Method for preparing supported biochar catalysis material

A catalytic material and biochar technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unstable material performance, easy falling off, agglomeration and oxidation, etc., to prevent secondary pollution , Good material stability and strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

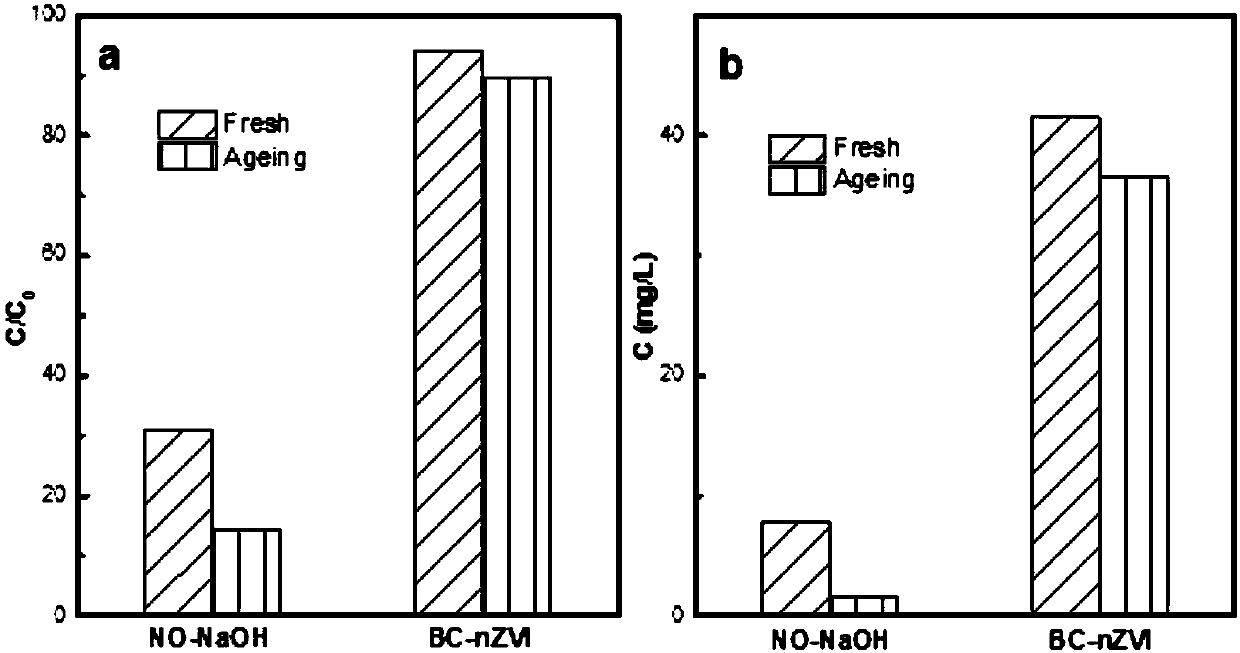

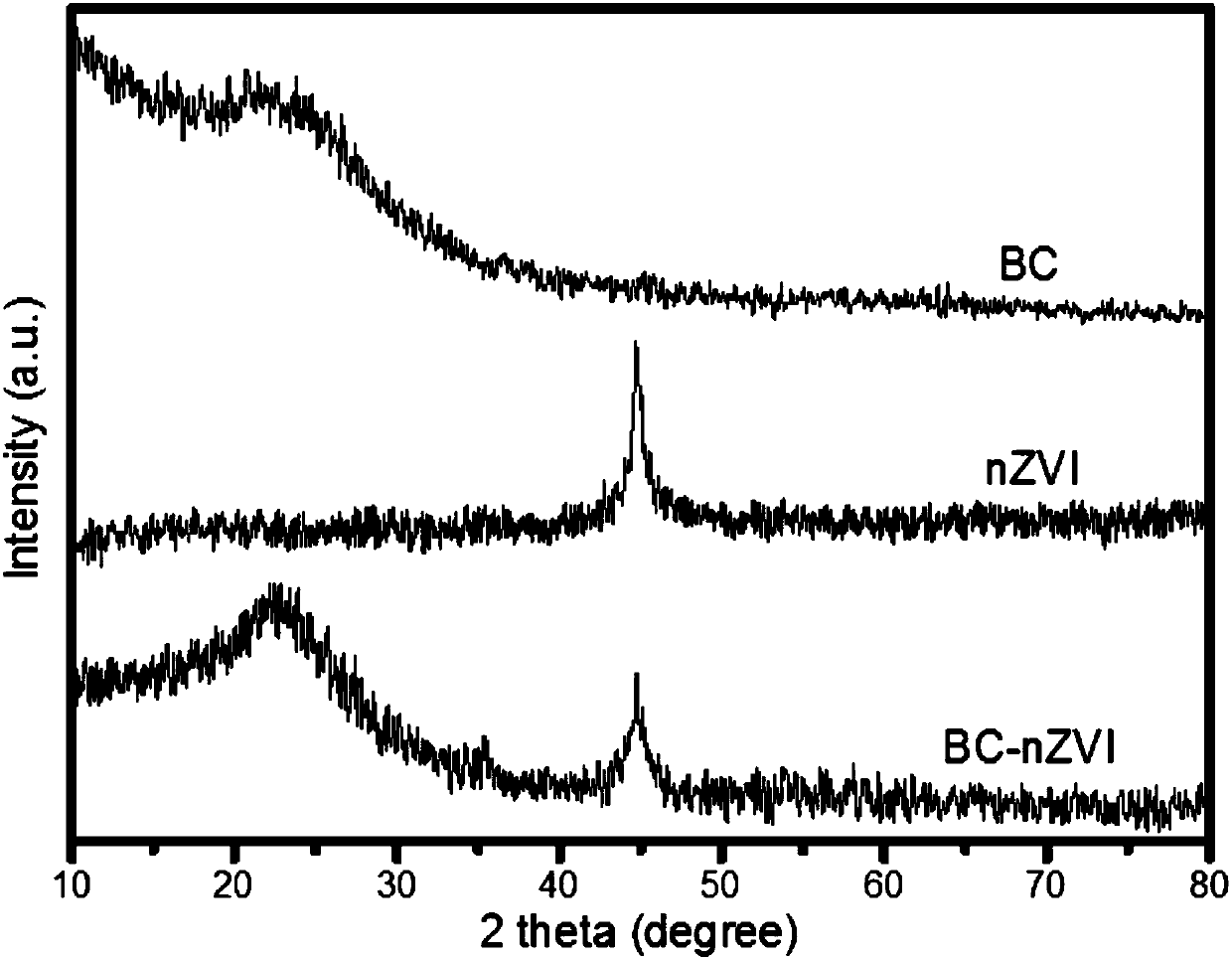

[0028] The mass ratio of Fe to biochar is 1:1, and the preparation steps of the supported biochar catalytic material BC-nZVI are as follows:

[0029] (1) Take the oak chips broken to below 200 mesh and put them into a porcelain boat, put the porcelain boat into a tube furnace, carbonize at 800°C for 4 hours in a nitrogen environment, cool to room temperature, and take out the biomass prepared by carbonization of oak. carbon.

[0030] (2) Add biochar to FeSO containing 0.5wt.% PEG-4000 and a concentration of 0.054mol / L 4 ·7H 2 In the O solution, the ratio of the impregnating liquid to biochar was 1L:3.016g, and it was impregnated for 1 hour under nitrogen atmosphere and vigorous stirring.

[0031] (3) Add dropwise in the mixed solution the NaOH containing 0.1wt.%, the NaBH whose concentration is 0.108mol / L 4 solution.

[0032] (4) Continue to stir for 0.5h after the dropwise addition.

[0033] (5) After the sample after step (4) is filtered under a nitrogen environment, it...

Embodiment 2

[0037] The mass ratio of Fe to biochar is 1:0.5, and the preparation steps of the supported biochar catalytic material BC-nZVI are as follows:

[0038] (1) Take the oak chips broken to below 200 mesh and put them into a porcelain boat, put the porcelain boat into a tube furnace, carbonize at 800°C for 4 hours in a nitrogen environment, cool to room temperature, and take out the biomass prepared by carbonization of oak. carbon.

[0039] (2) Add the biochar obtained in (1) to FeSO containing 0.5wt.% PEG-4000 and a concentration of 0.108mol / L 4 ·7H 2 In the O solution, the ratio of the impregnating liquid to biochar was 1L:3.016g, and it was impregnated for 1 hour under nitrogen atmosphere and vigorous stirring.

[0040](3) Add dropwise in the mixed solution the NaOH containing 0.1wt.%, the NaBH whose concentration is 0.22mol / L 4 solution.

[0041] (4) Continue to stir for 0.5h after the dropwise addition.

[0042] (5) The sample after the step (4) is filtered under a nitrog...

Embodiment 3

[0044] This example is basically the same as Example 1, the only difference is that the concentration of NaOH in the reduction stage is 1wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com