Compound coagulant used for treating rare-earth highly concentrated ammonian wastewater to recover industry ammonium chloride and treatment method

An ammonia nitrogen wastewater and coagulant technology, applied in chemical instruments and methods, ammonium halide, separation methods, etc., can solve problems such as reducing product purity, affecting the quality and sales of recovered ammonium salt products, and poor removal of impurities. Easy to handle, stable and non-toxic sludge volume, simple and easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

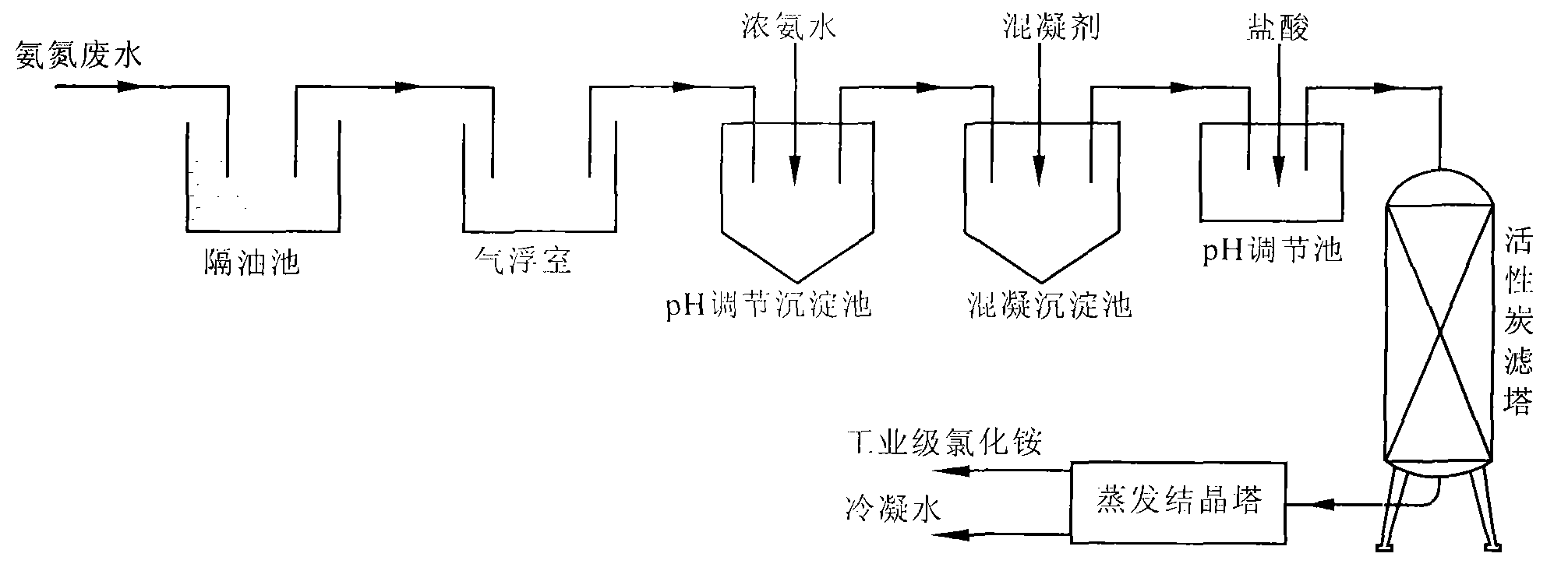

Image

Examples

Embodiment 1

[0021] Weigh 600g of ammonium oxalate, 200g of ammonium sulfate, 200g of heavy metal precipitant DTCR and 3g of PAM respectively, and then dissolve them in 13L of water in turn, stir and mix evenly to prepare a composite coagulant with a total mass concentration of 7.1%.

Embodiment 2

[0023] Weigh 450g of ammonium oxalate, 150g of ammonium sulfate, 200g of heavy metal precipitant DTCR and 2g of PAM respectively, and then dissolve them in 13L of water in turn, stir and mix evenly to prepare a composite coagulant with a total mass concentration of 5.8%.

[0024] The embodiment of the treatment method of using composite coagulant to process rare earth high concentration ammonia nitrogen wastewater to reclaim industrial grade ammonium chloride is as follows:

[0025] The numbers of the composite coagulants prepared in the above two application examples are sequentially No. 1 composite coagulant and No. 2 composite coagulant for treating sewage. The wastewater is taken from rare earth soap wastewater and ammonium bicarbonate precipitation mother liquor in a rare earth smelter, and its water quality characteristics are as follows:

[0026] Table 1 Rare earth soap wastewater water quality (pH=0.47, [Cl - ]=96800mg / L, the unit is mg / L)

[0027] NH 4 +...

Embodiment 3

[0031] a. Take 1m 3 The rare earth soap wastewater first enters the inclined plate grease trap, and the residence time of the wastewater is 2.5h, so that the slick oil in the rare earth wastewater and the larger oil droplets in the dispersed oil rise to the surface, scrape off the upper layer of slick oil, and then the wastewater enters the jet type The air flotation chamber is used to remove the emulsified oil and hydrophobic fine solid suspended matter in the wastewater by air flotation. After this step, the content of oil and extractant is 80mg / L.

[0032] b, the waste water after degreasing enters the pH adjustment sedimentation tank, then adding 16L concentration to the waste water is 30% strong ammonia water to adjust the pH to 8, then adds 1.5g PAM to the waste water and stirs the reaction for 15min, and leaves standstill for 40min, resulting in The sludge is discharged through the sludge discharge pipe at the bottom of the tank, and the supernatant and sludge filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com