROAD ENVIRONMENT TECH

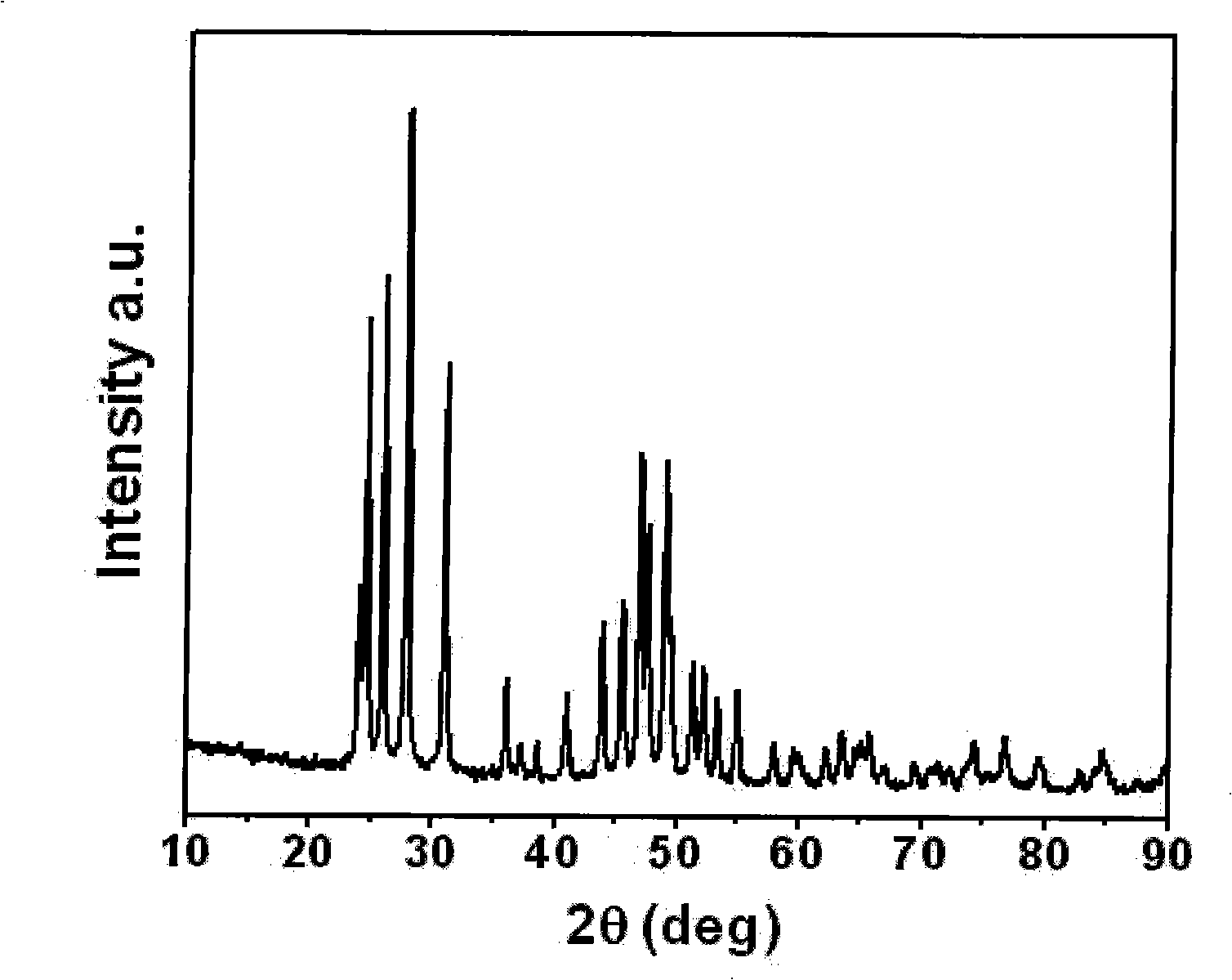

Method for preparing rare earth fluoride

InactiveCN101348274ALower decomposition temperatureWon't hurtRare earth metal compoundsAcetic acidRare earth

The invention provides a method for preparing rare earth fluoride, which is formed by the following: a. a step of preparing acetic acid rare earth aqueous solution, which is to dissolve rare earth oxide in diluted acetic acid with the concentration of between 20 and 40 percent, the molar ratio of the rare earth oxide to acetic acid is between 1 to 6 and 8, so as to form the acetic acid rare earth aqueous solution; b. a step of preparing an ammonium fluoride aqueous solution, which is to dissolve ammonium fluoride with 6 to 6.5 times the molar weight of the rare earth oxide into deionized water, so as to form the ammonium fluoride aqueous solution; c. a step of preparing rare earth fluoride, which is to mix the acetic acid rare earth aqueous solution in the step a and the ammonium fluoride aqueous solution in the step b for reaction and to precipitate the rare earth fluoride; and d. a step of drying and sintering, which is to drying the rare earth fluoride precipitated in the step c at a temperature between 70 and 100 DEG C and then to sinter the rare earth fluoride in a sintering furnace at a temperature between 250 and 350 DEG C for 5 to 10 hours. The method does not corrode equipment or pollute environment, is simple in process, low in energy consumption, convenient for industrial production and high in the purity of the prepared products.

Owner:SOUTHWEST JIAOTONG UNIV

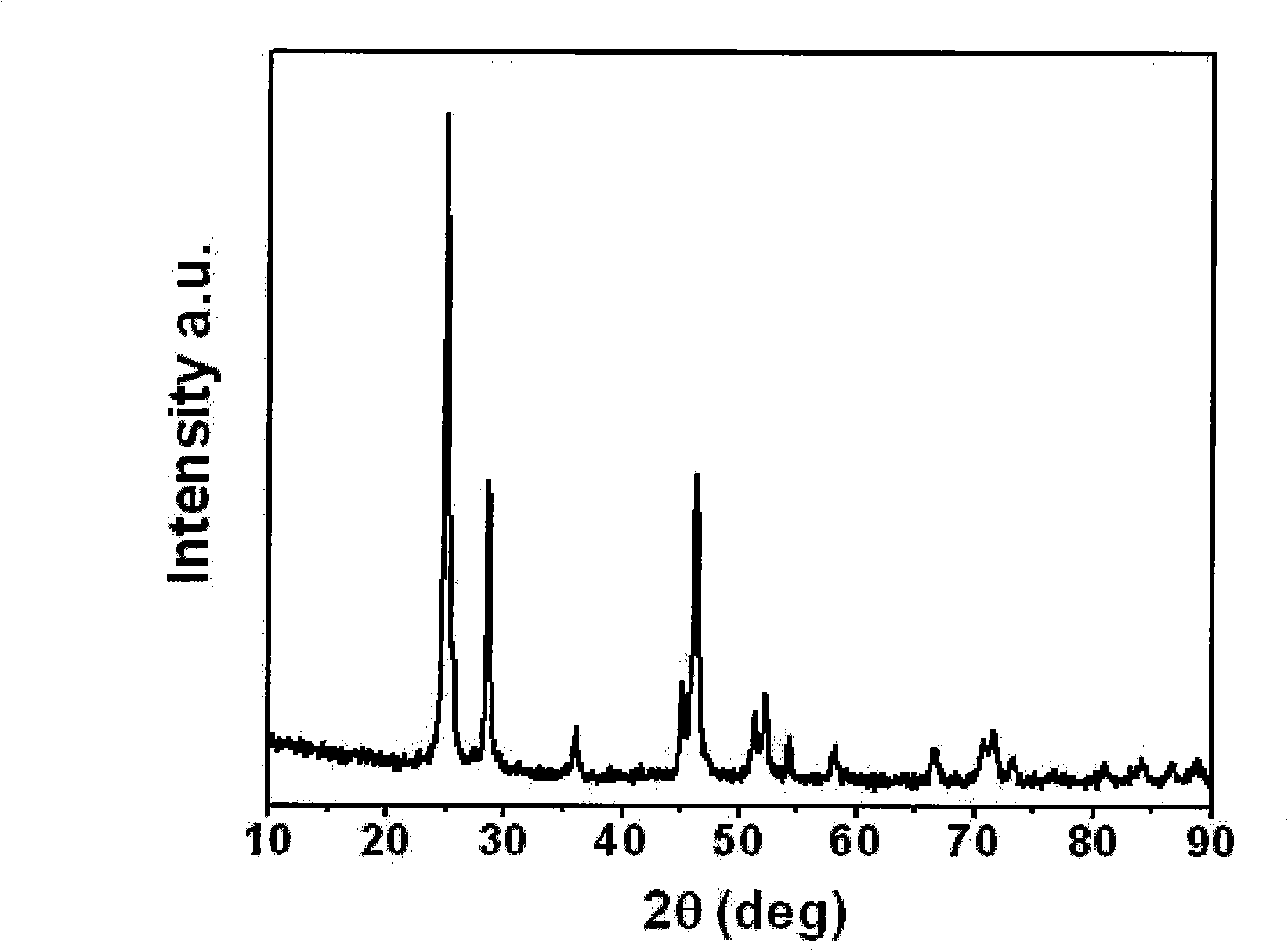

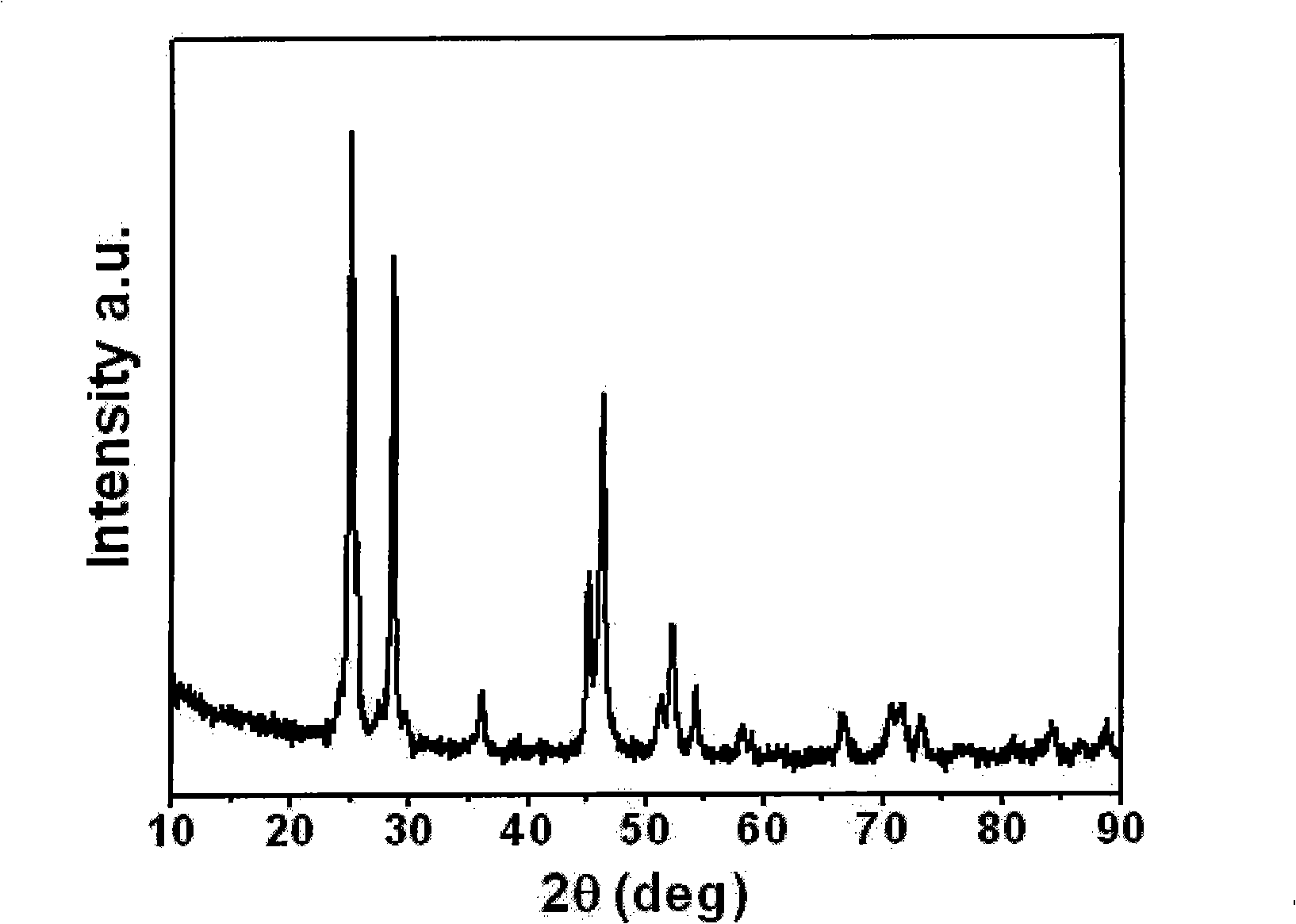

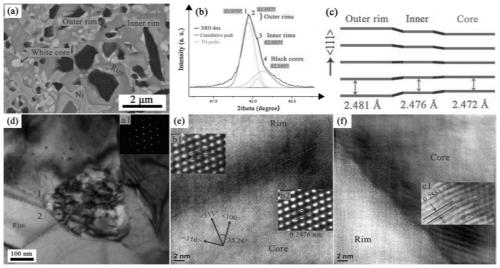

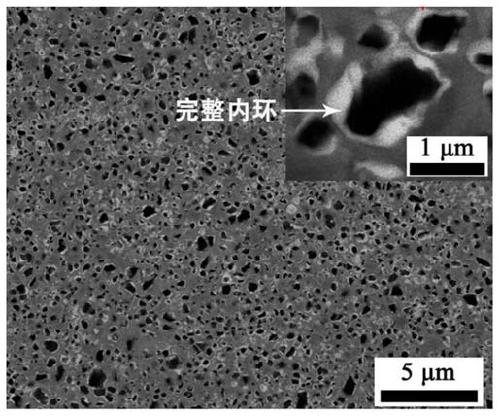

Ti (C, N) base metal ceramic with homogeneous ring core structure and preparation method thereof

ActiveCN110396632AFacilitated diffusion reaction rateInhibit denitrification behaviorSolid phasesTitanium carbide

The invention discloses a Ti (C, N) base metal ceramic with a homogeneous ring core structure and a preparation method thereof. The ring core structure of the metal ceramic has complete inner and outer ring phases, and ring core phases have narrow particle size distribution and uniform structure distribution. Raw material powder preparing the metal ceramic includes, by weight, 40-55 parts of Ti (C, N) powder, 0.5-5 parts of titanium carbide powder, 10-30 parts of transition group metal carbide powder, 8-25 parts of iron group metal binding phases and 0.05-1.5 parts of carbon powder. The preparation method of the metal ceramic is characterized by two-step ball milling and solid phase nitrogen partial pressure long time sintering. On the basis of keeping good wear resistance, the metal ceramic has higher bending strength and fracture toughness than a metal ceramic with a conventional ring core structure, and can be widely used in bearing materials, cutting tools, die materials and otherfields.

Owner:CENT SOUTH UNIV

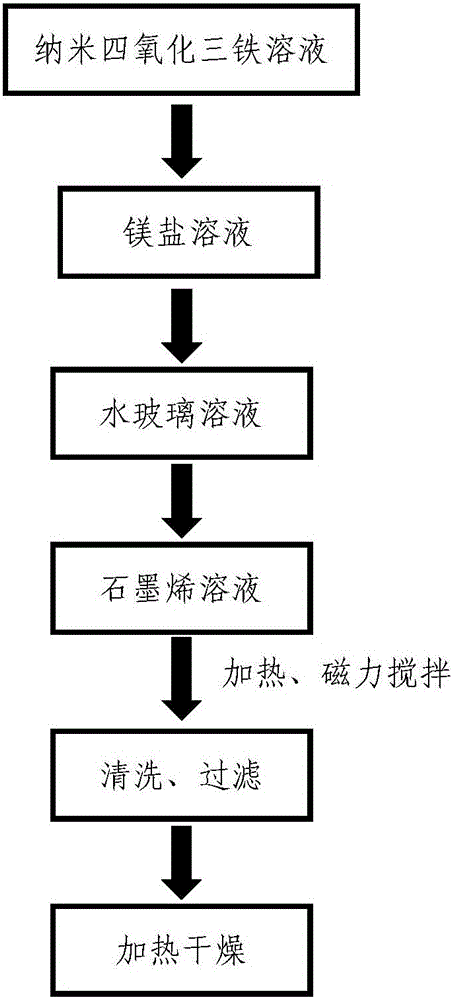

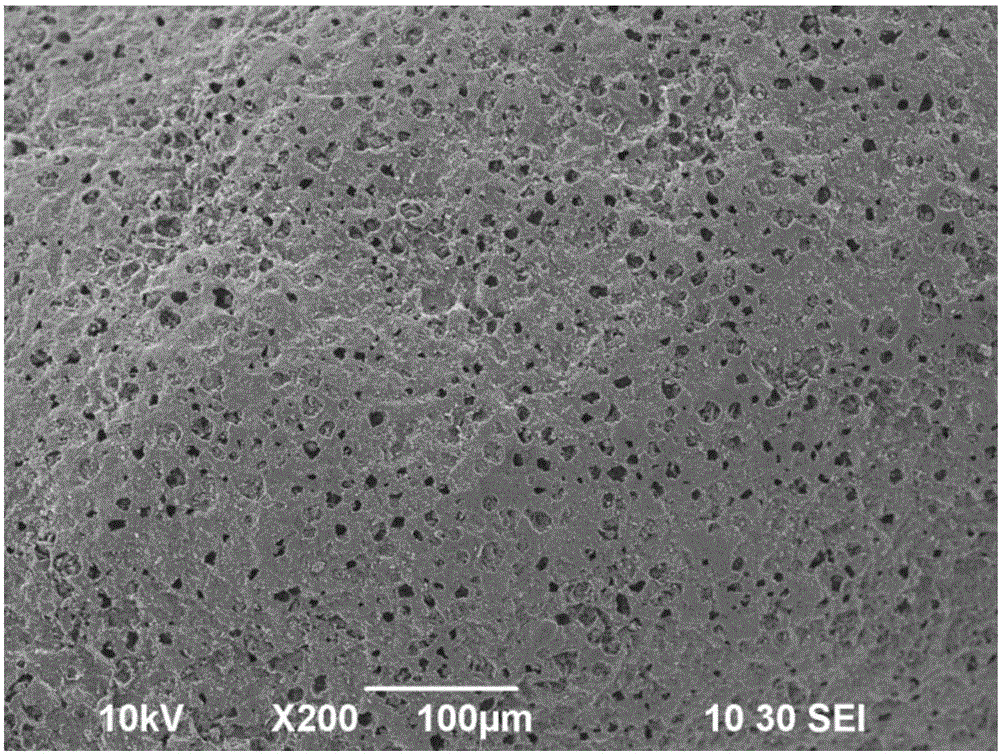

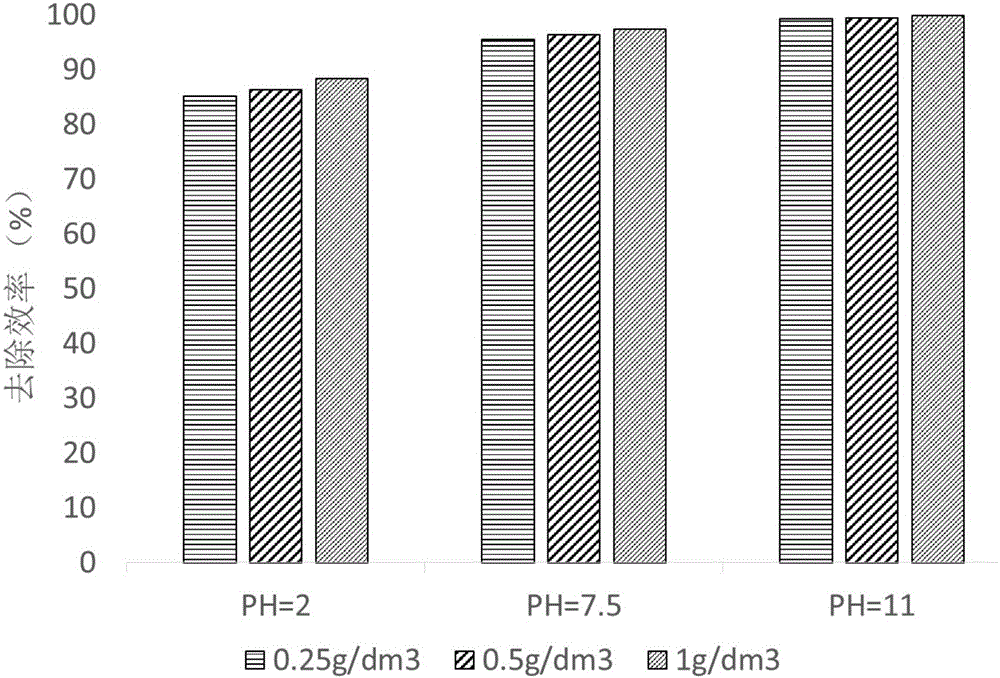

Heavy metal ion adsorbent, preparation method and application

ActiveCN106076261AHelps to completely removeRapid precipitationOther chemical processesWater contaminantsMagnesium saltSorbent

The invention provides a heavy metal ion adsorbent, a preparation method and application. The heavy metal ion adsorbent is prepared by mixing, by weight, 5-10 parts of graphene@Fe3O4@MgO.SiO2 composite particles, 10-25 parts of trithiocyanuric acid trisodium salt, 5-15 parts of hydroxide and 50-80 parts of deionized water. The composite particles are prepared from nano-iron oxide, graphene, magnesium salt and sodium silicate through a coprecipitation method. According to the adsorbent, heavy metal ions can be captured in a chemical chelation mode and then enriched in a physical absorption mode, a relatively stable structure can be rapidly formed, and the metal ions can be immobilized and prevented from being released to the environment; besides, the adsorbent can be treated in a burying mode, and secondary pollution to the environment can be avoided.

Owner:郑州普利飞尔环保科技有限公司

Treatment method of titanium-containing waste solution

ActiveCN104129812ARapid precipitationImprove processing efficiencyMultistage water/sewage treatmentTitanium halidesSolution treatmentOrganic solvent

The invention provides a treatment method of a titanium-containing waste solution which contains titanium tetrachloride, an organic solvent and halogenated alkoxy titanium and / or ester-titanium complexes. The method includes following steps: performing a separation process to the titanium-containing waste solution for separating the organic solvent and the titanium tetrachloride to enable the organic solvent in a residual solution to account for 0-20% by weight of the residual solution; and successively performing a temperature-decreasing process and a solid-liquid separation process to the residual solution. By means of the method, recovery rates of the titanium tetrachloride and the organic solvent can be significantly increased. In addition, solid can be precipitated at a high temperature, thereby increasing a precipitation efficiency of solid impurities and effectively increasing waste solution treatment efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

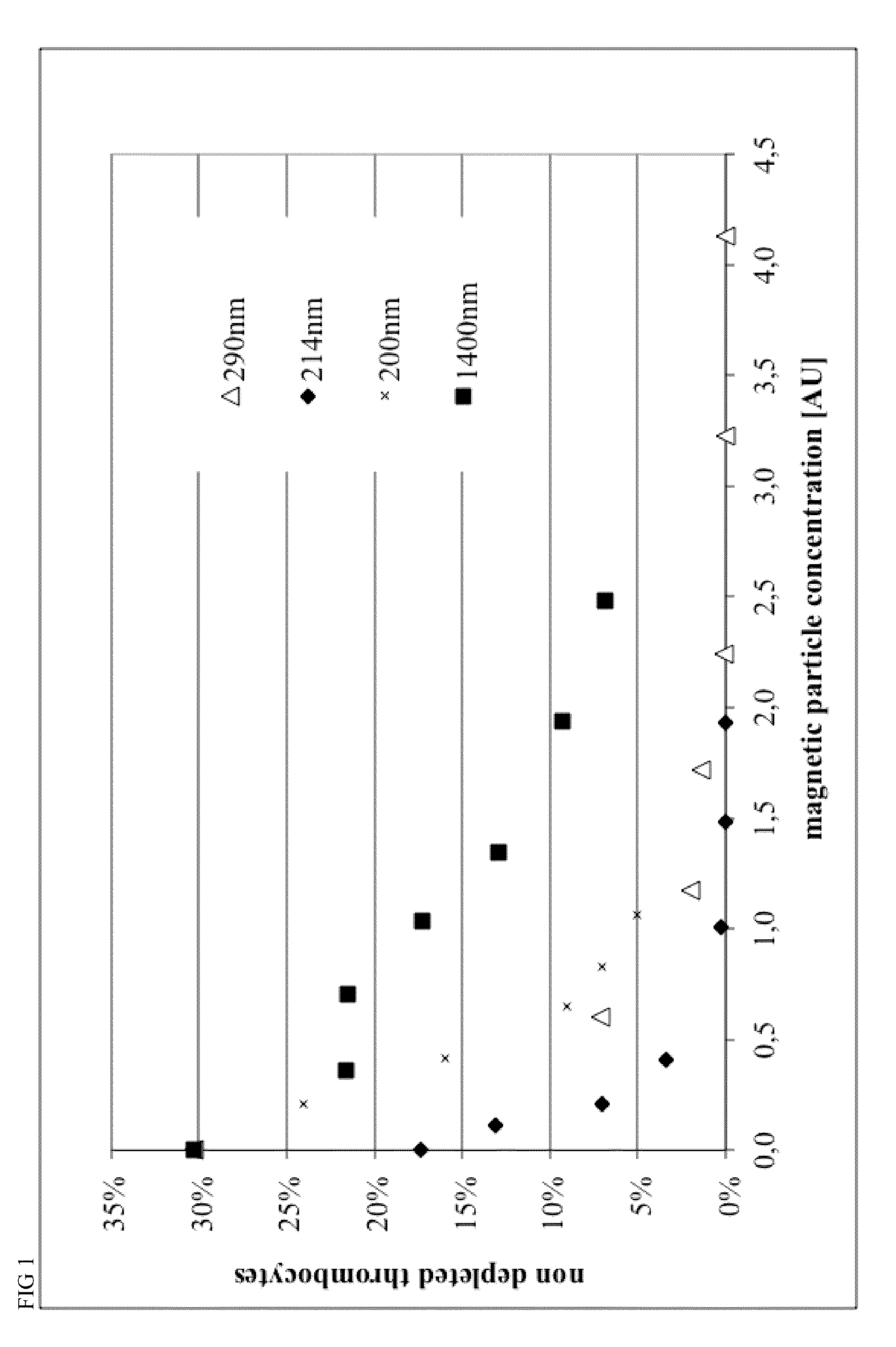

Cell separation method

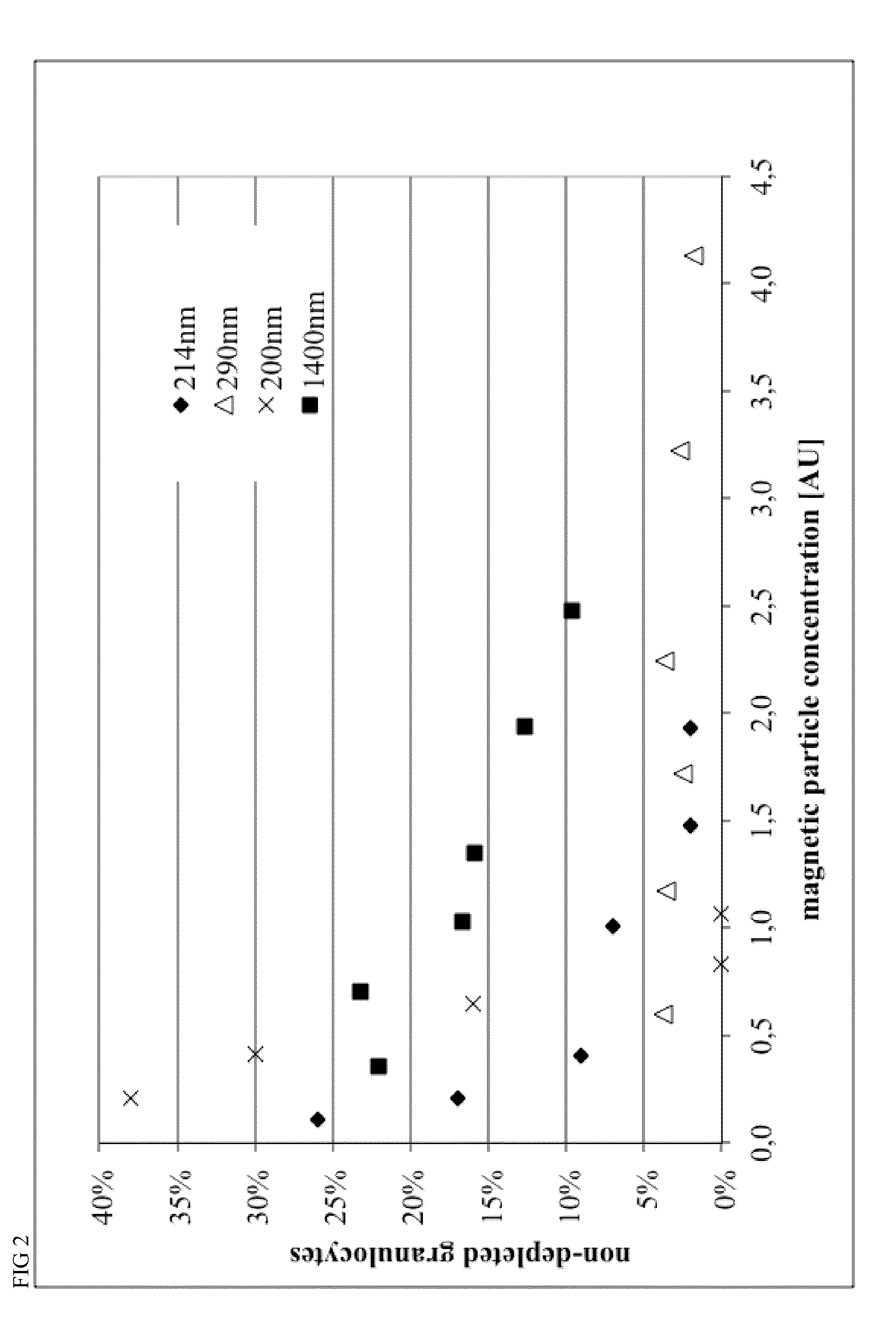

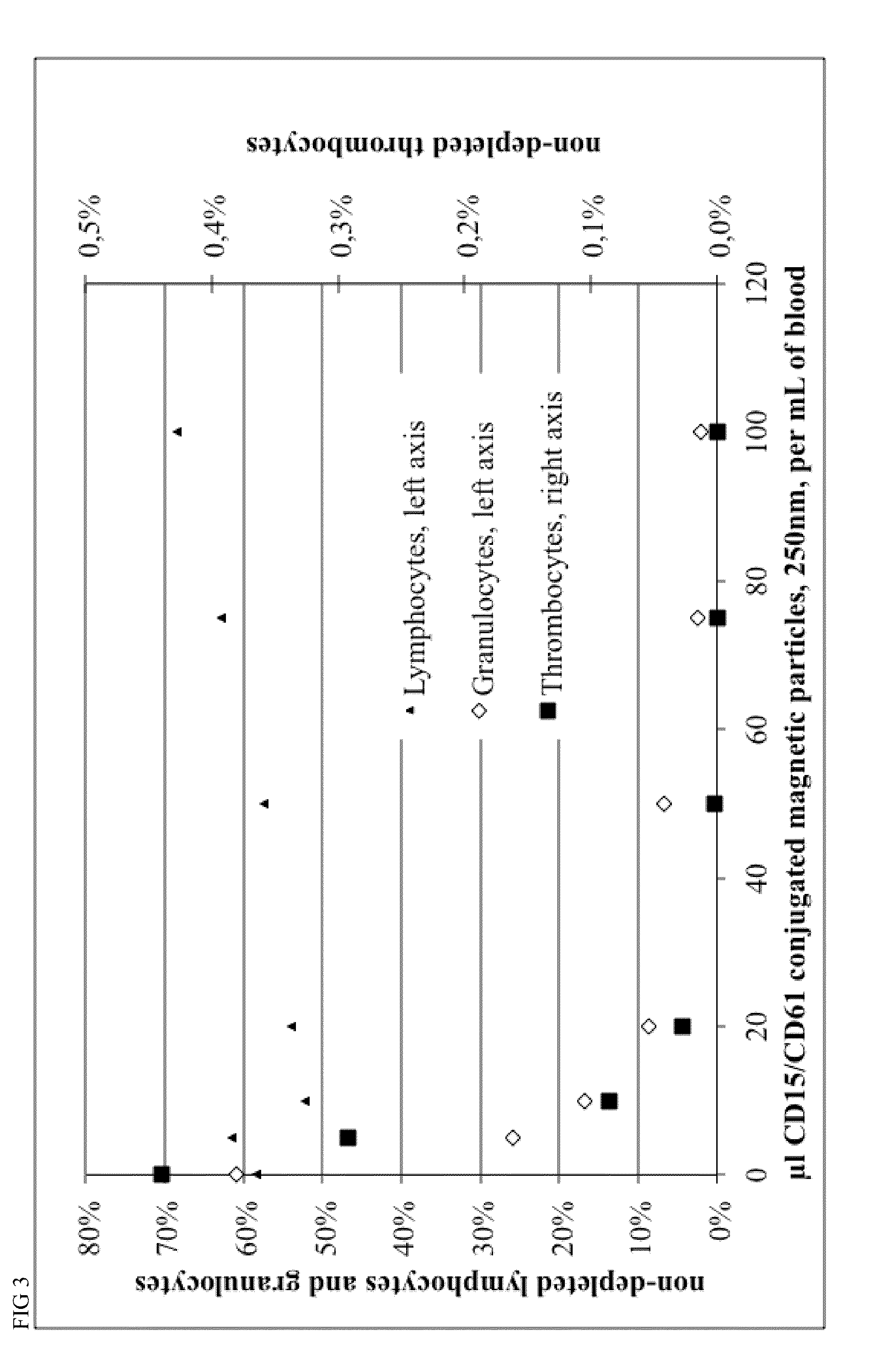

ActiveUS20140302483A1Rapid precipitationAccelerated precipitationElectrostatic separationMicrobiological testing/measurementMagnetic field gradientCellular component

The present invention provides methods and compositions for separating cells from a sample containing erythrocytes. The method is for recovering desired cells from a sample containing the desired cells, erythrocytes and undesired cells comprising: a) contacting the sample with a composition, said composition comprising: i) an erythrocytes aggregation reagent ii) at least one antigen recognizing moiety coupled to a magnetic particle, wherein said particle with said at least one antigen recognizing moiety specifically binds to at least one antigen specific for one or more undesired cellular components; b) applying simultaneously i) gravity sedimentation for sedimentation of erythrocytes and ii) a magnetic field gradient to said sample for immobilizing said magnetic particle generating a pellet and a supernatant phase, and c) recovering the desired cells from the supernatant phase. Compositions for the use within the present method are also disclosed.

Owner:MILTENYI BIOTEC B V & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com