Industrial sludge treatment method and method for preparing various fertilizers by using treated industrial sludge

A technology of industrial sludge and treatment methods, applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of environmental secondary pollution, farmland source pollution, groundwater pollution, etc., and achieve no secondary pollution , reduced tail gas odor, less pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: first four sludge treatment methods

[0045] (1) Put the first four kinds of sludge into the fermentation sedimentation tank in any proportion, mix and stir, and dilute to 14-15 degrees Baume.

[0046] (2) Add industrial sludge weight 0.2‰ heavy metal ion trapping precipitant (DTCR) in the fermentation sedimentation tank to generate water-insoluble chelate salt, then add industrial sludge weight 0.1‰ flocculant polyacrylamide to make Precipitation of heavy metal products. The amount of this sediment is small and easy to handle.

[0047] (3) remove above-mentioned flocculent precipitation and obtain product sludge water, add the potato water of sludge water weight 1% in sludge water, utilize the aerobic bacteria in sludge water and the sugar in potato water to promote sludge, fermentation time: summer 48 hours, 60 hours in spring and autumn, and 72 hours in winter; the fermentation temperature is 60-65°C in summer, 50-55°C in spring and autumn, and 40-45°...

Embodiment 2

[0048] Example 2: Recycling of the first four sludge fertilizers.

[0049] (4) Use a mud pump to add two flocculants to the settled and fermented sludge water: polyacrylamide with a sludge water weight of 0.5‰ and polyaluminum chloride with a sludge water weight of 3-5‰; The sludge dehydrated by the filter is cake-like, with a moisture content of 70-73% by mass, and then crushed into particles of ≤1.5mm; the filtrate flows back to the fermentation tank as a diluent for recycling;

[0050] (5) Put 10Kg of enzyme bacteria, 15Kg of brown sugar and 0.5Kg of honey into a container, add 250Kg of water and stir well, place for 4 hours in summer, 8 hours in spring and autumn, and 24 hours in winter; mix 500Kg of rice bran and 500Kg of furfural residue Lay it flat on the indoor concrete floor with a height of 10-15cm, then sprinkle the above enzyme mixture evenly on the mixture of rice bran and furfural slag and stir well, avoid direct sunlight, place it for 24 hours in summer, and 36 ...

Embodiment 3

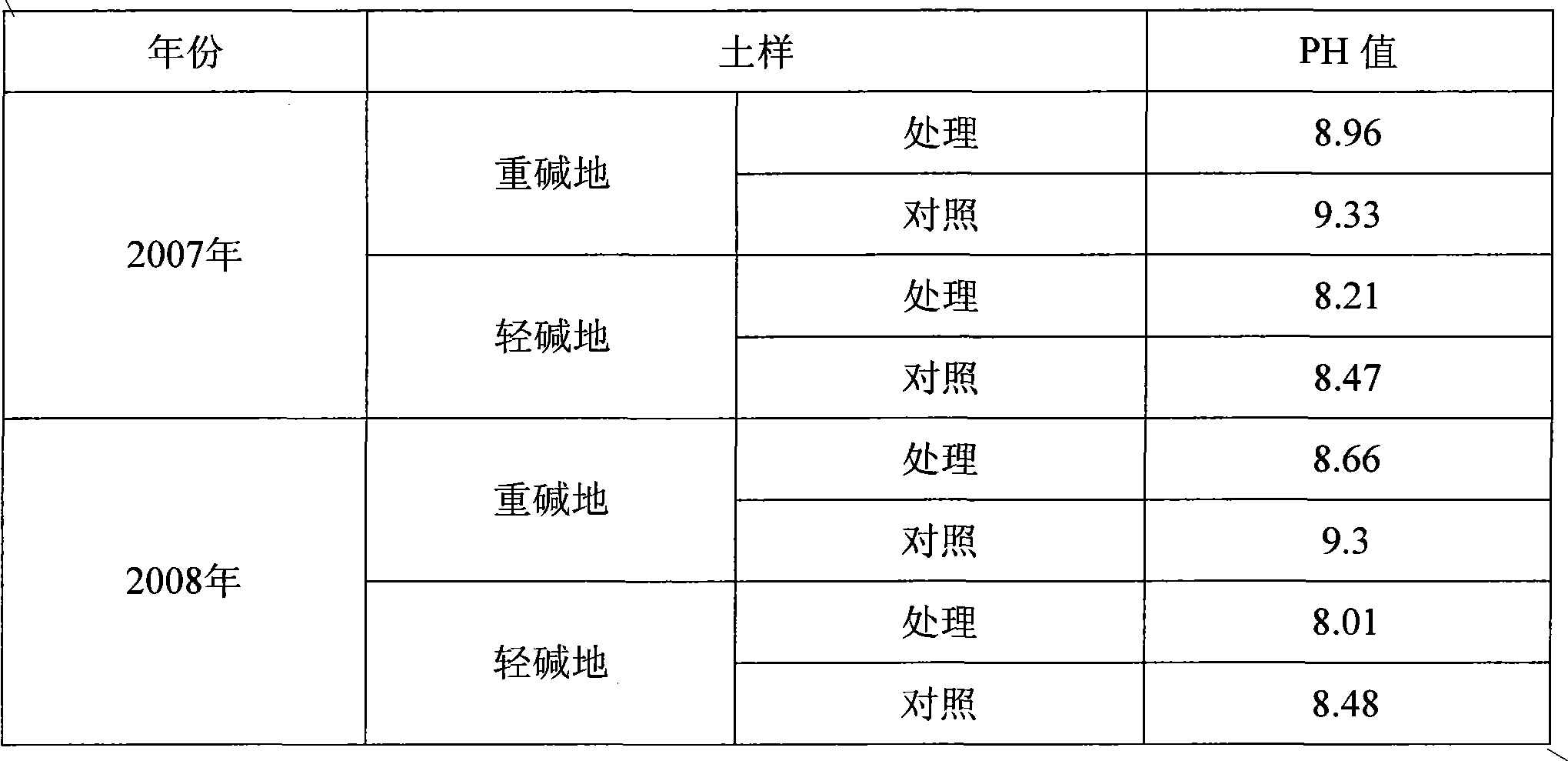

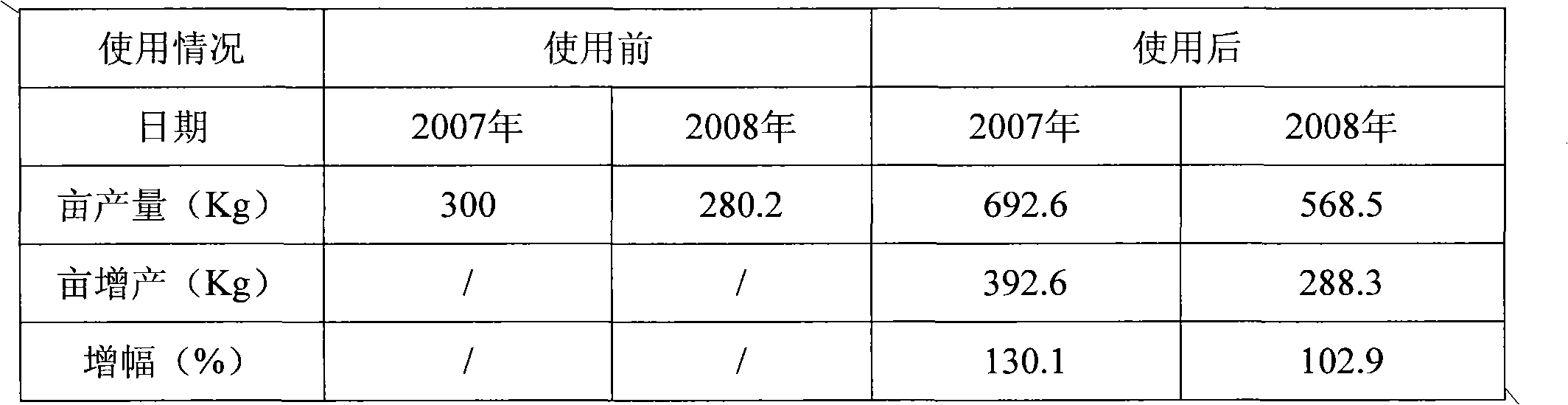

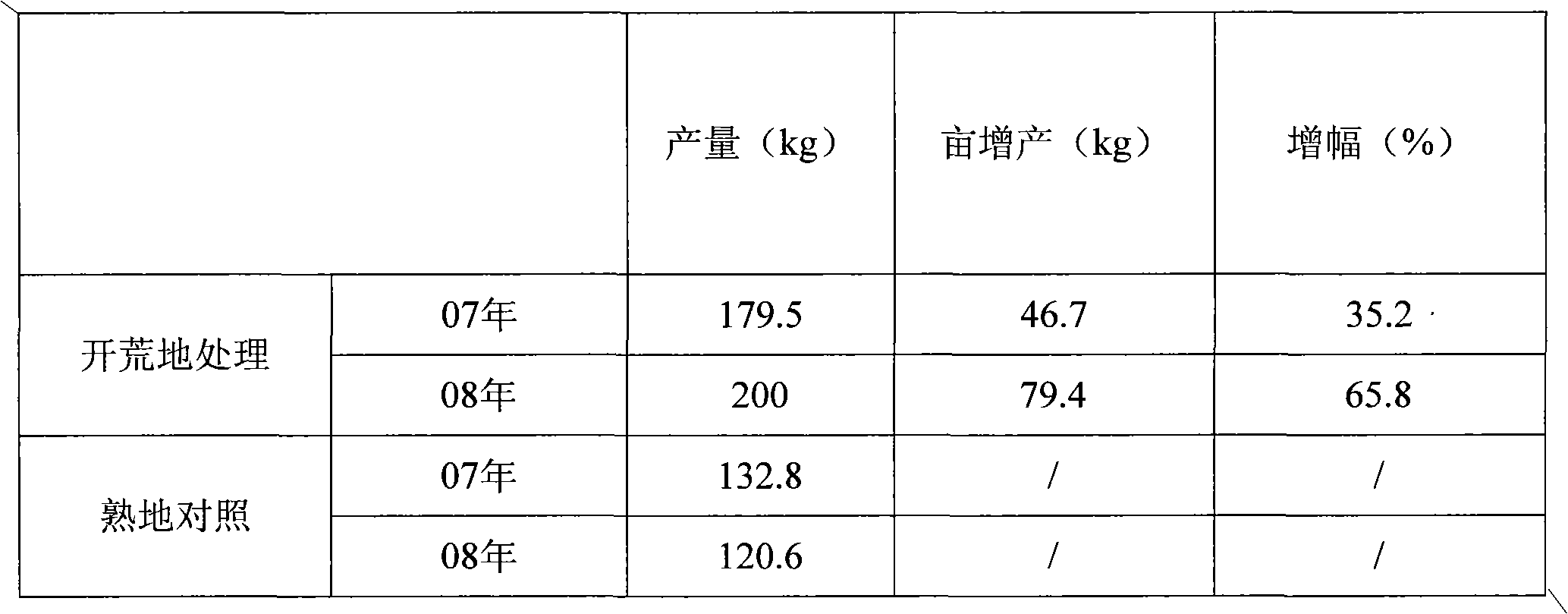

[0055] Example 3: The above four kinds of sludge and waste are made into fertilizers for transforming saline-alkali land into fertile land.

[0056] (9) Mix the powdered biological bacterial fertilizer produced in step 6 with the desulfurized gypsum of coal-fired power plant waste at a ratio of 1:4, pulverize into particles below 1.5mm, sieve and package as powdery fertilizer for transforming saline-alkali land.

[0057] (10) Mix powdery biological bacterial fertilizer, desulfurized gypsum, and bentonite in a weight ratio of 1:3:1, crush them into particles below 1.5mm, and send them to a disc granulator through a belt conveyor. After granulation, it is sent to the rotary dryer by the belt conveyor for drying, and the tail gas is dedusted, washed and vented through the treatment device. The temperature of the material out of the dryer is relatively high, and it is cooled by a rotary cooler to increase the particle strength and reduce moisture, and then pass through a coarse si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com