Automatic acid mixing apparatus and method thereof, and automatic pipeline iodic acid apparatus and method thereof

A pipeline and automatic technology, applied in chemical instruments and methods, peptide preparation methods, applications, etc., can solve the problems of low automation, product quality decline, labor waste, etc., achieve high automation, easy operation, and improve product quality and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

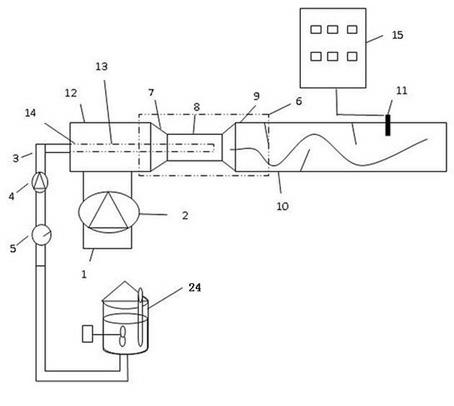

[0033] Embodiment 1: automatic pipeline point acid production casein

[0034] This embodiment is a method for producing casein using the automatic acid dispensing device and the automatic pipeline acid dispensing device of the present invention. Specific steps are as follows:

[0035] 1. Materials and instruments

[0036] Raw and auxiliary materials: Qula (45Kg), sodium sulfite (0.45Kg), hydrochloric acid (150g), hydrochloric acid, sodium hydroxide (20%), water.

[0037] 2. Experimental method

[0038] (1) Experimental process

[0039] Warm water (40°C)→caustic soda→sodium sulfite→raw material→dissolving→filtering→centrifugal degreasing→cooling→acidification→washing→dehydration→granulation→drying→finished product→inspection

[0040] (2) Technical points

[0041] Dissolve in warm water at 40°C, add sodium sulfite, stir for a while, add raw materials, adjust the pH value to 9.5 with 20% lye after stirring evenly, and start timing to dissolve when the temperature rises to ...

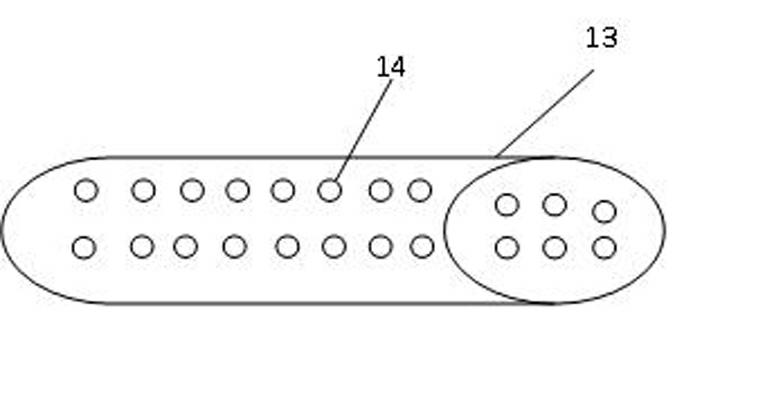

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com